1. Introduction

MnSn

2 crystallizes in a body-centered tetragonal C16 structure (CuAl

2-type), consisting of alternating layers of Mn and Sn perpendicular to the crystallographic

c-axis [

1]. Correlated with its structure, MnSn

2 exhibited unusual magnetic properties and thereby aroused great interest of researchers in the 1960s [

2]. Later in the 1980s, MnSn

2 was proposed as an erasable optical recording medium [

3]. In recent years, this intermetallic compound was studied more extensively because of its use as electrode materials [

4,

5,

6]. Despite these investigations, however, little work has been performed on the growth of MnSn

2 during solidification process, which is of practical significance considering its increasing use.

It is known that crystal growth is intimately correlated with internal structure. For the tetragonal crystals with the

c-axis shorter than the

a-axis, like Al

3Zr (

a = 3.998 Å and

c = 17.28 Å [

7]) [

8] and Al

3Ti (

a = 3.8537 Å and

c = 8.5839 Å [

9]) [

10], it has been found that they generally grow slowly along the <001> direction and finally exhibit tabular shapes. Based on the atomic arrangement in different crystallographic planes, it was concluded that their growth morphologies are, in a large part, determined by their structures. For the tetragonal crystals with the

c-axes shorter than the

a-axes, like CuAl

2 (

a = 6.067 Å and

c = 4.877 Å [

11]) [

12] and CoSn

2 (

a = 6.363 Å and

c = 5.456 Å [

13]) [

14], it has been shown that they usually form an elongated shape due to the preferential growth along the <001> direction. However, there are few studies that connect their growth morphologies with the internal structures. Therefore, it is of fundamental interest to investigate the growth of such type of crystals. The tetragonal MnSn

2 crystal just has a shorter

c-axis (

c = 5.447 Å) than the

a-axis (

a = 6.659 Å) [

13]. A study on its growth may further contribute to the understanding of the relationship between the external morphology and the internal structure of tetragonal crystals.

In view of this background, it was decided to study the growth of MnSn2 phase during the solidification process of Sn-Mn alloy from the point of view of crystallography.

2. Results and Discussion

Figure 1a shows the backscattered electron (BSE) image of the solidified Sn-Mn alloy. The dark gray primary MnSn

2 crystals embedded in the light gray

β-Sn matrix exhibit bar- or block-like shapes.

Figure 1b–e show some typical magnified shapes of the MnSn

2 crystals, which have ideal orientations with respect to the observation plane. In

Figure 1b, the bar-like crystal has macroscopically smooth interface along the long dimension but rounded ones at tops, showing a partially-faceted growth character. In

Figure 1c,d, both crystals possess octagonal shapes, but the former is approximately regular while the latter non-regular. In

Figure 1e, a square-shaped crystal can be observed (such square-shaped crystals are rarely spotted in the microstructure). Obviously, all the crystals in

Figure 1c–e reveal faceted growth characters.

To deeply understand the morphologies of the MnSn

2 crystals, a crystallographic analysis was also conducted. In

Figure 1b, the projection line OF in the <001> pole figure is parallel to the principal extension direction of the bar-like crystal, indicating a preferential growth along the <001> direction. In

Figure 1c–e, the poles A and B in the <100> pole figures are all located near the outermost circles, suggesting that the octagonal and square surfaces are parallel to the {001} plane. Based on this analysis along with the shapes above, it can be deduced that a typical primary SnMn

2 crystal should have an elongated prism-like shape in three dimensions. The two-dimensional (2D) octagonal and square shapes just result from the transverse cut of these prism-like crystals by the observation plane. To evidence this,

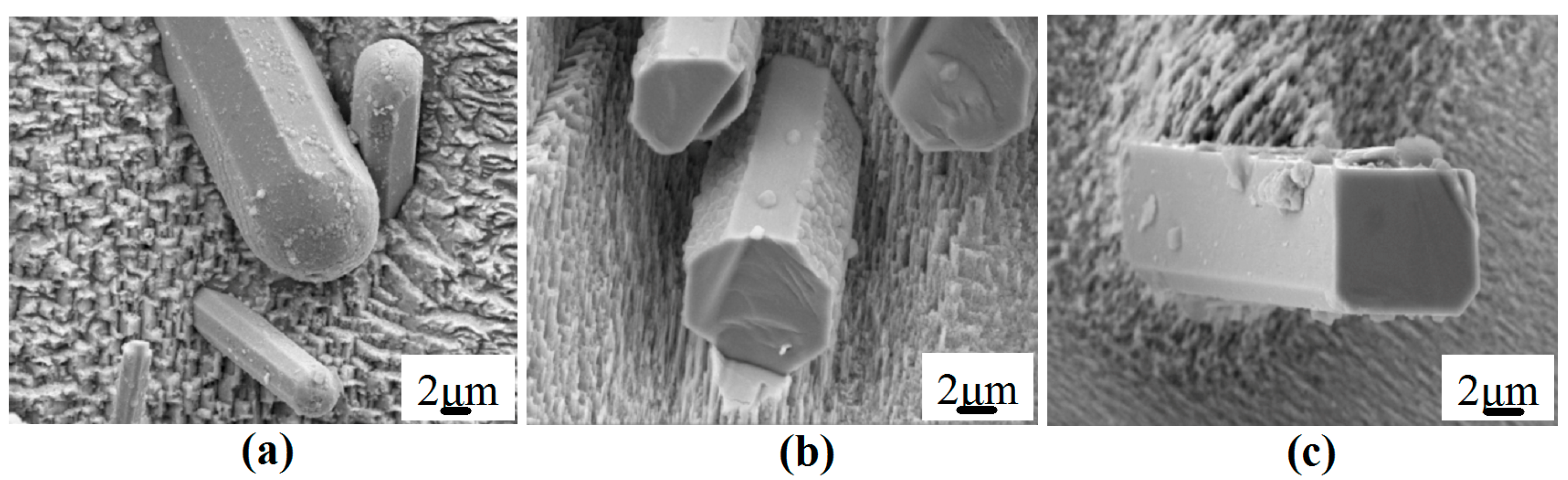

Figure 2a shows a deep-etched SEM image of some SnMn

2 crystals. Obviously, they follow an octagonal-base/spherical-cap geometric model, which is totally different from the aforementioned tabular Al

3Ti and Al

3Ti compounds [

8,

10]. The 3D shapes of truncated octagonal and square bases can be observed in

Figure 2b,c, respectively.

Since the caps of MnSn

2 crystals are spherical (non-faceted), it is difficult to determine a fixed crystallographic plane. However, the side facets can be crystallographically identified. With the indirect two-trace analysis method [

15,

16], it is determined that the side facets of the octagonal base are from the {100} and {110} families while those of the square base from the {110} family. This result can be further visually demonstrated by the <100> and <110> pole figures in

Figure 1c–e (the projection lines OA, OB, OC and OD are parallel to the normals OA, OB, OC and OD of the side surface traces of the MnSn

2 crystals, respectively). However, it is worth noting that both the shorter sides in

Figure 1d and the vanished sides in

Figure 1e correspond to the family of {100} planes.

Crystal growth is a stage following the nucleation, which in a large part determines the final solidification morphology of the crystals. So far, two major crystal growth mechanisms have been well developed [

17], i.e., the continuous growth mechanism and the two-dimensional nucleation mechanism. For the former, the solid-liquid interface is ideally diffusive, so most of the lattice sites are favorable for deposition of atoms. Consequently, the interface moves forward uniformly. Such growth mechanism is usually characterized by a relatively rapid growth, and the final morphology of the crystal is smooth in macroscopic scale (non-faceted). For the latter, the interface is assumed to be atomically smooth, so it is not easy for the lattice sites to absorb atoms. In this case, a distribution of surface clusters (suggested as monolayer island nuclei in the Gibbs–Volmer theory [

18]) must be formed on the plane surface before the crystal surface can continue to grow. This is because that the clusters (or nuclei) can provide energetically favorable steps for surface adsorbed atoms that become a part of the crystal structure [

19]. In such a lateral growth manner, the crystal surface advances continuously. By this growth mechanism, the surface of the final crystal often consists of particular edges and faces (faceted morphology) [

17].

In this work, the spherical caps of the MnSn

2 crystals should follow the continuous growth mechanism, as a result of which the MnSn

2 crystals grow rapidly along the <001> direction and finally form an elongated shape. For the side surfaces of the MnSn

2 crystals, the faceted morphology suggests that they should grow by the two-dimensional nucleation mechanism, i.e., clusters (or nuclei) are firstly formed on the plane surfaces to facilitate the atom absorption. However, it should be noted that the nucleation capabilities on different low index planes vary as their interface structures are different.

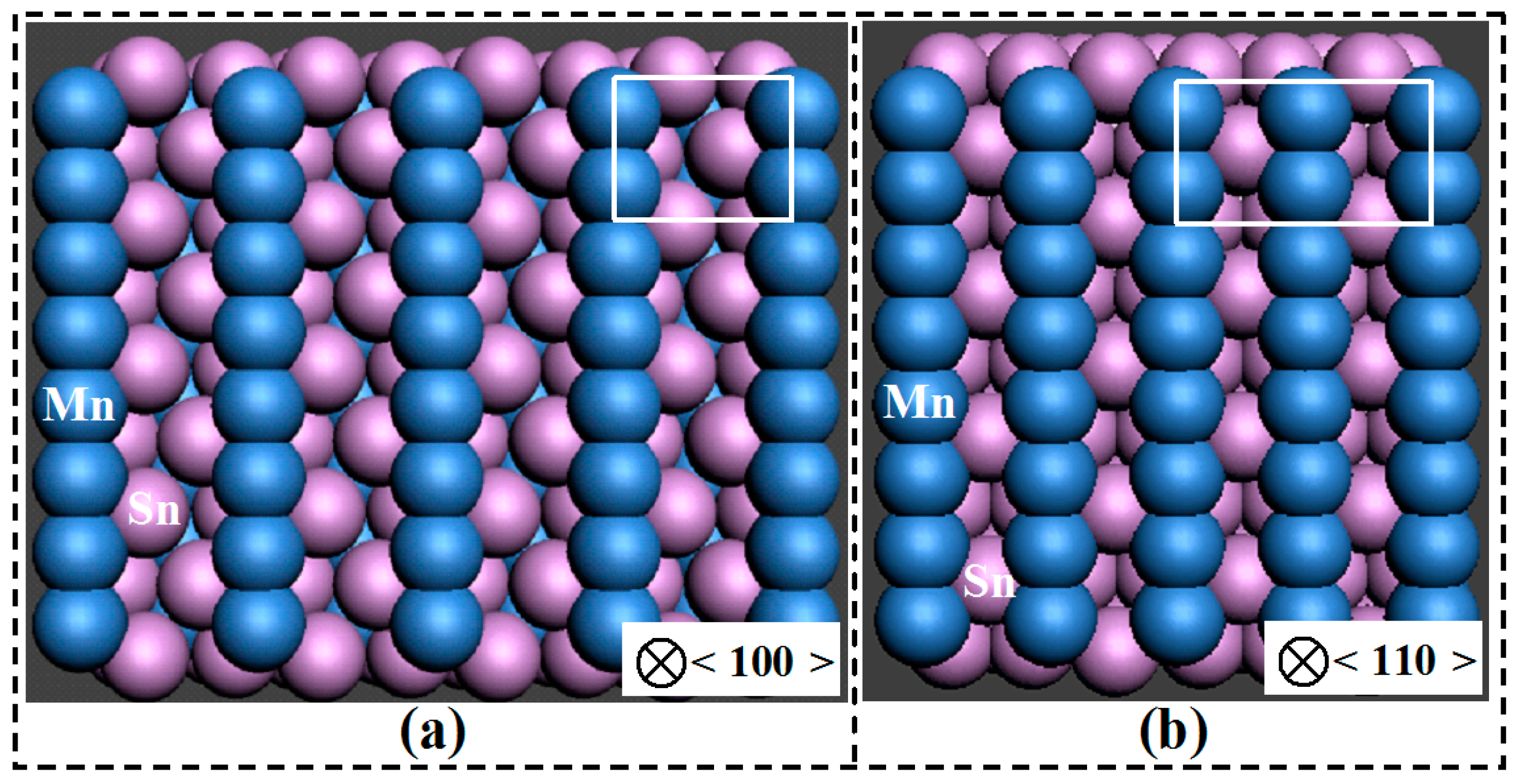

Figure 3a,b show the 3D atomic structures of the {100} and {110} planes of the MnSn

2 phase, respectively. From the Mn atom layers, it seems that the {110} plane is rougher than the {100} plane. To compare the structures of these two planes more quantitatively, a reticular density calculation is helpful. The reticular density

ρ is defined as the number of atoms per unit area on a plane [

20]. For

ρ{h k l}, the atoms involved in number counting usually only refer to those having centers that lie on the specific {h k l} plane. However, such density sometimes cannot reflect the underlying interface structure. This is because that there exist additional atom planes instead of only one within an interplanar spacing period (IPSP) in complex crystal structures.

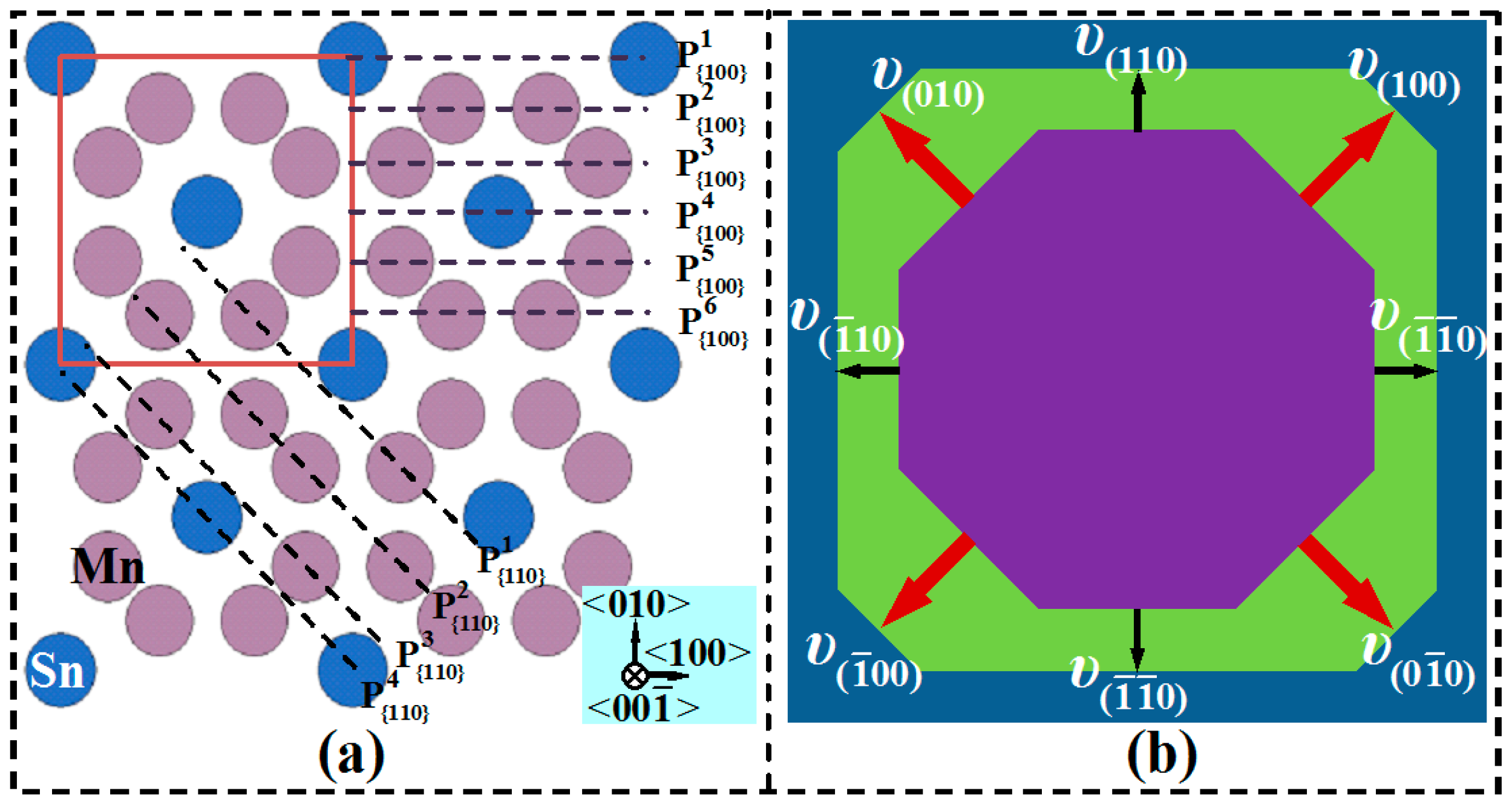

Figure 4a shows the

projection view of the MnSn

2 structure. As can be observed, there are six (

–

) and four (

–

) planes within the {100} and {110} IPSPs, respectively. Using the new planar density (equivalent to the reticular density

) calculating method [

21], we get

atoms/Å

2,

atoms/Å

2 and

atoms/Å

2. If we define the average reticular density within the {h k l} IPSP as

(

S is the area of the

plane), we obtain

<

(i.e., 0.05528 atoms/Å

2 < 0.05864 atoms/Å

2).

According to the Bravais Law [

22], the crystal planes having lower reticular density grow more rapidly than the planes of higher reticular density due to the larger attraction ability to the outside atoms. Thus, the {100} planes of the MnSn

2 crystals should have a higher 2D nucleation capability. In other words, the {100} planes can accumulate more critically sized clusters (or nuclei) than the {110} planes to cover the entire surface. As a consequence, the {100} planes have a faster growth rate than the {110} planes. This also explains why the {100} planes tend to get shorter (

Figure 1d) and then disappear (

Figure 1e), as schematically illustrated in

Figure 4b (the octagonal base tends to develop into a square base).

3. Materials and Methods

Sn-1.5 wt.% Mn alloy was prepared with pure metals of Sn (99.95 wt.%) and Mn (99.9 wt.%). A rod was cut from the alloy and then put into a tube of high-purity corundum crucible. The crucible containing the rod was placed in a vacuum resistance furnace and then heated up to 380 °C at a rate of 5 °C/min under argon atmosphere. After being held at this temperature for 20 min, the melt was furnace-cooled to room temperature (the average cooling rate was about 6 °C/min). A specimen was cut lengthwise from the solidified ingot (Φ 10 × 12 mm), following a standard mechanical polishing. The microstructure was observed by a Zeiss ULTRA PLUS FE-SEM (Field-Emission Scanning Electron Microscope, Carl Zeiss, Jena, Germany). After further polishing plus argon ion beam cleaning, individual EBSD (Electron Backscatter Diffraction) orientation measurements of the MnSn2 phase were performed on manually chosen points by the same FE-SEM (equipped with an Oxford-HKL Channel 5 system) as above. To reveal the 3D shape of the MnSn2 phase, a deep etching of the specimen was performed in a solution of 5% NaOH and 3.5% orthonitrophenol in distilled water at 60 °C for 3 min and washed in an ultrasonic ethanol bath.

The side facets binding the MnSn

2 phase were determined by an indirect two-trace method [

15,

16]. By making use of two independent interface trace vectors from one uniquely defined interface and the orientations of their adjacent crystals, this method determines the interface plane normal and thus the interface plane through numerical calculations concerning coordinate system change (based on the Euler angles (φ

1, φ, φ

2) obtained from the above-mentioned EBSD individual orientation measurements) (see Reference [

15] for more details). The reticular density was calculated by the position-duplication-number method developed by Fan [

21].

4. Conclusions

Sn-Mn alloy was solidified to crystallographically investigate the growth of MnSn2 phase. It was found that:

The non-faced spherical caps of the MnSn2 crystals follow the continuous growth mechanism to grow rapidly along the <001> direction; the side surfaces follow the two-dimensional nucleation mechanism to form the low index {100} and {110} facets.

With an interface structure analysis, it was found that the average reticular density of the atom planes within the {100} IPSP is lower than those within the {011} IPSP so that the {100} planes grow more rapidly than the {110} planes. As a result, the {100} side facets tend to get shorter and then disappear.

Finally, the partially faceted (i.e., non-faceted spherical caps and faceted side surfaces) MnSn2 crystals follow an octagonal-base/spherical-cap geometric model (few crystals possess square bases).