The Effect of High-Temperature Annealing on the Magnetic and Structural Properties of (MnFePSi)-Based Glass-Coated Microwires

Abstract

1. Introduction

2. Materials and Methods

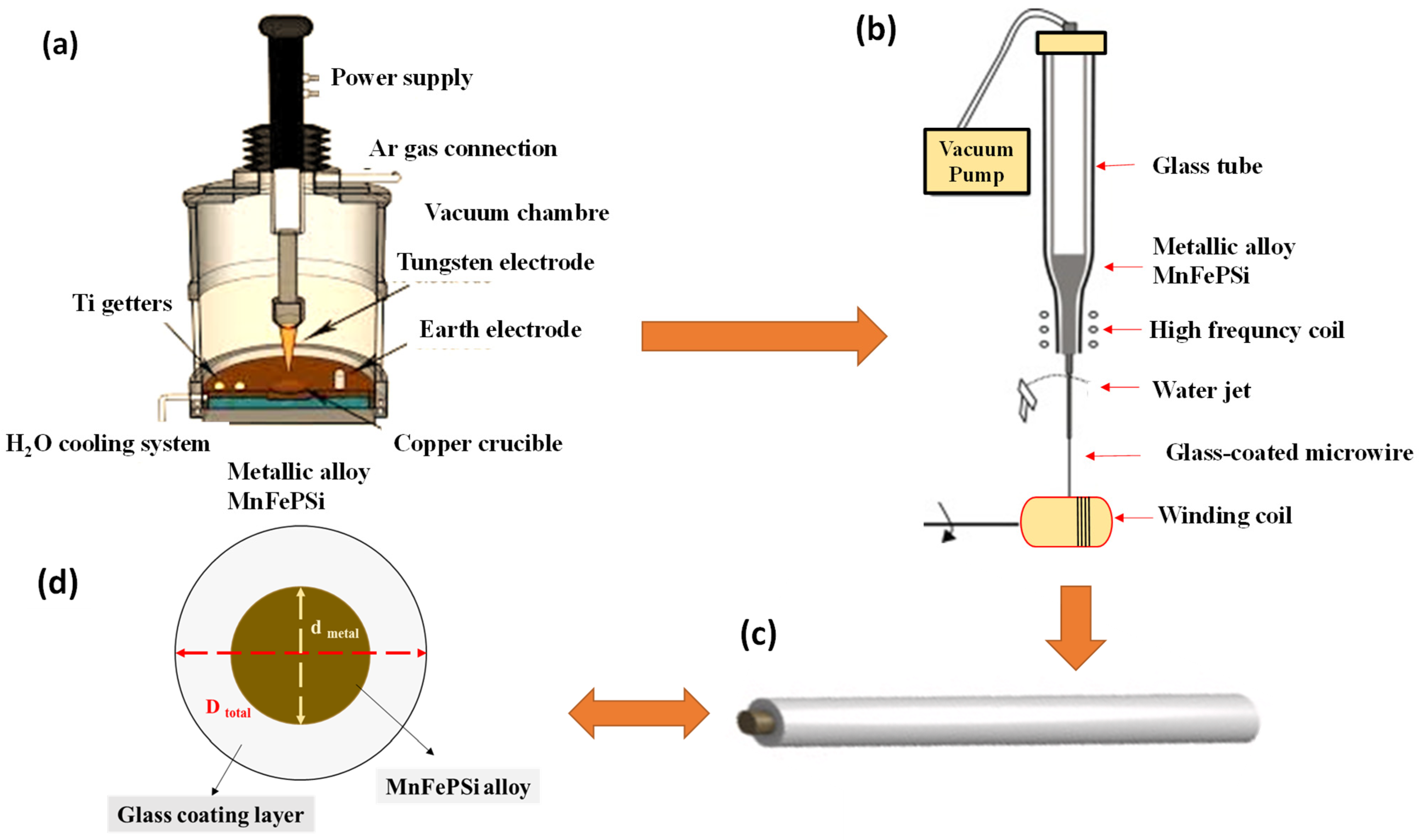

2.1. Fabrication of Bulk Mn–Fe–P–Si-Master Alloy

2.2. Preparation of Mn–Fe–P–Si Glass-Coated Microwires

2.3. Characterization of Structural and Magnetic Properties

3. Results

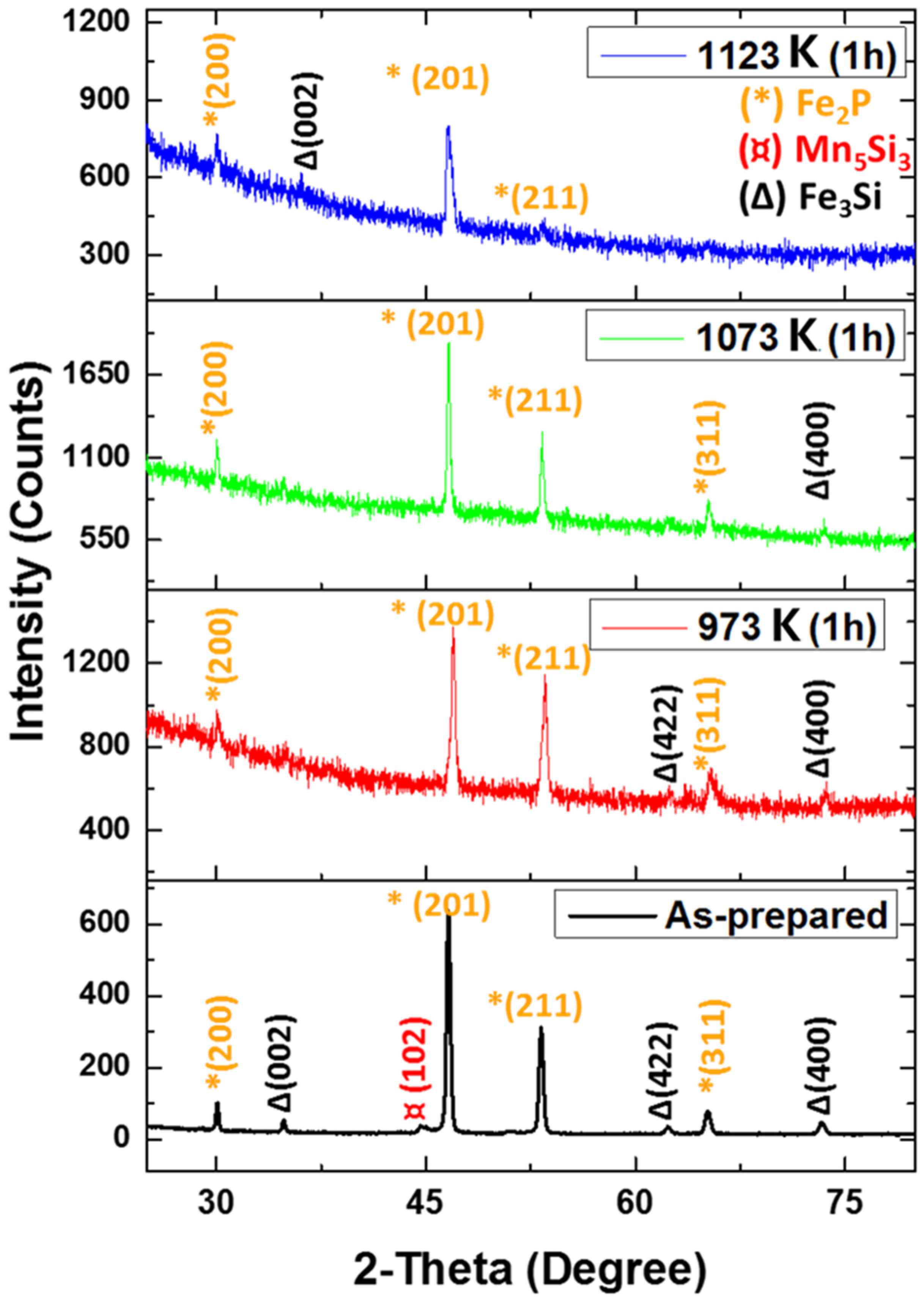

3.1. Structure Characterizations

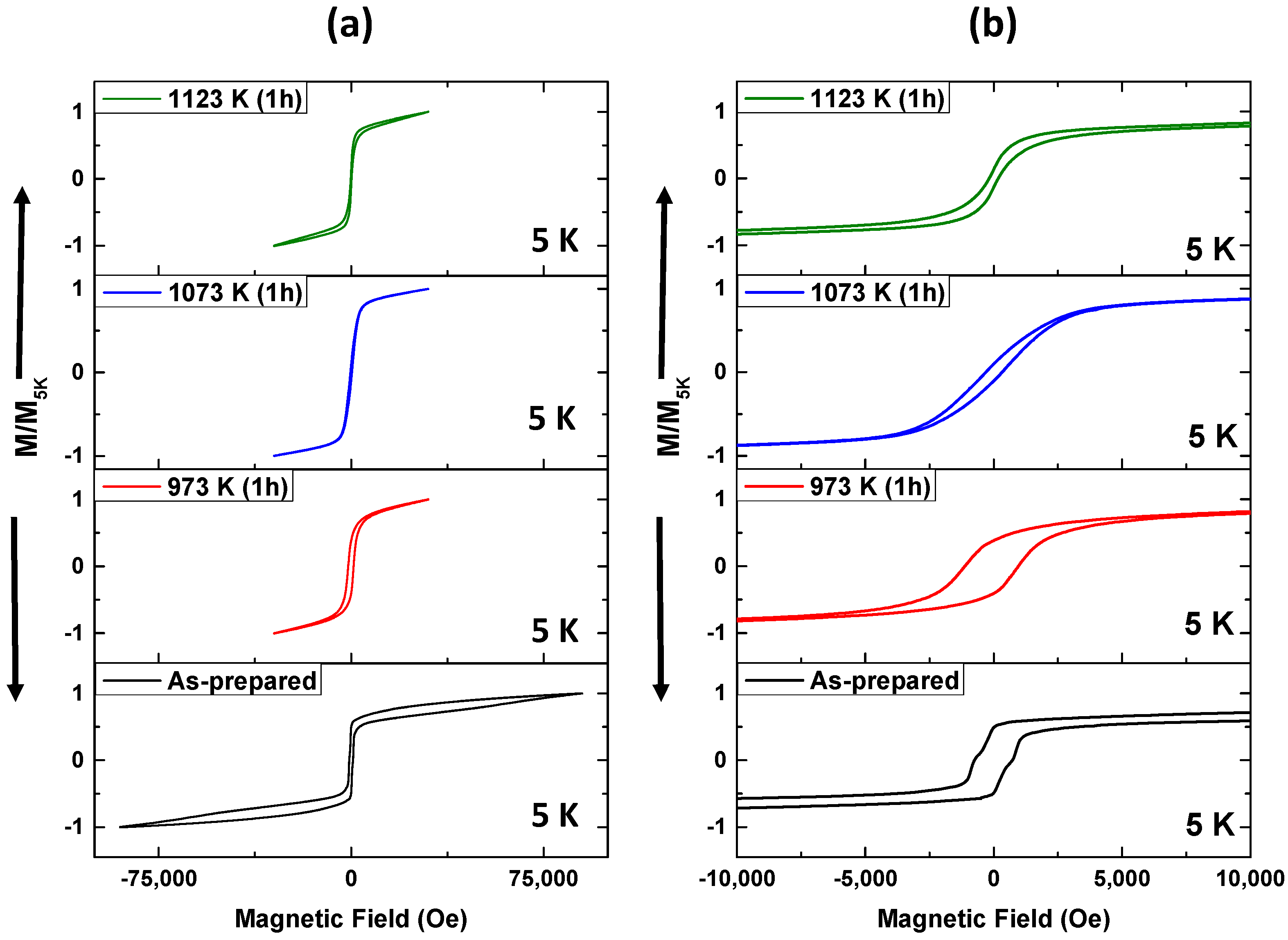

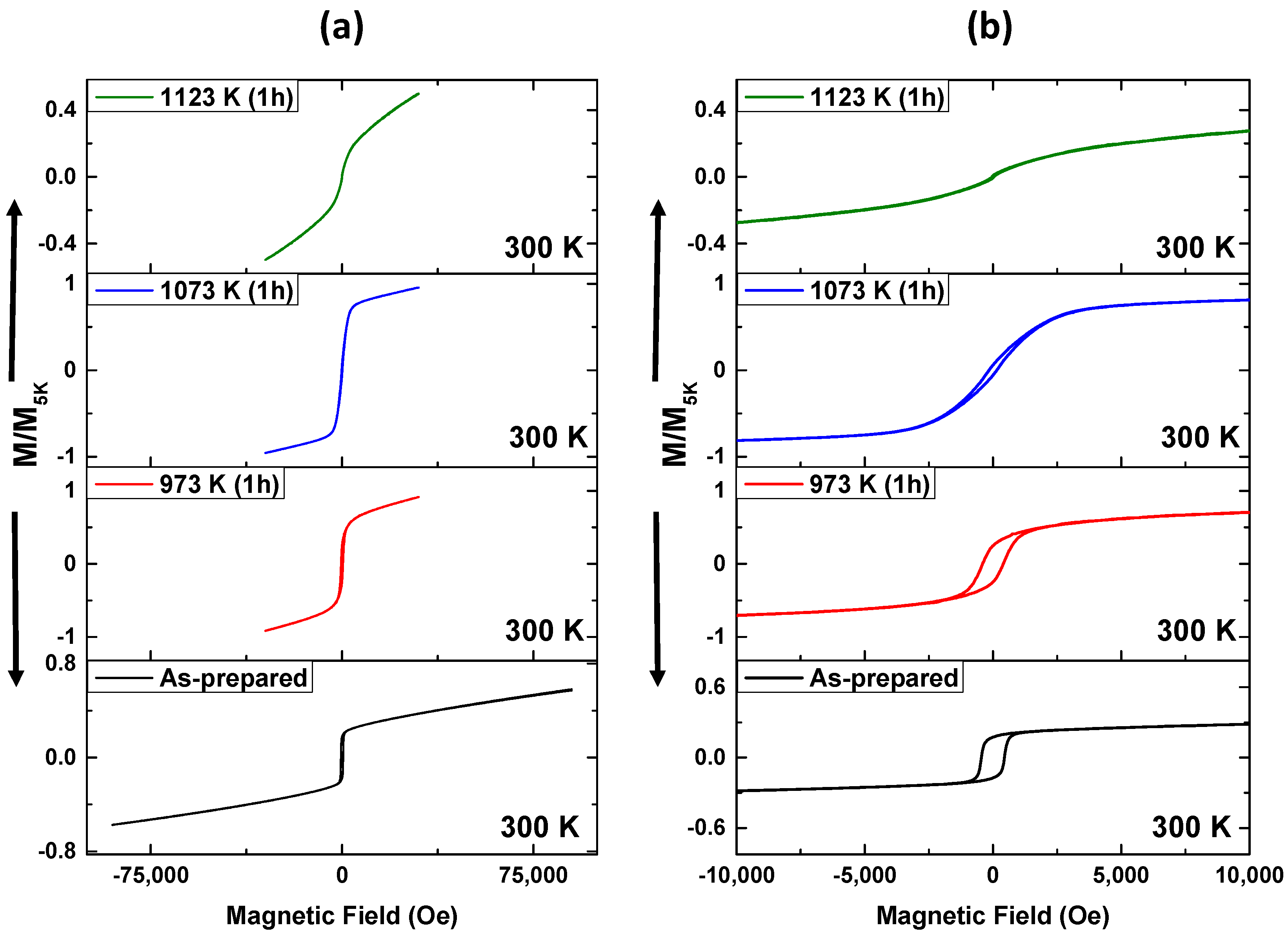

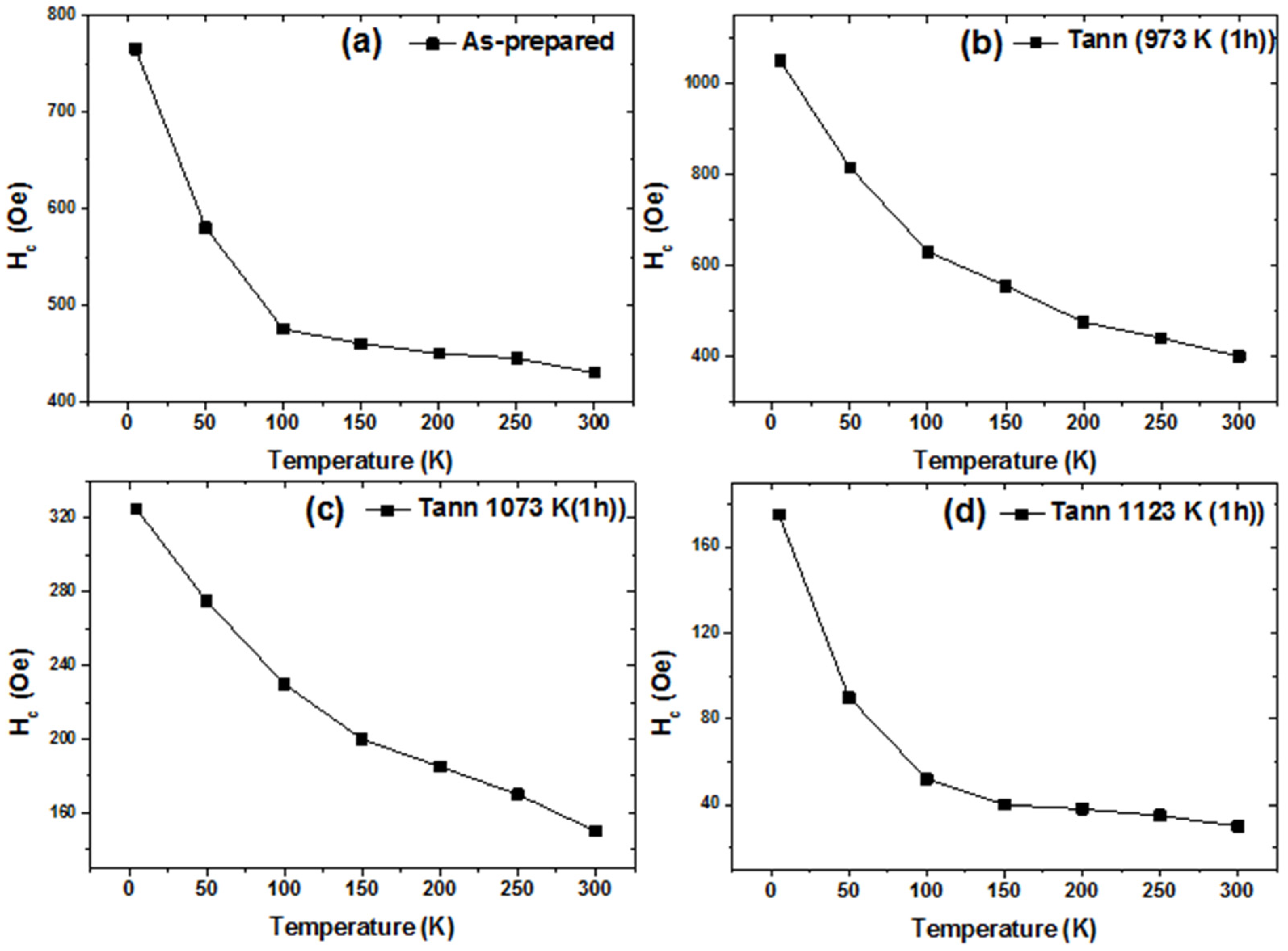

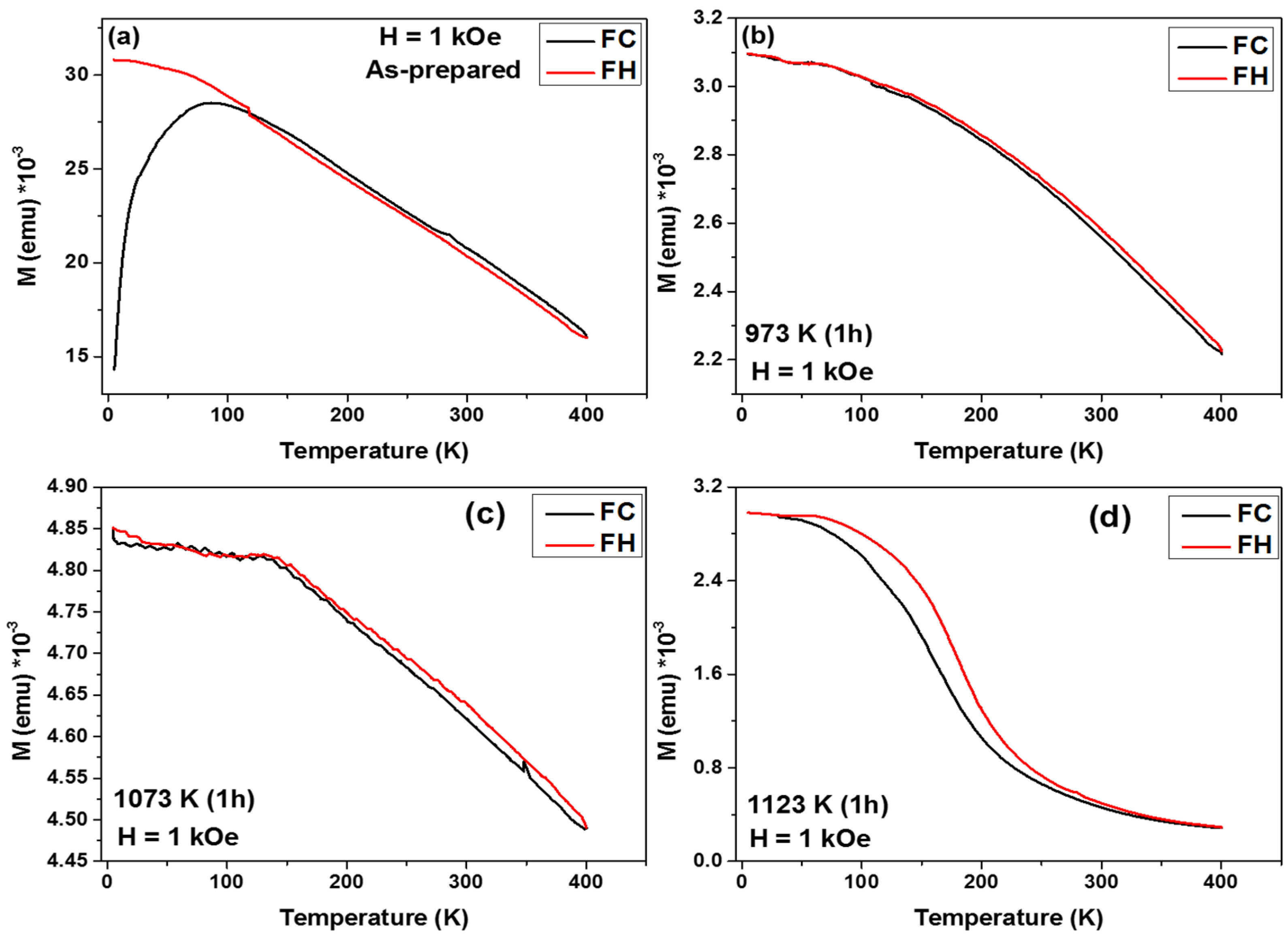

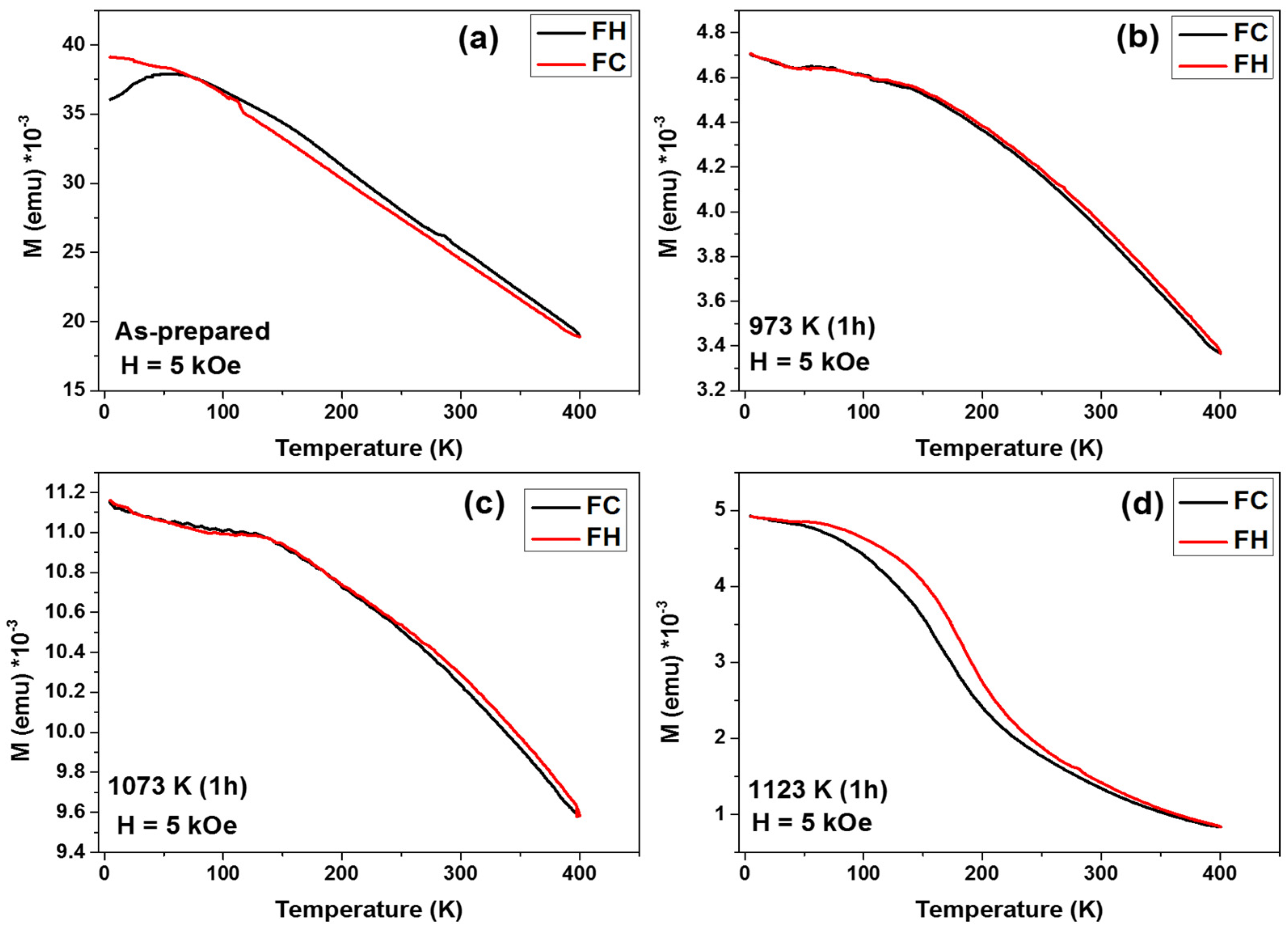

3.2. Magnetic Hysteresis Loops Characterization

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hou, Y.L.; Sellmyer, D.J. Magnetic Nanomaterials: Fundamentals, Synthesis and Applications; John Wiley & Sons: New York, NY, USA, 2017; pp. 3–546. [Google Scholar]

- Kitanovski, A. Energy applications of magnetocaloric materials. Adv. Energy Mater. 2020, 10, 1903741. [Google Scholar] [CrossRef]

- Burch, K.S.; Mandrus, D.; Park, J.G. Magnetism in two-dimensional van der Waals materials. Nature 2018, 563, 47–52. [Google Scholar] [CrossRef] [PubMed]

- Trevizoli, P.V.; Barbosa, J.R. Overview on magnetic refrigeration. In Encyclopedia of Smart Materials; Olabi, A., Ed.; Elsevier: Oxford, UK, 2022; pp. 395–406. [Google Scholar] [CrossRef]

- Phan, M.H.; Yu, S.C. Review of the magnetocaloric effect in manganite materials. J. Magn. Magn. Mater. 2007, 308, 325–340. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Abu-Dief, A.M.; El-Dabea, T. Functionalization of Nanomaterials for Energy Storage and Hydrogen Production Applications. Materials 2025, 18, 768. [Google Scholar] [CrossRef]

- Lu, A.H.; Salabas, E.L.; Schuth, F. Magnetic nanoparticles: Synthesis, protection, functionalization, and application. Angew. Chem. Int. Ed. 2007, 46, 1222–1244. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Zhukova, V.; Blanco, J.M.; Gonzalez, J.; Zhukov, A. The Impact of High-Temperature Annealing on Magnetic Properties, Structure and Martensitic Transformation of Ni2MnGa-based Glass-Coated Microwires. Ceram. Int. 2025, 51, 4378–4387. [Google Scholar] [CrossRef]

- Fernández-Pacheco, R.; Streubel, O.; Fruchart, O.; Hertel, R.; Fischer, P.; Cowburn, R.P. Three-dimensional nanomagnetism. Nat. Commun. 2017, 8, 15756. [Google Scholar] [CrossRef]

- Moya, X.; Kar-Narayan, S.; Mathur, N.D. Caloric materials near ferroic phase transitions. Nat. Mater. 2014, 13, 439–450. [Google Scholar]

- Wederni, A.; Salaheldeen, M.; Ipatov, M.; Zhukova, V.; Zhukov, A. Influence of the Geometrical Aspect Ratio on the Magneto-Structural Properties of Co2MnSi Microwires. Metals 2023, 13, 1692. [Google Scholar] [CrossRef]

- Manosa, L.; Planes, A. Materials with giant mechanocaloric effects: Cooling by strength. Adv. Mater. 2017, 29, 1603607. [Google Scholar]

- Salaheldeen, M.; Wederni, A.; Ipatov, M.; Gonzalez, J.; Zhukova, V.; Zhukov, A. Elucidation of the Strong Effect of the Annealing and the Magnetic Field on the Magnetic Properties of Ni2-Based Heusler Microwires. Crystals 2022, 12, 1755. [Google Scholar] [CrossRef]

- Li, L.; Wu, Z.; Yuan, S.; Zhang, X.B. Advances and challenges for flexible energy storage and conversion devices and systems. Energy Environ. Sci. 2014, 7, 2101–2122. [Google Scholar] [CrossRef]

- Alahmadi, M.; Mohamed, W.S.; Zhukov, A.; Salaheldeen, M.; Alsaedi, W.H.; Alhashmialameer, D.; Al-Ghamdi, K.; Abu Dief, A.M. One-step hydrothermal synthesis of flower-like MoS2/VS2 nanocomposite for biomedical applications. Inorg. Chem. Commun. 2023, 157, 111336. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Zhukova, V.; Ipatov, M.; Zhukov, A. GdFe-based nanostructured thin films with large perpendicular magnetic anisotropy for spintronic applications. AIP Adv. 2024, 14, 025308. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhao, X.; Xu, J.; Fang, Y.; Chen, G.; Song, Y.; Li, S.; Chen, J. Giant magnetoelastic effect in soft systems for bioelectronics. Nat. Mater. 2021, 20, 1670–1676. [Google Scholar] [CrossRef] [PubMed]

- Bonnot, E.; Romero, R.; Manosa, L.; Vives, E.; Planes, A. Elastocaloric effect associated with the martensitic transition in shape-memory alloys. Phys. Rev. Lett. 2008, 100, 125901. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Vega, V.; Ibabe, A.; Jaafar, M.; Asenjo, A.; Fernandez, A.; Prida, V.M. Tailoring of Perpendicular Magnetic Anisotropy in Dy13Fe87 Thin Films with Hexagonal Antidot Lattice Nanostructure. Nanomaterials 2018, 8, 227. [Google Scholar] [CrossRef] [PubMed]

- Salaheldeen, M.; Zhukova, V.; Gonzalez, J.; Zhukov, A. Anomalous magnetic behavior in MnFePSi glass-coated microwires. J. Alloys Compd. 2024, 1002, 175244. [Google Scholar] [CrossRef]

- Hu, J.M.; Nan, C.W. Opportunities and challenges for magnetoelectric devices. APL Mater. 2019, 7, 080905. [Google Scholar] [CrossRef]

- Liu, J.; Gottschall, T.; Skokov, K.P.; Moore, J.D.; Gutfleisch, O. Giant magnetocaloric effect driven by structural transitions. Nat. Mater. 2012, 11, 620–626. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Abu-Dief, A.M.; Martínez-Goyeneche, L.; Alzahrani, S.O.; Alkhatib, F.; Álvarez-Alonso, P.; Blanco, J.A. Dependence of the Magnetization Process on the Thickness of Fe70Pd30 Nanostructured Thin Film. Materials 2020, 13, 5788. [Google Scholar] [CrossRef] [PubMed]

- Cong, D.Y.; Huang, L.; Hardy, V.; Bourgault, D.; Sun, X.M.; Nie, Z.H.; Wang, M.G.; Ren, Y.; Entel, P.; Wang, Y.D. Low-field-actuated giant magnetocaloric effect and excellent mechanical properties in a NiMn-based multiferroic alloy. Acta Mater. 2018, 146, 142–151. [Google Scholar]

- Salaheldeen, M.; Talaat, A.; Ipatov, M.; Zhukova, V.; Zhukov, A. Preparation and Magneto-Structural Investigation of Nanocrystalline CoMn-Based Heusler Alloy Glass-Coated Microwires. Processes 2022, 10, 2248. [Google Scholar] [CrossRef]

- Narita, F.; Fox, M. A review on piezoelectric, magnetostrictive, and magnetoelectric materials and device technologies for energy harvesting applications. Adv. Eng. Mater. 2018, 20, 1700743. [Google Scholar] [CrossRef]

- Wu, Y.F.; Xuan, H.C.; Agarwal, S.; Xu, Y.K.; Zhang, T.; Feng, L.; Li, H.; Han, P.D.; Zhang, C.L.; Wang, D.H.; et al. Large magnetocaloric effect and magnetoresistance in Fe and Co co-doped Ni-Mn-Al Heusler alloys. Phys. Status Solidi A 2018, 215, 1700843. [Google Scholar]

- Franco, V.; Blázquez, J.S.; Ipus, J.J.; Law, J.Y.; Moreno-Ramírez, L.M.; Conde, A. Magnetocaloric effect: From materials research to refrigeration devices. Prog. Mater. Sci. 2018, 93, 112–232. [Google Scholar]

- Salaheldeen, M.; Zhukova, V.; Lopez Anton, R.; Zhukov, A. Dependence of Magnetic Properties of As-Prepared Nanocrystalline Ni2MnGa Glass-Coated Microwires on the Geometrical Aspect Ratio. Sensors 2024, 24, 3692. [Google Scholar] [CrossRef]

- Graf, T.; Parkin, S.S.P.; Felser, C. Heusler Compounds—A Material Class with Exceptional Properties. IEEE Trans. Magn. 2011, 47, 367–373. [Google Scholar]

- Otsuka, K.; Wayman, C.M. Shape Memory Materials; Cambridge University Press: Cambridge, UK, 1999. [Google Scholar]

- Salaheldeen, M.; Zhukova, V.; Ipatov, M.; Zhukov, A. Unveiling the Magnetic and Structural Properties of (X2YZ; X = Co and Ni, Y = Fe and Mn, and Z = Si) Full-Heusler Alloy Microwires with Fixed Geometrical Parameters. Crystals 2023, 13, 1550. [Google Scholar] [CrossRef]

- Pushin, V.G. Alloys with a Termomechanical Memory: Structure, properties and application. Phys. Met. Metallogr. 2000, 90 (Suppl. S1), S68–S95. [Google Scholar]

- Cesare, R.; Pons, J.; Santamarta, R.; Segui, C.; Chernenko, V.A. Ferromagnetic Shape Memory Alloys: An Overview. Arch. Metall. Mater. 2004, 49, 779–789. [Google Scholar]

- Salaheldeen, M.; Wederni, A.; Ipatov, M.; Zhukova, V.; Zhukov, A. Carbon-Doped Co2MnSi Heusler Alloy Microwires with Improved Thermal Characteristics of Magnetization for Multifunctional Applications. Materials 2023, 16, 5333. [Google Scholar] [CrossRef] [PubMed]

- Gschneidner, K.A.; Pecharsky, V.K. Thirty years of near room temperature magnetic cooling: Where we are today and future prospects. Int. J. Refrig. 2008, 31, 945–961. [Google Scholar] [CrossRef]

- Smith, A.; Bahl, C.R.H.; Bjørk, R.; Engelbrecht, K.; Nielsen, K.K.; Pryds, N. Materials challenges for high performance magnetocaloric refrigeration devices. Adv. Energy Mater. 2012, 2, 1288–1318. [Google Scholar] [CrossRef]

- Kuz’Min, M.D. Factors limiting the operation frequency of magnetic refrigerators. Appl. Phys. Lett. 2007, 90, 251916. [Google Scholar] [CrossRef]

- Vuarnoz, D.; Kawanami, T. Numerical analysis of a reciprocating active magnetic regenerator made of gadolinium wires. Appl. Therm. Eng. 2012, 37, 388–395. [Google Scholar] [CrossRef]

- Zhukov, A.; Ipatov, M.; del Val, J.J.; Zhukova, V.; Chernenko, V.A. Magnetic and structural properties of glass-coated Heusler-type microwires exhibiting martensitic transformation. Sci. Rep. 2018, 8, 621. [Google Scholar] [CrossRef]

- Miao, X.F.; Hu, S.Y.; Xu, F.; Brück, E. Overview of magnetoelastic coupling in (Mn, Fe)2(P,Si)-type magnetocaloric materials. Rare Met. 2018, 37, 723–733. [Google Scholar] [CrossRef]

- Gottschall, T.; Skokov, K.P.; Fries, M.; Taubel, A.; Radulov, I.; Scheibel, F.; Benke, D.; Riegg, S.; Gutfleisch, O. Making a cool choice: The materials library of magnetic refrigeration. Adv. Energy Mater. 2019, 9, 1901322. [Google Scholar] [CrossRef]

- Suye, B.; Yibole, H.; Guillou, F. Influence of the particle size on a MnFe(P,Si,B) compound with giant magnetocaloric effect. AIP Adv. 2023, 13, 025203. [Google Scholar] [CrossRef]

- Dung, N.H.; Zhang, L.; Ou, Z.Q.; Brück, E. From first-order magneto-elastic to magneto-structural transition in (Mn,Fe)1.95P0.50Si0.50 compounds. Appl. Phys. Lett. 2011, 99, 092511. [Google Scholar] [CrossRef]

- Hudl, M.; Nordblad, P.; Björkman, T.; Eriksson, O.; Häggström, L.; Sahlberg, M.; Andersson, Y.; Delczeg-Czirjak, E.K.; Vitos, L. Order-disorder induced magnetic structures of FeMnP0.75Si0.25. Phys. Rev. B 2011, 83, 134420. [Google Scholar] [CrossRef]

- Miao, X.F.; Caron, L.; Roy, P.; Dung, N.H.; Zhang, L.; Kockelmann, W.A.; de Groot, R.A.; van Dijk, N.H.; Brück, E. Tuning the phase transition in transition-metal-based magnetocaloric compounds. Phys. Rev. B 2014, 89, 174429. [Google Scholar] [CrossRef]

- Ou, Z.Q.; Zhang, L.; Dung, N.H.; Caron, L.; Brück, E. Structure, magnetism and magnetocalorics of Fe-rich (Mn,Fe)1.95P1−xSix melt-spun ribbons. J. Alloys Compd. 2017, 710, 446e51. [Google Scholar] [CrossRef]

- Dung, N.H.; Ou, Z.Q.; Caron, L.; Zhang, L.; Thanh, D.T.C.; de Wijs, G.A.; de Groot, R.A.; Buschow, K.H.J.; Brück, E. Mixed magnetism for refrigeration and energy conversion. Adv. Energy Mater. 2011, 1, 1215. [Google Scholar] [CrossRef]

- Neish, M.J.; Oxley, M.P.; Guo, J.; Sales, B.C.; Allen, L.J.; Chisholm, M.F. Local Observation of the Site Occupancy of Mn in a MnFePSi Compound. Phys. Rev. Lett. 2015, 114, 106101. [Google Scholar] [CrossRef] [PubMed]

- Miao, X.F.; Caron, L.; Gercsi, Z.; Daoud-Aladine, A.; van Dijk, N.H.; Brück, E. Thermal-history dependent magnetoelastic transition in (Mn,Fe)2(P,Si). Appl. Phys. Lett. 2015, 107, 042403. [Google Scholar] [CrossRef]

- Zhang, F.; Smits, S.; Kiecana, A.; Batashev, I.; Shen, Q.; van Dijk, N.; Brück, E. Impact of W doping on Fe-rich (Mn,Fe)2(P,Si) based giant magnetocaloric materials. J. Alloys Compd. 2023, 933, 167802. [Google Scholar] [CrossRef]

- Zheng, Z.; Wang, H.; Li, C.; Chen, X.; Zeng, D.; Yuan, S. Enhancement of magnetic properties and magnetocaloric effects for Mn0.975Fe0.975P0.5Si0.5 alloys by optimizing quenching temperature. Adv. Energy Mater. 2022, 25, 2200160. [Google Scholar] [CrossRef]

- He, A.; Svitlyk, V.; Mozharivskyj, Y. Synthetic approach for (Mn,Fe)2(Si,P) magnetocaloric materials: Purity, structural, magnetic, and magnetocaloric properties. Inorg. Chem. 2017, 56, 2827–2833. [Google Scholar] [CrossRef]

- Lai, J.; Huang, B.; You, X.; Maschek, M.; Zhou, G.; van Dijk, N.; Brück, E. Giant magnetocaloric effect for (Mn,Fe,V)2(P,Si) alloys with low hysteresis. J. Sci. Adv. Mater. Dev. 2024, 9, 100660. [Google Scholar] [CrossRef]

- Miao, X.F.; Caron, L.; Gubbens, P.C.M.; Yaouanc, A.; de R’eotier, P.D.; Luetkens, H.; Amato, A.; van Dijk, N.H.; Brück, E. Spin correlations in (Mn,Fe)2(P,Si) magnetocaloric compounds above Curie temperature. J. Sci. Adv. Mater. Dev. 2016, 1, 147–151. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Zhukova, V.; Rosero-Romo, J.J.; Ipatov, M.; Zhukov, A. Preparation and magnetic properties of MnFePSi-based glass-coated microwires. AIP Adv. 2024, 1, 015350. [Google Scholar]

- Zhang, H.; Gimaev, R.; Kovalev, B.; Kamilov, K.; Zverev, V.; Tishin, A. Review on the Materials and Devices for Magnetic Refrigeration in the Temperature Range of Nitrogen and Hydrogen Liquefaction. Phys. B Condens. Matter 2019, 558, 65–73. [Google Scholar]

- Lai, J.; You, X.; Dugulan, I.; Huang, B.; Liu, J.; Maschek, M.; van Eijck, L.; van Dijk, N.; Brück, E. Tuning the magneto-elastic transition of (Mn,Fe,V)2(P,Si) alloys to low magnetic field applications. J. Alloys Compd. 2020, 821, 153451. [Google Scholar]

- Lai, J.; Tang, X.; Sepehri-Amin, H.; Hono, K. Tuning transition temperature of magnetocaloric Mn1.8Fe0.2(P0.59Si0.41)x alloys for cryogenic magnetic refrigeration. Scr. Mater. 2020, 183, 127–132. [Google Scholar]

- Fries, M.; Pfeuffer, L.; Bruder, E.; Gottschall, T.; Ener, S.; Diop, L.V.B.; Gröb, T.; Skokov, K.P.; Gutfleisch, O. Microstructural and magnetic properties of Mn-Fe-P-Si (Fe2P-type) magnetocaloric compounds. Acta Mater. 2017, 132, 222–229. [Google Scholar]

- Tu, D.; Yan, J.; Xie, Y.; Li, J.; Feng, S.; Xia, M.; Li, J.; Leung, A.P. Accelerated design for magnetocaloric performance in Mn-Fe-P-Si compounds using machine learning. J. Mater. Sci. Technol. 2022, 96, 241–247. [Google Scholar]

- Guillou, F.; Porcari, G.; Yibole, H.; van Dijk, N.H.; Bruck, E. Taming the first-order transition in giant magnetocaloric materials. Adv. Mater. 2014, 26, 2671–2675. [Google Scholar]

- Dung, N.H.; Zhang, L.; Ou, Z.Q.; Zhao, L.; van Eijck, L.; Mulders, A.M.; Avdeev, M.; Suard, E.; van Dijk, N.H.; Bruck, E. High/low-moment phase transition in hexagonal Mn-Fe-P-Si compounds. Phys. Rev. B 2012, 86, 045134. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Zhukova, V.; Zhukov, A. Unraveling the impact of annealing and magnetic field on MnFePSi microwires. J. Appl. Phys. 2024, 136, 133902. [Google Scholar] [CrossRef]

- Tu, D.; Li, J.; Zhang, R.; Hu, Q.; Li, J. Microstructure evolution, solidification characteristic and magnetocaloric properties of MnFeP0.5Si0.5 particles by droplet melting. Intermetallics 2021, 131, 107102. [Google Scholar] [CrossRef]

- Yue, M.; Xu, M.F.; Zhang, H.G.; Zhang, D.T.; Liu, D.M.; Altounian, Z. Structural and magnetocaloric properties of MnFeP1 −xSix compounds prepared by spark plasma sintering. IEEE Trans. Magn. 2015, 51, 2504804. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Zhukova, V.; Rosero, J.; Salazar, D.; Zhukov, A. Annealing-induced softening and metamagnetic transition control in MnFePSi microwires. Intermetallics 2025, 181, 108742. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Ipatov, M.; Zhukova, V.; García-Gomez, A.; Gonzalez, J.; Zhukov, A. Preparation and magnetic properties of CO2-based Heusler alloy glass-coated microwires with high Curie temperature. AIP Adv. 2023, 13, 025325. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Ipatov, M.; Corte-Leon, P.; Zhukova, V.; Zhukov, A. Effect of Annealing on the Magnetic Properties of Co2MnSi-Based Heusler Alloy Glass-Coated Microwires. Metals 2023, 13, 412. [Google Scholar] [CrossRef]

- Chiriac, H.; Ovari, T.A. Amorphous glass-covered magnetic wires: Preparation, properties, applications. Prog. Mater. Sci. 1996, 40, 333–407. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Wederni, A.; Ipatov, M.; Zhukova, V.; Zhukov, A. Preparation and Magneto-Structural Investigation of High-Ordered (L21 Structure) Co2MnGe Microwires. Processes 2023, 11, 1138. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Garcia-Gomez, A.; Ipatov, M.; Corte-Leon, P.; Zhukova, V.; Blanco, J.M.; Zhukov, A. Fabrication and Magneto-Structural Properties of Co2-Based Heusler Alloy Glass-Coated Microwires with High Curie Temperature. Chemosensors 2022, 10, 225. [Google Scholar] [CrossRef]

- Zhukova, V.; Cobeño, A.F.; Zhukov, A.; Blanco, J.M.; Larin, V.; Gonzalez, J. Coercivity of glass-coated Fe73.4-xCu1Nb3.1Si13.4+xB9.1 (0≤x≤1.6) microwires. Nanostruct. Mater. 1999, 11, 1319–1327. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Wederni, A.; Ipatov, M.; Zhukova, V.; Lopez Anton, R.; Zhukov, A. Enhancing the Squareness and Bi-Phase Magnetic Switching of Co2FeSi Microwires for Sensing Application. Sensors 2023, 23, 5109. [Google Scholar] [CrossRef] [PubMed]

- Salaheldeen, M.; Zhukova, V.; Rosero, J.; Salazar, D.; Ipatov, M.; Zhukov, A. Comparison of the magnetic and structural properties of MnFePSi microwires and MnFePSi bulk alloy. Materials 2024, 17, 1874. [Google Scholar] [CrossRef]

- Vázquez, M. Soft magnetic wires. Phys. B Condens. Matter 2001, 299, 302–313. [Google Scholar]

- Salaheldeen, M.; Garcia-Gomez, A.; Corte-Leon, P.; Gonzalez, A.; Ipatov, M.; Zhukova, V.; Lopez Anton, R.; Zhukov, A. Manipulation of magnetic and structure properties of Ni2FeSi glass-coated microwires by annealing. J. Alloys Compd. 2023, 942, 169026. [Google Scholar] [CrossRef]

- López Antón, R.; Andres, J.P.; Gonzalez, J.A.; Garcia-Gomez, A.; Zhukova, V.; Chizhik, A.; Salaheldeen, M.; Zhukov, A. Tuning of magnetic properties and Giant Magnetoimpedance effect in multilayered microwires. J. Sci. Adv. Mater. Devices 2024, 9, 100821. [Google Scholar] [CrossRef]

- Herzer, G. Modern soft magnets: Amorphous and nanocrystalline materials. Acta Mater. 2013, 61, 718–734. [Google Scholar]

| Samples | Chemical Composition | Lattice Constant (nm) | Dg (nm) |

|---|---|---|---|

| As-prepared | Mn40Fe30P15Si15 | 0.58 | 36 |

| 973 K (1 h) | Mn40Fe30P15Si15 | 0.54 | 136 |

| 1073 K (1 h) | Mn40Fe30P15Si15 | 0.60 | 141 |

| 1123 K (1 h) | Mn40Fe30P15Si15 | 0.61 | 148 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salaheldeen, M.; Zhukova, V.; Gonzalez, J.; Zhukov, A. The Effect of High-Temperature Annealing on the Magnetic and Structural Properties of (MnFePSi)-Based Glass-Coated Microwires. Crystals 2025, 15, 311. https://doi.org/10.3390/cryst15040311

Salaheldeen M, Zhukova V, Gonzalez J, Zhukov A. The Effect of High-Temperature Annealing on the Magnetic and Structural Properties of (MnFePSi)-Based Glass-Coated Microwires. Crystals. 2025; 15(4):311. https://doi.org/10.3390/cryst15040311

Chicago/Turabian StyleSalaheldeen, Mohamed, Valentina Zhukova, Julian Gonzalez, and Arcady Zhukov. 2025. "The Effect of High-Temperature Annealing on the Magnetic and Structural Properties of (MnFePSi)-Based Glass-Coated Microwires" Crystals 15, no. 4: 311. https://doi.org/10.3390/cryst15040311

APA StyleSalaheldeen, M., Zhukova, V., Gonzalez, J., & Zhukov, A. (2025). The Effect of High-Temperature Annealing on the Magnetic and Structural Properties of (MnFePSi)-Based Glass-Coated Microwires. Crystals, 15(4), 311. https://doi.org/10.3390/cryst15040311