Abstract

This study investigates the tribo-mechanical properties of a modified Cu-Cr-Zr alloy with nickel addition, aimed at enhancing its suitability as a resistance spot welding (RSW) electrode material. Two alloy compositions, designated as Sample A (Cu-0.871%Cr-0.156%Zr) and Sample B (modified with 8.94% Ni), were prepared. Microstructural examination revealed a coarse, mixed equiaxed–columnar grain structure in Sample A, while Sample B exhibited a refined dendritic morphology of about 50 μm PDAS, due to nickel-induced solute partitioning, improving microhardness from 72.763 HV to 83.981 HV. The wear behavior was evaluated using a pin-on-disc tribometer with a full factorial design, assessing the effects of rotational speed, load, and time on mass loss and surface roughness. Sample A exhibited increased mass loss and roughness with higher loads and speeds, indicating severe wear. In contrast, Sample B showed reduced mass loss and roughness at higher loads, suggesting a polishing effect from plastic deformation. Design of experiments analysis identified load as the dominant factor for mass loss in Sample A, with speed primarily affecting roughness, while in Sample B, load negatively influenced both responses, with speed–time interactions being significant. These findings highlight the nickel-modified alloy’s superior wear resistance and hardness, making it a promising candidate for RSW electrodes in high-production environments.

1. Introduction

The substantial development of electric vehicles (EVs) has aligned with global zero emission policies, aiming at reducing the intensifying energy and climate crisis [1]. Using lightweight materials is one possibility to lower vehicle weight, which in turn reduces energy consumption [2]. A wide variety of sheet metal combinations can be used to join segments of light vehicle bodies by welding [3]. The predominant welding technique used in the automotive industry is resistance spot welding (RSW). Its simplicity and high efficiency make it suitable for car-body sheet welding [1,4]. The welds in this method are made by fusing the interface of workpieces at discrete spots using a combination of pressure, heat, and time [5,6]. The high production volume in the automotive industry influences the lifespan of the welding electrodes during the RSW process. The annual consumption of the automobile industry is around 107 RSW electrodes [7]. The cause of a short electrode lifetime is due to the high current density that generates extreme heat between the electrode and the workpiece. The extreme heat generated leads to a temperature variation at the electrode/workpiece interface and reduces the electrode’s hardness. As a direct result, an excessive amount of wear takes place at the electrode, and the weld quality deteriorates due to variations in current density [8]. The lifetime of RSW electrodes is considerably affected by several factors that include, but are not limited to, the material type, the tip design, the cooling process, and welding parameters [4]. RSW electrode materials must have a combination of high electrical and thermal conductivities, a low coefficient of thermal expansion, and sufficient strength to withstand deformation under pressure and temperature [6]. Copper alloys are considered the most suitable candidates for producing RSW electrodes [1,4,7,9]. Among these alloys, the Cu-Cr-Zr alloy is a functional material with a precipitation-hardening effect [10]. It possesses the demanded attributes of excellent electrical and thermal conductivities, thermal stability at elevated temperatures, relatively high strength with good ductility, exceptional corrosion resistance, good fatigue properties [10,11,12], and most importantly, excellent wear resistance [9,13,14] in order to serve as an electrode for the RSW process.

Several attempts have been made to improve the tribological behavior of Cu-Cr-Zr alloys, either by solution treatment after mechanical deformation [15,16] or by adding different alloying elements [17]. The wear behavior of an ultra-fine structured Cu–0.3Cr–0.5Zr alloy under dry sliding conditions was investigated by Zhilyaev et al. [18]. The wear test was carried out on a ball-on-disc tribometer using ∅ 6 mm steel balls at room temperature with a load of 1.5 N, a sliding speed of 0.04 m/s, and a sliding distance of 100 m. They found that the wear rate was highly influenced by plastic straining, but their study was limited to a single low-load condition at room temperature, which does not reflect the high-load, high-temperature conditions typical of RSW processes. Çelik et al. [10] studied the wear behavior of Cu-1Cr-0.1Zr alloys at room temperature and 300 °C using two types of tribometers. The room temperature specimen was tested using a ball-on-disc with ZrO2 balls as counterparts and a sliding speed of 0.15 m/s, a normal load of 10 N, and a total sliding distance of 150 m. In contrast, the high temperature specimen was tested using a block-on-cylinder tribometer against a 51CrV4 steel surface as a counterpart with 0.27 m/s, 50 N, and 1000 m test parameters. They reported that the wear rate increased with lower hardness in as-cast alloys compared to aged specimens. However, their study lacked a systematic investigation of multiple factors (e.g., load, speed, and time) and their interactions, limiting its applicability to optimizing RSW electrode performance. A comparative study into the wear characteristics of Cu-(Cd, Be) and Cu-Cr-Zr alloys was performed by Bachchhav et al. [6] using a pin-on-disc tribometer. The wear test parameters included a track radius of 100 mm, a time duration of 15, 30, and 45 min, a normal load of 50, 100, and 150 N, and a varied temperature of 50, 100, and 150 °C. They concluded that precipitates in Cu-Cr-Zr alloys enhanced wear resistance, but their study did not explore the influence of rotational speed or the combined effects of factors, which are critical for RSW applications. The wear characteristics of an Cu-Cr-Zr alloy were evaluated by Sirsath and Bachchhav [14] using a pin-on-disc tribometer against a AISI 52100 tool steel disc. The test parameters included a constant speed of 600 rpm, a track radius of 100 mm, sliding distances of 2.8 and 5.6 km, temperatures of 50 and 100 °C, and pressures of 1 and 2 MPa. The results indicated that increased temperature, sliding distance, and pressure elevated wear rates. However, their study used a constant rotational speed, missing the opportunity to assess the impact of varying speeds, a key parameter in RSW electrode wear. In an attempt to improve the wear resistance of an ultrafine-grained Cu-Cr-Zr alloy, Aksenov et al. [19] modified the alloy composition by adding 0.2 wt.% Cd. The wear test included a load of 1 N, a sliding speed of 3600 mm/min, and a path length of 1000 m. The results indicated that their study was conducted under low-load conditions. Furthermore, the use of Cd raises environmental and health concerns, limiting its practical applicability for industrial Cu-Cr-Zr RSW electrodes.

To the knowledge of the authors, no research containing data on how Ni affects the tribological properties of Cu-Cr-Zr RSW materials currently exists. The available studies focused on the influence of other alloying elements, such as La [13], Ti [20], Si [21], and others [22,23,24], on the tribological and/or mechanical properties of Cu-Cr-Zr alloys. The addition of these alloying elements showed varying degrees of success in enhancing the desired properties. Cu and Ni are completely soluble in each other at any composition, because they both have the same FCC crystal structure, similar atomic radii, electronegativity, and valencies [25]. Schell et al. [26] reported an increased wear resistance of Cu-Ni alloys with small amounts of Ni (up to 5 wt.%). They further revealed an increased hardness as the Ni increased up to 80%. Wear resistance is linearly proportional to hardness, as demonstrated through Archard’s equation [27]. The absence of intermetallic compounds and increased hardness in such alloying systems could enhance their tribological properties [28]. Despite these findings, the study of Schell et al. [26] focused on binary Cu-Ni alloys and did not address the complex interactions in a quaternary Cu-Cr-Zr-Ni system under RSW conditions. Therefore, it is expected that the addition of Ni to the Cu-Cr-Zr alloy may provide positive tribological properties.

The literature reveals a gap in understanding how Ni influences the tribo-mechanical properties of Cu-Cr-Zr alloys, particularly under the dynamic conditions of RSW. Previous studies focused on single-factor effects, used conditions unrepresentative of RSW (e.g., low loads or constant speeds), or lacked a comprehensive design of experiments (DOE) approach to evaluate factor interactions. To address these shortcomings, the present study aims to investigate the tribo-mechanical properties of the Cu-Cr-Zr-Ni quaternary alloy using a dry sliding wear test and a pin-on-disc tribometer. The tribo-mechanical properties will also be evaluated by evaluating the microhardness numbers and compression properties. The modified version of the ternary Cu-Cr-Zr alloy with the addition of nickel can be a promising alternative for RSW electrodes.

2. Materials and Methods

2.1. Materials and Sample Preparation

The starting materials for the alloys investigated were commercial Cu-Cr-Zr contact tips consisting of 1.0 wt.% Cr, 0.15 wt.% Zr, and the balance being wt.% Cu. The Ni shots, with 99.95% purity, were supplied by Fisher Scientific Inc. Two compositions were prepared by melting predetermined masses of the initial materials in a graphite crucible using a high-frequency induction melting furnace. Then, the molten metals were poured into a copper die with a cylindrical cavity that was 10 mm in diameter and 20 mm high.

The chemical composition of the alloys under investigation is provided in Table 1. The reference and modified specimens are designated as Sample A and Sample B throughout the manuscript, respectively. The composition of Sample A was determined according to the material provided by the manufacturer. However, for Sample B, it represents the nominal composition. The actual compositions of the constituent elements were verified using energy dispersive X-ray (EDS) area analysis, and their values were in close proximity to the nominal compositions. However, some deviations were recorded due to the errors in the EDS detection ranges, as will be discussed in the Results section.

Table 1.

The chemical composition of the investigated alloys.

The alloys were sliced into 2 mm-thick discs using a slow-cutting machine to minimize heat generation in order to avoid any microstructural changes. The sliced discs prepared for metallographic inspection were mounted in cold epoxy blocks, ground progressively from 120 to 2000 grit with SiC sandpapers, and polished with 1 µm diamond suspension. The polished specimens were cleaned in an ultrasonic bath containing ethanol and were chemically etched using 1.5 g FeCl3 + 5 mL HCl + 16 mL ethanol for 5–10 s of exposure to the solution.

2.2. Methods

The microstructural features were examined using a Leica DM750 M (Leica Microsystems, Wetzlar, Germany) optical microscope. The phase analysis was performed using a high-resolution field emission scanning electron microscope (FE-SEM) model Apreo 2S LoVac. The SEM images were captured using a 30 keV acceleration voltage and a 0.4 nA probe current. A conductive copper tape was used to connect the surface of the sample with the instrument stage to prevent sample charging during SEM examination.

An energy dispersive X-ray spectrometer (EDS) model UltraDry 129eV 30 mm2 system was employed to determine the phase composition with ±0.26, ±0.03, ±0.24, and ±0.10 wt.% error values for Cu, Cr, Zr, and Ni, respectively.

Microhardness tests were conducted on the polished surfaces using a Highwood HWDM-3 Vickers hardness tester with a 50 gf load for a duration of 10 s. The average HV number for each alloy was determined by taking five points at various locations.

The surface roughness values of all worn specimens were acquired using a Kosaka Surfcoder SE600 surface roughness measuring instrument in accordance with ISO 13565 (Rk) standards [29]. The measurement parameters included a transverse length of 4 mm, a cut-off length of 0.8 mm, and a pitch of 0.0005 mm to establish the surface height (μm) versus sampling length (mm) relationship for all specimens. The Kosaka Surfcoder SE600 (Kosaka Laboratory Ltd. (Tokyo, Japan)) offers a resolution of 0.01 µm and a repeatability of ±0.02 µm as per the manufacturer’s specifications, ensuring high precision in the measurements. The roughness values taken in the same experimental conditions at three time intervals were taken for surface variability. The average surface roughness (Ra) number was used to assess the surface quality of the worn specimens.

2.3. Pin-on-Disc Wear Test

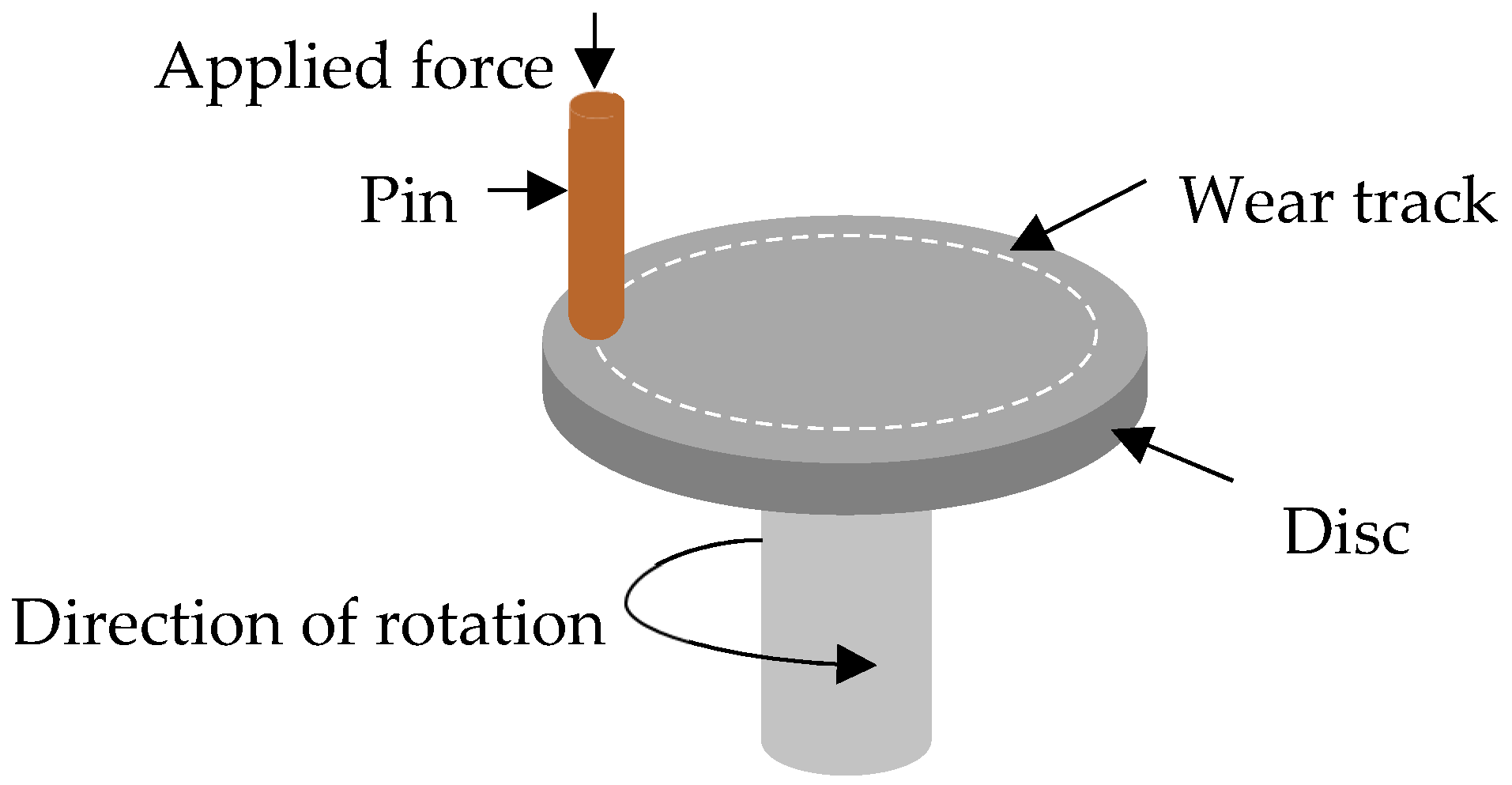

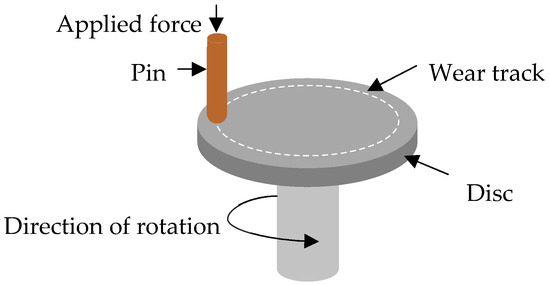

The wear behavior of the alloys was assessed using a pin-on-disc wear tribometer following the ASTM G99 standard test [30]. A schematic illustration of the pin-on-disc wear tribometer is shown in Figure 1. The tested specimens underwent dry sliding against a 160 mm in diameter carbon steel disc thermally coated with a hard WC layer of 63 HRC.

Figure 1.

Illustration of pin-on-disc wear tribometer setup.

The wear test using a pin-on-disc method was conducted on a track with a radius of 25 mm. The rotational speeds were 330, 380, and 430 rpm, with normal loads of 10, 25, and 50 N. Each experiment lasted a total of 15 min, during which the pin was weighed at 5 min intervals using a 0.1 mg balance. Table 2 summarizes the experimental conditions used in the wear test experiments. The frictional force was recorded from the test apparatus directly for each test individually. The wear behavior of the test specimen was evaluated in terms of mass loss. It is important to mention that the surfaces of the pin samples were ground before the wear test to ensure optimal surface contact with the disc. Furthermore, the influence of third-body particles on the wear test results was eliminated by cleaning the specimen and wear track surfaces with acetone.

Table 2.

Wear test experimental conditions.

2.4. Full Factorial Design of Experiments (DOE)

A full factorial design of experiments (DOE), in the form of (33) experiments, was utilized to examine the influence of three main factors (rotational speed, load, and time) on two response variables: mass loss and surface roughness. Each factor was tested at three levels: a rotational speed of 330, 380, and 430 rpm; a load of 10, 25, and 50 N; and a time of 5, 10, and 15 min. This design resulted in 27 unique experimental runs, allowing for the assessment of the main effects and interactions between factors. A confidence level of 0.95 was chosen to ensure statistical significance when analyzing the results, providing a robust framework to identify optimal conditions and understand factor contributions to the responses. The sliding radius was kept constant for all experiments at 50 mm.

3. Results and Discussion

3.1. Microstructure Analysis

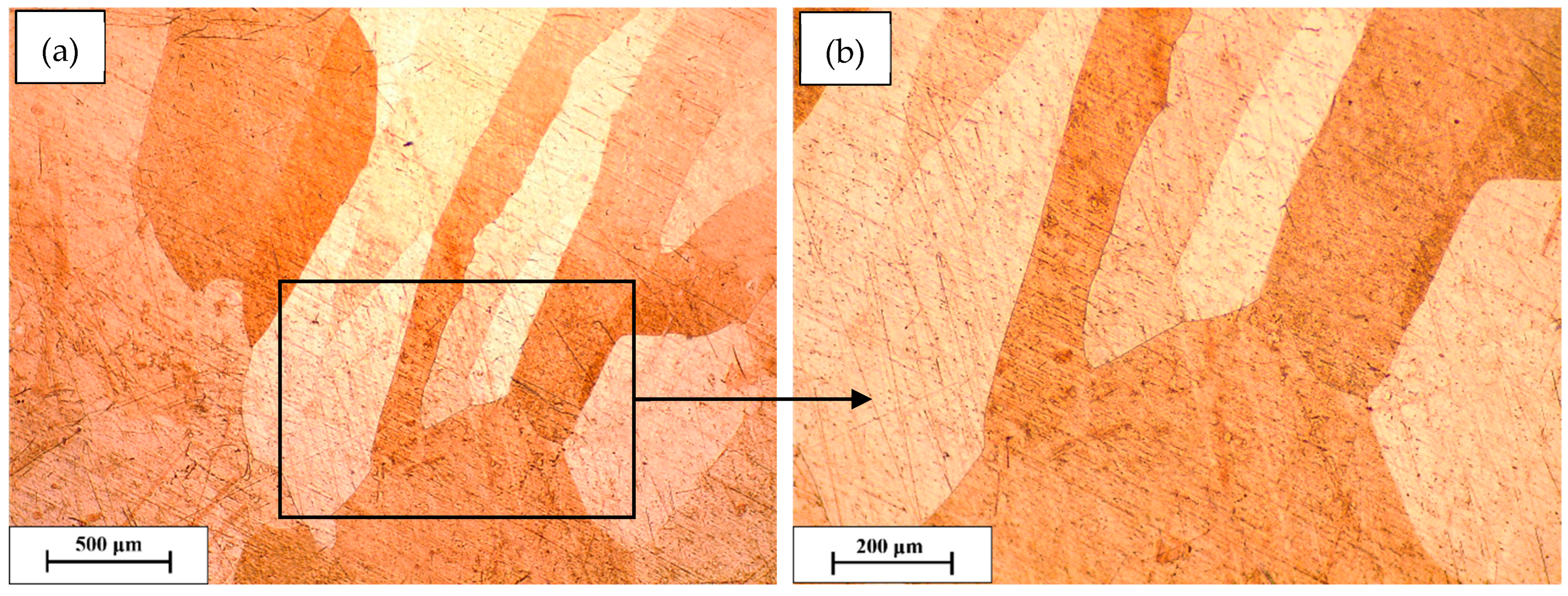

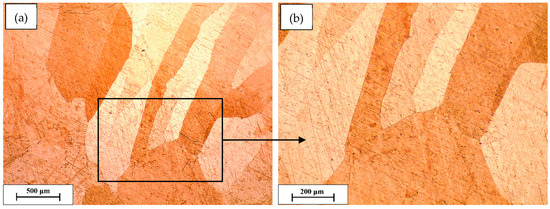

To examine the microstructural changes that occurred due to the addition of Ni to the Cu-Cr-Zr alloy, it is necessary to analyze and compare the microstructures of both samples. Figure 2 illustrates the as-cast microstructure of Sample A in the same location at different magnifications. A typical cast structure, containing equiaxed and columnar mixed grains, can be observed. The average grain size of the equiaxed grains was about 132 μm, and the average length-to-width ratio of the columnar grains was about 300:57 μm, which equals to 5.3:1. Such a microstructure may occur as a result of heterogeneous nucleation during solidification in the supercooled liquid ahead of the columnar dendrite tips, which prevents their growth [31]. Furthermore, the presence of Cr and Zr elements contributes to constitutional undercooling and heterogeneous nucleation, promoting the formation of equiaxed grains [13]. It was reported that the equiaxed grains may dominate the microstructure if the cooling rate is high due to increased nucleation throughout the melt [32]. However, the microstructure in Figure 2 is dominated by the columnar grains, which could occur due to the transition from columnar to equiaxed grains at moderate cooling rates. In a moderate cooling rate, the temperature gradient decreases sufficiently to allow equiaxed nucleation but not to the extent of complete equiaxed dominance. A similar microstructure was reported by Li et al. [13] for the as-cast Cu-Cr-Zr alloy. This coarser columnar structure is expected to influence mechanical properties, such as lower hardness and higher susceptibility to grain pull-out during wear, as discussed later.

Figure 2.

Optical micrographs of Sample A at different magnifications of (a) 50x and (b) 100x.

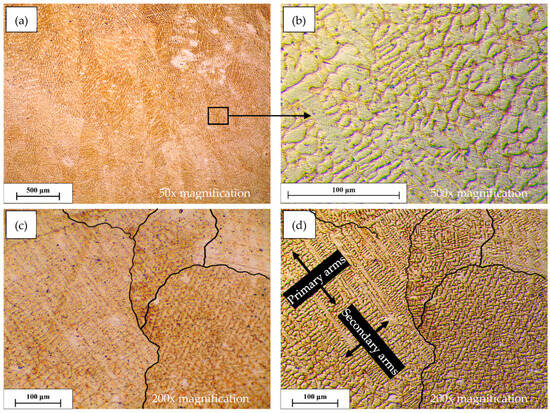

The microstructure of Sample B is shown in Figure 3. A distinct dendritic morphology is observed, which typically forms in the Cu-Ni alloys [33]. The average primary dendritic arm spacing (PDAS) is approximately 50 μm, and the average grain size is about 175 μm. A PDAS of about 50 μm indicates a fine dendritic structure [34]. The fine dendritic structure suggests improved hardness and resistance to wear, which will be correlated with the wear behavior results. The dendritic growth increases due to the presence of nickel, which promotes solute partitioning [35]. Figure 3a was captured at low magnification (50x) to observe the dendritic growth with respect to the grain size. Cellular morphology with an average cell size of less than 15 μm can be depicted from Figure 3b, which is a magnified area from Figure 3a. Figure 3c,d is taken from a grain boundary region at 200x magnification using both brightfield and differential interference contrast illumination modes, respectively. The grain boundaries were traced by the authors of this work to illustrate the direction of dendritic growth within each grain. The direction of both primary and secondary arms is also demonstrated for one grain, as shown in Figure 3d. It can be depicted that the interlacing behavior of the dendritic arrays at grain boundaries interrupted the grain growth, significantly influencing the competitive growth of neighboring grains. Chen et al. [36] reported a change in the dendritic spacing near the grain boundaries, which can similarly be observed in Figure 3c,d. The change in dendritic spacing occurs as a result of the continuous overgrowth of unfavorably oriented dendrites in the areas of large dendritic spacing, which normally takes place away from the dendrite nucleus [36].

Figure 3.

Optical micrographs of Sample B using (a,b) differential interference contrast illumination modes at 50x and 500x, respectively; (c,d) brightfield illumination and differential interference contrast illumination modes at 200x, respectively.

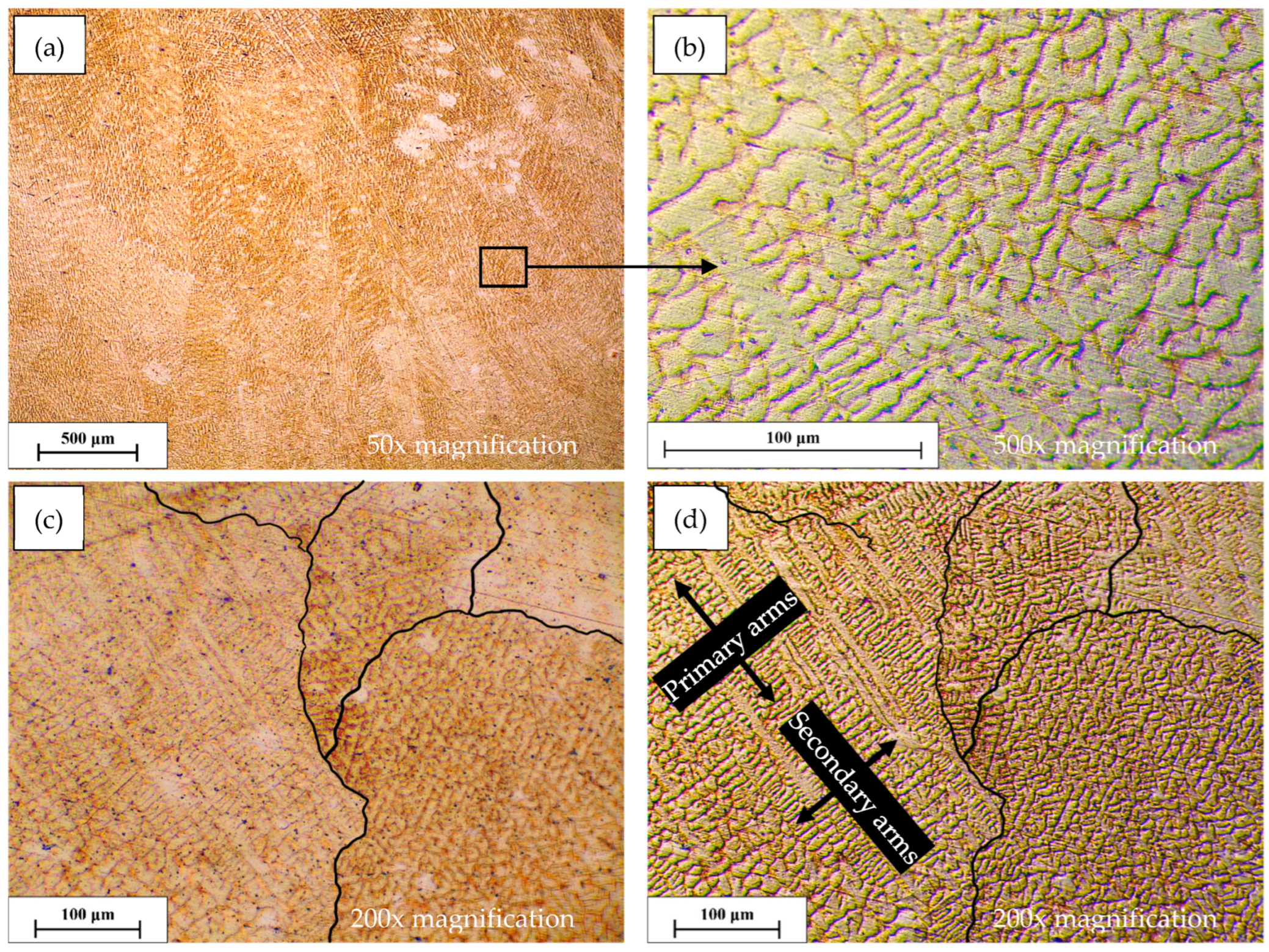

3.2. Phase Analysis

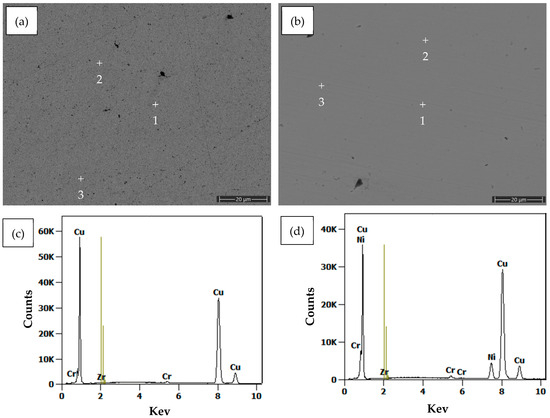

The SEM images, along with EDS spot analysis results, were used to investigate the phase content and phase composition of both Samples A and B, respectively. Figure 4a shows the SEM micrograph of Sample A. Only one phase could be detected, indicating that the alloy falls within the single-phase field near the Cu-rich corner in the Cu-Cr-Zr ternary system. The Cu-rich alloy is known to solidify as a supersaturated solid solution at room temperature, and then secondary phases precipitate after aging treatment [37]. Sample A is in as-cast condition, and no aging treatment was performed. Thus, it is expected to obtain a single phase only after cooling. The same case applies to Sample B, where a single-phase field was observed, as shown in Figure 4b. Since Cu and Ni exhibit mutual solid solubility at any composition in the binary system, it is logical to maintain the composition as a quaternary Cu-rich solid solution. A similar homogeneous microstructure was reported by Sirsath and Bachchhav [14]. EDS spot analysis was employed in several locations to confirm the presence of a single-phase field and to determine its composition. Typical EDS spectra are presented in Figure 4c,d. The peaks of constituent elements (Cu, Cr, Ni, and Zr) were positively identified; however, the peaks of the Zr element coincide with the peaks of background noise due to low counts.

Figure 4.

(a,b) Backscattered image for Samples A and B in the as-cast conditions at room temperature, respectively; (c,d) EDS spectra acquired from Samples A and B, respectively. The (+) sign is the location of interest for the EDS spot analysis, corresponding to these in Table 3.

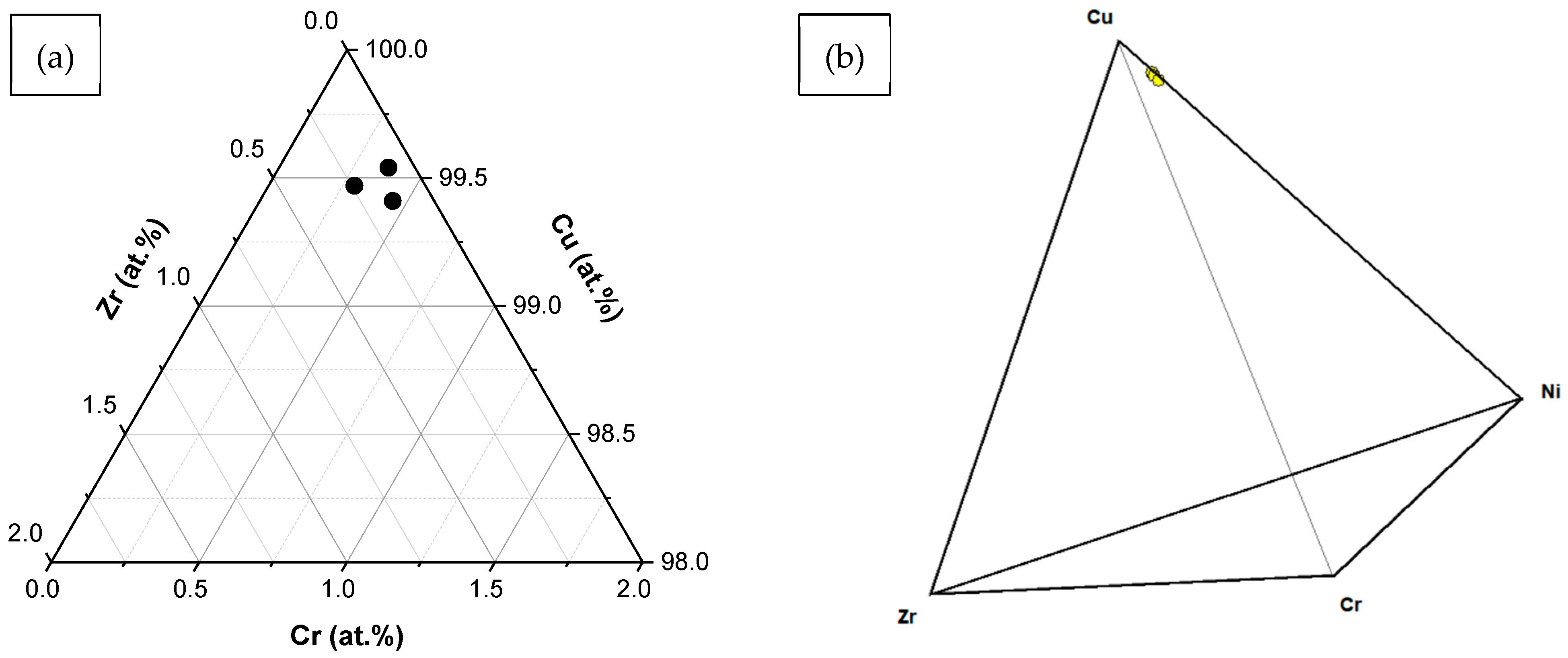

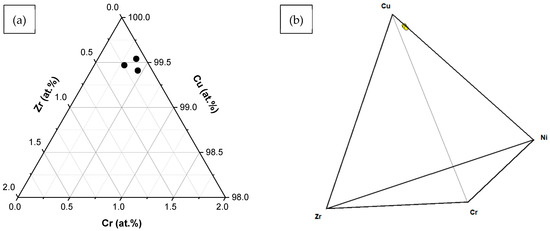

The results of EDS spot analysis are listed in Table 3, and the corresponding values are plotted in Figure 5. It is essential to note that the EDS points are not provided in Figure 4a,b because they were captured from locations different from those captured in the SEM images for the same area of interest. Furthermore, the error in wt.% is included to enhance the reliability of the results. Figure 5a is the graphical representation of the EDS spot analysis for Sample A. The EDS results are plotted in the Cu-Cr-Zr partial ternary phase diagram, appearing as points near the Cu-rich corner. These points are located within the same phase field with a range of compositions, indicating the ternary solid solubility of Cr and Zr in Cu.

Table 3.

EDS spot analysis results for Sample A and Sample B.

Figure 5.

EDS spot analysis cast on (a) the Cu-Cr-Zr partial ternary phase diagram for Sample A and (b) the Cu-Cr-Ni-Zr quaternary phase diagram for Sample B.

The same procedure was performed to graphically represent the EDS results of Sample B in the Cu-Cr-Ni-Zr quaternary phase diagram, as shown in Figure 5b. The three added elements in this study, namely Cr, Ni, and Zr, substitute Cu and form terminal solid solutions [38,39] rather than intermetallic compounds due to their low concentrations in the cases of Cr and Zr. In the case of Ni, despite its appreciated concentration, no intermetallic compounds can form in the Cu-Ni system. The EDS point analysis results show the composition points near the Cu-rich corner with an evident shift towards the Cu-Ni terminal line. The isothermal section of the Cu-Ni-Zr ternary system described by Hermana et al. [40] illustrates the mutual solid solubility between Cu and Ni near the Cu-Ni terminal line at low Zr concentrations.

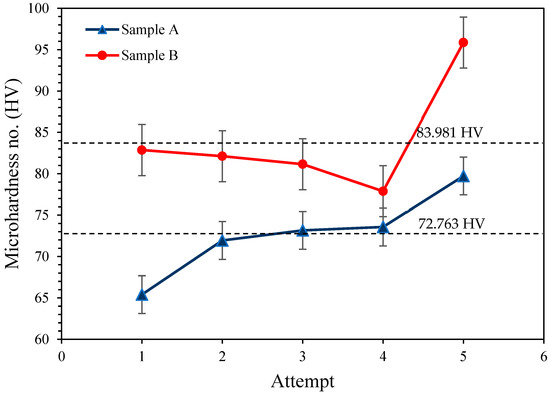

3.3. Microhardness Analysis

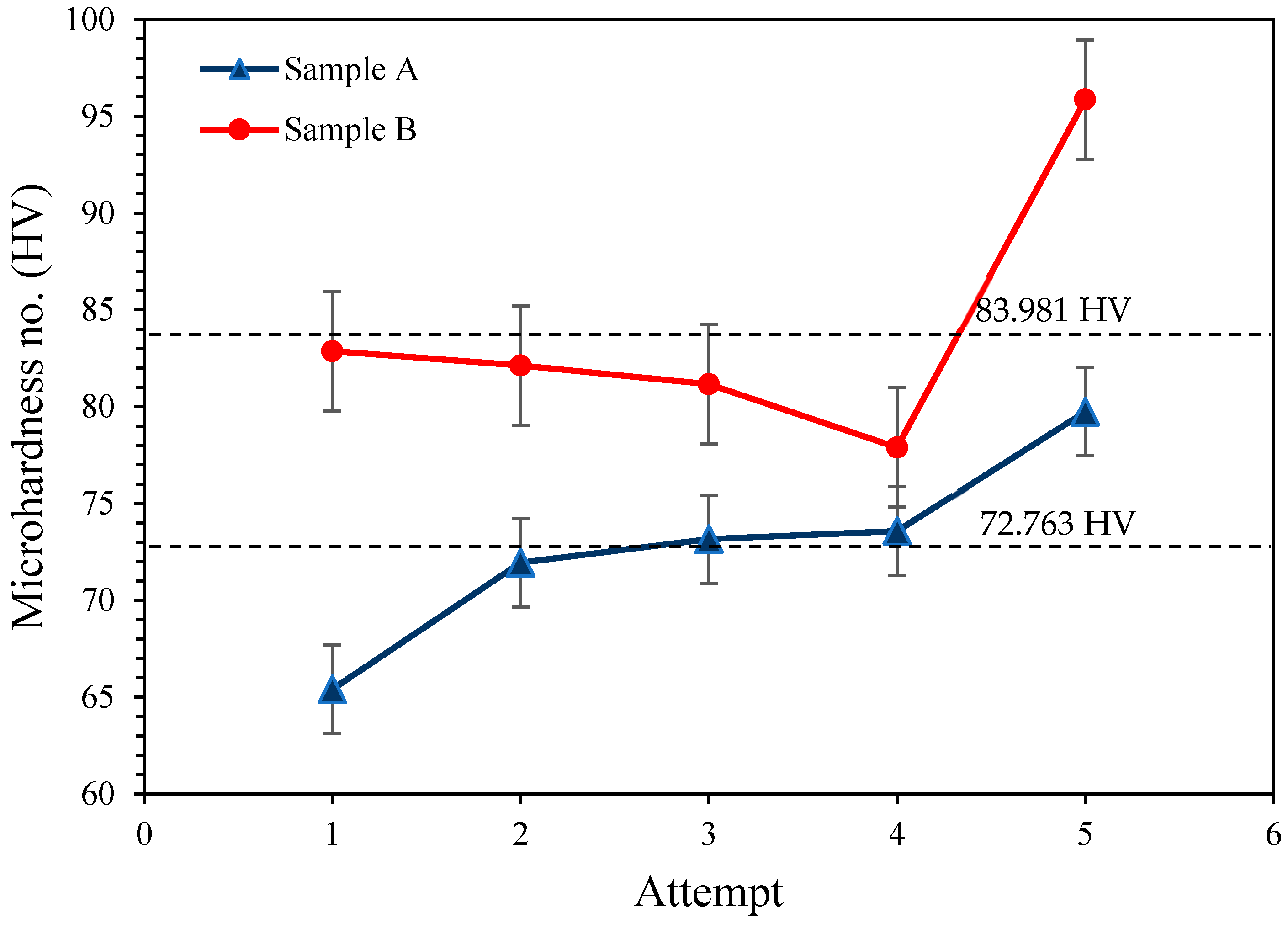

The microhardness values of both samples are plotted in Figure 6. The dashed lines drawn across the data points represent the average microhardness values, and their numbers are printed inside the figure. The average microhardness values recorded for Sample A and Sample B are 72.763 and 83.981 HV, respectively. The microhardness numbers obtained in this work for Cu-Cr-Zr alloy are in the same range as those reported by Singh et al. [41] (63.4–84.5 HV). The difference between the values of both samples is not significant. However, it can be concluded that the microhardness values of Sample B marginally increased when Ni was added. Such improvement is expected when considering the microstructure of Samples A and B, as illustrated in Figure 2 and Figure 3, respectively. The coarse grains that appeared in the cast structure of Sample A are an indication of a soft material [42]. However, the dendritic morphology observed in the cast structure of Sample B suggests that the segregated elements Cr and Zr are enriched in the interdendritic regions. These precipitates, along with the added Ni, are responsible for increasing the microhardness values of Sample B [33].

Figure 6.

Microhardness values and average microhardness numbers for both Samples A and B.

It is presumable that the microhardness values fluctuate around the average line due to different surface conditions under the microhardness indenter. For instance, surface scratches and imperfections are observed in Figure 4a,b, where the HV indenter landed on these features along with the base metal. However, most of the points align with the average microhardness values and are considered acceptable.

3.4. Wear Behavior

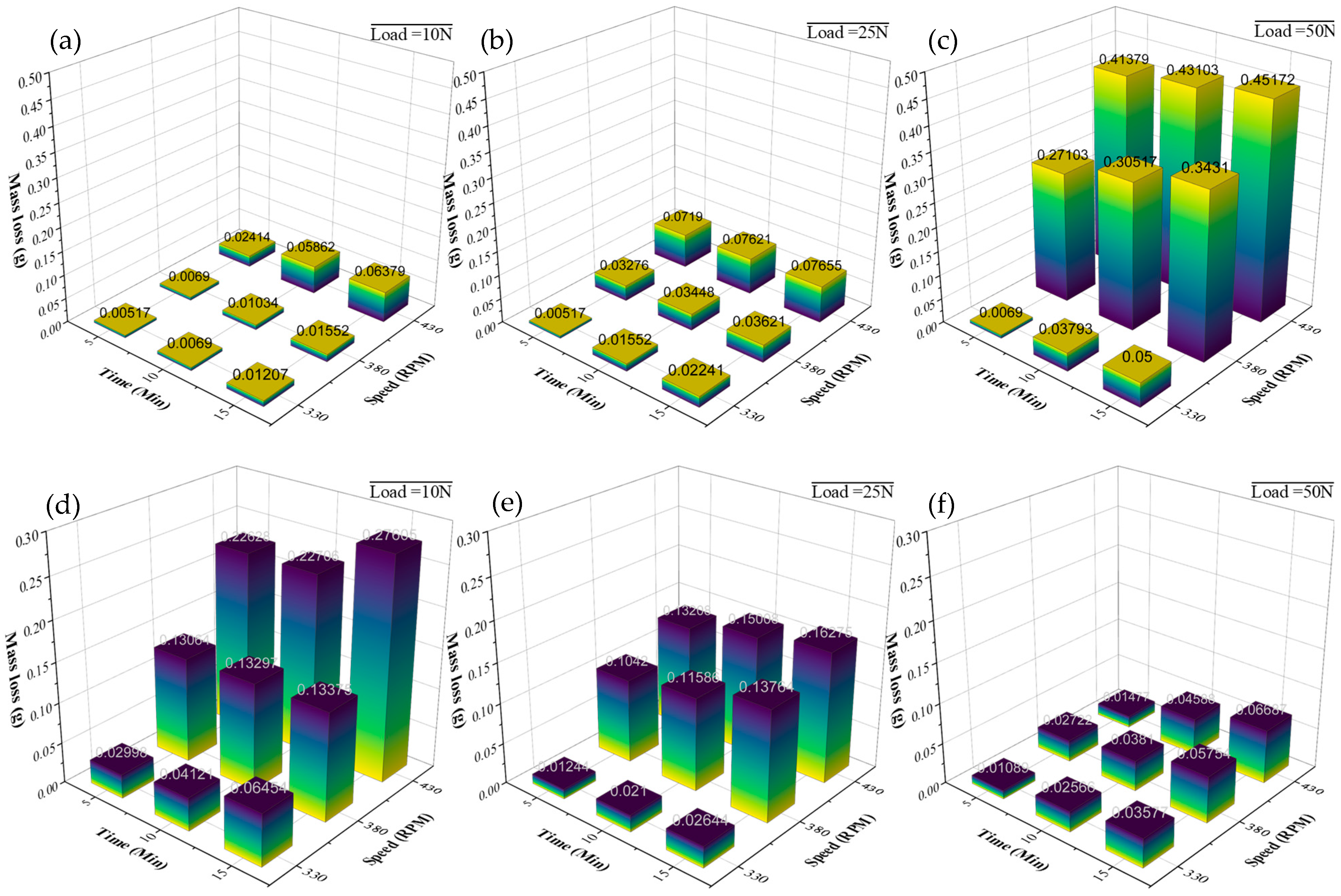

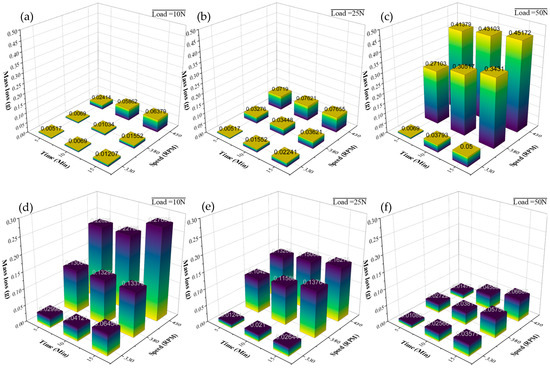

The wear behaviors of the investigated alloys were studied by using a dry sliding wear test on a pin-on-disc tribometer. The wear test conditions are listed in Table 2. Prior to each test, the pins were weighed to track the wear rates in terms of the mass loss, and the data were plotted considering the cumulative mass loss as a function of time. Figure 7 is the three-dimensional illustration of cumulative mass loss as a function of time and speed under each normal load. Figure 7a–c shows the wear test results of Sample A, and Figure 7d–f displays the results of Sample B. It is important to mention that the scale was preserved for the results of each sample to provide a visual illustration of the amount of mass loss. The numerical values of cumulative mass loss are listed in Table 4. The cumulative mass loss in Sample A appears to be greater than that of Sample B. Therefore, the plots of Sample A were scaled to 0.5 g, while those of Sample B were scaled to 0.3 g. It is apparent that the mass loss is greatly influenced by the other experimental parameters, i.e., the rotational speed, the applied load, and time.

Figure 7.

Cumulative mass loss vs. time plots as functions of normal load (10, 25, and 50 N) and rotational speed (330, 380, and 430 RPM) for (a–c) Sample A and (d–f) Sample B.

Table 4.

Cumulative mass loss values as functions speed, time, and load.

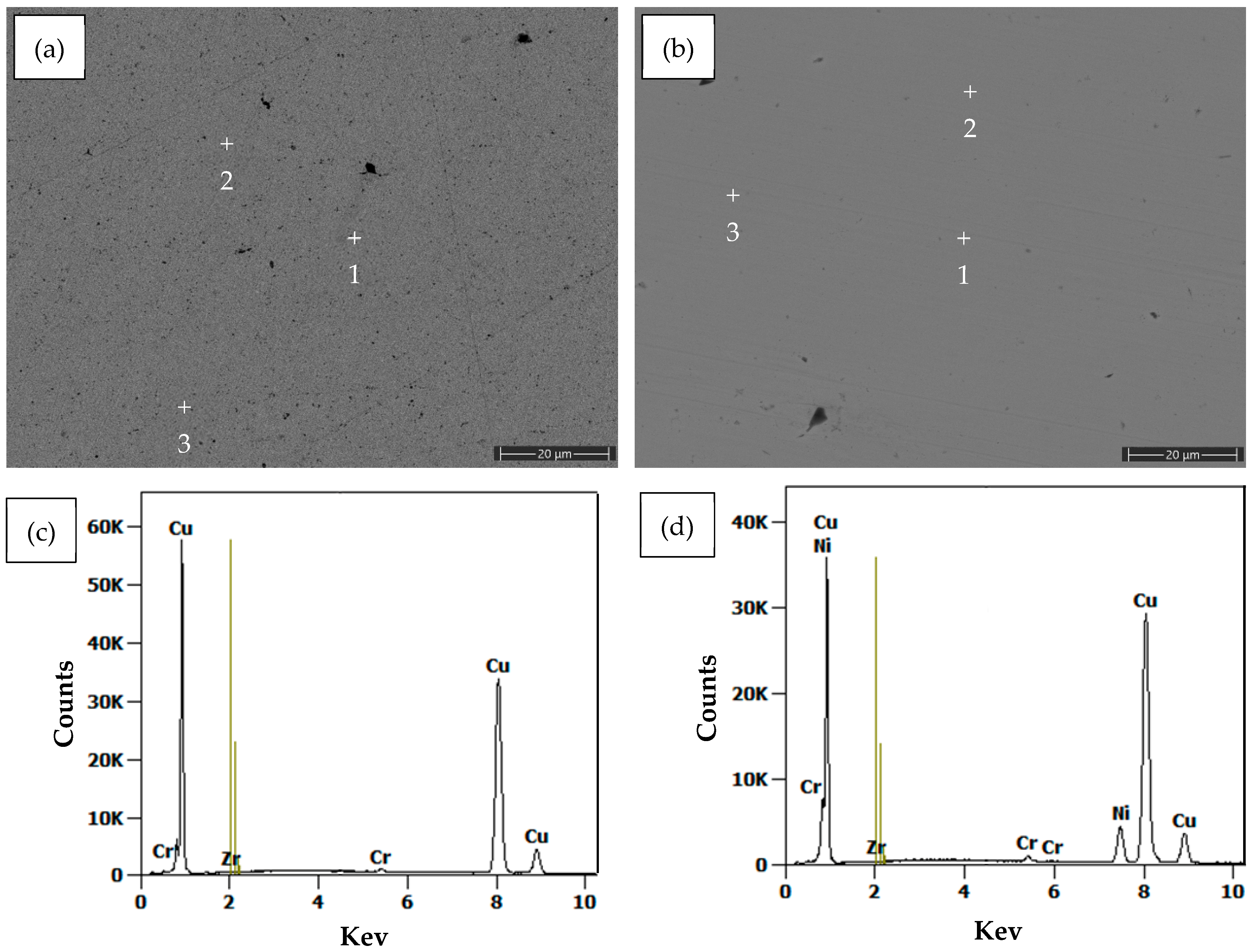

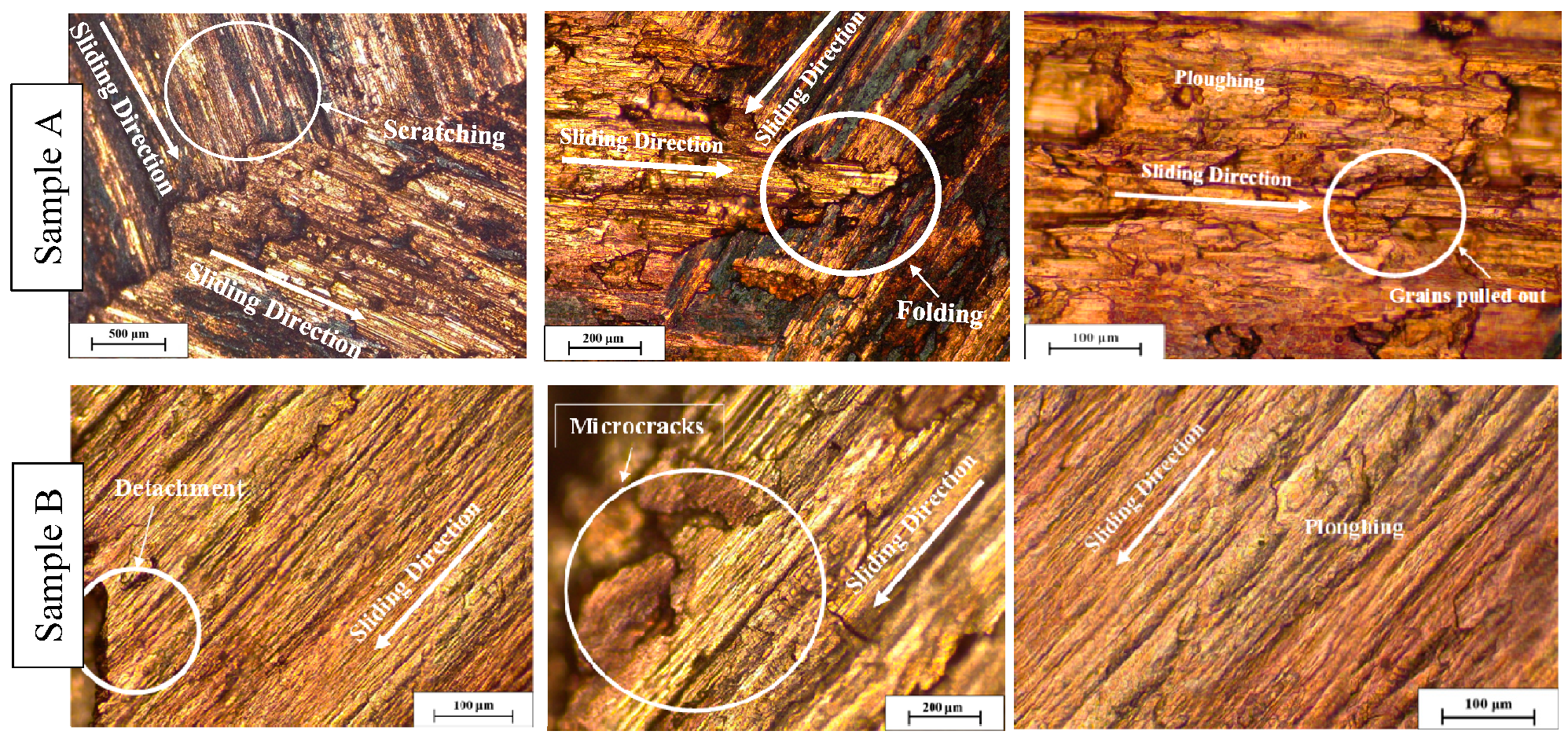

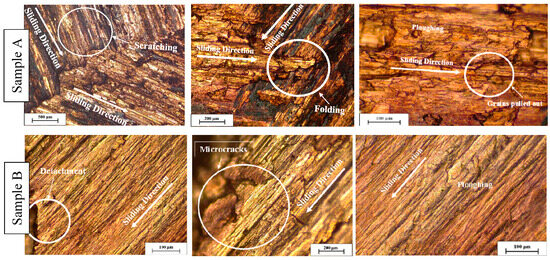

For all experiments, a direct relationship between the mass loss vs. the rotational speed and time was observed. However, the applied load was directly proportional to mass loss for Sample A, while it was inversely proportional to mass loss for Sample B. The maximum mass losses recorded for Sample A were 0.063, 0.076, and 0.451 g at applied loads of 10, 25, and 50 N, respectively. The increased mass loss with applied loads can occur because of the coarse-grained structure of Sample A, which exhibited higher values due to the grain pull-out, as can be seen in Figure 8. Furthermore, since the coarse-grained structures are less hard [43] as could be concluded from Figure 6, deep scratches may occur as a result of the pin rubbing against a hard counterpart. A higher surface roughness value is an indicator of severe ploughing wear and greater mass loss. The surface roughness results are illustrated in Figure 9.

Figure 8.

Optical micrographs of the worn samples after severe testing conditions (430 RPM, 15 min, and 50 N) for Sample A (Top) and Sample B (Bottom).

Figure 9.

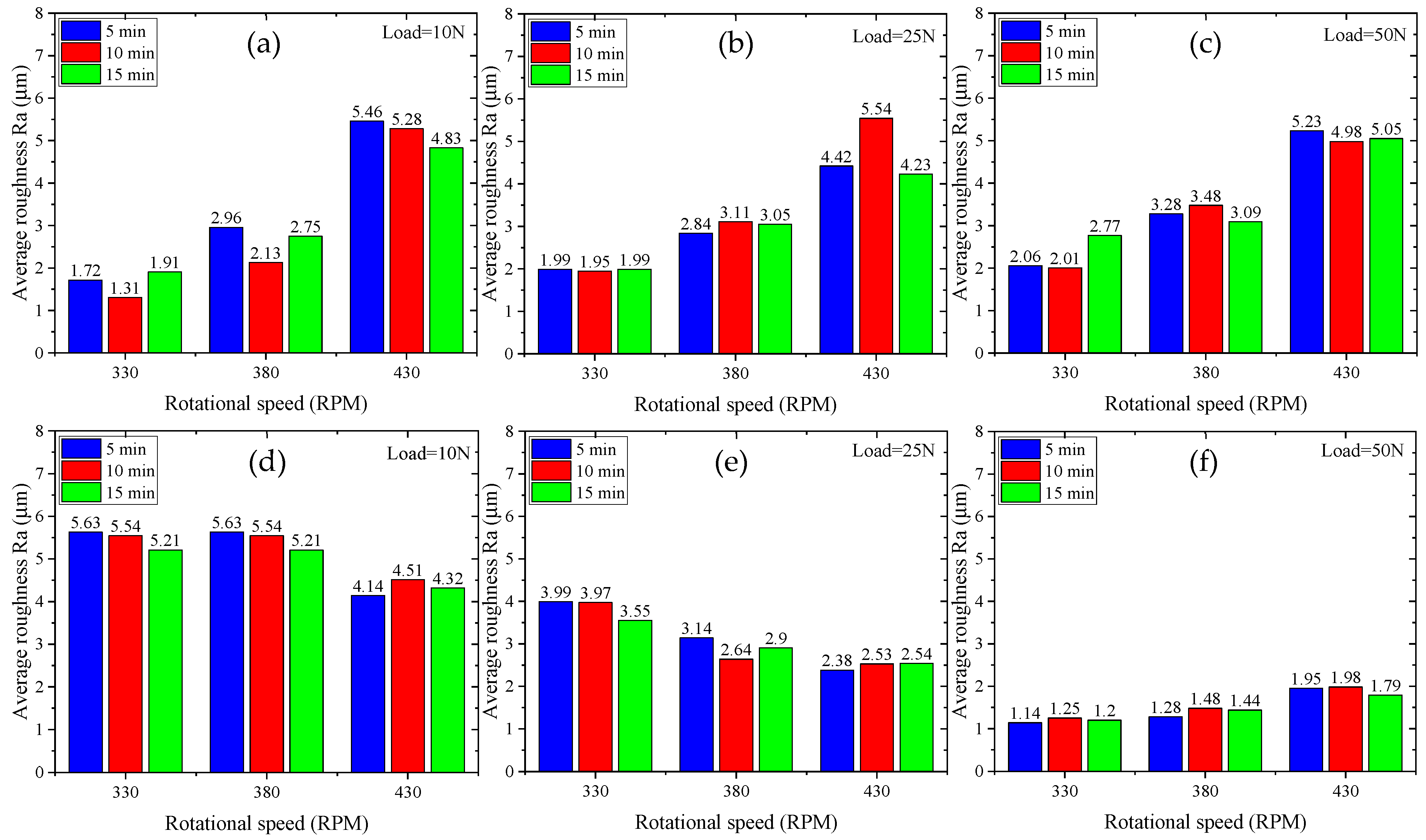

Average surface roughness Ra vs. rotational speed as functions of time and normal load for (a–c) Sample A and (d–f) Sample B.

The case is different for Sample B, where the maximum mass loss began high at 0.278 g at an applied load of 10 N and then gradually decreased to 0.162 and 0.066 g at 25 and 50 N, respectively. Such behavior indicates that the mass loss decreases as the applied load increases. This trend is primarily driven by the finer dendritic morphology of Sample B (Figure 3), which results in higher hardness (83.981 HV, Figure 6) due to Ni addition and segregated Cr and Zr in interdendritic regions. The wear behavior of Sample B in Figure 9 shows differences in the worn surface features. Instead of large grain detachments, both ploughing wear and microcracking due to plastic deformation can be observed. The reason for the reduced mass loss at higher loading in Sample B could be a result of the increased plastic deformation on the sample surface, as evidenced by the presence of surface microcracks. The applied load exerts residual stresses on the surface of the worn area, which in turn improve the surface integrity and minimize grain pull-out.

The worn surfaces of both samples were observed busing a light optical microscope, as illustrated in Figure 8. Images were captured at different magnifications to emphasize various features of the worn surfaces, such as sliding directions, ploughing wear, microcracks, and grain pull-out. The surface of Sample A exhibits dense adhesive layers in the form of deep ploughing due to the sliding of two solids against each other. Multidirectional sliding can also be observed, which results in the folding of the newly formed surface furrows on top of one another. Varying rotational speeds (330–430 rpm) and loads (10–50 N) cause the disc to create intersecting furrows as the pin rotates and slides. This is alleviated by the weak interfacial bonding between the coarse columnar grains, leading to material displacement and scratch formation. The scratch depth increases with higher loads and speeds due to intensified contact pressure and shear stress, contributing to the observed grain pull-out and surface cavities. Traces of grain pull-out in the form of surface cavities were also spotted, a phenomenon explained by the weak interfacial bonding between the coarse columnar grains. The influence of grain pull-out on the amount of mass loss was discussed earlier. The origin of the grain pull-out lies in the microstructural weaknesses inherent to the as-cast Cu-Cr-Zr alloy, where the lack of fine precipitates or grain refinement (as seen in Sample B) reduces resistance to shear stresses during sliding [42]. The high rotational speeds (330–430 rpm) and loads (10–50 N) amplify this effect by increasing the ploughing action of the hard counterpart surface against the softer Sample A surface, leading to grain detachment and cavity formation. This aligns with findings by Çelik et al. [10], who noted that coarse-grained Cu-Cr-Zr alloys exhibit higher wear rates due to grain pull-out under similar sliding conditions.

Similar surface features were observed on the worn surface of Sample B with less severity, along with the presence of several microcracks as evidence of increased contact pressure. This deformation leads to work hardening of the surface, enhancing its resistance to further material removal [10]. Additionally, the residual stresses generated by higher loads improve surface integrity, reducing grain pull-out and minimizing mass loss. This aligns with findings reported by Çelik et al. [10], who noted that increased hardness in Cu-Cr-Zr alloys reduces wear rates under higher loads, though their study was at elevated temperatures. The worn surfaces in Figure 8 further support these findings, showing dense adhesive layers and deep ploughing in Sample A, indicative of severe wear, while Sample B exhibits shallower ploughing and microcracks, reflecting improved wear resistance at higher loads.

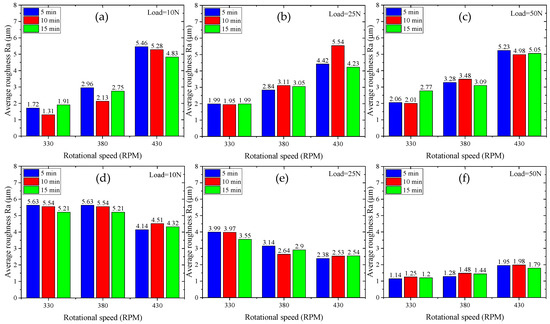

3.5. Surface Roughness

The surface roughness profiles of the tested samples were acquired after each dry sliding wear test under all conditions. Figure 9 presents the average roughness Ra versus rotational speed as a function of time and normal load. The charts in Figure 9a–c are presented to compare the results of Sample A with those of Sample B under similar testing conditions in Figure 9d–f. Obviously, an ascending trend can be generalized for the roughness values of Sample A under the same group of normal load conditions. For example, the average roughness values of the three time periods in Sample A, under three rotational speeds (330, 380, and 430 rpm) and 10 N normal load as given in Figure 9a, are 1.64 ± 0.03 μm, 2.61 ± 0.04 μm, and 5.19 ± 0.06 μm. The same ascending trend could be observed in Figure 9b,c under 25 and 50 N. The variation in the roughness values, within the consecutive time periods for each rotational speed, could be due to the multidirectional scratches that formed on the specimen surface after each wear test, which greatly influence the Ra values. The dense adhesive layers and deep ploughing wear, shown in Figure 8, are evidence of high surface roughness. It can be concluded that the average roughness values for Sample A are significantly influenced by the rotational speed.

In contrast, the average roughness values appear to descend with the increased applied load in Sample B, as shown in Figure 9d–f. For example, under a 10 N load (Figure 9d), the average roughness values are 4.82 ± 0.05 µm, 4.15 ± 0.04 µm, and 3.90 ± 0.03 µm at 330, 380, and 430 rpm, respectively, decreasing further with higher loads (25 N and 50 N). The same conclusion was drawn as the cumulative mass loss also decreased with the applied load (Figure 7d–f). The surface features of Sample B in Figure 8 clearly illustrate the shallow surface ploughing as an indication of reduced surface roughness values compared to those of Sample A. The applied load is found to be the main factor that influences the surface roughness values of Sample B. The experimental results regarding mass loss, microstructure, and surface roughness can be said to conform with one another.

The experimental results for mass loss, microstructure, and surface roughness are consistent, reinforcing the reliability of the measurement process. The inclusion of precision data and multiple measurements enhances the robustness of the surface roughness analysis, providing a solid basis for the DOE findings.

3.6. Design of Experiment Analysis

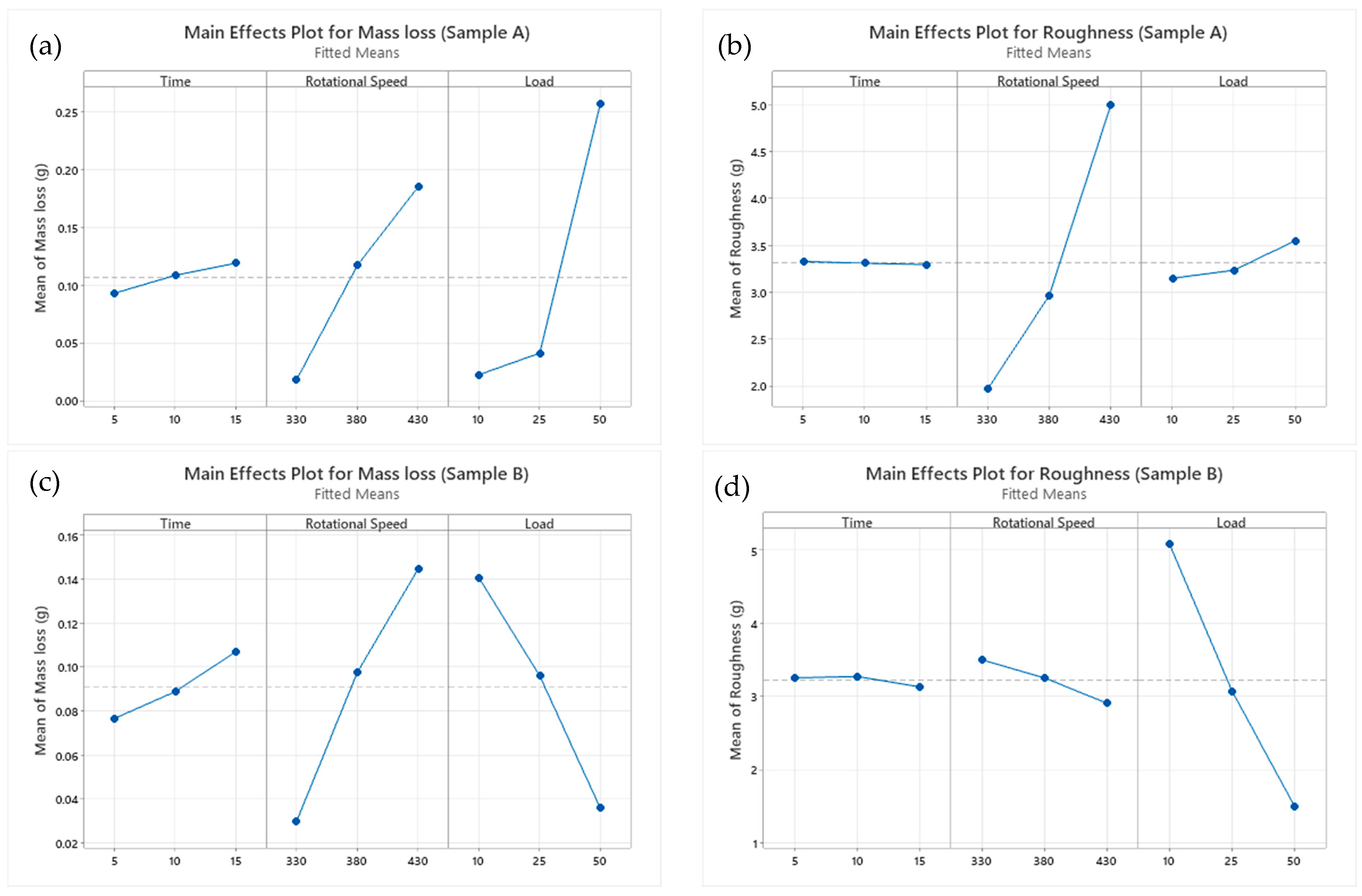

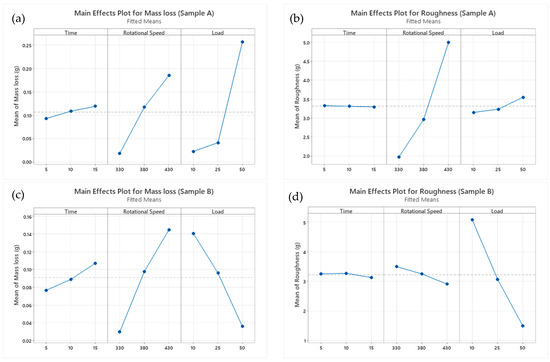

The main effect plots for mass loss and surface roughness of Samples A and B, based on the full factorial design with three factors (time, rotational speed, and load) at three levels each, are illustrated in Figure 10. These plots show the fitted means of the responses (mass loss and surface roughness) as each factor varies. Figure 10a shows that the mass loss increases slightly when the time interval is extended from 5 to 15 min, indicating a small effect of time on mass loss. A strong positive effect of rotational speed can be concluded as higher speeds lead to greater mass loss. However, load has the most pronounced effect on mass loss, resulting in a steep positive increase. These findings align well with those reported by Sirsath and Bachchhav [14] that the mass loss increases with higher rotational speed and applied load. In Figure 10b, the surface roughness remains nearly constant at ~3.5 µm across all time intervals, indicating that time has a minor to negligible effect on surface roughness. Roughness appears to increase sharply as speed increases. This demonstrates a strong positive effect, where higher speeds result in rougher surfaces. A modest increase in roughness was observed as the applied load increased. Although the load has a positive effect on roughness, it is still less significant compared to rotational speed. These findings align very well with the results of Sample A represented in Figure 9a–c.

Figure 10.

The main effects plots for the mass loss and surface roughness of (a,b) Sample A and (c,d) Sample B.

For Sample B, the mass loss in Figure 10c increases slightly as time extends from 5 to 15 min. Similar to Sample A, the effect is small, indicating a weak positive influence. As the speed increases, mass loss rises. This positive trend is consistent with Sample A; however, the magnitude of increase is slightly smaller. In contrast to Sample A, a negative trend in mass loss was observed as the load increased. This decrease suggests that higher loads reduce mass loss in Sample B due to severe plastic deformation, as discussed earlier. The surface roughness in Figure 10d remains nearly constant at ~3.5 µm, showing no significant effect, similar to Sample A. The roughness also slightly decreases as the speed increases from 330 to 430 rpm. This negative trend contrasts with Sample A, indicating that higher speeds lead to smoother surfaces in Sample B. The roughness decreases sharply as load increases from 10 to 50 N. This strong negative effect contrasts with Sample A, where load increased roughness.

It can be concluded from the main effect plots obtained by DOE analysis that the mass loss is dominated by load, while rotational speed dominates roughness for Sample A. However, for Sample B, load dominates both responses but in opposite directions (decreasing mass loss and roughness).

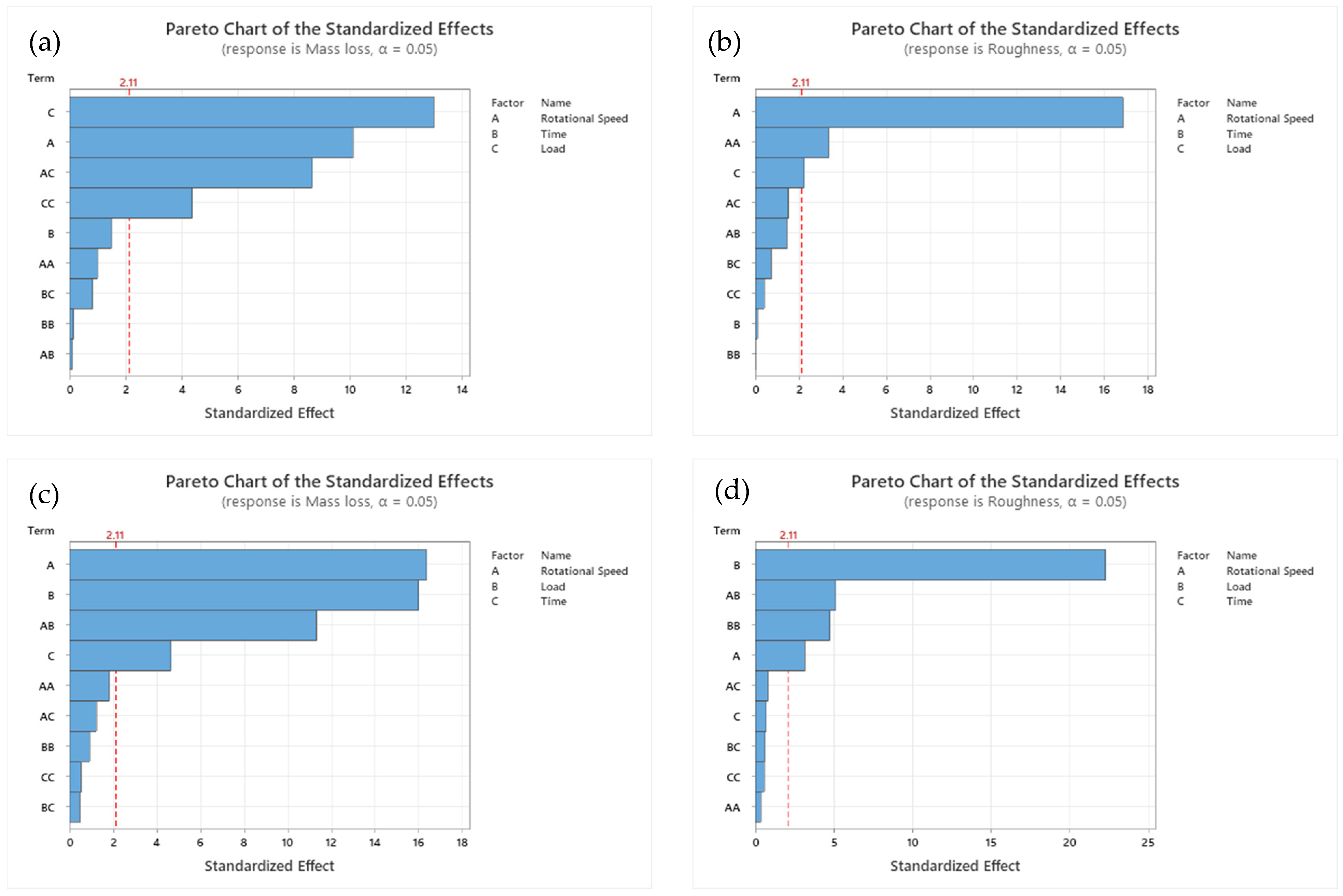

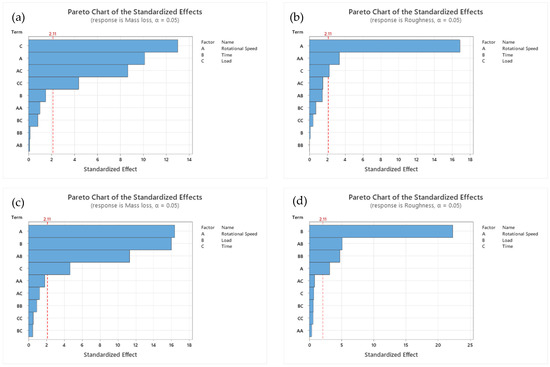

Pareto charts in Figure 11 have been developed to identify the most significant factors and interactions affecting the responses in the full factorial design. The vertical line marked at 2.11 represents the critical t-value for statistical significance at 95% confidence. Thus, the effects above 2.11 are considered significant, and those lower are considered non-significant. For Sample A, the significant effects that influence mass loss, as seen in Figure 11a, from largest to lowest are load (C), rotational speed (A), rotational speed/load (AC), and load quadratic (CC). The remaining are the non-significant effects. For surface roughness, as seen in Figure 11b, rotational speed (A) has the largest effect, with a non-linear component (AA) and a smaller contribution from load (C) and its interaction with speed (AC). Time (B) is not significant for either response. For mass loss in Sample B, as seen in Figure 11c, rotational speed (A) and time (B) are the most significant with a strong interaction (AB), while load (C) also plays a role. For surface roughness, as seen in Figure 11d, time (B) unexpectedly appears to be the most significant factor (possibly due to interactions), followed by the interaction between speed and time (AB), with speed (A) and load (C) also contributing. The non-linear effect of time (BB) is notable for roughness.

Figure 11.

Pareto charts of the standardized effects on mass loss and surface roughness values for (a,b) Sample A and (c,d) Sample B.

The full factorial design assumes negligible experimental error and factor interactions beyond second-order, which may not fully capture complex wear mechanisms, such as temperature rise during sliding, which was not controlled or measured but could influence mass loss and roughness [14]. The variability in surface roughness measurements suggests potential inconsistencies due to multidirectional scratches, particularly for Sample A, where roughness increases sharply with speed. The DOE did not account for environmental factors like humidity or potential oxidative wear, which could alter results under real RSW conditions [6]. These limitations suggest that while the DOE identifies key factors, its predictive accuracy for industrial applications may be constrained, necessitating further validation with additional variables.

The contrasting effects of load on Samples A and B (positive for A, negative for B) highlight material-specific responses, likely due to microstructural differences (coarse columnar grains in A vs. finer dendritic structure in B). However, the unexpected significance of time in the roughness values of Sample B (Figure 11d) despite its negligible main effect (Figure 10d) indicates potential overfitting in the model or unaccounted interactions, warranting further investigation into higher-order effects or experimental variability.

4. Conclusions

This research demonstrates that the addition of nickel to the Cu-Cr-Zr alloy significantly enhances its tribo-mechanical properties, making it a viable candidate for resistance spot welding (RSW) electrodes. The following conclusions can be drawn from this study:

- Microstructural analysis revealed that Sample A, the unmodified alloy, exhibits a coarse equiaxed–columnar grain structure with an average equiaxed grain size of 132 μm and a length-to-width ratio of 5.3:1 for columnar grains, while Sample B, with 8.94 wt.% nickel, develops a refined dendritic morphology with a primary dendrite arm spacing (PDAS) of about 50 μm. This refinement contributes to improved hardness (83.981 HV in Sample B vs. 72.763 HV in Sample A) due to precipitate enrichment.

- Wear behavior, evaluated through a full factorial design of experiments, showed distinct responses: Sample A experienced increased mass loss and surface roughness with higher loads and rotational speeds, driven by ploughing wear and grain pull-out, while Sample B exhibited a reduction in both responses under higher loads, attributed to plastic deformation and a polishing effect.

- The design of experiments analysis highlighted load as the primary factor influencing mass loss in Sample A, with rotational speed dominating roughness, whereas in Sample B, load negatively affected both mass loss and roughness, with significant speed–time interactions. These findings suggest that the Ni-modified Cu-Cr-Zr-Ni alloy offers superior wear resistance and surface integrity, particularly under high-load conditions, supporting its potential as an advanced RSW electrode material.

- Future research should investigate the applicability of Ni-modified Cu-Cr-Zr alloys in other high-wear industrial contexts, such as electrical connectors or high-temperature sliding contacts, to assess their versatility beyond RSW electrodes. Additionally, exploring a wider range of alloying elements and their synergistic effects with nickel could provide a broader framework for optimizing Cu-based alloys for tribo-mechanical applications.

- To enhance the current findings, future studies should conduct wear tests with controlled temperature conditions to simulate RSW electrode operation using a pin-on-disc setup with integrated thermocouples.

Author Contributions

Conceptualization, A.M.; Methodology, A.M.; Software, A.M.; Validation, R.A. (Reham Alhdayat); Formal analysis, R.A. (Reham Alhdayat); Investigation, R.A. (Reham Alhdayat); Resources, R.A. (Reham Alhdayat); Writing—original draft, R.A. (Reham Alhdayat); Writing—review & editing, A.M.; Supervision, A.M.; Project administration, A.M.; Funding acquisition, R.A. (Rasheed Abdullah). All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Spišák, E.; Kaščák, Ľ.; Viňáš, J. Application of resistance spot welding in car body production. Acta Mech. Slovaca 2015, 19, 28–34. [Google Scholar] [CrossRef]

- Zhou, X.; Jiang, J.; Hu, Z.; Hua, L. Lightweight Materials in Electric Vehicles. Int. J. Automot. Manuf. Mater. 2022, 1, 3. [Google Scholar] [CrossRef]

- Spišák, E.; Kaščák, Ľ. Joining Car Body Steel Sheets Using the Clinching Method. Acta Mech. Slovaca 2011, 15, 28–35. [Google Scholar] [CrossRef]

- Viňáš, J.; Kaščák, Ľ.; Ábel, M. Analysis of Materials for Resistance Spot Welding Electrodes. Strojarstvo 2012, 54, 393–397. [Google Scholar]

- Gupta, A.K.; Maddukuri, T.S.; Singh, S.K. Constrained groove pressing for sheet metal processing. Prog. Mater. Sci. 2016, 84, 403–462. [Google Scholar] [CrossRef]

- Bachchhav, B.D.; Chaitanya, S.V.; Salunkhe, S.; Chandrakumar, P.; Pagáč, M.; Nasr, E.A. Wear Performance of Cu–Cd, Cu–Be and Cu–Cr–Zr Spot Welding Electrode Materials. Lubricants 2023, 11, 291. [Google Scholar] [CrossRef]

- Helenius, A. Copper Alloy to be Used as Resistance Welding Electrode. 1989, pp. 1–9. Available online: https://patents.google.com/patent/EP0397061A1/en (accessed on 3 June 2025).

- Zhao, D.; Vdonin, N.; Slobodyan, M.; Butsykin, S.; Kiselev, A.; Gordynets, A. Assessing Electrode Characteristics in Continuous Resistance Spot Welding of BH 340 Steel Based on Dynamic Resistance. J. Manuf. Mater. Process. 2023, 7, 218. [Google Scholar] [CrossRef]

- Bachchhav, B.; Kumbhare, A.; Hoonur, C.; Kulkarni, S.; Kalankar, J. Grading of Spot Welding Electrode Material Properties Using AHP. J. Mod. Mech. Eng. Technol. 2020, 7, 59–65. [Google Scholar] [CrossRef]

- Çelik, G.A.; Atapek, Ş.H.; Polat, Ş. Tribological behavior of heat treated CuCrZr alloy. MATEC Web Conf. 2018, 188, 02002. [Google Scholar] [CrossRef]

- Davis, J.; Kalinin, G. Material properties and design requirements for copper alloys used in ITER. J. Nucl. Mater. 1998, 258–263, 323–328. [Google Scholar] [CrossRef]

- Wang, T.; Li, L.; Pallaka, M.R.; Das, H.; Whalen, S.; Soulami, A.; Upadhyay, P.; Kappagantula, K.S. Mechanical and microstructural characterization of AZ31 magnesium-carbon fiber reinforced polymer joint obtained by friction stir interlocking technique. Mater. Des. 2021, 198, 109305. [Google Scholar] [CrossRef]

- Li, J.; Chang, L.; Li, S.; Zhu, X.; An, Z. Microstructure and properties of as-cast Cu-Cr-Zr alloys with lanthanum addition. J. Rare Earths 2018, 36, 424–429. [Google Scholar] [CrossRef]

- Sirsath, K.G.; Bachchhav, B.D. Tribo-mechanical characterization of Cu-Cr-Zr ternary alloy aimed at fin-tube resistance welding electrode material. Ind. Lubr. Tribol. 2023, 75, 942–949. [Google Scholar] [CrossRef]

- Shen, Z.; Lin, Z.; Shi, P.; Zhu, J.; Zheng, T.; Ding, B.; Guo, Y.; Zhong, Y. Enhanced electrical, mechanical and tribological properties of Cu-Cr-Zr alloys by continuous extrusion forming and subsequent aging treatment. J. Mater. Sci. Technol. 2022, 110, 187–197. [Google Scholar] [CrossRef]

- Purcek, G.; Yanar, H.; Demirtas, M.; Shangina, D.V.; Bochvar, N.R.; Dobatkin, S.V. Microstructural, mechanical and tribological properties of ultrafine-grained Cu–Cr–Zr alloy processed by high pressure torsion. J. Alloys Compd. 2020, 816, 152675. [Google Scholar] [CrossRef]

- Ahaki, E.; Mahdavi, S.; Rezayat, M. Enhancing tribological performance of Cu-1Cr-0.15Zr alloy through optimized processing routes. J. Mater. Res. Technol. 2024, 33, 8530–8544. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Morozova, A.; Cabrera, J.M.; Kaibyshev, R.; Langdon, T.G. Wear resistance and electroconductivity in a Cu–0.3Cr–0.5Zr alloy processed by ECAP. J. Mater. Sci. 2017, 52, 305–313. [Google Scholar] [CrossRef]

- Aksenov, D.A.; Raab, G.I.; Asfandiyarov, R.N.; Semenov, V.I.; Shuster, L.S. Effect of Cd and SPD on structure, physical, mechanical, and operational properties of alloy of Cu-Cr-Zr. Rev. Adv. Mater. Sci. 2020, 59, 506–513. [Google Scholar] [CrossRef]

- Krishna, S.C.; Rao, G.S.; Jha, A.K.; Pant, B.; Venkitakrishnan, P.V. Strengthening in high strength Cu-Cr-Zr-Ti alloy plates produced by hot rolling. Mater. Sci. Eng. A 2016, 674, 164–170. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, Y.; Yang, H.; Su, L.; Wang, C.; Tong, C.; Zhou, J.; Chen, J.; Wang, B. Effects of Si addition on properties and microstructure of CuCrZr alloy. J. Alloys Compd. 2022, 906, 164277. [Google Scholar] [CrossRef]

- Su, J.; Dong, Q.; Liu, P.; Li, H.; Kang, B. Research on aging precipitation in a Cu–Cr–Zr–Mg alloy. Mater. Sci. Eng. A 2005, 392, 422–426. [Google Scholar] [CrossRef]

- Pang, Y.; Xia, C.; Wang, M.; Li, Z.; Xiao, Z.; Wei, H.; Sheng, X.; Jia, Y.; Chen, C. Effects of Zr and (Ni, Si) additions on properties and microstructure of Cu–Cr alloy. J. Alloys Compd. 2014, 582, 786–792. [Google Scholar] [CrossRef]

- Zhou, H.T.; Zhong, J.W.; Zhou, X.; Zhao, Z.K.; Li, Q.B. Microstructure and properties of Cu–1.0Cr–0.2Zr–0.03Fe alloy. Mater. Sci. Eng. A 2008, 498, 225–230. [Google Scholar] [CrossRef]

- Callister, W.; Rethwisch, D. Materials Science and Engineering: An Introduction; Wiley: Hoboken, NJ, USA, 2007; Volume 94, ISBN 9780471736967. [Google Scholar]

- Schell, J.; Heilmann, P.; Rigney, D.A. Friction and wear of Cu-Ni alloys. Wear 1982, 75, 205–220. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and Rubbing of Flat Surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Liu, C.; Dong, Y.; Lin, Y.; Yan, H.; Zhang, W.; Bao, Y.; Ma, J. Enhanced mechanical and tribological properties of graphene/bismaleimide composites by using reduced graphene oxide with non-covalent functionalization. Compos. Part B Eng. 2019, 165, 491–499. [Google Scholar] [CrossRef]

- ISO 13565-2; Geometrical Product Specifications (GPS)—Surface Texture: Profile Method; Surfaces Having Stratified Functional Properties—Part 2: Height Characterization Using the Linear Material Ratio Curve. International Organization for Standardization: Geneva, Switzerland, 1996.

- ASTM G99; Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus. ASTM International: West Conshohocken, PA, USA, 2016.

- Narayana Samy, V.P.; Schäfle, M.; Brasche, F.; Krupp, U.; Haase, C. Understanding the mechanism of columnar–to-equiaxed transition and grain refinement in additively manufactured steel during laser powder bed fusion. Addit. Manuf. 2023, 73, 103702. [Google Scholar] [CrossRef]

- Prasad, A.; Yuan, L.; Lee, P.; Patel, M.; Qiu, D.; Easton, M.; StJohn, D. Towards understanding grain nucleation under Additive Manufacturing solidification conditions. Acta Mater. 2020, 195, 392–403. [Google Scholar] [CrossRef]

- Doherty, R.D.; Feest, E.A.; Holm, K. Dendritic solidification of Cu-Ni alloys: Part I. Initial growth of dendrite structure. Metall. Trans. 1973, 4, 115–124. [Google Scholar] [CrossRef]

- Zeng, H.; Ai, X.; Chen, M.; Guan, R.; Chao, Y.; Zhang, J. Phase-field simulation study on dendritic growth behavior during bilateral directional solidification. Mater. Today Commun. 2024, 40, 109618. [Google Scholar] [CrossRef]

- Algoso, P.; Hofmeister, W.; Bayuzick, R. Solidification velocity of undercooled Ni–Cu alloys. Acta Mater. 2003, 51, 4307–4318. [Google Scholar] [CrossRef]

- Chen, C.; Sun, J.; Yang, Y.; Li, J.; Zhou, Y. Effect of dendrite arrays near grain boundary on the competitive growth of converging Ni-based bi-crystal superalloys. Mater. Lett. 2023, 344, 134477. [Google Scholar] [CrossRef]

- Li, H.; Xie, S.; Mi, X.; Wu, P. Phase and Microstructure Analysis of Cu-Cr-Zr Alloys. J. Mater. Sci. Technol. 2007, 23, 795–800. [Google Scholar]

- Wang, Y.; Lan, X.; Shi, Y.; Hu, B.; Sheng, S.; Zhang, C. Phase equilibria of the Cr−Zr−Ni and Cu−Cr−Zr−Ni systems supported by key experiment and thermodynamic calculation. Mater. Today Commun. 2025, 42, 111484. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, P.; Liu, S.; Du, Y. Experimental investigation and thermodynamic description of the Cu-Cr-Zr system. Calphad 2017, 59, 1–11. [Google Scholar] [CrossRef]

- Hermana, G.N.; Huang, T.-T.; Chen, C.-M.; Lin, C.-H.; Iikubo, S.; Yen, Y.-W. Phase equilibria of the Cu-Ni-Zr ternary systems at 800 °C and thermodynamic assessment and metallic glass region prediction for the Cu-Ni-Zr ternary system. J. Non-Cryst. Solids 2018, 481, 612–621. [Google Scholar] [CrossRef]

- Singh, K.P.; Patel, A.; Bhope, K.; Khirwadkar, S.S.; Mehta, M. Optimization of the diffusion bonding parameters for SS316L/CuCrZr with and without Nickel interlayer. Fusion Eng. Des. 2016, 112, 274–282. [Google Scholar] [CrossRef]

- Al-Qawabah, S.M.A.; Shaban, N.A.; Al-Aboshi, A. Investigation of Roller Burnishing Process on the Mechanical Characteristics, and Micro-hardness of Al-4 wt% Cu Under Hot Work Conditions. In International Conference on Engineering, Project, and Product Management; Springer: Berlin/Heidelberg, Germany, 2018; pp. 209–214. [Google Scholar]

- Mostafa, A.O. Mechanical Properties and Wear Behavior of Aluminum Grain Refined by Ti and Ti+B. Int. J. Surf. Eng. Interdiscip. Mater. Sci. 2019, 7, 1–19. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).