A Preliminary Investigation on the Identification of Artificial Irradiation in Thermoluminescence Pre-Dose Dating of Ancient Chinese Porcelain

Abstract

1. Introduction

2. Samples and Experiment

2.1. Equipment

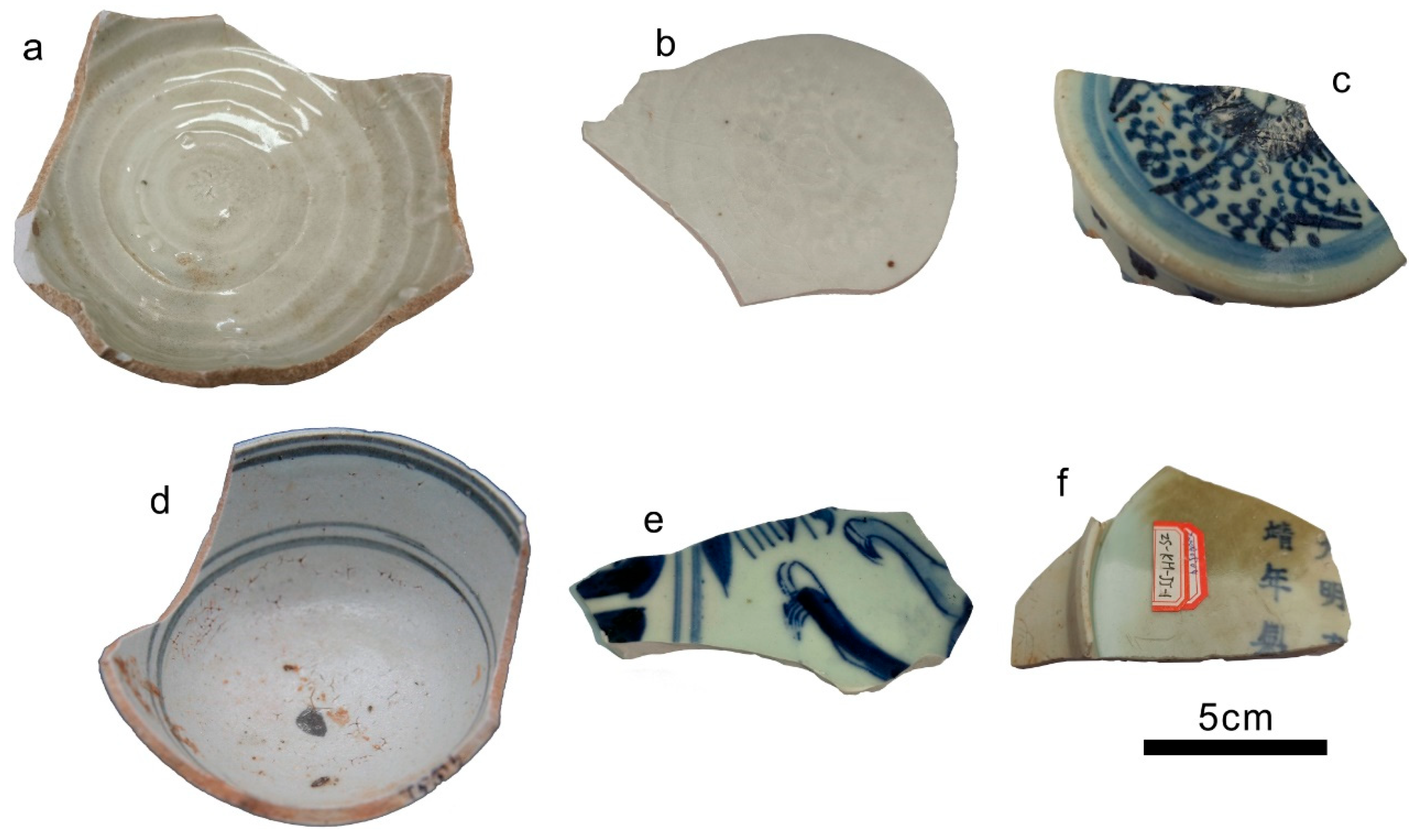

2.2. Samples and Preparation

2.3. TL Measurements

3. Results and Discussion

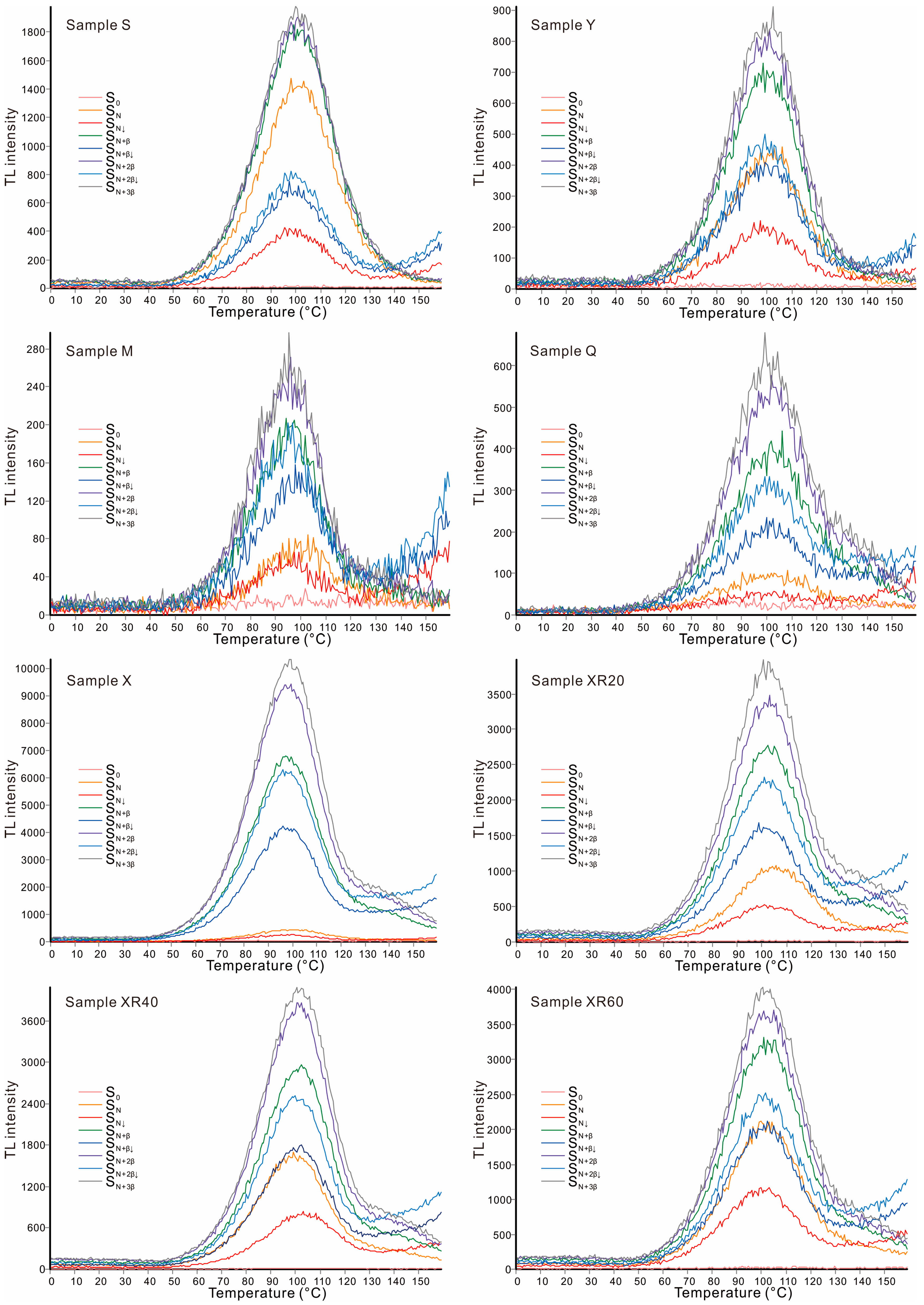

3.1. TL Glow Curve and Data

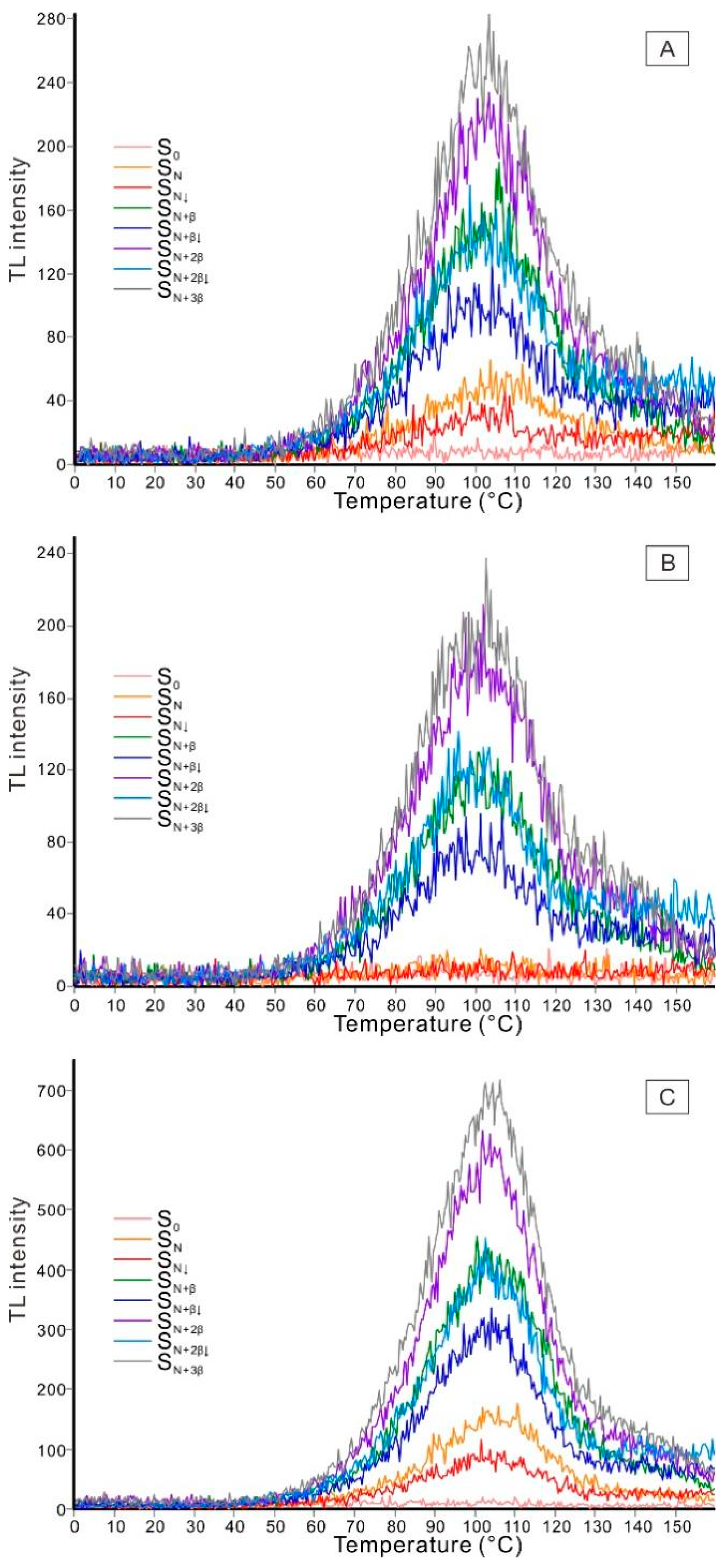

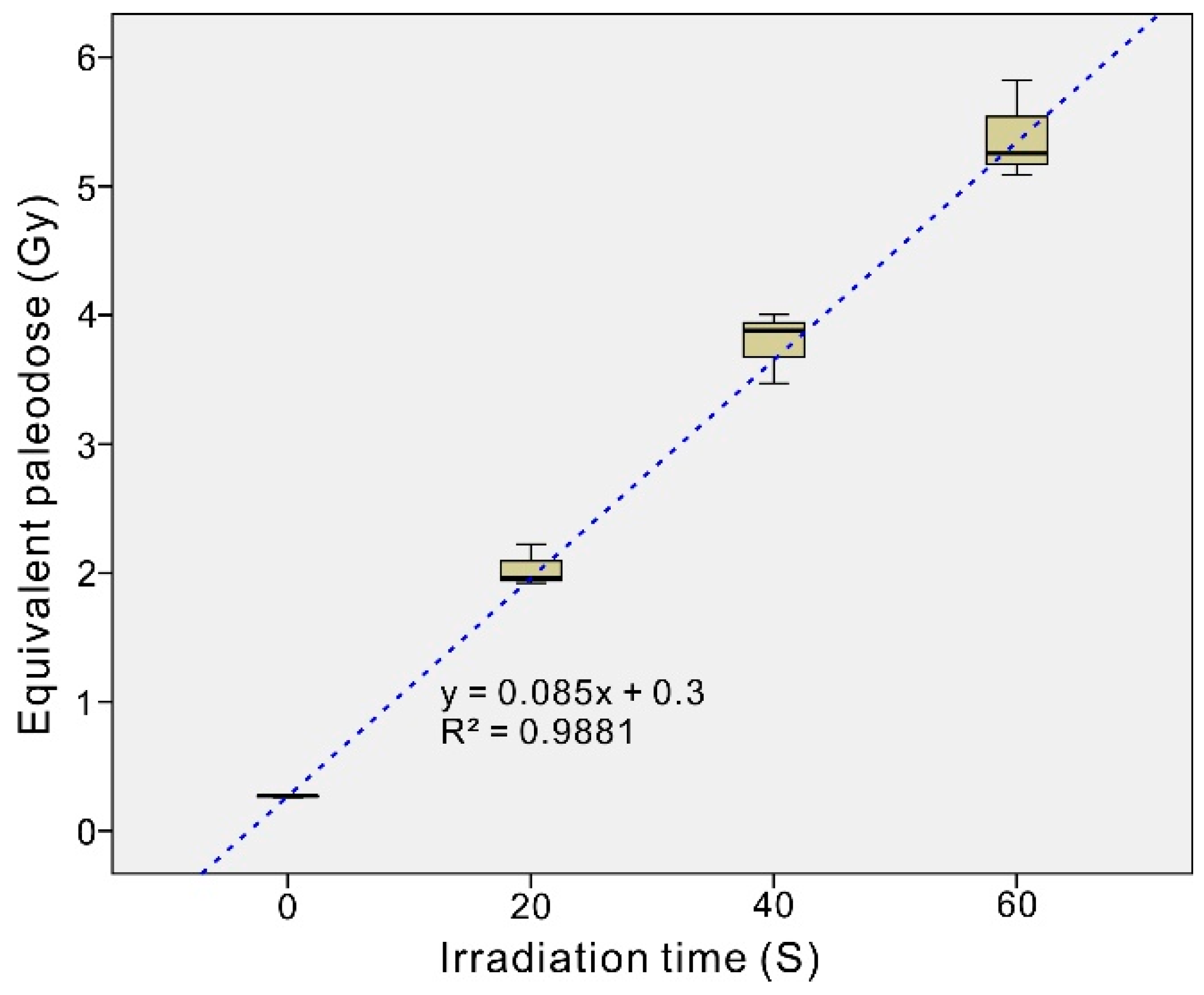

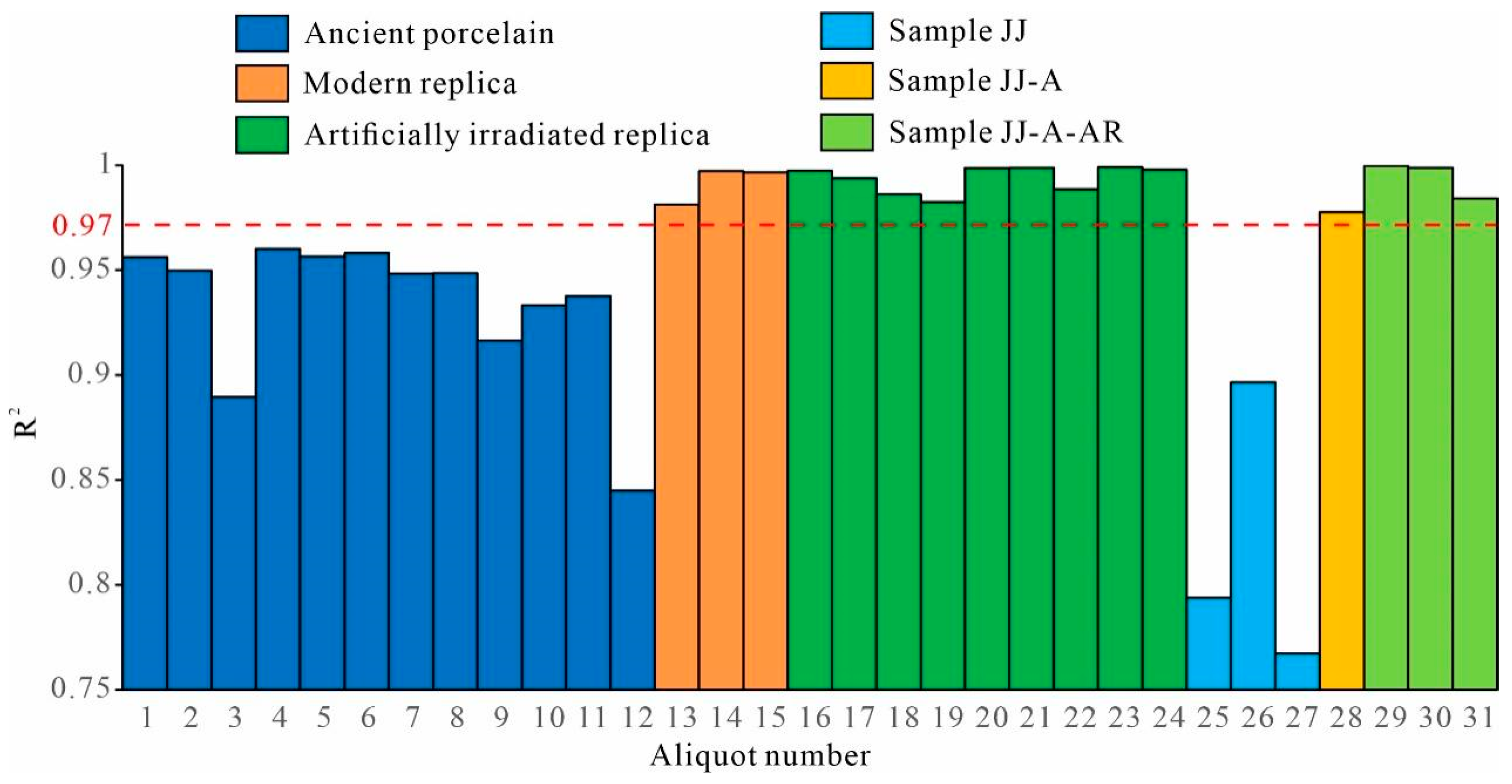

3.2. Contrasts Between Ancient Porcelains and Artificially Irradiated Replicas

3.3. A Methodology for the Identification of Imitations

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aitken, M.J. Thermoluminescence dating: Past progress and future trends. Nucl. Tracks Radiat. Meas. 1985, 10, 3–6. [Google Scholar] [CrossRef]

- Wintle, A.G. Luminescence dating: Laboratory procedures and protocols. Radiat. Meas. 1997, 27, 769–817. [Google Scholar] [CrossRef]

- Dykeman, D.D.; Towner, R.H.; Feathers, J.K. Correspondence in tree-ring and thermoluminescence dating: A protohistoric Navajo pilot study. Am. Antiq. 2002, 67, 145–164. [Google Scholar] [CrossRef]

- Lawless, J.L.; Lam, S.K.; Lo, D. Nondestructive in situ thermoluminescence using CO2 laser heating. Opt. Express 2002, 10, 291–296. [Google Scholar] [CrossRef] [PubMed]

- Zacharias, N.; Michael, C.; Philaniotou-Hadjlanastasiou, O.; Hein, A.; Bassiakos, Y. Fine-grain TL dating of archaeometallurgical furnace walls. J. Cult. Herit. 2006, 7, 23–29. [Google Scholar] [CrossRef]

- Spencer, J.Q.G.; Sanderson, D.C.W. Decline in firing technology or poorer fuel resources? High-temperature thermoluminescence (HTTL) archaeothermometry of Neolithic ceramics from Pool, Sanday, Orkney. J. Archaeol. Sci. 2012, 39, 3542–3552. [Google Scholar] [CrossRef]

- Liritzis, I.; Polymeris, G.S.; Vafiadou, A.; Sideris, A.; Levy, T.E. Luminescence dating of stone wall, tomb and ceramics of Kastrouli (Phokis, Greece) Late Helladic settlement: Case study. J. Cult. Herit. 2019, 35, 76–85. [Google Scholar] [CrossRef]

- Galli, A.; Sibilia, E.; Martini, M. Ceramic chronology by luminescence dating: How and when it is possible to date ceramic artefacts. Archaeol. Anthrop. Sci. 2020, 12, 190. [Google Scholar] [CrossRef]

- Guidorzi, L.; Fantino, F.; Durisi, E.; Ferrero, M.; Re, A.; Vigorelli, L.; Visca, L.; Gulmini, M.; Dughera, G.; Giraudo, G.; et al. Age determination and authentication of ceramics: Advancements in the thermoluminescence dating laboratory in Torino (Italy). Acta Imeko 2021, 10, 32–39. [Google Scholar] [CrossRef]

- Wang, C.X.; Ji, X.; Wu, Y.; Jin, Z.; Zhang, Y.; Chen, M.; Wang, N.; Fan, A. Quartz OSL and TL dating of pottery, burnt clay, and sediment from Beicun archaeological site, China. Quat. Geochronol. 2022, 70, 101281. [Google Scholar] [CrossRef]

- Burbidge, C.I.; Rodrigues, A.L.; Dias, M.I.; Prudêncio, M.I.; Cardoso, G. Optimisation of preparation and measurement protocols for luminescence dating of small samples from a suite of porcelains and faiences. Mediterr. Archaeol. Archaeom. 2010, 10, 53. [Google Scholar]

- Zimmerman, D.W. Thermoluminescent dating using fine grains from pottery. Archaeometry 1971, 13, 29–52. [Google Scholar] [CrossRef]

- Fleming, S.J. Thermoluminescent dating: Refinement of the quartz inclusion method. Archaeometry 1970, 12, 13–143. [Google Scholar] [CrossRef]

- Yang, B.; Leung, P.L.; Townsend, P.D. Studies on thermoluminescence and radioluminescence spectra of synthetic mullite. Nucl. Instrum. Meth. B 2000, 171, 414–416. [Google Scholar] [CrossRef]

- Fleming, S.J. The pre-dose technique: A new thermoluminescent dating method. Archaeometry 1973, 15, 13–30. [Google Scholar] [CrossRef]

- Dai, G.F.; Yuan, S.; Chang, H.; Sun, K.; Zhang, L. The study on pre-dose effect of quartz. Radiat. Prot. Dosim. 1998, 77, 51–53. [Google Scholar] [CrossRef]

- Chen, R.; Leung, P.L. Modelling the pre-dose effect in thermoluminescence. Radiat. Prot. Dosim. 1999, 84, 43–46. [Google Scholar] [CrossRef]

- Polymeris, G.S.; Oniya, E.O.; Jibiri, N.N.; Tsirliganis, N.C.; Kitis, G. In-homogeneity in the pre-dose sensitization of the 110°C TL peak in various quartz samples: The influence of annealing. Nucl. Instrum. Meth. B 2012, 274, 105–110. [Google Scholar] [CrossRef]

- Stoneham, D. Porcelain dating. PACT 1983, 9, 227–239. [Google Scholar]

- Stoneham, D. The use of porcelain as a low-dose background dosimeter. Nucl. Tracks Radiat. Meas. 1985, 10, 509–512. [Google Scholar] [CrossRef]

- Bailiff, I.K. The pre-dose technique. Radiat. Meas. 1994, 23, 471–479. [Google Scholar] [CrossRef]

- Adamiec, G.; Stoneham, D.; Göksu, Y. Accident dose estimation using porcelain. A comparison between different thermoluminescence methods. Radiat. Meas. 1997, 27, 389–392. [Google Scholar] [CrossRef]

- Leung, P.L.; Yang, B. Thermoluminescence and X-ray diffraction studies on sliced ancient porcelain samples. Nucl. Instrum. Meth. B 1999, 155, 452–458. [Google Scholar] [CrossRef]

- Li, S.H.; Miao, J.M. Effects of light exposure on the TL dating of pottery. Sci. China Ser. D-Earth Sci. 2001, 44, 1038–1042. [Google Scholar] [CrossRef]

- Wang, W.D.; Xia, J.D.; Zhou, Z.X. Thermoluminescence dating of the ancient Chinese porcelain using a regression method of saturation exponential in pre-dose technique. Sci. China Ser. E-Technol. Sci. 2006, 49, 194–209. [Google Scholar] [CrossRef]

- Wu, J.W.; Xia, J.D.; Gong, Y.W. Research on thermal luminescence characteristics and the production age of Yao-zhou kiln porcelain. Sci. Conserv. Archaeol. 2016, 28, 89–96. (In Chinese) [Google Scholar]

- Xia, J.D.; Wang, D.Y.; Chen, J.B.; Hu, F.Q.; Wang, B.C.; Ji, X.D.; Zhou, S.H. TL Dating of Porcelains from Fuping Yingou Remains in Shaanxi. Chin. Ceram. 2017, 1, 50–65. (In Chinese) [Google Scholar]

- Wu, J.W.; Xiong, Y.F.; Gong, Y.W.; Wang, E.Y.; Wang, J.W. Research on the thermoluminescent characteristics of porcelain and brick samples unearthed from Qinglong Town in Shanghai. Sci. Conserv. Archaeol. 2018, 30, 36–49. (In Chinese) [Google Scholar]

- Sfampa, I.K.; Malletzidou, L.; Pandoleon, P.; Kitis, G. Thermoluminescence measurements of in-vitro and in-vivo aged porcelain. Radiat. Meas. 2019, 125, 7–14. [Google Scholar] [CrossRef]

- Stoneham, D.; Stoneham, M. Beating the forger: Authenticating ceramic antiquities. Contemp. Phys. 2010, 51, 397–411. [Google Scholar] [CrossRef]

- Wang, W.D.; Leung, P.L.; Xia, J.D. Distinguishing of artificial irradiation by α dose: A method of discriminating imitations of ancient pottery. Nucl. Tech. 2003, 26, 48–52. (In Chinese) [Google Scholar]

- Zink, A.J.C.; Dabis, S.; Porto, E.; Castaing, J. Alpha efficiency under TL and OSL—A subtraction technique using OSL and TL to detect artificial irradiation. Radiat. Meas. 2010, 45, 649–652. [Google Scholar] [CrossRef]

- Wang, W.D. Thermal activation and radiation quenching characteristics and their application to the pre-dose dating of porcelain. Sci. China Ser. E-Technol. Sci. 2009, 52, 324–331. [Google Scholar] [CrossRef]

- Wu, J.W.; Gong, Y.W. Comparison study of two sampling methods for thermoluminescence dating of ancient porcelain. Sci. Conserv. Archaeol. 2011, 23, 29–35. (In Chinese) [Google Scholar]

- Li, J. History of Science in China (Volume on Ceramics); China Science Publishing & Media: Beijing, China, 1998. [Google Scholar]

- Yu, K.N.; Miao, J.M. Locating the origins of blue and white porcelains using EDXRF. Appl. Radiat. Isot. 1997, 48, 959–963. [Google Scholar] [CrossRef]

- Leung, P.L.; Luo, H.J. A study of provenance and dating of ancient Chinese porcelain by x-ray fluorescence spectrometry. X-ray Spectrom. 2000, 29, 34–38. [Google Scholar] [CrossRef]

- Zhu, J.; Solbrekken, G.; Hao, W.T.; Li, Y.; Zhen, J.; Zhen, T.; Glascock, M.D. Neutron activation analysis of bulk samples from Chinese ancient porcelain to provenance research. J. Radioanal. Nucl. Chem. 2013, 298, 237–242. [Google Scholar] [CrossRef]

- Dias, M.I.; Prudêncio, M.I.; De Matos, M.P.; Rodrigues, A.L. Tracing the origin of blue and white Chinese Porcelain ordered for the Portuguese market during the Ming dynasty using INAA. J. Archaeol. Sci. 2013, 40, 3046–3057. [Google Scholar] [CrossRef]

| No. | Description |

|---|---|

| S | White porcelain from the Song Dynasty |

| Y | White porcelain from the Yuan Dynasty |

| M | Blue-and-white porcelain from the Ming Dynasty |

| Q | Blue-and-white porcelain from the Qing Dynasty |

| JJ | Blue-and-white porcelain featuring Chinese characters, produced in the Jiajing period of the Ming Dynasty |

| JJ-A | Sample JJ underwent rapid thermal annealing |

| JJ-A-AR | Sample JJ-A exposed to 90Sr/90Y β source for 22 s (2133.6 mGy) |

| X | Modern replica porcelain |

| XR20 | Sample X exposed to 90Sr/90Y β source for 20 s (1939.6 mGy) |

| XR40 | Sample X exposed to 90Sr/90Y β source for 40 s (3879.2 mGy) |

| XR60 | Sample X exposed to 90Sr/90Y β source for 60 s (5818.8 mGy) |

| Run No. | Procedure |

|---|---|

| 1 | Heat to 160 °C to remove possible hybrid peaks, return to room temperature (25 °C) |

| 2 | Give 2 s (194 mGy) test dose (β0), heat to 160 °C to measure S0 |

| 3 | Heat to TAC temperature (680 °C), return to room temperature (25 °C), give 2 s (194 mGy) test dose (β0), heat to 160 °C to measure SN |

| 4 | Give 60 s (5818.8 mGy) laboratory β dose, measure SN↓ |

| 5 | Heat to TAC temperature (680 °C), return to room temperature (25 °C), give 2 s (194 mGy) test dose (β0), heat to 160 °C to measure SN+β |

| 6 | Give 60 s (5818.8 mGy) laboratory β dose, measure SN+β↓ |

| 7 | Heat to TAC temperature (680 °C), return to room temperature (25 °C), give 2 s (194 mGy) test dose (β0), heat to 160 °C to measure SN+2β |

| 8 | Give 60 s (5818.8 mGy) laboratory β dose, heat to 160 °C to measure SN+2β↓ |

| 9 | Heat to TAC temperature (680 °C), return to room temperature (25 °C) give 2 s (194 mGy) test dose (β0), heat to 160 °C to measure SN+3β |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Wu, A.; Long, D.; Lin, Z.; Gao, J.; Fang, T.; Li, Q.; Zhang, M. A Preliminary Investigation on the Identification of Artificial Irradiation in Thermoluminescence Pre-Dose Dating of Ancient Chinese Porcelain. Crystals 2025, 15, 503. https://doi.org/10.3390/cryst15060503

Li J, Wu A, Long D, Lin Z, Gao J, Fang T, Li Q, Zhang M. A Preliminary Investigation on the Identification of Artificial Irradiation in Thermoluminescence Pre-Dose Dating of Ancient Chinese Porcelain. Crystals. 2025; 15(6):503. https://doi.org/10.3390/cryst15060503

Chicago/Turabian StyleLi, Jinwei, Anjian Wu, Dengchuang Long, Ziwei Lin, Jinjun Gao, Tao Fang, Qijiang Li, and Maolin Zhang. 2025. "A Preliminary Investigation on the Identification of Artificial Irradiation in Thermoluminescence Pre-Dose Dating of Ancient Chinese Porcelain" Crystals 15, no. 6: 503. https://doi.org/10.3390/cryst15060503

APA StyleLi, J., Wu, A., Long, D., Lin, Z., Gao, J., Fang, T., Li, Q., & Zhang, M. (2025). A Preliminary Investigation on the Identification of Artificial Irradiation in Thermoluminescence Pre-Dose Dating of Ancient Chinese Porcelain. Crystals, 15(6), 503. https://doi.org/10.3390/cryst15060503