A Study of the Effects of Mechanical Alloying Fraction, Solution Treatment Temperature and Pre-Straining Degree on the Structure and Properties of a Powder Metallurgy-Produced FeMnSiCrNi Shape Memory Alloy

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

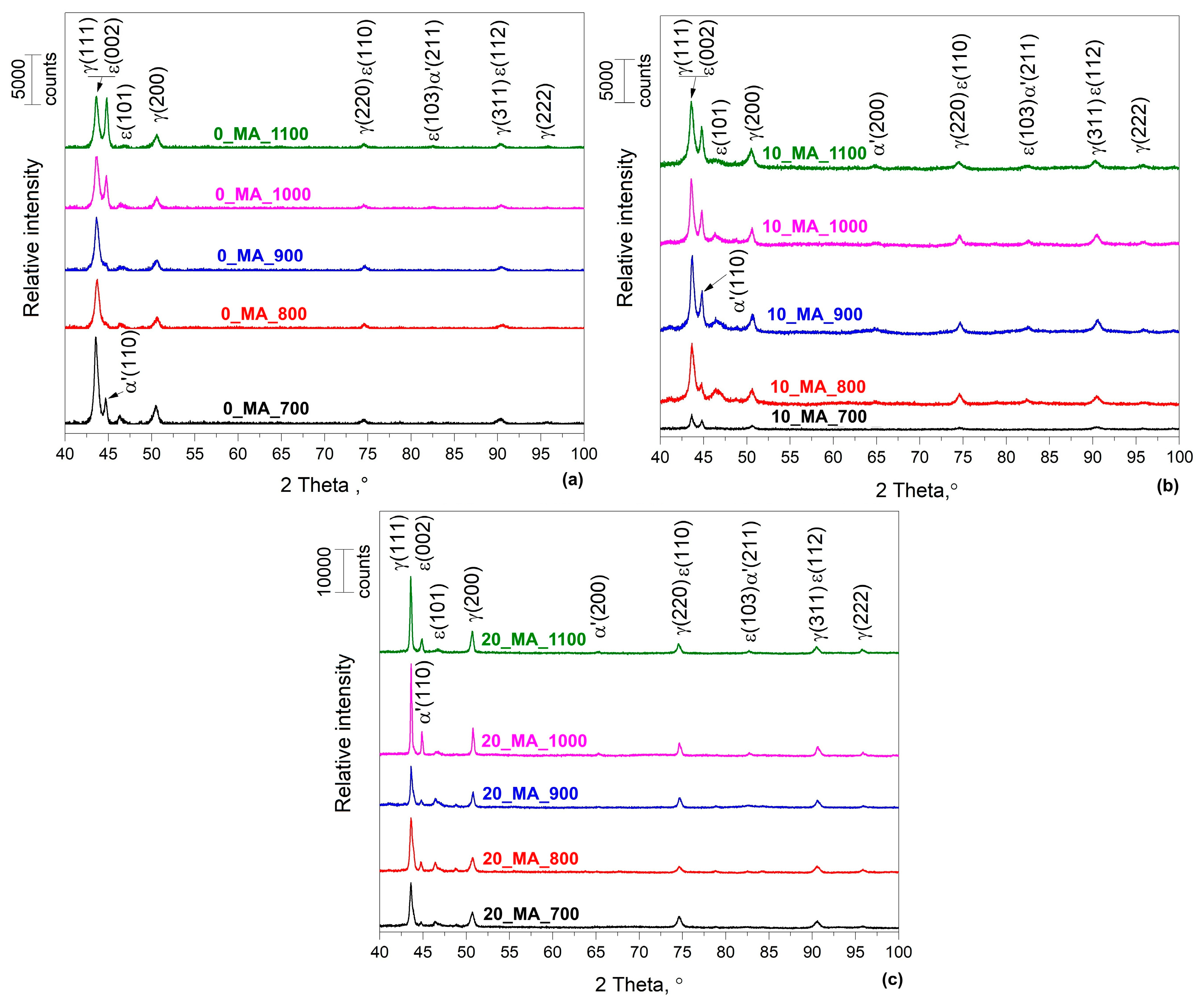

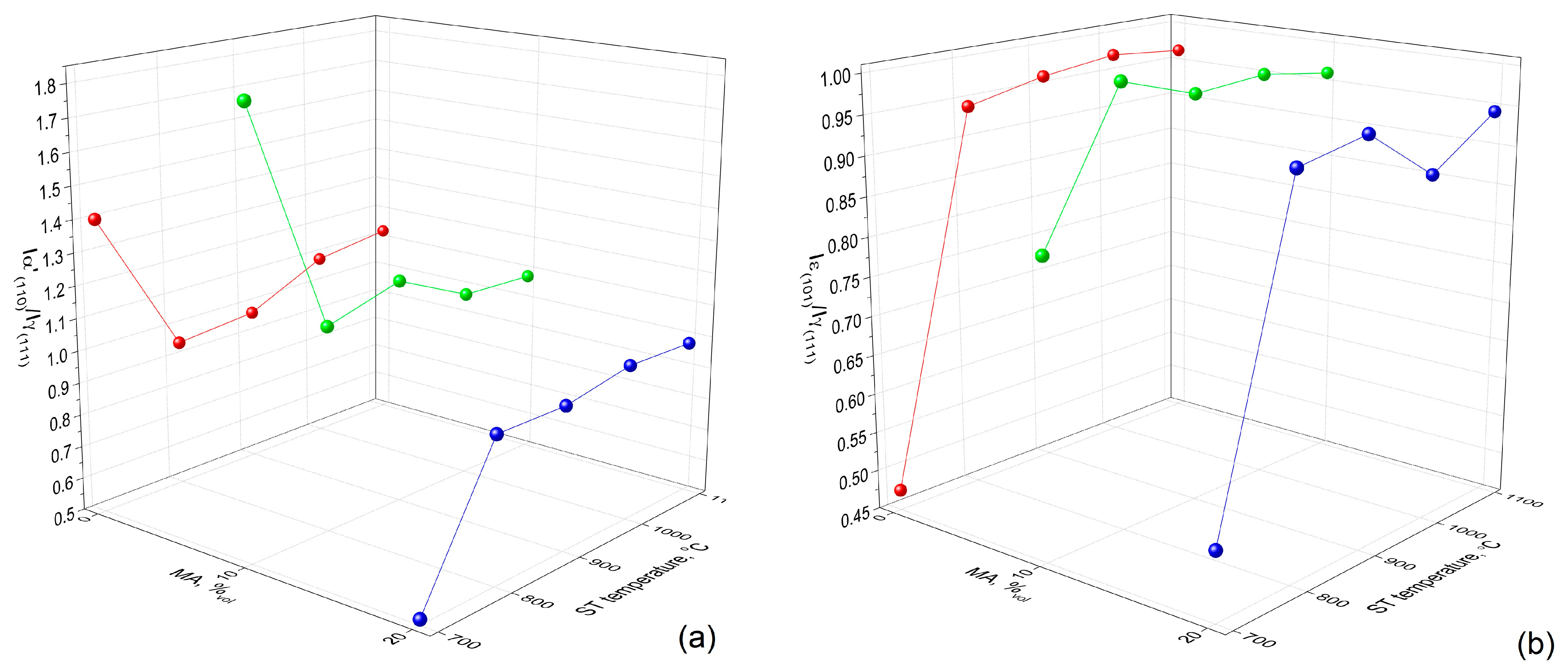

3.1. Mechanical Alloying and Solution Treatment Effects

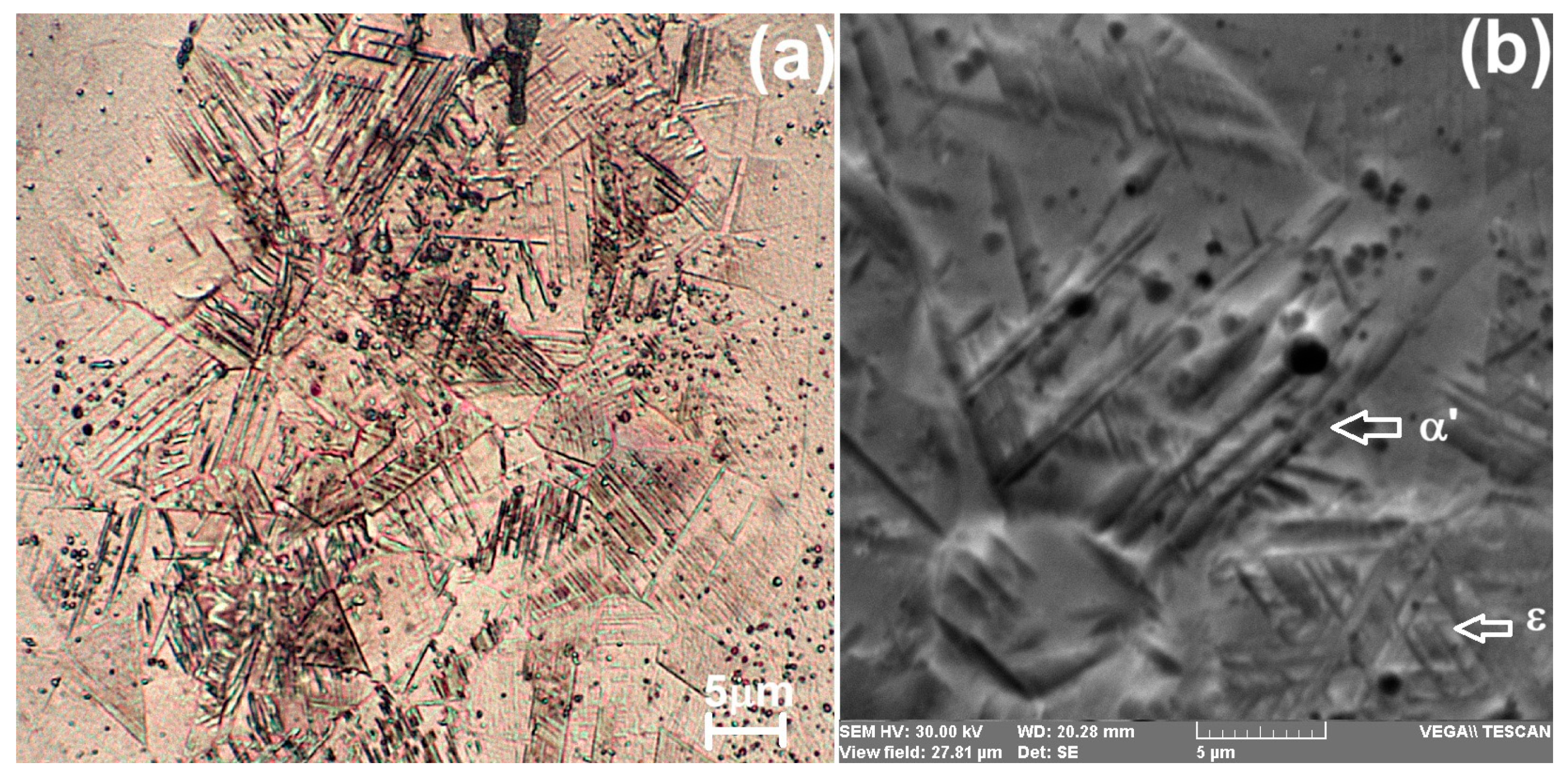

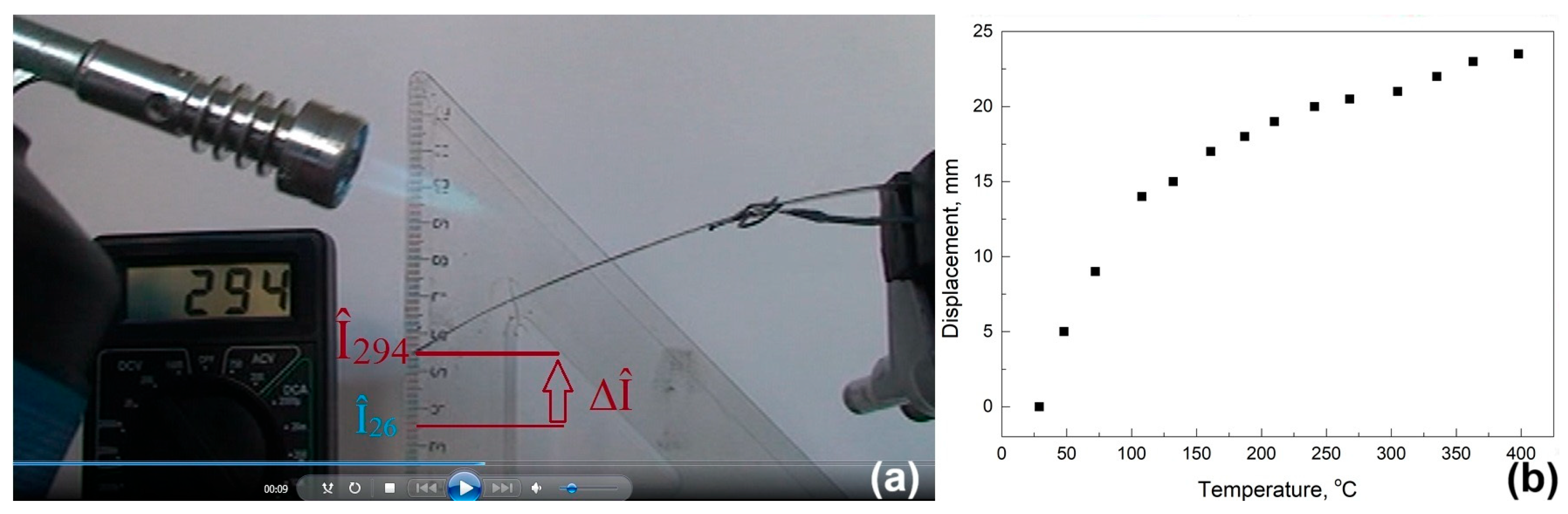

3.2. Tensile Pre-Straining Effects

4. Summary and Conclusions

- The amount of α′—bcc martensite experienced an increasing tendency, which was observed in the evolution of the ratio of the relative intensities of α′(110)/γ(200) being favored by the rise in MA volume fraction and ST temperature;

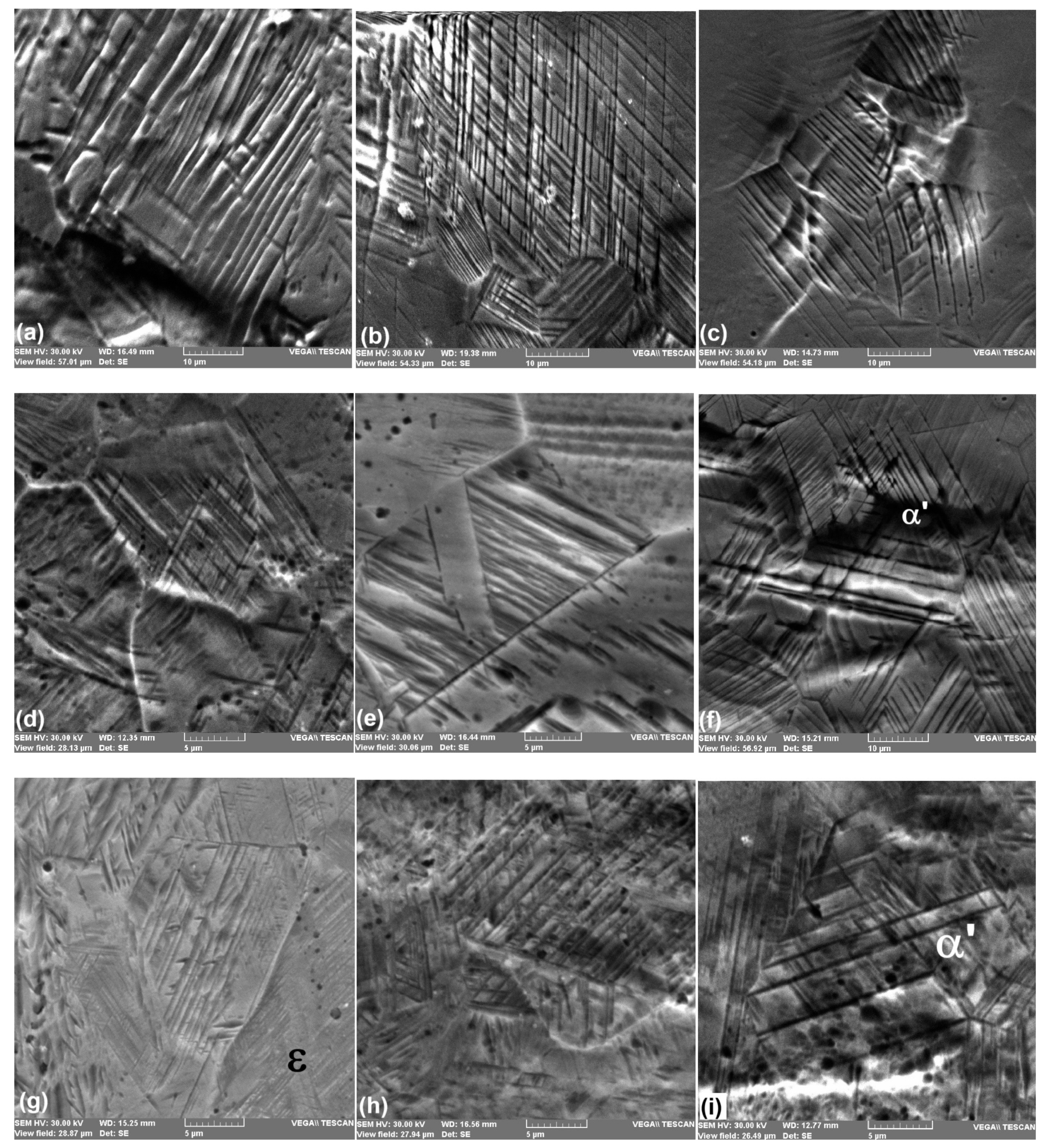

- α′—bcc martensite plates were short lenticular-shaped, with deep surface relief;

- Despite the amount of α′—bcc martensite, which was larger than that of ε—hcp martensite, the specimens could develop free-recovery SME;

- During thermomechanical training, increases in both the recoverable deformation and the displacement rate of specimens’ free end were observed;

- After training, the free end’s displacement exceeded 23 mm, and its rate reached 2 mm/s;

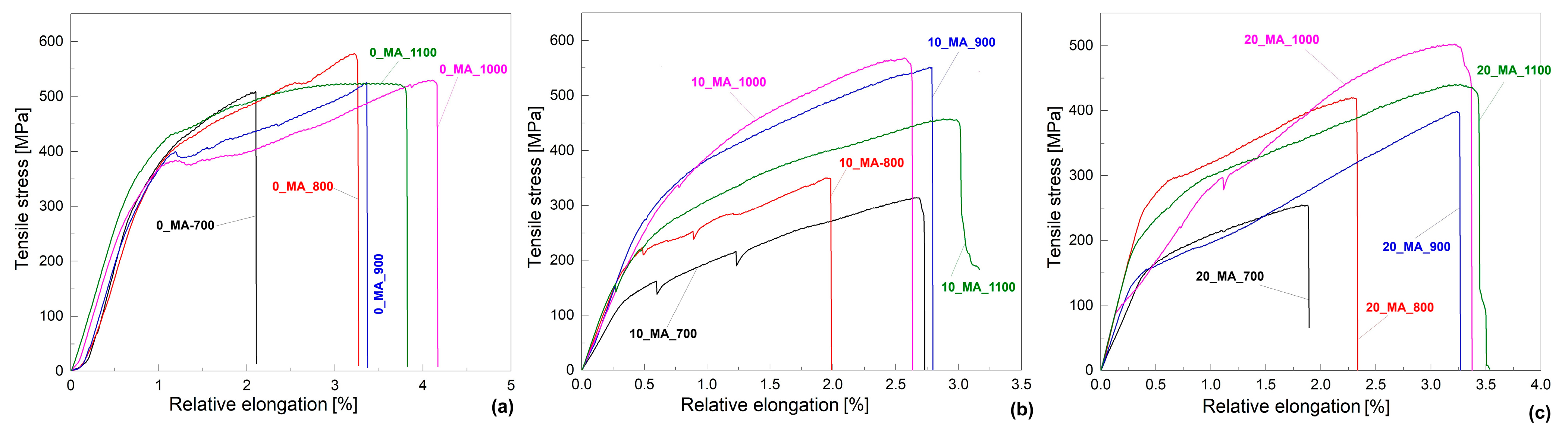

- Due to the large amount of α′—bcc thermally induced martensite, the specimens were brittle and failed at tensile strains between 2 and 4% and ultimate stress between 250 and 650 MPa;

- The evolution in the specimens’ three-phase structure, observed by XRD, caused variations in yield strength and Young’s modulus, as well as total and permanent relative elongations;

- No direct quantitative correlation could be found between the fraction of the bcc phase and the evolution tendencies of the tensile ultimate strains and stresses.

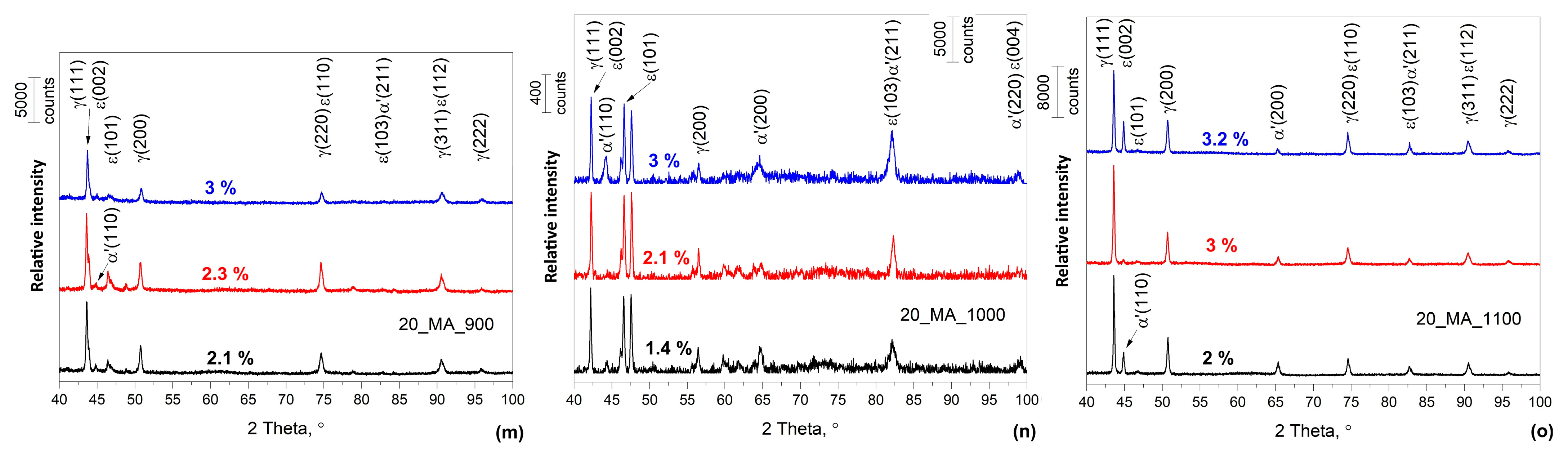

- Regardless of the MA volume fraction, ST temperature and pre-straining degree, the evolution of the relative intensities of α′(110)/γ(200) and ε(101)/γ(200) suggested that the amount of α′—bcc martensite was larger than that of ε—hcp martensite;

- Based on the evolution of the relative intensity of α′(110)/γ(200), with the increase in the pre-straining degree, it can be concluded that the total amount of α′—bcc martensite had a decreasing tendency after pre-straining, compared to the amount of thermally induced martensite determined after solution treatment;

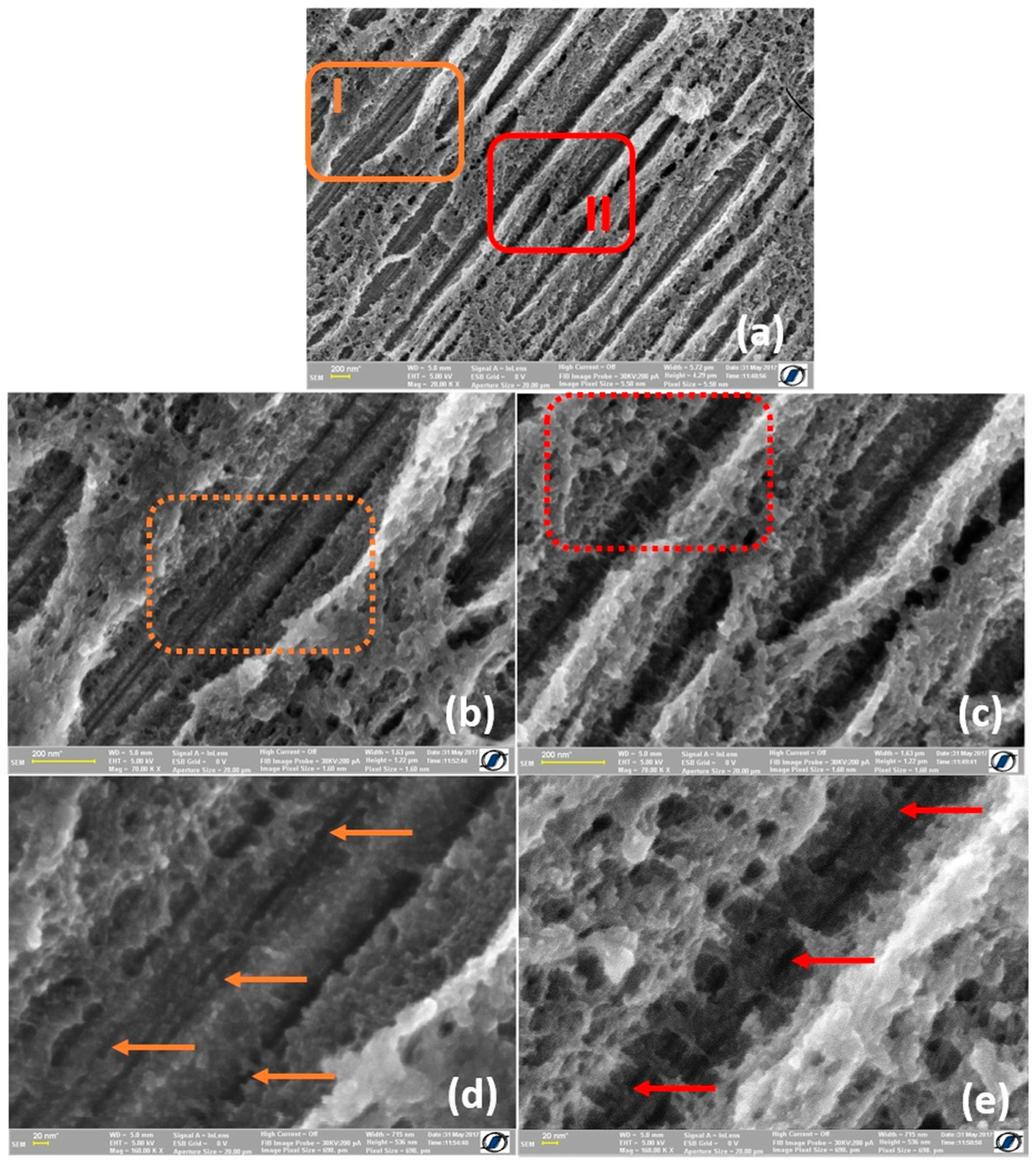

- The internal sub-bands observed by HR-SEM in the nanostructure of α′—bcc thermally induced martensite have the potential to impede the growth of stress-induced martensite during pre-straining.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sato, A.; Chishima, E.; Soma, K.; Mori, T. Shape memory effect in γ⇄ɛ transformation in Fe-30Mn-1Si alloy single crystals. Acta Metall. 1982, 30, 1177–1183. [Google Scholar] [CrossRef]

- Maki, T. Ferrous shape memory alloys. In Shape Memory Materials; Otsuka, K., Wayman, C.M., Eds.; University Press: Cambridge, UK, 1998; pp. 117–132. [Google Scholar]

- Arruda, G.J.; Buono, V.T.L.; Andrade, M.S. The influence of deformation on the microstructure and transformation temperatures of Fe–Mn–Si–Cr–Ni shape memory alloys. Mater. Sci. Eng. A 1999, 273–275, 528–532. [Google Scholar] [CrossRef]

- Otsuka, H.; Yamada, H.; Maruyama, T.; Tanahashi, H.; Matsuda, S.; Murakami, M. Effects of alloying additions on Fe-Mn-Si shape memory alloys. ISIJ Int. 1990, 30, 675–679. [Google Scholar] [CrossRef]

- Moriya, Y.; Kimura, H.; Ishizaki, S.; Hashizume, S.; Suzuki, S.; Suzuki, H.; Sampei, T. Properties of Fe-Cr-Ni-Mn-Si (-Co) shape memory alloys. J. Phys. IV 1991, 4, 433–437. [Google Scholar] [CrossRef]

- Kajiwara, S. Characteristic features of shape memory effect and related transformation behavior in Fe-based alloys. Mater. Sci. Eng. A 1999, 273–275, 67–88. [Google Scholar] [CrossRef]

- Berns, H.; Theisen, W. Ferrous Materials: Steel and Cast Iron; Springer: Berlin/Heidelberg, Germany, 2008; pp. 190–207. [Google Scholar] [CrossRef]

- Pricop, B.; Soyler, A.U.; Ozkal, B.; Bujoreanu, L.G. Powder Metallurgy: An Alternative for FeMnSiCrNi Shape Memory Alloys Processing. Front. Mater. 2020, 7, 247. [Google Scholar] [CrossRef]

- Kim, Y.; Song, Y.-B.; Lee, S.H. Microstructure and inter mediate-temperature mechanical properties of powder metallurgy Ti–6Al–4V alloy prepared by the prealloyed approach. J. Alloys Compd. 2015, 637, 234–241. [Google Scholar] [CrossRef]

- Saito, T.; Kapusta, C.; Takasaki, A. Synthesis and characterization of Fe–Mn–Si shape memory alloy by mechanical alloying and subsequent sintering. Mat. Sci. Eng. A 2014, 592, 88–94. [Google Scholar] [CrossRef]

- Soyler, U.A.; Ozkal, B.; Bujoreanu, L.G. Improved shape memory characteristics of FE-14Mn-6Si-9Cr-5Ni alloy via mechanical alloying. J. Mater. Eng. Perform. 2014, 23, 2357–2361. [Google Scholar] [CrossRef]

- Baghdadi, F.; Uzumcu, A.; Mutlu, I. Production and Nondestructive Characterization of Shape Memory Alloys. Braz. J. Phys. 2022, 52, 175. [Google Scholar] [CrossRef]

- Pricop, B.; Söyler, U.; Özkal, B.; Suru, M.G.; Lohan, N.M.; Comăneci, R.I.; Cimpoeşu, N.; Muşat, V.; Gurău, G.; Istrate, B.; et al. A study of martensite formation in powder metallurgy Fe-Mn-Si-Cr-Ni shape memory alloys. Mater. Today Proc. 2015, 2, 789–792. [Google Scholar] [CrossRef]

- Mihalache, E.; Pricop, B.; Suru, M.G.; Lohan, N.M.; Comaneci, R.I.; Istrate, B.; Özkal, B.; Bujoreanu, L.-G. Factors influencing martensite transitions in Fe-based shape memory alloys. MATEC Web Conf. 2015, 33, 04002. [Google Scholar] [CrossRef]

- Mihalache, E.; Pricop, B.; Comãneci, R.I.; Suru, M.G.; Lohan, N.M.; Mocanu, M.; Özkal, B.; Bujoreanu, L.G. Structural Effects of Thermomechanical Processing on the Static and Dynamic Responses of Powder Metallurgy Fe-Mn-Si Based Shape Memory Alloys. Adv. Sci. Technol. 2017, 97, 153–158. [Google Scholar] [CrossRef]

- Pricop, B.; Mihalache, E.; Stoian, G.; Borza, F.; Özkal, B.; Bujoreanu, L.G. Thermo-mechanical effects caused by martensite formation in powder metallurgy FeMnSiCrNi shape memory alloys. Powder Met. 2018, 61, 348–356. [Google Scholar] [CrossRef]

- Söyler, A.U.; Özkal, B.; Bujoreanu, L.G. Sintering Densification and Microstructural Characterization of Mechanical Alloyed Fe-Mn-Si based Powder Metal System. In Proceedings of the Minerals, Metals and Materials Society, Warrendale, PA, USA, 14–18 February 2010; pp. 785–792. [Google Scholar]

- Söyler, A.U.; Özkal, B.; Bujoreanu, L.G. Investigation of Mechanical Alloying Process Parameters on Fe-Mn-Si Based System. Suppl. Proc. Mater. Process. Energy Mater. 2011, 1, 577–583. [Google Scholar]

- Pricop, B.; Grigoras, M.; Borza, F.; Özkal, B.; Bujoreanu, L.-G. On the Possible Cause of Sudden Storage Modulus Increase during the Heating of PM FeMnSiCrNi SMAs. Nanomaterials 2022, 12, 2342. [Google Scholar] [CrossRef]

- Cimpoesu, N.; Mihalache, E.; Lohan, N.-M.; Suru, M.-G.; Comãneci, R.I.; Özkal, B.; Bujoreanu, L.-G.; Pricop, B. Structural morphological fluctuations induced by thermomechanical treatment in a Fe–Mn–Si shape memory alloy. Met. Sci. Heat Treat. 2018, 60, 471–477. [Google Scholar] [CrossRef]

- Bowman, H.A.; Schoonover, R.M.; Carroll, C.L. A Density Scale Based on Solid Objects. J. Res. Natl. Bur. Standards Sect. A Phys. Chem. 1974, 78, 13–40. [Google Scholar] [CrossRef]

- Pricop, B.; Borza, F.; Ozkal, B.; Bujoreanu, L.G. Influence of Thermal and Mechanical/Powder Processing on Microstructure and Dynamic Stiffness of Fe-Mn-Si-Cr-Ni Shape Memory Alloy. Trans. Indian Inst. Met. 2021, 74, 1409–1418. [Google Scholar] [CrossRef]

- Sava, S.-D.; Lohan, N.-M.; Pricop, B.; Popa, M.; Cimpoeșu, N.; Comăneci, R.-I.; Bujoreanu, L.-G. On the Thermomechanical Behavior of 3D-Printed Specimens of Shape Memory R-PETG. Polymers 2023, 15, 2378. [Google Scholar] [CrossRef]

- Bergeon, N.; Guenin, G. Optical Microscope Study of the y(FCC)↔(HC) Martensitic Transformation of a Fe-16%Mn-9% Cr-5% Si-4% Ni Shape Memory Alloy. J. Phys. IV 1995, 5, 439–444. [Google Scholar] [CrossRef][Green Version]

- Ammonium Bifluoride. Available online: https://pubchem.ncbi.nlm.nih.gov/compound/Ammonium-bifluoride#section=Personal-Protective-Equipment-%28PPE%29 (accessed on 10 January 2025).

- Sun, Q.; Bo, C.; Takeshi, I.; Tao, S. Effect of impact deformation on shape recovery behavior in Fe-Mn-Si shape memory alloy under shape memory training process with cyclic thermo-mechanical loading. Sci. China Technol. Sci. 2021, 64, 1389–1400. [Google Scholar] [CrossRef]

- Park, J.; Lee, S.; Jafter, O.F.; Cheonabc, J.; Lungerich, D. Electron beam-induced demetallation of Fe, Co, Ni, Cu, Zn, Pd, and Pt metalloporphyrins: Insights in e-beam chemistry and metal cluster formations. Phys. Chem. Chem. Phys. 2024, 26, 8051–8061. [Google Scholar] [CrossRef] [PubMed]

- Maji, B.C.; Madangopal, K.; Rama Rao, V.V. The microstructure of an Fe–Mn–Si–Cr–Ni stainless steel shape memory alloy. Metall. Mater. Trans. A 2003, 34, 1029–1042. [Google Scholar] [CrossRef]

- Kirindi, T.; Güler, E.; Dikici, M. Effects of homogenization time on the both martensitic transformations and mechanical properties of Fe–Mn–Si–Cr–Ni shape memory alloy. J. Alloys Compd. 2007, 433, 202–206. [Google Scholar] [CrossRef]

- Sawaguchi, T.; Bujoreanu, L.-G.; Kikuchi, T.; Ogawa, K.; Yin, F. Effects of Nb and C in Solution and in NbC Form on the Transformation-related Internal Friction of Fe–17Mn (mass%) Alloys. ISIJ Int. 2008, 48, 99–106. [Google Scholar] [CrossRef]

- Bakrudeen, A.S.B.; Jeyasimman, D.; Balaji, A. Fabrication and characterization of nanostructured Fe–28Mn–6Si–5Cr shape memory alloy. Int. J. Adv. Appl. Sci. 2022, 9, 33–40. [Google Scholar] [CrossRef]

- Malamud, F.; Castro, F.; Guerrero, L.M.; La Roca, P.; Sade, M.; Baruj, A. High-precision face-centered cubic–hexagonal close-packed volume-change determination in high-Mn steels by X-ray diffraction data refinements. J. Appl. Crystall. 2020, 53, 34–44. [Google Scholar] [CrossRef]

- Singh, D.; Tasaki, W.; Yoshinaka, F.; Takamori, S.; Emura, S.; Tsuchiya, K.; Sawaguchi, T. Unweiling the transformation pathways of hierarchical γ90-εtwin-α′ triple phase structure formation at ε-ε martensite intersection. Mater. Charact. 2023, 205, 113358. [Google Scholar] [CrossRef]

- Baruj, A.; Kikuchi, T.; Kajiwara, S.; Shinya, N. Improvement of shape memory properties of NbC containing Fe–Mn–Si based shape memory alloys by simple thermomechanical treatments. Mater. Sci. Eng. A 2004, 378, 333–336. [Google Scholar] [CrossRef]

- Wen, Y.H.; Li, N.; Xiong, L.R. Composition design principles for Fe–Mn–Si–Cr–Ni based alloys with better shape memory effect and hi gher recovery stress. Mater. Sci. Eng. A 2005, 407, 31–35. [Google Scholar] [CrossRef]

- Yang, Q.; Sun, Q.; Yang, W.; Hao, Q.; Wang, X.; Zhang, B. Correlation between microstructure evolution and mechanical response in a moderately low stacking-fault-energy austenitic Fe–Mn–Si–Al alloy during low-cycle fatigue deformation. Mater. Sci. Eng. A 2021, 824, 141766. [Google Scholar] [CrossRef]

- Akhondzadeh, A.; Zangeneh-Madar, K.; Abbasi, S.M. Influence of annealing temperature on the shape memory effect of Fe–14Mn–5Si–9Cr–5Ni alloy after training treatment. Mater. Sci. Eng. A 2008, 489, 267–272. [Google Scholar] [CrossRef]

- Mihalache, E. Factors That Influence the Martensitic Transformations from Fe Based Shape Memory Alloys. Ph.D. Thesis, “Gheorghe Asachi” Technical University of Iași, Iași, Romania, 2017. (In Romanian). [Google Scholar]

- Spandana, D.; Desai, H.; Chakravarty, D.; Vijay, R.; Hembram, K. Fabrication of a biodegradable Fe-Mn-Si alloy by field assisted sintering. Adv. Powder Technol. 2020, 31, 4577–4584. [Google Scholar] [CrossRef]

- Kuramoto, S.; Kawano, Y.; Mori, Y.; Kobayashi, J.; Emura, S.; Sawaguchi, T. Mechanical Properties and Deformation Behavior in Severely Cold-Rolled FeNiAlC Alloys with Lüders Deformation—Overview with Recent Experimental Results. Mater. Trans. 2023, 64, 1410–1418. [Google Scholar] [CrossRef]

| Specimen | Pre-Strain | α′(110)/ γ(200) | ε(101)/ γ (200) | Specimen | Pre-Strain | α′(110)/ γ(200) | ε(101)/ γ(200) | Specimen | Pre-Strain | α′(110)/ γ(200) | ε(101)/ γ(200) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| % | % | % | % | % | % | % | % | % | |||

| 0_MA_700 | 0 | 1.4054 | 0.4759 | 10_MA_700 | 0 | 1.8274 | 0.8230 | 20_MA_700 | 0 | 0.5177 | 0.5372 |

| 0.7 | 1.0687 | 0.3818 | 1.5 | 2.2570 | 0.4643 | 1.0 | 0.5847 | 0.5699 | |||

| 1.2 | 1.0846 | 0.9620 | 2.4 | 1.1272 | 0.9716 | 1.4 | 0.8908 | 0.8817 | |||

| 1.4 | 0.8829 | 0.8755 | 1.8 | 0.9049 | 0.9244 | ||||||

| 2.0 | 1.0757 | 0.9785 | |||||||||

| 2.1 | 1.0141 | 0.9920 | |||||||||

| 0_MA_800 | 0 | 0.9552 | 0.9424 | 10_MA_800 | 0 | 1.1284 | 1.0031 | 20_MA_800 | 0 | 0.9470 | 0.9385 |

| 1.3 | 1.7779 | 1.6763 | 1.0 | 1.4709 | 0.6398 | 1.7 | 0.4966 | 0.4808 | |||

| 1.7 | 1.4287 | 1.0610 | 1.2 | 0.9778 | 0.9353 | 1.9 | 0.9172 | 0.9067 | |||

| 2.0 | 1.5065 | 0.9519 | 1.4 | 1.1114 | 0.9658 | 2.2 | 0.9412 | 0.9351 | |||

| 2.1 | 1.2355 | 1.0539 | |||||||||

| 3.3 | 1.0020 | 0.9964 | |||||||||

| 0_MA_900 | 0 | 1.9792 | 0.9626 | 10_MA_900 | 0 | 1.1958 | 0.9705 | 20_MA_900 | 0 | 0.9431 | 0.9551 |

| 1 | 1.4369 | 0.8514 | 1.5 | 1.2187 | 0.4533 | 2.1 | 0.4916 | 0.6102 | |||

| 1.6 | 0.9837 | 0.9697 | 2.4 | 1.0358 | 0.8919 | 2.3 | 0.8331 | 0.9290 | |||

| 1.8 | 1.0249 | 0.9775 | 2.7 | 1.0898 | 0.9285 | 3. | 0.9744 | 0.9705 | |||

| 2.0 | 1.0619 | 1.0039 | |||||||||

| 0_MA_1000 | 0 | 1.0915 | 0.9740 | 10_MA_1000 | 0 | 1.0848 | 0.9767 | 20_MA_1000 | 0 | 1.9828 | 0.8857 |

| 1.2 | 0.8995 | 0.3275 | 1.4 | 1.9653 | 0.4171 | 1.4 | 0.8252 | 1.7065 | |||

| 1.7 | 0.9018 | 0.8899 | 1.8 | 1.0526 | 0.9054 | 2.1 | 0.8772 | 1.3079 | |||

| 3.4 | 1.0282 | 0.9847 | 2.0 | 0.9390 | 0.8850 | 3 | 1.0269 | 1.2301 | |||

| 4.0 | 0.9943 | 0.9761 | |||||||||

| 0_MA_1100 | 0 | 1.4255 | 0.9642 | 10_MA_1100 | 0 | 1.0760 | 0.9614 | 20_MA_1100 | 0 | 1.9749 | 0.9423 |

| 1.1 | 1.3367 | 0.1809 | 1.5 | 1.7346 | 0.2534 | 2.0 | 0.6598 | 0.2533 | |||

| 1.5 | 0.9807 | 0.9191 | 2.5 | 1.6668 | 0.8802 | 3.0 | 0.8186 | 0.8118 | |||

| 2.0 | 1.1431 | 0.9320 | 3.2 | 0.9955 | 0.8897 | ||||||

| 2.1 | 1.0009 | 0.9390 | |||||||||

| 3.8 | 1.0038 | 0.9877 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matcovschi, E.; Pricop, B.; Lohan, N.-M.; Popa, M.; Bădărău, G.; Cimpoeșu, N.; Ozkal, B.; Bujoreanu, L.-G. A Study of the Effects of Mechanical Alloying Fraction, Solution Treatment Temperature and Pre-Straining Degree on the Structure and Properties of a Powder Metallurgy-Produced FeMnSiCrNi Shape Memory Alloy. Crystals 2025, 15, 105. https://doi.org/10.3390/cryst15020105

Matcovschi E, Pricop B, Lohan N-M, Popa M, Bădărău G, Cimpoeșu N, Ozkal B, Bujoreanu L-G. A Study of the Effects of Mechanical Alloying Fraction, Solution Treatment Temperature and Pre-Straining Degree on the Structure and Properties of a Powder Metallurgy-Produced FeMnSiCrNi Shape Memory Alloy. Crystals. 2025; 15(2):105. https://doi.org/10.3390/cryst15020105

Chicago/Turabian StyleMatcovschi, Elena, Bogdan Pricop, Nicoleta-Monica Lohan, Mihai Popa, Gheorghe Bădărău, Nicanor Cimpoeșu, Burak Ozkal, and Leandru-Gheorghe Bujoreanu. 2025. "A Study of the Effects of Mechanical Alloying Fraction, Solution Treatment Temperature and Pre-Straining Degree on the Structure and Properties of a Powder Metallurgy-Produced FeMnSiCrNi Shape Memory Alloy" Crystals 15, no. 2: 105. https://doi.org/10.3390/cryst15020105

APA StyleMatcovschi, E., Pricop, B., Lohan, N.-M., Popa, M., Bădărău, G., Cimpoeșu, N., Ozkal, B., & Bujoreanu, L.-G. (2025). A Study of the Effects of Mechanical Alloying Fraction, Solution Treatment Temperature and Pre-Straining Degree on the Structure and Properties of a Powder Metallurgy-Produced FeMnSiCrNi Shape Memory Alloy. Crystals, 15(2), 105. https://doi.org/10.3390/cryst15020105