Temperature Dependence of the Thermal, Electrical Resistivity, Dielectric and Piezoelectric Properties of CaYAl3O7 Crystal

Abstract

:1. Introduction

2. Experimental

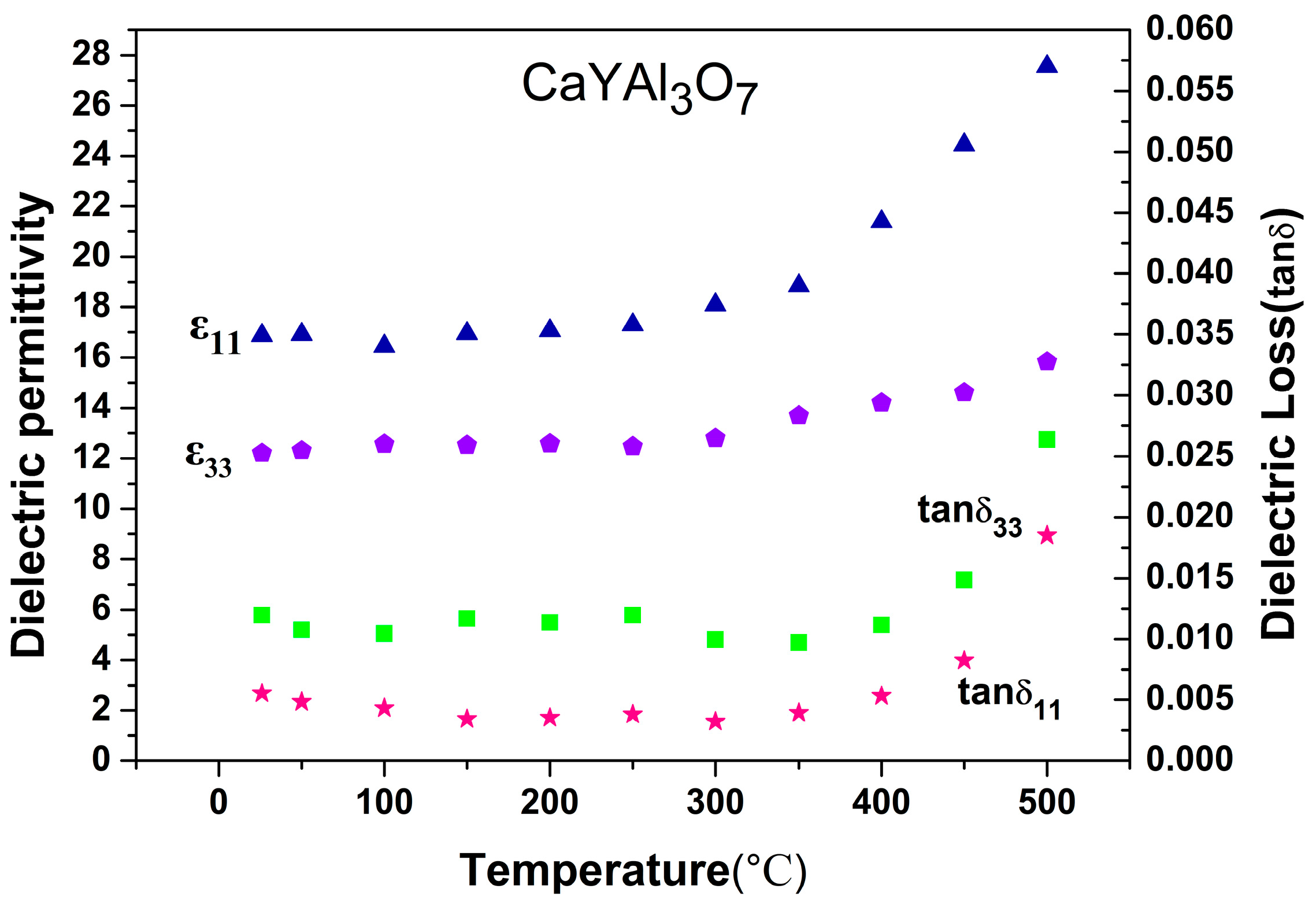

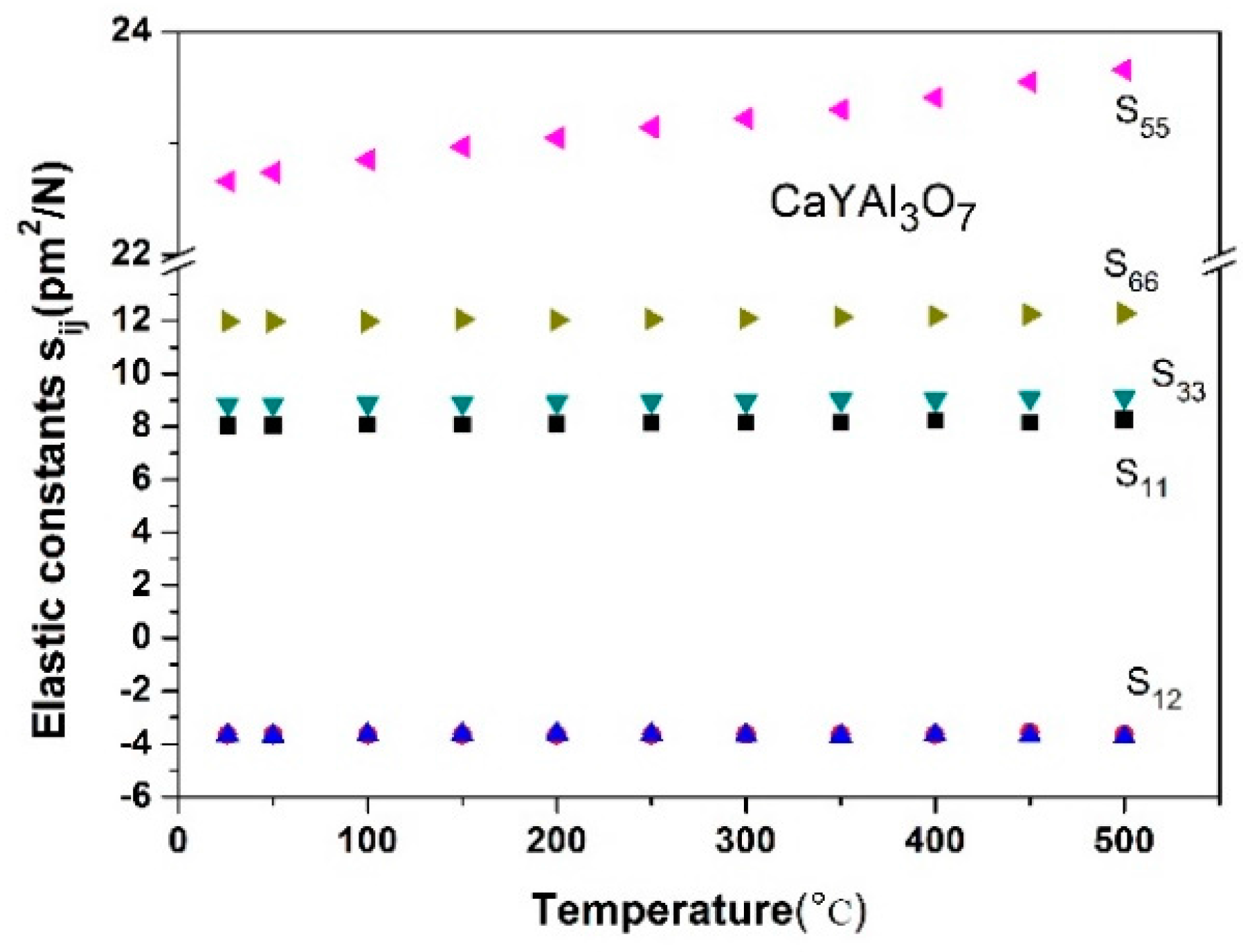

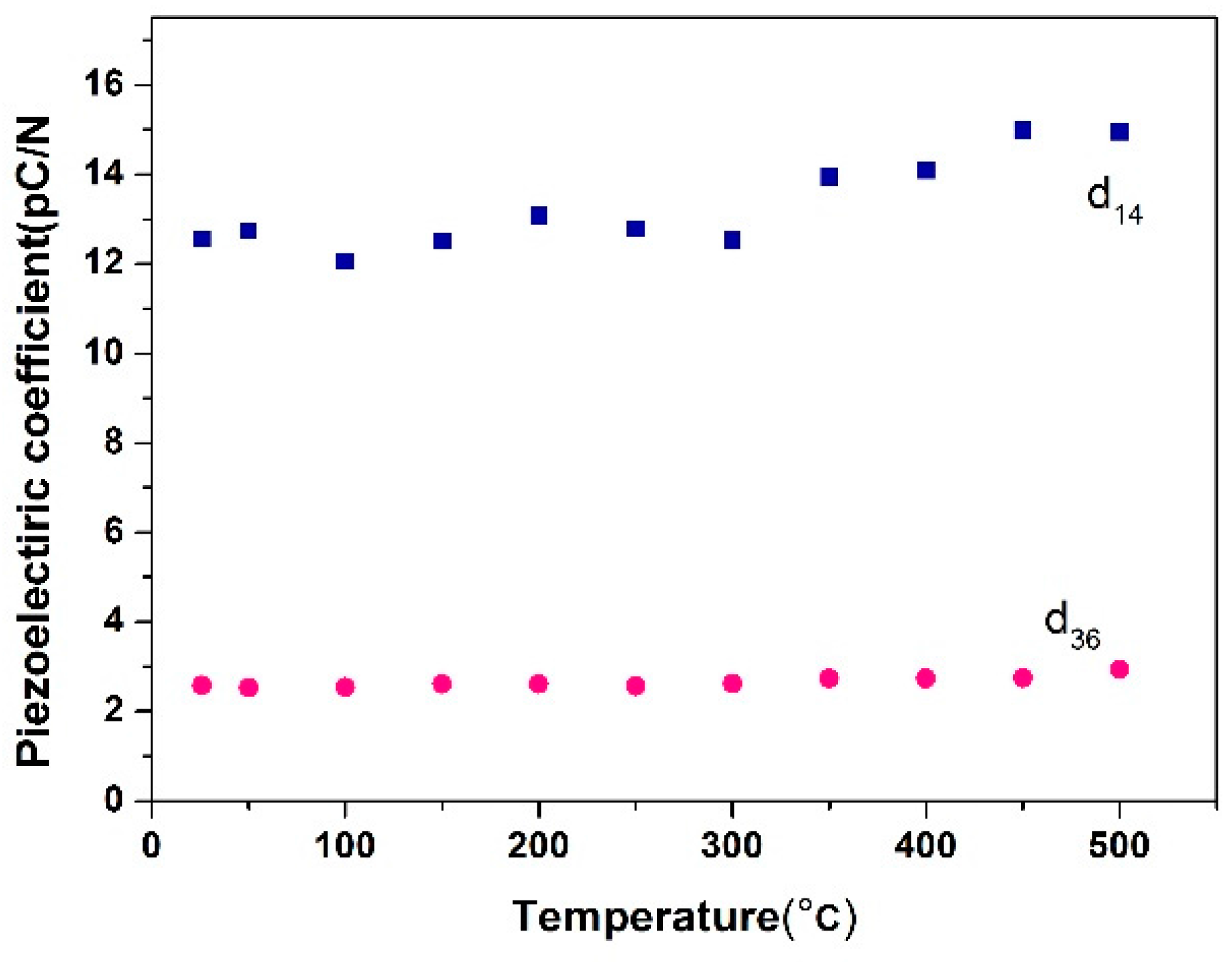

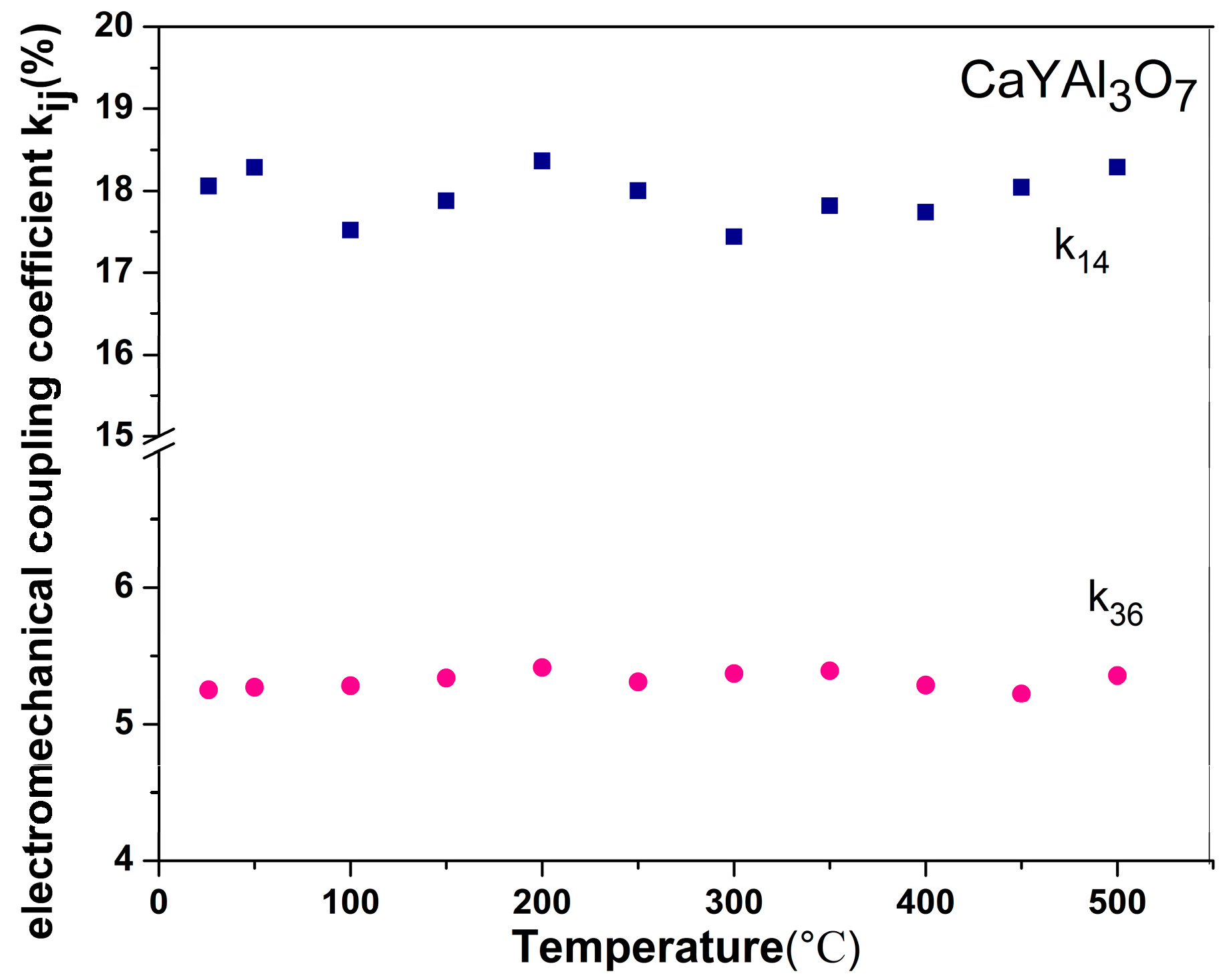

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhang, S.; Yu, F.; Green, D.J. Piezoelectric materials for high temperature sensors. J. Am. Ceram. Soc. 2011, 94, 3153–3170. [Google Scholar] [CrossRef]

- Zhang, S.; Zheng, Y.; Kong, H.; Xin, J.; Frantz, E.; Shrout, T.R. Characterization of high temperature piezoelectric crystals with an ordered langasite structure. J. Appl. Phys. 2009, 105, 114107. [Google Scholar] [CrossRef]

- Shrout, T.R.; Zhang, S.J. Lead-free piezoelectric ceramics: Alternatives for PZT? J. Electroceram. 2007, 19, 113–126. [Google Scholar] [CrossRef]

- Fu, H.; Cohen, R.E. Polarization rotation mechanism for ultrahigh electromechanical response in single-crystal piezoelectrics. Nature 2000, 403, 281. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.-T.; Kounga, A.B.; Aulbach, E.; Deng, Y. Temperature-dependent electrical properties of 0.94Bi0.5Na0.5TiO3–0.06BaTiO3 ceramics. J. Am. Ceram. Soc. 2008, 91, 3950–3954. [Google Scholar] [CrossRef]

- Baba, A.; Searfass, C.T.; Tittmann, B.R. High temperature ultrasonic transducer up to 1000 °C using lithium niobate single crystal. Appl. Phys. Lett. 2010, 97, 232901. [Google Scholar]

- Turner, R.C.; Fuierer, P.A.; Newnham, R.E.; Shrout, T.R. Materials for high temperature acoustic and vibration sensors: A review. Appl. Acoust. 1994, 41, 299–324. [Google Scholar] [CrossRef]

- Fritze, H.; Tuller, H.L. Langasite for high-temperature bulk acoustic wave applications. Appl. Phys. Lett. 2001, 78, 976–977. [Google Scholar] [CrossRef]

- Shen, C.; Zhang, Y.; Yu, H.; Zhang, S.; Cao, W.; Wang, J.; Zhang, H. Dielectric, elastic and piezoelectric properties of SrLaGa3O7 and BaLaGa3O7 crystals with melilite structure. J. Alloys Compd. 2015, 647, 1069–1074. [Google Scholar] [CrossRef]

- Smith, R.T.; Welsh, F.S. Temperature dependence of the elastic, piezoelectric, and dielectric constants of lithium tantalate and lithium niobate. J. Appl. Phys. 1971, 42, 2219–2230. [Google Scholar] [CrossRef]

- Xia, H.; Feng, J.; Wang, Y.; Li, J.; Ji, Y.; Jia, Z.; Tu, C. The effects of Ho3+ and Pr3+ ions on the spectroscopic properties of Er3+ doped SrGdGa3O7 crystals used in mid-infrared lasers. J. Phys. D Appl. Phys. 2015, 48, 435106. [Google Scholar] [CrossRef]

- Shen, C.; Zhang, S.; Wang, D.; Xu, T.; Yu, H.; Cao, W.; Wang, J.; Zhang, H. Growth and property characterization of CaNdGa3O7 and SrNdGa3O7 melilite single crystals. CrystEngComm 2015, 17, 1791–1799. [Google Scholar] [CrossRef]

- Zhang, Y.; Yin, X.; Yu, H.; Cong, H.; Zhang, H.; Wang, J.; Boughton, R.I. Growth and piezoelectric properties of melilite ABC3O7 crystals. Cryst. Growth Des. 2012, 12, 622–628. [Google Scholar] [CrossRef]

- Shimamura, K.; Takeda, H.; Kohno, T.; Fukuda, T. Growth and characterization of lanthanum gallium silicate La3Ga5SiO14 single crystals for piezoelectric applications. J. Crys. Growth 1996, 163, 388–392. [Google Scholar] [CrossRef]

- Philippot, E.; Ibanez, A.; Goiffon, A.; Cochez, M.; Zarka, A.; Capelle, B.; Schwartzel, J.; Détaint, J. A quartz-like material: Gallium phosphate (GaPo4); crystal growth and characterization. J. Cryst. Growth 1993, 130, 195–208. [Google Scholar] [CrossRef]

- Tichý, J.; Privatska, J.; Prívratská, J.; Kittinger, E.; Erhart, J.; Janovec, V. Fundamentals of piezoelectric sensorics : Mechanical, dielectric, and thermodynamical properties of piezoelectric materials. Cheminform 2010, 34, 1423–1440. [Google Scholar]

- Hagiwara, M.; Noguchi, H.; Hoshina, T.; Takeda, H.; Fujihara, S.; Kodama, N.; Tsurumi, T. Growth and characterization of Ca2Al2SiO7 piezoelectric single crystals for high-temperature sensor applications. Jpn. J. Appl. Phys. 2013, 52, 09KD03. [Google Scholar] [CrossRef]

- Philippen, J.; Guguschev, C.; Klimm, D. Single crystal fiber growth of cerium doped strontium yttrate, SrY2O4:Ce3+. J. Cryst. Growth 2017, 459, 17–22. [Google Scholar] [CrossRef]

- Park, S.H.; Lee, K.H.; Unithrattil, S.; Yoon, H.S.; Jang, H.G.; Im, W.B. Melilite-structure CaYAl3O7:Eu3+ phosphor: Structural and optical characteristics for near-UV led-based white light. J. Phys. Chem. C Nanomater. Interfaces 2012, 116, 26850–26856. [Google Scholar] [CrossRef]

- Kodama, N.; Takahashi, T.; Yamaga, M.; Tanii, Y.; Qiu, J.; Hirao, K. Long-lasting phosphorescence in Ce3+-doped Ca2Al2SiO7 and CaYAl3O7 crystals. Appl. Phys. Lett. 1999, 75, 1715–1717. [Google Scholar] [CrossRef]

- Yuan, D.; Jia, Z.; Wang, J.; Gao, Z.; Zhang, J.; Fu, X.; Shu, J.; Yin, Y.; Hu, Q.; Tao, X. Bulk growth, structure, and characterization of the new monoclinic TbCa4O(BO3)3 crystal. CrystEngComm 2014, 16, 4008–4015. [Google Scholar] [CrossRef]

- Meitzler, A.H.; Berlincourt, D.; Welsh, F.S.; Tiersten, H.F.; Coquin, G.A.; Warner, A.W. 176-1987 IEEE Standard on Piezoelectricity; IEEE: Piscataway, NJ, USA, 1988. [Google Scholar]

- Gao, Z.; Yin, X.; Zhang, W.; Wang, S.; Jiang, M.; Tao, X. Temperature dependence of elastic properties and piezoelectric applications of BaTeMo2O9 single crystal. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2011, 58, 2753. [Google Scholar] [CrossRef] [PubMed]

- Hu, Q.; Jia, Z.; Tang, C.; Lin, N.; Zhang, J.; Jia, N.; Wang, S.; Zhao, X.; Tao, X. The origin of coloration of CaGdAlO4 crystals and its effect on their physical properties. CrystEngComm 2017, 19, 537–545. [Google Scholar] [CrossRef]

| Specimen | Electric Field Direction | Coefficients |

|---|---|---|

| X-cut square plate | X | ε11, s44 = s55 |

| Z-cut square plate | Z | ε33, s66 |

| (XYt)5° (XYt)45° and (XYt)85° bars | X | s11, s33, 2s13 + s55, d14, k36 |

| (ZXt)45° bar | Z | 2s12 + s66, d36, k14 |

| CaYAl3O7 | ||

|---|---|---|

| <100> | <001> | |

| Hv (kg/mm2) | 1188 | 833 |

| HM | 7.14 | 6.35 |

| Ts11 | Ts12 | Ts13 | Ts33 | Ts55 | Ts66 | |

|---|---|---|---|---|---|---|

| first order 10−6/°C | 442 | 144 | 164 | 670 | 2820 | −53 |

| second order 10−9/°C2 | −255 | −29 | 136 | −1110 | −4285 | 1846 |

| third order 10−12/°C3 | 751 | −43 | 228 | 1992 | 5718 | −962 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Jia, Z.; Yin, Y.; Hu, Q.; Mu, W.; Zhang, J.; Yu, X.; Tao, X. Temperature Dependence of the Thermal, Electrical Resistivity, Dielectric and Piezoelectric Properties of CaYAl3O7 Crystal. Crystals 2018, 8, 34. https://doi.org/10.3390/cryst8010034

Li Y, Jia Z, Yin Y, Hu Q, Mu W, Zhang J, Yu X, Tao X. Temperature Dependence of the Thermal, Electrical Resistivity, Dielectric and Piezoelectric Properties of CaYAl3O7 Crystal. Crystals. 2018; 8(1):34. https://doi.org/10.3390/cryst8010034

Chicago/Turabian StyleLi, Yang, Zhitai Jia, Yanru Yin, Qiangqiang Hu, Wenxiang Mu, Jian Zhang, Xiaoqiang Yu, and Xutang Tao. 2018. "Temperature Dependence of the Thermal, Electrical Resistivity, Dielectric and Piezoelectric Properties of CaYAl3O7 Crystal" Crystals 8, no. 1: 34. https://doi.org/10.3390/cryst8010034

APA StyleLi, Y., Jia, Z., Yin, Y., Hu, Q., Mu, W., Zhang, J., Yu, X., & Tao, X. (2018). Temperature Dependence of the Thermal, Electrical Resistivity, Dielectric and Piezoelectric Properties of CaYAl3O7 Crystal. Crystals, 8(1), 34. https://doi.org/10.3390/cryst8010034