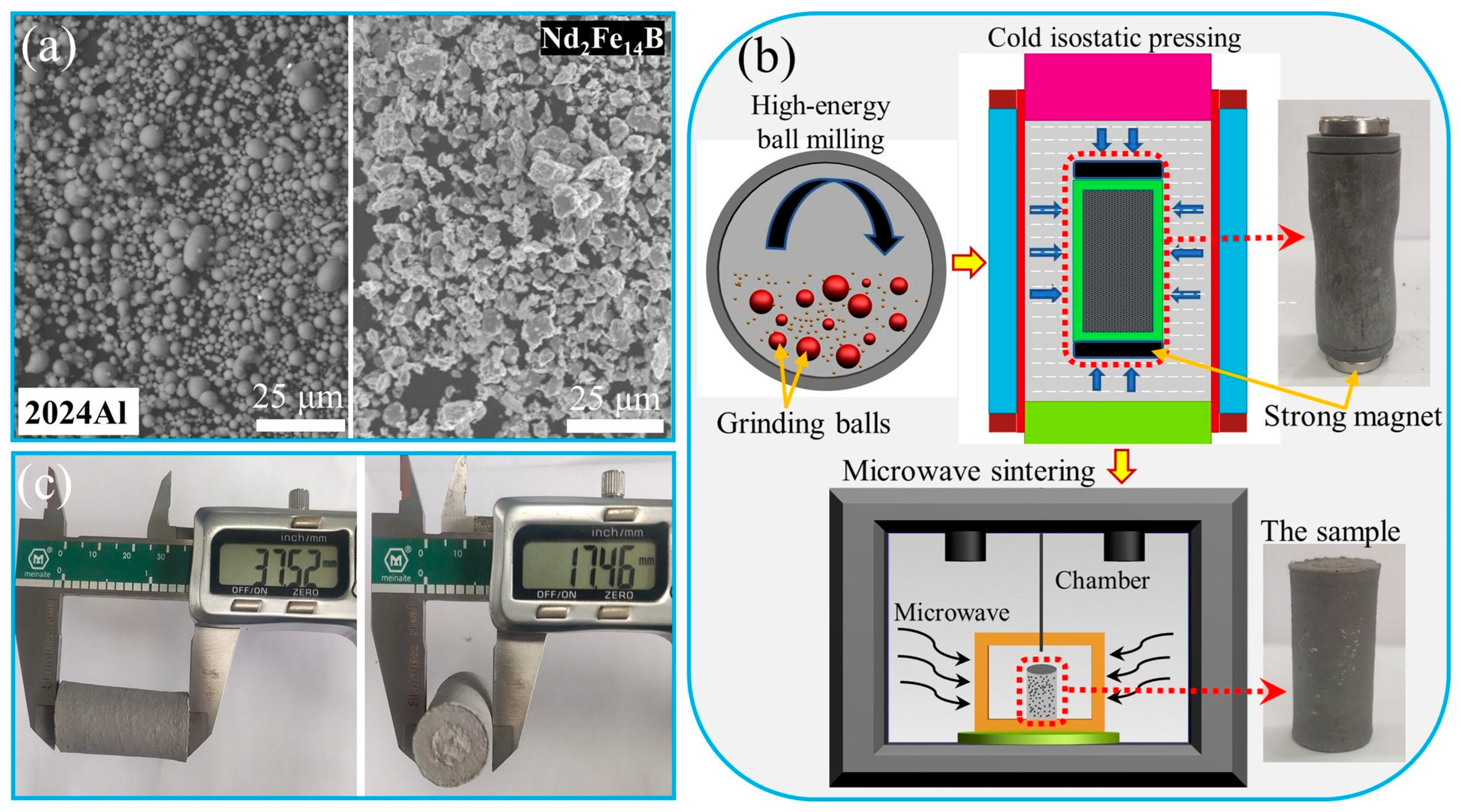

3.1. Influence of Powder Particle Size on Microstructure and Mechanical Properties

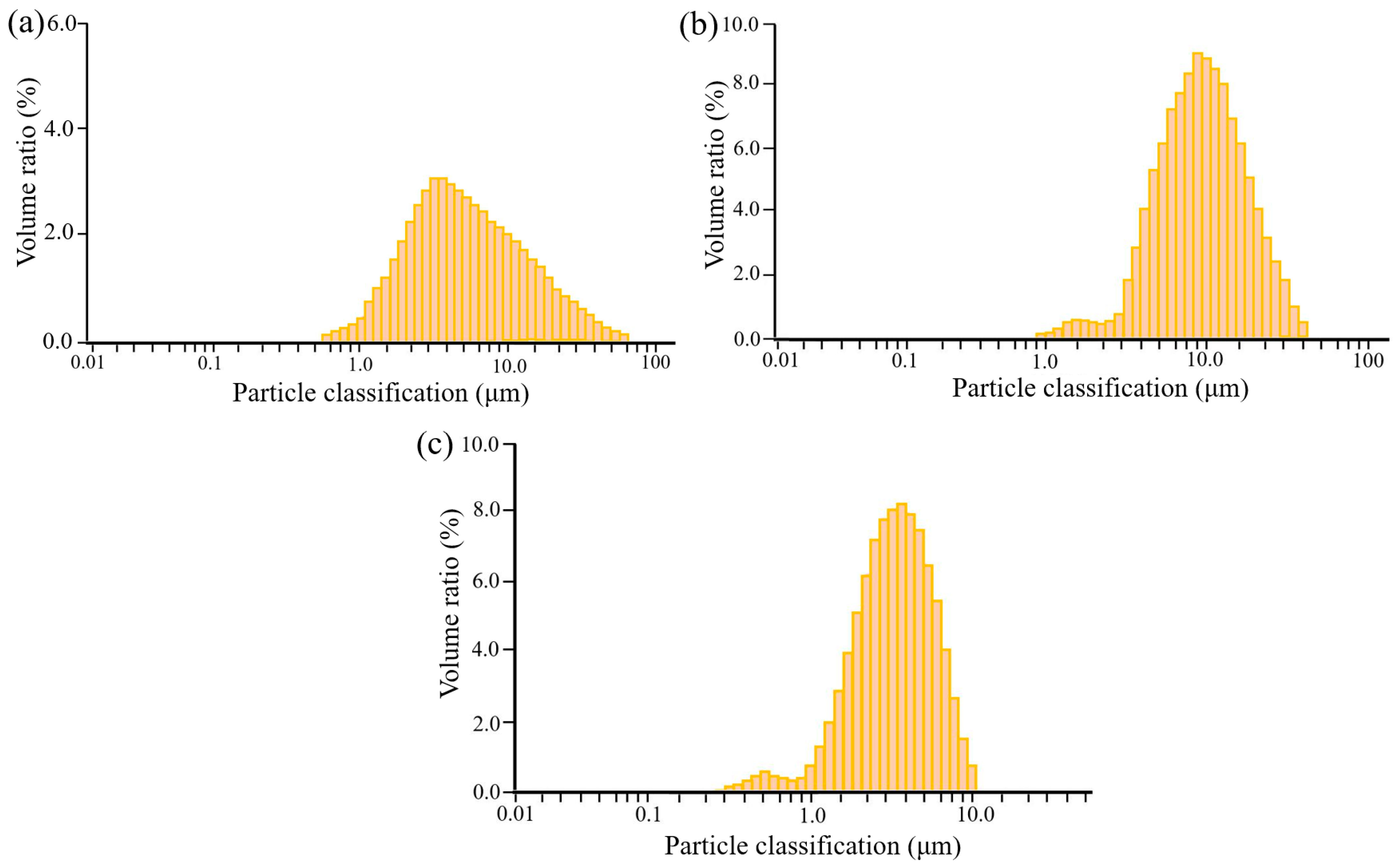

Figure 2a–c show a particle size distribution diagram of the composite mixed powder prepared under different ball milling times. The ball diameter ratio is 1:2:4, the ball-to-powder ratio is 5:1, and the ball milling times are 6 h, 8 h, and 10 h. The average particle sizes of the prepared composite powders are 25 μm, 10 μm, and 5 μm, respectively. When the ball milling time is 6 h, the mixed powder undergoes a relatively short duration, resulting in insufficient mechanical alloying. The coarse particles are not fully impacted and crushed, leading to a larger average particle size of the powder. According to the action principle of microwave sintering on metal particles, powder with such a particle size is not suitable for microwave sintering materials [

20]. With the increase in ball milling time, the average particle size of the mixed powder decreases significantly. When the ball milling time is 10 h, the average particle size of the powder drops to about 5 μm. It is found that sufficient ball milling time can significantly increase the number of collisions between grinding balls and the ball mill tank, as well as between grinding balls themselves. At the same time, it increases the system energy inside the ball mill tank, enabling the powder to be fully impacted and crushed, thus effectively improving the mechanical alloying effect of ball milling.

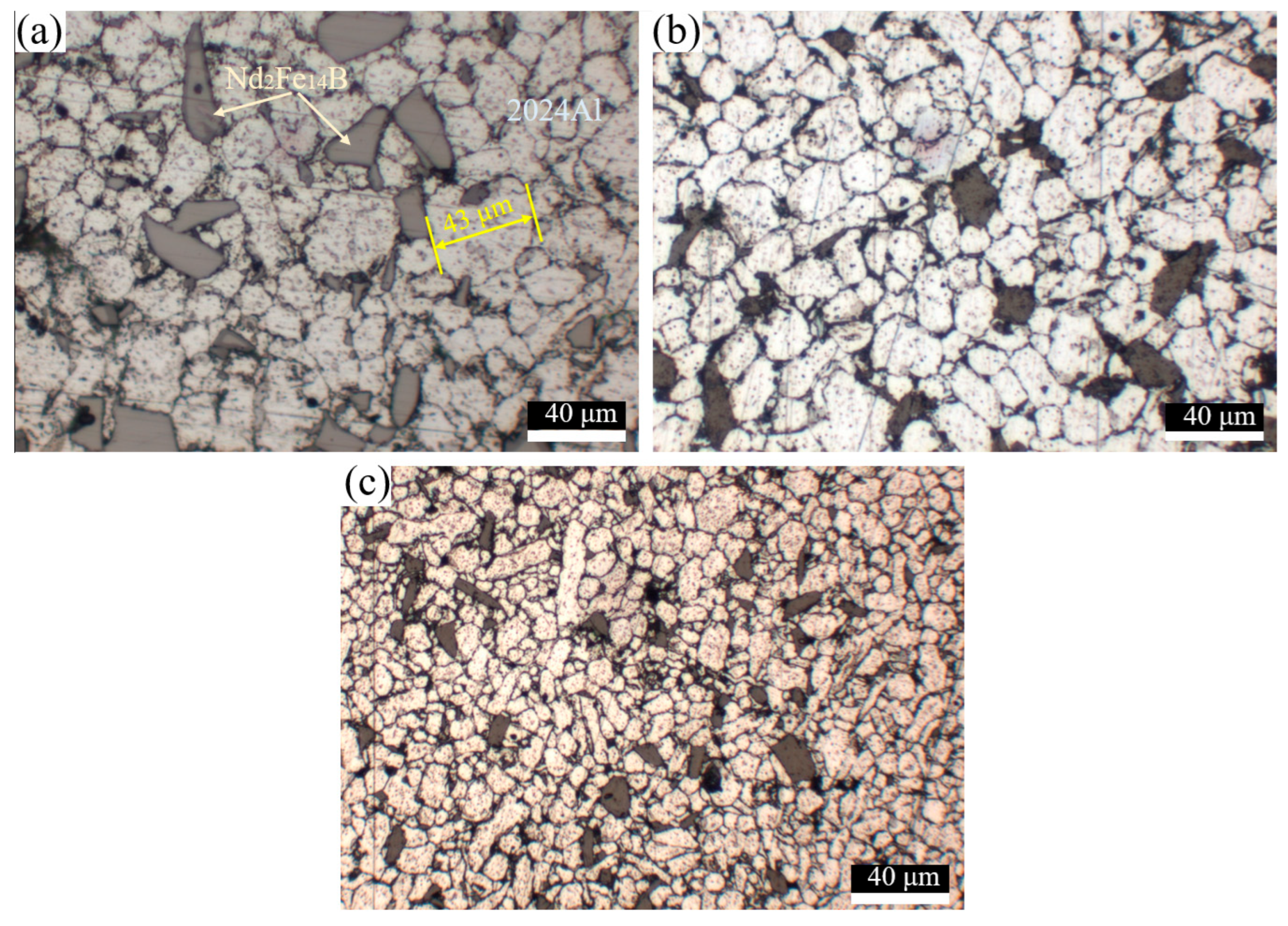

Figure 3a–c show the optical metallographic structure diagrams of Nd

2Fe

14B

p/2024Al composites with different powder particle sizes (25 μm, 10 μm, 5 μm) prepared by microwave sintering, where the addition amount of Nd

2Fe

14B powder is 15% and the sintering temperature is 490 °C. It can be seen that the particle size of the mixed powder has a significant impact on the microstructure of the composite. When the powder particle size is 25 μm, the grain size of the composite sample is relatively coarse and uneven, with the grain size in some local areas reaching 43 μm (as marked in

Figure 3a). Most of the Nd

2Fe

14B phases in the composite present sharp acute angles, which can easily split the matrix and destroy the continuity of it, and are not conducive to the exertion of the mechanical properties of the composite. When the powder particle size is 10 μm, the grain size of the composite is optimized, the average grain size is reduced to about 20 μm, the interface between the matrix and the particle phase is well bonded, and the morphology of the Nd

2Fe

14B phase is improved with relatively uniform distribution. As the powder particle size is 5 μm, the grain size of the 2024Al matrix in the composite is significantly reduced, with an average grain size of about 10 μm (as shown in

Figure 3c). The surface morphology of the matrix is uniform and flat, and the distribution uniformity of the Nd

2Fe

14B particle phase is significantly improved, showing a characteristic of dispersed distribution. It is found that during microwave sintering, a smaller particle size is helpful for microwaves to fully penetrate into the core of metal particles. The overall heating mode of powder particles from the surface to the interior, where microwave energy is converted into heat energy, achieves higher heating efficiency, and gives full play to the advantage of “low-temperature and fast sintering” of microwave sintering. Under higher superheat, it promotes phase transformation nucleation during the sintering process, the number of crystal nuclei is greatly increased, and the grains are refined [

21].

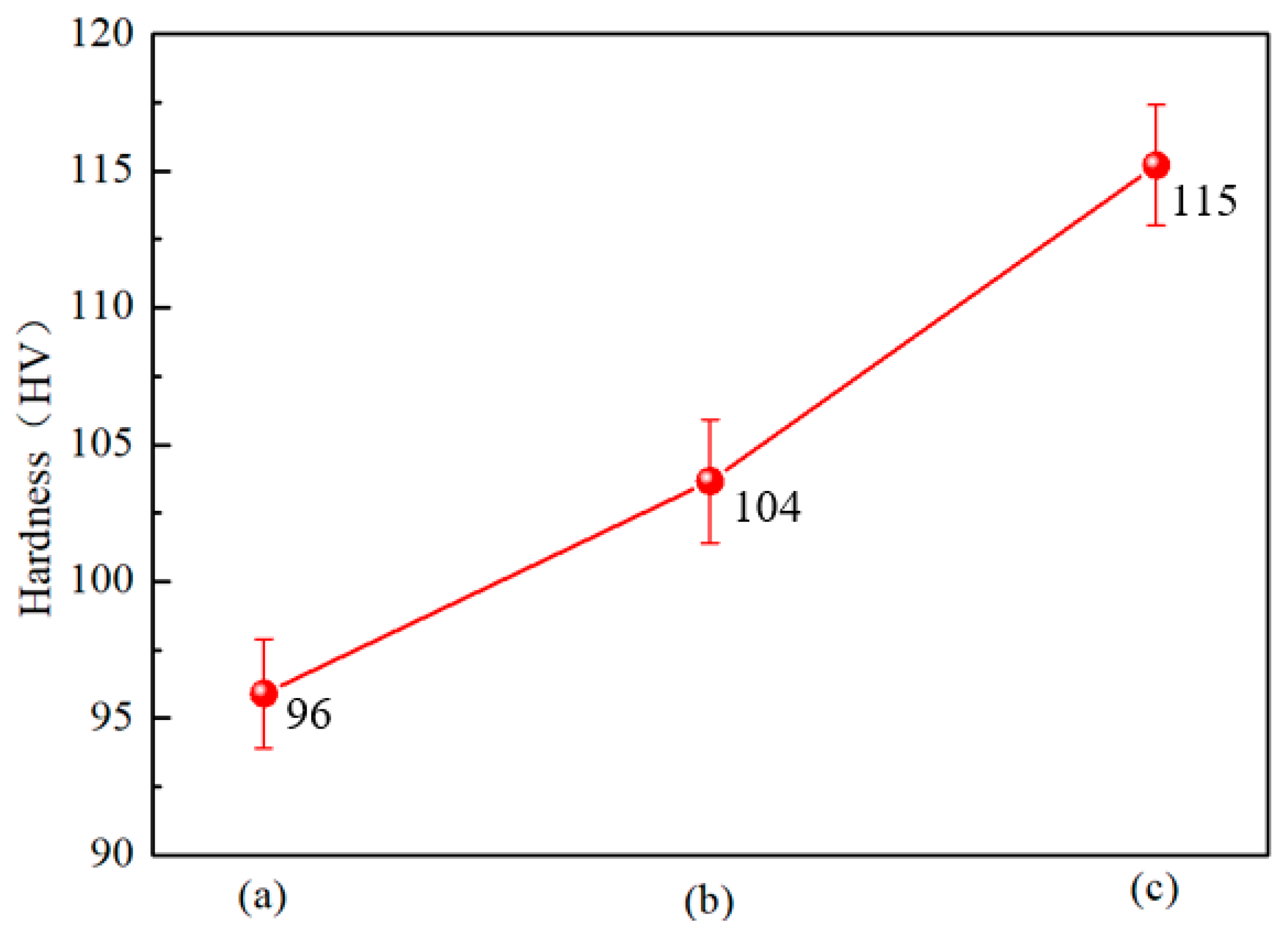

As depicted in

Figure 4, the microhardness of the composites increased monotonically with decreasing powder composites and increased monotonically with decreasing powder particle size, peaking at 115 HV for the 5 μm sample. When the powder particle size is large, the Nd

2Fe

14B particle phase is coarse and distributed in the matrix in an irregular shape with sharp corners (as shown in

Figure 3a), which is not conducive to the interface bonding between the reinforcing phase and the matrix. When the average particle size of the powder is 5 μm, the Nd

2Fe

14B phase is mainly in a nearly spherical shape and distributed relatively uniformly in the matrix, thus making the composite show a higher overall hardness.

Analysis indicates that the factors influencing the hardness of the composite mainly include compactness, the morphology and quantity of reinforcing phase particles, and their distribution state in the 2024Al matrix. During the sintering process, the densification of the green compact is mainly achieved through the diffusion and rearrangement of atoms. When the particle size of the composite powder is small, the grains of the composite synthesized by microwave sintering are also small, and its mechanical properties such as strength and toughness are better. In this experiment, a small powder particle size may be closer to the skin depth δ of the microwave used, and the proportion of the particle depth that microwaves can penetrate is larger. Therefore, the composite powder with a small particle size can better absorb microwave energy and convert it into heat energy, reaching the preset sintering temperature in a shorter time, which is conducive to the rapid densification of the material. From a thermodynamic perspective, metal powders with small particle sizes have a larger specific surface area, thus higher surface energy and greater activity, which further promotes the densification process during sintering.

Figure 5 is a schematic diagram showing the densification process of the sample compact during microwave sintering.

Figure 5a presents the state of particles inside the compact before the start of sintering, that is, the state after cold isostatic pressing. During the cold isostatic pressing process, migration and deformation occur between particles, leading to an increase in the number of internal defects in the particles. The increase in defects will promote the diffusion of atoms during microwave sintering. Meanwhile, under the high-strength load of cold isostatic pressing, tight bonds are formed between powder particles, which helps to promote the formation of sintering necks between particles during sintering.

Figure 5b shows the formation of sintering necks during the sintering process.

When the compact is sintered, under the action of the microwave field, material migration first occurs on the surface layer of the compact. Among them, the migration phenomenon is most significant in adjacent particles or areas with small gaps between them, and the material migration mainly proceeds through volume diffusion. The result of material migration is the formation of “bubbles” on the surface of powder particles due to the aggregation of atoms, as shown in

Figure 5a. With the continuous aggregation of atoms during the heating process, the “bubbles” continue to grow and connect with the surfaces of adjacent particles or between “bubbles”, realizing the connection between powder particles and forming sintering necks (as shown in

Figure 5b).

Table 1 shows the compactness of bulk composites calculated from the theoretical density and actual density for the three samples. As the particle size of the composite powder decreases, the measured density of the samples gradually increases, and the corresponding density gradually increases. When the average particle size is 5 μm, the compactness is 94.3%. It can be known that the same metal powder has the same penetration depth in the microwave field of the same frequency [

22]. For compacts with the same mass and volume, the finer the original powder, the more particles it contains. Therefore, combined with the microwave sintering densification principle, when the microwave penetration depth is constant, the finer the original powder particles in the compact, the larger the volume ratio penetrated by microwaves, the more sufficient the microwave absorption, and the higher the quality of microwave sintering. On the other hand, the finer the powder particles, the higher their surface energy and surface activity [

23], and the lower the activation energy required in the microwave sintering process, which is conducive to achieving a high densification process of the composite at a lower temperature in a short time. This is also in line with the “low-temperature and fast sintering” characteristics of microwave sintering.

3.2. Influence of Nd2Fe14B Addition Amount on the Microstructure

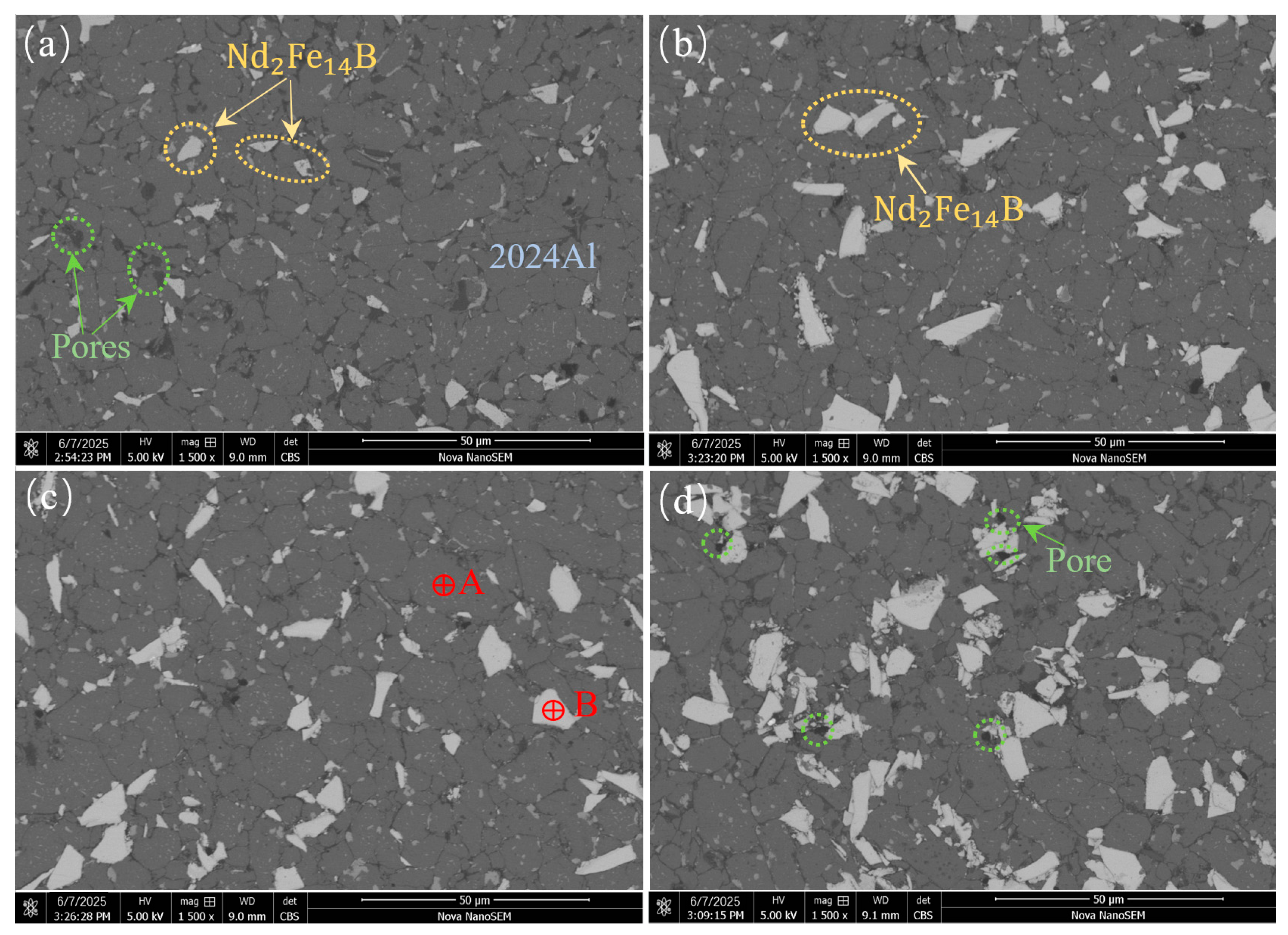

Figure 6a–d show the SEM morphology of Nd

2Fe

14B

p/2024Al composites with different amounts of Nd

2Fe

14B added. When the addition is 5 wt.%, the Nd

2Fe

14B phase is relatively sporadically distributed on the matrix. At this time, the grain size of the matrix is relatively coarse and has poor uniformity, and some pores can be observed in the matrix, as shown in the marked area of

Figure 6a. When the addition of Nd

2Fe

14B reaches 10 wt.% (

Figure 6b), the grain size of the 2024Al matrix decreases, and the pores between the grains reduce compared to

Figure 6a. The distribution of the Nd

2Fe

14B phase on the matrix is relatively uniform, but the morphology tends to exhibit irregular and sharp angular shapes. When the addition is 15 wt.% (

Figure 6c), compared to

Figure 6b, the number of grains with sharp angular morphology has notably decreased, and the distribution in the matrix is relatively uniform, with no obvious aggregation observed. Additionally, the number of visible pores in the matrix has also decreased. When the addition of Nd

2Fe

14B reaches 20 wt.% (as shown in

Figure 6d), the packing density of the Nd

2Fe

14B particle phase on the matrix is higher, and nearby particles tend to stick together and aggregate [

24]. Meanwhile, it is evident that a larger number of pores are formed at the interface between the Nd

2Fe

14B phase and the 2024Al matrix, as indicated by the green dashed lines in

Figure 6d. Therefore, from the perspective of the microstructure, when the addition of Nd

2Fe

14B is 15 wt.%, the microstructure of the Nd

2Fe

14B

p/2024Al composites is more ideal.

For particle-reinforced aluminum matrix composites prepared by powder metallurgy, there is a limit to the addition amount of reinforcing phase particles. When the volume fraction of the reinforcing phase exceeds this limit, agglomeration occurs. The influencing factors of this limit value mainly include the particle morphology of the matrix and reinforcing phase, the size ratio of matrix particles to reinforcing phase particles, and the preparation process of the composite. At present, the calculation method for the maximum volume fraction of enhanced phase particles is mostly based on the mathematical model obtained from the mixing ratio, while research on the influence trend of ball mill preparation parameters on particle distribution is relatively rare. For the calculation of the limit value of the volume ratio of reinforcing phase particles, the model proposed by Slipenyuk et al. is commonly used [

25], as shown in Formula (4).

In the formula,

Wcrit represents the maximum volume ratio at which the particle reinforcing phase in the composite can be uniformly distributed in the matrix;

δ is a constant whose value is based on parameters such as the particle size distribution and morphology of the actual powder particles, and the commonly used value is 0.18;

d is the actual diameter of the reinforcing phase particles;

D is the actual diameter of the matrix phase particles;

λ is the extrusion ratio. In this experiment, the limit value of the particle volume ratio of the Nd

2Fe

14B phase calculated by using this model formula is 13.1%. However, as shown in

Figure 6, when the addition amount of the Nd

2Fe

14B phase reaches 15%, it is still uniformly distributed in the composite matrix. This indicates that the previous high-energy ball milling has promoted the uniform distribution of the Nd

2Fe

14B phase.

Figure 7a shows the XRD patterns of the composite before and after sintering. It can be seen that no new phases were generated after sintering, as the sintering temperature was 490 °C, which is far below the melting point of Nd

2Fe

14B (1150 °C) and 2024Al (655 °C). Moreover, the XRD peaks of Nd

2Fe

14B are consistent with each other, showing no changes or shifts. This indicates that the structure of Nd

2Fe

14B remains stable during the sintering process, thereby ensuring the magnetic properties of Nd

2Fe

14B. Meanwhile, no other new phases or oxides are formed in the composite, as the sintering process is carried out under the protection of an argon atmosphere, which effectively inhibits the oxidation of the composite. The EDS spectroscopy (

Figure 7b) analysis was conducted on points A and B in

Figure 6c, indicating that the compositions are 2024Al matrix and Nd

2Fe

14B phase, respectively.

3.3. Mechanical Characterization

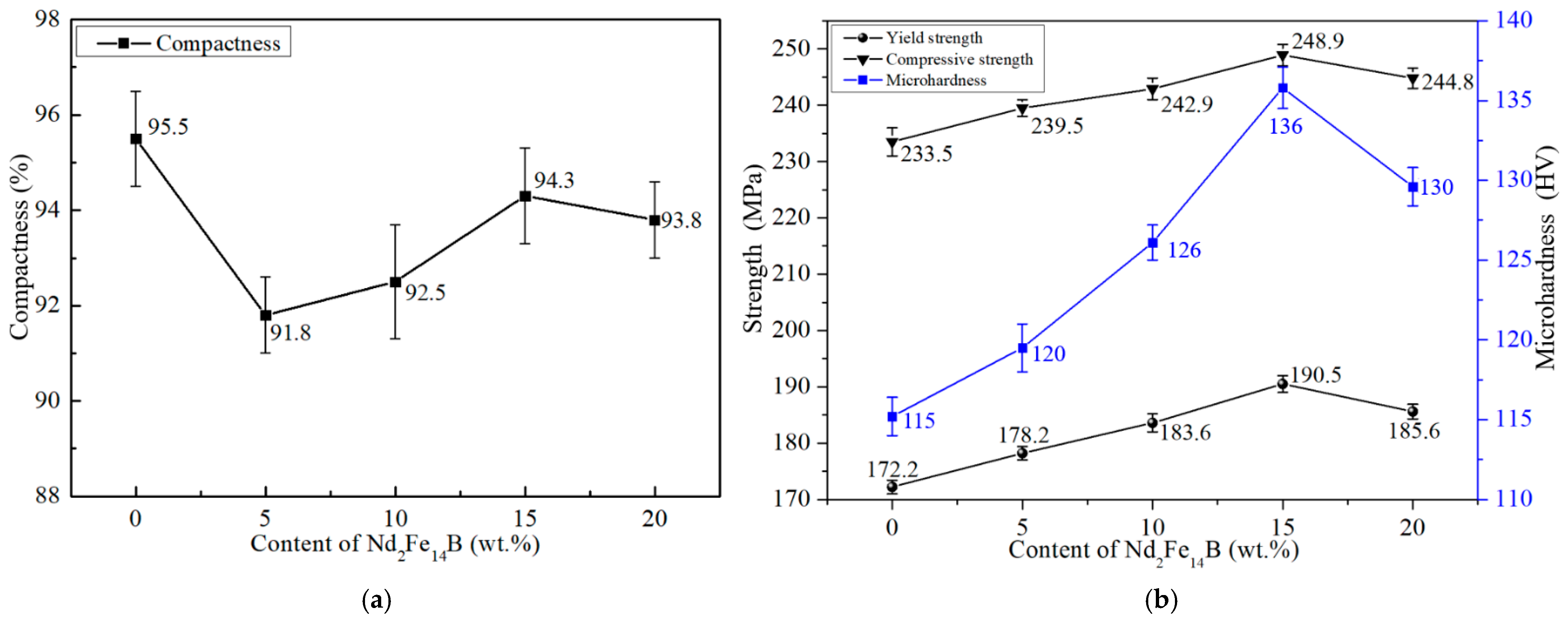

Figure 8a shows the trend of the compactness of the composite as the content of Nd

2Fe

14B changes. When Nd

2Fe

14B is not added, the compactness of the 2024Al alloy is approximately 95.5%. However, after adding different amounts of Nd

2Fe

14B powder, the compactness of the composite first decreases and then increases. As the addition varies at 5 wt.%, 10 wt.%, and 15 wt.%, the compactness of the composite gradually increases, reaching the highest value at the addition of 15 wt.% Nd

2Fe

14B. As the amount of Nd

2Fe

14B increases, the thermal effect of the reinforcing phase in the composite during the microwave sintering process becomes more significant, contributing increasingly to the absorption and conversion of microwave energy in the overall heating, and resulting in a more uniform microstructure and refined grains, thus increasing the compactness. However, when the addition of Nd

2Fe

14B reached 20 wt.%, the mobility of the Nd

2Fe

14B particles was weakened during the cold isostatic pressure process, leading to aggregation and an increase in the number of gaps between particles [

26], which subsequently decreases the compactness of the composite.

Figure 8b shows the trend of the mechanical properties of the composite with different Nd

2Fe

14B content. As the amount of Nd

2Fe

14B increases, the microhardness, yield strength, and compressive strength first increase and then decrease, reaching the peak when the Nd

2Fe

14B content is 15 wt.%, at 136 HV, 190.5 MPa, and 248.9 MPa, respectively. Compared to the control sample, these values are increased by 17.9%, 10.6%, and 6.6%, respectively. As the content of Nd

2Fe

14B increases to 20 wt.%, the microhardness, yield strength, and compressive strength of the composite slightly decrease. The Nd

2Fe

14B phases have extremely high hardness, they are distributed in the 2024Al matrix as the reinforcing phases. With the increase in the addition amount, the surface area of Nd

2Fe

14B particles on the matrix is expanded, the effective load-bearing capacity of the composite is improved, the ability of the composite to bear deformation is enhanced, and the deformation resistance of the micro-regions of the material is increased. In other words, the dispersively distributed Nd

2Fe

14B particles restrict the deformation of the matrix grains in local regions, thus improving the macroscopic hardness of the composite. However, when the addition amount of Nd

2Fe

14B particles reaches 20 wt.%, the Nd

2Fe

14B phases agglomerate to a certain extent, as can be seen from

Figure 6d. This is not conducive to the improvement of the effective load-bearing capacity of the composite; on the contrary, it may even reduce it [

27]. Moreover, it will cause uneven deformation resistance in various regions of the material surface, so the mechanical property decreases.

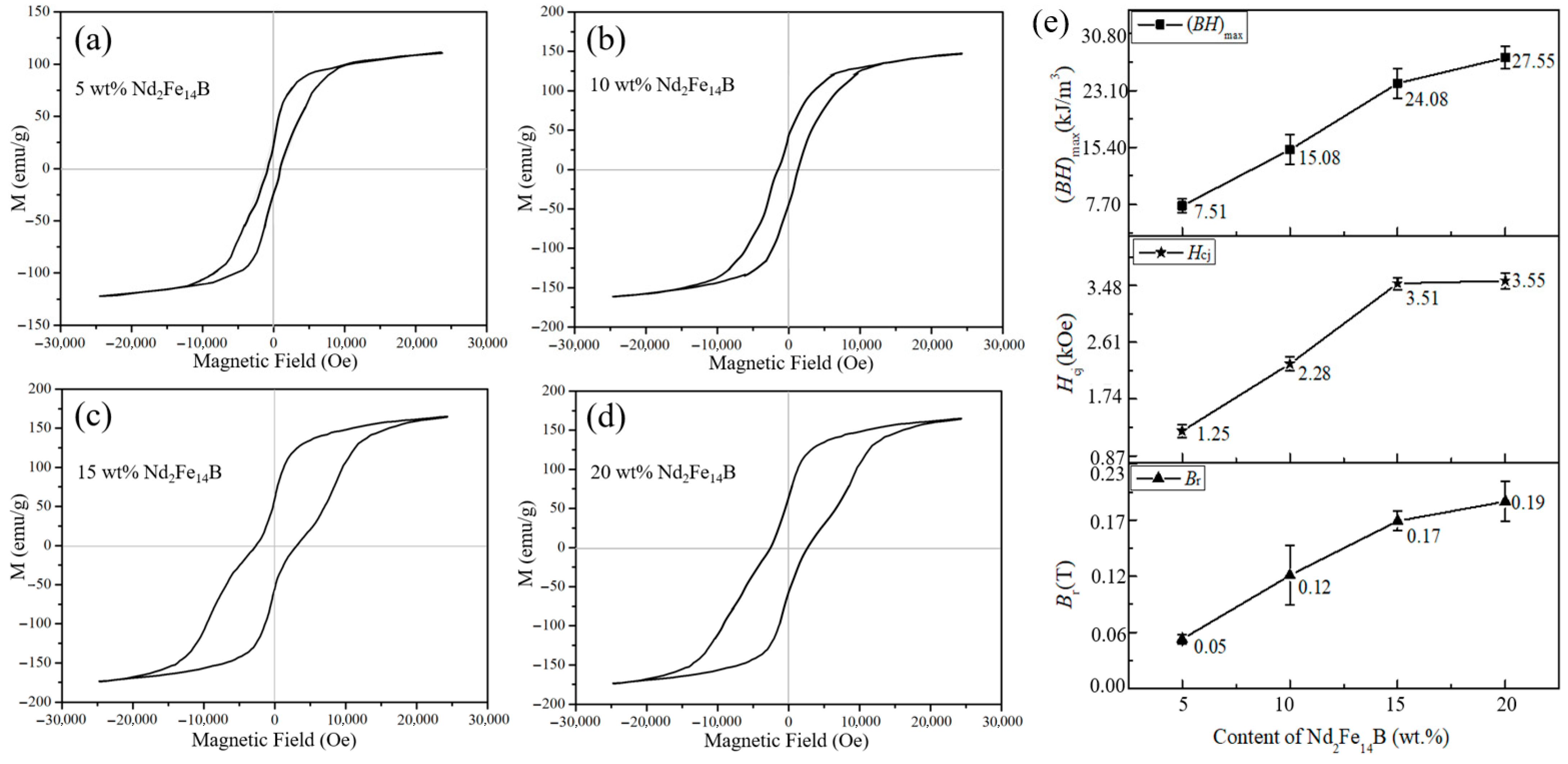

3.4. Characterization of Magnetic Properties

Figure 9a–d show the VSM (vibrating sample magnetometer) curves of composites with different Nd

2Fe

14B content, which were measured and characterized using an oscillating sample magnetometer to assess the magnetic properties of the materials. The magnetic properties’ parameters of the composite, such as remanence (

Br), coercivity (

Hcj), and maximum magnetic energy product ((

BH)

max), can be calculated through the VSM curve, as shown in

Figure 9e.

From

Figure 7a,b in

Section 3.2, it can be seen that no new phases were generated during the sintering process. Therefore, the magnetic properties of composite are closely related to the amount of Nd

2Fe

14B added. It is generally believed that the magnetic properties of composite increase with the increase in Nd

2Fe

14B content, and the experimental results have also verified this. At the same time, we also noticed that when the Nd

2Fe

14B content increased from 15 wt.% to 20 wt.%, the increasing trend of the magnetic performance parameters of the composite slowed down, with only an increase of 14.4%, 1.1%, and 11.8%, all significantly lower than the previous growth level.

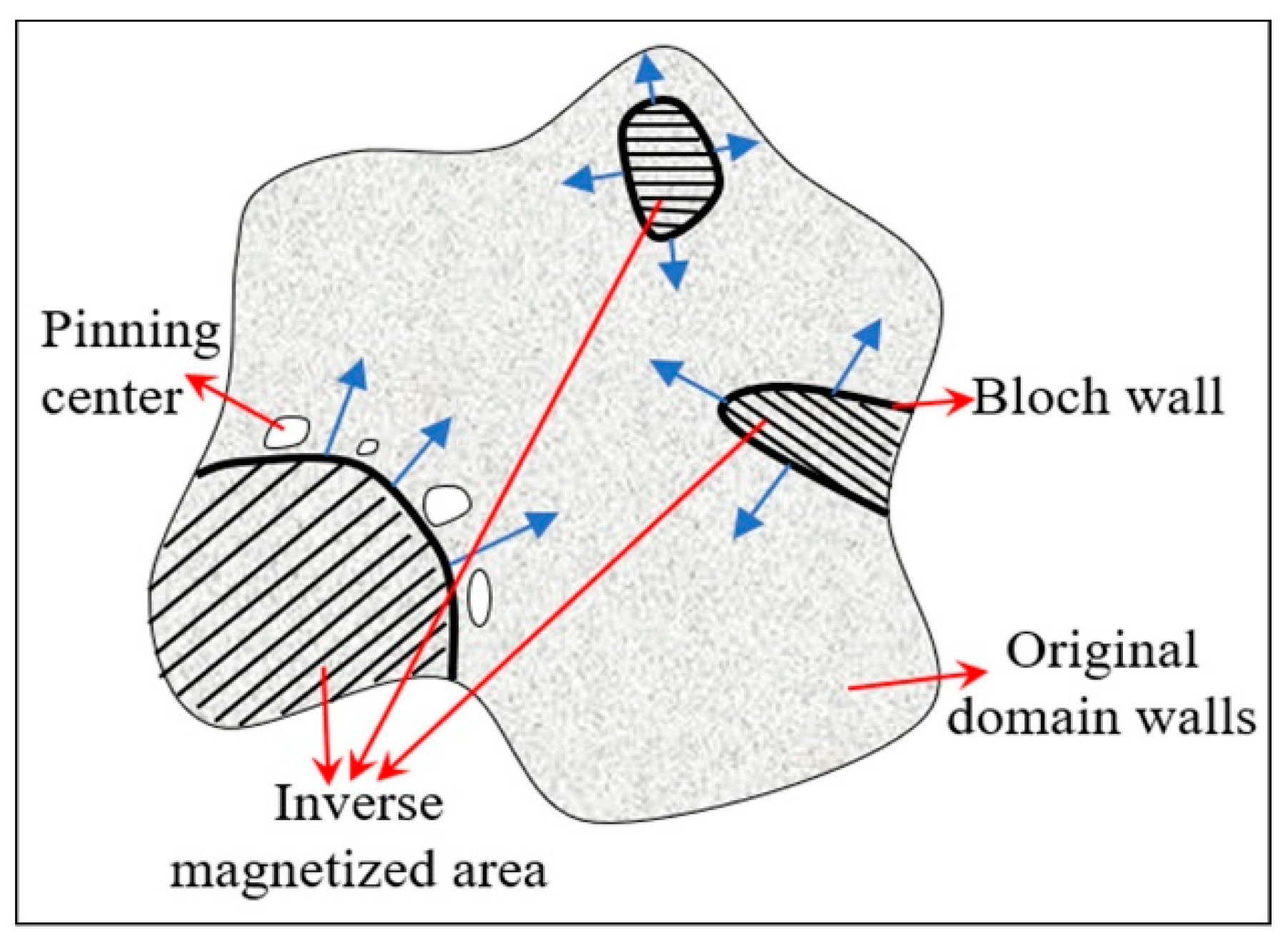

The magnetic properties of the composite are influenced by both the amount of Nd

2Fe

14B added and the microstructure and compactness. The pores inside the composite and the sharp corners of irregularly shaped particles have low energy barriers. When magnetized, these defects are prone to form uneven and dispersed reverse magnetic fields, leading to the occurrence of the demagnetization phenomenon (as shown in

Figure 10) and reducing the magnetic properties of the material [

28]. When the addition amount is 20 wt.%, the Nd

2Fe

14B particles agglomerate and there are more pores in the microstructure (

Figure 6d). These areas can form more reverse magnetic fields during the magnetization process, affecting the exchange coupling between Nd

2Fe

14B magnetic particles and resulting in a decrease in the overall magnetic properties of the composite.

Based on the comprehensive effect of Nd2Fe14B addition on the compactness, mechanical properties, and magnetic properties of the composite, from the perspective of preparing high-magnetic and high-performance aluminum-based composite, it is believed that the optimal value for Nd2Fe14B addition is 15 wt.%