Effect of Annealing Process on Microstructure and Properties of Tin Bronze/Steel Bimetallic

Abstract

1. Introduction

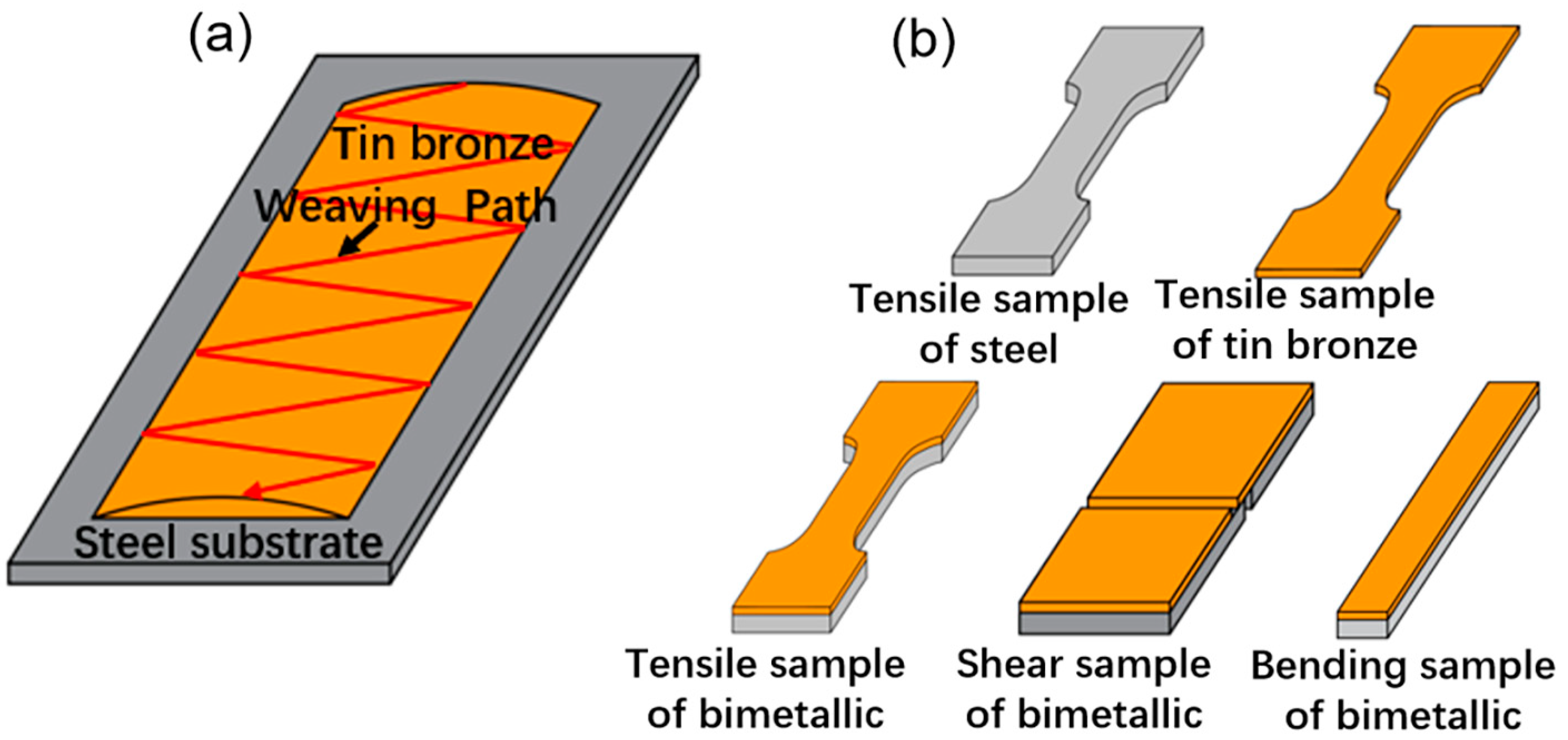

2. Materials and Methods

3. Results and Discussion

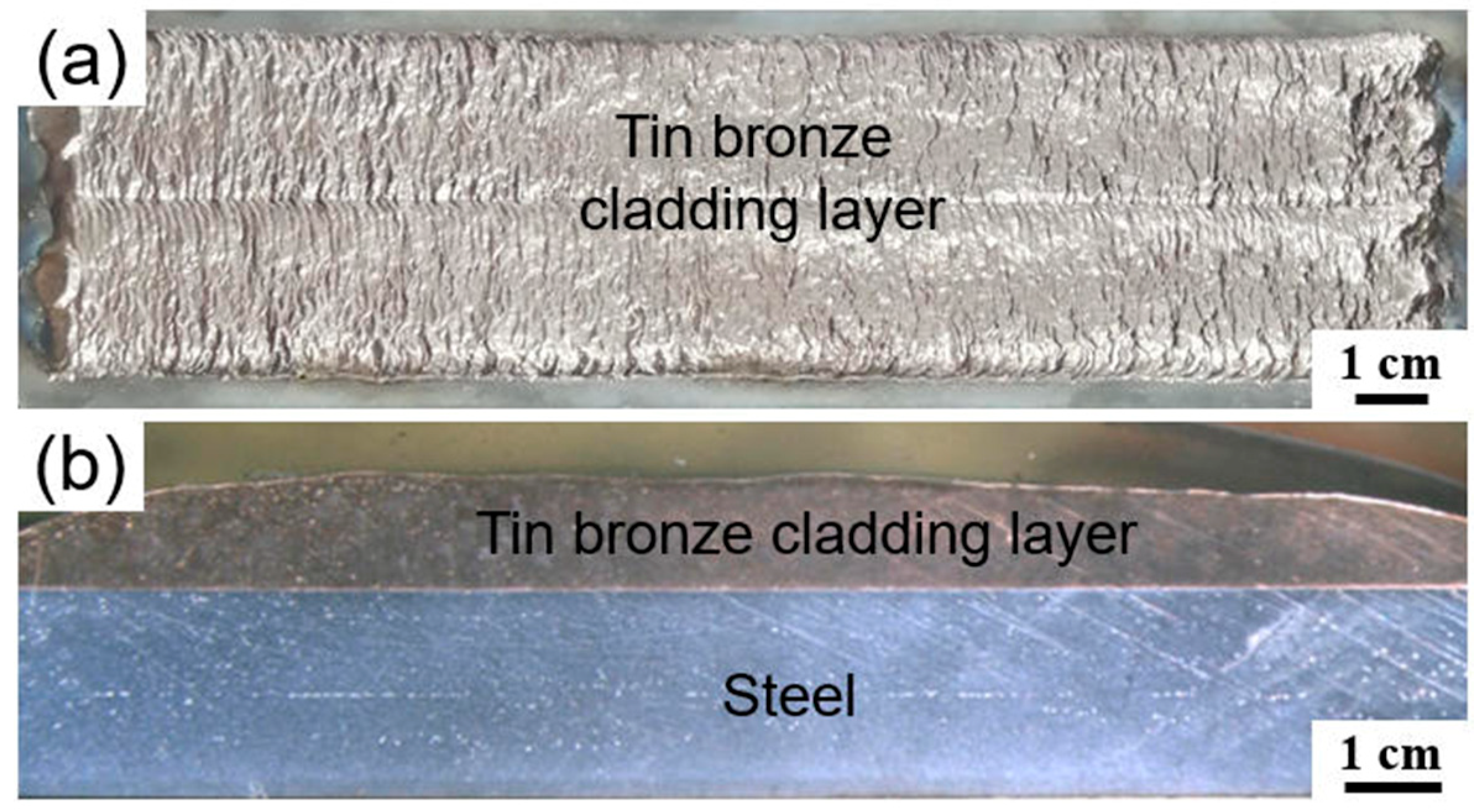

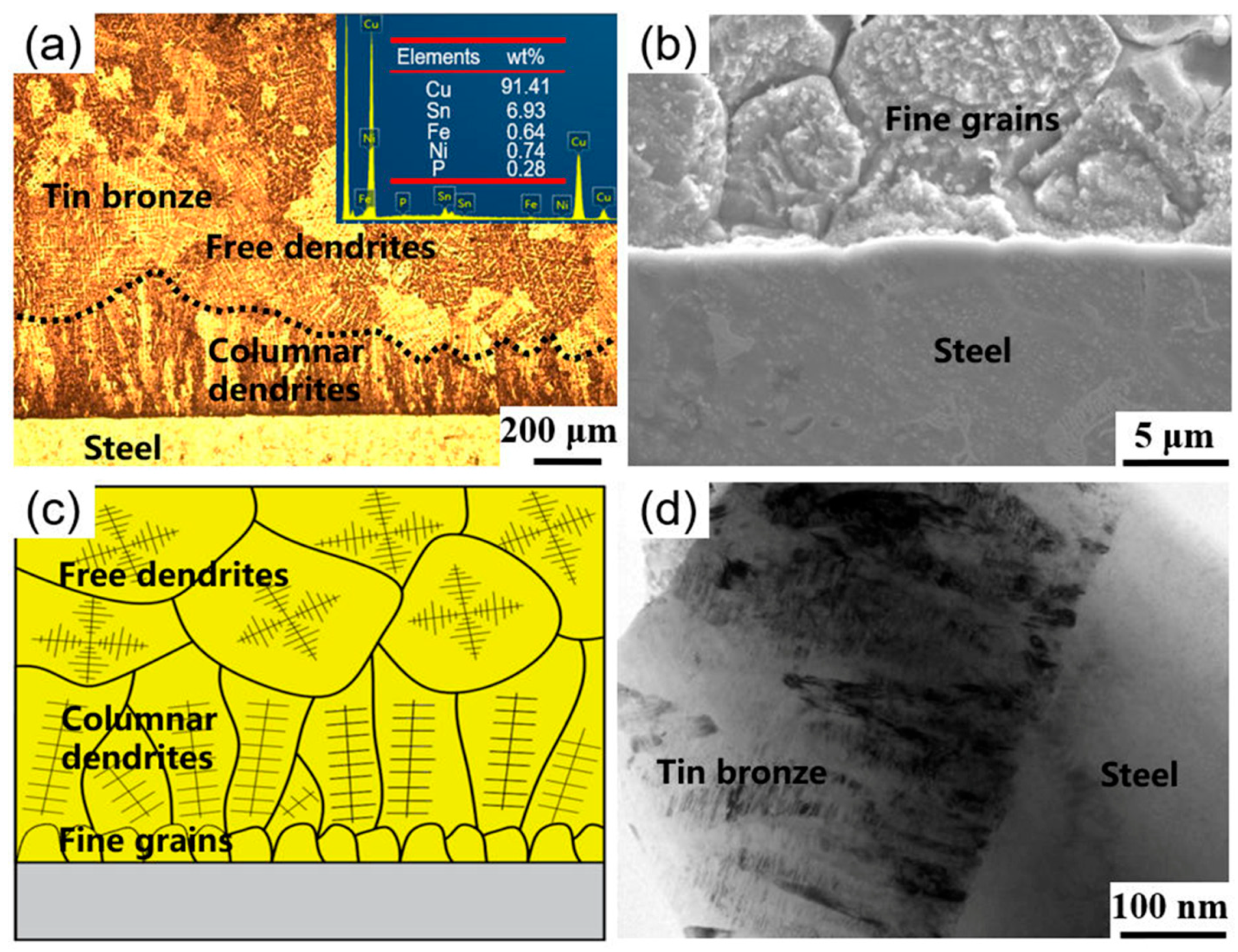

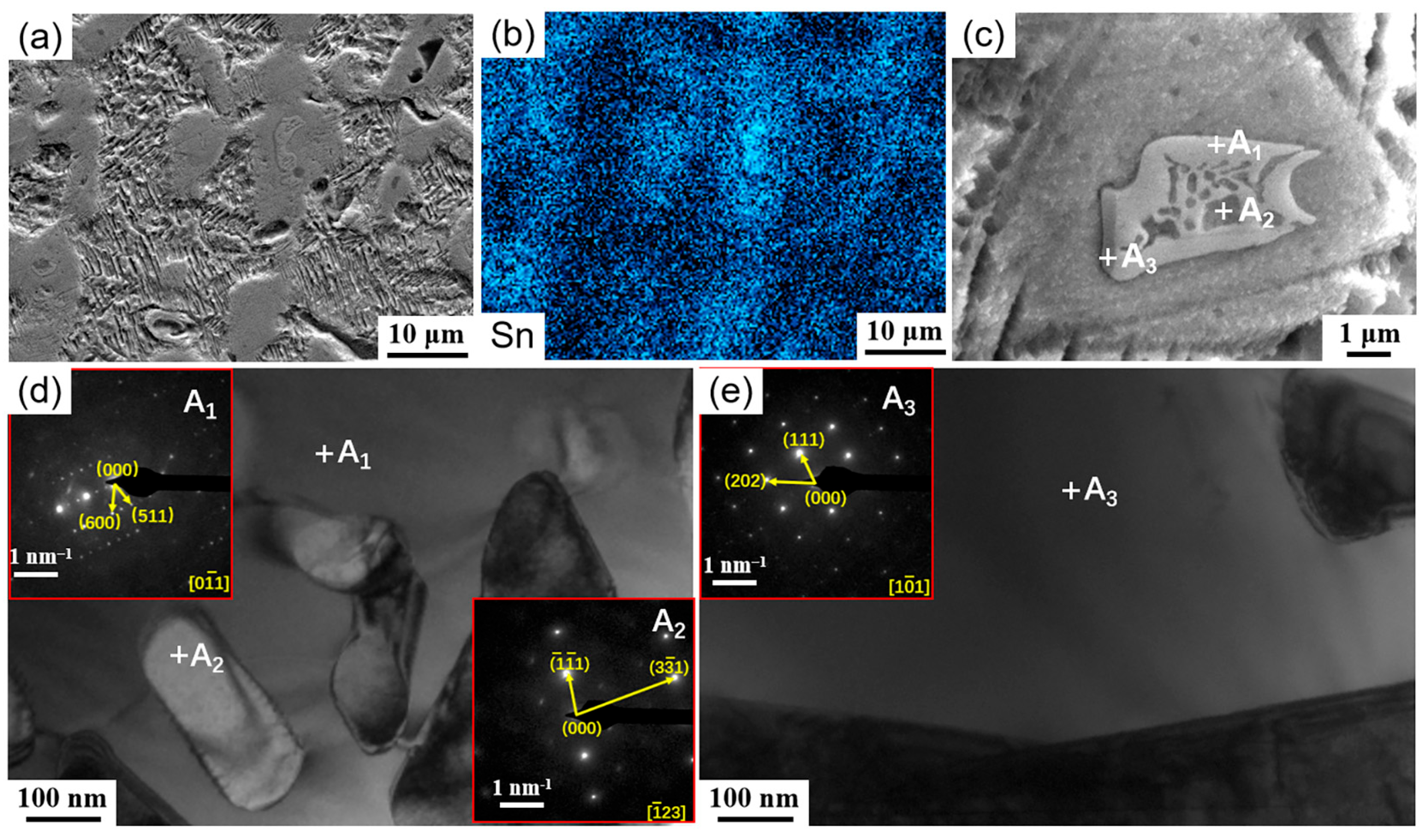

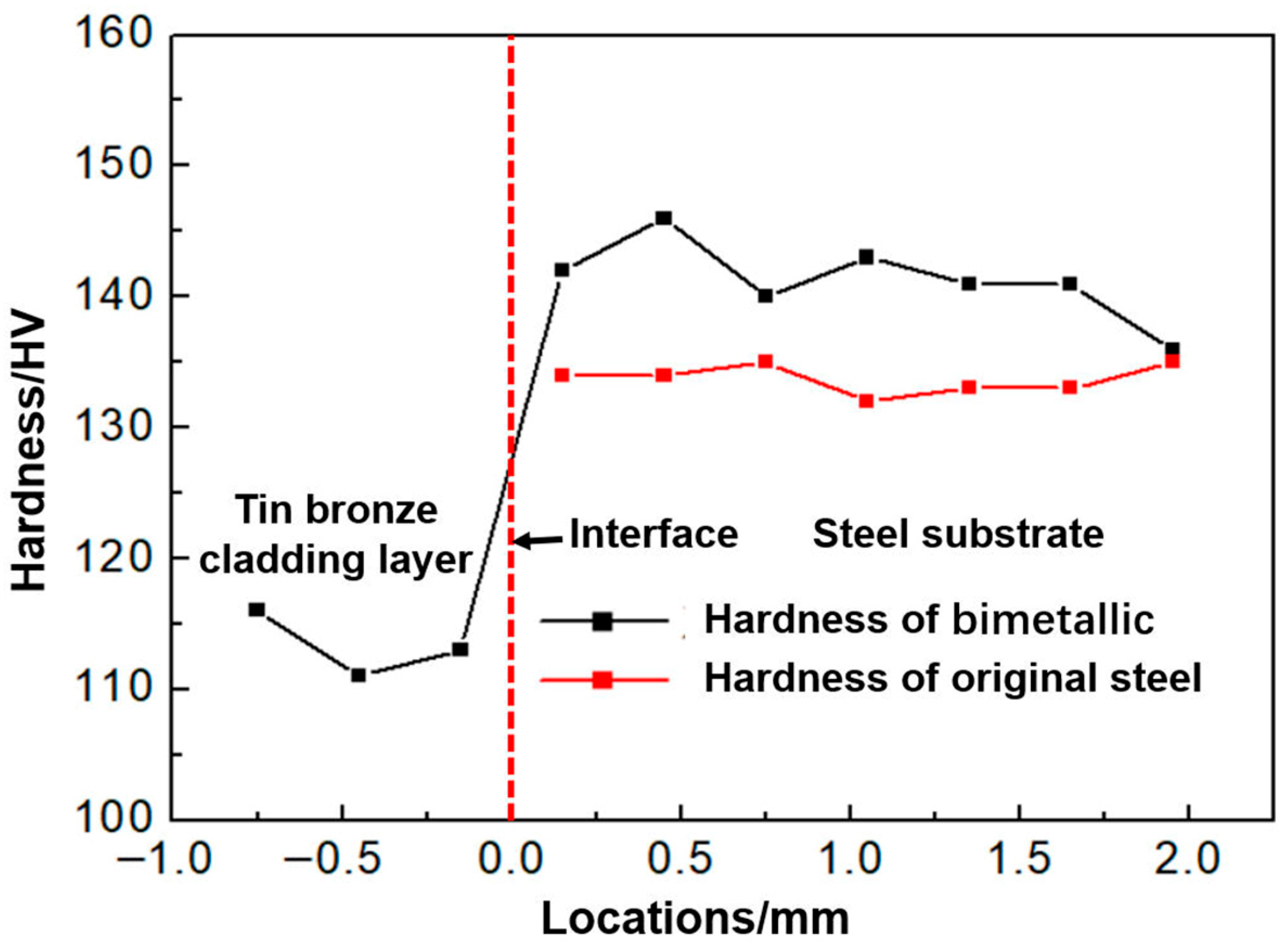

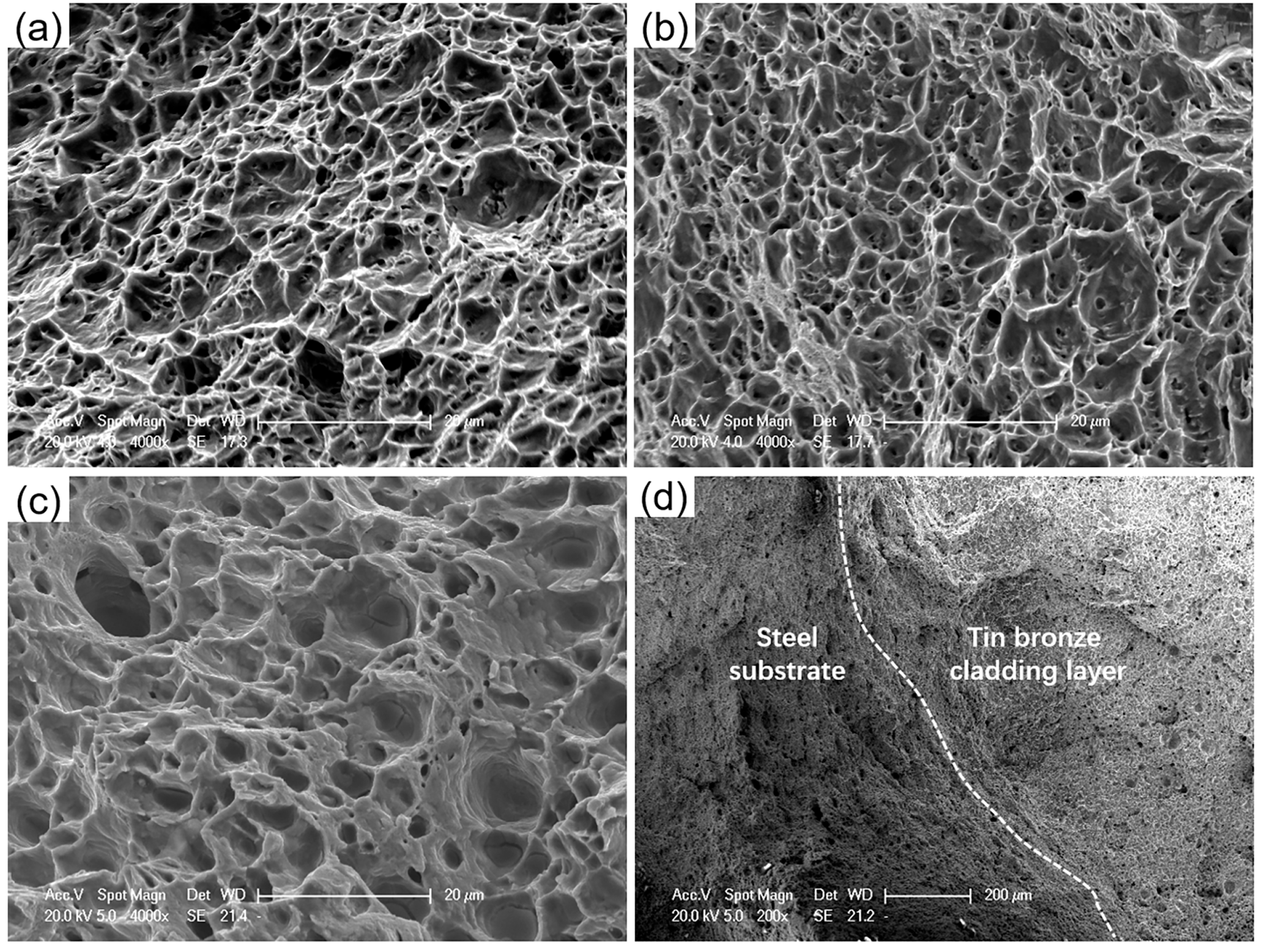

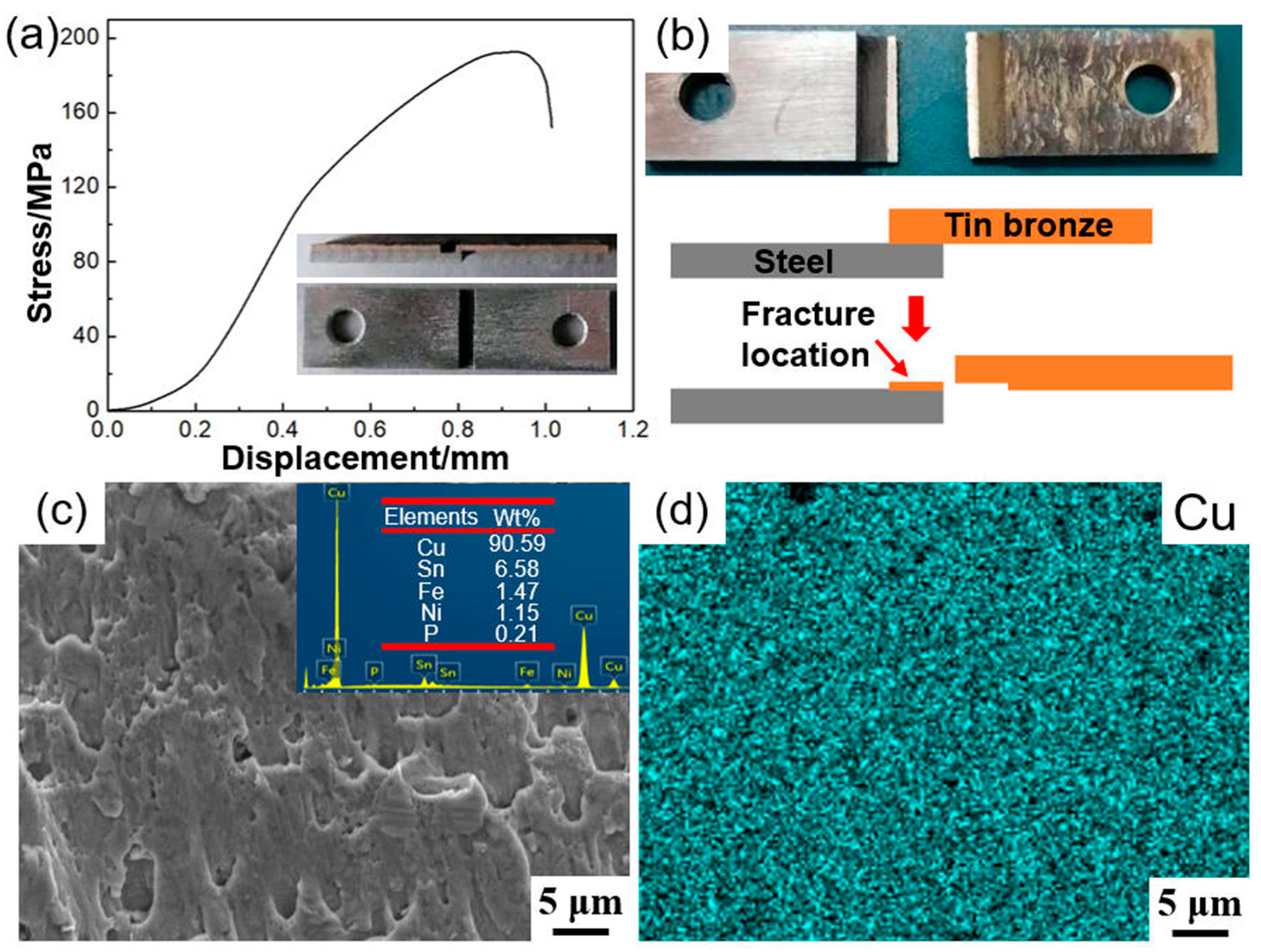

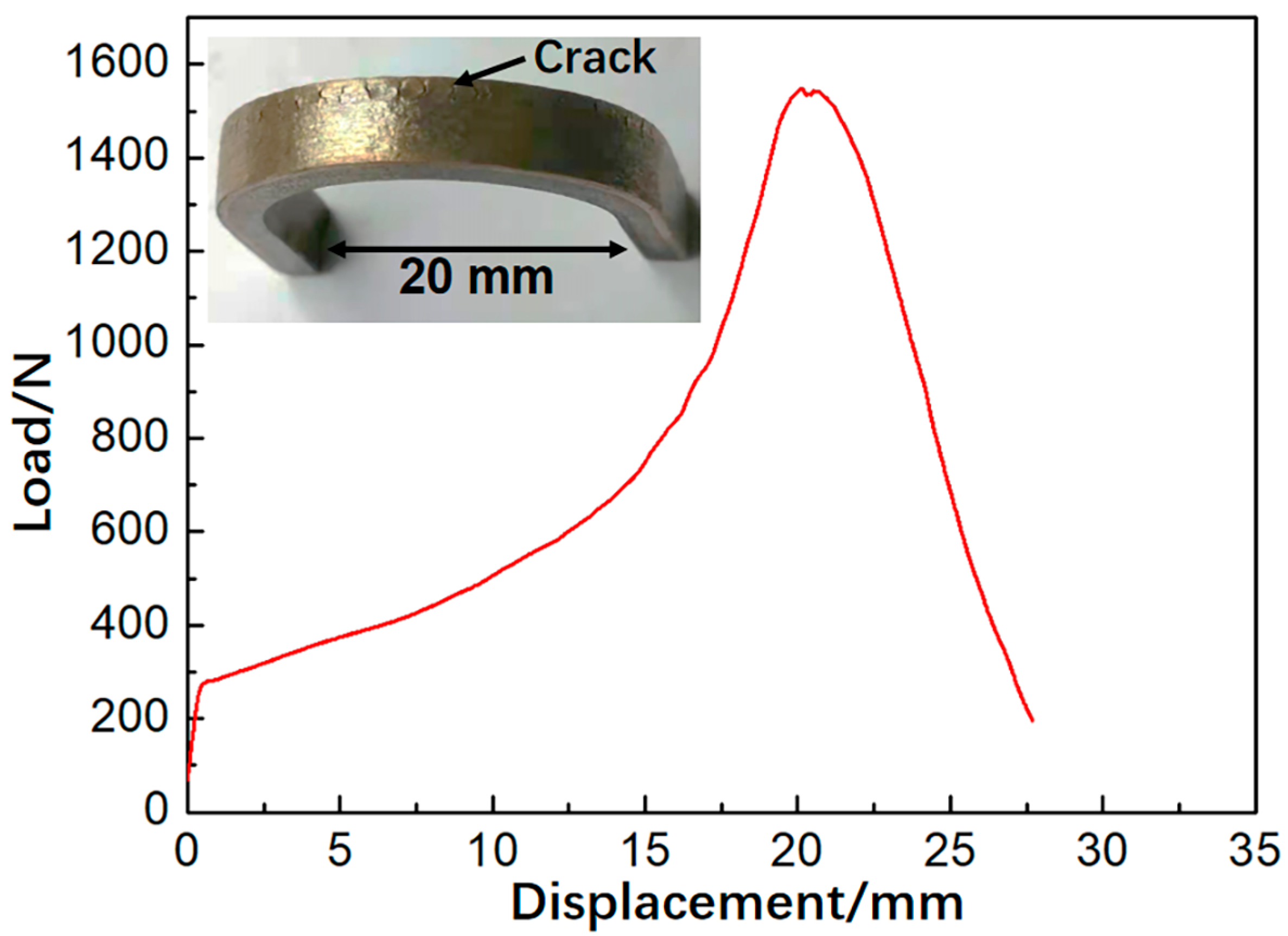

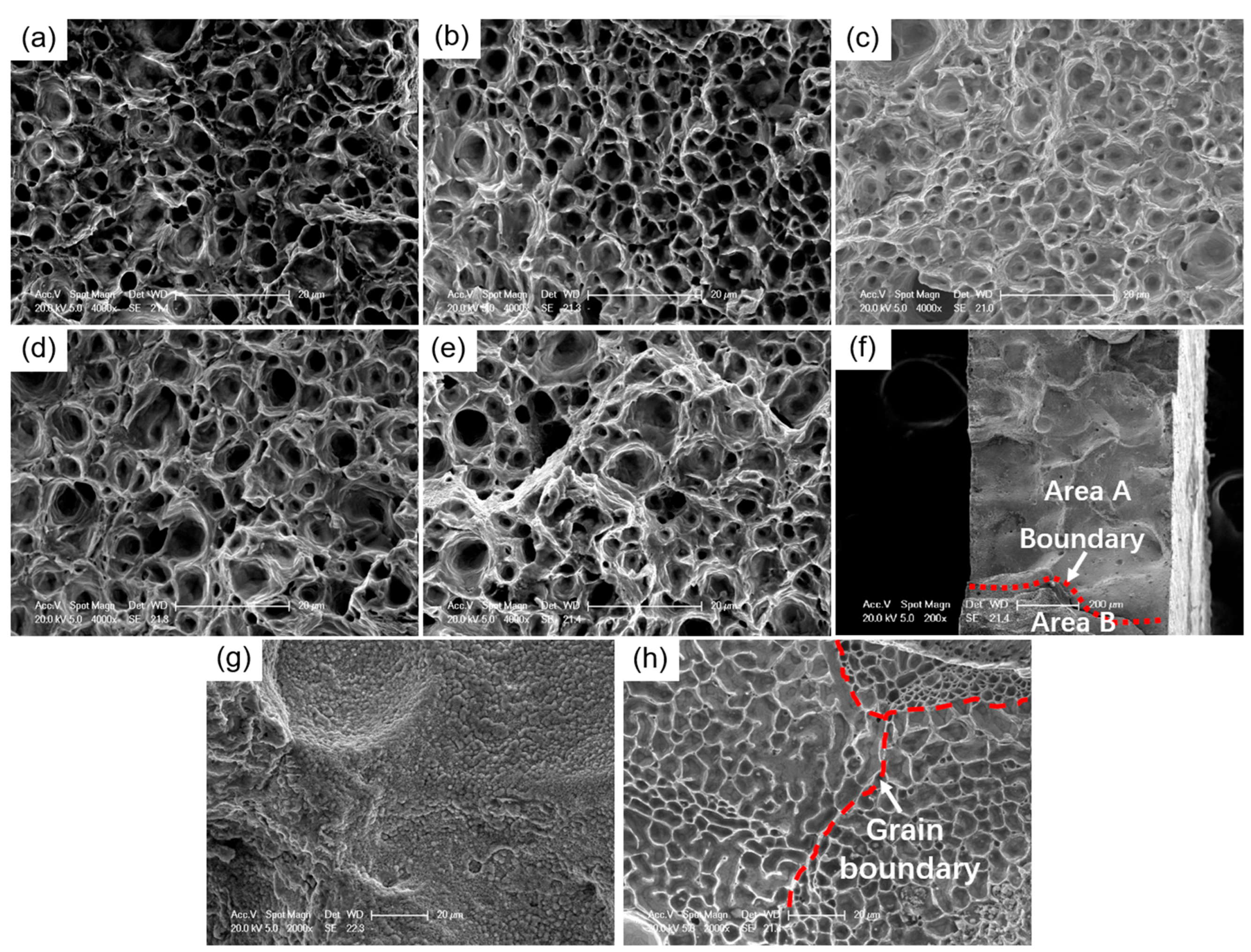

3.1. Microstructure and Properties Before Annealing

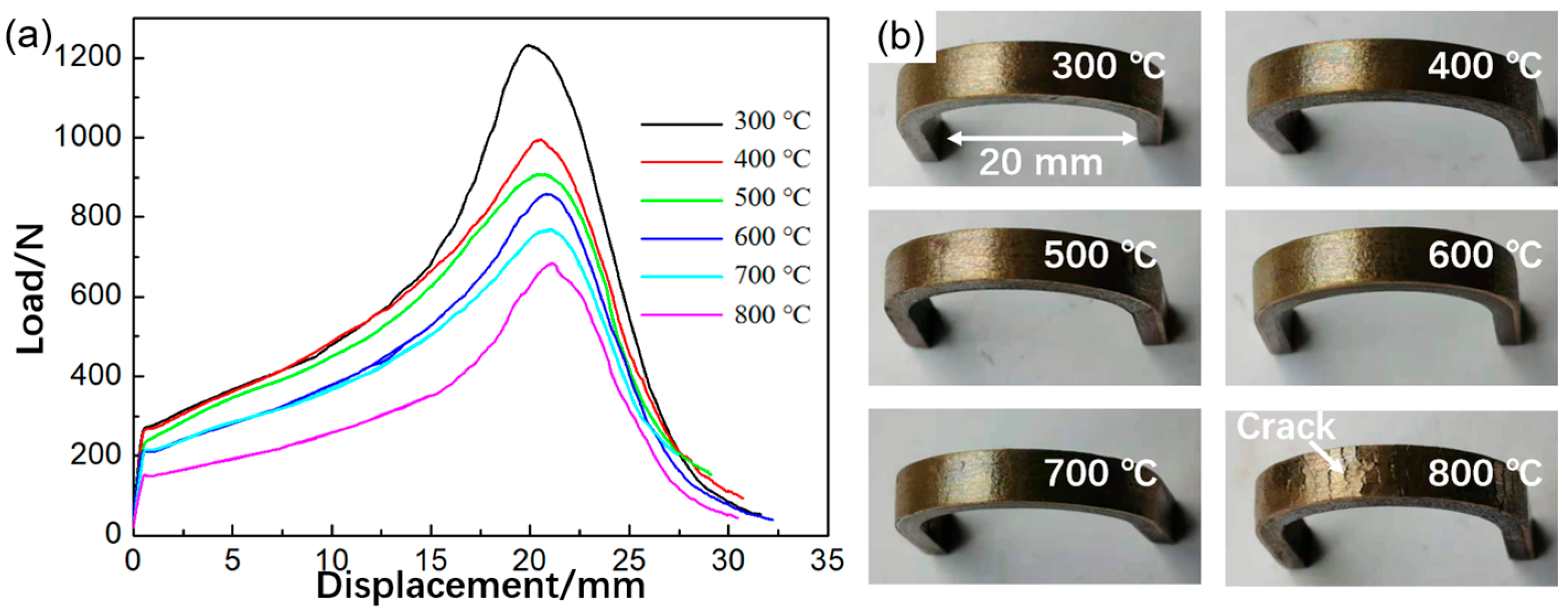

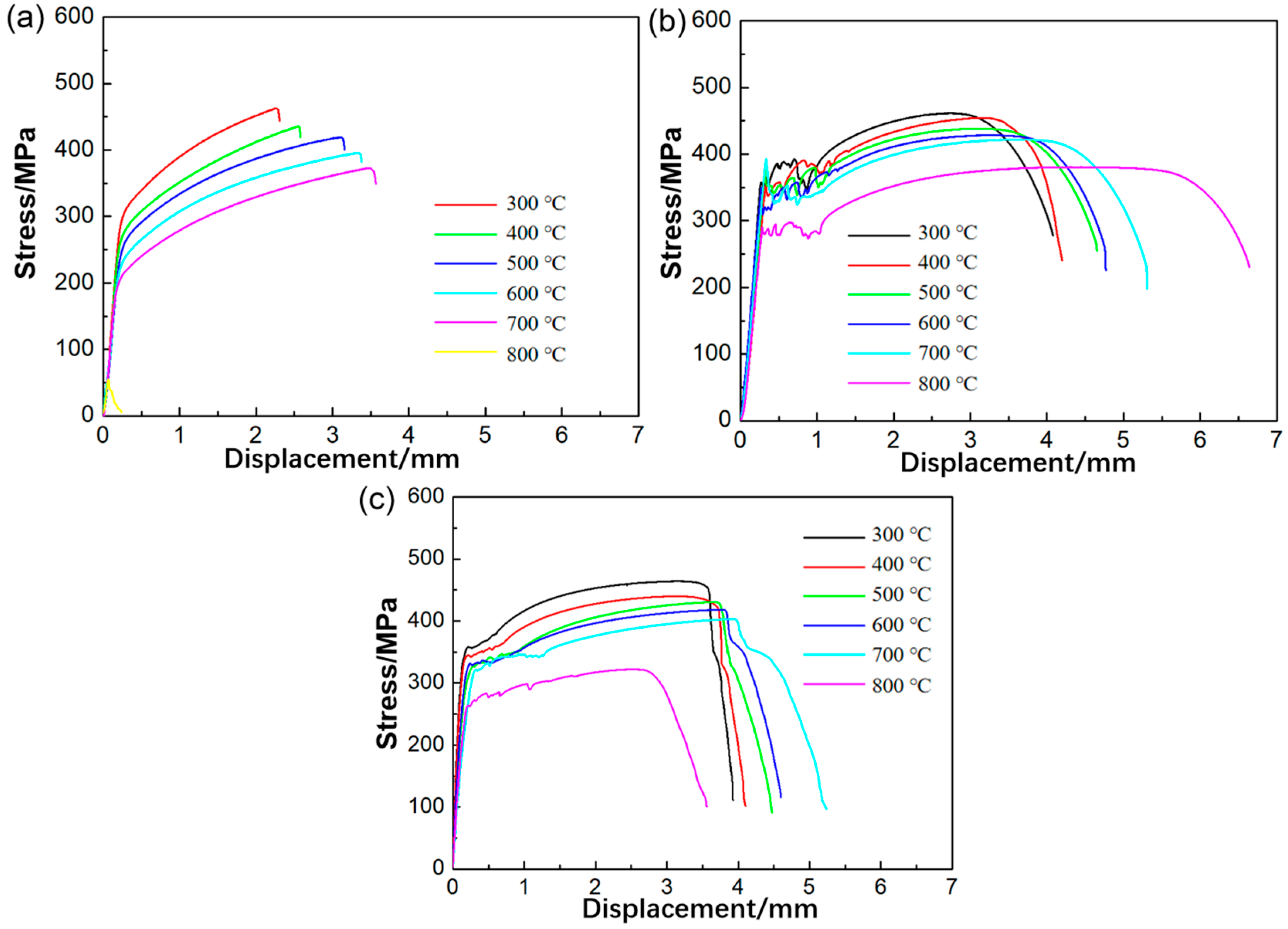

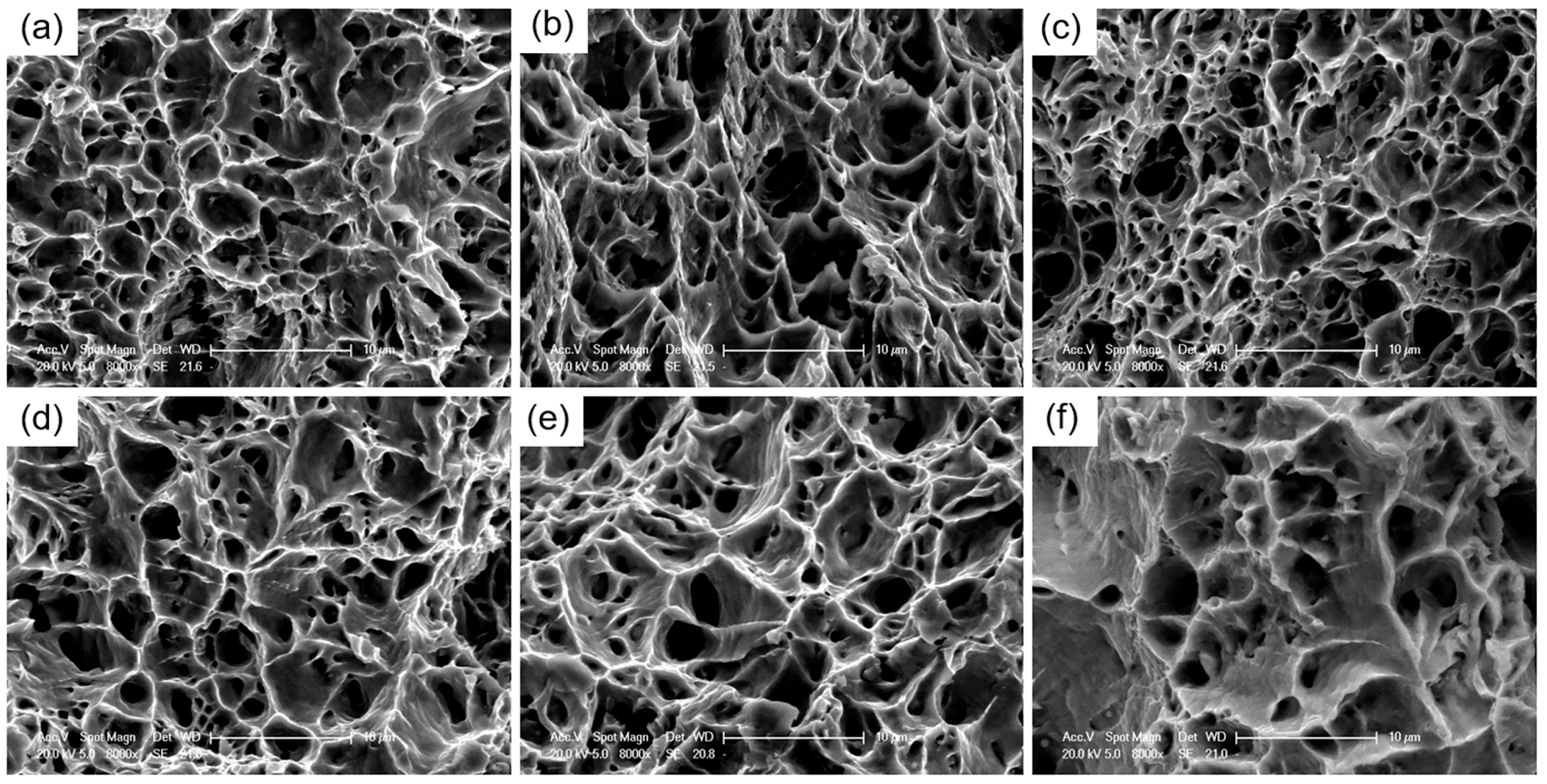

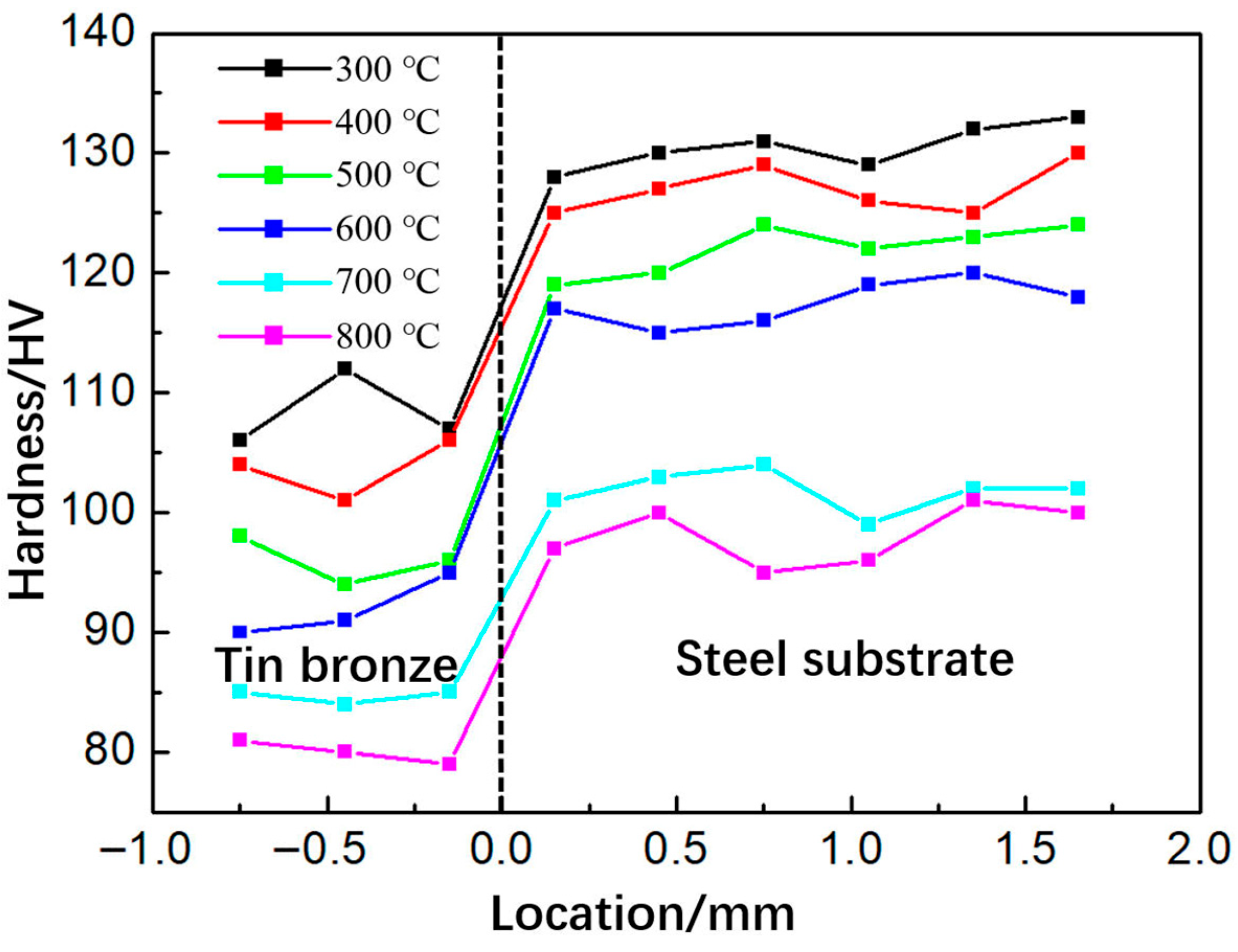

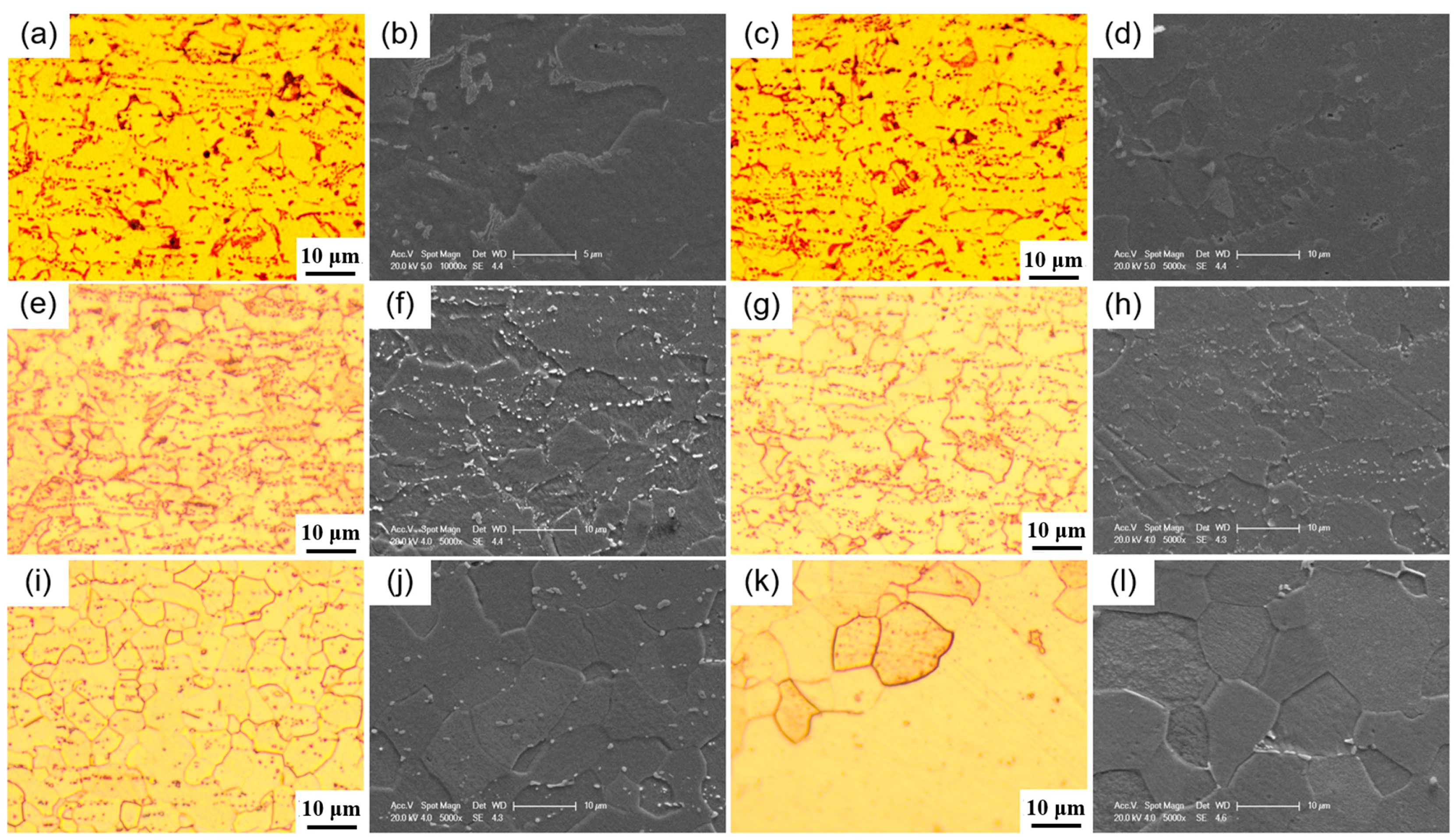

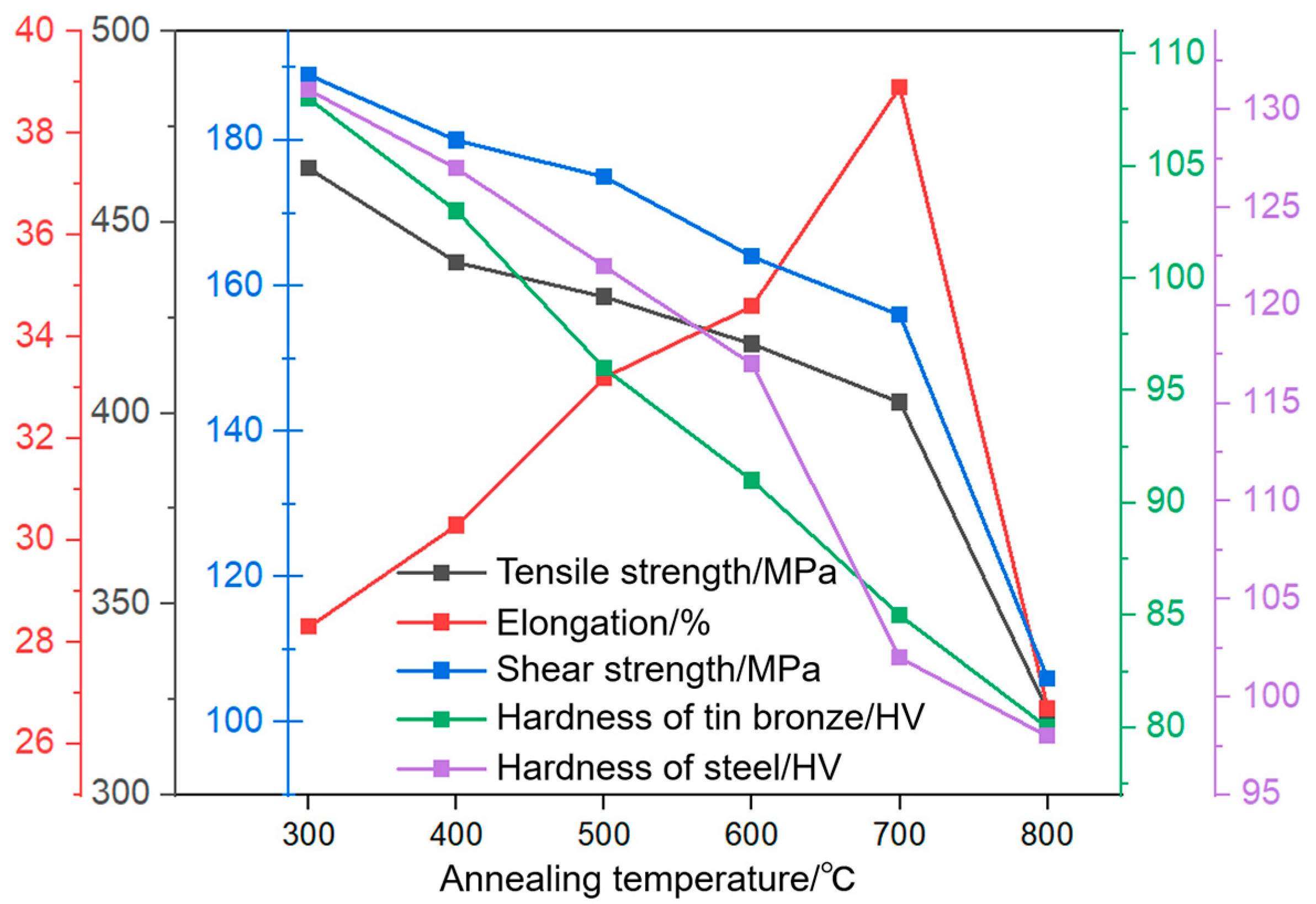

3.2. Microstructure and Properties After Annealing

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Z.; Huo, D.; Sun, Y.; Li, Y.; Zhou, R.; Li, Z.; Liu, Z. Unveiling ultra-high plasticity and the mechanism of microstructural evolution in semi-solid squeeze-cast leaded nickel-tin bronze through solution treatment. Mater. Charact. 2025, 229, 115521. [Google Scholar] [CrossRef]

- Jin, X.; Hou, J.; Chen, Z. Research on the influence of titanium addition on the structure and frictional performance of laser clad tin bronze coating. J. Laser. Appl. 2025, 37, 012008. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, L.; Li, X. Tribological Properties of Cu-Based Self-Lubricating Materials Composed with Cu- or Ni-Plated Graphite. Lubricants 2023, 11, 271. [Google Scholar] [CrossRef]

- Marklund, P.; Berglund, K.; Larsson, R. The influence on boundary friction of the permeability of sintered bronze. Tribol. Lett. 2008, 31, 1–8. [Google Scholar] [CrossRef]

- Kostornov, A.G.; Fushchich, O.I.; Chevichelova, T.M. Structurization in sintering of antifriction powder materials based on iron-copper alloys. Powder Metall. Met. Ceram. 2007, 46, 589–594. [Google Scholar] [CrossRef]

- Santos, C.A.; Spim, J.A.; Garcia, A. Modeling of solidification in twin-roll strip casting. J. Mater. Process. Tech. 2000, 102, 33–39. [Google Scholar] [CrossRef]

- Kim, J.U.; Shojaee, M.; Sherepenko, O.; Ramachandran, D.; Betiku, O.T.; Midawi, A.R.H.; Ghassemi-Armaki, H.; Biro, E. Half-sectioned spot weld parameter optimisation for liquid metal embrittlement analysis in advanced high-strength steels. Sci. Technol. Weld. Join. 2024, 29, 61–69. [Google Scholar] [CrossRef]

- Xiao, P.; Wang, L.; Tang, Y.; Tu, X.; Song, X.; Chen, L.; Liu, F.; Zhang, Y. Effect of wire composition on microstructure and penetration crack of laser-cold metal transfer hybrid welded Cu and stainless steel joints. Mater. Chem. Phys. 2023, 299, 127480. [Google Scholar] [CrossRef]

- Sage, D.; Fink, C. Understanding temperature and dwell time dependence of liquid metal embrittlement in austenitic stainless steel by liquid zinc and copper. Materialia 2022, 24, 101502. [Google Scholar] [CrossRef]

- Chen, C.; Li, W.; Tu, F.; Qin, T. Effect of Heat Input on Tin Bronze-Induced Intergranular Cracks During Arc Cladding. Crystals 2024, 14, 926. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, H.; Wang, Y.; Hao, Y.; Lu, F. Formation mechanism of liquid metal embrittlement in laser lap welding of zinc-coated GEN3 steels. Mater. Sci. Eng. A 2021, 800, 140229. [Google Scholar] [CrossRef]

- Wang, S.; Chen, C.; Ju, J.; Zhou, J.; Xue, F. Effect of Al Bronze Interlayer on Liquid-Solid Compound Interface of Sn Bronze/Steel. Adv. Eng. Mater. 2023, 25, 2201227. [Google Scholar]

- Arias-Gonzalez, F.; Del Val, J.; Comesana, R.; Penide, J.; Pou, J. Laser cladding of phosphor bronze. Surf. Coat. Tech. 2017, 313, 248–254. [Google Scholar] [CrossRef]

- Zhao, L.; Li, J.; Yang, Q.; Wang, Y.; Zhang, X.; Li, H.; Yang, Z.; Xu, D.; Liu, J. Study on Friction and Wear Properties of New Self-Lubricating Bearing Materials. Crystals 2022, 12, 834. [Google Scholar] [CrossRef]

- Evangeline, A.; Sathiya, P. Cold metal arc transfer (CMT) metal deposition of Inconel 625 superalloy on 316L austenitic stainless steel: Microstructural evaluation, corrosion and wear resistance properties. Mater. Res. Express 2019, 6, 066516. [Google Scholar] [CrossRef]

- Wei, M.; Sun, K.; Zhang, X.; Zhang, C.; Chen, Z.; Zhou, J.; Xue, F. Microstructure and bonding strength of tin-based Babbitt alloy on ASTM 1045 steel by MIG arc brazing. J. Adhes. Sci. Technol 2018, 32, 2150–2160. [Google Scholar] [CrossRef]

- Chen, C.; Zhao, J.; Zhou, J.; Xu, F. Arc deposited AlSi12 cladding layer on steel plate without zinc coating. Mater. Sci. Tech. 2020, 36, 100–107. [Google Scholar] [CrossRef]

- Chen, J.; Yang, Y.; Song, C.; Zhang, M.; Wu, S.; Wang, D. Interfacial microstructure and mechanical properties of 316L/CuSn10 multi-material bimetallic structure fabricated by selective laser melting. Mater. Sci. Eng. A 2019, 752, 75–85. [Google Scholar] [CrossRef]

- Zhang, H.; Jiao, K.; Zhang, J.; Liu, J. Comparisons of the microstructures and micro-mechanical properties of copper/steel explosive-bonded wave interfaces. Mater. Sci. Eng. A 2019, 756, 430–441. [Google Scholar] [CrossRef]

- Liac, X.; Ivas, T.; Spierings, A.; Wegener, K.; Leinenbach, C. Phase and microstructure formation in rapidly solidified Cu-Sn and Cu-Sn-Ti alloys. J. Alloys Compd. 2018, 735, 1374–1382. [Google Scholar]

- Chen, C.; Zhou, J.; Yu, J.; Ju, J.; Zhang, Y.; Wang, J.; Fan, B. Interfacial microstructures and infiltrated cracks in tin bronze/steel bimetallic materials fabricated by arc cladding. J. Mater. Sci. 2023, 58, 4679–4693. [Google Scholar] [CrossRef]

- Chen, C.; Sun, K.; Zhao, J.; Zhou, J.; Xue, F. Effect of current on microstructures and properties of tin bronze/steel bimetallic sheets fabricated by arc deposited technique. Mater. Res. Express. 2019, 6, 126534. [Google Scholar] [CrossRef]

- Song, Q.; He, M.; Li, T.; Han, J.; He, C.; Guo, X.; Feng, G.; Xiong, L. Design and mechanism research of online control and monitoring system for laser welding quality. Mater. Des. 2025, 259, 114849. [Google Scholar] [CrossRef]

- Valloton, J.; Wagniere, J.D.; Rappaz, M. Competition of the primary and peritectic phases in hypoperitectic Cu-Sn alloys solidified at low speed in a diffusive regime. Acta. Mater. 2012, 60, 3840–3848. [Google Scholar] [CrossRef]

- Asadian, M.; Zabihi, F.; Saeedi, H. Segregation and constitutional supercooling in Nd:YAG Czochralski crystal growth. J. Cryst. Growth 2024, 630, 127605. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, R.; Li, Y.; Sun, Y.; Huo, D.; Zhang, H.; Li, Y.; Li, Z. Synergistic enhancement of strength and ductility in leaded nickel-tin bronze by constructing a core-rim dual-phase microstructure via semi-solid squeeze casting. Mater. Sci. Eng. A 2025, 944, 148902. [Google Scholar] [CrossRef]

- Liang, Y.; Jiang, H.; Lei, Q.; Jiang, L.; Zhang, X.; Xiao, S.; Liu, X.; Li, L.; Pei, Z.; Li, Q. Cr3C2 reinforced tin-bronze matrix composites with enhanced mechanical properties and wear resistance. Mater. Charact. 2024, 210, 113805. [Google Scholar] [CrossRef]

- Peng, B.; Jie, J.; Wang, M.; Dong, B.; Wang, X.; Li, S.; Li, T. Microstructure characteristics and deformation behavior of tin bronze/1010 steel bimetal layered composite by continuous solid/liquid bonding. Mater. Sci. Eng. A 2022, 844, 143155. [Google Scholar] [CrossRef]

- Ding, F.; Zhang, T.; Wang, C.; Sui, J.; Zhu, X.; Gao, K. Mechanism of chip segmentation transition from shear slip to shear fracture of Zirconium-based bulk metallic glass in mechanical machining. J. Mater. Res. Technol. 2024, 30, 7398–7412. [Google Scholar] [CrossRef]

- Zhang, H.; Ma, Z.; Li, C.; Yuan, H.; Cheng, X. Solute-vacancy complexes govern Cu diffusion anisotropy in β-Sn: Insights from first-principles and experiments. Mater. Today Commun. 2025, 48, 113364. [Google Scholar] [CrossRef]

| Fe | C | Si | Mn | S | P | Sn | Cu | |

|---|---|---|---|---|---|---|---|---|

| Tin bronze wire (Brand: S213) | - | - | - | - | - | 0.05–0.35 | 7.5–8.5 | Bal |

| Steel plate (Brand: ST37) | Bal | 0.1–0.2 | 0.05–0.01 | 0.5–0.8 | ≤0.0035 | ≤0.0035 | - | Bal |

| Current/A | Voltage/V | Cladding Speed/mm × s−1 | Swing/mm | Heat Input /J × mm−1 |

|---|---|---|---|---|

| 75 | 13.5 | 2.5 | 11 | 344 |

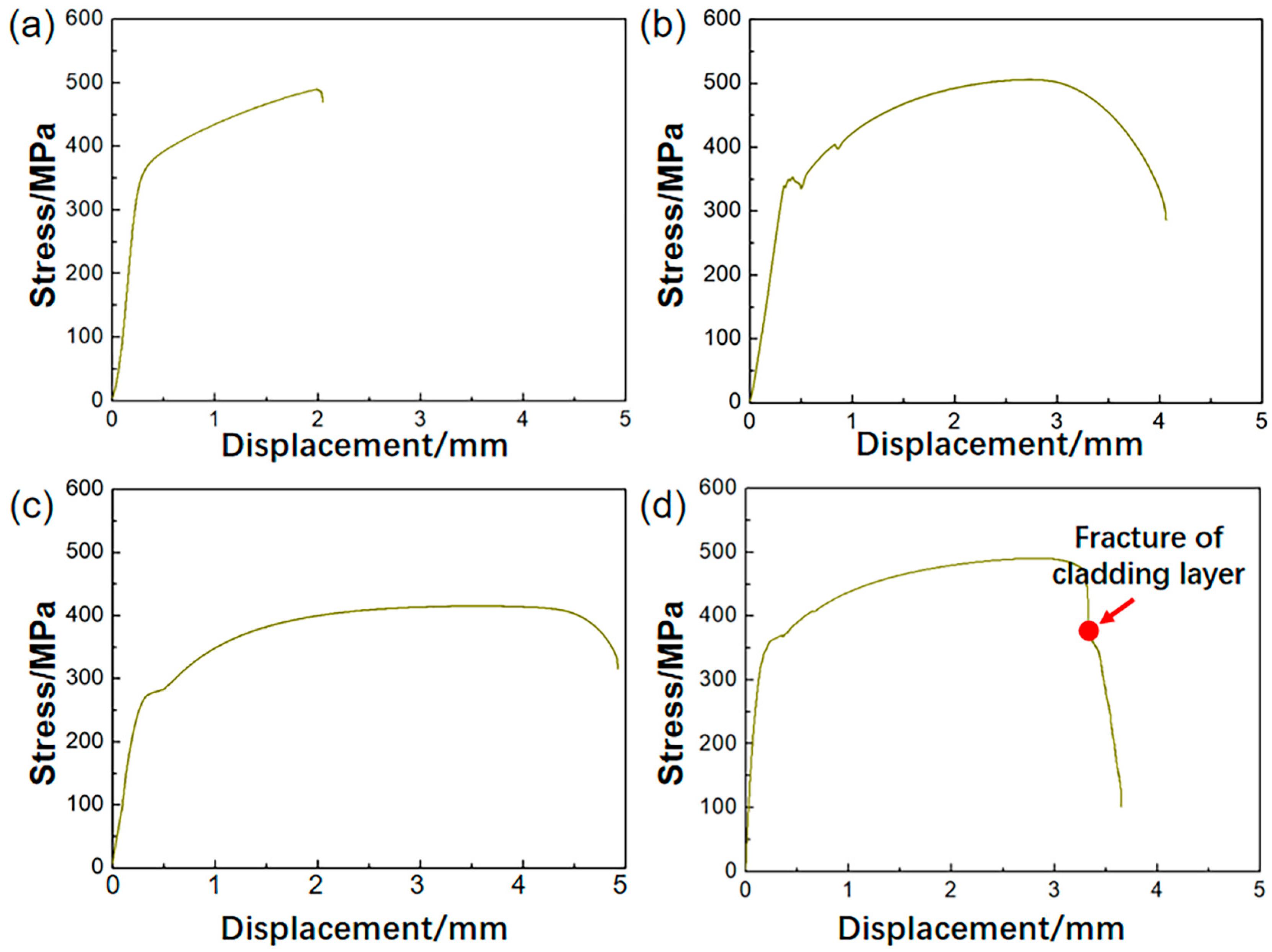

| Tensile Strength/MPa | Elongation/% | |

|---|---|---|

| Tin bronze | 487.0 | 14.3 |

| Steel substrate after arc cladding | 505.1 | 29.1 |

| Steel substrate before arc cladding | 414.9 | 36.8 |

| Tin bronze/steel bimetallic | 490.1 | 26.6 |

| Tin Bronze | Steel Substrate | Tin Bronze/Steel Bimetallic | ||||

|---|---|---|---|---|---|---|

| Annealing Temperature | Strength/MPa | Elongation/% | Strength/MPa | Elongation/% | Strength/MPa | Elongation/% |

| Unannealed | 487.0 | 14.3 | 505.1 | 29.1 | 490.1 | 26.6 |

| 300 °C | 462.1 | 15.3 | 467.1 | 29.8 | 464.1 | 28.3 |

| 400 °C | 435.2 | 16.8 | 454.3 | 30.9 | 439.5 | 30.3 |

| 500 °C | 416.8 | 21.6 | 438.1 | 33.9 | 430.5 | 33.2 |

| 600 °C | 391.9 | 24.0 | 428.1 | 35.1 | 418.1 | 34.6 |

| 700 °C | 372.8 | 25.2 | 421.9 | 39.7 | 402.8 | 38.9 |

| 800 °C | 56.7 | 0 | 380.6 | 49.6 | 322.1 | 26.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Z.; Chen, C. Effect of Annealing Process on Microstructure and Properties of Tin Bronze/Steel Bimetallic. Crystals 2025, 15, 961. https://doi.org/10.3390/cryst15110961

Yu Z, Chen C. Effect of Annealing Process on Microstructure and Properties of Tin Bronze/Steel Bimetallic. Crystals. 2025; 15(11):961. https://doi.org/10.3390/cryst15110961

Chicago/Turabian StyleYu, Zhangyong, and Chen Chen. 2025. "Effect of Annealing Process on Microstructure and Properties of Tin Bronze/Steel Bimetallic" Crystals 15, no. 11: 961. https://doi.org/10.3390/cryst15110961

APA StyleYu, Z., & Chen, C. (2025). Effect of Annealing Process on Microstructure and Properties of Tin Bronze/Steel Bimetallic. Crystals, 15(11), 961. https://doi.org/10.3390/cryst15110961