Investigation of the Mechanical and Thermal Properties of MWCNT/SiC-Filled Ethylene–Butene–Terpolymer Rubber

Abstract

1. Introduction

2. Materials and Test Procedures

2.1. Materials

2.2. Surface Modification of SiC

2.3. Preparation of SiC/CNT/EBT Composite Rubber

2.4. Characterization

3. Results and Discussion

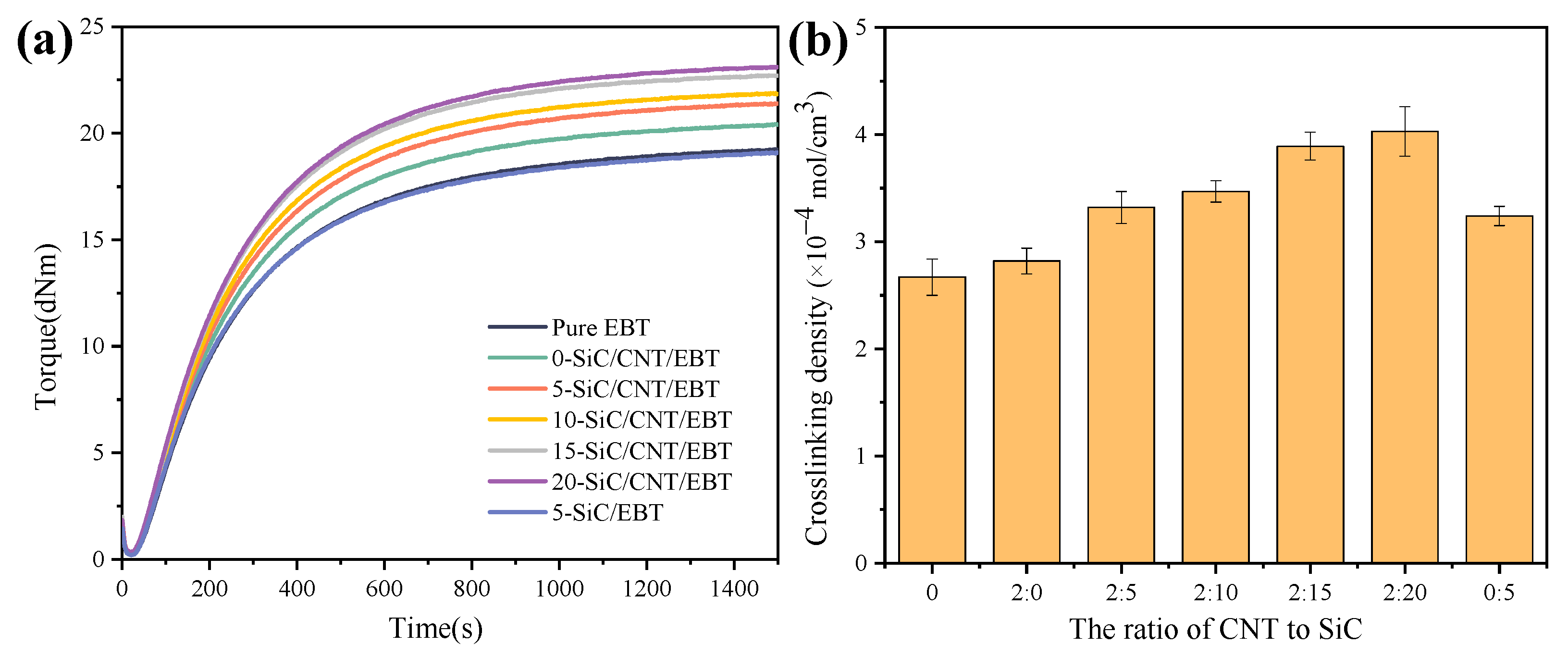

3.1. Vulcanization Performances

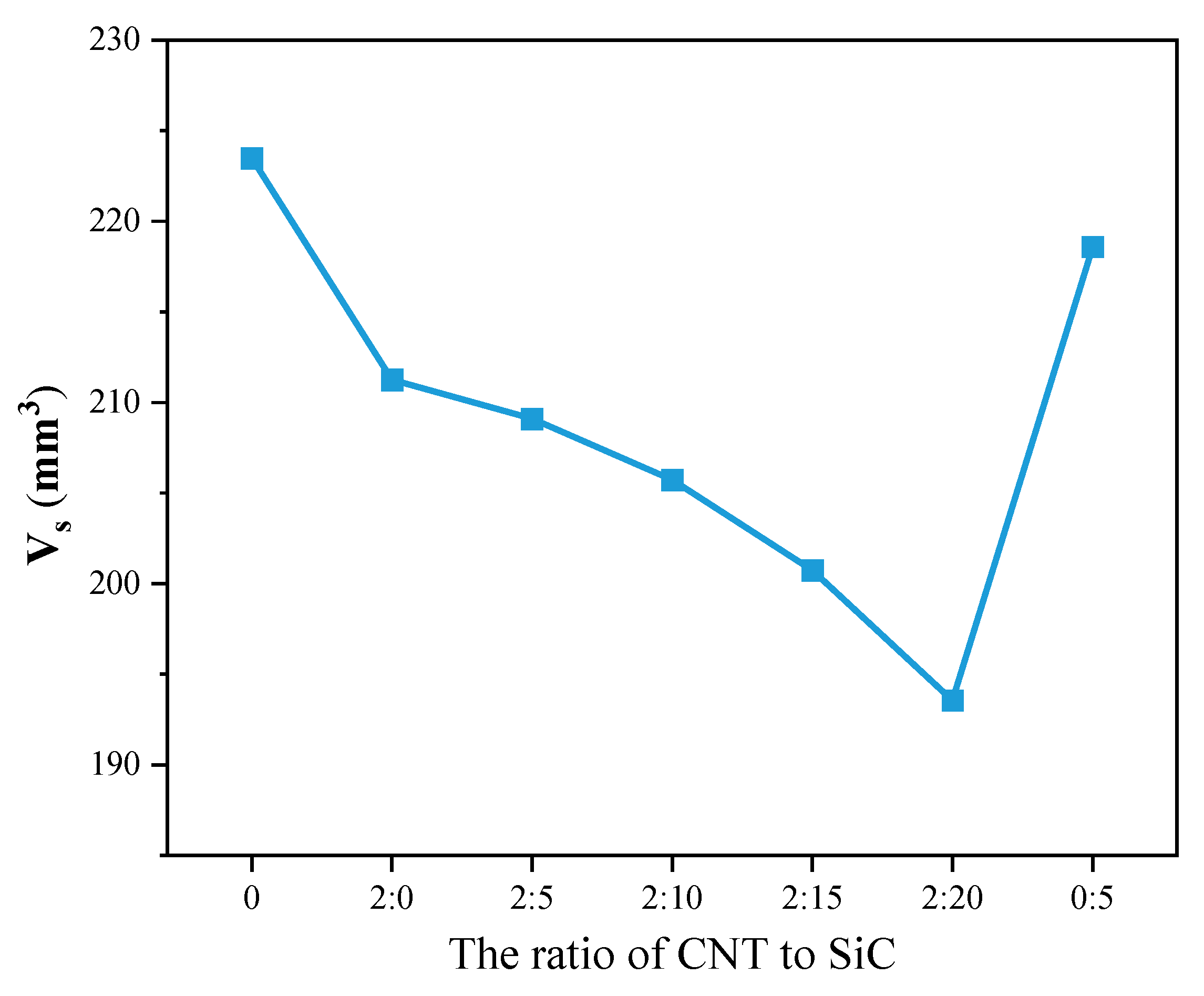

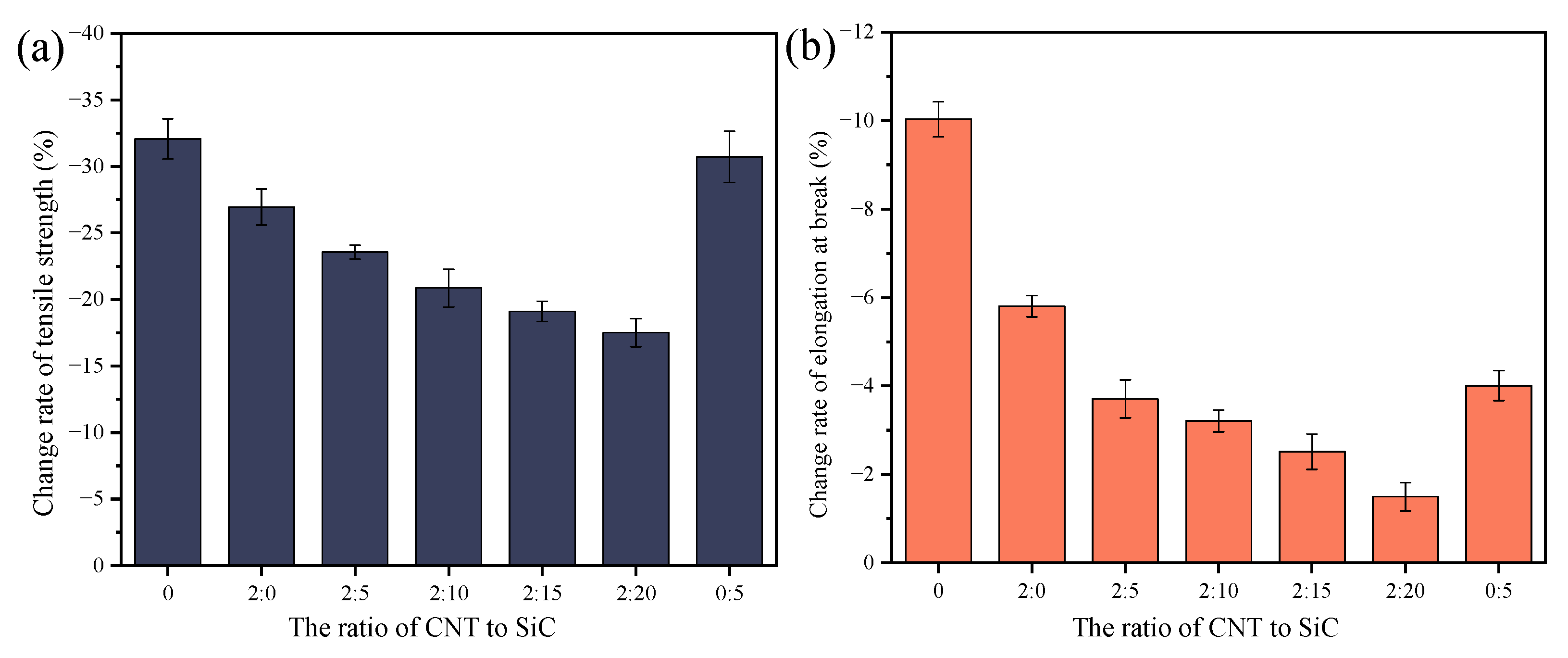

3.2. Mechanical Properties

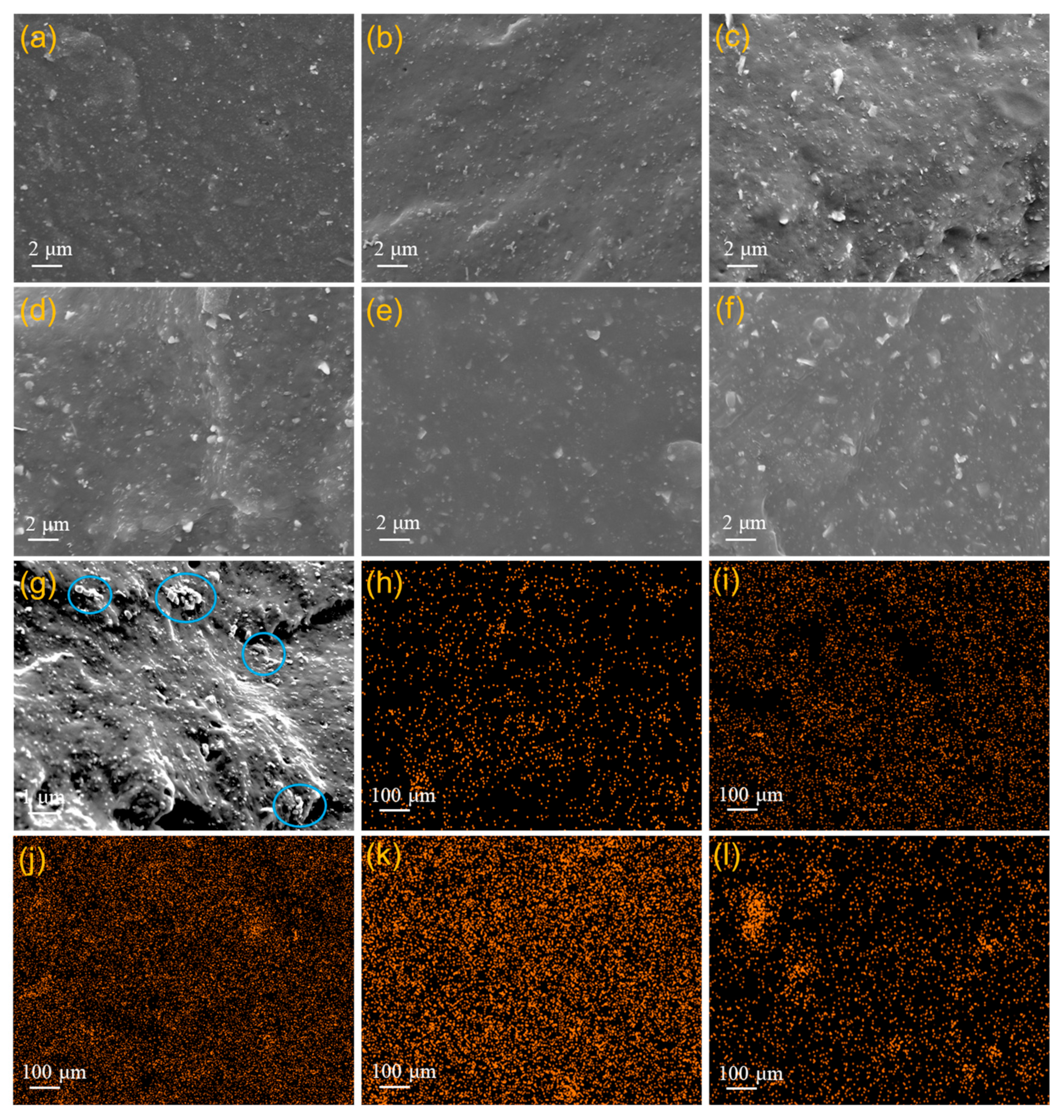

3.3. Morphology

3.4. Payne Effect

3.5. Dynamic Mechanical Analysis (DMA)

3.6. Thermal Stability

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lee, H.; Kim, Y.S.; Choi, W.H.; Yun, D.W.; Lee, J.; Song, J.M.; Kim, S.; Kim, J.; Kim, S.Y. Processing temperature window design via controlling matrix composition for polypropylene-based self-reinforced composites. Compos. Part A Appl. Sci. Manuf. 2021, 143, 106301. [Google Scholar] [CrossRef]

- Mohammed, A.A.; Sukkar, K.A.; Shnain, Z.Y. Effect of graphene and multiwalled carbon nanotube additives on the properties of nano-reinforced rubber. Chem. Pap. 2021, 75, 3265–3272. [Google Scholar] [CrossRef]

- Kueseng, K.; Jacob, K.I. Natural rubber nanocomposites with SiC nanoparticles and carbon nanotubes. Eur. Polym. J. 2006, 42, 220–227. [Google Scholar] [CrossRef]

- Utara, S.; Jantachum, P.; Sukkaneewat, B. Effect of surface modification of silicon carbide nanoparticles on the properties of nanocomposites based on epoxidized natural rubber/natural rubber blends. J. Appl. Polym. Sci. 2017, 134, 45289. [Google Scholar] [CrossRef]

- Guo, M.; Li, J.; Xi, K.; Liu, Y.; Ji, J.; Ye, C. Effects of multi-walled carbon nanotubes on char residue and carbothermal reduction reaction in ethylene propylene diene monomer composites at high temperature. Compos. Sci. Technol. 2020, 186, 107916. [Google Scholar] [CrossRef]

- Li, J.; Hu, B.; Hui, K.; Li, K.; Wang, L. Effects of inorganic nanofibers and high char yield fillers on char layer structure and ablation resistance of ethylene propylene diene monomer composites. Compos. Part A Appl. Sci. Manuf. 2021, 150, 106633. [Google Scholar] [CrossRef]

- Pushpakaran, B.N.; Subburaj, A.S.; Bayne, S.B.; Mookken, J. Impact of silicon carbide semiconductor technology in Photovoltaic Energy System. Renew. Sustain. Energy Rev. 2016, 55, 971–989. [Google Scholar] [CrossRef]

- Xun, Q.; Xun, B.; Li, Z.; Wang, P.; Cai, Z. Application of SiC power electronic devices in secondary power source for aircraft. Renew. Sustain. Energy Rev. 2017, 70, 1336–1342. [Google Scholar] [CrossRef]

- Samsudin, S.S.; Abdul Majid, M.S.; Mohd Jamir, M.R.; Osman, A.F.; Jaafar, M.; Alshahrani, H.A. Physical, thermal transport, and compressive properties of epoxy composite filled with graphitic-and ceramic-based thermally conductive nanofillers. Polymers 2022, 14, 1014. [Google Scholar] [CrossRef]

- Zhang, J.; Chang, Y.; Yang, H.; Chen, S.; Zhang, W.; Chen, Y. Study on the preparation and performance of SiC nanoparticle reinforced polyurethane coatings. J. Appl. Polym. Sci. 2023, 140, e54096. [Google Scholar] [CrossRef]

- Hong, Z.; Jiang, H.; Xue, M.; Ke, C.; Luo, Y.; Yin, Z.; Xie, C.; Zhang, F.; Xing, Y. SiC-enhanced polyurethane composite coatings with excellent anti-fouling, mechanical, thermal, chemical properties on various substrates. Prog. Org. Coat. 2022, 168, 106909. [Google Scholar] [CrossRef]

- Chi, Q.; Fang, H.; Meng, Z.; Zhang, C.; Li, Z.; Tang, C.; Zhang, T. Improved electrical, thermal, and mechanical properties of silicone rubber-based composite dielectrics by introducing one-dimensional SiC fillers. J. Mater. Sci. Mater. Electron. 2022, 33, 21336–21350. [Google Scholar] [CrossRef]

- Kumar, S.; Panda, B.P.; Mohanty, S.; Nayak, S.K. Effect of silicon carbide on the mechanical and thermal properties of ethylene propylene diene monomer-based carbon fiber composite material for heat shield application. J. Appl. Polym. Sci. 2020, 137, 49097. [Google Scholar] [CrossRef]

- Anancharoenwong, E.; Marthosa, S.; Suklueng, M.; Niyomwas, S.; Chaiprapat, S. Effect of silicon carbide on the properties of natural rubber blends with EPDM rubber. Int. J. Integr. Eng. 2020, 12, 234–240. [Google Scholar] [CrossRef]

- Tan, X.; Gu, W.; Tao, Z.; Chen, X.; Li, S.; Xia, A.; Ji, G. Carbon-based materials for radar-infrared compatible stealth technology. Chem. Eng. J. 2025, 507, 160168. [Google Scholar] [CrossRef]

- Nguyen, T.H.; Vu, M.T.; Le, V.T.; Nguyen, T.A. Effect of carbon nanotubes on the microstructure and thermal property of phenolic/graphite composite. Int. J. Chem. Eng. 2018, 2018, 6329651. [Google Scholar] [CrossRef]

- Mirzapour, M.; Cousin, P.; Robert, M.; Benmokrane, B. Dispersion Characteristics, the Mechanical, Thermal Stability, and Durability Properties of Epoxy Nanocomposites Reinforced with Carbon Nanotubes, Graphene, or Graphene Oxide. Polymers 2024, 16, 1836. [Google Scholar] [CrossRef]

- de Paula Santos, L.F.; Moraes, C.E.; do Amaral, T.R.; da Silva Silveira, M.R.; Ferreira, C.A.; Ribeiro, B.; Costa, M.L.; Botelho, E.C. Influence of carboxylated multi-walled carbon nanotube on the thermostability, and viscoelastic properties of poly (ether imide)/carbon fiber laminates. Diam. Relat. Mater. 2022, 126, 109113. [Google Scholar] [CrossRef]

- Madhu, B.M.; Rashmi; Sailaja, R.R.N.; Sundara Rajan, J. Combined effect of multiwalled carbon nanotubes, graphene nanoplatelets, and aluminum trihydride on the thermal stability of epoxy composites. Polym. Compos. 2022, 43, 1343–1356. [Google Scholar]

- Cai, J.; Yang, X.; Jiao, R.; He, X.; Cao, X.; Xu, F.; Hou, Z.; Ma, Z.; Zhang, X. Effect of pulverized coal/carbon black hybrid fillers on mechanical properties and thermal stability of styrene butadiene rubber composites. J. Appl. Polym. Sci. 2024, 141, e55363. [Google Scholar] [CrossRef]

- van Lier, G.; van Alsenoy, C.; van Doren, V.; Geerlings, P. Ab initio study of the elastic properties of single-walled carbon nanotubes and graphene. Chem. Phys. Lett. 2000, 326, 181–185. [Google Scholar] [CrossRef]

- Yu, M. Strength and Breaking Mechanism of Multiwalled Carbon Nanotubes Under Tensile Load. Science 2000, 287, 637–640. [Google Scholar] [CrossRef] [PubMed]

- Cao, J.M.; Du, B.S.; Fan, Z.B.; Xing, Y.Q.; Liu, T.G. Influence of short-term high heat on the microstructure and electrical properties of blended polypropylene cable insulation. Guangdong Electr. Power 2024, 37, 111–118. [Google Scholar]

- Fu, Q.; Peng, L.; Li, Z.; Lin, M.S.; Zhang, L.; Xie, S.; Hou, Y.; Kong, X.; Du, B. Development and challenges of environmentally friendly insulating materials for dry-type transformers. Guangdong Electr. Power 2024, 37, 69–83. [Google Scholar]

- Liu, G.; Wang, H.; Ren, T.; Chen, Y.; Liu, S. Systematic investigation of the degradation properties of Nitrile-Butadiene Rubber/Polyamide Elastomer/Single-Walled carbon nanotube composites in Thermo-Oxidative and hot oil environments. Polymers 2024, 16, 226. [Google Scholar] [CrossRef]

- Xu, X.; You, Y.; Liu, X.; Wei, D.; Guan, Y.; Zheng, A. Experimental and density functional theory investigations on the antioxidant mechanism of carbon nanotubes. Carbon 2021, 177, 189–198. [Google Scholar] [CrossRef]

- Duan, X.; Tao, R.; Chen, Y.; Zhang, Z.; Zhao, G.; Liu, Y.; Cheng, S. Improved mechanical, thermal conductivity and low heat build-up properties of natural rubber composites with nano-sulfur modified graphene oxide/silicon carbide. Ceram. Int. 2022, 48, 22053–22063. [Google Scholar] [CrossRef]

- Sethulekshmi, A.S.; Saritha, A.; Joseph, K. A comprehensive review on the recent advancements in natural rubber nanocomposites. Int. J. Biol. Macromol. 2022, 194, 819–842. [Google Scholar] [CrossRef]

- Roy, K.; Debnath, S.C.; Potiyaraj, P. A critical review on the utilization of various reinforcement modifiers in filled rubber composites. J. Elastomers Plast. 2020, 52, 167–193. [Google Scholar] [CrossRef]

- GB/T 531.1; Rubber, Vulcanized or Thermoplastic—Determination of Indentation Hardness—Part 1: Durometer Method (Shore Hardness) (S). National Standards of the People’s Republic of China: Beijing, China, 2008.

- GB/T 528; Rubber, Vulcanized or Thermoplastic—Determination of Tensile Stress-Strain Properties (S). National Standards of the People’s Republic of China: Beijing, China, 2009.

- GB/T 40396; Test Method for Glass Transition Temperature of Polymer Matrix Composites by Dynamic Mechanical Analysis (DMA) (S). National Standards of the People’s Republic of China: Beijing, China, 2021.

- Stelescu, M.D.; Airinei, A.; Bargan, A.; Bargan, A.; Fifere, N.; Georgescu, M.; Sonmez, M.; Nituica, M.; Alexandrescu, L.; Stefan, A. Mechanical Properties and Equilibrium Swelling Characteristics of Some Polymer Composites Based on Ethylene Propylene Diene Terpolymer (EPDM) Reinforced with Hemp Fibers. Materials 2022, 15, 6838. [Google Scholar] [CrossRef]

- Flory, P.J.; Rehner, J. Statistical Mechanics of Cross-Linked Polymer Networks I. Rubberlike Elasticity. J. Chem. Phys. 1943, 11, 512–521. [Google Scholar] [CrossRef]

- Szadkowski, B.; Marzec, A.; Rybiński, P.; Zukowski, W.; Zaborski, M. Characterization of ethylene-propylene composites filled with perlite and vermiculite minerals: Mechanical, barrier, and flammability properties. Materials 2020, 13, 585. [Google Scholar] [CrossRef] [PubMed]

- Masłowski, M.; Miedzianowska, J.; Strzelec, K. Hybrid straw/perlite reinforced natural rubber biocomposites. J. Bionic Eng. 2019, 16, 1127–1142. [Google Scholar] [CrossRef]

- Damampai, K.; Pichaiyut, S.; Stöckelhuber, K.W.; Das, A.; Nakason, C. Ferric ions crosslinked epoxidized natural rubber filled with carbon nanotubes and conductive carbon black hybrid fillers. Polymers 2022, 14, 4392. [Google Scholar] [CrossRef]

- Siriwas, T.; Pichaiyut, S.; Susoff, M.; Petersen, S.; Nakason, C. Enhancing curing, mechanical and electrical properties of epoxidized natural rubber nanocomposites with graphene and carbon nanotubes hybrid fillers. J. Mater. Sci. 2023, 58, 15676–15695. [Google Scholar] [CrossRef]

- Kitisavetjit, W.; Nakaramontri, Y.; Pichaiyut, S.; Wisunthorn, S.; Nakason, C.; Kiatkamjornwong, S. Influences of carbon nanotubes and graphite hybrid filler on properties of natural rubber nanocomposites. Polym. Test. 2020, 93, 106981. [Google Scholar] [CrossRef]

- Rooj, S.; Das, A.; Stöckelhuber, K.W.; Wießner, S.; Fischer, D.; Reuter, U.; Heinrich, G. ‘Expanded organoclay’assisted dispersion and simultaneous structural alterations of multiwall carbon nanotube (MWCNT) clusters in natural rubber. Compos. Sci. Technol. 2015, 107, 36–43. [Google Scholar] [CrossRef]

- Pichaiyut, S.; Kitisavetjit, W.; Nakason, C. Synergistic effects of graphite and carbon nanotube hybrid fillers on key properties of epoxidized natural rubber nanocomposites. J. Polym. Res. 2023, 30, 412. [Google Scholar] [CrossRef]

- Alam, M.N.; Kumar, V.; Potiyaraj, P.; Lee, D.J.; Choi, J. Mutual dispersion of graphite-silica binary fillers and its effects on curing, mechanical, and aging properties of natural rubber composites. Polym. Bull. 2021, 79, 2707–2724. [Google Scholar] [CrossRef]

| Pure EBT | 0-SiC/ CNT/EBT | 5-SiC/ CNT/EBT | 10-SiC/ CNT/EBT | 15-SiC/ CNT/EBT | 20-SiC/ CNT/EBT | 5- SiC/EBT | |

|---|---|---|---|---|---|---|---|

| CNT/phr | 0 | 2 | 2 | 2 | 2 | 2 | 0 |

| SiC/phr | 0 | 0 | 5 | 10 | 15 | 20 | 5 |

| ML (dNm) | MH (dNm) | MH-ML (dNm) | Tc10 (min) | Tc90 (min) | |

|---|---|---|---|---|---|

| Pure EBT | 0.23 | 19.24 | 19.01 | 1.15 | 11.21 |

| 0-SiC/CNT/EBT | 0.27 | 20.43 | 20.16 | 1.14 | 11.04 |

| 5-SiC/CNT/EBT | 0.29 | 21.40 | 21.11 | 1.15 | 10.94 |

| 10-SiC/CNT/EBT | 0.30 | 21.88 | 21.58 | 1.11 | 10.72 |

| 15-SiC/CNT/EBT | 0.32 | 22.72 | 22.40 | 1.09 | 10.60 |

| 20-SiC/CNT/EBT | 0.34 | 23.12 | 22.78 | 1.10 | 10.86 |

| 5-SiC/EBT | 0.20 | 19.11 | 18.91 | 1.09 | 11.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Liu, J.; Li, D.; Sun, W.; Li, Z.; Liang, Y.; Fu, Q.; Tang, N.; Zhang, B.; Huang, F.; et al. Investigation of the Mechanical and Thermal Properties of MWCNT/SiC-Filled Ethylene–Butene–Terpolymer Rubber. Crystals 2025, 15, 539. https://doi.org/10.3390/cryst15060539

Zhang L, Liu J, Li D, Sun W, Li Z, Liang Y, Fu Q, Tang N, Zhang B, Huang F, et al. Investigation of the Mechanical and Thermal Properties of MWCNT/SiC-Filled Ethylene–Butene–Terpolymer Rubber. Crystals. 2025; 15(6):539. https://doi.org/10.3390/cryst15060539

Chicago/Turabian StyleZhang, Li, Jianming Liu, Duanjiao Li, Wenxing Sun, Zhi Li, Yongchao Liang, Qiang Fu, Nian Tang, Bo Zhang, Fei Huang, and et al. 2025. "Investigation of the Mechanical and Thermal Properties of MWCNT/SiC-Filled Ethylene–Butene–Terpolymer Rubber" Crystals 15, no. 6: 539. https://doi.org/10.3390/cryst15060539

APA StyleZhang, L., Liu, J., Li, D., Sun, W., Li, Z., Liang, Y., Fu, Q., Tang, N., Zhang, B., Huang, F., Fan, X., Bai, P., Wang, Y., Liu, Z., Zhu, S., & Qiao, D. (2025). Investigation of the Mechanical and Thermal Properties of MWCNT/SiC-Filled Ethylene–Butene–Terpolymer Rubber. Crystals, 15(6), 539. https://doi.org/10.3390/cryst15060539