Study of Detector-Grade CdMnTe:In Crystals Obtained by a Multi-Step Post-Growth Annealing Method

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Effect of Multi-Step Annealing on the Concentration of Mn

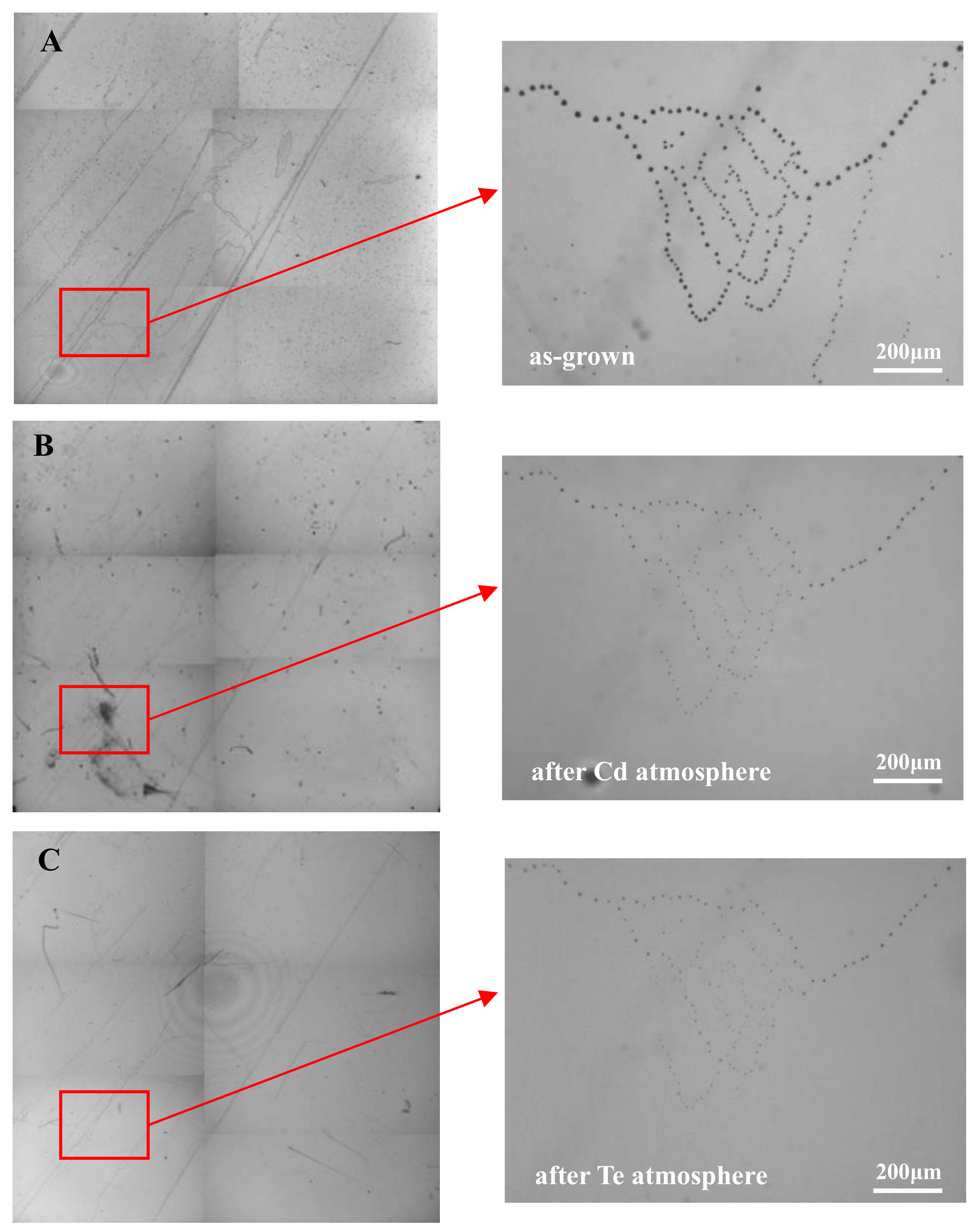

3.2. Effect of Multi-Step Annealing on Te Inclusions

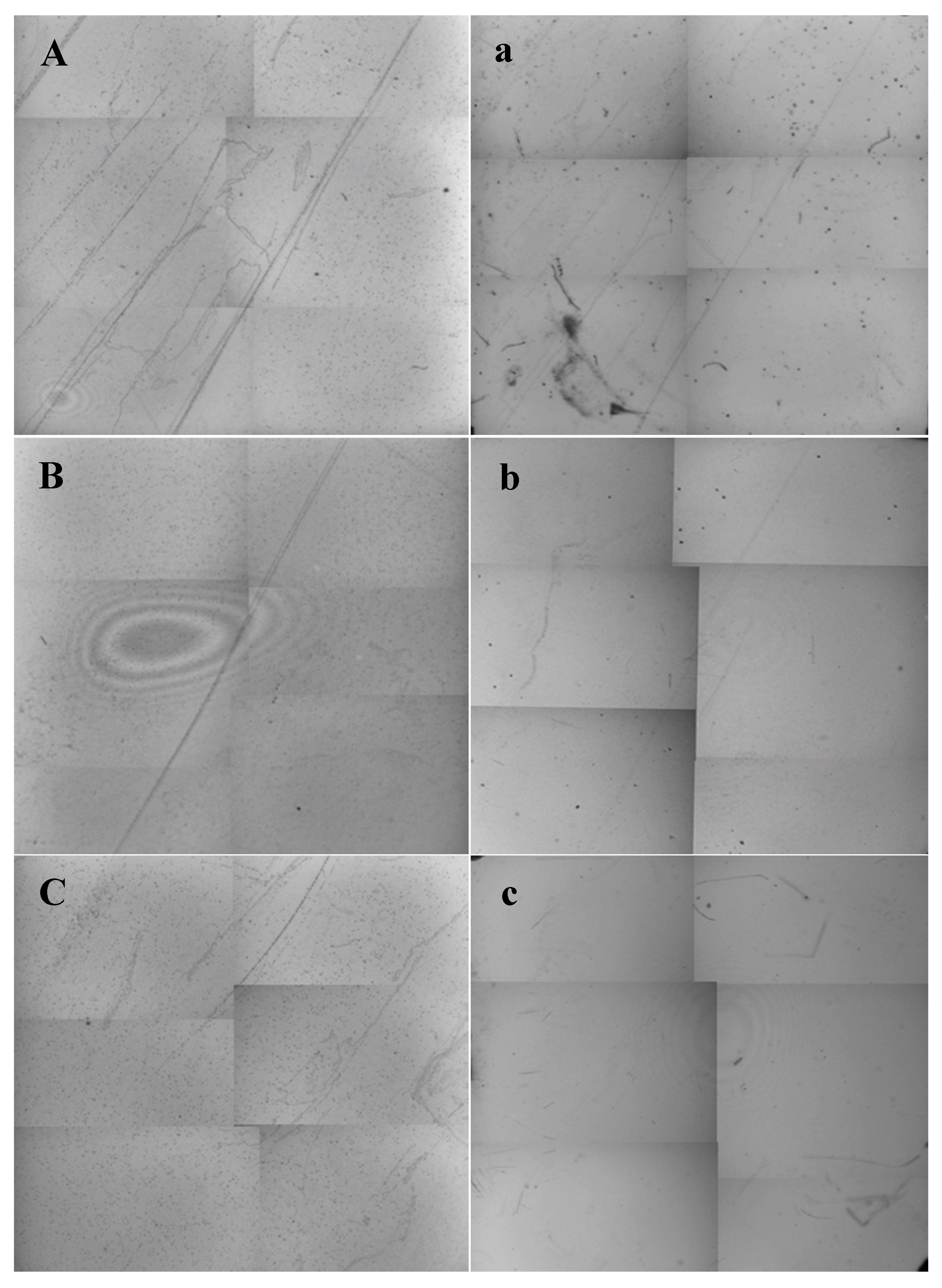

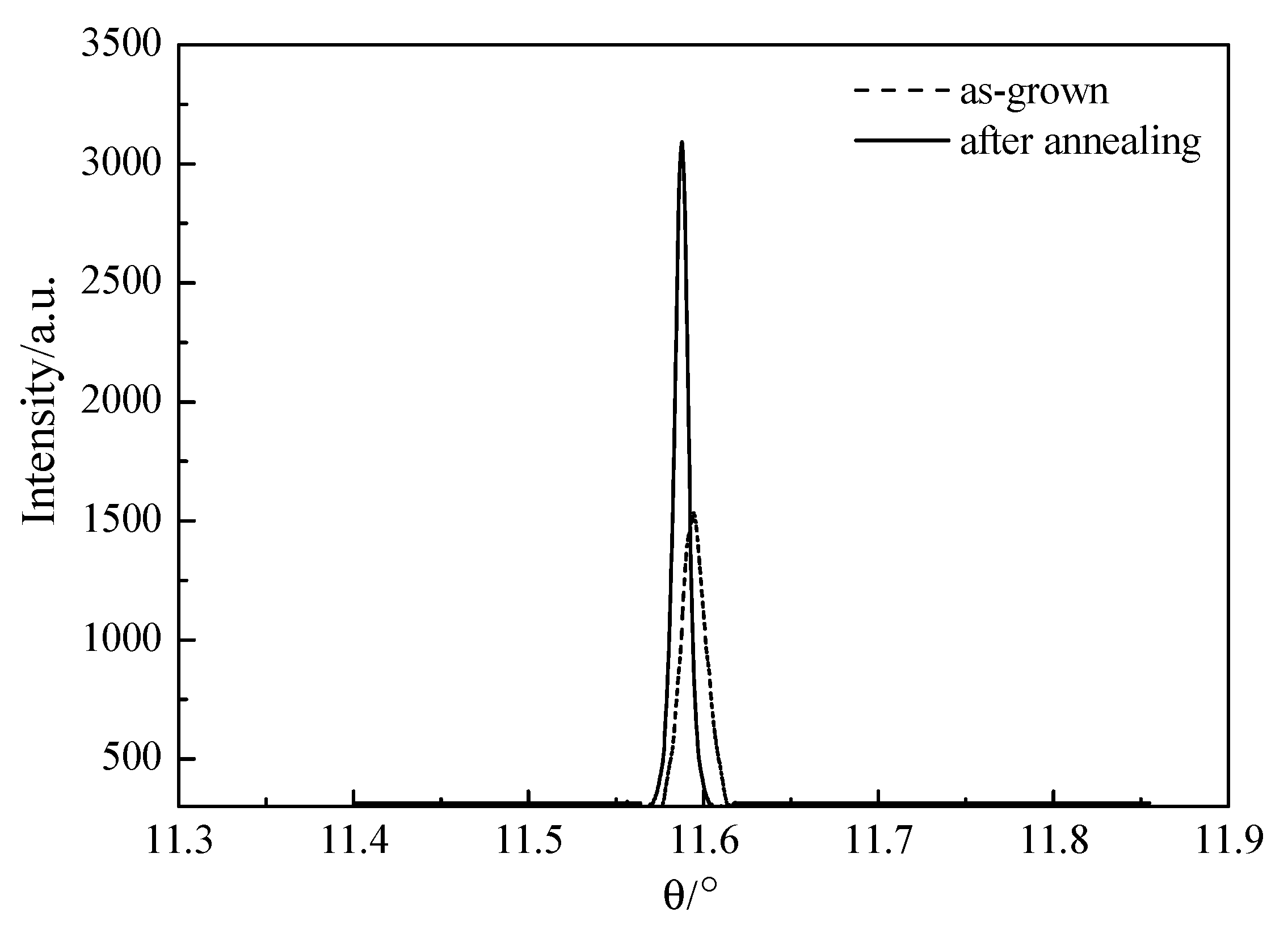

3.3. Effect of Multi-Step Annealing on Crystal Quality

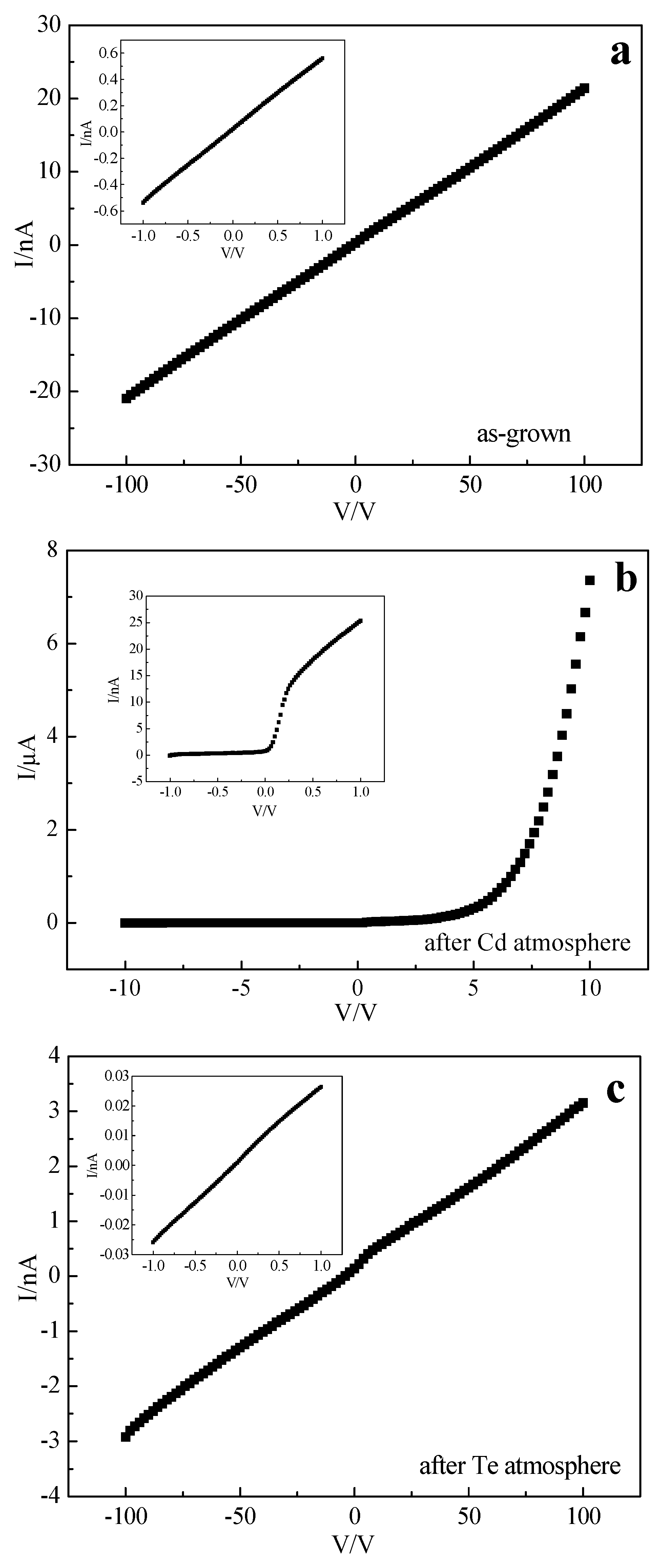

3.4. Effect of Multi-Step Annealing on Resistivity

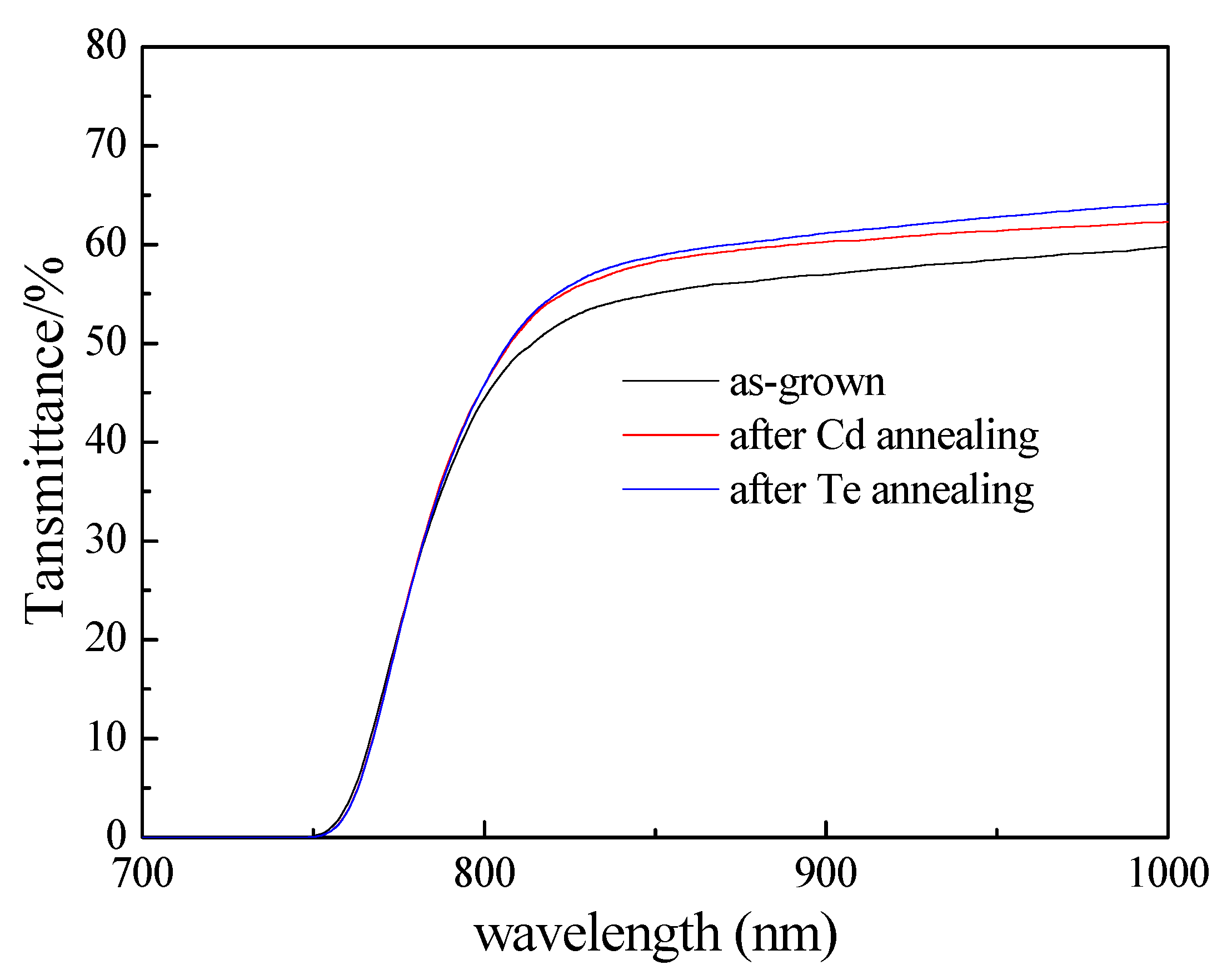

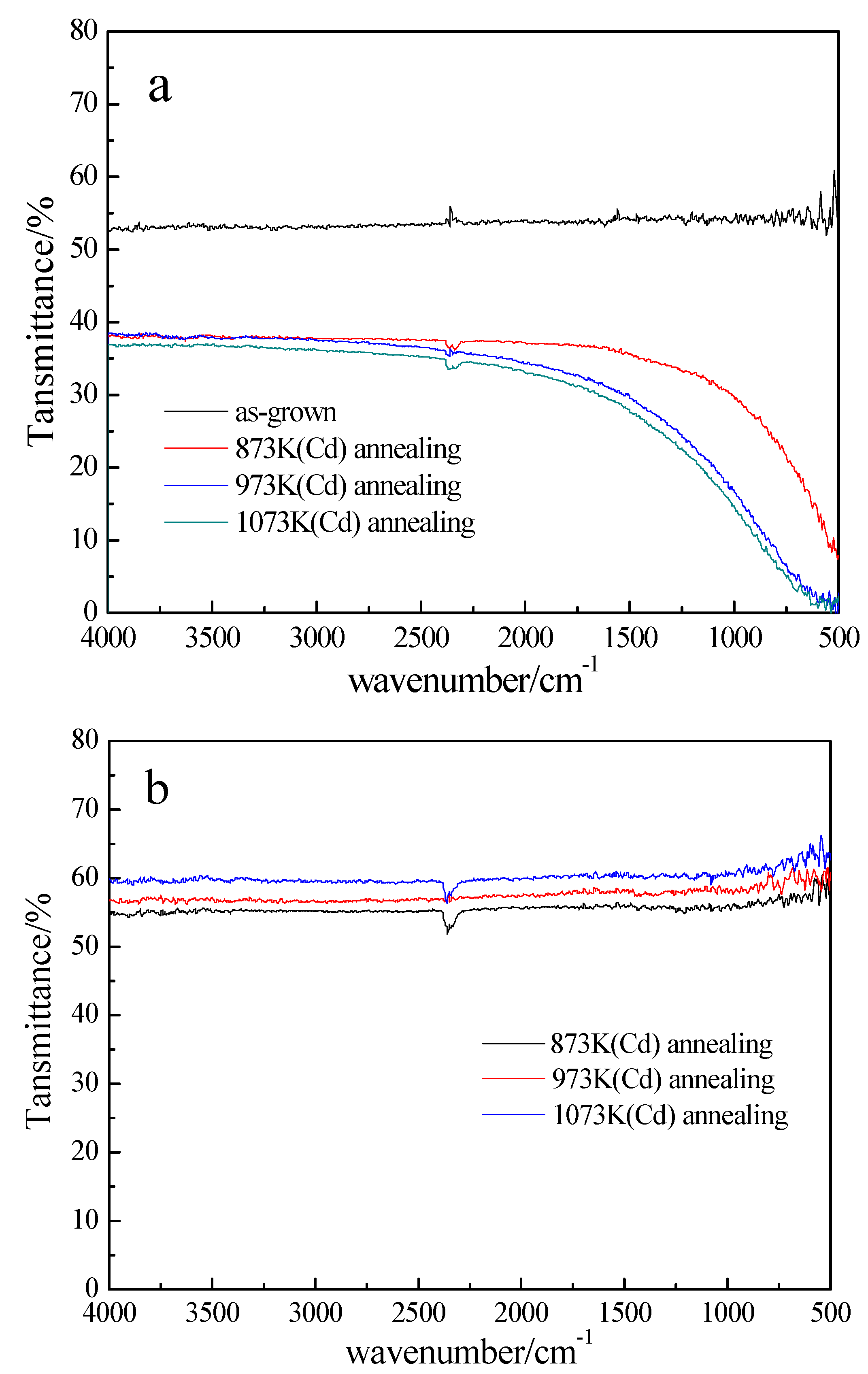

3.5. Effect of Multi-Step Annealing on IR Transmittance Spectra

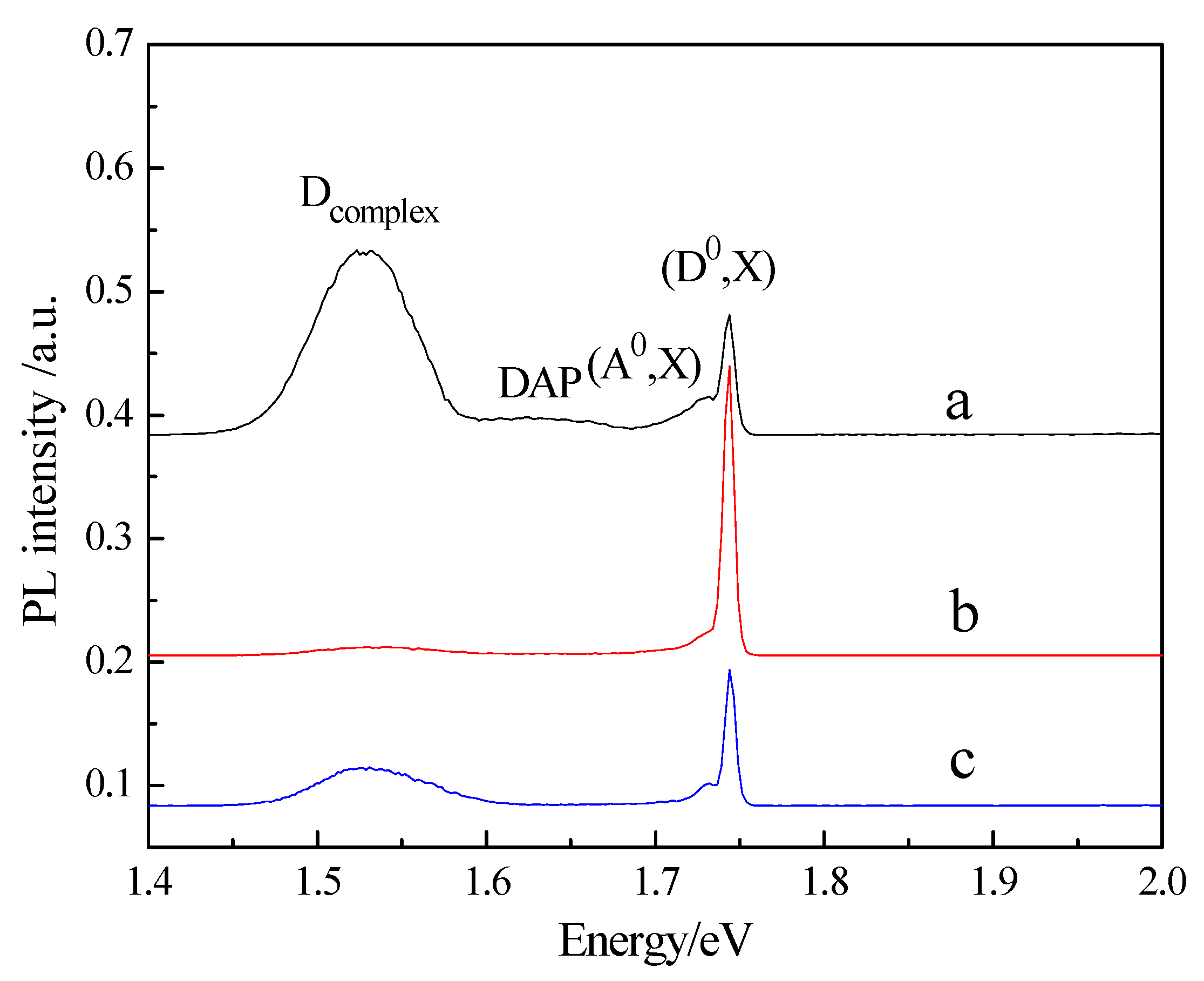

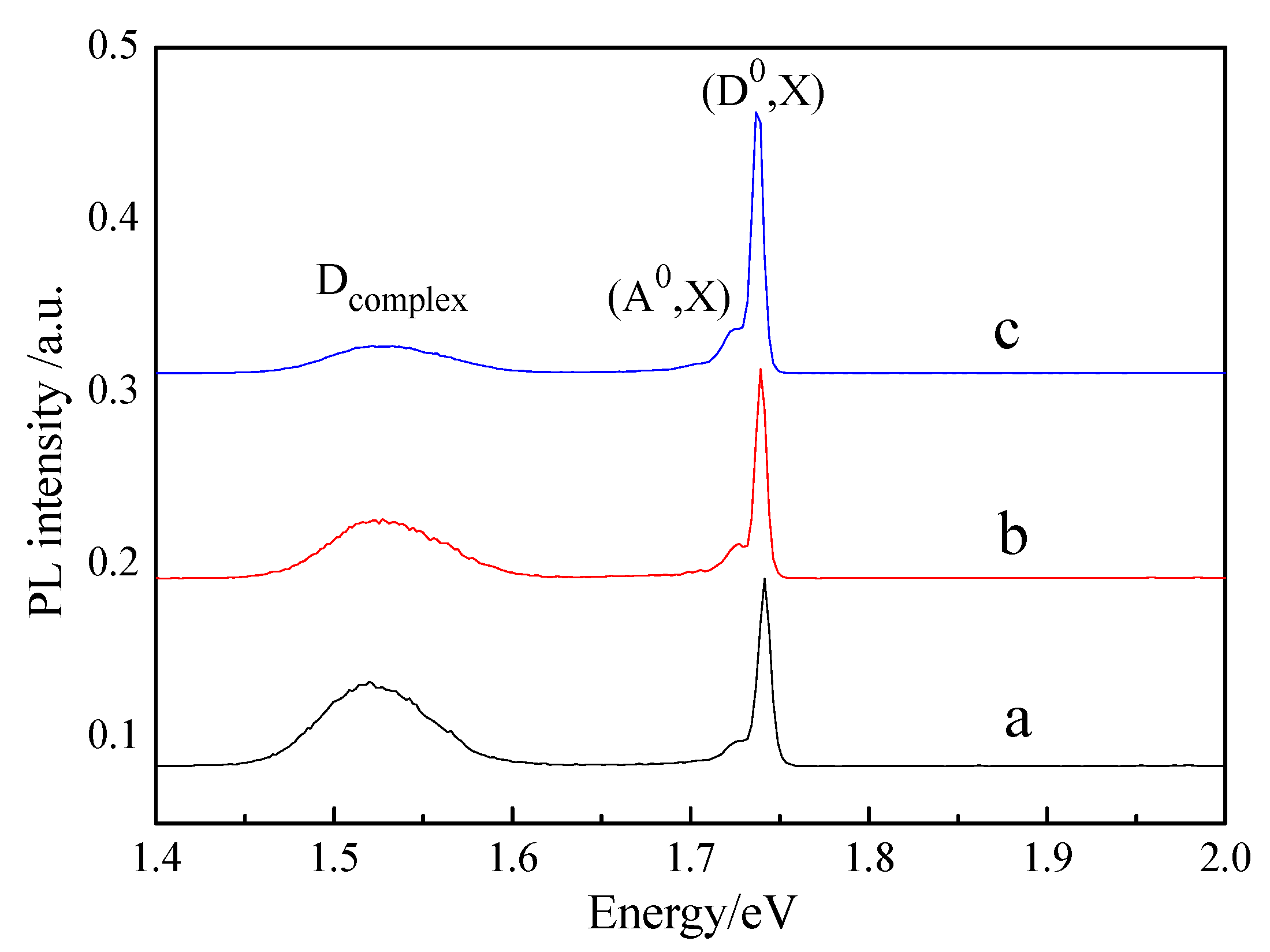

3.6. Effect of Multi-Step Annealing on PL Spectra

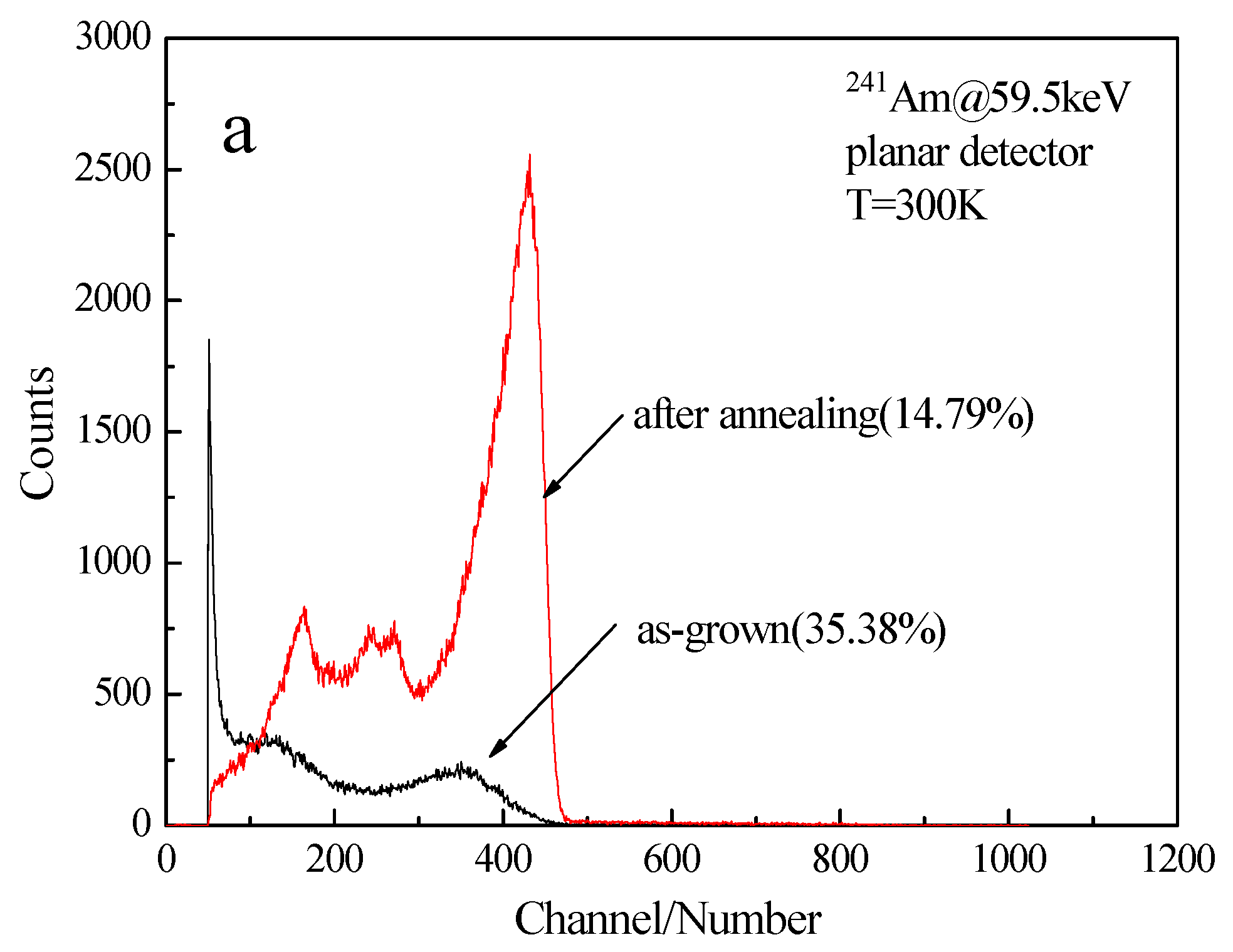

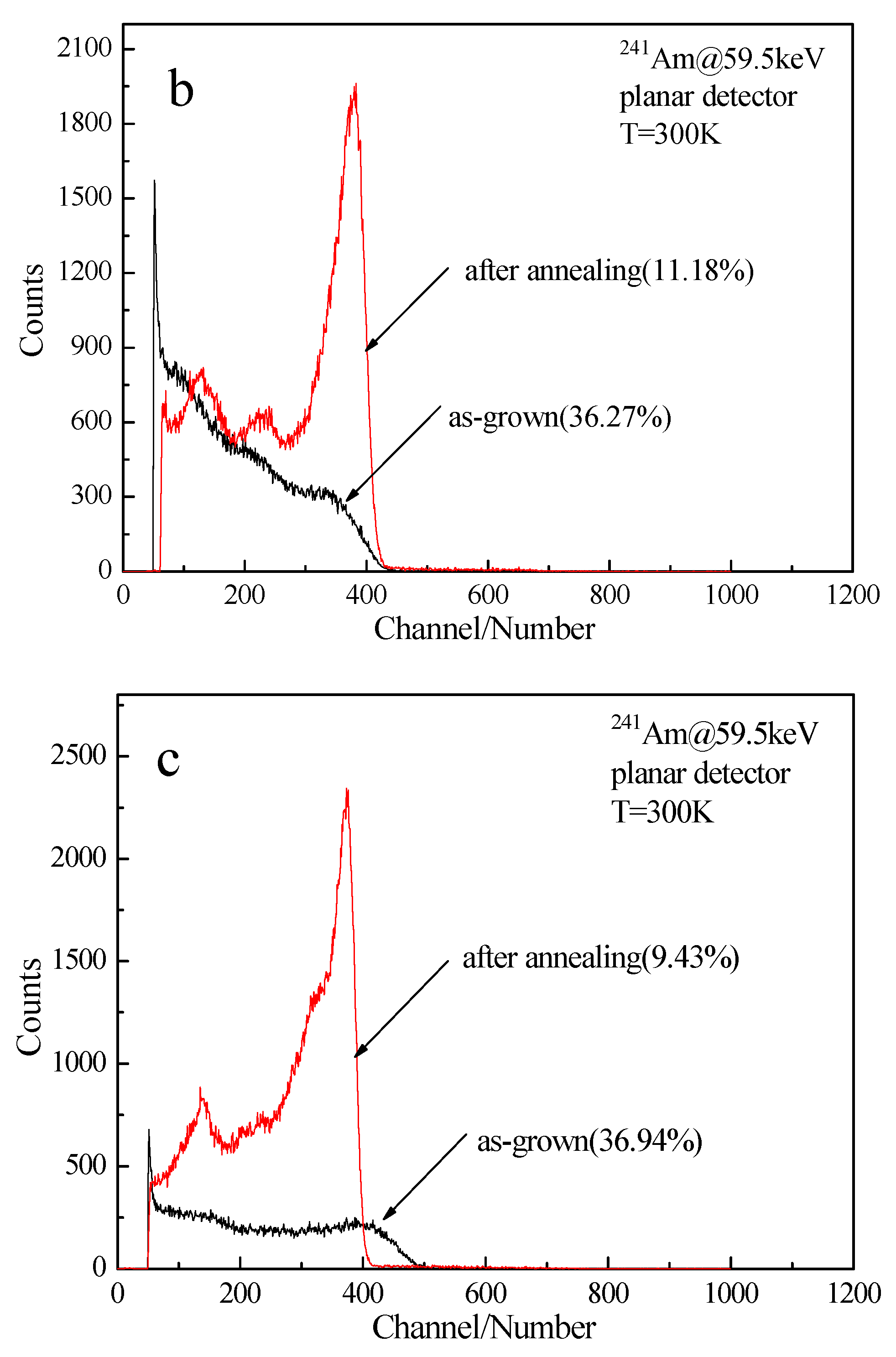

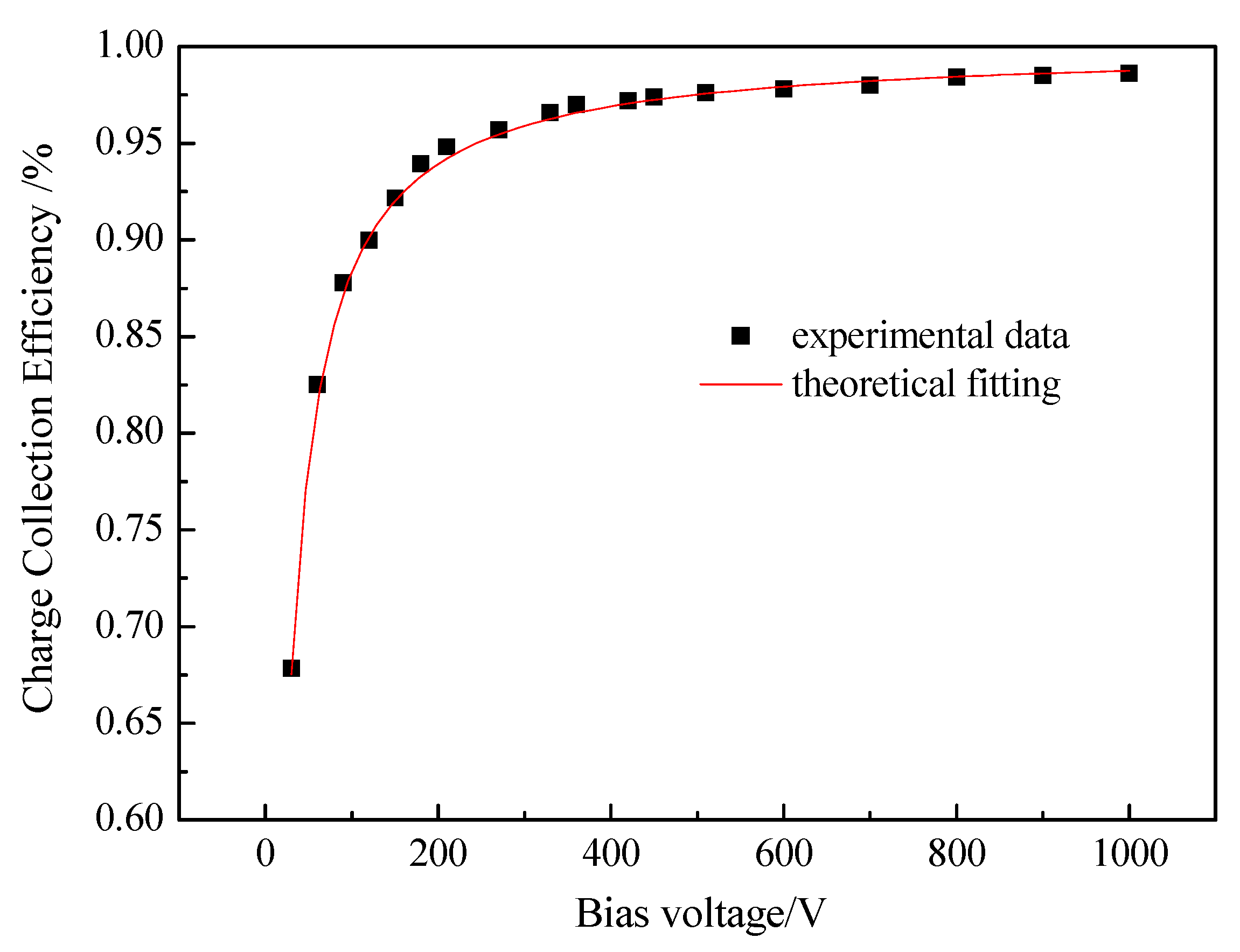

3.7. Effect of Multi-Step Annealing on the Performance of Detectors

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Parkin, J.; Sellin, P.J.; Davies, A.W.; Lohstroh, A.; Özsan, M.E.; Seller, P. α Particle response of undoped CdMnTe. Nucl. Instrum. Meth. A 2007, 573, 220–223. [Google Scholar] [CrossRef]

- Hossain, A.; Cui, Y.; Bolltnikov, A.E.; Camarda, G.S.; Yang, G.; Kochanowska, D.; Witkowska-baran, M.; Mycielski, A.; James, R.B. Vanadium-doped cadmium manganese telluride (Cd1−xMnxTe) crystals as x- and gamma-ray detectors. J. Electron. Mater. 2009, 38, 1593–1599. [Google Scholar] [CrossRef]

- Roy, U.N.; Camarda, G.S.; Cui, Y.; Gu, G.; Gul, R.; Hossain, A.; Yang, G.; Egarievwe, S.U.; James, R.B. Growth and characterization of CdMnTe by the vertical Bridgman technique. J. Cryst. Growth 2016, 437, 53–58. [Google Scholar] [CrossRef]

- Babalola, O.S.; Bolotnikov, A.E.; Groza, M.; Hossain, A.; Egarievwe, S.; James, R.B.; Burger, A. Study of Te inclusions in CdMnTe crystals for nuclear detector applications. J. Cryst. Growth 2009, 311, 3702–3707. [Google Scholar] [CrossRef]

- Du, Y.Y.; Jie, W.Q.; Zheng, X.; Wang, T.; Bai, X.X.; Yu, H. Growth interface of In-doped CdMnTe from Te solution with vertical Bridgman method under ACRT technique. Trans. Nonferrous Met. Soc. China 2012, 22, s143–s147. [Google Scholar] [CrossRef]

- Hossain, A.; Gu, G.D.; Bolltnikov, A.E.; Camarda, G.S.; Cui, Y.; Yang, G.; Roy, U.N.; Yang, G.; Liu, T.; Zhong, R.; et al. Material and detector properties of cadmium manganese telluride (Cd1−xMnxTe) crystals grown by the modified floating-zone method. Nucl. Instrum. Meth. A 2015, 784, 33–36. [Google Scholar] [CrossRef]

- Kochanowska, D.; Mycielski, A.; Witkowska-Baran, M.; Szadkowski, A.; Witkowska, B.; Kaliszek, W.; Cui, Y.; James, R.B. Influence of annealing on tellurium precipitates in (Cd,Mn)Te:V crystals. IEEE Nucl. Sci. Symp. Conf. Rec. 2009, NSS’08, 202–206. [Google Scholar]

- Zhang, J.J.; Wang, L.J.; Min, J.H.; Qin, K.F.; Huang, J.; Tang, K.; Liang, X.Y.; Shen, P. Annealing of indium-doped CdMnTe single crystals under Cd vapors. J. Cryst. Growth 2012, 358, 12–15. [Google Scholar] [CrossRef]

- Zhang, J.J.; Wang, L.J.; Min, J.H.; Qin, K.F.; Shi, Z.B.; Liang, X.Y. Te vapor annealing of indium-doped CdMnTe crystals. J. Semicond. 2015, 34, 033002. [Google Scholar] [CrossRef]

- Adams, A.L.; Agbalagba, E.O.; Jow, J.O.; Mwathi, J.G.; Egarievwe, A.A.; Chan, W.; Dowdell, M.C.; Roy, U.N.; Egarievwe, S.U. Thermal annealing of CdMnTe material being developed for nuclear radiation detection applications. IOSR J. Mech. Civil Eng. 2016, 14, 1–5. [Google Scholar] [CrossRef]

- Bugár, M.; Belas, E.; Procházka, J.; Hlídek, P.; Grill, R.; Franc, J.; Höschl, P. IR transmittance of CdTe after high-temperature annealing. Nucl. Instrum. Meth. A 2011, 633, S83–S85. [Google Scholar] [CrossRef]

- Kim, K.; Bolotnikov, A.E.; Camarda, G.S.; Hossain, A.; James, R.B. Overcoming Zn segregation in CdZnTe with the temperature gradient annealing. J. Cryst. Growth 2016, 442, 98–101. [Google Scholar] [CrossRef]

- Egarievwe, S.U.; Yang, G.; Egarievwe, A.A.; Okwechime, I.O.; Gray, J.; Hales, Z.M.; Hossain, A.; Camarda, G.S.; Bolotnikov, A.E.; James, R.B. Post-growth annealing of Bridgman-grown CdZnTe and CdMnTe crystals for room-temperature nuclear radiation detectors. Nucl. Instrum. Meth. A 2015, 784, 51–55. [Google Scholar] [CrossRef]

- Chu, M.; Terterian, S.; Ting, D.; Wang, C.C.; Dinan, J.H.; James, R.B.; Burger, A. Effects of excess tellurium on the properties of CdZnTe radiation detectors. J. Electron. Mater. 2003, 32, 779–782. [Google Scholar] [CrossRef]

- Yang, G.; Bolotnikov, A.E.; Fochuk, P.M.; Kopach, O.; Franc, J.; Belas, E.; Kim, K.H.; Camarda, G.S.; Hossain, A.; Cui, Y.; et al. Post-growth thermal annealing study of CdZnTe for developing room-temperature X-ray and gamma-ray detectors. J. Cryst. Growth 2013, 379, 16–20. [Google Scholar] [CrossRef]

- Li, G.Q.; Zhang, X.L.; Jie, W.Q.; Hui, C. Thermal treatment of detector-grade CdZnTe. J. Cryst. Growth 2006, 295, 31–35. [Google Scholar] [CrossRef]

- Yu, P.F.; Xu, Y.D.; Luan, L.J.; Du, Y.Y.; Zheng, J.H.; Li, H.; Jie, W.Q. Quality improvement of CdMnTe:In single crystals by an effective post- growth annealing. J. Cryst. Growth 2016, 451, 194–199. [Google Scholar] [CrossRef]

- Vydyanath, H.R.; Ellsworth, J.A.; Parkinson, J.B.; Kennedy, J.J.; Dean, B.; Johnson, C.J.; Neugebauer, G.T.; Sepich, J.; Liao, P. Thermomigration of Te precipitates and improvement of (Cd,Zn)Te substrate characteristics for the fabrication of LWIR (Hg, Cd)Te photodiodes. J. Electron. Mater. 1993, 22, 1073–1080. [Google Scholar] [CrossRef]

- Anthony, T.R.; Cline, H.E. Thermal migration of liquid droplets through solids. J. Appl. Phys. 1971, 42, 3380–3387. [Google Scholar] [CrossRef]

- Yu, P.F.; Jie, W.Q. Observation, morphology evolution and elimination of Te inclusions in CdZnTe:In single crystals. J. Cryst. Growth 2013, 381, 57–60. [Google Scholar] [CrossRef]

- Lyahovitskaya, V.; Chernyak, L.; Greenberg, J.; Kaplan, L.; Cahen, D. n- And p-type post-growth self-doping of CdTe single crystals. J. Cryst. Growth 2000, 214, 1155–1157. [Google Scholar] [CrossRef]

- Du, Y.Y.; Jie, W.Q.; Wang, T.; Zheng, X.; Xu, Y.D.; Luan, L.J. Solution growth of In-doped CdMnTe crystals by the vertical Bridgman method with the ACRT technique. J. Cryst. Growth 2012, 355, 33–37. [Google Scholar] [CrossRef]

- Yu, P.F.; Luan, L.J.; Du, Y.Y.; Zheng, J.H.; Jie, W.Q. Investigation of Te atmosphere annealing on the properties of detector-grade CdMnTe:In single crystals. J. Cryst. Growth 2015, 430, 103–107. [Google Scholar] [CrossRef]

- Zhang, J.J.; Wang, L.J.; Min, J.H.; Huang, J.; Liang, X.Y.; Tang, K.; Shen, P.; Shen, M.; Liang, W.; Huang, N.S.; Xia, Y.B. Characterization of CdMnTe crystal grown with vertical Bridgman method under Te-rich conditions. Phys. Status Solidi C 2014, 11, 1174–1177. [Google Scholar] [CrossRef]

- Li, Q.; Jie, W.Q.; Fu, L.; Wang, T.; Yang, G.; Bai, X.X.; Zha, G.Q. Optical and electrical properties of indium-doped Cd0.9Zn0.1Te crystal. J. Cryst. Growth 2006, 295, 124–128. [Google Scholar] [CrossRef]

- Jones, K.A.; Ciampi, G.; Skrip, C.E.; Lynn, K.G. Vertical Bridgman growth of Cd1-xZnxTe for room temperature radiation detectors. Proc. SPIE 2007, 6706, 670607. [Google Scholar]

- Kim, K.; Jeng, G.; Kim, P.; Choi, J.; Bolotnikov, A.E.; Camarda, G.S.; James, R.B. Influence of the cooling scheme on the performance and presence of carrier traps for CdMnTe detectors. J. Appl. Phys. 2013, 114, 063706. [Google Scholar] [CrossRef]

- Chen, H.; Awadalla, S.A.; Iniewski, K.; Lu, P.H.; Harris, F.; Mackenzie, J.; Hasanen, T.; Chen, W.; Redden, R.; Bindley, G.; et al. Characterization of large cadmium zinc telluride crystals grown by traveling heater method. J. Appl. Phys. 2008, 103, 014903. [Google Scholar] [CrossRef]

- Yu, P.F.; Jie, W.Q. Effects of post-growth annealing on the performance of CdZnTe: In radiation detectors with different thickness. Nucl. Instrum. Meth. A 2014, 737, 29–32. [Google Scholar] [CrossRef]

- Yu, P.F.; Xu, Y.D.; Chen, Y.R.; Song, J.; Zhu, Y.; Zhang, M.J.; Zhang, B.G.; Wang, Y.; Li, W.; Luan, L.J.; et al. Investigation of effective annealing on CdMnTe:In crystals with different thickness for gamma-ray detectors. J. Cryst. Growth 2018, 483, 94–101. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, P.; Chen, Y.; Li, W.; Liu, W.; Liu, B.; Yang, J.; Ni, K.; Luan, L.; Zheng, J.; Li, Z.; et al. Study of Detector-Grade CdMnTe:In Crystals Obtained by a Multi-Step Post-Growth Annealing Method. Crystals 2018, 8, 387. https://doi.org/10.3390/cryst8100387

Yu P, Chen Y, Li W, Liu W, Liu B, Yang J, Ni K, Luan L, Zheng J, Li Z, et al. Study of Detector-Grade CdMnTe:In Crystals Obtained by a Multi-Step Post-Growth Annealing Method. Crystals. 2018; 8(10):387. https://doi.org/10.3390/cryst8100387

Chicago/Turabian StyleYu, Pengfei, Yongren Chen, Wei Li, Wenfei Liu, Bin Liu, Jie Yang, Kun Ni, Lijun Luan, Jiahong Zheng, Zhuo Li, and et al. 2018. "Study of Detector-Grade CdMnTe:In Crystals Obtained by a Multi-Step Post-Growth Annealing Method" Crystals 8, no. 10: 387. https://doi.org/10.3390/cryst8100387

APA StyleYu, P., Chen, Y., Li, W., Liu, W., Liu, B., Yang, J., Ni, K., Luan, L., Zheng, J., Li, Z., Bai, M., Sun, G., Li, H., & Jie, W. (2018). Study of Detector-Grade CdMnTe:In Crystals Obtained by a Multi-Step Post-Growth Annealing Method. Crystals, 8(10), 387. https://doi.org/10.3390/cryst8100387