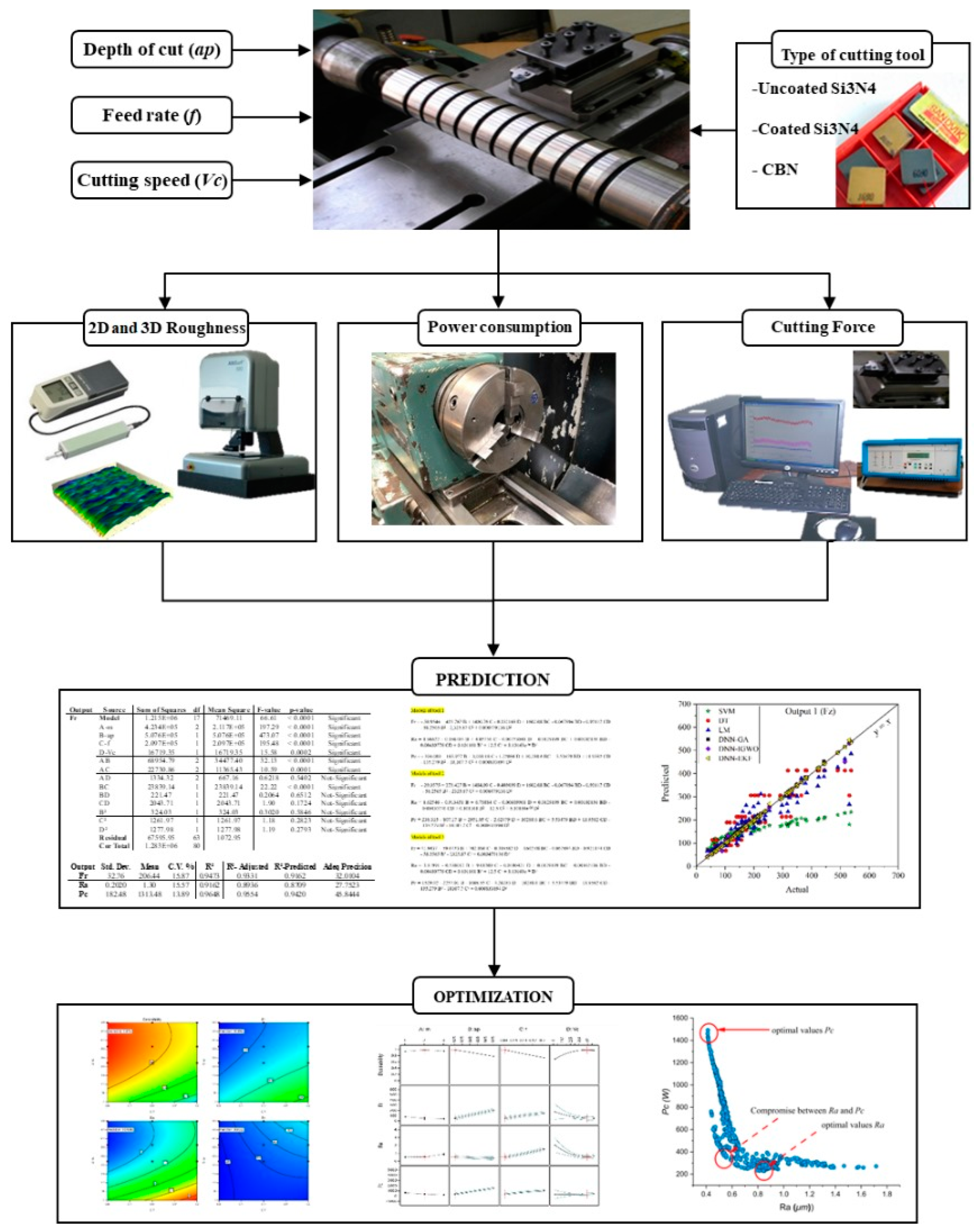

Integration of Hybrid Machine Learning and Multi-Objective Optimization for Enhanced Turning Parameters of EN-GJL-250 Cast Iron

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

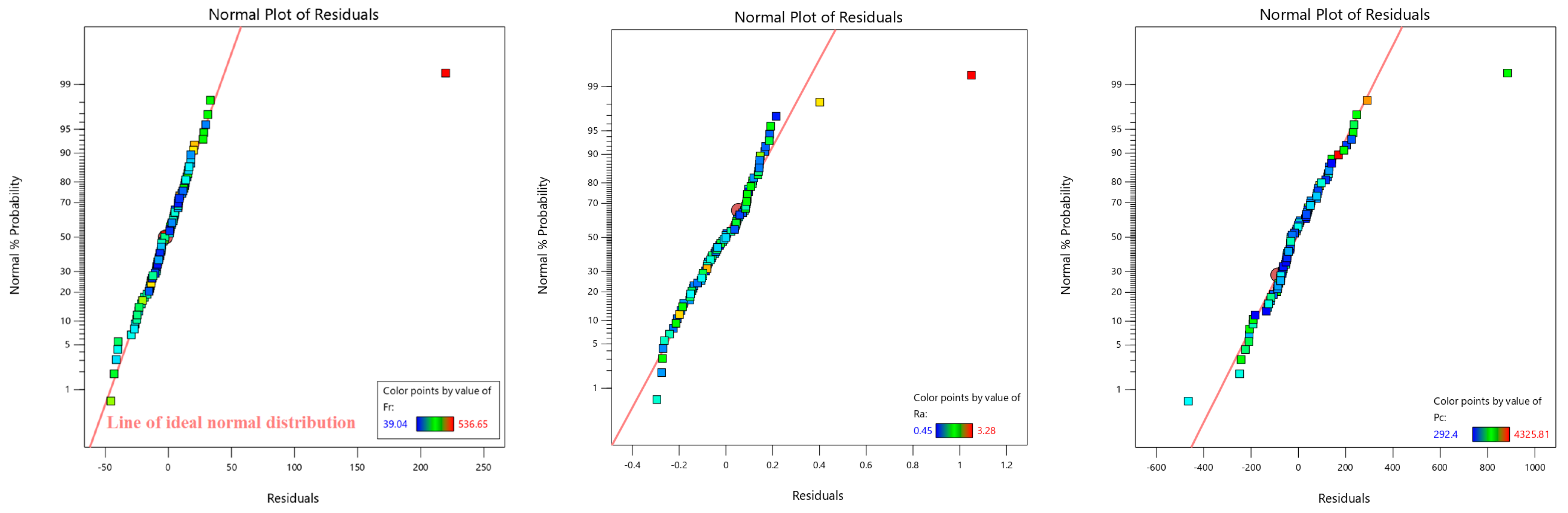

3.1. Analysis of Variance (ANOVA)

- Full models of uncoated Si3N4 ceramic

- Full models of coated Si3N4 ceramic

- Full models of CBN

- Reduced models of uncoated Si3N4 ceramic

- Reduced models of coated Si3N4 ceramic

- Reduced models of CBN

3.2. Prediction of Surface Roughness Parameters Using DNN

3.2.1. Optimization of the DNN Architecture

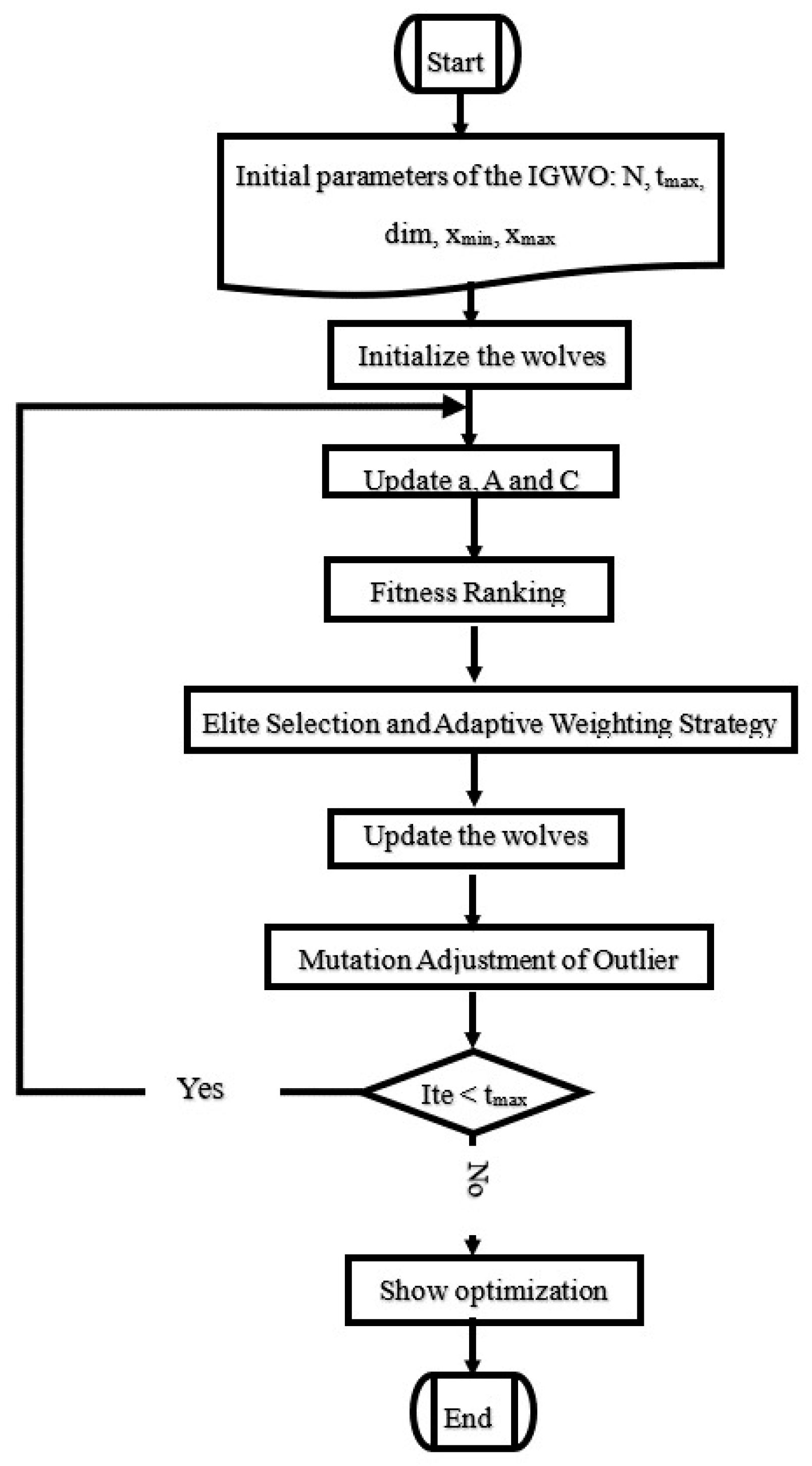

3.2.2. Improved Grey Wolf Optimizer (IGWO)

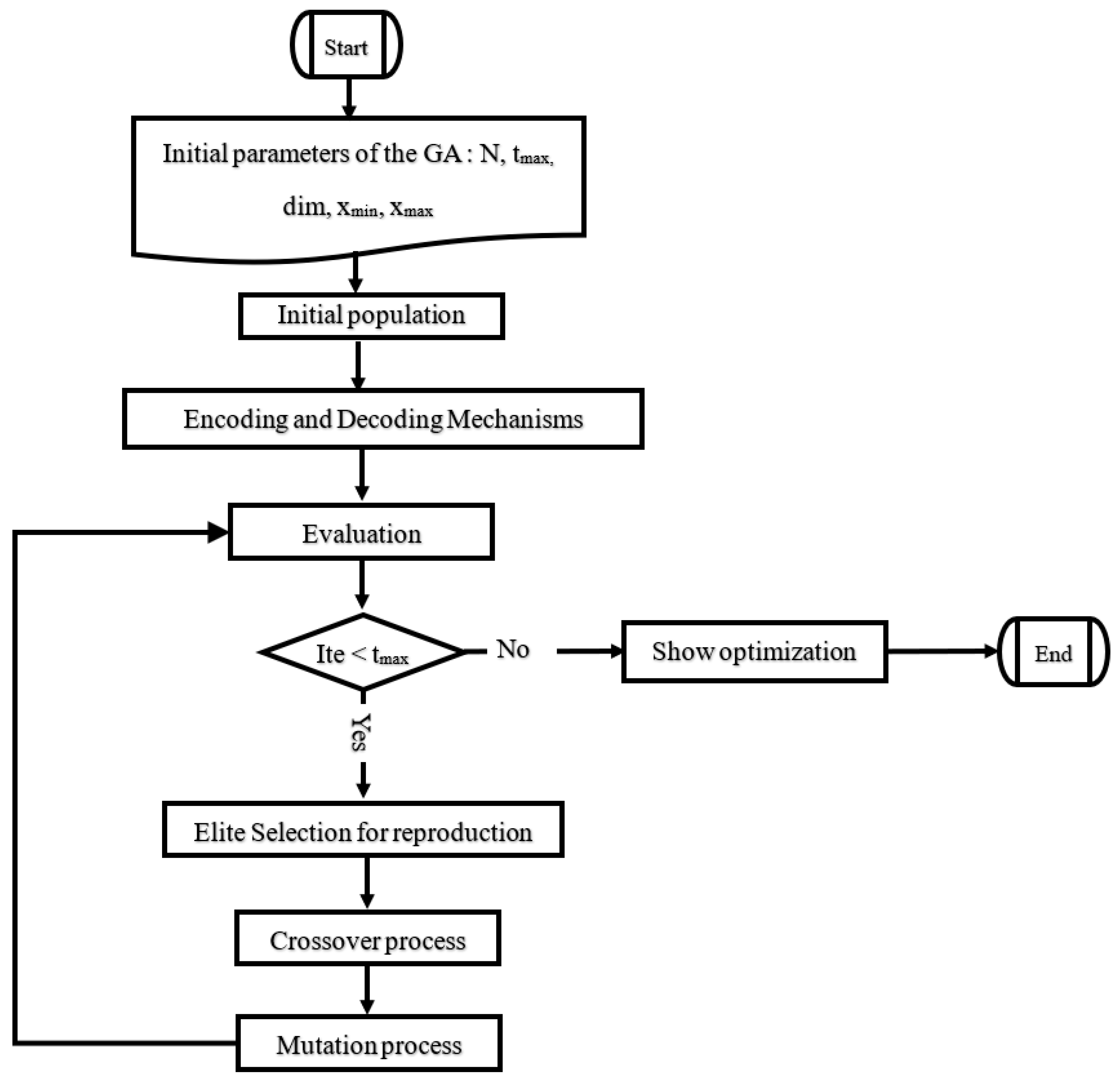

3.2.3. Genetic Algorithms for Neural Network Optimization

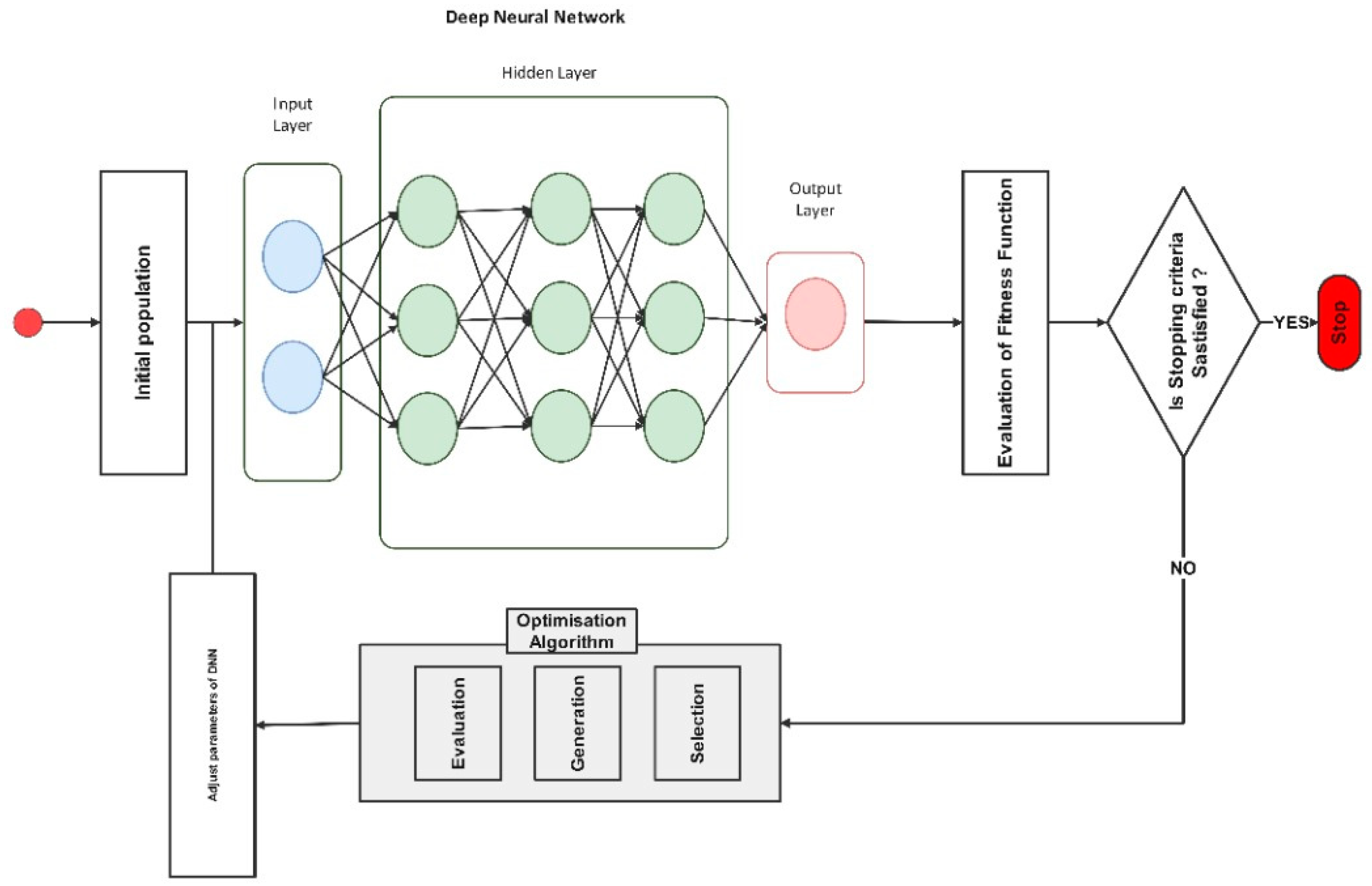

3.2.4. Hybrid Algorithms

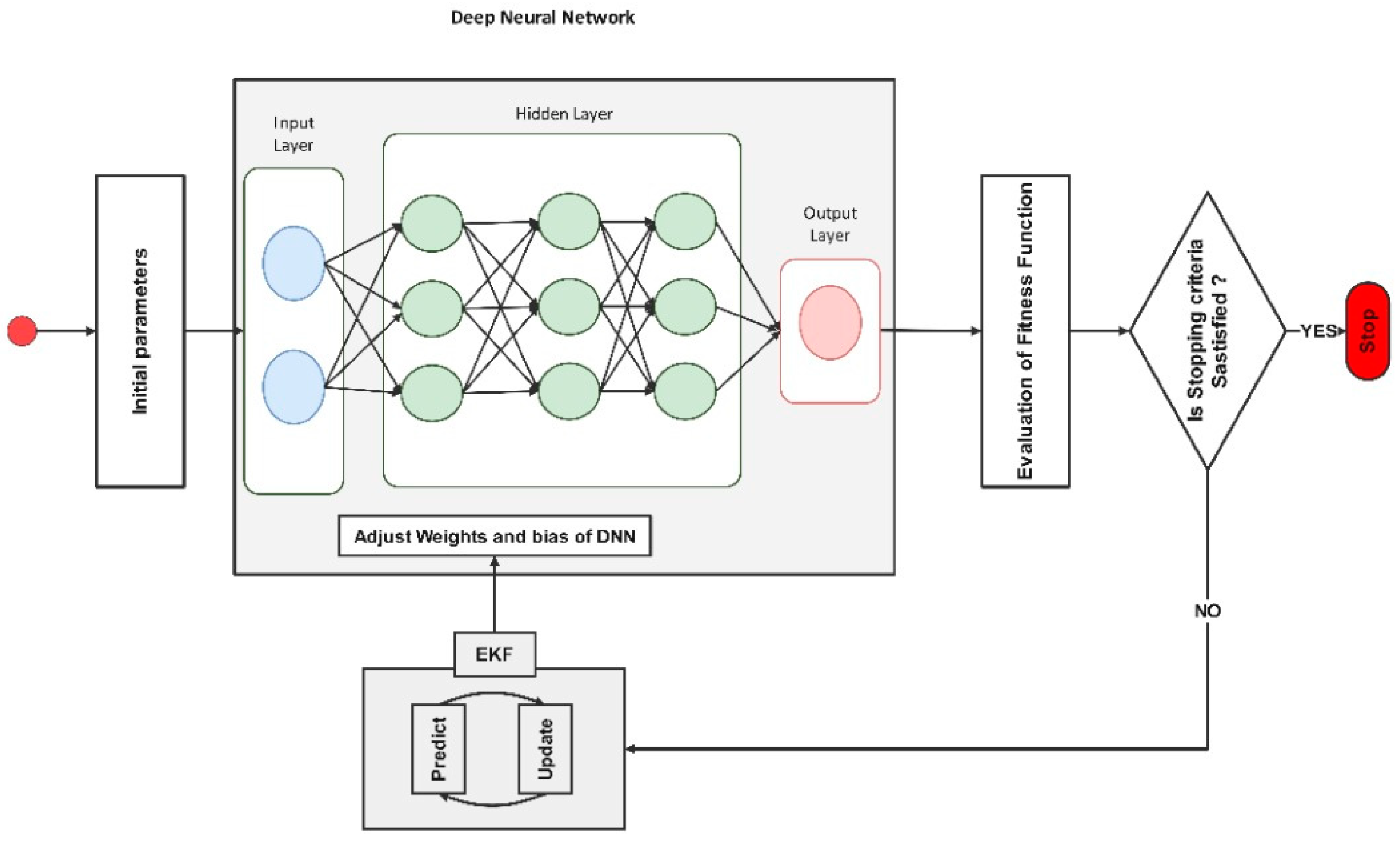

3.2.5. Kalman Filter with Artificial Deep Neural Network (DNN-EKF)

- for predictions:

- for measurements:

- for updates:

3.2.6. Performance Criteria for Optimizing DNN Structures

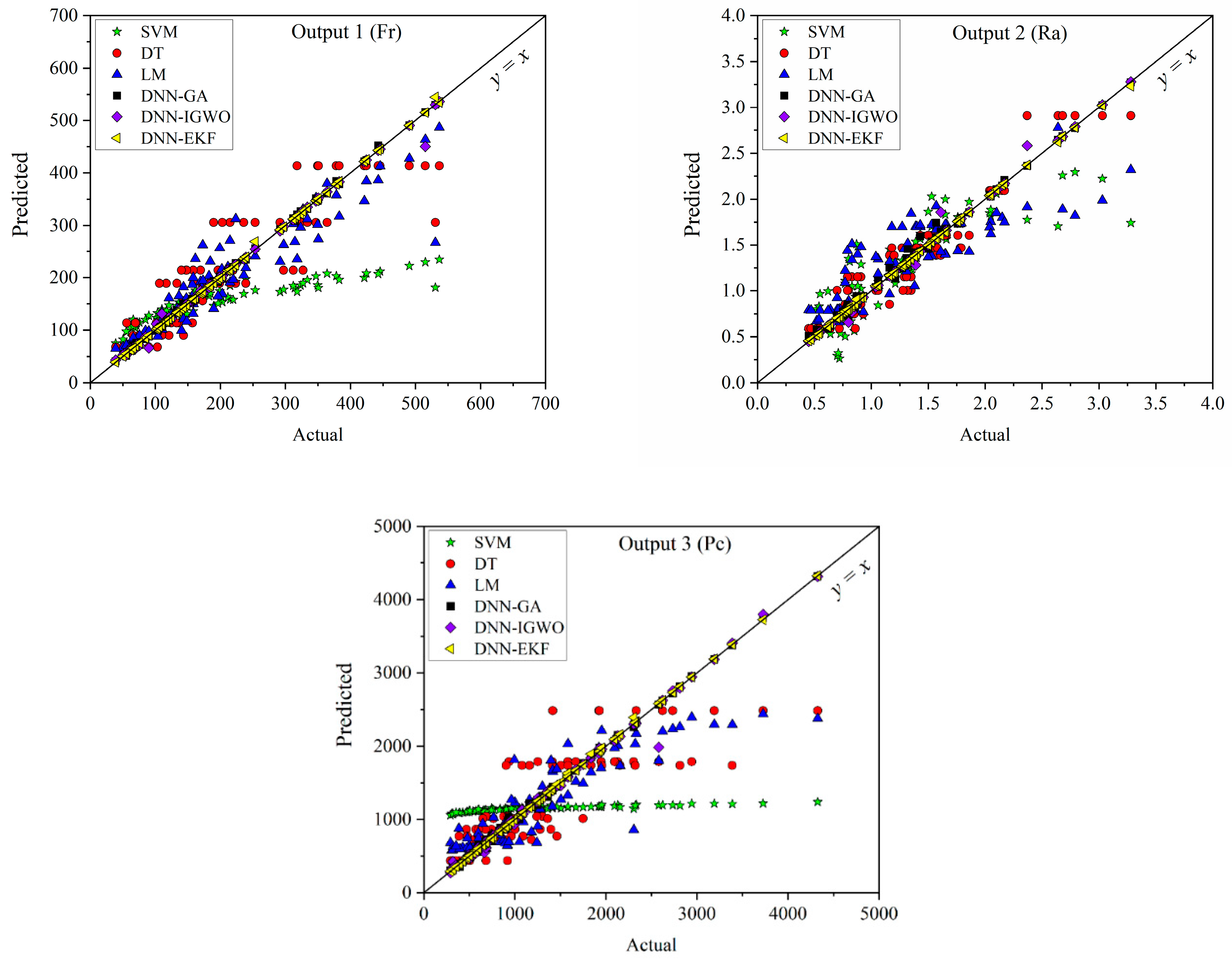

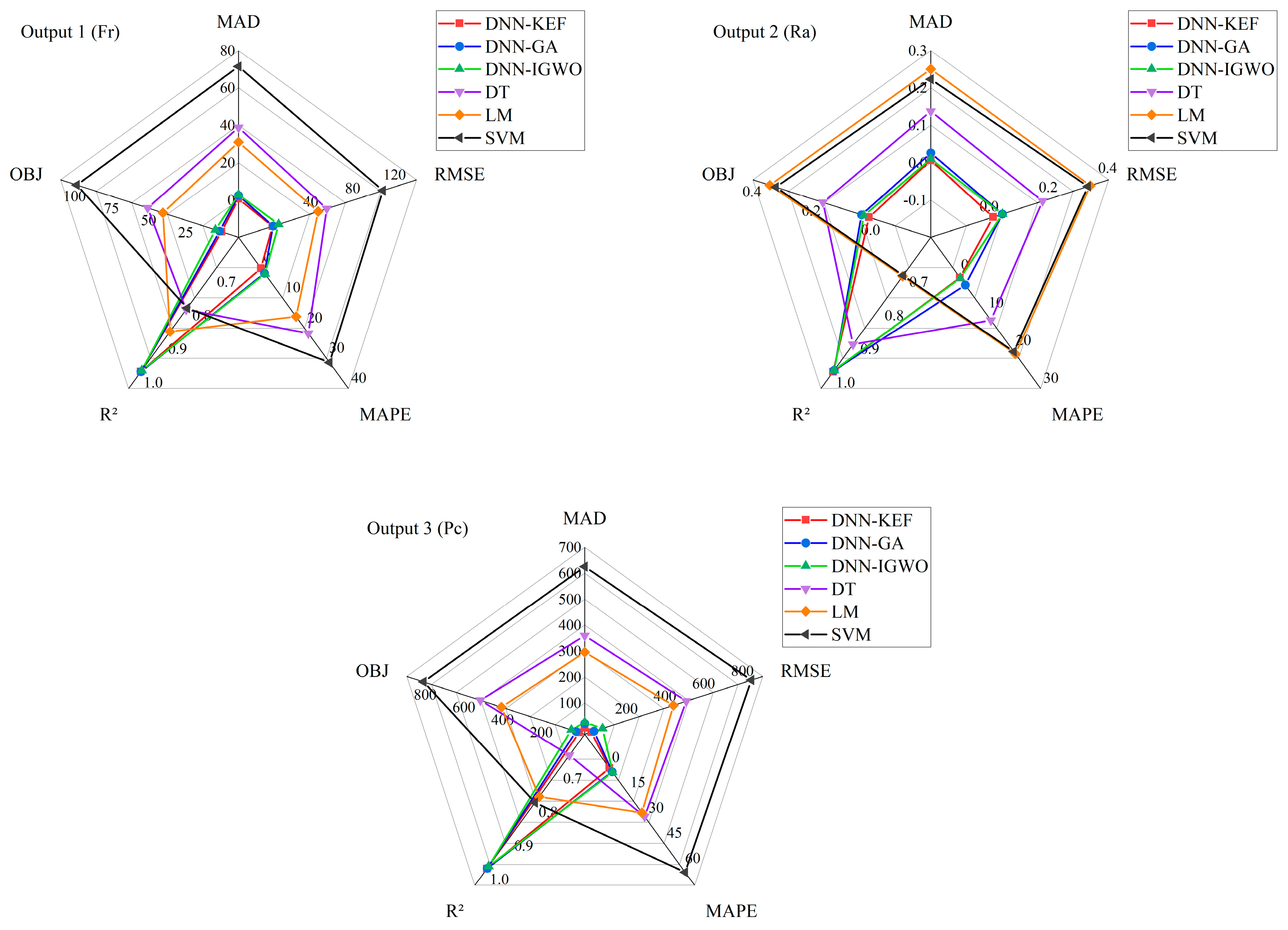

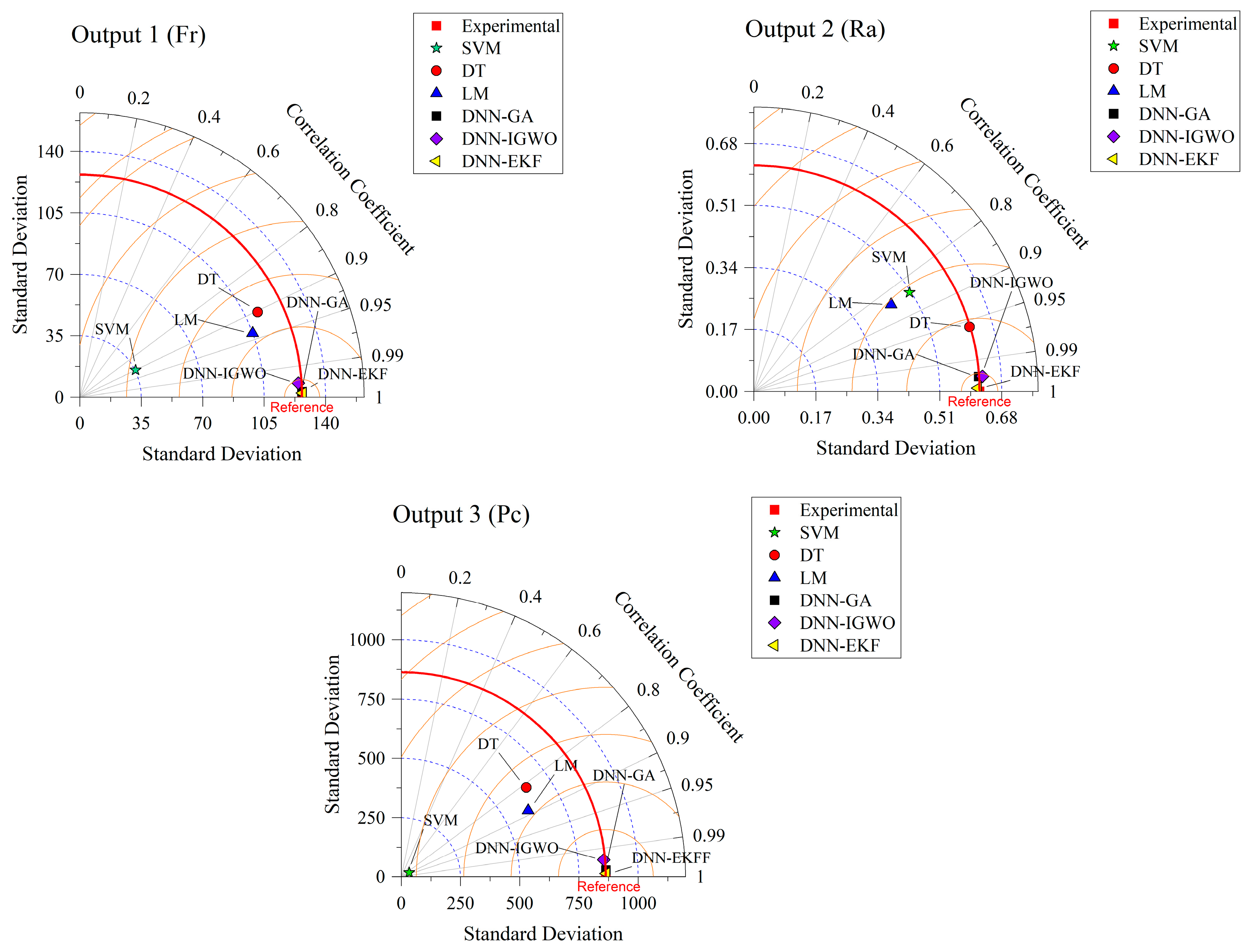

3.2.7. DNN Model Results

3.3. Multi-Objective Optimization of Cutting Parameters

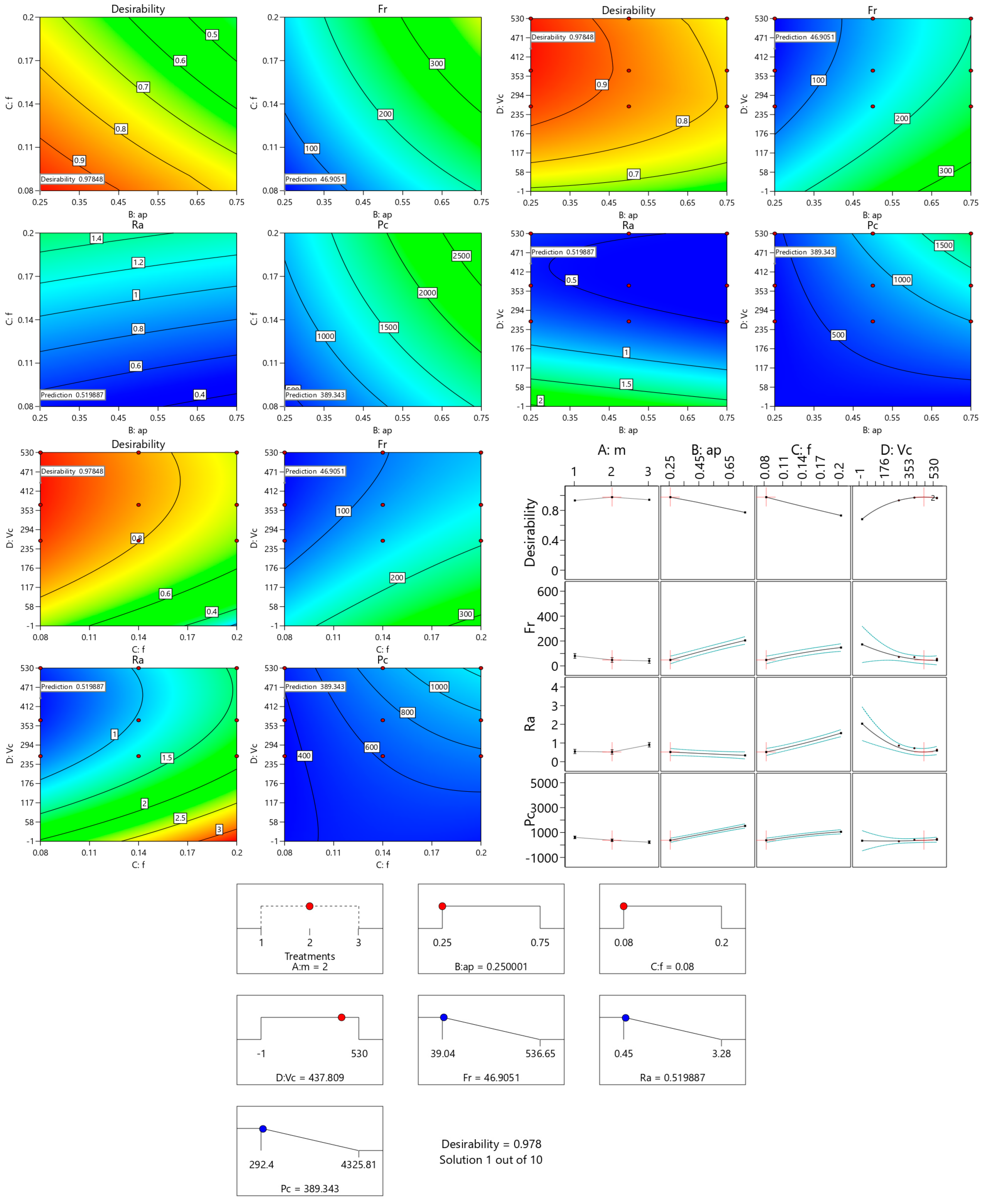

3.3.1. Desirability Function Method (DF)

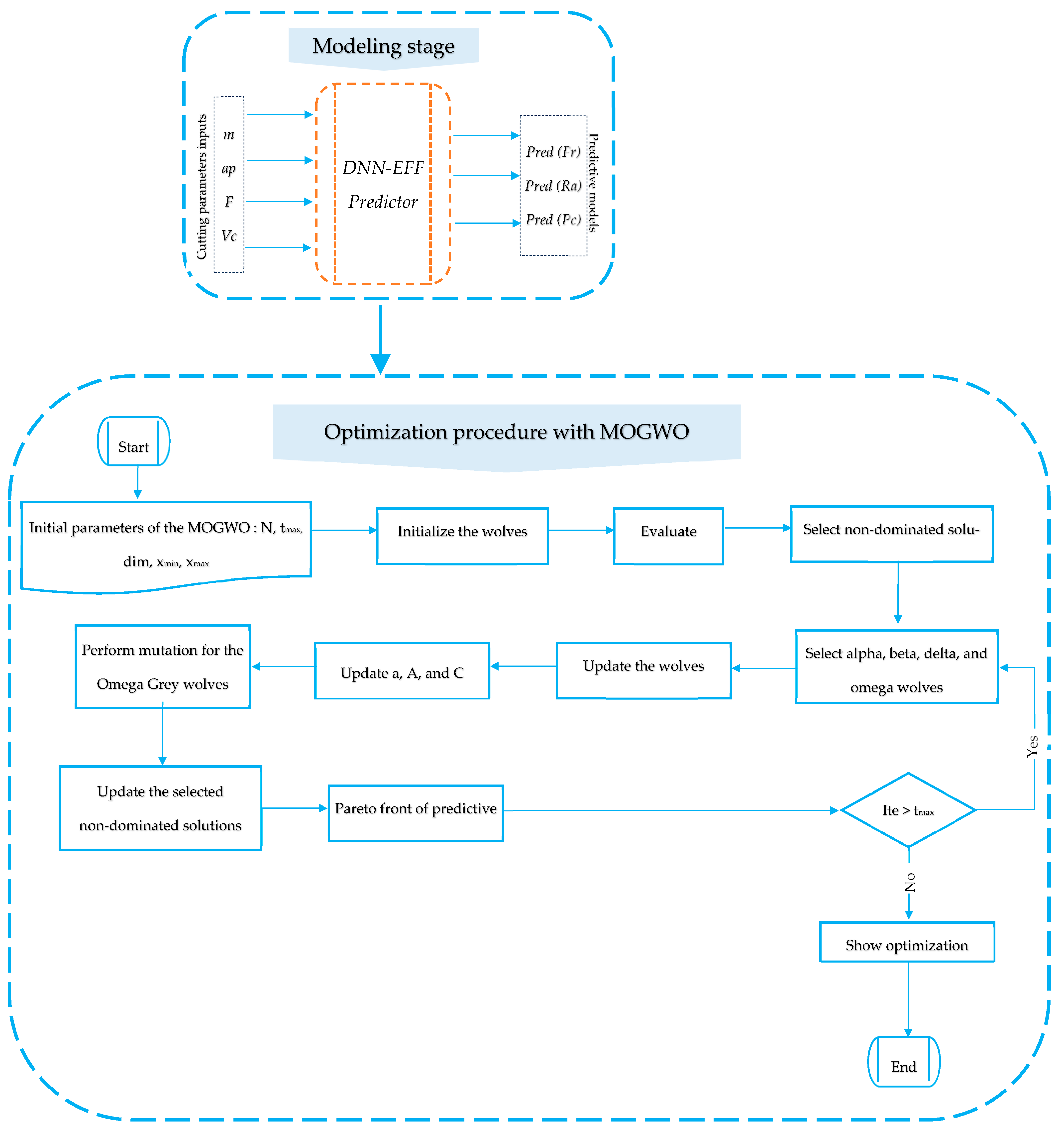

3.3.2. Optimization of DNN-EKF Prediction Model Using MOGWO

Single-Objective Optimization Analysis of Fr, Ra, and Pc

Bi-Objective Optimization Analysis of Output Parameters

Simultaneous Optimization Analysis of Fr, Ra, and Pc

3.3.3. Experimental Validation of Optimized Machining Parameters

4. Conclusions

- -

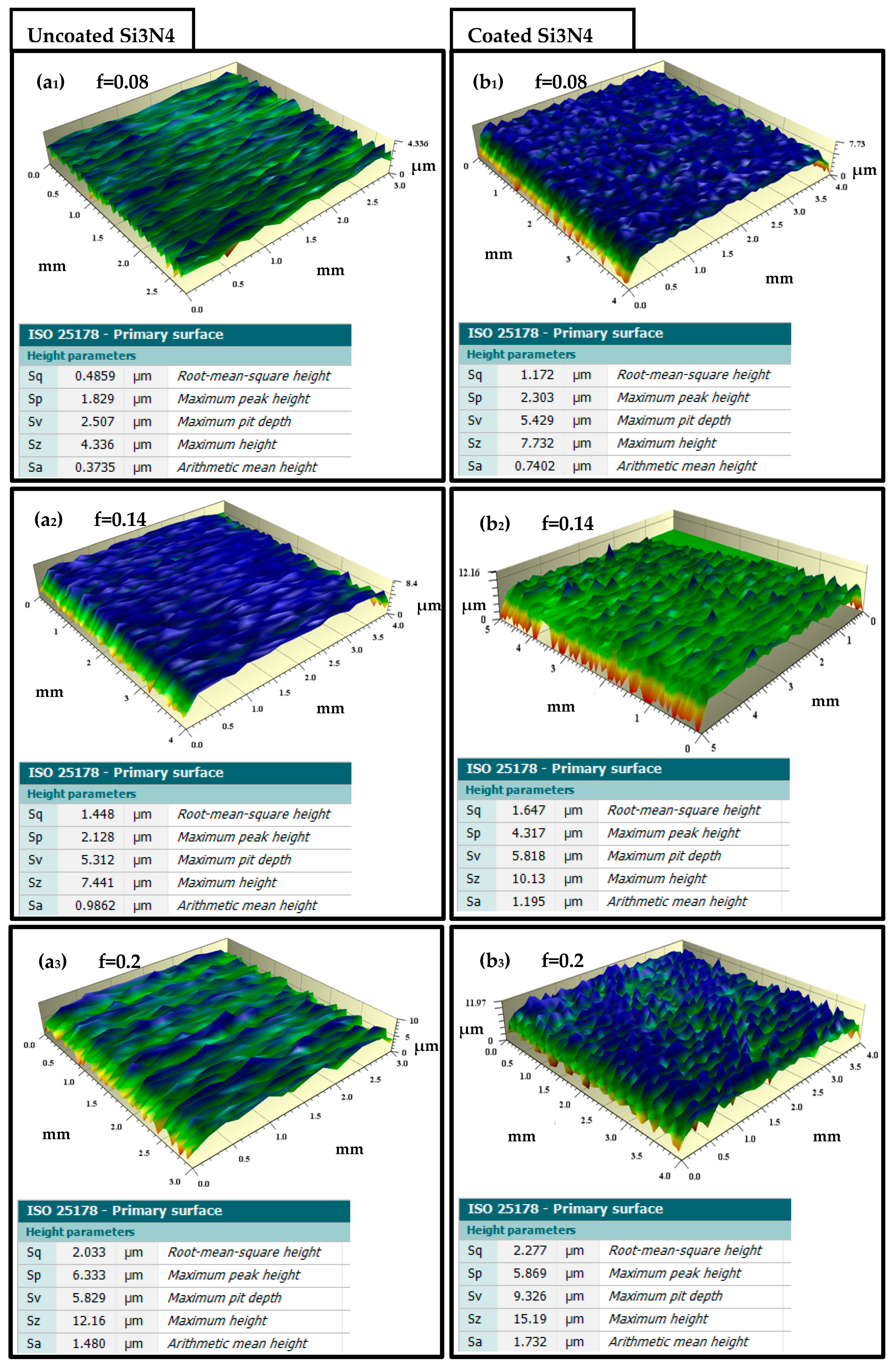

- The coated Si3N4 tool (m2) consistently outperformed both the uncoated Si3N4 (m1) and the CBN (m3) tools, achieving an exceptional surface finish with a Ra as low as 0.45 µm.

- -

- ANOVA of the RSM model confirmed robust and statistically significant relationships between machining parameters and performance outputs, with high coefficients of determination (R2 of 0.94 for cutting force, 0.92 for surface roughness, and 0.95 for power consumption).

- -

- The DNN-EKF model demonstrated outstanding predictive performance, with a Scatter Index of 0.03 and correlation coefficients exceeding 0.98, thereby outperforming traditional methods such as SVM, Decision Trees, and LM-trained networks, as well as models developed using RSM.

- -

- Multi-objective optimization using the desirability function and multi-objective grey wolf optimization (MOGWO) effectively balanced the conflicting objectives of minimizing cutting force, surface roughness, and power consumption. The analysis identified near-optimal machining settings for the coated Si3N4 tool, specifically a feed rate of 0.08 mm/rev, a cutting speed of 530 m/min, and a depth of cut between 0.25 and 0.56 mm.

- -

- The integration of these advanced optimization methods with deep learning establishes a robust, transferable predictive framework that enhances machining efficiency and product quality, while being adaptable to a variety of industrial applications.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Si3N4 | Silicon nitride |

| CBN | Cubic boron nitride |

| ap | Depth of cut |

| f | Feed rate |

| Vc | Cutting speed |

| Ra | Surface roughness |

| Fr | Cutting force |

| Pc | Power consumption |

| DNN-IGWO | Improved grey wolf optimizer-deep neural network |

| DNN-GA | Genetic algorithm–deep neural network |

| DNN-EKF | Deep neural network–extended Kalman filter |

| SVM | Support Vector Machines |

| DT | Decision Trees |

| LM | Levenberg–Marquardt |

| DF | Desirability Function |

| MOGWO | Multi-objective grey wolf optimization |

Appendix A

| N° | Input Factors | Output Parameters | |||||

|---|---|---|---|---|---|---|---|

| m | ap | f | Vc | Fr | Ra | Pc | |

| 1 | 3 | 0.3 | 0.08 | 273 | 63.9 | 1.35 | 292.4 |

| 2 | 3 | 0.6 | 0.08 | 273 | 84.85 | 1.32 | 386.04 |

| 3 | 3 | 0.9 | 0.08 | 273 | 143.41 | 1.28 | 648.76 |

| 4 | 3 | 0.3 | 0.14 | 273 | 69.91 | 2.64 | 319.56 |

| 5 | 3 | 0.6 | 0.14 | 273 | 133.26 | 3.28 | 598.57 |

| 6 | 3 | 0.9 | 0.14 | 273 | 199 | 2.37 | 903.97 |

| 7 | 3 | 0.3 | 0.2 | 273 | 103.28 | 3.03 | 468.75 |

| 8 | 3 | 0.6 | 0.2 | 273 | 182.64 | 2.68 | 832.14 |

| 9 | 3 | 0.9 | 0.2 | 273 | 239.17 | 2.79 | 1078.33 |

| 10 | 3 | 0.3 | 0.08 | 382 | 50.33 | 1.04 | 318.6 |

| 11 | 3 | 0.6 | 0.08 | 382 | 75.65 | 1.06 | 478.06 |

| 12 | 3 | 0.9 | 0.08 | 382 | 121.02 | 1.06 | 766.03 |

| 13 | 3 | 0.3 | 0.14 | 382 | 62.14 | 1.57 | 393.67 |

| 14 | 3 | 0.6 | 0.14 | 382 | 117.13 | 1.57 | 743.29 |

| 15 | 3 | 0.9 | 0.14 | 382 | 184.55 | 1.61 | 1161.11 |

| 16 | 3 | 0.3 | 0.2 | 382 | 90.17 | 2.1 | 570.92 |

| 17 | 3 | 0.6 | 0.2 | 382 | 171.25 | 2.15 | 1091.21 |

| 18 | 3 | 0.9 | 0.2 | 382 | 223.67 | 2.17 | 1413.75 |

| 19 | 3 | 0.3 | 0.08 | 546 | 39.04 | 0.7 | 354.83 |

| 20 | 3 | 0.6 | 0.08 | 546 | 65.98 | 0.8 | 607.74 |

| 21 | 3 | 0.9 | 0.08 | 546 | 109.99 | 0.79 | 994.59 |

| 22 | 3 | 0.3 | 0.14 | 546 | 55.4 | 1.16 | 505.81 |

| 23 | 3 | 0.6 | 0.14 | 546 | 106.41 | 1.2 | 961.86 |

| 24 | 3 | 0.9 | 0.14 | 546 | 173.43 | 1.38 | 1583.91 |

| 25 | 3 | 0.3 | 0.2 | 546 | 66 | 2.05 | 600.81 |

| 26 | 3 | 0.6 | 0.2 | 546 | 158.71 | 2.04 | 1461.69 |

| 27 | 3 | 0.9 | 0.2 | 546 | 214.90 | 2.05 | 1934.67 |

References

- Dogra, M.; Sharma, V.S.; Sachdeva, A.; Suri, N.M.; Dureja, J.S. Tool Wear, Chip Formation and Workpiece Surface Issues in CBN Hard Turning: A Review. Int. J. Precis. Eng. Manuf. 2010, 11, 341–358. [Google Scholar] [CrossRef]

- Akinwekomi, A.D.; Lawal, A.I. Neural Network-Based Model for Predicting Particle Size of AZ61 Powder During High-Energy Mechanical Milling. Neural Comput. Appl. 2021, 33, 17611–17619. [Google Scholar] [CrossRef]

- Saha, S.; Mondal, A.K.; Čep, R.; Joardar, H.; Haldar, B.; Kumar, A.; Alsalah, N.A.; Ataya, S. Multi-Response Optimization of Electrochemical Machining Parameters for Inconel 718 via RSM and MOGA-ANN. Machines 2024, 12, 335. [Google Scholar] [CrossRef]

- Kumar, R.; Kumar, A.; Kant, L.; Prasad, A.; Bhoi, S.; Meena, C.S.; Singh, V.P.; Ghosh, A. Experimental and RSM-Based Process-Parameters Optimisation for Turning Operation of EN36B Steel. Materials 2022, 16, 339. [Google Scholar] [CrossRef]

- Abdelrazek, A.H.; Choudhury, I.A.; Nukman, Y.; Kazi, S.N. Metal Cutting Lubricants and Cutting Tools: A Review on the Performance Improvement and Sustainability Assessment. Int. J. Adv. Manuf. Technol. 2020, 106, 4221–4245. [Google Scholar] [CrossRef]

- Zhuang, K.; Fu, C.; Weng, J.; Hu, C. Cutting Edge Microgeometries in Metal Cutting: A Review. Int. J. Adv. Manuf. Technol. 2021, 116, 2045–2092. [Google Scholar] [CrossRef]

- Altınsoy, Ş.; Üllen, N.B.; Ersoy, M.; Can, D. Machining Performance of Uncoated and Carbide Coated Cutting Inserts in Ti6Al4V Turning: An Experimental and Numerical Approach. J. Mater. Eng. Perform. 2024, 1–19. [Google Scholar] [CrossRef]

- Tan, L.; Yao, C.; Li, X.; Fan, Y.; Cui, M. Effects of Machining Parameters on Surface Integrity When Turning Inconel 718. J. Mater. Eng. Perform. 2022, 31, 4176–4186. [Google Scholar] [CrossRef]

- Sales, W.F.; Schoop, J.; da Silva, L.R.R.; Machado, Á.R.; Jawahir, I.S. A Review of Surface Integrity in Machining of Hardened Steels. J. Manuf. Process 2020, 58, 136–162. [Google Scholar] [CrossRef]

- Shihab, S.K.; Khan, Z.A.; Mohammad, A.; Siddiquee, A.N. A Review of Turning of Hard Steels Used in Bearing and Automotive Applications. Prod. Manuf. Res. 2014, 2, 24–49. [Google Scholar] [CrossRef]

- Kundrák, J.; Karpuschewski, B.; Gyani, K.; Bana, V. Accuracy of Hard Turning. J. Mater. Process Technol. 2008, 202, 328–338. [Google Scholar] [CrossRef]

- Panda, A.; Sahoo, A.K.; Kumar, R.; Das, D. A Concise Review of Uncertainty Analysis in Metal Machining. Mater. Today Proc. 2020, 26, 1734–1739. [Google Scholar] [CrossRef]

- Touati, S.; Mekhilef, S. Statistical Analysis of Surface Roughness in Turning Based on Cutting Parameters and Tool Vibrations with Response Surface Methodology (RSM). Matér. Tech. 2017, 105, 401. [Google Scholar] [CrossRef]

- Tosun, N.; Ozler, L. Optimisation for Hot Turning Operations with Multiple Performance Characteristics. Int. J. Adv. Manuf. Technol. 2004, 23, 777–782. [Google Scholar] [CrossRef]

- Kara, F.; Aslantas, K.; Çiçek, A. ANN and Multiple Regression Method-Based Modelling of Cutting Forces in Orthogonal Machining of AISI 316L Stainless Steel. Neural Comput. Appl. 2015, 26, 237–250. [Google Scholar] [CrossRef]

- Chetan; Ghosh, S.; Venkateswara Rao, P. Application of Sustainable Techniques in Metal Cutting for Enhanced Machinability: A Review. J. Clean. Prod. 2015, 100, 17–34. [Google Scholar] [CrossRef]

- Ming, W.; Shen, F.; Zhang, G.; Liu, G.; Du, J.; Chen, Z. Green Machining: A Framework for Optimization of Cutting Parameters to Minimize Energy Consumption and Exhaust Emissions During Electrical Discharge Machining of Al 6061 and SKD 11. J. Clean. Prod. 2021, 285, 124889. [Google Scholar] [CrossRef]

- Pimenov, D.Y.; Mia, M.; Gupta, M.K.; Machado, Á.R.; Pintaude, G.; Unune, D.R.; Khanna, N.; Khan, A.M.; Tomaz, Í.; Wojciechowski, S.; et al. Resource Saving by Optimization and Machining Environments for Sustainable Manufacturing: A Review and Future Prospects. Renew. Sustain. Energy Rev. 2022, 166, 112660. [Google Scholar] [CrossRef]

- Saez, M.; Barton, K.; Maturana, F.; Tilbury, D.M. Modeling Framework to Support Decision Making and Control of Manufacturing Systems Considering the Relationship Between Productivity, Reliability, Quality, and Energy Consumption. J. Manuf. Syst. 2022, 62, 925–938. [Google Scholar] [CrossRef]

- Li, B.; Tian, X.; Zhang, M. Modeling and Multi-Objective Optimization Method of Machine Tool Energy Consumption Considering Tool Wear. Int. J. Precis. Eng. Manuf.-Green. Technol. 2022, 9, 127–141. [Google Scholar] [CrossRef]

- Sharma, S.; Das, P.P.; Ladakhi, T.Y.; Pradhan, B.B.; Phipon, R. Performance Evaluation and Parametric Optimization of Turning Operation of Ti6Al-4V Alloy Under Dry and Minimum Quantity Lubrication Cutting Environments. J. Mater. Eng. Perform. 2023, 32, 5353–5364. [Google Scholar] [CrossRef]

- Singh, J.; Gill, S.S.; Mahajan, A. Experimental Investigation and Optimizing of Turning Parameters for Machining of Al7075-T6 Aerospace Alloy for Reducing the Tool Wear and Surface Roughness. J. Mater. Eng. Perform. 2023, 33, 8745–8756. [Google Scholar] [CrossRef]

- Abellán-Nebot, J.V.; Vila Pastor, C.; Siller, H.R. A Review of the Factors Influencing Surface Roughness in Machining and Their Impact on Sustainability. Sustainability 2024, 16, 1917. [Google Scholar] [CrossRef]

- Mou, W.; Zhu, S. Vibration, Tool Wear and Surface Roughness Characteristics in Turning of Inconel 718 Alloy with Ceramic Insert Under LN2 Machining. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 1–12. [Google Scholar] [CrossRef]

- Gaitonde, V.N.; Karnik, S.R.; Figueira, L.; Paulo Davim, J. Machinability Investigations in Hard Turning of AISI D2 Cold Work Tool Steel with Conventional and Wiper Ceramic Inserts. Int. J. Refract. Met. Hard Mater. 2009, 27, 754–763. [Google Scholar] [CrossRef]

- Chinchanikar, S.; Choudhury, S.K. Investigations on Machinability Aspects of Hardened AISI 4340 Steel at Different Levels of Hardness Using Coated Carbide Tools. Int. J. Refract. Met. Hard Mater. 2013, 38, 124–133. [Google Scholar] [CrossRef]

- Abainia, S.; Ouelaa, N. Experimental Study of the Combined Influence of the Tool Geometry Parameters on the Cutting Forces and Tool Vibrations. Int. J. Adv. Manuf. Technol. 2015, 79, 1127–1138. [Google Scholar] [CrossRef]

- Tian, P.; He, L.; Zhou, T.; Du, F.; Zou, Z.; Zhou, X. Experimental Characterization of the Performance of MQL-Assisted Turning of Solution Heat-Treated and Aged Inconel 718 Alloy. Int. J. Adv. Manuf. Technol. 2023, 125, 3839–3851. [Google Scholar] [CrossRef]

- Gao, H.; Ma, B.; Singh, R.P.; Yang, H. Areal Surface Roughness of AZ31B Magnesium Alloy Processed by Dry Face Turning: An Experimental Framework Combined with Regression Analysis. Materials 2020, 13, 2303. [Google Scholar] [CrossRef]

- Dahbi, S.; Ezzine, L.; El Moussami, H. Modeling of Cutting Performances in Turning Process Using Multiple Regression Method. Int. J. Eng. Res. Afr. 2017, 29, 54–69. [Google Scholar] [CrossRef]

- Kechagias, J.D.; Aslani, K.E.; Fountas, N.A.; Vaxevanidis, N.M.; Manolakos, D.E. A Comparative Investigation of Taguchi and Full Factorial Design for Machinability Prediction in Turning of a Titanium Alloy. Measurement 2020, 151, 107213. [Google Scholar] [CrossRef]

- Stamenković, O.S.; Kostić, M.D.; Radosavljević, D.B.; Veljković, V.B. Comparison of Box-Behnken, Face Central Composite and Full Factorial Designs in Optimization of Hempseed Oil Extraction by n-Hexane: A Case Study. Period. Polytech. Chem. Eng. 2018, 62, 359–367. [Google Scholar] [CrossRef]

- Kouahla, I.; Yallese, M.A.; Belhadi, S.; Safi, K.; Nouioua, M. Tool Vibration, Surface Roughness, Cutting Power, and Productivity Assessment Using RSM and GRA Approach During Machining of Inconel 718 with PVD-Coated Carbide Tool. Int. J. Adv. Manuf. Technol. 2022, 122, 1835–1856. [Google Scholar] [CrossRef]

- Awale, A.; Inamdar, K. Multi-Objective Optimization of High-Speed Turning Parameters for Hardened AISI S7 Tool Steel Using Grey Relational Analysis. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 1–17. [Google Scholar] [CrossRef]

- Zhao, X.; Du, X.; Xu, F.; Zuo, D.; Li, Z.; Lu, W.; Zhang, Q. Cutting Parameters Optimization and Cutting Performance of Ti(C,N)-Based Cermets by Reactive Hot-Pressing from Co–Ti–C–BN System in Dry Turning Austenitic Stainless Steels. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 1–11. [Google Scholar] [CrossRef]

- Zhao, Y.; Cui, L.; Sivalingam, V.; Sun, J. Understanding Machining Process Parameters and Optimization of High-Speed Turning of NiTi SMA Using Response Surface Method (RSM) and Genetic Algorithm (GA). Materials 2023, 16, 5786. [Google Scholar] [CrossRef]

- Myśliwiec, P.; Kubit, A.; Szawara, P. Optimization of 2024-T3 Aluminum Alloy Friction Stir Welding Using Random Forest, XGBoost, and MLP Machine Learning Techniques. Materials 2024, 17, 1452. [Google Scholar] [CrossRef]

- Vukelic, D.; Simunovic, K.; Kanovic, Z.; Saric, T.; Tadic, B.; Simunovic, G. Multi-Objective Optimization of Steel AISI 1040 Dry Turning Using Genetic Algorithm. Neural Comput. Appl. 2021, 33, 12445–12475. [Google Scholar] [CrossRef]

- Mia, M.; Khan, M.A.; Rahman, S.S.; Dhar, N.R. Mono-Objective and Multi-Objective Optimization of Performance Parameters in High Pressure Coolant Assisted Turning of Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2017, 90, 109–118. [Google Scholar] [CrossRef]

- Laouissi, A.; Yallese, M.A.; Belbah, A.; Belhadi, S.; Haddad, A. Investigation, Modeling, and Optimization of Cutting Parameters in Turning of Gray Cast Iron Using Coated and Uncoated Silicon Nitride Ceramic Tools. Based on ANN, RSM, and GA Optimization. Int. J. Adv. Manuf. Technol. 2019, 101, 523–548. [Google Scholar] [CrossRef]

- Laouissi, A.; Nouioua, M.; Yallese, M.A.; Abderazek, H.; Maouche, H.; Bouhalais, M.L. Machinability Study and ANN-MOALO-Based Multi-Response Optimization During Eco-Friendly Machining of EN-GJL-250 Cast Iron. Int. J. Adv. Manuf. Technol. 2021, 117, 1179–1192. [Google Scholar] [CrossRef]

- Nouioua, M.; Laouissi, A.; Yallese, M.A.; Khettabi, R.; Belhadi, S. Multi-Response Optimization Using Artificial Neural Network-Based GWO Algorithm for High Machining Performance with Minimum Quantity Lubrication. Int. J. Adv. Manuf. Technol. 2021, 116, 3765–3778. [Google Scholar] [CrossRef]

- Safi, K.; Yallese, M.A.; Belhadi, S.; Mabrouki, T.; Laouissi, A. Tool Wear, 3D Surface Topography, and Comparative Analysis of GRA, MOORA, DEAR, and WASPAS Optimization Techniques in Turning of Cold Work Tool Steel. Int. J. Adv. Manuf. Technol. 2022, 121, 701–721. [Google Scholar] [CrossRef]

- Nouioua, M.; Laouissi, A.; Brahami, R.; Blaoui, M.M.; Hammoudi, A.; Yallese, M.A. Evaluation of: MOSSA, MOALO, MOVO and MOGWO Algorithms in Green Machining to Enhance the Turning Performances of X210Cr12 Steel. Int. J. Adv. Manuf. Technol. 2022, 120, 2135–2150. [Google Scholar] [CrossRef]

- ISO 5610-1:2010; Holders with Rectangular Shanks for Cutting Inserts, Part 1—General Review, Correlation, and Parameter Definition. ISO: Geneva, Switzerland, 2010.

- Chihaoui, S.; Yallese, M.A.; Belhadi, S.; Belbah, A.; Safi, K.; Haddad, A. Coated CBN Cutting Tool Performance in Green Turning of Gray Cast Iron EN-GJL-250: Modeling and Optimization. Int. J. Adv. Manuf. Technol. 2021, 113, 3643–3665. [Google Scholar] [CrossRef]

- Chihaoui, S. Evaluation Des Performances Des Outils En Cbn Revêtus Lors De L’usinage À Sec De La Fonte Grise—Approche Statistique Et Optimisation Multi Objectifs. Ph.D. Thesis, 8 Mai 1945 University, Guelma, Algeria, 2021. [Google Scholar]

- Kellouche, Y.; Tayeh, B.A.; Chetbani, Y.; Zeyad, A.M.; Mostafa, S.A. Comparative Study of Different Machine Learning Approaches for Predicting the Compressive Strength of Palm Fuel Ash Concrete. J. Build. Eng. 2024, 88, 109187. [Google Scholar] [CrossRef]

- Abidi, A.; Ben Salem, S.; Yallese, M.A. Machining Quality of High Speed Helical Milling of Carbon Fiber Reinforced Plastics. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 236, 1049–1066. [Google Scholar] [CrossRef]

- Del Pino, G.G.; Bezazi, A.; Boumediri, H.; Kieling, A.C.; Garcia, S.D.; Torres, A.R.; De Souza Soares, R.; De Macêdo Neto, J.C.; Dehaini, J.; Panzera, T.H. Optimal Tensile Properties of Biocomposites Made of Treated Amazonian Curauá Fibres Using Taguchi Method. Mater. Res. 2021, 24, e20210326. [Google Scholar] [CrossRef]

- Mirjalili, S.; Mirjalili, S.M.; Lewis, A. Grey Wolf Optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef]

- Nadimi-Shahraki, M.H.; Taghian, S.; Mirjalili, S. An Improved Grey Wolf Optimizer for Solving Engineering Problems. Expert. Syst. Appl. 2021, 166, 113917. [Google Scholar] [CrossRef]

- Elsayed, S.M.; Sarker, R.A.; Essam, D.L. A New Genetic Algorithm for Solving Optimization Problems. Eng. Appl. Artif. Intell. 2014, 27, 57–69. [Google Scholar] [CrossRef]

- Yuan, Y.; Wang, W.; Pang, W. A Genetic Algorithm with Tree-Structured Mutation for Hyperparameter Optimisation of Graph Neural Networks. In Proceedings of the 2021 IEEE Congress on Evolutionary Computation, CEC 2021, Krakow, Poland, 28 June–1 July 2021; pp. 482–489. [Google Scholar] [CrossRef]

- Touati, S.; Boumediri, H.; Karmi, Y.; Chitour, M.; Boumediri, K.; Zemmouri, A.; Moussa, A.; Fernandes, F. Performance Analysis of Steel W18CR4V Grinding Using RSM, DNN-GA, KNN, LM, DT, SVM Models, and Optimization via Desirability Function and MOGWO. Heliyon 2025, 11, e42640. [Google Scholar] [CrossRef]

- Reffas, O.; Boumediri, H.; Karmi, Y.; Kahaleras, M.S.; Bousba, I.; Aissa, L. Statistical Analysis and Predictive Modeling of Cutting Parameters in EN-GJL-250 Cast Iron Turning: Application of Machine Learning and MOALO Optimization. Int. J. Adv. Manuf. Technol. 2025, 137, 1991–2009. [Google Scholar] [CrossRef]

- Gaytan, A.; Begovich-Mendoza, O.; Arana-Daniel, N. Training of Convolutional Neural Networks for Image Classification with Fully Decoupled Extended Kalman Filter. Algorithms 2024, 17, 243. [Google Scholar] [CrossRef]

- Sum, J.; Leung, C.S.; Young, G.H.; Kan, W.K. On the Kalman Filtering Method in Neural-Network Training and Pruning. IEEE Trans. Neural Netw. 1999, 10, 161–166. [Google Scholar] [CrossRef]

- Crassidis, J.L.; Junkins, J.L. Optimal Estimation of Dynamic Systems; Chapman and Hall/CRC: Boca Raton, FL, USA, 2012. [Google Scholar]

- Haykin, S. Neural Networks: A Comprehensive Foundation by Simon Haykin. Knowl. Eng. Rev. 1999, 13, 409–412. [Google Scholar]

- Touati, S.; Ghelani, L.; Zemmouri, A.; Boumediri, H. Optimization of Gas Carburizing Treatment Parameters of Low Carbon Steel Using Taguchi and Grey Relational Analysis (TA-GRA). Int. J. Adv. Manuf. Technol. 2022, 120, 7937–7949. [Google Scholar] [CrossRef]

- Touati, S.; Boumediri, H.; Mansouri, K.; Chitour, M.; Reffas, O.; Karmi, Y.; Boumediri, K.; Zemmouri, A. Optimization of Cutting Conditions for the Metallic Surfaces of 50CrNi3Mn Alloy Steel Using Box-Behnken Design, ANOVA, and Desirability Function (Box-ANOVA-DF). J. Nano-Electron. Phys. 2025, 17, 1004. [Google Scholar] [CrossRef]

- Mirjalili, S.; Saremi, S.; Mirjalili, S.M.; Coelho, L.D.S. Multi-Objective Grey Wolf Optimizer: A Novel Algorithm for Multi-Criterion Optimization. Expert. Syst. Appl. 2016, 47, 106–119. [Google Scholar] [CrossRef]

| Parameters | Level | |||

|---|---|---|---|---|

| 1 | 2 | 3 | ||

| Type of tools | m | 1 | 2 | - |

| Depth of cut | ap (mm) | 0.25 | 0.5 | 0.75 |

| Feed rate | f (mm/rev) | 0.08 | 0.14 | 0.2 |

| Cutting speed | Vc (m/min) | 260 | 370 | 530 |

| N° | Input Factors | Output Parameters | |||||

|---|---|---|---|---|---|---|---|

| m | ap (mm) | f (mm/rev) | Vc (m/min) | Fr (N) | Ra (µm) | Pc (W) | |

| 1 | 1 | 0.25 | 0.08 | 260 | 124.65 | 0.82 | 541.61 |

| 2 | 1 | 0.25 | 0.08 | 370 | 107.41 | 0.77 | 664.44 |

| 3 | 1 | 0.25 | 0.08 | 530 | 101.78 | 0.72 | 896.11 |

| 4 | 1 | 0.25 | 0.14 | 260 | 157.08 | 1.29 | 680.57 |

| 5 | 1 | 0.25 | 0.14 | 370 | 136.31 | 0.91 | 839.77 |

| 6 | 1 | 0.25 | 0.14 | 530 | 133.06 | 0.83 | 1182.64 |

| 7 | 1 | 0.25 | 0.2 | 260 | 172.87 | 1.53 | 745.43 |

| 8 | 1 | 0.25 | 0.2 | 370 | 161.60 | 1.39 | 1000.93 |

| 9 | 1 | 0.25 | 0.2 | 530 | 158.15 | 1.18 | 1397.22 |

| 10 | 1 | 0.5 | 0.08 | 260 | 202.30 | 0.75 | 877.18 |

| 11 | 1 | 0.5 | 0.08 | 370 | 169.46 | 0.73 | 1052.04 |

| 12 | 1 | 0.5 | 0.08 | 530 | 147.73 | 0.70 | 1301.71 |

| 13 | 1 | 0.5 | 0.14 | 260 | 323.52 | 1.35 | 1411.42 |

| 14 | 1 | 0.5 | 0.14 | 370 | 314.48 | 0.88 | 1947.25 |

| 15 | 1 | 0.5 | 0.14 | 530 | 291.86 | 0.79 | 2580.65 |

| 16 | 1 | 0.5 | 0.2 | 260 | 364.11 | 1.78 | 1583.53 |

| 17 | 1 | 0.5 | 0.2 | 370 | 346.99 | 1.43 | 2130.87 |

| 18 | 1 | 0.5 | 0.2 | 530 | 333.84 | 1.27 | 2942.99 |

| 19 | 1 | 0.75 | 0.08 | 260 | 327.16 | 0.93 | 1416.84 |

| 20 | 1 | 0.75 | 0.08 | 370 | 312.20 | 0.85 | 1921.57 |

| 21 | 1 | 0.75 | 0.08 | 530 | 297.35 | 0.71 | 2622.97 |

| 22 | 1 | 0.75 | 0.14 | 260 | 445.56 | 1.31 | 1929.74 |

| 23 | 1 | 0.75 | 0.14 | 370 | 442.81 | 1.21 | 2733.56 |

| 24 | 1 | 0.75 | 0.14 | 530 | 421.40 | 1.06 | 3725.98 |

| 25 | 1 | 0.75 | 0.2 | 260 | 536.65 | 1.79 | 2333.46 |

| 26 | 1 | 0.75 | 0.2 | 370 | 515.17 | 1.58 | 3189.26 |

| 27 | 1 | 0.75 | 0.2 | 530 | 490.58 | 1.40 | 4325.81 |

| 28 | 2 | 0.25 | 0.08 | 260 | 70.85 | 0.86 | 307.49 |

| 29 | 2 | 0.25 | 0.08 | 370 | 69.36 | 0.72 | 427.16 |

| 30 | 2 | 0.25 | 0.08 | 530 | 56.18 | 0.64 | 498.78 |

| 31 | 2 | 0.25 | 0.14 | 260 | 116.01 | 1.16 | 500.32 |

| 32 | 2 | 0.25 | 0.14 | 370 | 110.93 | 0.91 | 683.06 |

| 33 | 2 | 0.25 | 0.14 | 530 | 103.91 | 0.83 | 919.44 |

| 34 | 2 | 0.25 | 0.2 | 260 | 156.50 | 1.86 | 677.29 |

| 35 | 2 | 0.25 | 0.2 | 370 | 145.78 | 1.76 | 895.13 |

| 36 | 2 | 0.25 | 0.2 | 530 | 143.20 | 1.66 | 1277.12 |

| 37 | 2 | 0.5 | 0.08 | 260 | 158.40 | 0.55 | 685.28 |

| 38 | 2 | 0.5 | 0.08 | 370 | 148.26 | 0.52 | 917.54 |

| 39 | 2 | 0.5 | 0.08 | 530 | 140.39 | 0.45 | 1241.25 |

| 40 | 2 | 0.5 | 0.14 | 260 | 215.05 | 0.88 | 935.83 |

| 41 | 2 | 0.5 | 0.14 | 370 | 202.97 | 0.81 | 1252.28 |

| 42 | 2 | 0.5 | 0.14 | 530 | 189.85 | 0.77 | 1669.62 |

| 43 | 2 | 0.5 | 0.2 | 260 | 530.60 | 1.65 | 2305.69 |

| 44 | 2 | 0.5 | 0.2 | 370 | 253.60 | 1.65 | 1581.76 |

| 45 | 2 | 0.5 | 0.2 | 530 | 236.05 | 1.65 | 2094.45 |

| 46 | 2 | 0.75 | 0.08 | 260 | 211.71 | 0.62 | 928.85 |

| 47 | 2 | 0.75 | 0.08 | 370 | 219.77 | 0.54 | 1359.93 |

| 48 | 2 | 0.75 | 0.08 | 530 | 196.56 | 0.47 | 1749.49 |

| 49 | 2 | 0.75 | 0.14 | 260 | 349.67 | 0.87 | 1505.57 |

| 50 | 2 | 0.75 | 0.14 | 370 | 350.78 | 0.80 | 2155.17 |

| 51 | 2 | 0.75 | 0.14 | 530 | 318.01 | 0.77 | 2812.83 |

| 52 | 2 | 0.75 | 0.2 | 260 | 424.48 | 1.53 | 1835.91 |

| 53 | 2 | 0.75 | 0.2 | 370 | 378.36 | 1.50 | 2321.90 |

| 54 | 2 | 0.75 | 0.2 | 530 | 382.82 | 1.43 | 3387.45 |

| Source | Sum of Squares | df | Mean Square | F-Value | p-Value | Remarks | |

|---|---|---|---|---|---|---|---|

| Fr | Model | 1.215 × 106 | 17 | 71,469.11 | 66.61 | <0.0001 | Significant |

| A-m | 4.234 × 105 | 2 | 2.117 × 105 | 197.29 | <0.0001 | Significant | |

| B-ap | 5.076 × 105 | 1 | 5.076 × 105 | 473.07 | <0.0001 | Significant | |

| C-f | 2.097 × 105 | 1 | 2.097 × 105 | 195.48 | <0.0001 | Significant | |

| D-Vc | 16,719.35 | 1 | 16,719.35 | 15.58 | 0.0002 | Significant | |

| AB | 68,954.79 | 2 | 34,477.40 | 32.13 | <0.0001 | Significant | |

| AC | 22,730.86 | 2 | 11,365.43 | 10.59 | 0.0001 | Significant | |

| AD | 1334.32 | 2 | 667.16 | 0.6218 | 0.5402 | Not Significant | |

| BC | 23,839.14 | 1 | 23,839.14 | 22.22 | <0.0001 | Significant | |

| BD | 221.47 | 1 | 221.47 | 0.2064 | 0.6512 | Not Significant | |

| CD | 2043.71 | 1 | 2043.71 | 1.90 | 0.1724 | Not Significant | |

| B2 | 324.03 | 1 | 324.03 | 0.3020 | 0.5846 | Not Significant | |

| C2 | 1261.97 | 1 | 1261.97 | 1.18 | 0.2823 | Not Significant | |

| D2 | 1277.98 | 1 | 1277.98 | 1.19 | 0.2793 | Not Significant | |

| Residual | 67,595.95 | 63 | 1072.95 | ||||

| Cor Total | 1.283 × 106 | 80 | |||||

| Ra | Model | 28.11 | 17 | 1.65 | 40.53 | <0.0001 | Significant |

| A-m | 8.16 | 2 | 4.08 | 99.99 | <0.0001 | Significant | |

| B-ap | 0.0066 | 1 | 0.0066 | 0.1611 | 0.6895 | Not Significant | |

| C-f | 13.85 | 1 | 13.85 | 339.55 | <0.0001 | Significant | |

| D-Vc | 2.85 | 1 | 2.85 | 69.76 | <0.0001 | Significant | |

| AB | 0.2971 | 2 | 0.1485 | 3.64 | 0.0319 | Not Significant | |

| AC | 0.7721 | 2 | 0.3860 | 9.46 | 0.0003 | Significant | |

| AD | 1.73 | 2 | 0.8629 | 21.15 | <0.0001 | Not Significant | |

| BC | 1.550 × 10−6 | 1 | 1.550 × 10−6 | 0.0000 | 0.9951 | Not Significant | |

| BD | 0.0501 | 1 | 0.0501 | 1.23 | 0.2719 | Not Significant | |

| CD | 0.0447 | 1 | 0.0447 | 1.10 | 0.2993 | Not Significant | |

| B2 | 0.0010 | 1 | 0.0010 | 0.0239 | 0.8775 | Not Significant | |

| C2 | 0.0365 | 1 | 0.0365 | 0.8935 | 0.3482 | Not Significant | |

| D2 | 0.3654 | 1 | 0.3654 | 8.96 | 0.0039 | Not Significant | |

| Residual | 2.57 | 63 | 0.0408 | ||||

| Cor Total | 30.68 | 80 | |||||

| Pc | Model | 5.757 × 107 | 17 | 3.386 × 106 | 101.70 | <0.0001 | Significant |

| A-m | 1.823 × 107 | 2 | 9.116 × 106 | 273.77 | <0.0001 | Significant | |

| B-ap | 2.109 × 107 | 1 | 2.109 × 107 | 633.32 | <0.0001 | Significant | |

| C-f | 8.355 × 106 | 1 | 8.355 × 106 | 250.89 | <0.0001 | Significant | |

| D-Vc | 6.718 × 106 | 1 | 6.718 × 106 | 201.75 | <0.0001 | Significant | |

| AB | 3.058 × 106 | 2 | 1.529 × 106 | 45.92 | <0.0001 | Significant | |

| AC | 8.721 × 105 | 2 | 4.361 × 105 | 13.10 | <0.0001 | Significant | |

| AD | 1.464 × 106 | 2 | 7.320 × 105 | 21.98 | <0.0001 | Significant | |

| BC | 9.832 × 105 | 1 | 9.832 × 105 | 29.53 | <0.0001 | Significant | |

| BD | 1.472 × 106 | 1 | 1.472 × 106 | 44.20 | <0.0001 | Significant | |

| CD | 3.444 × 105 | 1 | 3.444 × 105 | 10.34 | 0.0021 | Significant | |

| B2 | 1747.23 | 1 | 1747.23 | 0.0525 | 0.8196 | Not Significant | |

| C2 | 76,489.60 | 1 | 76,489.60 | 2.30 | 0.1346 | Not Significant | |

| D2 | 3871.05 | 1 | 3871.05 | 0.1163 | 0.7343 | Not Significant | |

| Residual | 2.098 × 106 | 63 | 33,299.08 | ||||

| Cor Total | 5.967 × 107 | 80 |

| Output | Std. Dev. | Mean | C.V. % | R2 | R2-Adjusted | R2-Predicted | Adeq Precision |

|---|---|---|---|---|---|---|---|

| Fr | 32.76 | 206.44 | 15.87 | 0.95 | 0.93 | 0.93 | 32.01 |

| Ra | 0.2020 | 1.30 | 15.57 | 0.92 | 0.89 | 0.87 | 27.75 |

| Pc | 182.48 | 1313.48 | 13.89 | 0.97 | 0.96 | 0.94 | 45.84 |

| Hidden Layers | Hidden Layer Size | Learning Algorithms | Activation Functions |

|---|---|---|---|

| Min: 1 Max: 10 | Min: 1 Max: 10 | trainlm: Levenberg–Marquardt backpropagation | Compet: Competitive transfer function |

| trainbr: Bayesian Regulation backpropagation | elliotsig: Elliot sigmoid transfer function | ||

| trainbfg: BFGS quasi-Newton backpropagation | hardlim: Positive hard limit transfer function | ||

| traincgb: Conjugate gradient backpropagation with Powell–Beale restarts | hardlims: Symmetric hard limit transfer function | ||

| traincgf: Conjugate gradient backpropagation with Fletcher–Reeves updates | logsig: Logarithmic sigmoid transfer function | ||

| traincgp: Conjugate gradient backpropagation with Polak–Ribiere updates | netinv: Inverse transfer function | ||

| traingd: Gradient descent backpropagation | poslin: Positive linear transfer function | ||

| traingda: Gradient descent with adaptive lr backpropagation | purelin: Linear transfer function | ||

| traingdm: Gradient descent with momentum | radbas: Radial basis transfer function | ||

| Traingdx: Gradient descent w/momentum and adaptive lr backpropagation | radbasn: Radial basis normalized transfer function | ||

| trainoss: One-step secant backpropagation | satlin: Positive saturating linear transfer function | ||

| trainrp: RPROP backpropagation | satlins: Symmetric saturating linear transfer function | ||

| trainscg: Scaled conjugate gradient backpropagation | softmax: Soft max transfer function | ||

| tansig: Symmetric sigmoid transfer function | |||

| tribas: Triangular basis transfer function |

| Criteria | Formula |

|---|---|

| RMSE | |

| MAPE (%) | |

| MAE | |

| R2 | |

| OBJ | |

| SI |

| Parameter | DNN Models | HLayer Number | HLayer Size | Learning-Algorithm | Act-Fct |

|---|---|---|---|---|---|

| Fr | DNN-IGWO | 6 | 5 | trainbr | logsig |

| 10 | softmax | ||||

| 2 | tribas | ||||

| 9 | netinv | ||||

| 5 | purelin | ||||

| 3 | netinv | ||||

| Ra | DNN-IGWO | 2 | 7 | trainbr | radbas |

| 7 | radbas | ||||

| Pc | DNN-IGWO | 3 | 8 | trainbr | radbas |

| 3 | elliotsig | ||||

| 4 | radbas |

| Parameter | DNN Models | HLayer Number | HLayer Size | Learning-Algorithm | Act-Fct |

|---|---|---|---|---|---|

| Fr | DNN-GA | 3 | 4 | trainbr | radbas |

| 9 | elliotsig | ||||

| 10 | radbas | ||||

| Ra | DNN-GA | 2 | 8 | trainbr | elliotsig |

| 10 | elliotsig | ||||

| Pc | DNN-GA | 3 | 8 | trainbr | radbas |

| 3 | elliotsig | ||||

| 4 | radbas |

| Parameter | DNN Models | HLayer Number | HLayer Size | Learning-Algorithm | Act-Fct |

|---|---|---|---|---|---|

| Fr | DNN-EKF | 2 | 3 | trainlm | tansig |

| 8 | tansig | ||||

| Ra | DNN-EKF | 2 | 7 | trainlm | tansig |

| 10 | tansig | ||||

| Pc | DNN-EKF | 2 | 7 | trainlm | tansig |

| 4 | tansig |

| Number | m | ap | f | Vc | Fr | Ra | Pc | Desirability |

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 0.250 | 0.080 | 437.762 | 46.908 | 0.520 | 389.322 | 0.978 |

| 2 | 2 | 0.250 | 0.080 | 438.086 | 46.885 | 0.520 | 389.467 | 0.978 |

| 3 | 2 | 0.250 | 0.080 | 437.681 | 46.915 | 0.520 | 389.289 | 0.978 |

| 4 | 2 | 0.250 | 0.080 | 438.364 | 46.865 | 0.520 | 389.597 | 0.978 |

| 5 | 2 | 0.250 | 0.080 | 435.778 | 47.059 | 0.520 | 388.446 | 0.978 |

| 6 | 2 | 0.250 | 0.080 | 440.297 | 46.723 | 0.520 | 390.456 | 0.978 |

| 7 | 2 | 0.250 | 0.080 | 433.456 | 47.237 | 0.520 | 387.421 | 0.978 |

| 8 | 2 | 0.250 | 0.080 | 442.554 | 46.564 | 0.521 | 391.483 | 0.978 |

| 9 | 2 | 0.250 | 0.080 | 431.367 | 47.405 | 0.520 | 386.518 | 0.978 |

| 10 | 2 | 0.250 | 0.080 | 444.596 | 46.424 | 0.521 | 392.412 | 0.978 |

| N° | m | ap | f | Vc | Fr | Ra | Pc |

|---|---|---|---|---|---|---|---|

| 1 | 2 | 0.25 | 0.08 | 530 | 56.18 | 0.64 | 492.55 |

| 2 | 3 | 0.6 | 0.08 | 546 | 42.80 | 0.81 | 389.48 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karmi, Y.; Boumediri, H.; Reffas, O.; Chetbani, Y.; Ataya, S.; Khan, R.; Yallese, M.A.; Laouissi, A. Integration of Hybrid Machine Learning and Multi-Objective Optimization for Enhanced Turning Parameters of EN-GJL-250 Cast Iron. Crystals 2025, 15, 264. https://doi.org/10.3390/cryst15030264

Karmi Y, Boumediri H, Reffas O, Chetbani Y, Ataya S, Khan R, Yallese MA, Laouissi A. Integration of Hybrid Machine Learning and Multi-Objective Optimization for Enhanced Turning Parameters of EN-GJL-250 Cast Iron. Crystals. 2025; 15(3):264. https://doi.org/10.3390/cryst15030264

Chicago/Turabian StyleKarmi, Yacine, Haithem Boumediri, Omar Reffas, Yazid Chetbani, Sabbah Ataya, Rashid Khan, Mohamed Athmane Yallese, and Aissa Laouissi. 2025. "Integration of Hybrid Machine Learning and Multi-Objective Optimization for Enhanced Turning Parameters of EN-GJL-250 Cast Iron" Crystals 15, no. 3: 264. https://doi.org/10.3390/cryst15030264

APA StyleKarmi, Y., Boumediri, H., Reffas, O., Chetbani, Y., Ataya, S., Khan, R., Yallese, M. A., & Laouissi, A. (2025). Integration of Hybrid Machine Learning and Multi-Objective Optimization for Enhanced Turning Parameters of EN-GJL-250 Cast Iron. Crystals, 15(3), 264. https://doi.org/10.3390/cryst15030264