Evolution of Microstructure, Tensile Mechanical and Corrosion Properties of a Novel Designed TRIP-Aided Economical 19Cr Duplex Stainless Steel After Aging Treatment

Abstract

1. Introduction

2. Experimental Details

3. Results and Discussion

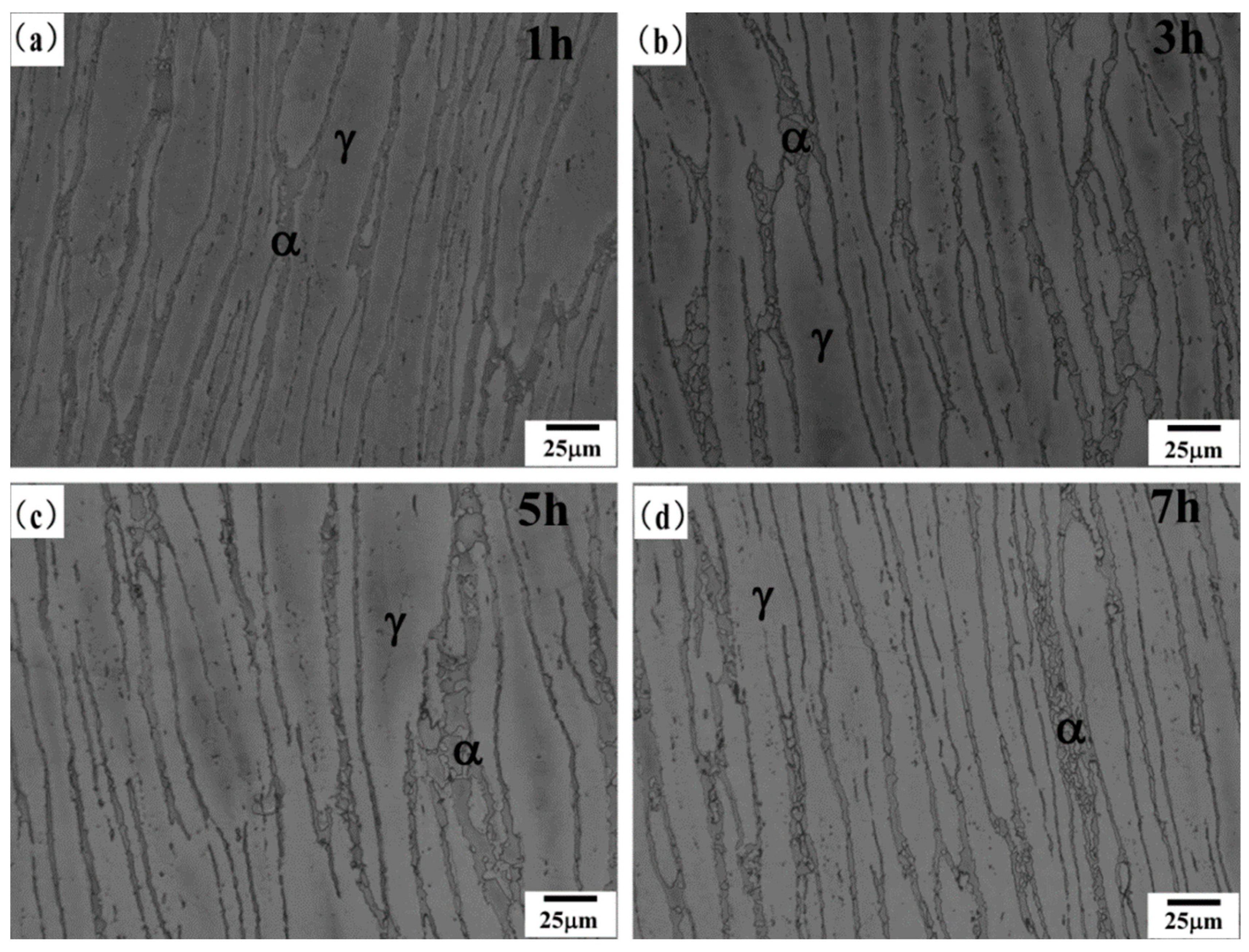

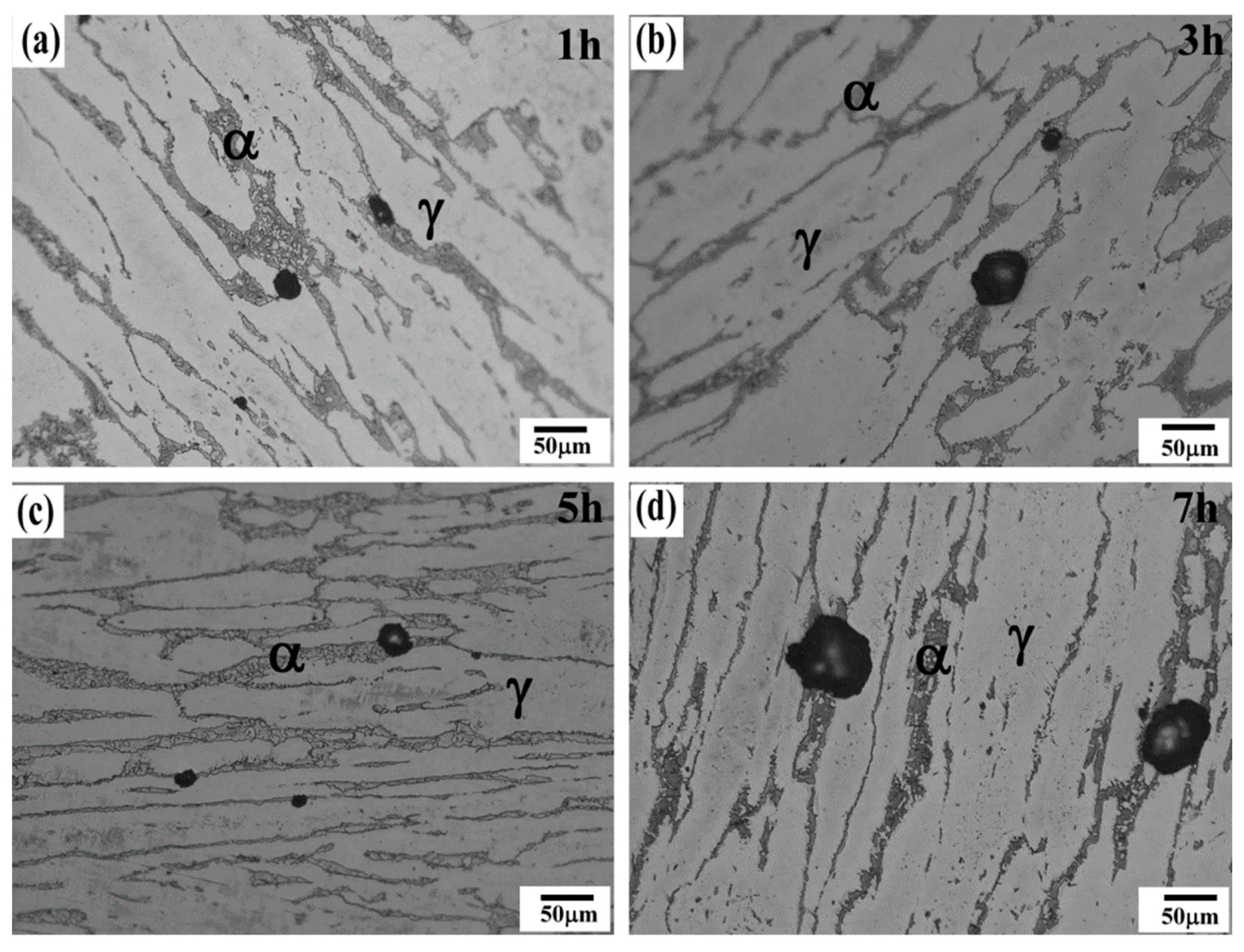

3.1. Effect of 750 °C Aging Treatment on Microstructure Evolution of This Novel Designed DSS

3.2. Effect of 750 °C Aging Heat Treatment on Tensile Mechanical Properties at Room Temperature

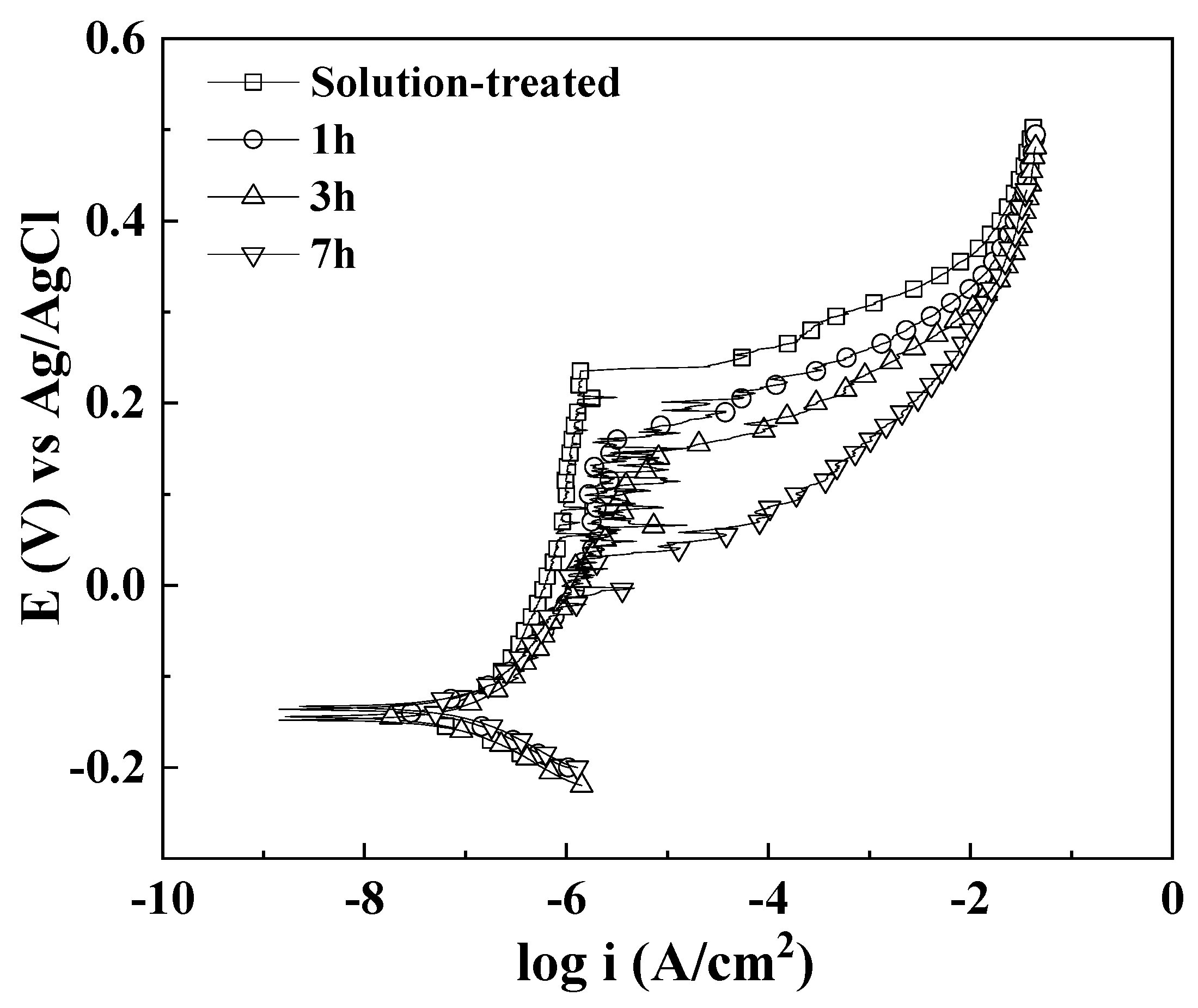

3.3. Effect of Aging Treatment at 750 °C on Pitting Corrosion Properties

4. Conclusions

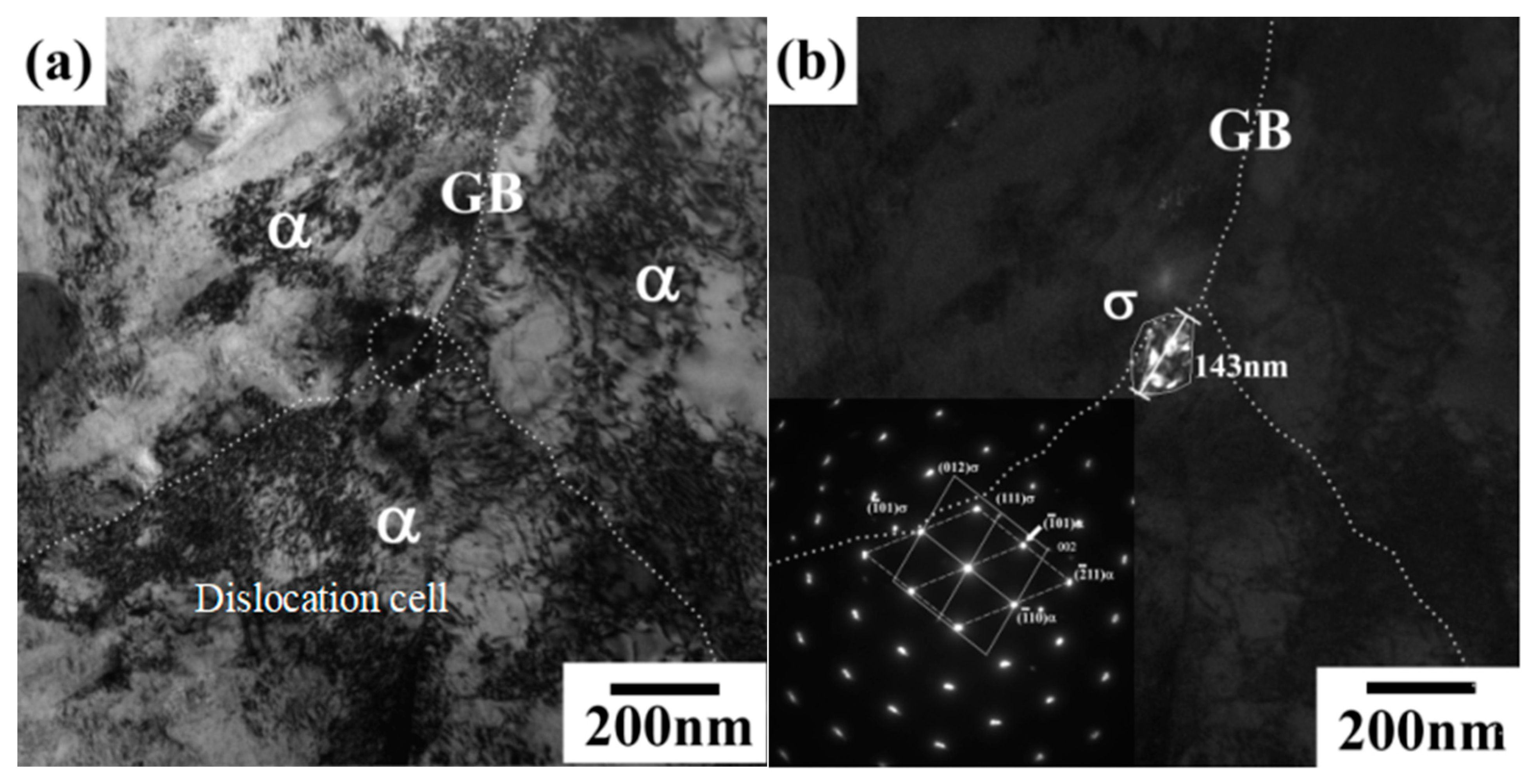

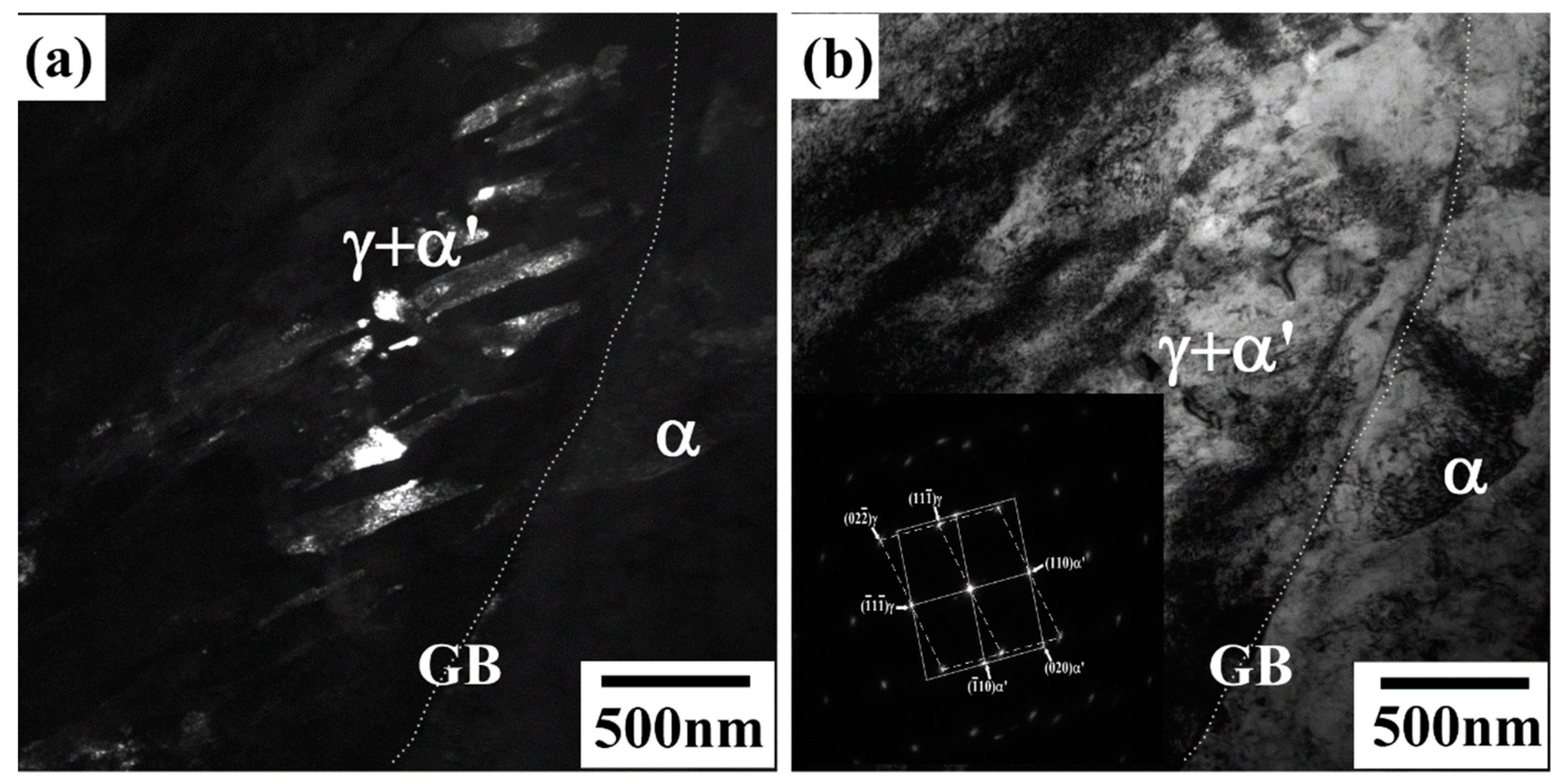

- Solution-treated specimens exhibited an exceptional combination of strength and ductility, with an ultimate tensile strength of approximately 820 MPa and a fracture elongation approaching 70%. This superior mechanical performance originates from the coordinated deformation mechanisms: dislocation slip-dominated deformation in ferrite, which forms dislocation cells, and strain-induced martensitic transformation in austenite.

- Aging treatment at 750 °C induced a time-dependent evolution of mechanical properties. The tensile strength increased by 16.3%, from 820 MPa to 954 MPa, after 7 h of aging, while the elongation reduced by 38.6%, from 70% to 43%. This hardening effect is attributed to σ-phase precipitation at the ferrite triple junctions, which impedes dislocation motion effectively.

- Pitting corrosion resistance showed progressive deterioration with increasing aging duration. Evidence of this includes a 52% decrease in pitting potential after 7 h of aging. The increased susceptibility correlates with σ-phase acting as preferential sites for corrosion initiation.

- Microstructural analysis revealed that the phase-specific deformation mechanisms remained unchanged post-aging. No secondary phase formation occurred except for σ precipitates in the ferrite boundaries. The stability of austenite was maintained during deformation, as confirmed by the retained TRIP effect.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bao, S.; Feng, H.; Song, Z.; He, J.; Wu, X.; Gu, Y. Study on Fatigue Fracture Behavior of S32750 Duplex Stainless Steel at Different Solution Temperatures. Crystals 2024, 15, 44. [Google Scholar] [CrossRef]

- Gao, H.; An, Z.; Yao, L.; Wang, J.; Zhai, L.; Ding, B.; Peng, J.; Zhou, L.; Cao, X. Microstructural Evolution and Strengthening of Dual-Phase Stainless Steel S32750 during Heavily Cold Drawing. Crystals 2024, 14, 621. [Google Scholar] [CrossRef]

- Junior, C.D.J.E.; Varasquim, A.D.F.M.F.; Ventrella, A.V.; Calliari, I.; Gennair, C.; Selote, B.B.; Zambon, A.; Settimi, G.A. Influence of cobalt addition in the fusion zone of duplex stainless steel welded with pulsed Nd:YAG laser. Weld. World 2025, prepublish, 1–8. [Google Scholar]

- Ajenifuja, E.; Popoola, A.; Popoola, O. Comparative analysis of structural and mechanical properties of duplex stainless steel (DSS) weldments prepared by flux core arc welding and shielded metal arch welding processes. J. Adv. Join. Process. 2025, 11, 100295. [Google Scholar] [CrossRef]

- Kısasöz, Ö.B. Influence of initial grain size on the formation of sigma and its effect on corrosion and wear properties of 2205 duplex stainless steel. Mater. Chem. Phys. 2025, 339, 130693. [Google Scholar] [CrossRef]

- Roh, H.; Seo, W.K.; Jeong, C.; Hyekim, J.; Park, C.N.; Kim, J.Y.; Jang, C. Dynamic behavior of duplex stainless steel with improved chloride-induced stress corrosion cracking resistance in drop scenarios for dry storage containers. Nucl. Eng. Technol. 2025, 57, 103522. [Google Scholar] [CrossRef]

- Shen, Y.; Wang, L.; Li, L.; Kong, D.; Ma, R.; Liu, L.; Li, P. Microstructure evolution of 2205 duplex stainless steel (DSS) and inconel 718 dissimilar welded joints and impact on corrosion and mechanical behavior. Mater. Sci. Eng. A 2025, 929, 148136. [Google Scholar] [CrossRef]

- Yang, J.; Gao, B.; Huma, T.; Li, X.; Gong, Y.; Li, C.; Pan, H.; Zhou, H.; Tan, Z.; Zhu, X. Better mechanical properties of SAF2507 duplex stainless steel formed by cold rolling and normalizing. J. Mater. Res. Technol. 2024, 32, 3105–3119. [Google Scholar] [CrossRef]

- Gong, W.; Zhang, L.; Zhang, L.; Jiang, Z.; Wang, E. Influence of Ce Addition on Microstructure and Corrosion Resistance of 2101 Duplex Stainless Steel. Steel Res. Int. 2021, 92, 2100003. [Google Scholar] [CrossRef]

- Tahaei, A.; Abbasi, M.; Vanani, B.; Zanotto, F.; Fabiola, A.; Perez, M. The Role of Nitrogen Gas and PWHT on Pitting Corrosion Behavior of Duplex Stainless-Steel Joint Made by GTAW. Metallogr. Microstruct. Anal. 2024, 13, 624–639. [Google Scholar] [CrossRef]

- Abdo, H.S.; Seikh, A.H.; Abdus Samad, U.; Fouly, A.; Mohammed, J.A. Electrochemical Corrosion Behavior of Laser Welded 2205 Duplex Stainless-Steel in Artificial Seawater Environment under Different Acidity and Alkalinity Conditions. Crystals 2021, 11, 1025. [Google Scholar] [CrossRef]

- Li, Y.; Liu, N.; Tian, L.; Lu, X.; Li, Y. Effect of Heat Treatment on Performance of 2205 Base Equipment and Pipes. Eng. Rep. 2025, 7, e13108. [Google Scholar] [CrossRef]

- Kumar, A.M.; Chandan, P.; Rahul, C. Dissimilar welding of duplex stainless steel with Ni alloys: A review. Int. J. Press. Vessel. Pip. 2021, 192, 104439. [Google Scholar]

- Liu, P.; Liu, M.; Zheng, Q.; Xu, L.; Qiao, L.; Yan, Y. Study on the failure mechanism of the heat-affected zone in 2205 duplex stainless steel weld-joints induced by hydrogen. Corros. Sci. 2025, 244, 112657. [Google Scholar] [CrossRef]

- Zhang, W.; Jin, M.; Hao, S.; Huo, M.; Huang, Z.; Chen, L.; Xia, W. The interfacial damage of the deformation heterogeneity in the transformation-induced plasticity (TRIP)-assisted duplex stainless steel. Int. J. Plast. 2025, 184, 104209. [Google Scholar] [CrossRef]

- Li, Y.; Wang, W.; Wang, Z.; Chen, C.; Yang, Z. The Effect of σ Phase Content on the Hot Working Properties of Super Austenitic Stainless Steel Containing 7Mo-0.42N. Coatings 2024, 14, 1514. [Google Scholar] [CrossRef]

- Yoon, B.-J.; Ahn, Y.-S. Effect of Aging on Pitting Corrosion Resistance of 21Cr Lean Duplex Stainless Steel with Different Molybdenum Contents. J. Mater. Eng. Perform. 2023, 32, 5593–5601. [Google Scholar] [CrossRef]

- Hou, Y.; Xu, Z.; Xiong, G.; Li, G. Effects of Cu Content on Inclusions and Pitting Corrosion in S32205 Duplex Stainless Steel. Steel Res. Int. 2023, 94, 10. [Google Scholar] [CrossRef]

- Zhou, Y.; Engelberg, L.D. Application of a modified bi-polar electrochemistry approach to determine pitting corrosion characteristics. Electrochem. Commun. 2018, 93, 158–161. [Google Scholar] [CrossRef]

- Hao, S.; Pang, B.; Sun, Z.; Zhang, W.; Jin, M.; Chen, L.; Yang, K. Low-cycle fatigue behavior of Mn-N bearing duplex stainless steel under consideration of deformation-induced martensitic transformation. Mater. Sci. Eng. A 2025, 925, 147905. [Google Scholar] [CrossRef]

- Ran, Q.; Yang, X.; Meng, Y.; Jiang, X.; Hai, R.; Wang, S.; Jiao, Y.; Cao, Y.; Feng, Z. Phase Transformation-Induced Strain-Rate Dependence Effect in Economical Transformation-Induced Plasticity-Aided Duplex Stainless Steel. J. Mater. Eng. Perform. 2022, 31, 5063–5069. [Google Scholar] [CrossRef]

- Herrera, C.; Ponge, D.; Raabe, D. Design of a novel Mn-based 1GPa, duplex stainless TRIP steel with 60% ductility by a reduction of austenite stability. Acta Mater. 2011, 59, 4653–4664. [Google Scholar] [CrossRef]

- Choi, Y.J.; Ji, H.J.; Hwang, W.S. Effects of nitrogen content on TRIP of Fe–20Cr–5Mn–x N duplex stainless steel. Mater. Sci. Eng. A 2012, 534, 673–680. [Google Scholar] [CrossRef]

- Pan, J.; Xu, P.; Li, W.; Li, Q.; Ma, F.; Zhang, K. Study of a nearly Ni-free V-containing lean duplex stainless steel and the deformation mechanism. Mater. Sci. Eng. A 2023, 865, 16. [Google Scholar] [CrossRef]

- Zhai, D.; Zou, Z.; Jin, M.; Cui, Z.; Wang, T. Constitutive Model of TRIP-Type Duplex Stainless Steel Under Symmetrical Strain Cyclic Loading Considering the Effect of Martensitic Transformation. Metall. Mater. Trans. A 2024, 56, 587–599. [Google Scholar] [CrossRef]

- Wan, J.; He, B.; Yang, X.; Kong, L.B.; Zuo, X.; Jiao, Z. Dislocation accumulation-induced strength-ductility synergy in TRIP-aided duplex stainless steel. Int. J. Plast. 2024, 182, 104130. [Google Scholar] [CrossRef]

- Zheng, B.; Chen, Z.; Yao, J.; Fu, H.; Wang, L.; Shu, G. Tests on seismic performance of hot-rolled stainless steel circular hollow section beam-columns. Structures 2025, 74, 108611. [Google Scholar] [CrossRef]

- Badji, R.; Cheniti, B.; Kahloun, C.; Chauveau, T.; Hadji, M.; Bacroix, B. Microstructure, mechanical behavior, and crystallographic texture in a hot forged dual-phase stainless steel. Int. J. Adv. Manuf. Technol. 2021, 116, 1115–1132. [Google Scholar] [CrossRef]

- Li, X.; Elsiddieg, M.A.; Alqahtani, M.A.; Ammar, B.M.; Alzahrani, A.; Hussien, M.; Mahamad, S. Numerical and experimental evaluation of temperature field and melt flow in keyhole laser welding of dissimilar duplex stainless steel and nickel base alloy. Int. J. Therm. Sci. 2025, 214, 109858. [Google Scholar] [CrossRef]

- Choi, J.Y.; Park, K.-T. Secondary Austenite Formation During Aging of Hot-Rolled Plate of a TRIP-Aided Mo-Free Lean Duplex Stainless Steel. Met. Mater. Int. 2021, 27, 3105–3114. [Google Scholar] [CrossRef]

- Liu, R.; Hu, Z.; Lin, C.; Yang, D.; Gu, X.; Xu, X.; Guo, J. A Novel Design to Eliminate Lüders Band in Medium-Mn Steel and Its Microstructure-Property Relationship. Crystals 2023, 6, 936. [Google Scholar] [CrossRef]

- Pan, Y.; Sun, B.; Wang, L.; Liu, Z.; Jiang, B.; Yang, W.; Deng, Y.; Li, X. Investigating the correlation of microstructure with stress corrosion cracking of the high-temperature heat treated 2205 duplex stainless steel. J. Mater. Res. Technol. 2025, 35, 6280–6295. [Google Scholar] [CrossRef]

- Hassel, A.T.; Marken, A.L.; Arbo, M.S.; Rorvik, G.; Du, Q.; Brotan, V.; Sorby, K. Microstructure Development in Duplex Stainless Steels from Additive Manufacturing with Coaxial Directed Energy Deposition and Heat Treatment. Metall. Mater. Trans. A 2024, 56, 474–505. [Google Scholar] [CrossRef]

- Gudikandula, S.; Kumar, A.; Dandekar, R.T.; Sharma, A.; Khatirkar, K.R. Correlation of heat treatment and welding processes with microstructure, mechanical properties and corrosion behaviour of lean duplex stainless steels: A review. Sādhanā 2025, 50, 32. [Google Scholar] [CrossRef]

- Nguyen, P.V.; Nguyen, L.P.N.; Le, C.C.; Dang, T.N. Effect of annealing process on microstructure, residual stress, and fatigue behaviour of AISI 2205 duplex stainless steel. Can. Metall. Q. 2025, 64, 130–138. [Google Scholar] [CrossRef]

- Zhang, W.; Guo, S.; Liu, S.; Lia, X.; Hao, S.; Jin, M.; Cai, X.; Chen, L. Quantitatively assessing the contributions of temperature-dependent deformation-induced martensitic transformation to uniform elongation and work hardening of TRIP-assisted duplex stainless steel via crystal plasticity. Mater. Sci. Eng. A 2023, 887, 6. [Google Scholar] [CrossRef]

- Yuan, Y.; Yuan, S.; Wang, Y.; Li, Q.; Deng, Z.; Xie, Y.; Ke, Y.; Xu, J.; Yu, H.; Sun, D.; et al. Nanostructure, Mechanical Properties, and Corrosion Resistance of Super Duplex Stainless Steel 2507 Aged at 500 °C. Crystals 2023, 13, 243. [Google Scholar] [CrossRef]

- Trentin, A.; Mardoukhi, A.; Lambai, A.; Pohjanne, P.; Saarivirta, H.E. Pitting corrosion of austenitic and duplex stainless steels in dilute acids at elevated temperature: Effect of electrolyte chemistry and material microstructure. Corros. Sci. 2025, 247, 112769. [Google Scholar] [CrossRef]

| Steel | Cr | Ni | Si | Mn | C | N | Fe |

|---|---|---|---|---|---|---|---|

| Cr19 | 18.9 | 0.3 | 0.5 | 10.1 | 0.030 | 0.261 | Bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, X.; Liu, S.; Chen, S.; Ran, Q.; Liang, B.; Yan, X. Evolution of Microstructure, Tensile Mechanical and Corrosion Properties of a Novel Designed TRIP-Aided Economical 19Cr Duplex Stainless Steel After Aging Treatment. Crystals 2025, 15, 419. https://doi.org/10.3390/cryst15050419

Shi X, Liu S, Chen S, Ran Q, Liang B, Yan X. Evolution of Microstructure, Tensile Mechanical and Corrosion Properties of a Novel Designed TRIP-Aided Economical 19Cr Duplex Stainless Steel After Aging Treatment. Crystals. 2025; 15(5):419. https://doi.org/10.3390/cryst15050419

Chicago/Turabian StyleShi, Xi, Shan Liu, Shuaiwei Chen, Qingxuan Ran, Bo Liang, and Xiaoliang Yan. 2025. "Evolution of Microstructure, Tensile Mechanical and Corrosion Properties of a Novel Designed TRIP-Aided Economical 19Cr Duplex Stainless Steel After Aging Treatment" Crystals 15, no. 5: 419. https://doi.org/10.3390/cryst15050419

APA StyleShi, X., Liu, S., Chen, S., Ran, Q., Liang, B., & Yan, X. (2025). Evolution of Microstructure, Tensile Mechanical and Corrosion Properties of a Novel Designed TRIP-Aided Economical 19Cr Duplex Stainless Steel After Aging Treatment. Crystals, 15(5), 419. https://doi.org/10.3390/cryst15050419