Further Studies into the Growth of Small Naturally Occurring Three-Dimensional Cracks in Additively Manufactured and Conventionally Built Materials

Abstract

1. Introduction

- (i)

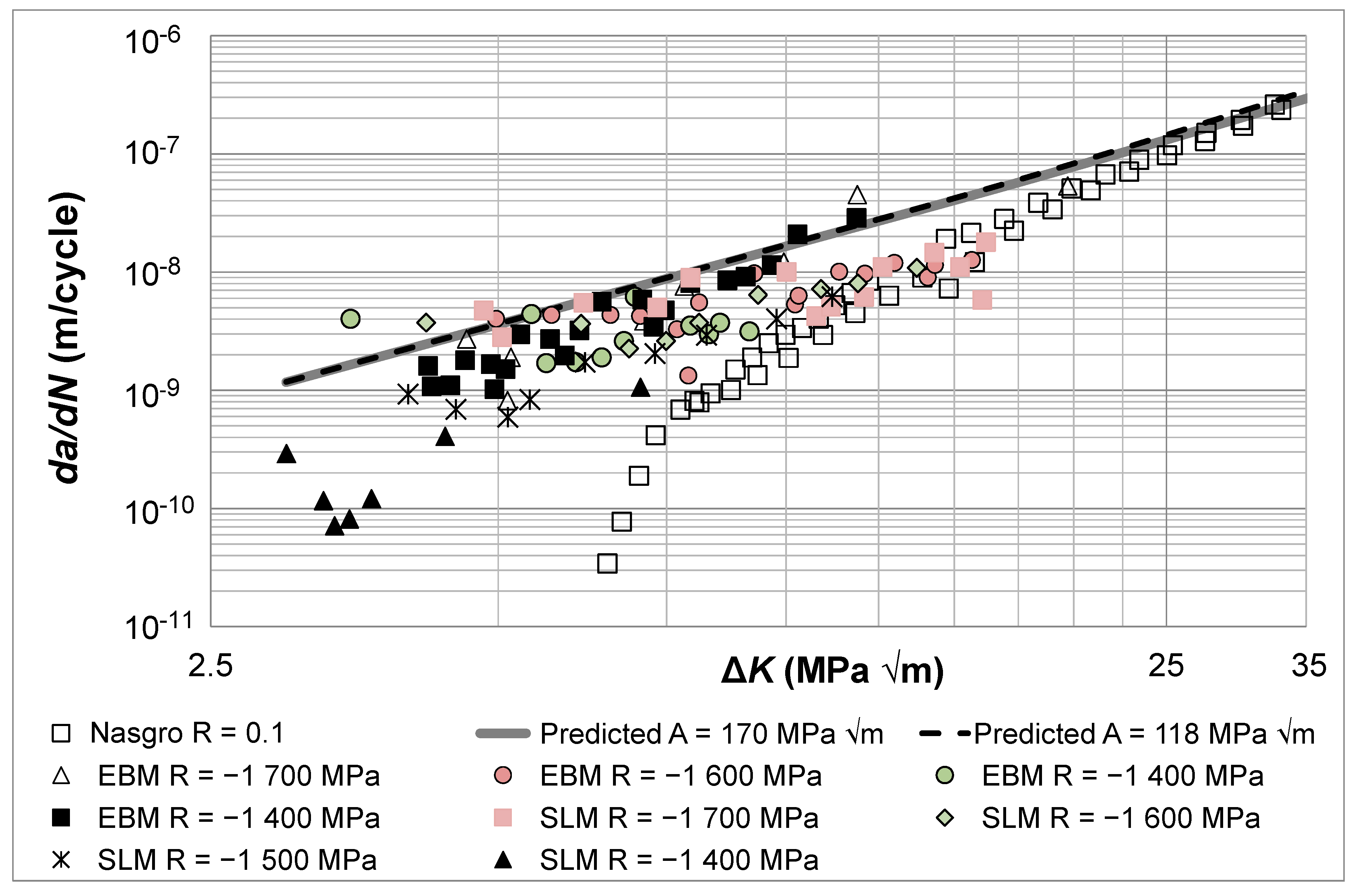

- The Hartman-Schijve crack growth equation, i.e., Equations (1) and (2), is unique in that for long cracks in AM materials, it has been shown [22,23,24,25,26,27,28] that the variability in the long crack growth curves due to different build protocols, material anisotropy, material variability and R ratio is often uniquely captured by allowing for the variability in just two fracture mechanics parameters, namely, the fracture toughness (A) and the fatigue threshold term (ΔKthr).

- (ii)

- (iii)

- References [27,32] revealed that Equations (1) and (2) could be used to represent the growth of long cracks in a range of AM materials, including the variability in the da/dN versus ∆K curves due to the build process as well to represent the growth of long cracks in cold spray additively manufactured (CSAM) materials and plasma sprayed refractory metals and alloys [33].

- (iv)

2. Methods and Materials

- (a)

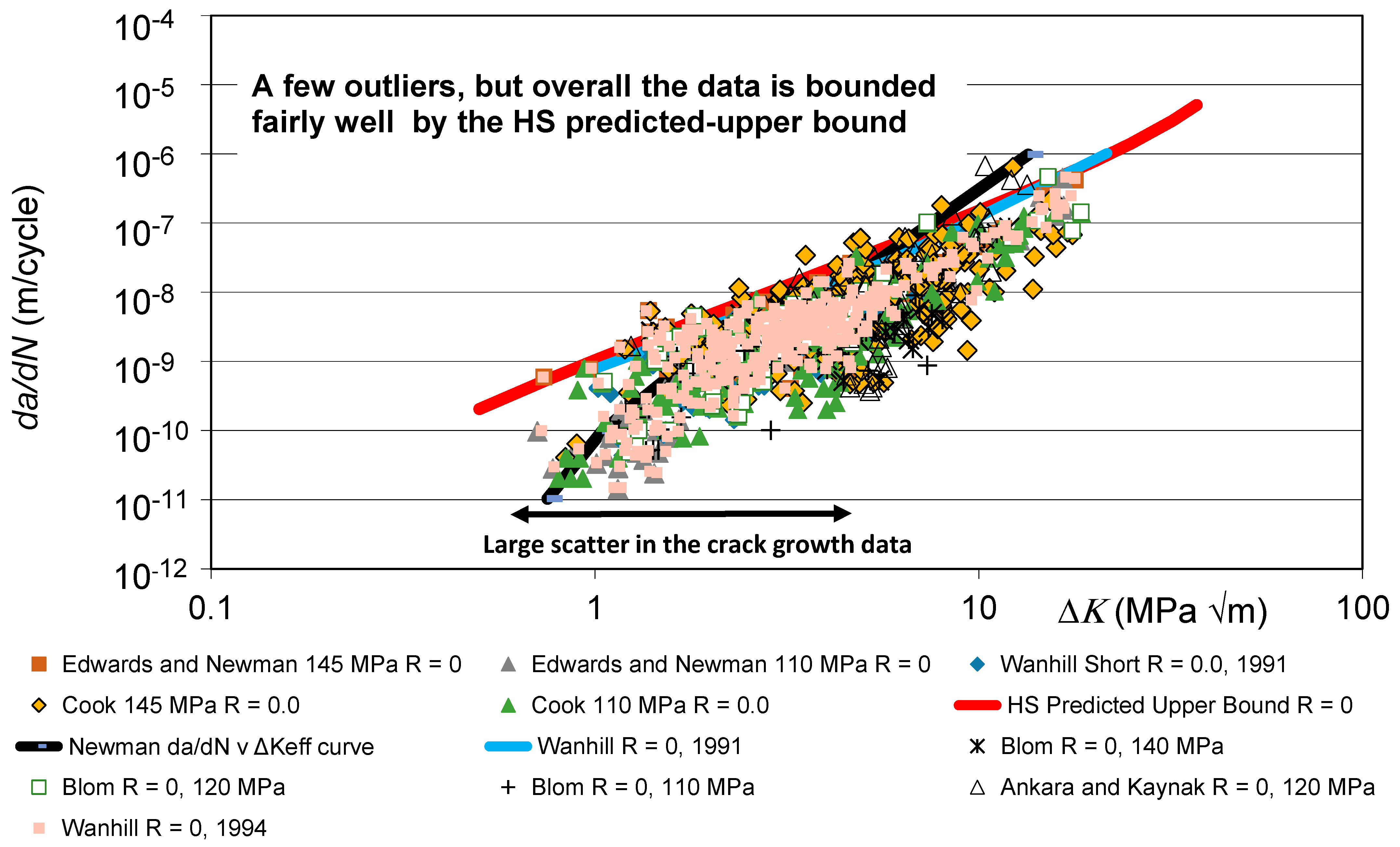

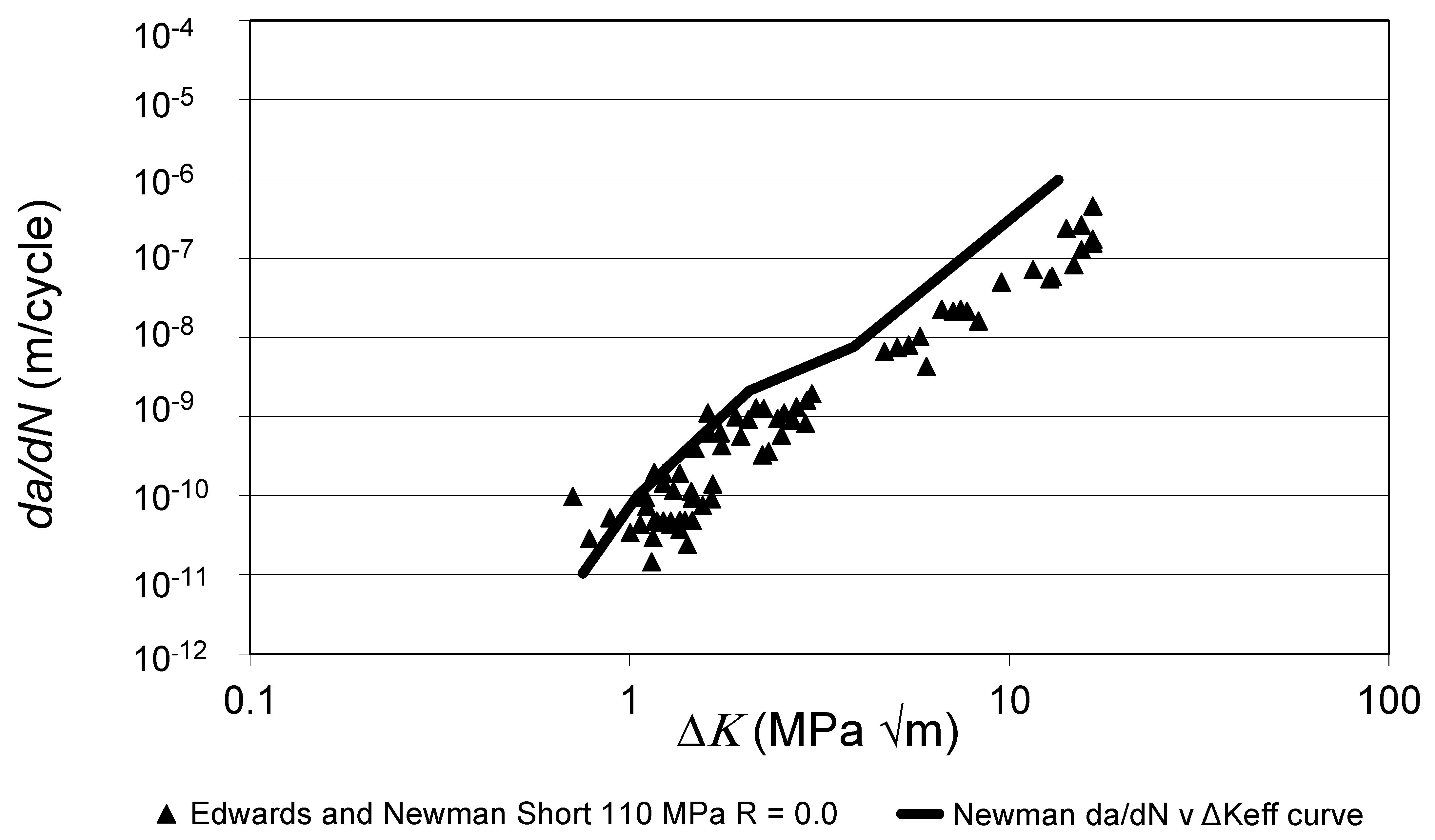

- The hypothesis that crack-closure-based approaches can be used to give reasonable upper-bound (worst-case) estimates for the small crack da/dN versus ΔK curve is contradicted by the experimental data given in [39].

- (b)

- Prior studies into the ability of the Hartman-Schijve equation to predict the crack growth histories associated with the growth of naturally occurring 3D cracks in AM materials had studied laser powder built (LPBF) Scalmalloy, which is an additively manufactured aluminium alloy, with both as-built and machined surfaces, as well as Scalmalloy subjected to prolonged exposure to an ASTM B117-19 5% NaCl salt fog at 35 °C, wire arc additively manufactured (WAAM) 18Ni 250 Maraging steel, and WAAM built Ti-6Al-4V.

- (c)

- The variability in crack growth in AM materials due to different build protocols, material anisotropy, material variability and R ratio is uniquely captured by allowing for the variability in just two parameters, viz., A and ΔKthr.

- The similarity in the mechanical properties;

- That, as stated in the US Department of Transportation Federal Highway Administration’s report [43], the fatigue performance of many steels are sufficiently similar that it is unnecessary to generate data for every type of structural steel;

- The fact that, as shown in [17], the da/dN versus ΔK curves associated with many steels, which have a wide range of chemical compositions, hardness, microstructure and yield stresses, are very similar;

3. Crack Growth in WAAM CP-Ti Specimens

Computing the Growth of Natural 3D Cracks in WAAM CP-Ti

4. Predicting the Growth of Small Cracks in Additively Manufactured Inconel 718

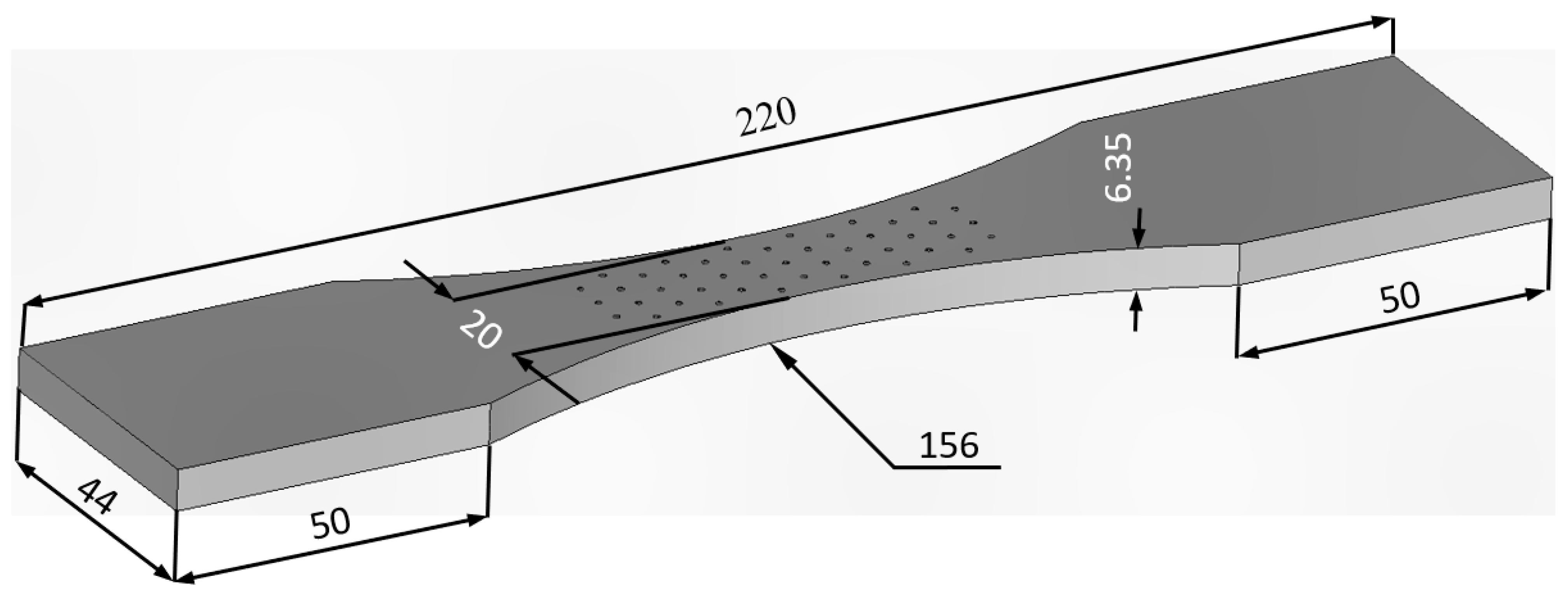

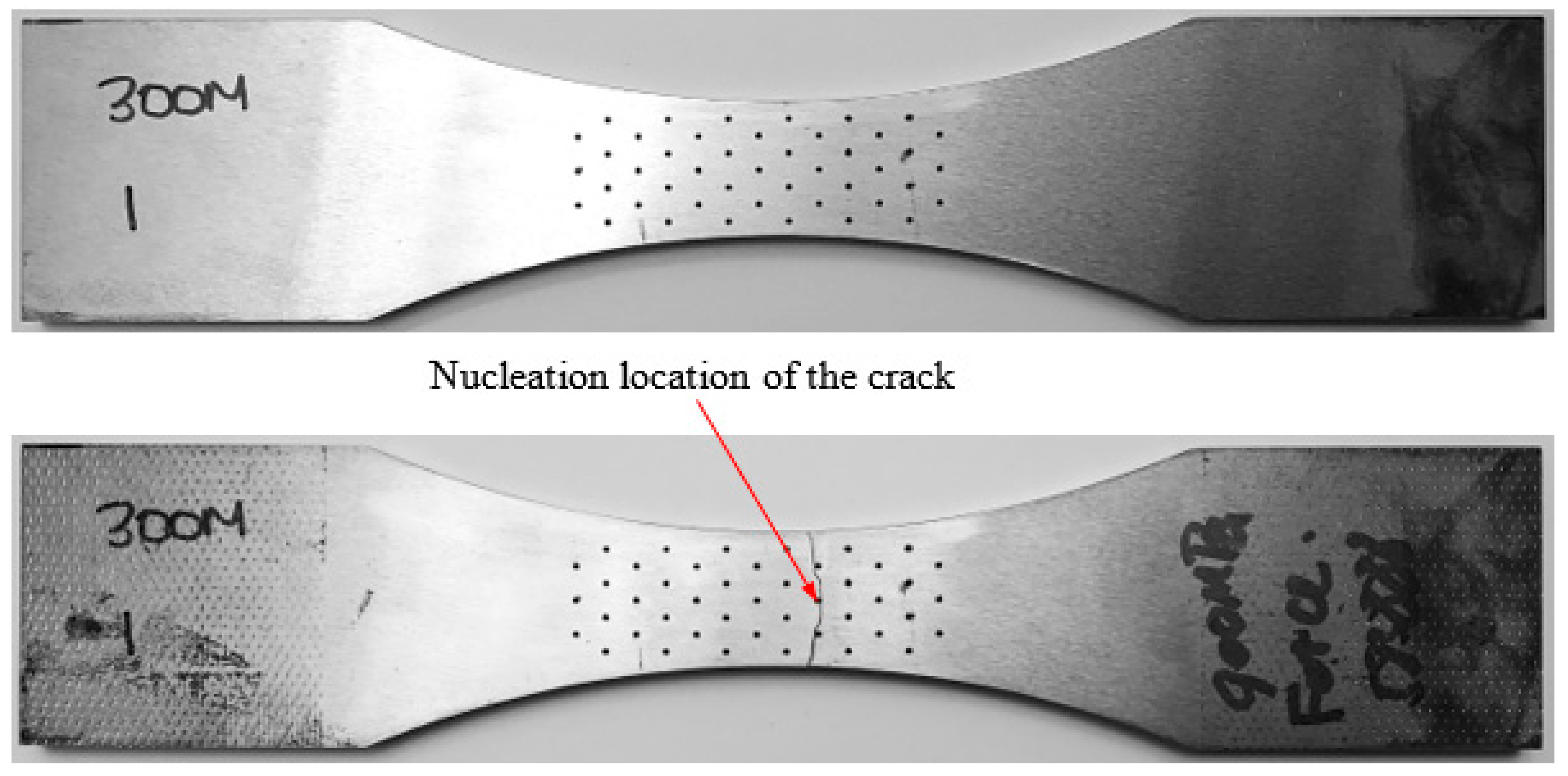

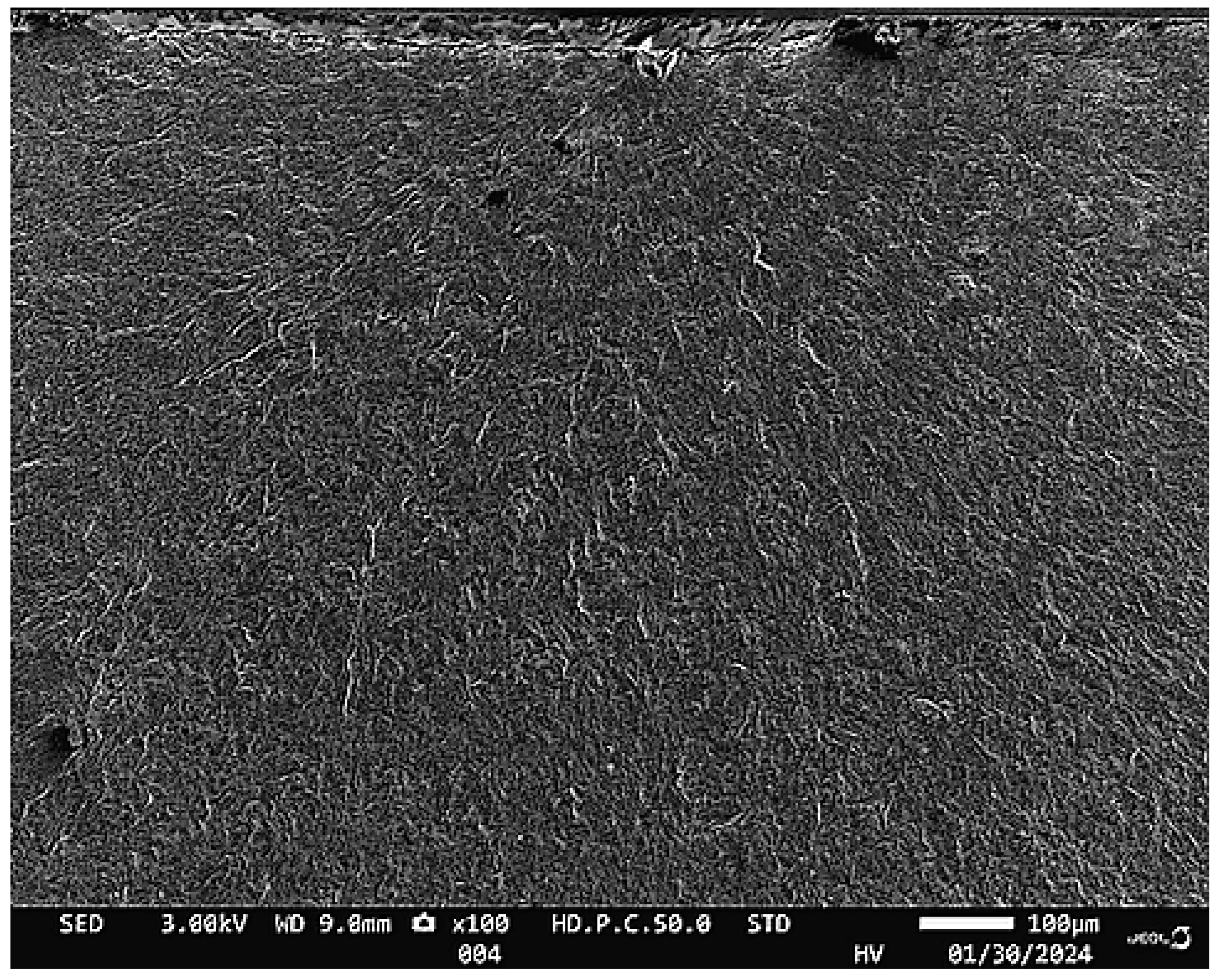

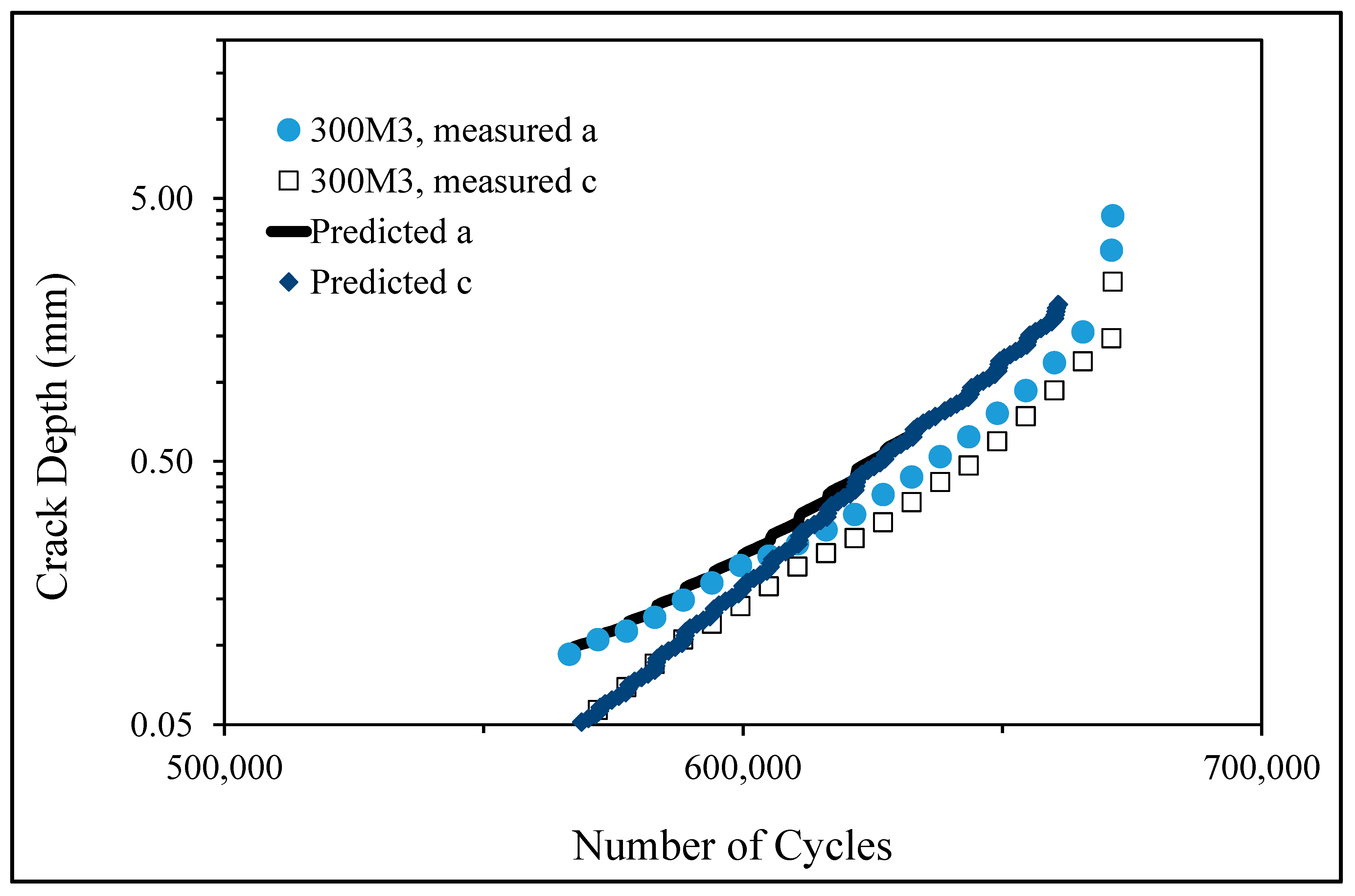

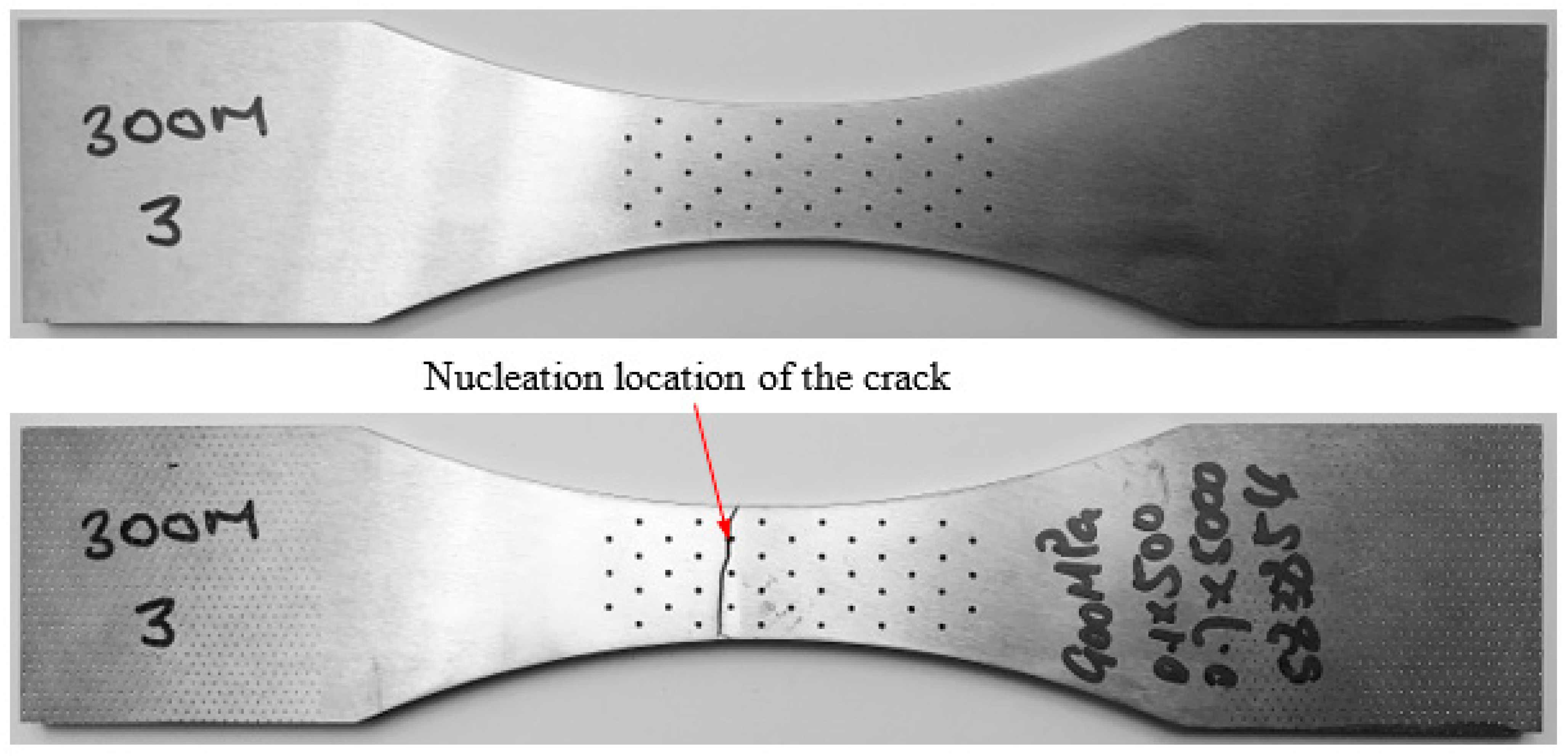

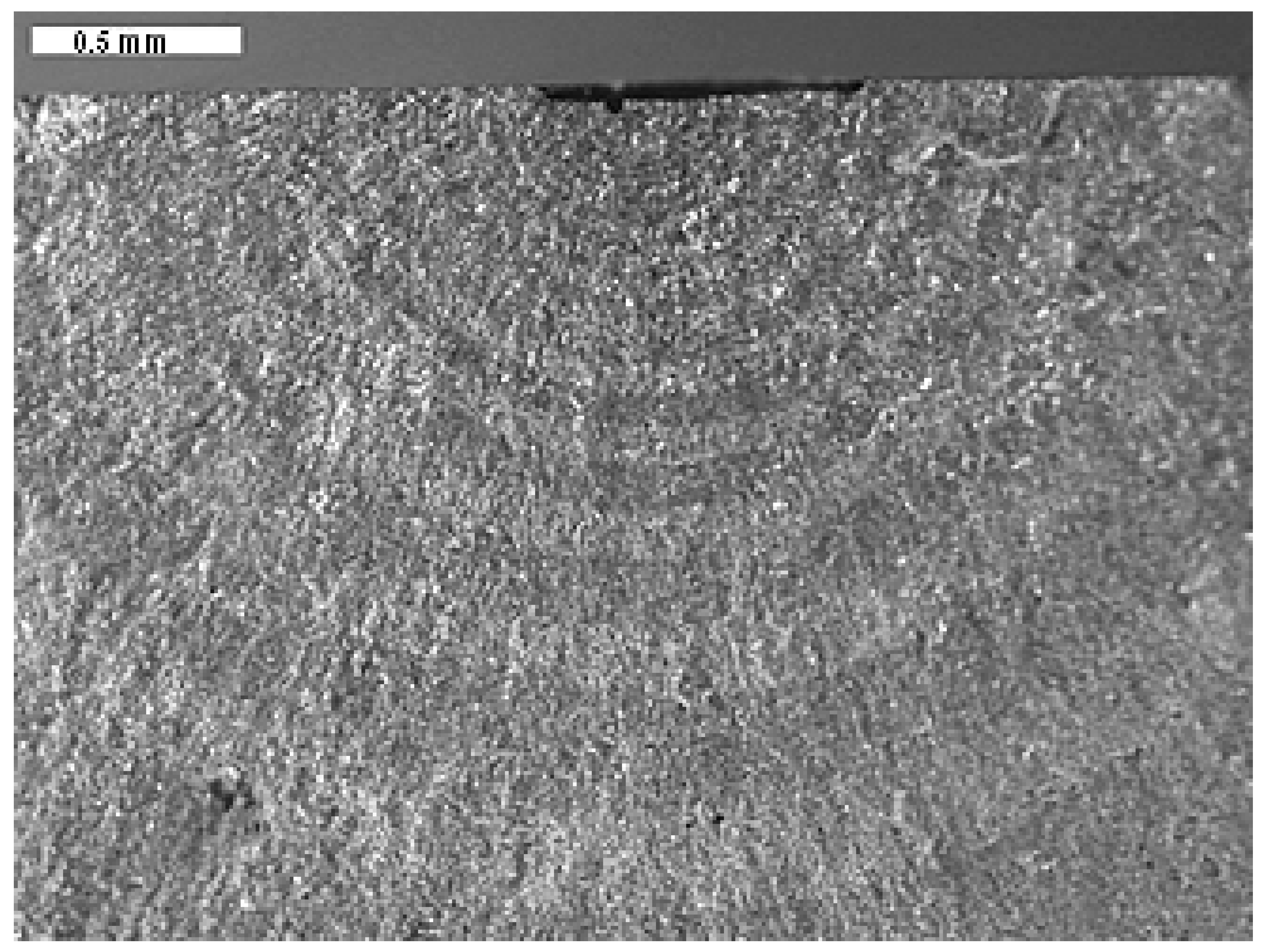

5. Predicting the Growth of Natural 3D Cracks in Conventionally Manufactured M300 Steel

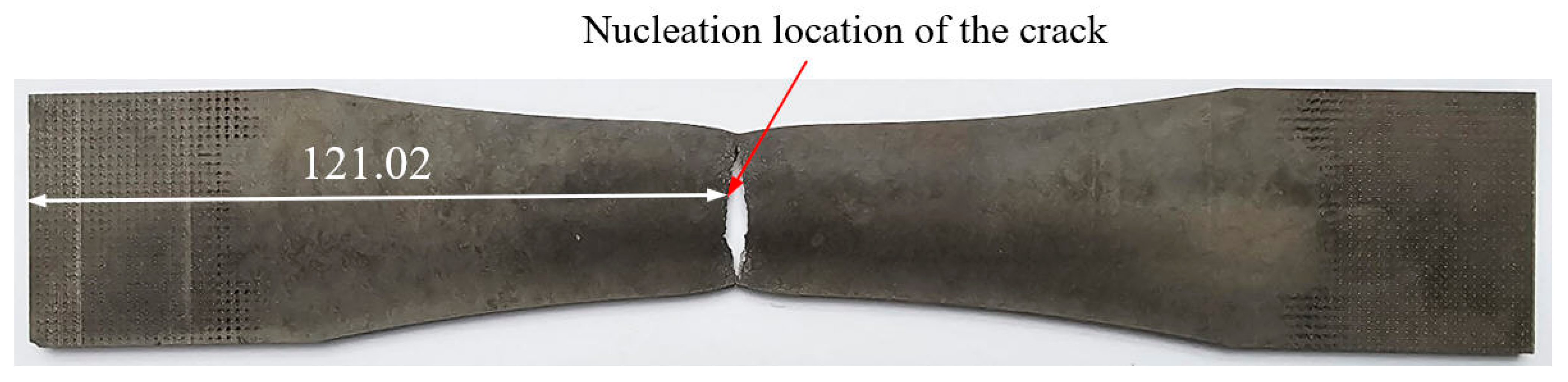

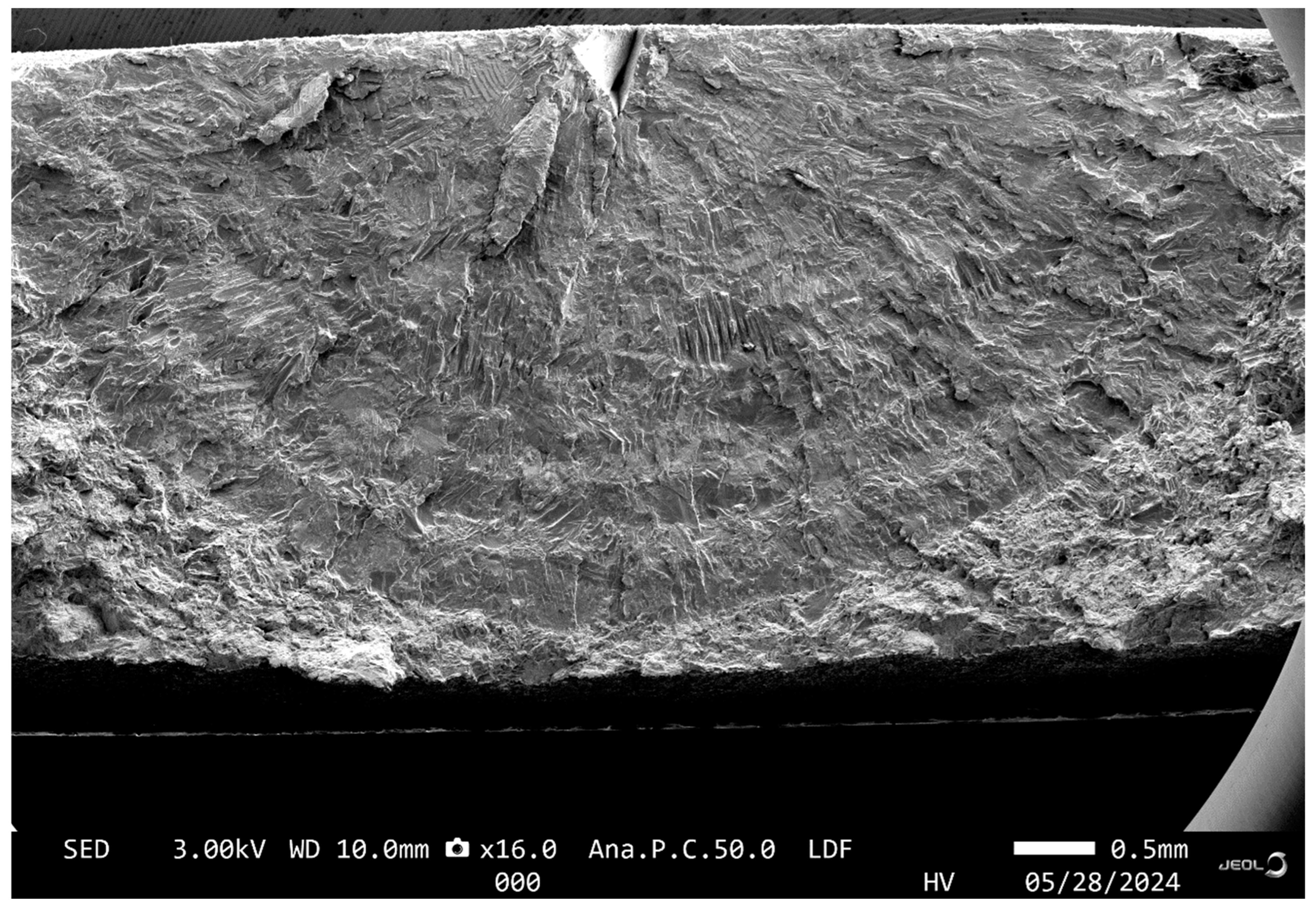

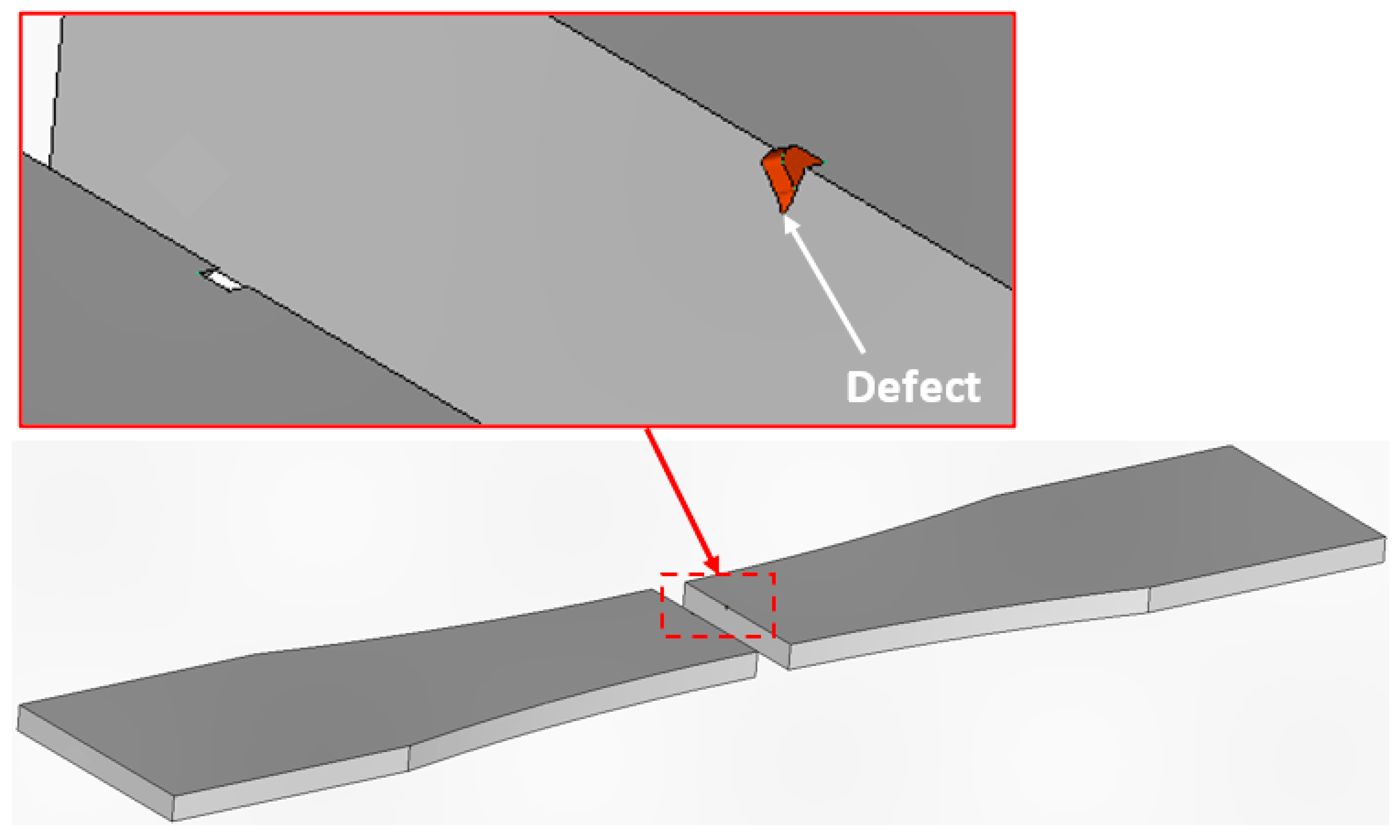

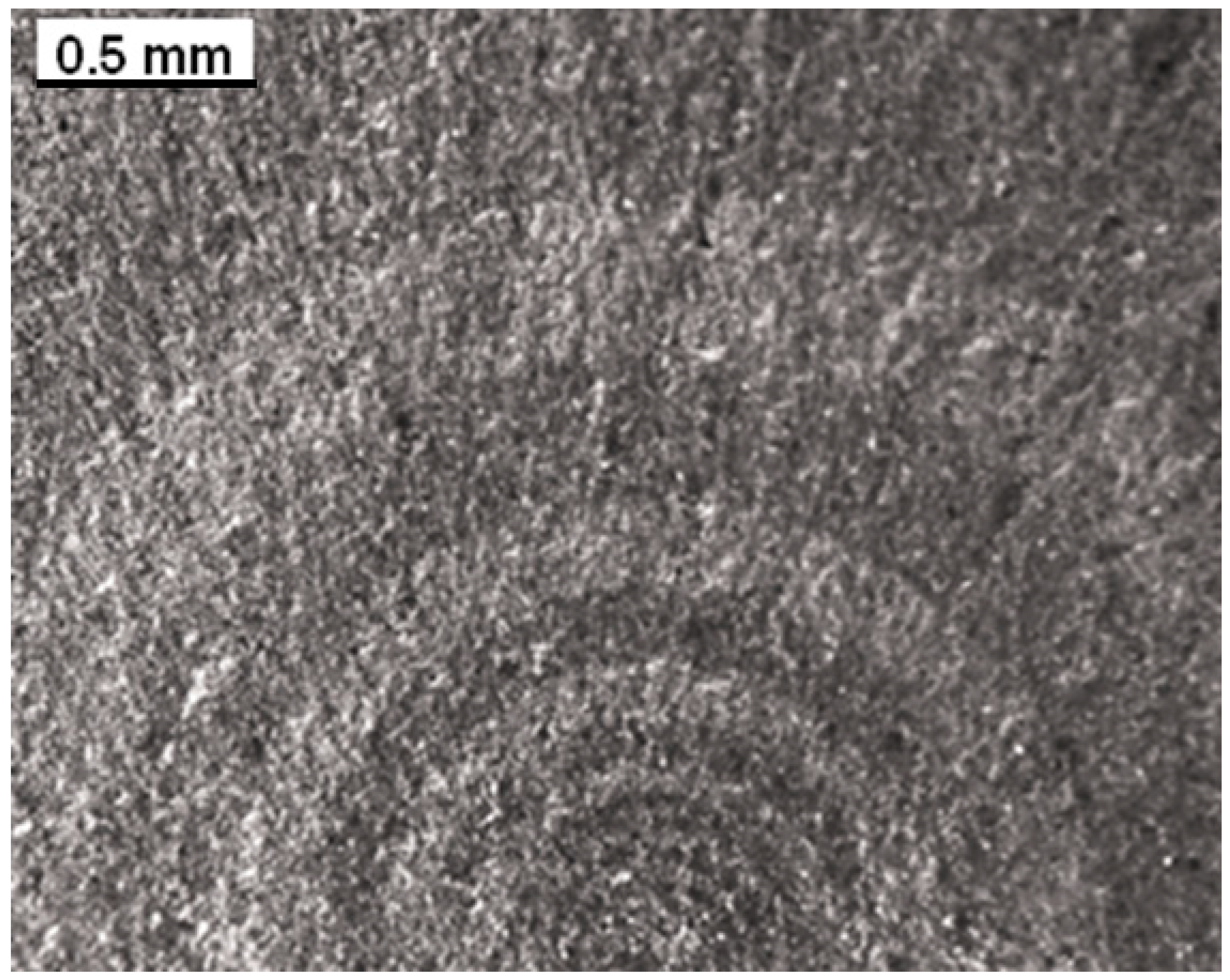

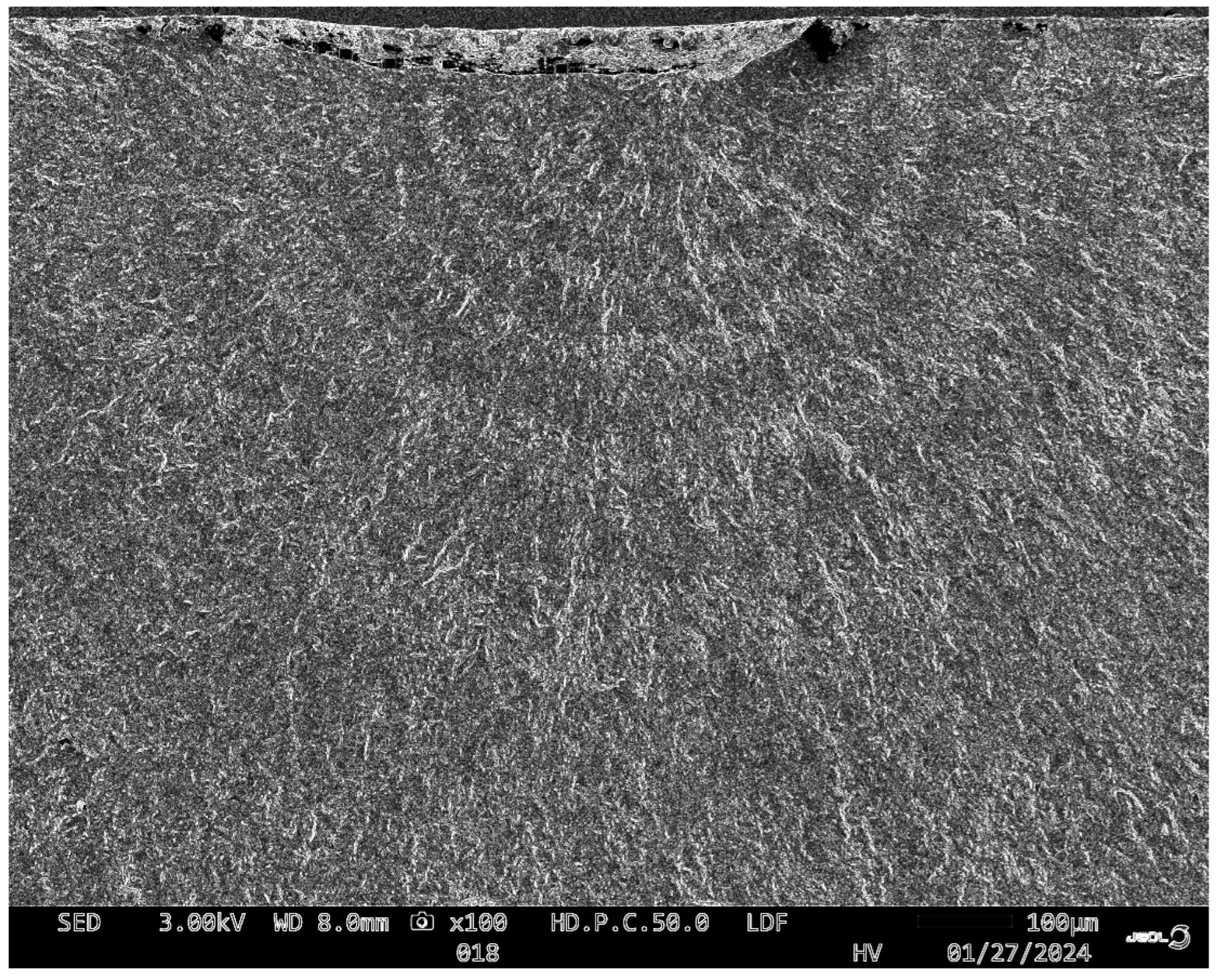

5.1. Specimen M3001

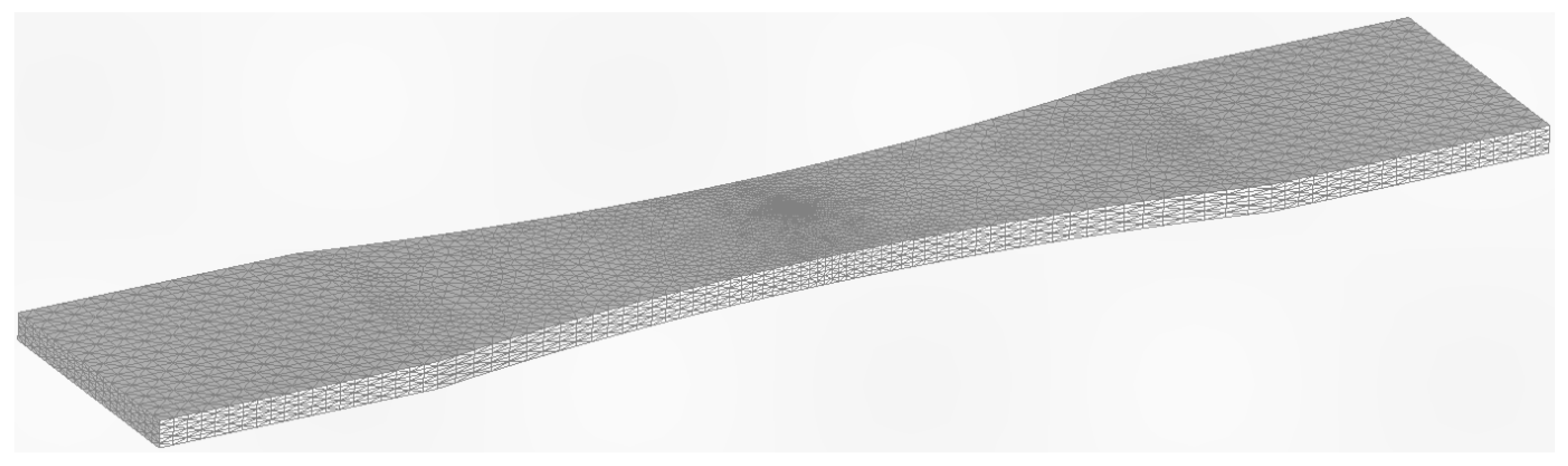

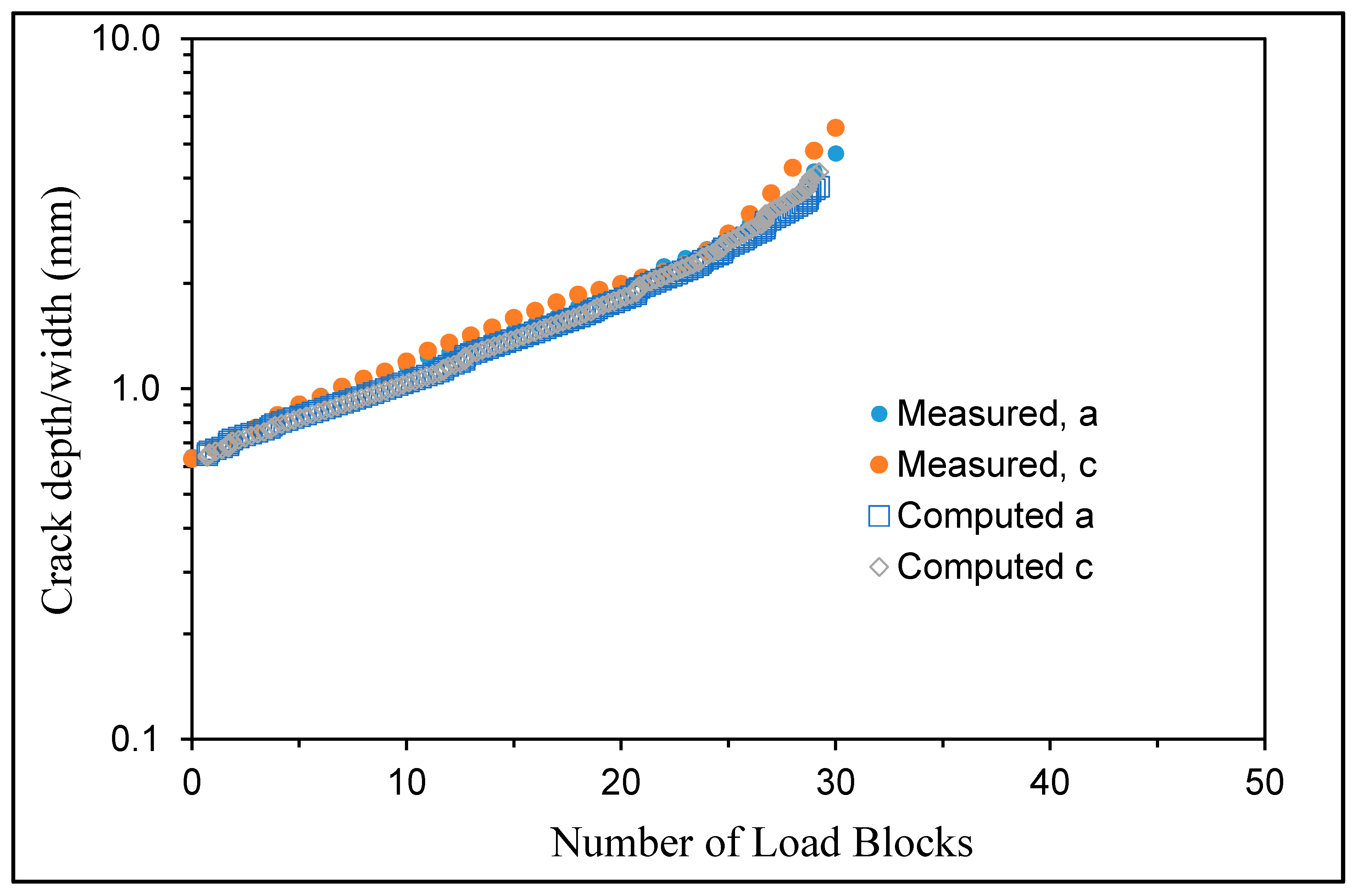

Predicting the Crack Growth History for Specimen 300M1

5.2. Specimen 300M3

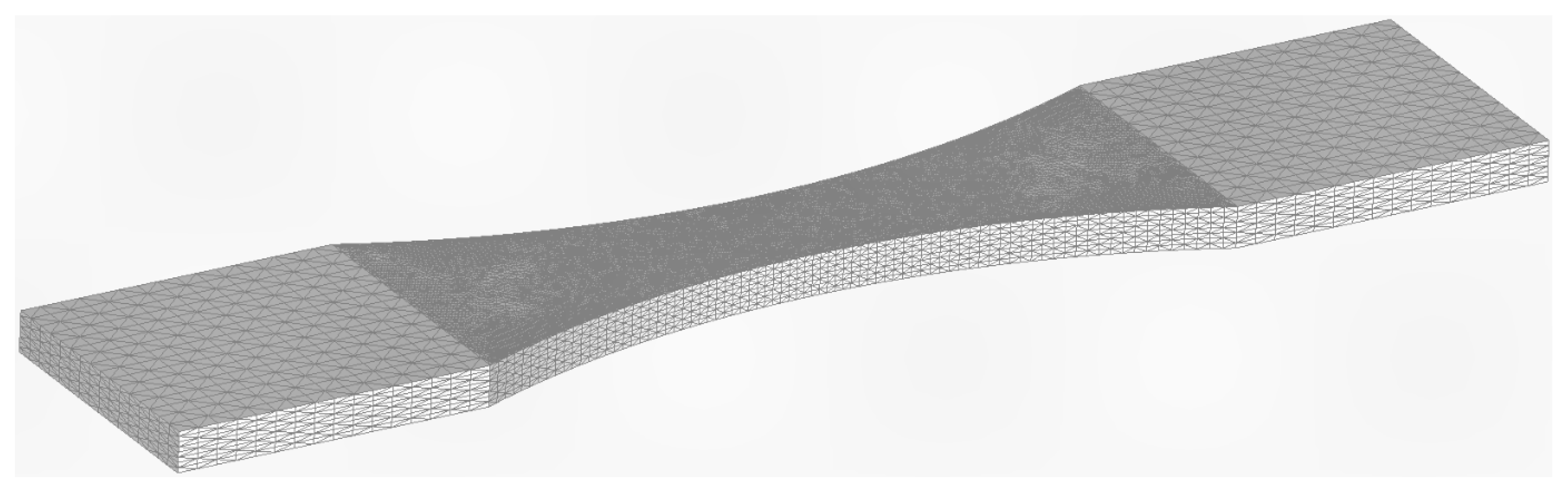

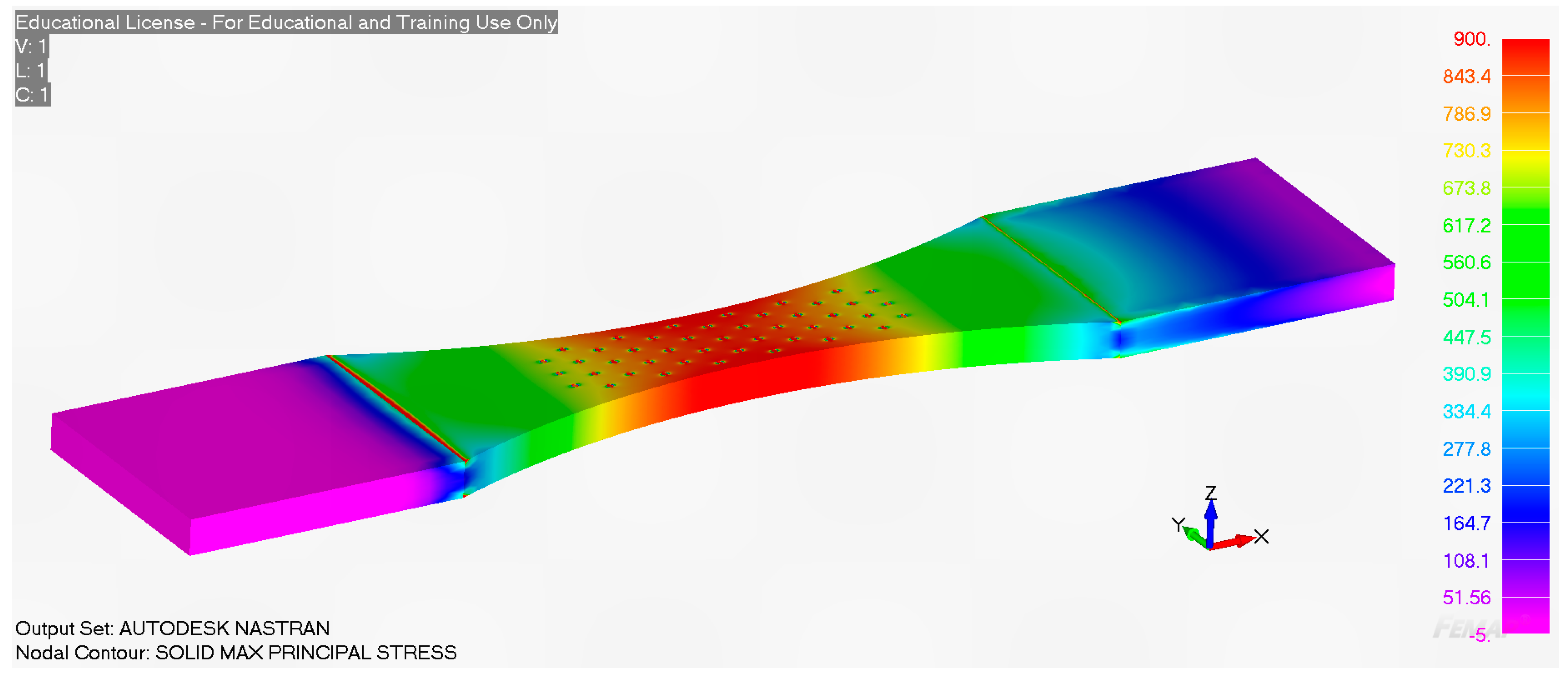

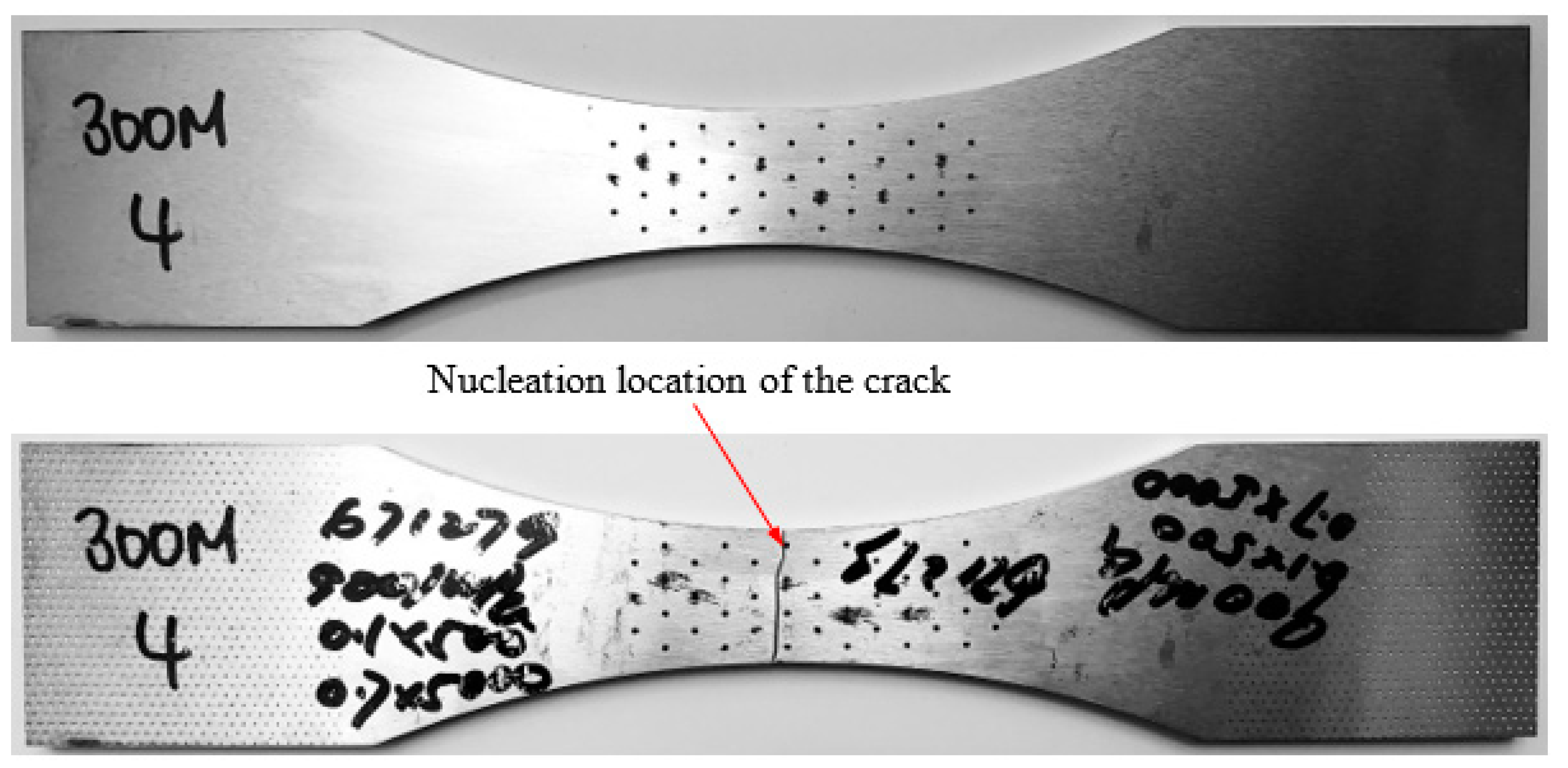

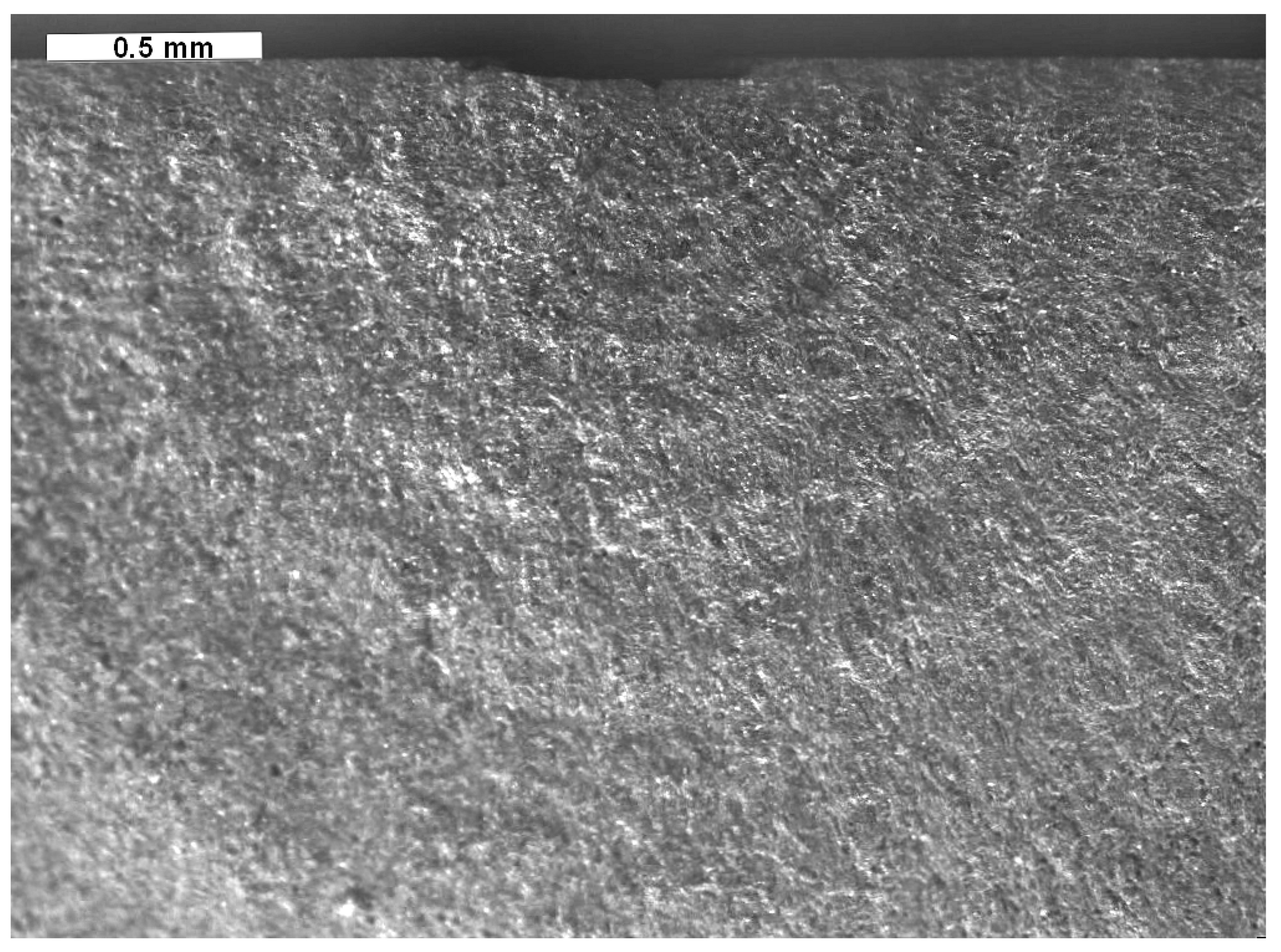

5.3. Specimen of 300M4

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- United States Air Force. Durability and Damage Tolerance Certification for Additive Manufacturing of Aircraft Structural Metallic Parts; Structures Bulletin EZ-SB-19-01; Wright Patterson Air Force Base: Dayton, OH, USA, 2019; Available online: https://daytonaero.com/usaf-structures-bulletins-library/ (accessed on 15 February 2025).

- MIL-STD-1530D; Department of Defense Standard Practice Aircraft Structural Integrity Program (ASIP) (31 August 2016). USAF: Washington, DC, USA, 2016. Available online: http://everyspec.com/MIL-STD/MIL-STD-1500-1599/MIL-STD-1530D_55392/ (accessed on 1 June 2025).

- JSSG-2006; Department of Defense Joint Service Specification Guide; Aircraft Structures (30 October 1998). USAF: Washington, DC, USA, 2006. Available online: http://everyspec.com/USAF/USAF-General/JSSG-2006_10206/ (accessed on 15 March 2025).

- NASA-HDBK-5010; Fracture Control Handbook for Payloads, Experiments, and Similar Hardware. Revalidated 2012; NASA: Washington, DC, USA, 2005. Available online: https://standards.nasa.gov/standard/nasa/nasa-hdbk-5010 (accessed on 15 February 2025).

- NASA-HDBK-5026; Guidance on Strength, Fatigue, and Fracture Control Requirements for Additively Manufactured Spaceflight Hardware. NASA: Washington, DC, USA, 2024. Available online: https://standards.nasa.gov/standard/NASA/NASA-HDBK-5026 (accessed on 15 February 2025).

- Jones, R. Fatigue crack growth and damage tolerance. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 463–483. [Google Scholar] [CrossRef]

- Peng, D.; Jones, R.; Ang, A.S.M.; Michelson, A.; Champagne, V.; Birt, A.; Pinches, S.; Kundu, S.; Alankar, A.; Singh Raman, R.K. Computing the durability of WAAM 18Ni 250 Maraging steel specimens. Fatigue Fract. Eng. Mater. Struct. 2022, 45, 3535–3545. [Google Scholar] [CrossRef]

- Peng, D.; Champagne, V.K.; Ang, A.S.M.; Birt, A.; Michelson, A.; Pinches, S.; Jones, R. Computing the Durability of WAAM 18Ni-250 Maraging Steel Specimens with Surface Breaking Porosity. Crystals 2023, 13, 443. [Google Scholar] [CrossRef]

- Shamir, M.; Zhang, X.; Syed, A.K. Characterising and representing small crack growth in an additive manufactured titanium alloy. Eng. Fract. Mech. 2021, 253, 107876. [Google Scholar] [CrossRef]

- Dastgerdi, J.N.; Jaberi, O.; Remes, H.; Lehto, P.; Toudeshky, H.H.; Kuva, J. Fatigue damage process of additively manufactured 316L steel using X-ray computed tomography imaging. Addit. Manuf. 2023, 70, 103559. [Google Scholar] [CrossRef]

- Jones, R.; Ang, A.; Aston, R.W.; Schoenborn, N.D.; Champagne, V.K.; Peng, D.; Phan, N. On the Growth of Small Cracks in 2024-T3 and Boeing Space, Intelligence and Weapon Systems AM LPBF Scalmalloy®. Fatigue Fract. Eng. Mater. Struct. 2024, 48, 31–43. [Google Scholar] [CrossRef]

- Jones, R.; Cizek, J.; Kovarik, O.; Ang, A.; Champagne, V.K. Observations on comparable aluminium alloy crack growth curves: Additively manufactured Scalmalloy® as an alternative to AA5754 and AA6061-T6 alloys? Addit. Manuf. Lett. 2022, 2, 100026. [Google Scholar] [CrossRef]

- Markham, M.J.; Fatemi, A.; Nam, P. Mixed-Mode Small Fatigue Crack Growth Rates and Modelling in Additively Manufactured Metals. Int. J. Fatigue 2024, 183, 108258. [Google Scholar] [CrossRef]

- Tang, D.; He, X.; Wu, B.; Dang, L.; Xin, H.; Li, Y. A fatigue life prediction approach for porosity defect-induced failures in directed energy deposited Ti-6Al-4V considering crack growth environment. Int. J. Fatigue 2014, 184, 108272. [Google Scholar] [CrossRef]

- Han, S.; Dung Dinh, T.; De Baere, I.; Boone, M.; Josipovic, I.; Van Paepegem, W. Study of the effect of defects on fatigue life prediction of additive manufactured Ti-6Al-4V by combined use of micro-computed tomography and fracture-mechanics-based simulation. Int. J. Fatigue 2023, 180, 108110. [Google Scholar] [CrossRef]

- Shamir, M.; Zhang, X.; Syed, A.K.; Sadler, W. Predicting the Effect of Surface Waviness on Fatigue Life of a Wire Arc Additive Manufactured Ti-6Al-4V Alloy. Materials 2023, 16, 5355. [Google Scholar] [CrossRef] [PubMed]

- Jones, R.; Singh Raman, R.K.; McMillan, A.J. Crack growth: Does microstructure play a role? Eng. Fract. Mech. 2018, 187, 190–210. [Google Scholar] [CrossRef]

- Main, B.; Evans, R.; Walker, K.; Yu, X.; Molent, L. Lessons from a fatigue prediction challenge for an aircraft wing shear tie post. Int. J. Fatigue 2019, 123, 53–65. [Google Scholar] [CrossRef]

- Wanhill, R.J.; Stanzl-Tschegg, S.E. Short/small fatigue crack growth, thresholds and environmental effects: A tale of two engineering paradigms. Corros. Rev. 2021, 39, 165–175. [Google Scholar] [CrossRef]

- Tan, J.; Chen, B. Coalescence and growth of two coplanar short cracks in AA7050-T7451 aluminium alloys. Eng. Fract. Mech. 2013, 102, 324–333. [Google Scholar] [CrossRef]

- Tan, J.; Chen, B. A new fracture area method for predicting the growth of a newly coalesced crack in AA7050-T7451 aluminium alloy. Theor. Appl. Fract. Mech. 2015, 75, 146–150. [Google Scholar] [CrossRef]

- Iliopoulos, A.P.; Jones, R.; Michopoulos, J.G.; Phan, N.; Rans, C. Further Studies into Crack Growth in Additively Manufactured Materials. Materials 2020, 13, 2223. [Google Scholar] [CrossRef]

- Jones, R.; Ang, A.; Peng, D.; Champagne, V.K.; Michelson, A.; Birt, A. Modelling Crack Growth in Additively Manufactured Inconel 718 and Inconel 625. Metals 2023, 13, 1300. [Google Scholar] [CrossRef]

- Ye, J.; Syed, A.K.; Zhang, X.; Eimer, E.; Williams, S. Fatigue crack growth behaviour in an aluminium alloy Al-Mg-0.3Sc produced by wire based directed energy deposition process. Fatigue Fract. Eng. Mater. Struct. 2023, 46, 3927–3938. Available online: https://onlinelibrary.wiley.com/doi/epdf/10.1111/ffe.14113 (accessed on 18 April 2025). [CrossRef]

- Jones, R.; Michopoulos, J.G.; Iliopoulos, A.P.; Singh Raman, R.K.; Phan, N.; Nguyen, T. Representing Crack Growth in Additively Manufactured TI-6AL-4V. Int. J. Fatigue 2018, 111, 610–622. [Google Scholar] [CrossRef]

- Iliopoulos, A.P.; Jones, R.; Michopoulos, J.G.; Phan, N.; Singh Raman, R.K. Crack growth in a range of additively manufactured aerospace structural materials, Special Issue, Civil and Military Airworthiness: Recent Developments and Challenges. Aerospace 2018, 5, 118–136. [Google Scholar] [CrossRef]

- Jones, R.; Kovarik, O.; Bagherifard, S.; Cizek, J.; Lang, J. Damage tolerance assessment of AM 304L and cold spray fabricated 316L steels and its implications for attritable aircraft. Eng. Fract. Mech. 2021, 254, 107916. [Google Scholar] [CrossRef]

- Kovarik, O.; Cech, J.; Kiziklioglu, E.; Cizek, J.; Stittgen, T. Anisotropy of Mechanical Properties of DMD Build Inconel 738. In Proceedings of the Thermal Spray 2023: Proceedings from the International Thermal Spray Conference, Québec City, QC, Canada, 22–25 May 2023; ASM International: Township, OH, USA, 2023. Paper No: itsc2023p0473. pp. 473–479. [Google Scholar] [CrossRef]

- Markham, M.J.; Fatemi, A. Multiaxial Fatigue Life Predictions of Additively Manufactured Metals Using a Hybrid of Linear Elastic Fracture Mechanics and a Critical Plane Approach. Int. J. Fatigue 2023, 178, 107979. [Google Scholar] [CrossRef]

- Sanaei, N.; Fatemi, A. Defect-based multiaxial fatigue life prediction of L-PBF additive manufactured metals. Fatigue Fract. Eng. Mater. Struct. 2021, 44, 1897–1915. [Google Scholar] [CrossRef]

- Sanaei, N.; Fatemi, A. Defects in additive manufactured metals and their effect on fatigue performance: A state-of-the-art review. Prog. Mater. Sci. 2020, 117, 100724. [Google Scholar] [CrossRef]

- Jones, R.; Kovarik, O.; Cizek, J.; Ang, A.; Lang, J. Crack growth in conventionally manufactured pure nickel, titanium and aluminium and the cold spray additively manufactured equivalents. Addit. Manuf. Lett. 2022, 3, 100043. [Google Scholar] [CrossRef]

- Kovarik, O.; Cizek, J.; Klecka, J. Fatigue Crack Growth Rate Description of RF-Plasma-Sprayed Refractory Metals and Alloys. Materials 2023, 16, 1713. [Google Scholar] [CrossRef]

- Godefroid, L.B.; Moreir, L.P.; Vilel, T.C.G.; Fari, G.L.; Candid, L.C.; Pinto, E.S. Effect of chemical composition and microstructure on the fatigue crack growth resistance of pearlitic steels for railroad application. Int. J. Fatigue 2019, 120, 241. [Google Scholar] [CrossRef]

- Zhang, Y.; Zheng, K.; Heng, J.; Zhu, J. Corrosion-Fatigue Evaluation of Uncoated Weathering Steel Bridges. Appl. Sci. 2019, 9, 3461. [Google Scholar] [CrossRef]

- Walker, K.F.; Wang, C.H.; Newman, J.C., Jr. Closure measurement and analysis for small cracks from natural discontinuities in an aluminium alloy. Int. J. Fatigue 2016, 82, 256–262. [Google Scholar] [CrossRef]

- Newman, J.C.; Phillips, E.P.; Everett, R.A. Fatigue Analyses Under Constant and Variable-Amplitude Loading Using Small-Crack Theory. NASA/TM-1999-209329, 1 May 1999. Available online: https://ntrs.nasa.gov/citations/19990046065 (accessed on 15 February 2025).

- Today in Science History. Available online: https://todayinsci.com/F/Fermi_Enrico/FermiEnrico-Quotations.htm (accessed on 18 May 2025).

- Newman, J.C., Jr.; Edwards, P.R. Short-Crack Growth Behaviour in an Aluminium Alloy—An AGARD Cooperative Test Programme. AGARD-R-732, 1 December 1988. Available online: https://ntrs.nasa.gov/citations/19890007916 (accessed on 18 May 2025).

- Jones, R.; Lang, J.; Papyan, V.; Peng, D.; Lua, J.; Ang, A. Characterising crack growth in commercially pure titanium. Eng. Fail. Anal. 2021, 122, 105287. [Google Scholar] [CrossRef]

- Steel 300M. Available online: https://www.techsteel.net/alloy/steel/300m (accessed on 27 March 2025).

- Mills, T.; Clark, G.; Loader, C.; Sharp, P.K.; Schmidt, R. Review of F-111 Structural Materials, Department of Defence; Technical Report DSTO-TR-1118; Defence Science Technology Organisation: Canberra, ACT, Australia, 2001. Available online: https://apps.dtic.mil/sti/tr/pdf/ADA393097.pdf (accessed on 27 March 2025).

- Dexter, R.J.; Ocel, J.M. Manual for Repair and Retrofit of Fatigue Cracks in Steel Bridges; Federal Highway Administration Report FHWA-IF-13-020; US Department of Transportation: Washington, DC, USA, 2013. Available online: https://www.fhwa.dot.gov/bridge/steel/pubs/hif13020/hif13020.pdf (accessed on 18 April 2025).

- Nishioka, T.; Atluri, S.N. Analytical solution for embedded elliptical cracks, and finite element alternating method for elliptical surface cracks, subjected to arbitrary loadings. Eng. Fract. Mech. 1983, 17, 247–268. [Google Scholar] [CrossRef]

- Pipkins, S.D.; Atluri, S.N. Applications of the three dimensional method finite element alternating method. Finite Elem. Anal. Des. 1996, 23, 133–153. [Google Scholar] [CrossRef]

- Simon, H.L.; O’Donoghue, P.E.; Atluri, S.N. A finite-element-alternating technique for evaluating mixed modes stress intensity factors for part-elliptical surface flaws. Int. J. Numer. Methods Eng. 1987, 24, 689–709. [Google Scholar] [CrossRef]

- Park, J.H. A Review on Finite Element Alternating Methods for Analyzing 2D and 3D Cracks. Digit. Eng. Digit. Twin 2024, 2, 79–101. [Google Scholar] [CrossRef]

- Wang, L.; Atluri, S.N. Recent advances in the alternating method for elastic and inelastic fracture analyses. Comput. Methods Appl. Mech. Eng. 1996, 137, 1–58. [Google Scholar] [CrossRef]

- Simcenter Femap Software. Available online: https://plm.sw.siemens.com/en-US/simcenter/mechanical-simulation/femap/ (accessed on 18 April 2025).

- Timbrell, C.; Chandwan, R. Whats New in Zencrack. Zenteck International Limited. 2024. Available online: https://zentech.co.uk/software/zencrack/whats-new/version921 (accessed on 25 May 2025).

- Nishikawa, H.; Furuya, Y.; Kitano, H.; Nakamura, T.; Kuwabara, K.; Kanegae, Y.; Kang, D.S.; Aotam, K. In-situ observation of microstructurally small fatigue crack initiation and growth behaviors of additively-manufactured alloy 718. Mater. Sci. Eng. A 2022, 835, 142682. [Google Scholar] [CrossRef]

- NASGRO® Fracture Mechanics & Fatigue Crack Growth Software. Available online: https://www.swri.org/markets/chemistry-materials/materials/mechanics-materials/nasgro-fracture-mechanics-fatigue-crack-growth-software (accessed on 18 April 2025).

- Newman, J.C., Jr.; Yamada, Y. Compression Precracking Methods to Generate Near-Threshold Fatigue-Crack-Growth-Rate Data. Int. J. Fatigue 2010, 32, 879–885. [Google Scholar] [CrossRef]

- Morgan, K.; Wells, D. Overview of Fatigue and Damage Tolerance Performance of SLM Alloy 718. In Proceedings of the 2016 National Space and Missile Materials Symposium, Westminster, CO, USA, 20–23 June 2016; Available online: https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20160007853.pdf (accessed on 18 April 2025).

- Konecná, R.; Kunz, L.; Nicoletto, G.; Baca, A. Fatigue crack growth behavior of Inconel 718 produced by selective laser melting. Frat. Ed. Integrità Strutt. 2016, 35, 31–40. [Google Scholar] [CrossRef]

- Yadollahi, A.; Mahtabi, M.J.; Khalili, A.; Doude, H.R.; Newman, J.C., Jr. Fatigue life prediction of additively manufactured material: Effects of surface roughness, defect size, and shape. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 1602–1614. [Google Scholar] [CrossRef]

- Ostergaard, H.E.; Pribe, J.D.; Hasib, M.T.; Paradowska, A.M.; Siegmund, T.; Kruzic, J.J. Near-threshold fatigue crack growth in laser powder bed fusion produced alloy 718. Int. J. Fatigue 2022, 163, 107041. [Google Scholar] [CrossRef]

- Kim, S.; Choi, H.; Lee, J.; Kim, S. Room and elevated temperature fatigue crack propagation behavior of Inconel 718 alloy fabricated by laser powder bed fusion. Int. J. Fatigue 2020, 140, 105802. [Google Scholar] [CrossRef]

- Yu, X.; Lin, X.; Tan, H.; Hu, Y.; Zhang, S.; Liu, F.; Yang, H.; Huang, W. Microstructure and fatigue crack growth behavior of Inconel 718 superalloy fabricated via laser directed energy deposition additive manufacturing. Int. J. Fatigue 2021, 143, 106005. [Google Scholar] [CrossRef]

- Paluskiewicz, S.A.; Narasimhachary, S.B.; Shinde, S.R.; Kain, C.; Towner, Z.B.; Muhlstein, C.L. Crack closure of Ni-based superalloy 718 at high negative stress ratios. Int. J. Fatigue 2022, 160, 106822. [Google Scholar] [CrossRef]

- Elber, W. Fatigue crack cyclic closure tension under cyclic tension. Eng. Fract. Mech. 1970, 2, 37–45. [Google Scholar]

- Elber, W. The significance of crack closure. In Damage Tolerance in Aircraft Structures; ASTM International: West Conshohocken, PA, USA, 1971; pp. 230–242. [Google Scholar]

- Ribeiro, V.; Correia, J.; Lesiuk, G.; Gonçalves, A.; De Jesus, A.; Berto, F. Application and discussion of various crack closure models to predict fatigue crack growth in 6061-T651 aluminium alloy. Int. J. Fatigue 2021, 153, 106472. [Google Scholar] [CrossRef]

- Liu, J.Z.; Wu, X.R.; Ding, C.F.; Hu, B.R.; Wang, L.F.; Annigeri, B.; Vestergaard, L.H.; Romanowski, A.; Schneider, G.J.; Forth, S.C. Crack growth behavior and fatigue-life prediction based on worst-case near-threshold data of a large crack for 9310 steel. Fatigue Fract. Eng. Mater. Struct. 2002, 25, 467–480. [Google Scholar] [CrossRef]

- Newman, J.C., Jr. Fatigue and Crack Growth under Constant and Variable-Amplitude Loading in 9310 Steel Using “Rainflow-on-the-Fly” Methodology. Metals 2021, 11, 807. [Google Scholar] [CrossRef]

- Newman, J.C., Jr. A crack opening stress equation for fatigue crack growth. Int. J. Fatigue 1984, 24, R131–R135. [Google Scholar] [CrossRef]

- Edwards, P.R.; Newman, J.C., Jr. Short-Crack Growth Behaviour in Various Aircraft Materials; AGARD-R-767; AGARD: Neuilly sur Seine, France, 1990; Available online: https://www.sto.nato.int/publications/AGARD/AGARD-R-767/AGARD-R-767.pdf (accessed on 15 February 2025.).

- Cook, R. The Growth of Short Fatigue Cracks in an Aluminium Alloy; Technical Report 92063; Defence Research Agency: Farnborough, UK, 1992. Available online: https://apps.dtic.mil/sti/pdfs/ADA262064.pdf (accessed on 15 February 2024).

- Blom, A. Short crack growth under realistic flight loading: Model predictions and experimental results for al 2024 and Al-Li 2090. In Short-Crack Growth Behaviour in Various Aircraft Materials; AGARD Report No 767; AGARD: Neuilly sur Seine, France, 1990; pp. 6-1–6-15. Available online: https://www.sto.nato.int/publications/AGARD/AGARD-R-767/AGARD-R-767.pdf (accessed on 15 February 2025).

- Kaynak, C.; Ankara, A. Short fatigue crack growth AL 2024-T3 and AL 7075T6. Eng. Fract. Mech. 1992, 43, 769–778. [Google Scholar] [CrossRef]

- Wanhill, R.J.H. Durability Analysis Using Short and Long Fatigue Crack Growth Data. In Proceedings of the International Conference on Aircraft Damage Assessment and Repair, Melbourne, VIC, Australia, 26–28 August 1991; Jones, R., Miller, N.J., Eds.; The Institution of Engineers Australia: Barton, ACT, Australia, 1991; ISBN 85825 537. Available online: https://www.researchgate.net/publication/325102704_Durability_Analysis_Using_Short_and_Long_Fatigue_Crack_Growth_Data (accessed on 5 February 2025).

- Wanhill, R. Some Practical Considerations for Fatigue and Corrosion Assessment of Ageing Aircraft; NLR Technical Publication TP 96253 L; National Aerospace Laboratory NLR: Amsterdam, The Netherlands, 1996; Available online: https://www.researchgate.net/publication/333965628_NLR_Technical_Publication_TP_96253_L_Some_Practical_Considerations_For_Fatigue_And_Corrosion_Damage_Assessment_Of_Ageing_Aircraft (accessed on 18 April 2025).

- Jones, R.; Molent, L.; Walker, K. Fatigue crack growth in a diverse range of materials. Int. J. Fatigue 2012, 40, 43–50. [Google Scholar] [CrossRef]

- Jones, R.; Raman, R.K.S.; Iliopoulos, A.P.; Michopoulos, J.G.; Phan, N.; Peng, D. Additively manufactured Ti-6Al-4V replacement parts for military aircraft. Int. J. Fatigue 2019, 124, 227–235. [Google Scholar] [CrossRef]

- Tiffany, C.F.; Gallagher, J.P.; Babish, C.A., IV. Threats to Aircraft Structural Safety, Including a Compendium of Selected Structural Accidents/Incidents; ASC-TR-2010-5002; Aeronautical Systems Center, Engineering Directorate, Wright-Patterson Air Force Base: Dayton, OH, USA, 2010; Available online: https://apps.dtic.mil/sti/tr/pdf/ADA519867.pdf (accessed on 18 April 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chan, S.; Peng, D.; Ang, A.S.M.; Nicholas, M.B.; Champagne, V.K.; Birt, A.; Michelson, A.; Langan, S.; Watts, J.; Jones, R. Further Studies into the Growth of Small Naturally Occurring Three-Dimensional Cracks in Additively Manufactured and Conventionally Built Materials. Crystals 2025, 15, 544. https://doi.org/10.3390/cryst15060544

Chan S, Peng D, Ang ASM, Nicholas MB, Champagne VK, Birt A, Michelson A, Langan S, Watts J, Jones R. Further Studies into the Growth of Small Naturally Occurring Three-Dimensional Cracks in Additively Manufactured and Conventionally Built Materials. Crystals. 2025; 15(6):544. https://doi.org/10.3390/cryst15060544

Chicago/Turabian StyleChan, Shareen, Daren Peng, Andrew S. M. Ang, Michael B. Nicholas, Victor K. Champagne, Aron Birt, Alex Michelson, Sean Langan, Jarrod Watts, and Rhys Jones. 2025. "Further Studies into the Growth of Small Naturally Occurring Three-Dimensional Cracks in Additively Manufactured and Conventionally Built Materials" Crystals 15, no. 6: 544. https://doi.org/10.3390/cryst15060544

APA StyleChan, S., Peng, D., Ang, A. S. M., Nicholas, M. B., Champagne, V. K., Birt, A., Michelson, A., Langan, S., Watts, J., & Jones, R. (2025). Further Studies into the Growth of Small Naturally Occurring Three-Dimensional Cracks in Additively Manufactured and Conventionally Built Materials. Crystals, 15(6), 544. https://doi.org/10.3390/cryst15060544