Dynamic Fracture Mechanism of Quasicrystal-Containing Al–Cr–Fe Consolidated Using Spark Plasma Sintering

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Nanoindentation Tests

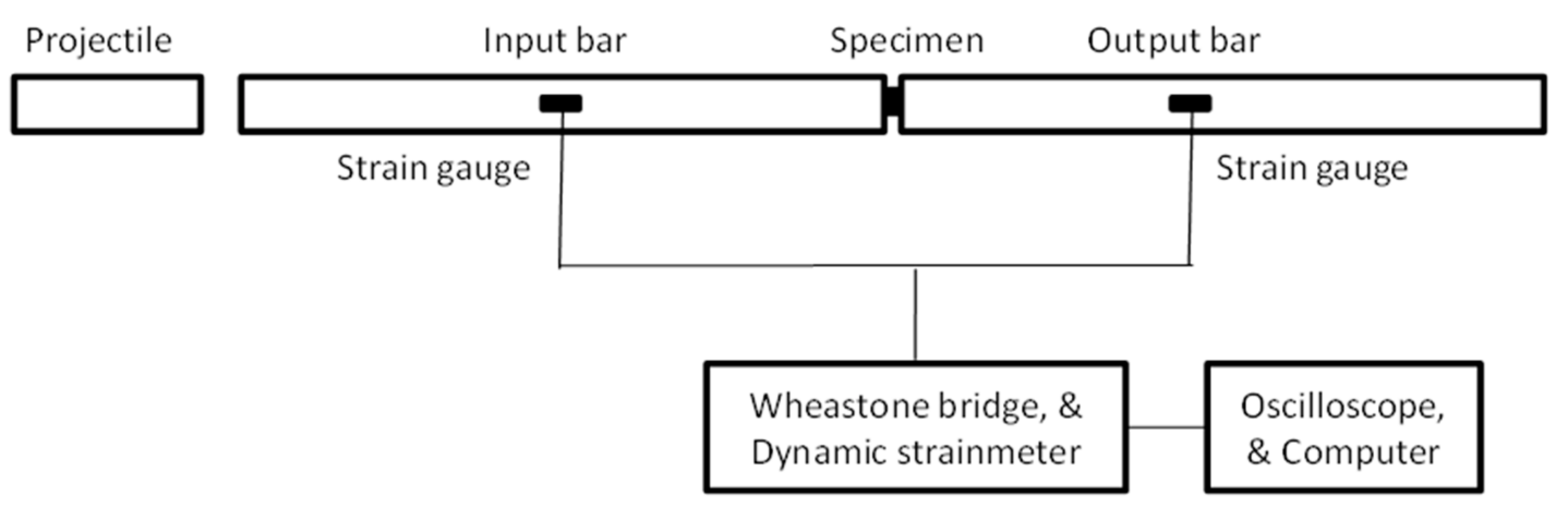

2.3. Split-Hopkinson Pressure Bar Experiments

2.4. Microstructural Characterization

3. Results

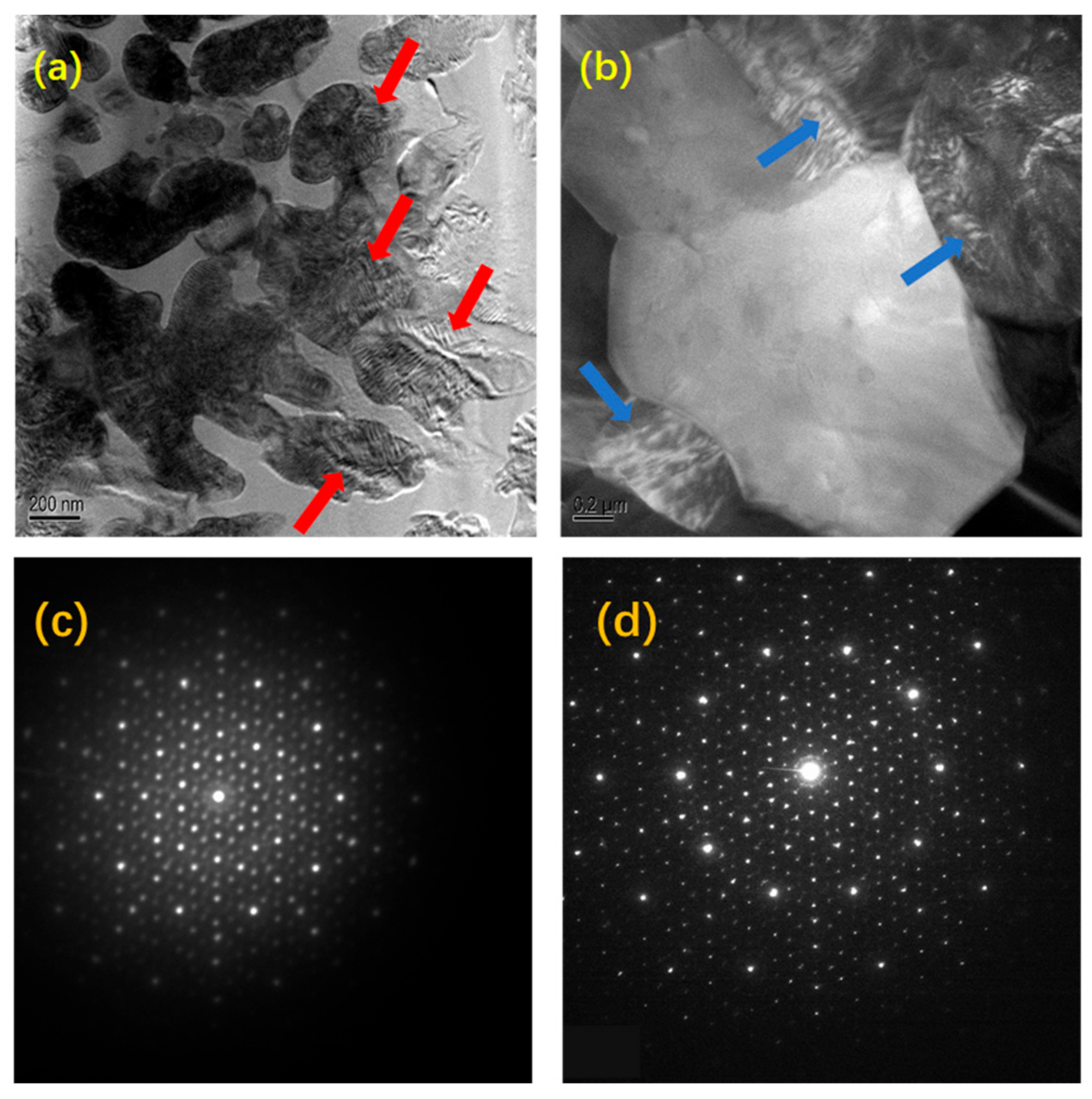

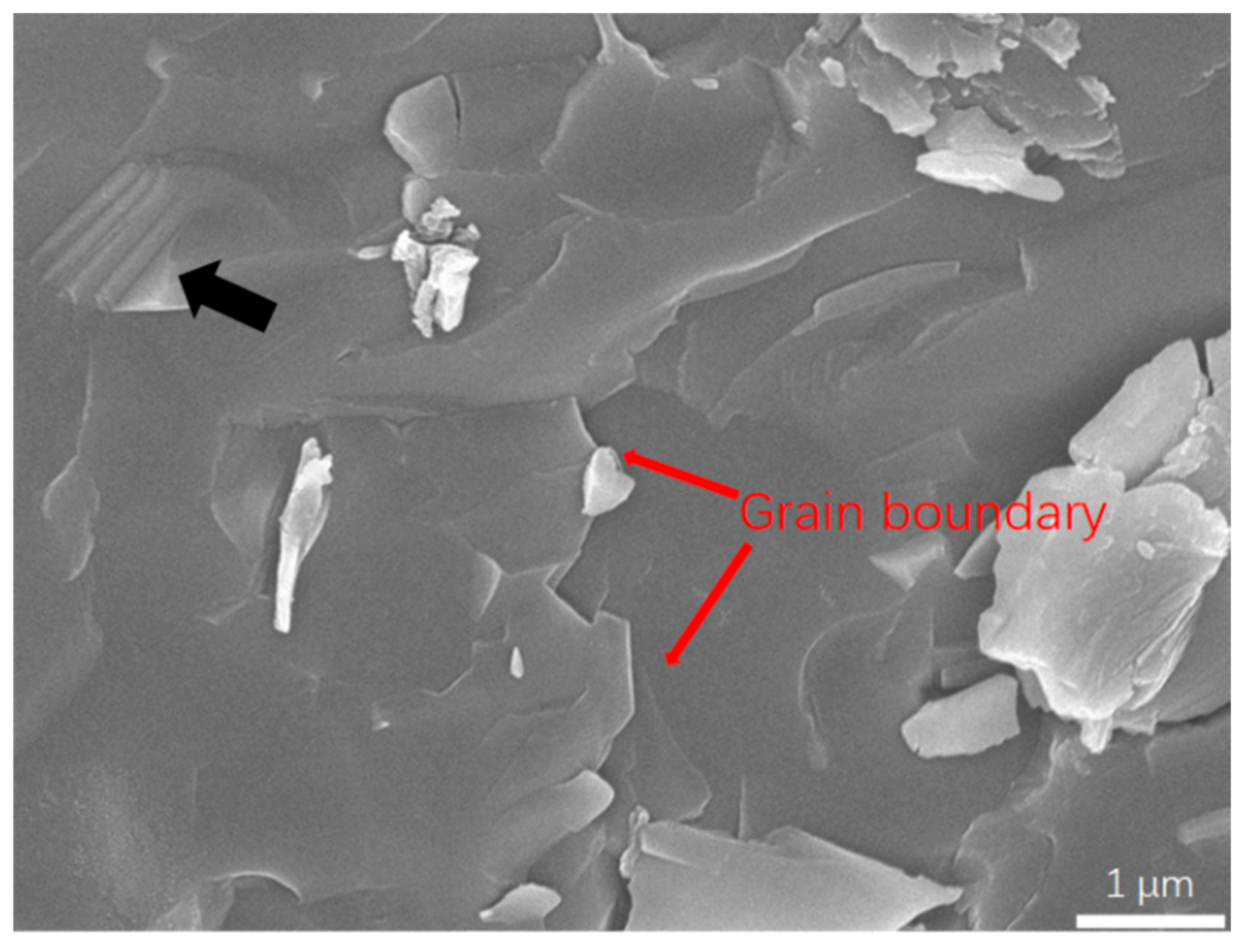

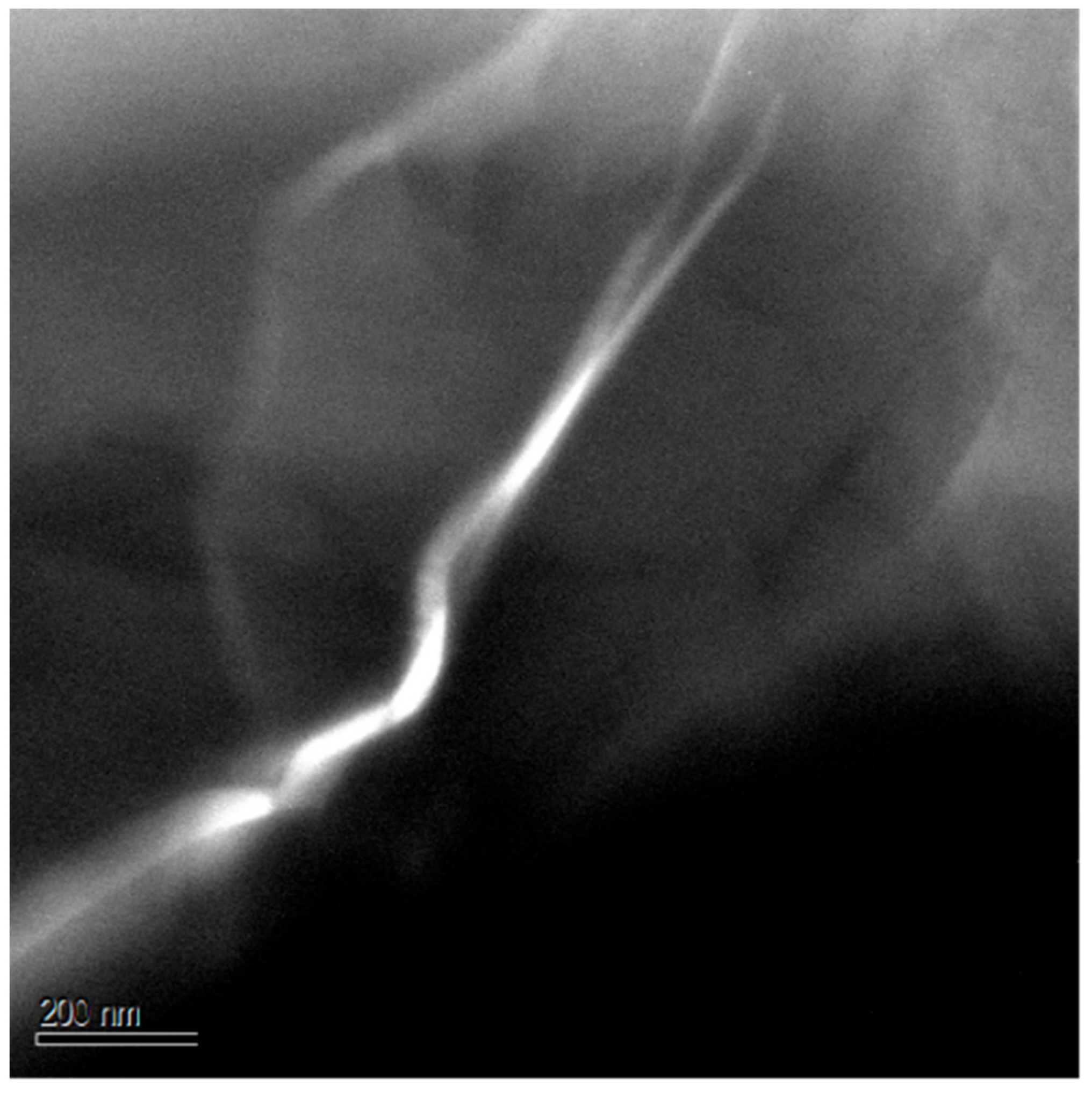

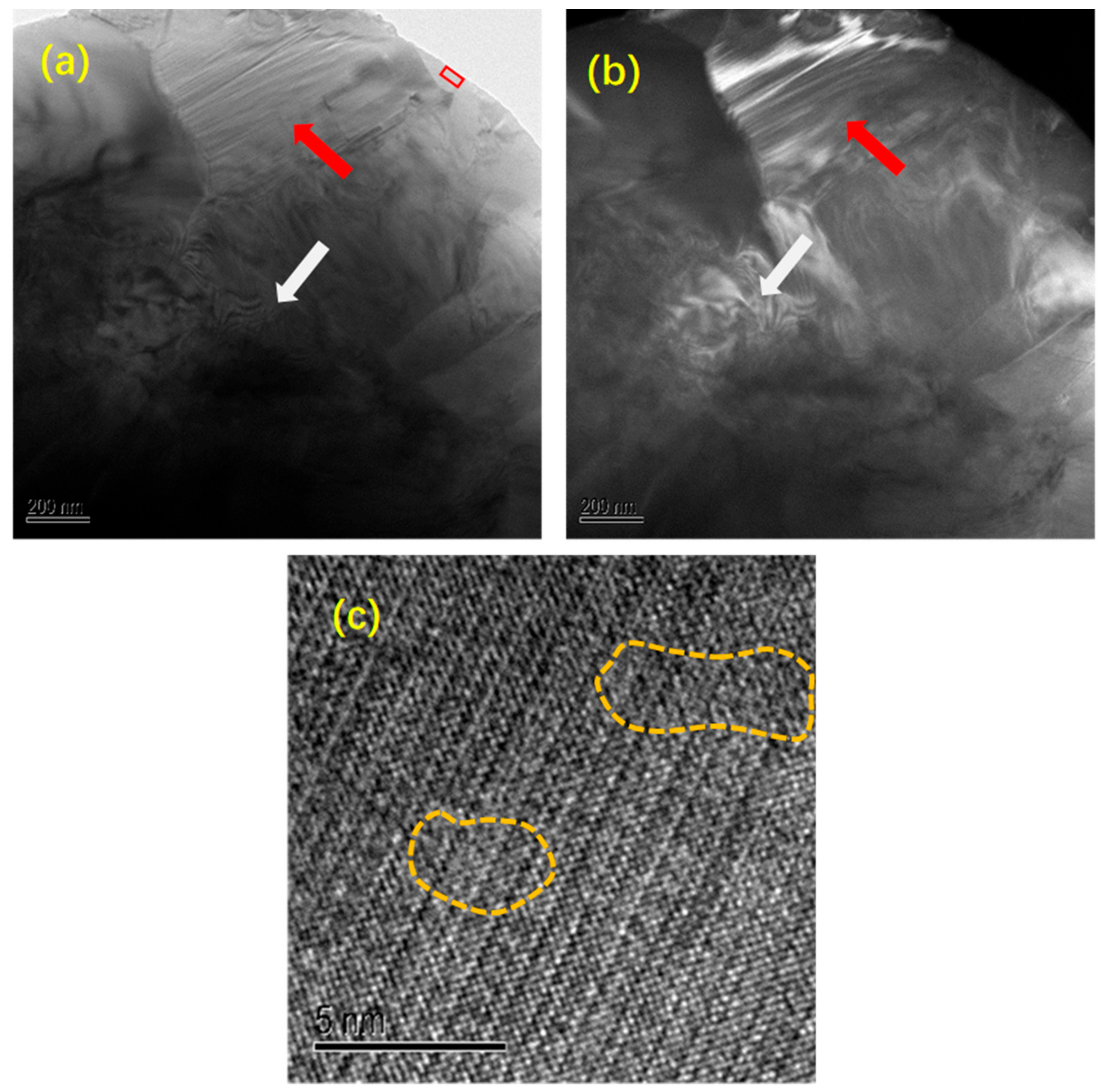

3.1. Microstructure

3.2. Microhardness and Young’s Modulus

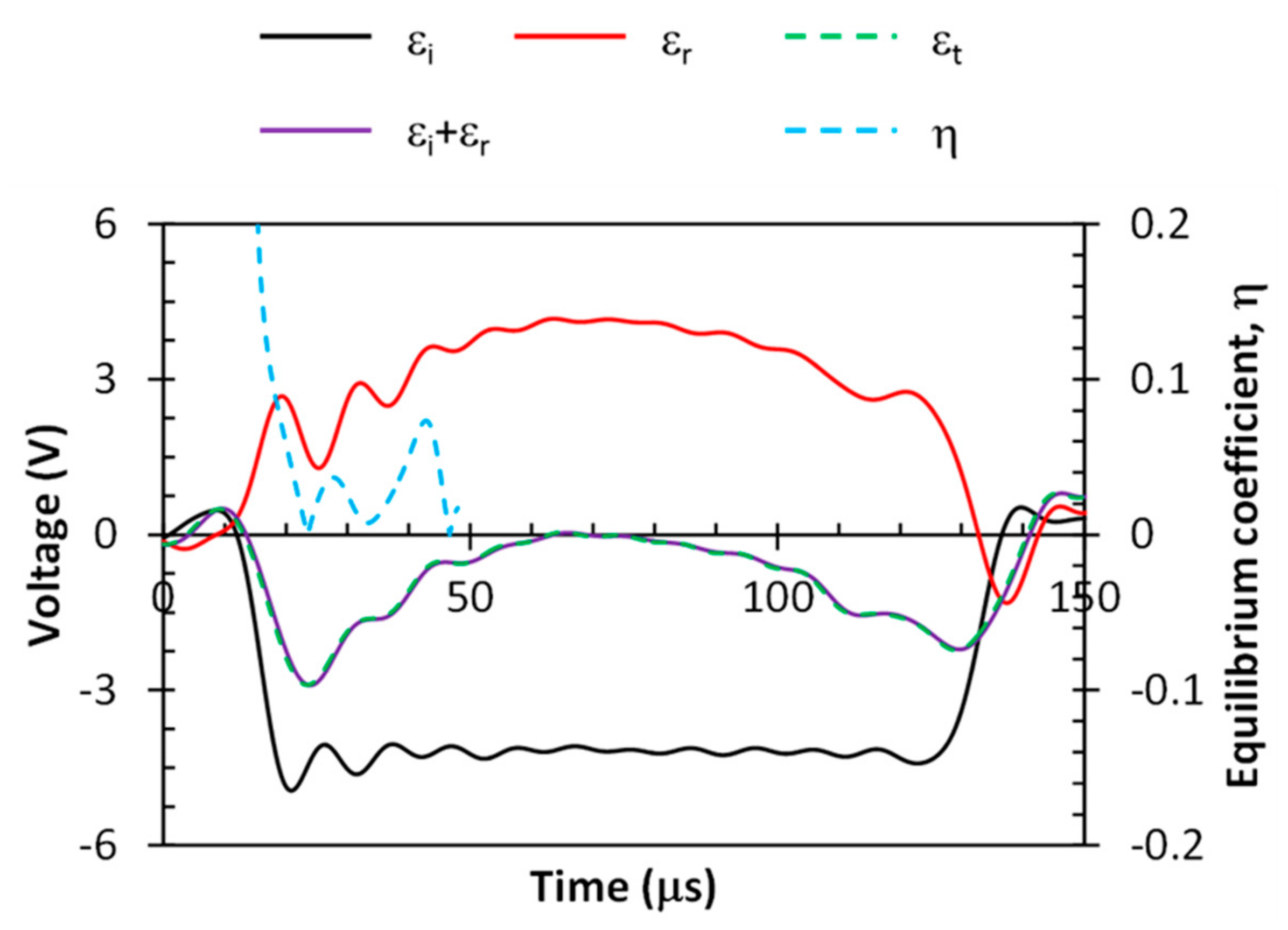

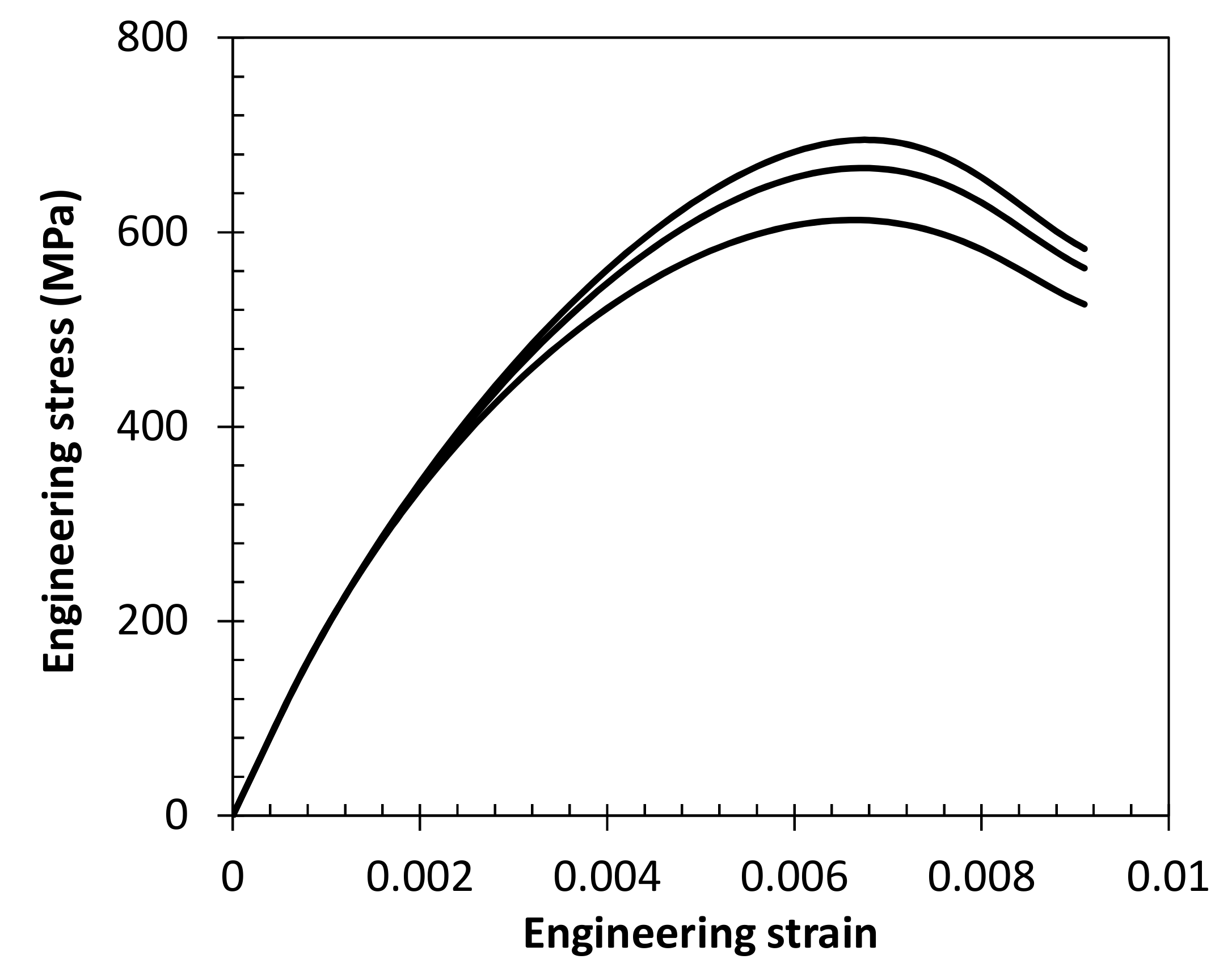

3.3. Dynamic Mechanical Response

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wolf, B.; Bambauer, K.-O.; Paufler, P. On the temperature dependence of the hardness of quasicrystals. Mater. Sci. Eng. A 2001, 298, 284–295. [Google Scholar] [CrossRef]

- Dubois, J.-M. New prospects from potential applications of quasicrystalline materials. Mater. Sci. Eng. A 2000, 294, 4–9. [Google Scholar] [CrossRef]

- Fu, Y.; Kang, N.; Liao, H.; Gao, Y.; Coddet, C. An investigation on selective laser melting of Al-Cu-Fe-Cr quasicrystal: From single layer to multilayers. Intermetallics 2017, 86, 51–58. [Google Scholar] [CrossRef]

- Zhao, J.; Zhai, X.; Tao, X.; Li, Z.; Wang, Q.; Liu, W.; Wang, L. Improved electrochemical hydrogen storage capacity of Ti45Zr38Ni17 quasicrystal by addition of ZrH2. J. Mater. Sci. Technol. 2017, 34, 995–998. [Google Scholar] [CrossRef]

- Li, R.; Murugan, V.K.; Dong, Z.; Khor, K.A. Comparative Study on the Corrosion Resistance of Al–Cr–Fe Alloy Containing Quasicrystals and Pure Al. J. Mater. Sci. Technol. 2016, 32, 1054–1058. [Google Scholar] [CrossRef]

- Dubois, J.-M. Properties-and applications of quasicrystals and complex metallic alloys. Chem. Soc. Rev. 2012, 41, 6760–6777. [Google Scholar] [CrossRef] [PubMed]

- Ali, F.; Scudino, S.; Anwar, M.; Shahid, R.; Srivastava, V.; Uhlenwinkel, V.; Stoica, M.; Vaughan, G.; Eckert, J. Al-based metal matrix composites reinforced with Al–Cu–Fe quasicrystalline particles: Strengthening by interfacial reaction. J. Alloy. Compd. 2014, 607, 274–279. [Google Scholar] [CrossRef]

- Li, R.; Dong, Z.; Khun, N.W.; Khor, K.A. Novel Ti based metal matrix composites reinforced with Al–Cr–Fe quasicrystals approximants. Mater. Sci. Technol. 2015, 31, 688–694. [Google Scholar] [CrossRef]

- Demange, V.; Machizaud, F.; Dubois, J.M.; Anderegg, J.W.; Thiel, P.A.; Sordelet, D.J. New approximants in the Al–Cr–Fe system and their oxidation resistance. J. Alloy. Compd. 2002, 342, 24–29. [Google Scholar] [CrossRef]

- Pavlyuchkov, D.; Balanetskyy, S.; Kowalski, W.; Surowiec, M.; Grushko, B. Stable decagonal quasicrystals in the Al-Fe-Cr and Al-Fe-Mn alloy systems. J. Alloy. Compd. 2009, 477, L41–L44. [Google Scholar] [CrossRef]

- Demange, V.; Ghanbaja, J.; Beeli, C.; Machizaud, F.; Dubois, J.M. Study of decagonal approximant and γ-brass-type compounds in Al Cr Fe thin films. J. Mater. Res. 2004, 19, 2285–2297. [Google Scholar] [CrossRef]

- Palm, M. The Al–Cr–Fe system–Phases and phase equilibria in the Al-rich corner. J. Alloy. Compd. 1997, 252, 192–200. [Google Scholar] [CrossRef]

- Demange, V.; Anderegg, J.W.; Ghanbaja, J.; Machizaud, F.; Sordelet, D.J.; Besser, M.; Thiel, P.A.; Dubois, J.M. Surface oxidation of Al–Cr–Fe alloys characterized by X-ray photoelectron spectroscopy. Appl. Surf. Sci. 2001, 173, 327–338. [Google Scholar] [CrossRef]

- Demange, V.; Milandri, A.; De Weerd, M.C.; Machizaud, F.; Jeandel, G.; Dubois, J.M. Optical conductivity of Al-Cr-Fe approximant compounds. Phys. Rev. B 2002, 65, 144205. [Google Scholar] [CrossRef]

- Shaĭtura, D.; Enaleeva, A. Fabrication of quasicrystalline coatings: A review. Crystallogr. Rep. 2007, 52, 945–952. [Google Scholar] [CrossRef]

- Li, R.; Dong, Z.; Khor, K.A. Spark plasma sintering of Al–Cr–Fe quasicrystals: Electric field effects and densification mechanism. Scr. Mater. 2016, 114, 88–92. [Google Scholar] [CrossRef]

- Gendre, M.; Maitre, A.; Trolliard, G. A study of the densification mechanisms during spark plasma sintering of zirconium (oxy-) carbide powders. Acta Mater. 2010, 58, 2598–2609. [Google Scholar] [CrossRef]

- Zheng, J.-C.; Huan, C.; Wee, A.; Van Hove, M.A.; Fadley, C.S.; Shi, F.; Rotenberg, E.; Barman, S.R.; Paggel, J.J.; Horn, K. Atomic-scale structure of the fivefold surface of an AlPdMn quasicrystal: A quantitative x-ray photoelectron diffraction analysis. Phys. Rev. B 2004, 69, 134107. [Google Scholar] [CrossRef]

- Shulyatev, D.; Klyueva, M.; Devaradjan, U. Anisotropy of the electric transport properties of decagonal Al–Cu–Co (Fe) quasicrystals. Phys. Met. Metallogr. 2016, 117, 883–888. [Google Scholar] [CrossRef]

- Suck, J.-B.; Schreiber, M.; Häussler, P. Quasicrystals: An Introduction to Structure, Physical Properties and Applications; Springer Science & Business Media: Berlin, Germany, 2013. [Google Scholar]

- Chen, Y.; Qiang, J.; Dong, C. Smearing-type wear behavior of Al62Cu25.5Fe12.5 quasicrystal abrasive on soft metals. Intermetallics 2016, 68, 23–30. [Google Scholar] [CrossRef]

- Laplanche, G.; Bonneville, J.; Joulain, A.; Gauthier-Brunet, V.; Dubois, S. Mechanical properties of Al–Cu–Fe quasicrystalline and crystalline phases: An analogy. Intermetallics 2014, 50, 54–58. [Google Scholar] [CrossRef]

- Mordyuk, B.; Prokopenko, G.; Milman, Y.V.; Iefimov, M.; Grinkevych, K.; Sameljuk, A.; Tkachenko, I. Wear assessment of composite surface layers in Al–6Mg alloy reinforced with AlCuFe quasicrystalline particles: Effects of particle size, microstructure and hardness. Wear 2014, 319, 84–95. [Google Scholar] [CrossRef]

- Watanuki, T.; Kashimoto, S.; Ishimasa, T.; Machida, A.; Yamamoto, S.; Tanaka, Y.; Mizumaki, M.; Kawamura, N.; Watanabe, S. Thermal expansion of a Au–Al–Yb intermediate valence quasicrystal. Solid State Commun. 2015, 211, 19–22. [Google Scholar] [CrossRef]

- Tsai, A.P.; Suenaga, H.; Ohmori, M.; Yokoyama, Y.; Inoue, A.; Masumoto, T. Temperature dependence of hardness and expansion in an icosahedral Al-Pd-Mn alloy. Jpn. J. Appl. Phys. 1992, 31, 2530–2531. [Google Scholar] [CrossRef]

- Yokoyama, Y.; Tsai, A.-P.; Inoue, A.; Masumoto, T. Production of Quasicrystalline Al–Pd–Mn Alloys with Large Single Domain Size. Mater. Trans. JIM 1991, 32, 1089–1097. [Google Scholar] [CrossRef]

- Louzguine-Luzgin, D.; Inoue, A. Formation and properties of quasicrystals. Annu. Rev. Mater. Res. 2008, 38, 403–423. [Google Scholar] [CrossRef]

- Kang, H.; Li, X.; Wang, T.; Liu, D.; Su, Y.; Hu, Z.; Guo, J.; Fu, H. Crystal–quasicrystal transition depending on cooling rates in directionally solidified Al–3Mn–7Be (at.%) alloy. Intermetallics 2014, 44, 101–105. [Google Scholar] [CrossRef]

- Li, P.; Wang, Z. Experimental Characterization and Modified Constitutive Modeling of the Strain Rate Dependent Compressive Behavior of Adhesives. Macromol. Mater. Eng. 2016, 301, 577–585. [Google Scholar] [CrossRef]

- Wang, Z.; Li, P. Characterisation of dynamic behaviour of alumina ceramics: Evaluation of stress uniformity. AIP Adv. 2015, 5, 107224. [Google Scholar] [CrossRef]

- Wang, Z.; Li, P. Dynamic failure and fracture mechanism in alumina ceramics: Experimental observations and finite element modelling. Ceram. Int. 2015, 41, 12763–12772. [Google Scholar] [CrossRef]

- Forrestal, M.; Wright, T.; Chen, W. The effect of radial inertia on brittle samples during the split Hopkinson pressure bar test. Int. J. Impact. Eng. 2007, 34, 405–411. [Google Scholar] [CrossRef]

- Li, P.; Siviour, C.; Petrinic, N. The effect of strain rate, specimen geometry and lubrication on responses of aluminium AA2024 in uniaxial compression experiments. Exp. Mech. 2009, 49, 587–593. [Google Scholar] [CrossRef]

- Klein, H.; Feuerbacher, M.; Schall, P.; Urban, K. Novel Type of Dislocation in an Al-Pd-Mn Quasicrystal Approximant. Phys. Rev. Lett. 1999, 82, 3468–3471. [Google Scholar] [CrossRef]

- Li, R.; Dong, Z.; Murugan, V.K.; Zhang, Z.; Khor, K.A. Microstructure characterization of Al–Cr–Fe quasicrystals sintered using spark plasma sintering. Mater. Charact. 2015, 110, 264–271. [Google Scholar] [CrossRef]

- Suárez, M.; Esquivel, R.; Alcántara, J.; Dorantes, H.; Chávez, J. Effect of chemical composition on the microstructure and hardness of Al–Cu–Fe alloy. Mater. Charact. 2011, 62, 917–923. [Google Scholar] [CrossRef]

- Yokoyama, Y.; Inoue, A.; Masumoto, T. Mechanical properties, fracture mode and deformation behavior of Al70Pd20Mn10 single-quasicrystal. Mater. Trans. JIM 1993, 34, 135–145. [Google Scholar] [CrossRef]

- Zhu, J.; Hu, S.; Wang, L. An analysis of stress uniformity for concrete-like specimens during SHPB tests. Int. J. Impact. Eng. 2009, 36, 61–72. [Google Scholar] [CrossRef]

- Subhash, G.; Ravichandran, G. Mechanical behaviour of a hot pressed aluminum nitride under uniaxial compression. J. Mater. Sci. 1998, 33, 1933–1939. [Google Scholar] [CrossRef]

- Takeuchi, S.; Iwanaga, H.; Shibuya, T. Hardness of quasicrystals. Jpn. J. Appl. Phys. 1991, 30, 561–562. [Google Scholar] [CrossRef]

- Mikulla, R.; Stadler, J.; Krul, F.; Trebin, H.-R.; Gumbsch, P. Crack propagation in quasicrystals. Phys. Rev. Lett. 1998, 81, 3163–3166. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, R.; Wang, Z.; Li, Z.; Khor, K.A.; Dong, Z. Dynamic Fracture Mechanism of Quasicrystal-Containing Al–Cr–Fe Consolidated Using Spark Plasma Sintering. Crystals 2018, 8, 385. https://doi.org/10.3390/cryst8100385

Li R, Wang Z, Li Z, Khor KA, Dong Z. Dynamic Fracture Mechanism of Quasicrystal-Containing Al–Cr–Fe Consolidated Using Spark Plasma Sintering. Crystals. 2018; 8(10):385. https://doi.org/10.3390/cryst8100385

Chicago/Turabian StyleLi, Ruitao, Zhiyong Wang, Zhong Li, Khiam Aik Khor, and Zhili Dong. 2018. "Dynamic Fracture Mechanism of Quasicrystal-Containing Al–Cr–Fe Consolidated Using Spark Plasma Sintering" Crystals 8, no. 10: 385. https://doi.org/10.3390/cryst8100385

APA StyleLi, R., Wang, Z., Li, Z., Khor, K. A., & Dong, Z. (2018). Dynamic Fracture Mechanism of Quasicrystal-Containing Al–Cr–Fe Consolidated Using Spark Plasma Sintering. Crystals, 8(10), 385. https://doi.org/10.3390/cryst8100385