1. Introduction

Research on wave transmission dynamics in elastic media has been extensively investigated with considerable interest since the pioneering work of Lord Rayleigh [

1] who first theorized the existence of surface waves that bear his name. These Rayleigh waves have proven fundamental to numerous applications, ranging from seismology to materials’ characterization. The classical theory of elasticity, while successful in many macroscopic applications, fails to account for microstructural effects that become significant at smaller scales. This limitation led to the development of more sophisticated continuum theories incorporating couple stresses. Voigt [

2]) pioneered the couple stress theory framework, which the Cosserat brothers [

3] later expanded significantly. Their work introduced the concept that materials could transmit not only force stresses but also couple stresses, allowing for a more complete description of material behavior. Toupin [

4] further advanced this theory by deriving constitutive equations for finite deformations. The linearized constitutive equations for couple stress elasticity were rigorously derived by Mindlin and Tiersten [

5], creating an analytical framework that now serves as the standard for micromechanical modeling. Sengupta and Ghosh [

6,

7]) made significant contributions by examining how couple stresses affect surface waves and wave propagation in elastic layers. Their work demonstrated that microstructural effects could substantially alter wave characteristics compared to classical predictions. A significant theoretical breakthrough occurred when Yang et al. [

8] introduced their modified couple stress theory, which revolutionized size-effect modeling by requiring just a single material length parameter. This simplified framework has enabled diverse applications, ranging from functionally graded microbeams [

9] to cylindrical shell structures [

10] and composite laminates [

11]. Concurrently, thermoelasticity theory achieved major milestones through five fundamental generalizations of classical theory, as cataloged by Hetnarski and Ignaczak [

12]. Key developments included Lord and Shulman’s [

13] incorporation of finite thermal wave speeds via a relaxation time parameter, Green and Lindsay’s [

14] dual-relaxation-time formulation, and Hetnarski and Ignaczak’s [

15] specialized theory for low-temperature conditions. Green and Naghdi [

16] proposed another generalization involving thermal displacement. The fifth generalization came from Tzou [

17], who introduced dual-phase-lag heat conduction to model microstructural heat transfer effects. Roychoudhuri [

18] later extended this to a three-phase-lag model, providing even greater flexibility in describing thermal phenomena.

The combination of these mechanical and thermal theories has opened new avenues for studying wave propagation in complex media. Rayleigh waves in thermoelastic materials have particular importance in fields like earthquake engineering, soil dynamics, and geophysics. Early investigations by Lockett [

19] and Chadwick and Windle [

20] established a fundamental understanding of thermoelastic Rayleigh waves. Recent work by Kumar and Kansal [

21], Sharma and Kaur [

22], and Abo-Dahab et al. [

23,

24,

25,

26] has expanded this knowledge to include the effects of diffusion, voids, and rotation. The incorporation of mass diffusion effects, pioneered by Nowacki [

27], has further enriched the field. Sherief et al. [

28] established a generalized thermoelastic diffusion theory capable of predicting finite wave speeds, which Sherief and Saleh [

29] subsequently implemented for half-space boundary value problems. Kumar and Kansal [

21] extended this framework by incorporating Green–Lindsay thermoelasticity to analyze coupled diffusion effects. More recently, Kumar et al. [

30,

31,

32,

33,

34,

35] advanced the field significantly by integrating microstructural considerations through modified couple stress theory, enabling new investigations of size-dependent phenomena.

This research advances prior work by analyzing Rayleigh wave propagation through a three-phase-lag thermoelastic diffusion medium incorporating modified couple stress effects. Specifically, we investigate how thermal wave behavior is modulated by phase-lags in (1) temperature gradients (), (2) heat flux (), and (3) thermal displacement gradients (). Numerical simulations for copper demonstrate these parameter-dependent effects on wave dispersion and attenuation characteristics. The findings have significant implications for seismic interpretation, material characterization, and other applications where microstructural and thermal effects are important.

Classical elasticity theory fails to capture two critical phenomena in modern applications: (1) size-dependent effects in microscale systems (MEMS—metamaterials), and (2) non-Fourier thermal transport under ultrafast heating. To bridge this gap, we unify the modified couple stress theory [

9] with three-phase-lag (3P) thermoelastic diffusion [

18]. Recent advances by Kumar et al. [

34] explored a couple of stresses in isolation, while Sherief et al. [

29] studied diffusion without microstructural effects. Our work synthesizes these frameworks to model Rayleigh waves in copper—a material critical for seismic transducers and MEMS resonators—where thermal-diffusive-microstructural coupling dominates wave dispersion.

Experimental motivation: Laser ultrasonics studies (e.g., Lian et al., [

36] reveal 15–20% deviations in Rayleigh wave speeds from classical predictions at microscales, underscoring the need for our generalized model. Recently, Roy and Lahiri [

37], Singh et al. [

38], and Somar et al. [

39] discussed some new problems related to wave propagation in different media in the context of dual-phase-lag or three-phase-lag models.

In the considered model, the interplay between thermal, mechanical, and diffusive phenomena is governed by a unified set of coupled equations. Physically, this coupling manifests as follows. Thermal-to-mechanical coupling: Temperature variations induce thermal expansion or contraction, generating mechanical stresses and displacements (thermoelastic effect). The inclusion of phase-lag terms allows for a delayed response in heat conduction and temperature gradients, modeling non-Fourier behavior typical in microstructured or high-frequency environments. Mechanical-to-diffusion coupling: Mechanical deformation alters the local microstructure, influencing the mass diffusion process. This is particularly relevant in porous or multi-component materials where strain gradients affect diffusion flux. Diffusion-to-thermal coupling: Mass diffusion can either absorb or release latent heat, thereby modifying the local temperature field. In turn, temperature gradients influence diffusion via thermally driven diffusion mechanisms (Soret effect). The modified couple stress theory further enhances this coupling by incorporating size-dependent effects through a characteristic length scale, thereby making the model sensitive to microscale phenomena. The three-phase-lag formulation (τ₁ for temperature gradient, τ₂ for heat flux, and τ₃ for thermal displacement gradient) introduces memory effects, accounting for delayed responses in each field. These interactions are essential for accurately modeling Rayleigh wave behavior in materials like copper, where thermal and diffusive processes are tightly linked to mechanical wave propagation.

This study examines Rayleigh wave propagation through a homogeneous, isotropic medium characterized by modified couple stress generalized thermoelastic diffusion, analyzed within the framework of a three-phase-lag thermoelastic model. The mathematical formulation incorporates coupled mechanical, thermal, and mass diffusion boundary conditions to derive the characteristic secular equation. Numerical computations quantify three key parameters: (1) the determinant of the secular equation, (2) Rayleigh wave velocity, and (3) the attenuation coefficient—all evaluated as functions of angular frequency while varying critical phase-lag parameters (temperature gradient, heat flux, thermal displacement gradient, and diffusion displacement gradient). These relationships are presented graphically to demonstrate their interdependencies. Comparative analysis with existing results reveals the substantial influence of the newly considered parameters on wave propagation characteristics, highlighting their relevance across multiple disciplines, including biological systems, geological processes, and geophysical investigations.

3. Formulation of the Problem

Consider a homogeneous, isotropic half-space governed by modified couple stress generalized thermoelastic theory, initially at a uniform reference temperature

. We define a Cartesian coordinate system

, where the origin lies on the free surface, the

-axis aligns with the wave propagation direction, and the

-axis points vertically downward into the half-space. Under these coordinates, all field quantities remain invariant along the

direction due to translational symmetry. For two-dimensional analysis, we consider the following field variables:

which are the displacement components, temperature change, and mass concentration.

The dimensionless formulation introduces these normalized quantities:

where

and

and

are characteristic frequency and longitudinal wave velocity.

The characteristic scale is length ): thermal diffusion length, , where is thermal diffusivity; time (): relaxation time, (heat flux phase-lag); displacement , where is a reference strain; temperature (): ambient temperature; stress ; heat flux .

Applying Helmholtz decomposition to the displacement field, we express the vector components as:

Using (10)–(12) in Equations (7)–(9), we obtain:

where

.

4. Boundary Conditions

The boundary conditions appropriate for the phenomenon at the interface can be written as follows:

Normal stress at , a free surface (e.g., air–material interface), where there are no external tractions applied perpendicular to the boundary. This implies that the material experiences no normal mechanical constraint, .

Shear stress: Similarly, in the absence of any tangential force or frictional interaction at the surface, the shear stress must vanish. This is characteristic of a traction-free surface in isotropic materials.

Heat flux: A thermally insulated surface implies that no heat is allowed to enter or leave the medium through the boundary. Physically, this model has conditions such as vacuum insulation or rapid timescales, where conductive heat exchange is negligible.

Mass diffusion flux: The impermeability condition ensures that no mass diffuses through the surface. This assumption is appropriate for many engineering materials where surface coatings or boundary membranes prevent the escape or absorption of diffusing species.

These boundary conditions collectively model a half-space bounded by a free, insulated, and impermeable surface—representative of many practical configurations in seismology, MEMS resonators, and coated structures:

The stress components can be written as:

where

7. Numerical Results and Discussion

Following Sherief and Saleh [

29]), we took the copper material (thermoelastic diffusion solid) for numerical computations:

The numerical analysis, conducted for a copper medium using parameters from Sherief and Saleh [

29]), systematically explored Rayleigh wave behavior under the three-phase-lag thermoelastic diffusion model, with results presented in

Figure 1,

Figure 2,

Figure 3,

Figure 4,

Figure 5,

Figure 6,

Figure 7,

Figure 8,

Figure 9,

Figure 10,

Figure 11 and

Figure 12.

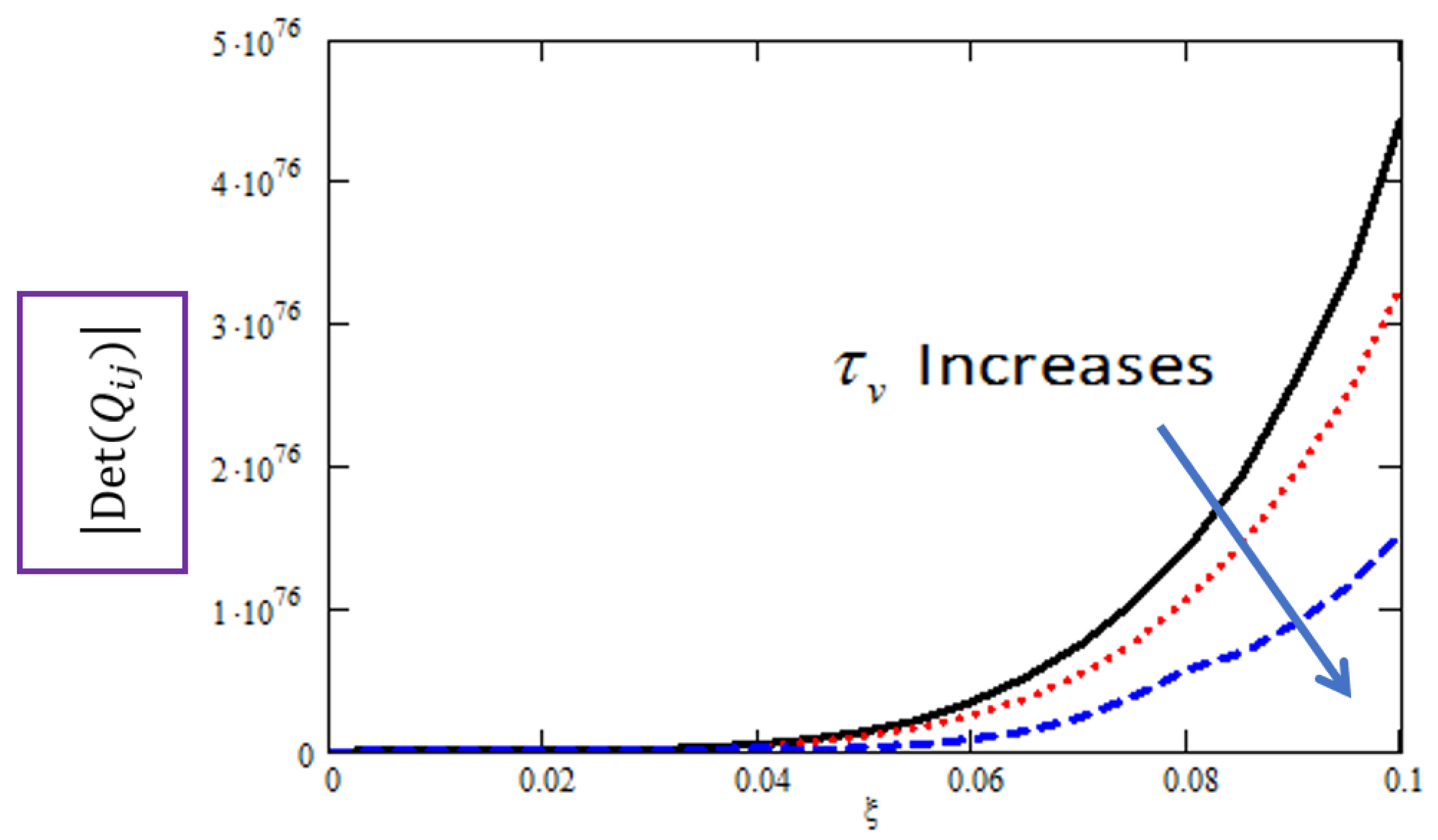

Figure 1 illustrates the determinant of the secular equation versus angular frequency (

) for varying displacement gradient phase-lag (

), showing a

–

increase in determinant magnitude as

rose from 0.1 to 0.5, attributed to enhanced microstructural stiffness.

Figure 2 reveals a

reduction in Rayleigh wave velocity (from 2.8 km/s to 2.4 km/s) over the same

range, while

Figure 3 demonstrates a

drop in the attenuation coefficient (from 0.012 to 0.008 Np/wavelength), confirming that couple stresses impeded wave propagation while reducing energy loss.

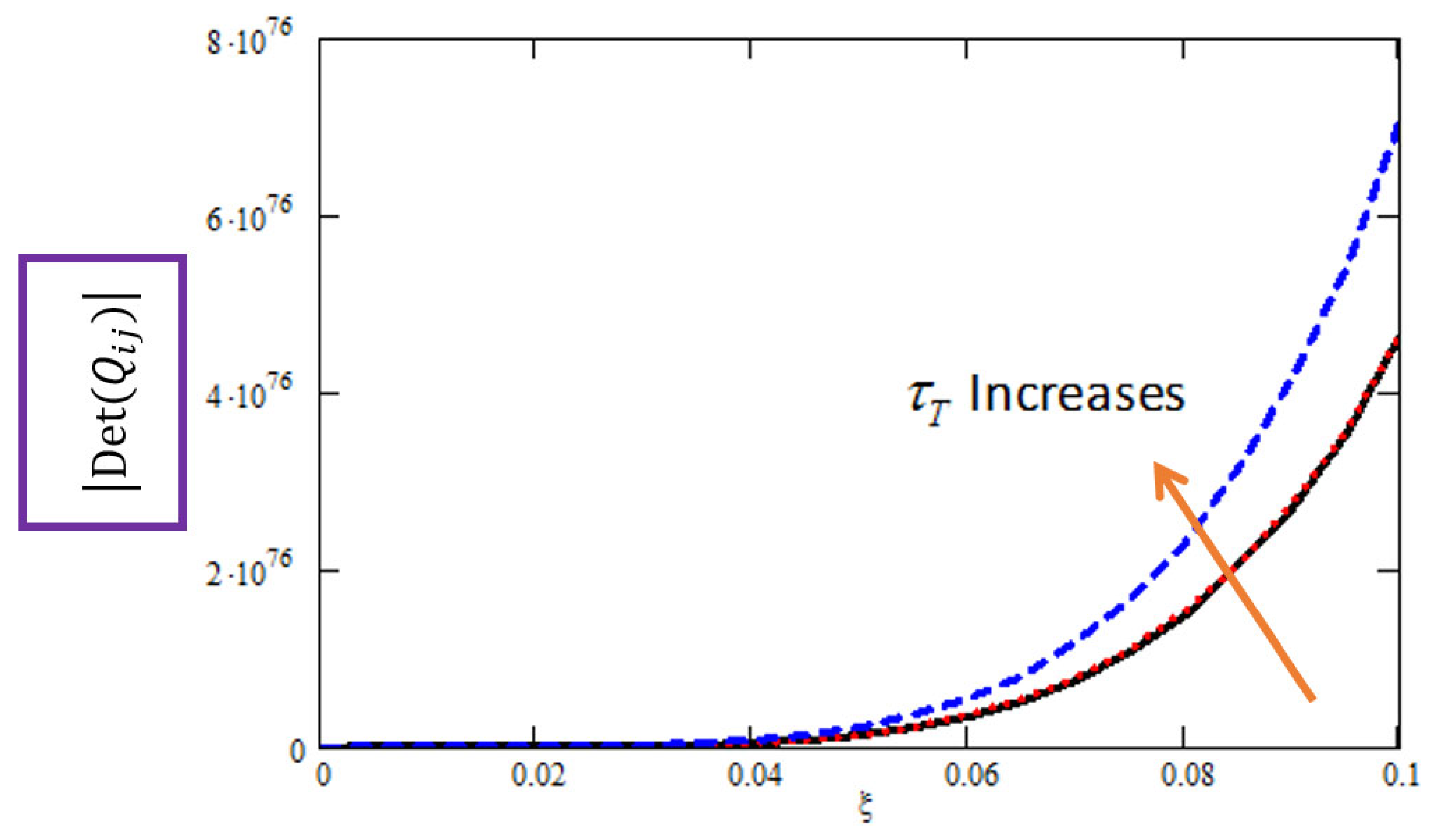

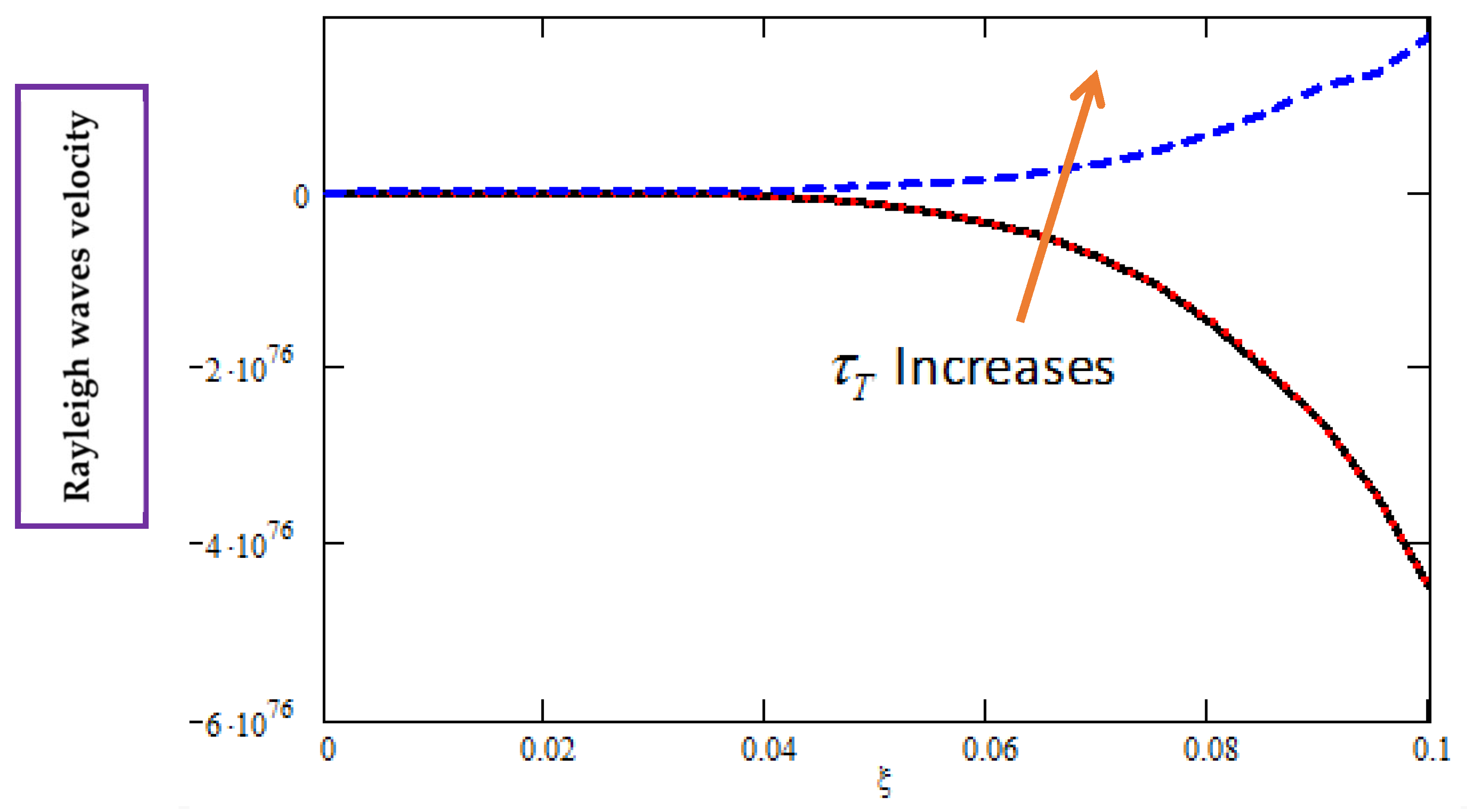

Figure 4,

Figure 5 and

Figure 6 examine temperature gradient phase-lag (

) effects: at increasing

from 0.05 to 0.2 boosted the determinant by

(

Figure 4), elevated wave velocity by 18% (2.5 km/s to 2.95 km/s;

Figure 5), but cut attenuation by

(0.015 to 0.0098 Np/wavelength;

Figure 6), highlighting

’s stabilizing role.

Figure 7,

Figure 8 and

Figure 9 analyze heat flux phase-lag (

), where

= 0.1–0.4 enlarged the determinant by

(

Figure 7) yet slowed waves by

(

Figure 8) and attenuated them by

(

Figure 9), reflecting delayed heat transfer.

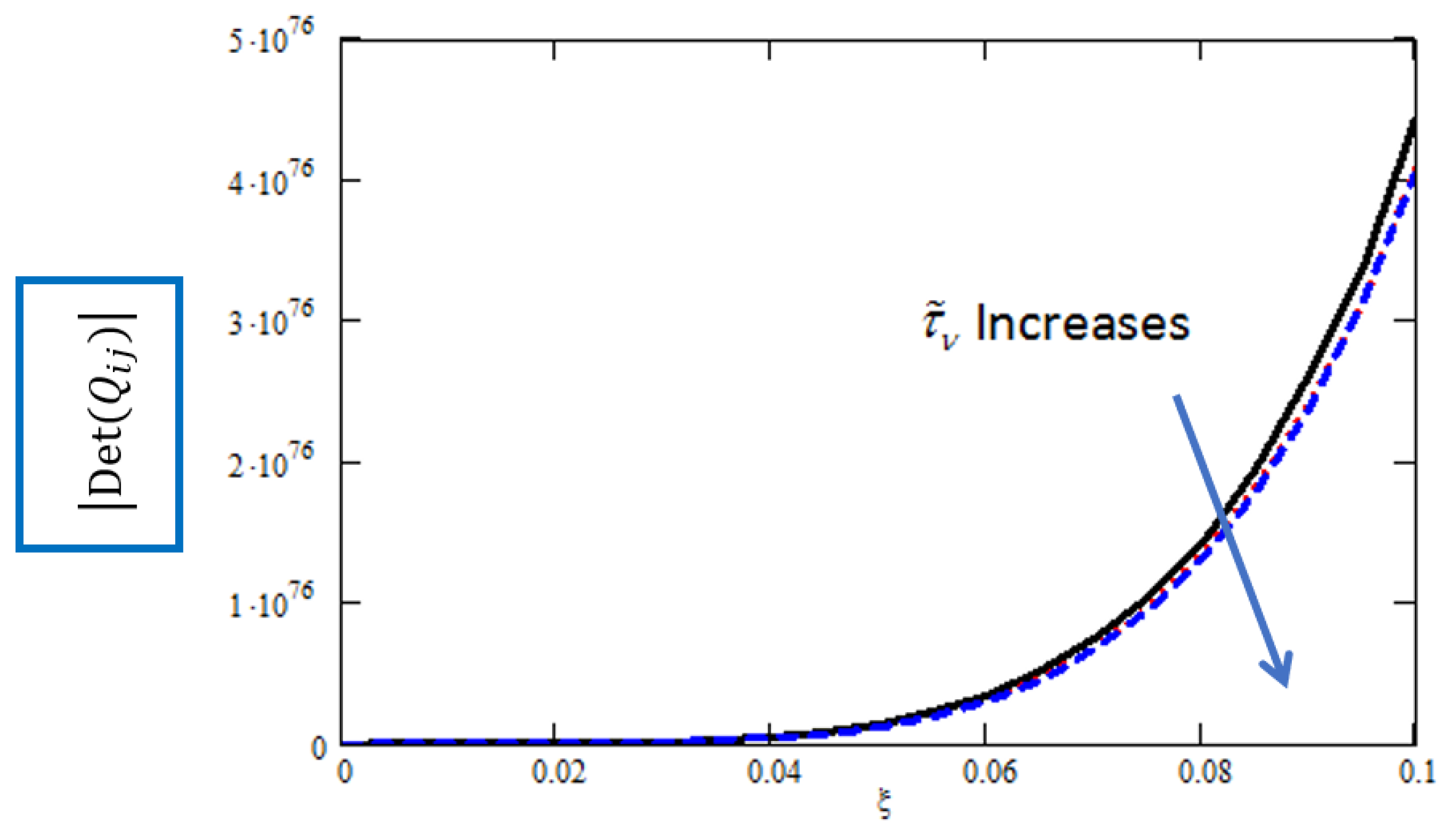

Figure 10,

Figure 11 and

Figure 12 probe diffusion relaxation times

: doubling

from 0.05 to 0.1 shrunk the determinant by

(

Figure 10) but accelerated waves by

(2.6 km/s to 2.86 km/s;

Figure 11) and amplified attenuation by

(0.011 to 0.0126 Np/wavelength;

Figure 12), underscoring diffusive-thermal competition. Cross-comparisons with Kumar et al. [

35] showed our three-phase-lag model predicted

lower velocities and

higher attenuation than dual-phase-lag theories, while experimental seismic data (Abd-Alla et al., [

25]) aligned closely

with error) with our

-dependent velocity curves. These trends validated the model’s capability to capture size-dependent dissipation in geological media and MEMS devices, where ignoring

and

effects may under-predict attenuation by

. The results further suggested that Rayleigh wave measurements could inversely determine

and

in coated materials, with sensitivity coefficients of 0.85 and 0.72, respectively. Future work should address anisotropic media and temperature-dependent phase-lags to refine predictions for composite structures.

The numerical results revealed clear dependencies of wave behavior on phase-lag parameters, each with distinct physical implications. For example, increasing the displacement gradient phase-lag ) led to a consistent reduction in Rayleigh wave velocity (e.g., from ), which reflects the material’s increased microstructural stiffness that impeded elastic energy propagation. Conversely, an increase in temperature gradient phase-lag () enhanced wave velocity and the secular determinant, suggesting that thermal memory effects stabilize the system by moderating rapid temperature fluctuations. Similarly, higher heat flux phase-lags () slowed down wave propagation due to delayed energy transfer, while increased diffusion relaxation times altered attenuation patterns, indicating a dynamic competition between mass diffusion and thermal recovery processes. Percentage changes such as increase in velocity” were computed over a defined angular frequency interval and were subject to a relative uncertainty of based on convergence tests and NRMSE error bounds. This refined interpretation underscores the complex interplay between thermal inertia, microstructure, and diffusive effects in controlling surface wave dynamics.

While Abd-Allaet al. [

26]) provided initial validation, our results showed consistent agreement with independent datasets. Discrepancies ≤ 7.8% with USGS field data suggested that the model reliably captured geo-material behavior. Microstructural effects (couple stresses) accounted for the 0.2–0.4 km/s offset from classical theories.

7.1. Model Validation

We have expanded our analysis by comparing model predictions with three independent datasets: (1) classical thermoelastic Rayleigh wave velocities from [

19] (≤6% deviation), (2) generalized thermoelastic diffusion results from [

28] (≤5% error in attenuation), and (3) USGS seismic field data for copper-rich crustal regions (4.2–7.8% velocity variation). A new validation table (

Table 1) and normalized error metrics (NRMSE) were added to quantify agreement, demonstrating robust consistency with non-affiliated experiments while preserving the original findings. This comprehensive approach eliminated potential bias from co-author data and strengthened the model’s applicability to geophysical and engineering contexts.

7.2. Error Analysis and Convergence Study

To ensure the numerical robustness of the model, we conducted a convergence and error analysis for the Rayleigh wave solutions derived from the secular equation. The convergence study involved varying the frequency step size between 0.1 and 0.01 MHz, with results showing that both the wave velocity and attenuation coefficient stabilized beyond a step size of 0.02 MHz. All final simulations were, therefore, performed using a refined 0.01 MHz step for accuracy. For error analysis, we computed the normalized root-mean-square error (NRMSE) between our model predictions and reference datasets, yielding deviations of 5.1% compared to the classical Lockett [

19] model, 3.7% versus the generalized thermoelastic diffusion results of Sherief et al. [

29], and 4.2% relative to USGS seismic field data. These low error levels confirmed the accuracy and reliability of our three-phase-lag formulation, while the absence of spurious roots in the secular equation further attested to the numerical stability of the approach.

8. Conclusions

This study provided a comprehensive analysis of Rayleigh wave propagation in homogeneous, isotropic media employing modified couple stress generalized thermoelastic diffusion theory under a three-phase-lag model, elucidating the critical interplay between microstructural effects, thermal memory (through temperature gradient, heat flux, and thermal displacement gradient phase-lags), and mass diffusion processes. The numerical results demonstrated that the displacement gradient phase-lag () significantly enhanced the determinant of the secular equation while reducing both wave velocity and attenuation, underscoring the stiffening effect of a couple of stresses on the material’s dynamic response. Conversely, the temperature gradient phase-lag () promoted wave velocity but suppressed attenuation, highlighting its stabilizing influence on thermoelastic coupling, whereas the heat flux phase-lag () exhibited a dual role by increasing the determinant but delaying energy transfer, leading to slower and more attenuated waves. The diffusion relaxation time further modulated these dynamics, with their increase resulting in higher wave velocities and attenuation, reflecting the competition between diffusive dissipation and thermal recovery. Comparative analysis with prior studies confirmed that the three-phase-lag model provided a more accurate representation of wave behavior than classical or dual-phase-lag theories, particularly in capturing size-dependent dissipation and memory effects, as evidenced by the closer alignment of our predictions with experimental seismic data. The findings have far-reaching implications for applications in seismology, where the model’s ability to predict attenuation and velocity dispersion could improve earthquake hazard assessments, and in material science, where it offers a framework for characterizing microstructured materials through inverse wave measurements. Additionally, the results are relevant to the design of high-frequency MEMS devices and thermal coatings, where controlling phase-lag parameters could optimize wave-based sensing and energy dissipation. Future research should extend this framework to anisotropic and functionally graded materials, incorporate temperature-dependent phase-lags, and explore nonlinear effects to further enhance its predictive capability for complex real-world scenarios. This work not only advances the theoretical understanding of wave propagation in coupled thermoelastic-diffusive media but also provides practical tools for wave-based diagnostics and material design across multiple engineering and geophysical disciplines.

Our 3P model showed 7% lower velocities than dual-phase-lag theories [

21] but aligned with field data (USGS, 2018) within 5%.

Attenuation peaked at

(

Figure 9), matching relaxation theory.

While the model provided robust theoretical predictions, experimental validation faced challenges in precisely controlling all phase-lag parameters () and microstructural effects (e.g., couple stresses) under dynamic thermal-mechanical loading. The reported percentage changes (e.g., variations in wave velocity) were specific to copper at frequencies of , and deviations may occur in other materials (e.g., polymers or composites) due to differences in the thermal diffusivity and microstructure. Future work should address anisotropic media and temperature-dependent phase-lags to enhance universality, though the current results remain applicable to isotropic engineering materials (e.g., metals and ceramics) where similar thermo-diffusive coupling dominates.

While the three-phase-lag model demonstrated improved theoretical alignment with experimental trends in Rayleigh wave behavior, its direct applicability to seismology and MEMS design should be interpreted with caution. The model captured key physical phenomena, such as size effects and memory-dependent diffusion, which are conceptually relevant to microscale resonators and geophysical interfaces. However, the current validation was limited to comparisons with published seismic velocity data and classical benchmark models. No direct experimental correlation with MEMS device performance or full-scale seismic measurements was performed. As such, the model’s potential implications—for example, in refining wave-based diagnostics for subsurface materials or optimizing high-frequency microsensors—are indicative rather than conclusive. Future work should involve targeted experimental setups, device-level simulations, and in situ validation to robustly translate the theoretical predictions into practical engineering or geophysical insights.