Study of the Tribological Properties of Self-Fluxing Nickel-Based Coatings Obtained by Gas-Flame Spraying

Abstract

1. Introduction

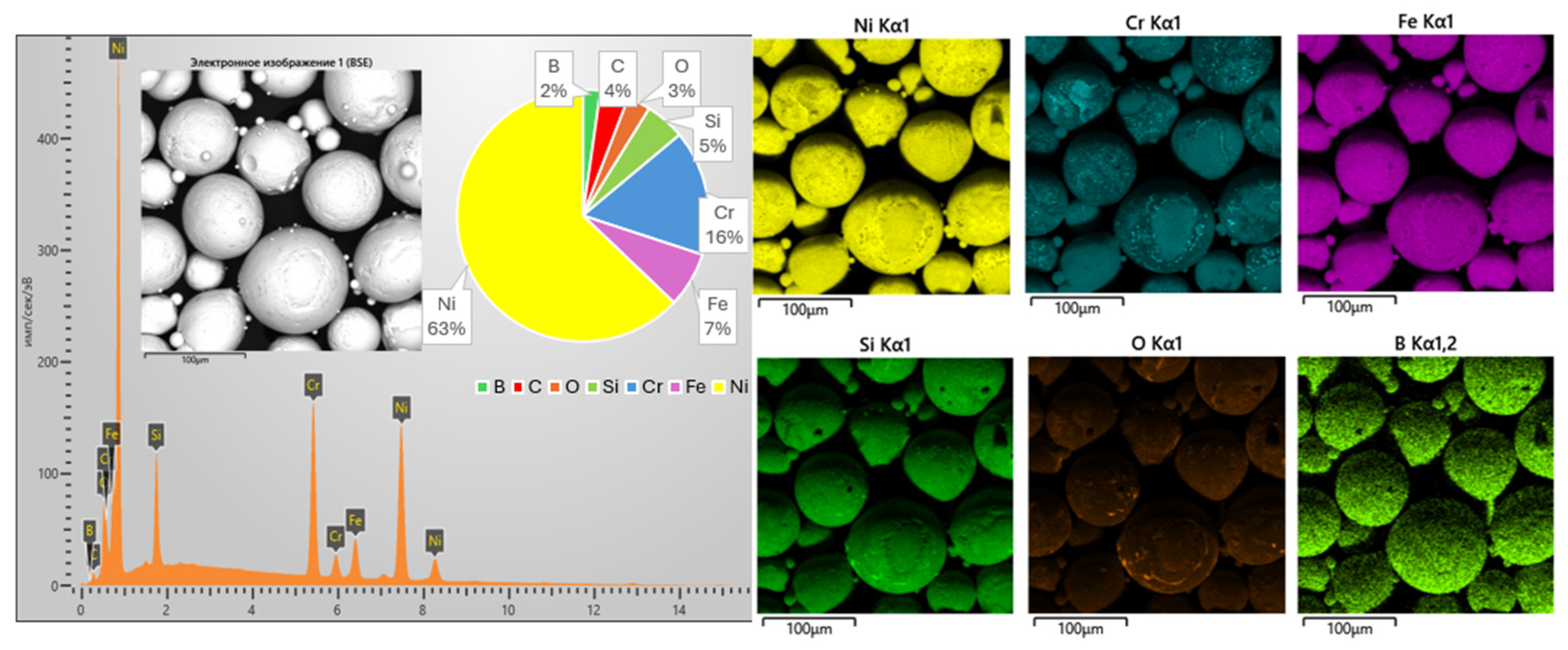

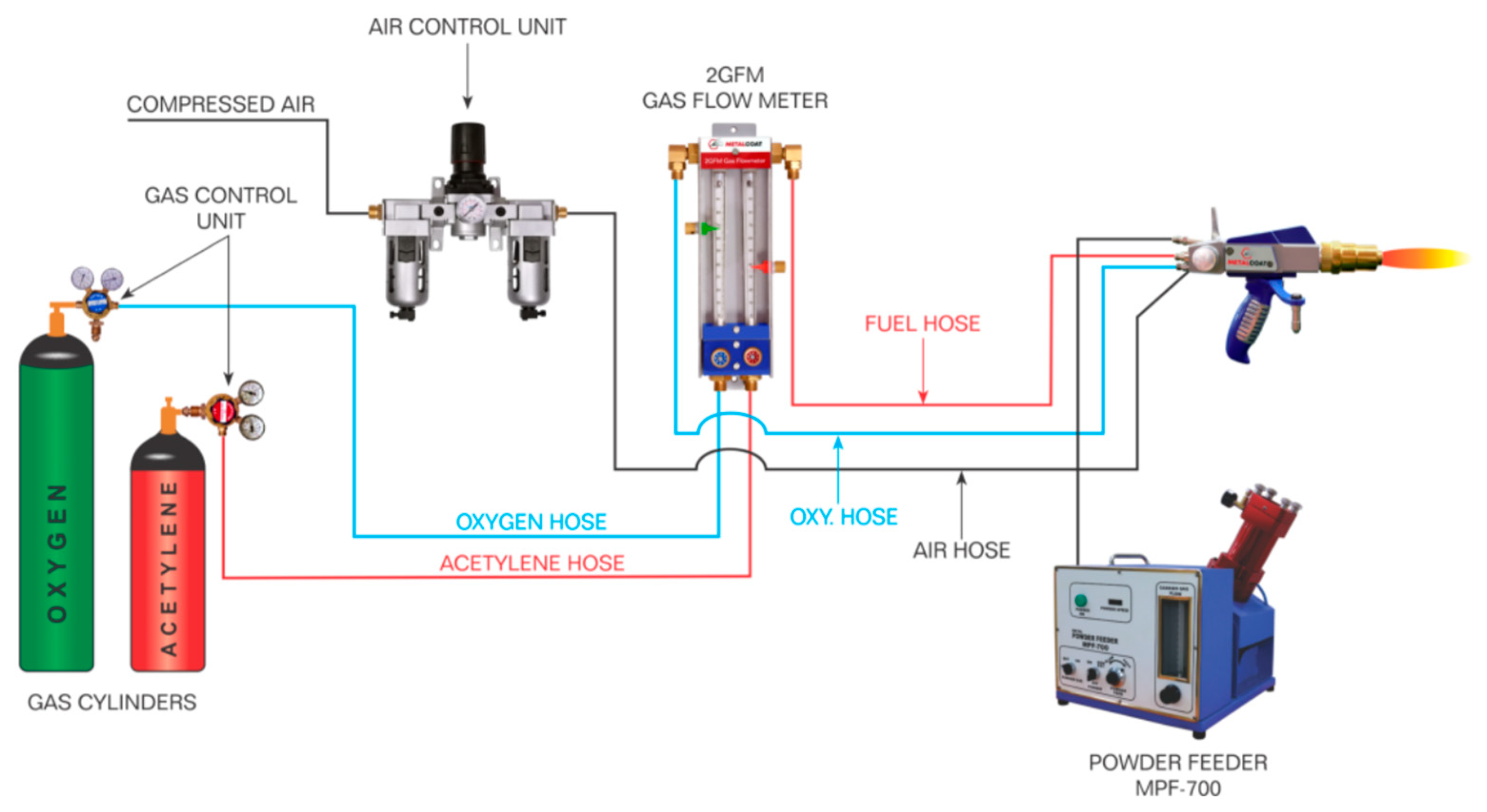

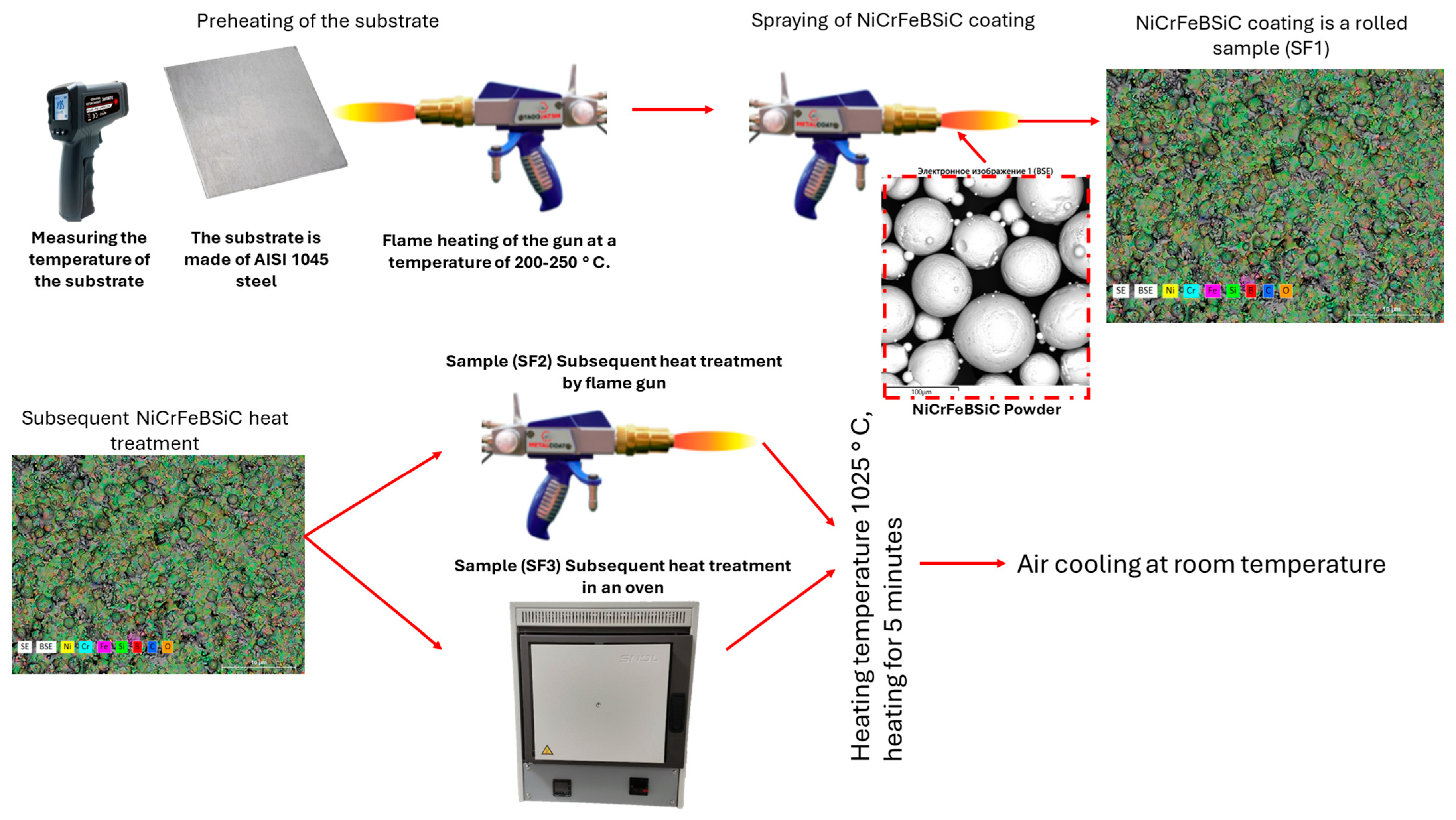

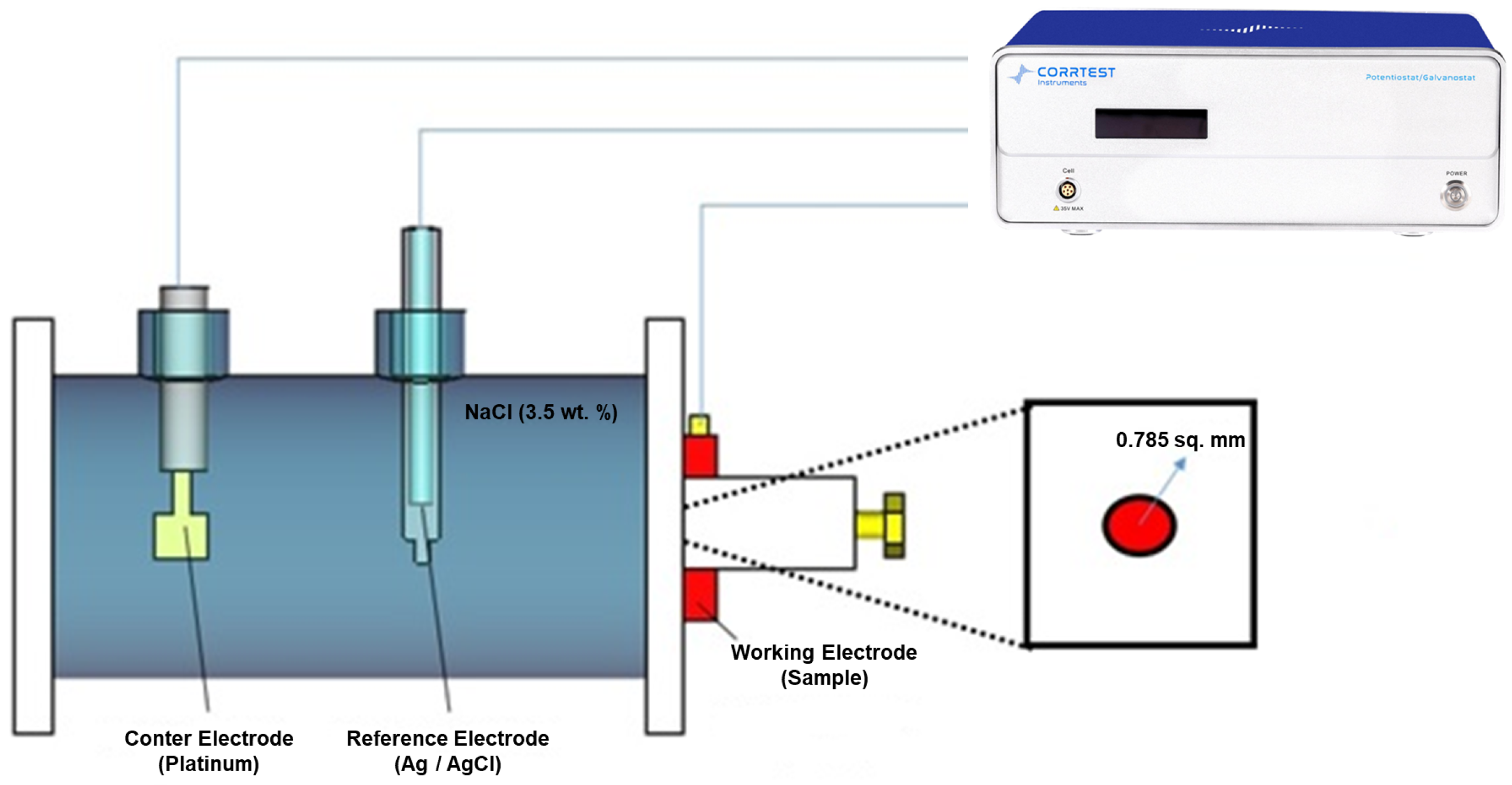

2. Materials and Methods

3. Results

- -

- The decrease in the intensity of diffraction peaks during spraying indicates that the coating obtained using the spraying method became more amorphous compared to the initial powder. This may occur due to limited cooling and rapid formation of the coating, during which large crystalline structures do not have time to form. This may also indicate the presence of micropores, which reduce the amount of crystalline phases observable in X-ray diffraction.

- -

- The increase in intensity after flame remelting compared to the sprayed layer may indicate the onset of crystallization and structural stabilization of the material. The flame remelting process leads to local heating of the coating, which promotes a more complete formation of crystalline phases. However, the intensity is still lower than that of the initial powder, indicating the presence of a considerable amount of amorphous or microcrystalline regions.

- -

- A significant increase in intensity after furnace heating indicates a more complete crystalline transformation of the material. At the high temperatures that can be reached in the furnace, the formation of a more stable and ordered crystalline structure is promoted. The increase in peak diffraction intensity at this stage may indicate crystal growth and an enhancement in lattice ordering. This is particularly noticeable with respect to the Ni peaks, which are broadened in the case of the coating. The broadening of the peaks may be associated with distortion of the crystalline structure caused by the rapid cooling of the material during the laser treatment, which is characteristic of thermally treated coatings, as demonstrated in the work of Li et al. (2001) [23].

4. Conclusions

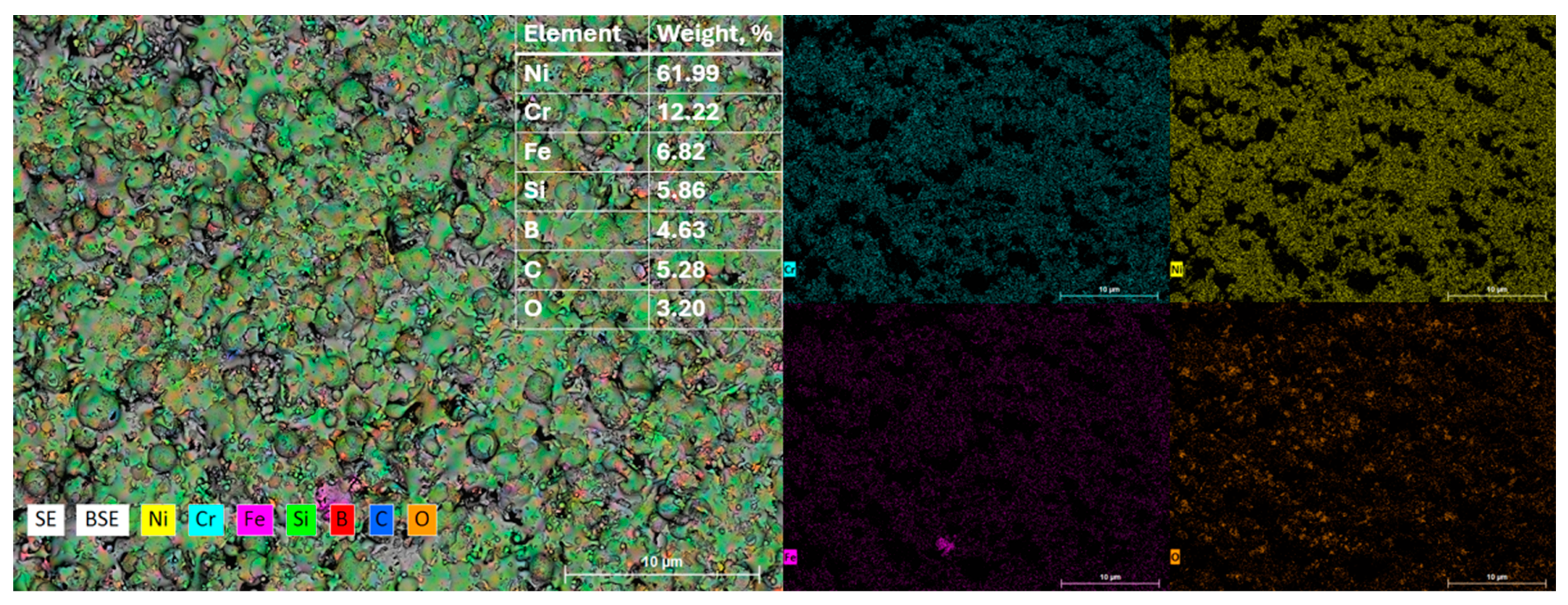

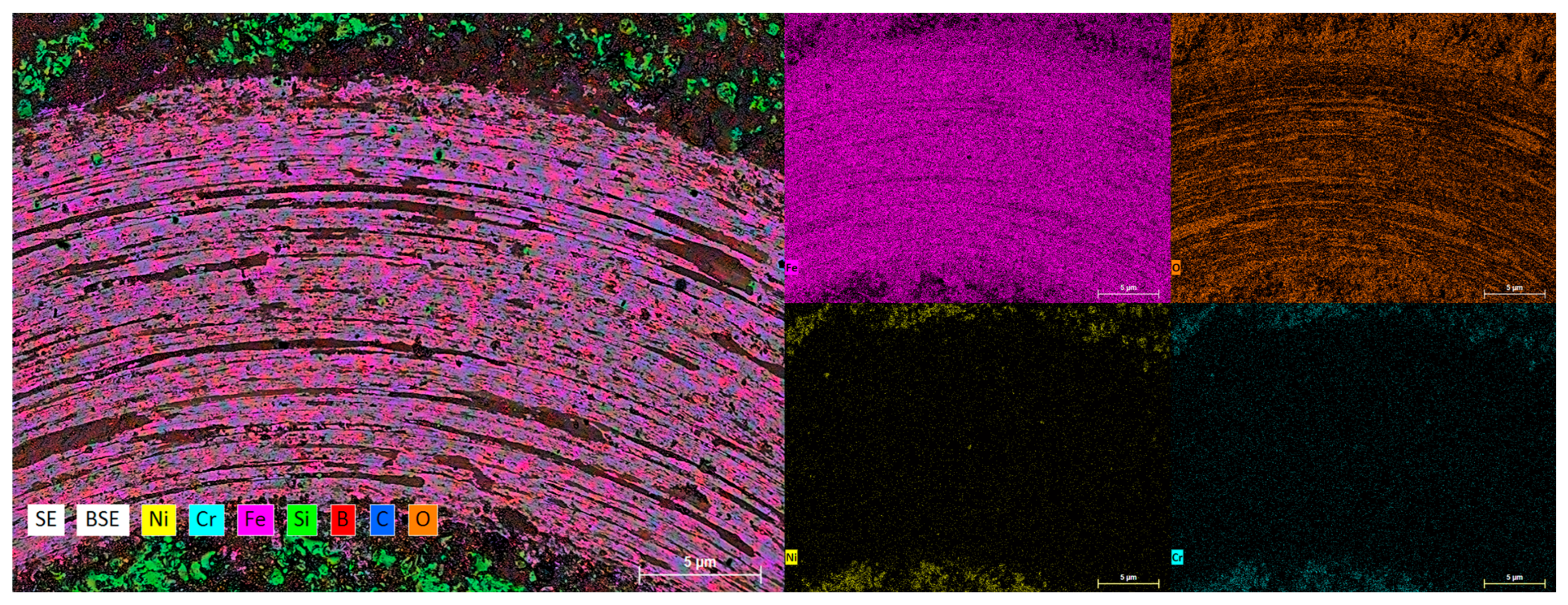

- Phase composition (XRD): The coatings contain FeNi3 and strengthening carbides/borides (e.g., Cr7C3, Fe23(C,B)6); after heat treatment, the lattice becomes more ordered with an increase in the Ni solid-solution lattice parameter (3.55 → 3.57 Å).

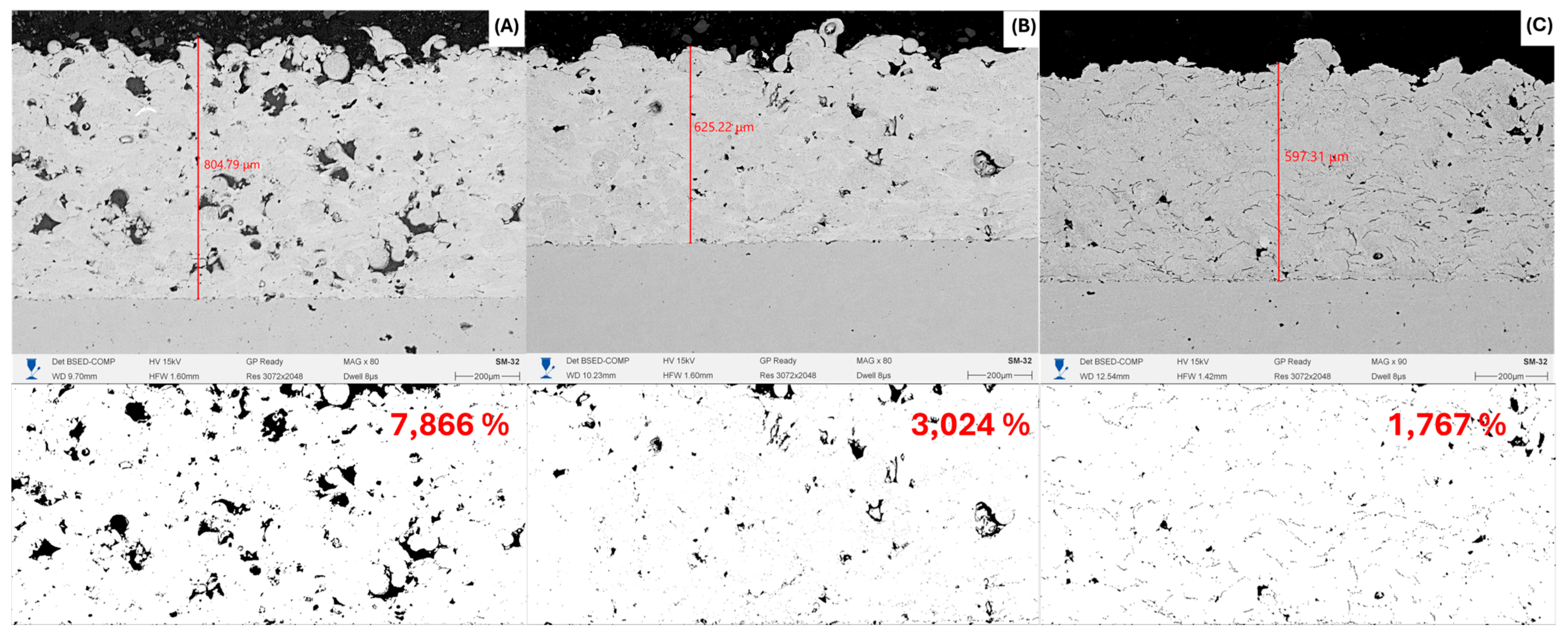

- Thickness and porosity: Cross-section shows densification (thickness ~805 → 625 → 597 μm), with porosity reduced 7.866% → 3.024% → 1.767% from as-sprayed to flame-remelted to furnace-treated.

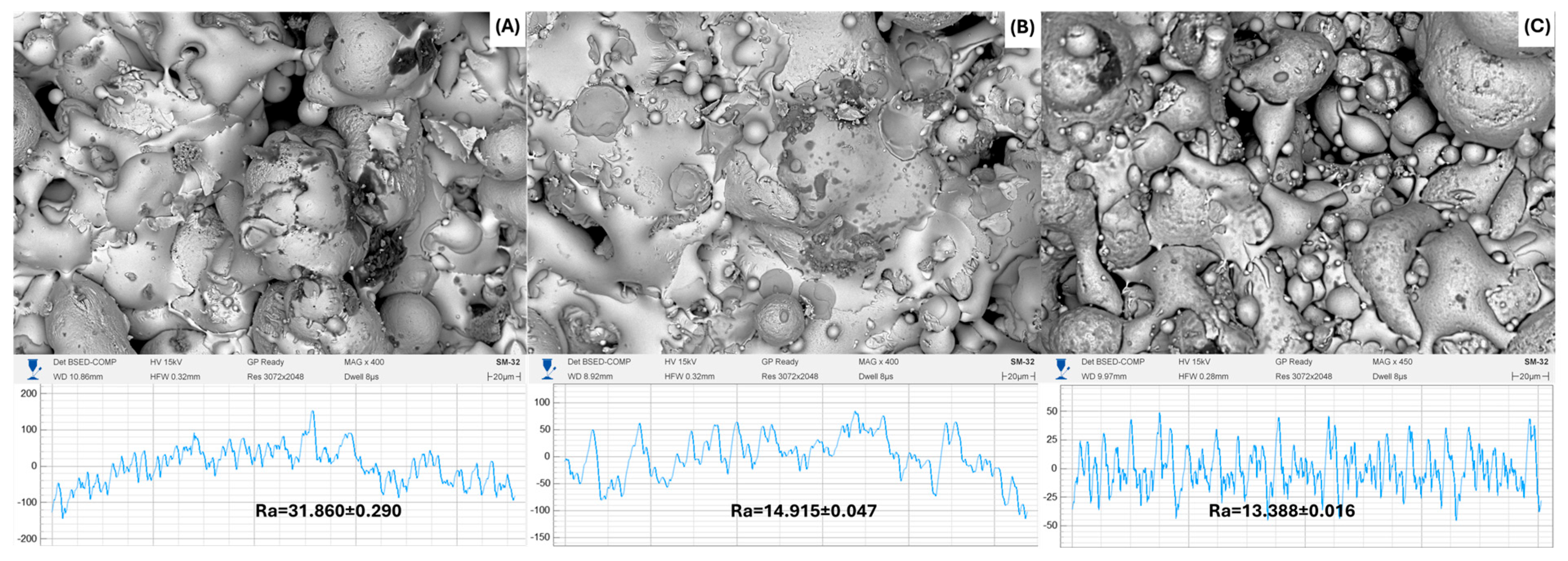

- Roughness (Ra): Surface smoothing with post-treatments: 31.860 → 14.915 → 13.388 μm (minimum after furnace treatment).

- Microhardness: Near-surface HV increases 528.7 ± 2.3 → 771.6 ± 4.6 → 922.4 ± 5.7 HV, reflecting lower porosity and a stabilized binder.

- Adhesion strength (ASTM C633): 18 → 27 → 34 MPa; the furnace treatment gives the highest coating–substrate bonding.

- Wettability (contact angle): Surface becomes less wettable as density increases: 53.152° → 79.875° → 89.603°.

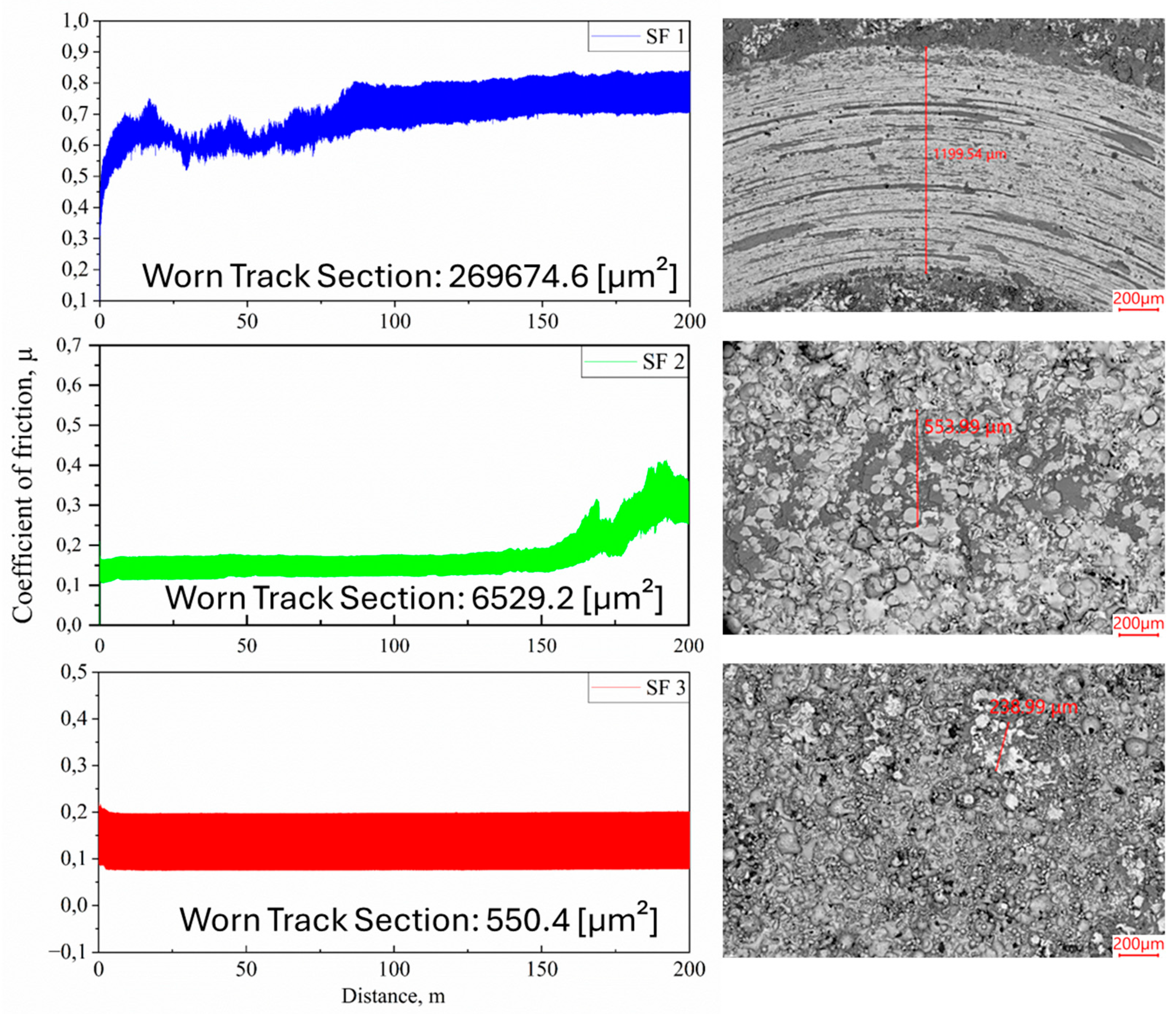

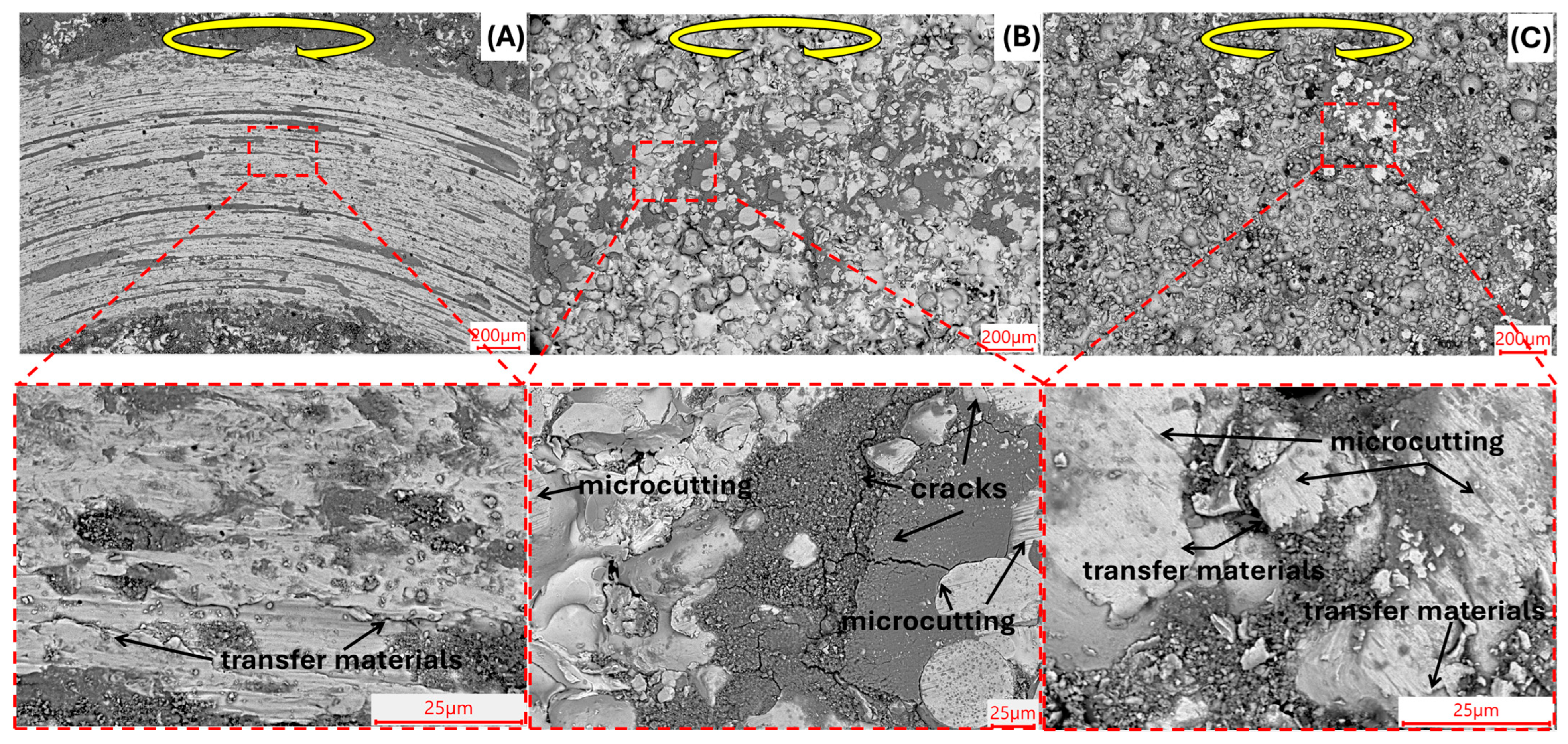

- Coefficient of friction (dry, ball-on-disk): μ decreases and stabilizes with post-treatments: 0.648 ± 0.070 → 0.173 ± 0.050 → 0.138 ± 0.003; furnace treatment shows the smallest fluctuations.

- Wear-track morphology: Evolves from pronounced micro-grooves and cracking (as-sprayed) to a more uniform, “polishing-like” track with a thin tribo-film (furnace).

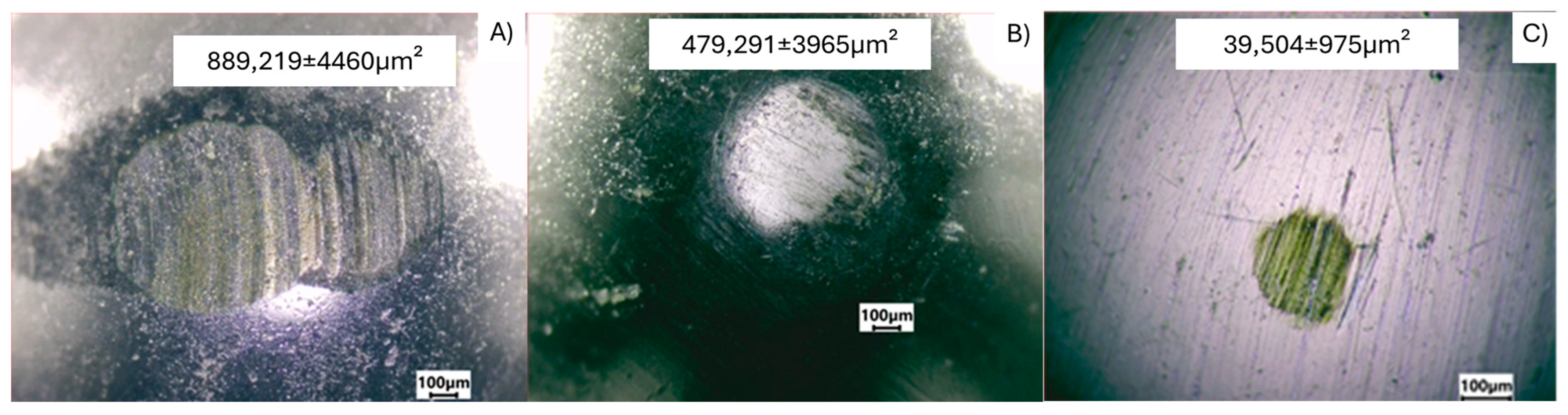

- Counterbody wear (100Cr6 ball): Wear-scar area shrinks with coating modification (0.889 → 0.479 → 0.0395 mm2), confirming improved tribological compatibility.

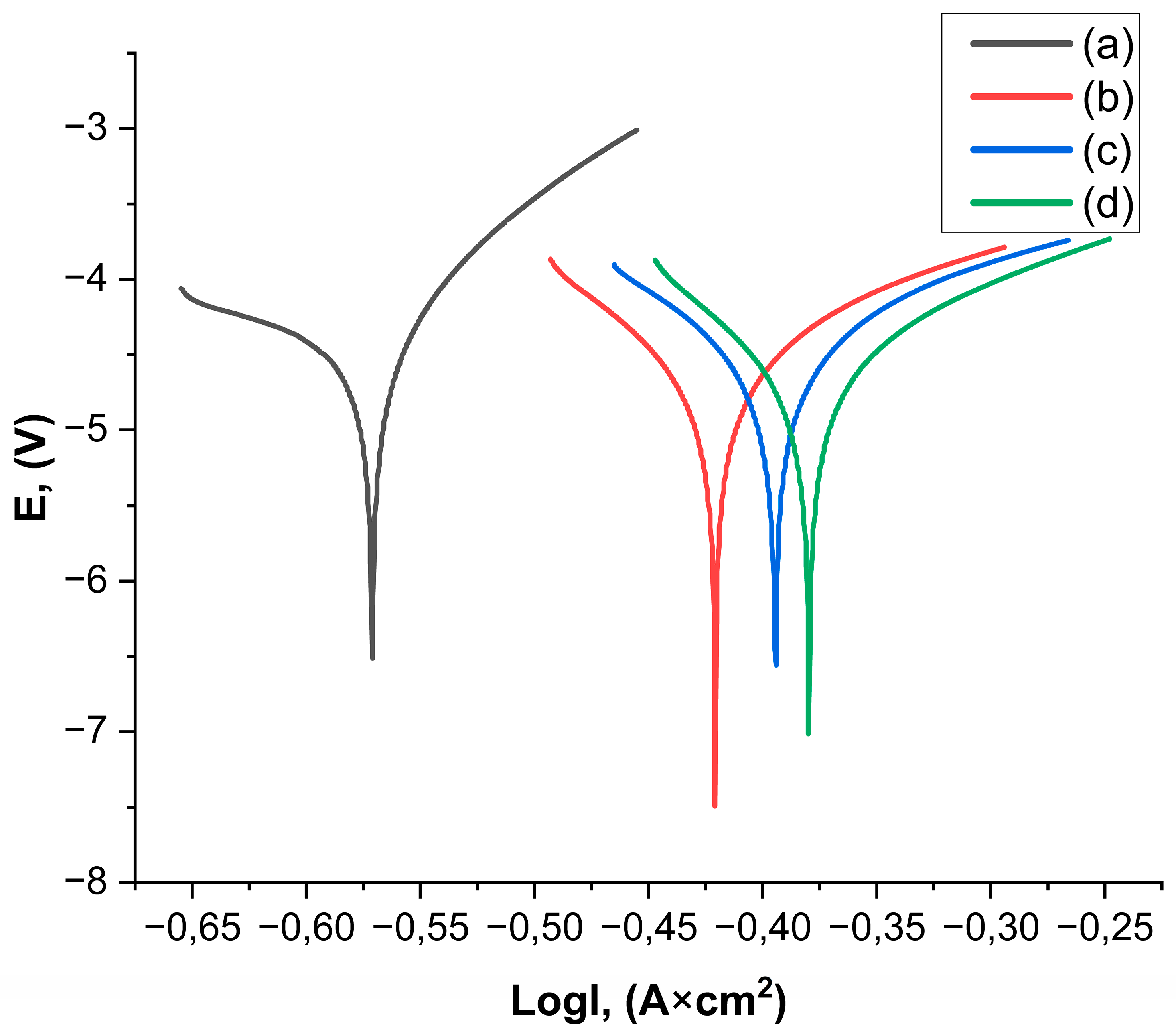

- Corrosion resistance (Tafel): Furnace treatment yields the lowest icorr/CR (e.g., CR ≈ 0.005678 mm·year−1), outperforming AISI 1045 steel and the flame-remelted state.

- Overall: Among the tested routes, furnace heat treatment at 1025 °C/5 min provides the best structure–property balance (minimum Ra and porosity, maximum HV and adhesion, low and stable μ, enhanced corrosion resistance) and is recommended to extend the service life of NiCrFeBSiC coatings under dry sliding.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kusumar, Nerlfi & Growney Publish Third Global Paint & Coatings Report, 2016–2021. Available online: https://www.coatingsworld.com/issues/2017-09-01/view_market-research/kusumgar-nerlfi-amp-growney-publish-third-global-p/ (accessed on 13 May 2025).

- Pawlowski, L. The Science and Engineering of Thermal Spray Coatings, 2nd ed.; John Wiley & Sons, Ltd.: Chichester, UK, 2008. [Google Scholar]

- Havrlisan, S.; Simunovic, K.; Vukelic, D. Modelling of abrasive wear of Ni-based self-fluxing alloy coatings by the application of experimental design. Tech. Gaz. 2006, 23, 1687–1693. [Google Scholar] [CrossRef][Green Version]

- Váz, R.; Tristante, R.; Pukasiewicz, A.; Capra, A.; Chicoski, A.; Filippin, C. Welding and thermal spray processes for maintenance of hydraulic turbine runners: Case studies. Soldag. Inspeção. 2021, 25, 2540. [Google Scholar] [CrossRef]

- Vardavoulias, M. Industrial component restoration using thermal spray technologies. In Industrial Component Restoration Using Thermal Spray Technologies; CRC Press: Boca Raton, FL, USA, 2023. [Google Scholar] [CrossRef]

- Vernhes, L. Thin Coatings for Heavy Industry: Advanced Coatings for Pipes and Valves. Ph.D. Thesis, Université de Montréal, Montréal, QC, Canada, 2015. Available online: https://publications.polymtl.ca/1686/1/2015_LucVernhes.pdf (accessed on 21 September 2025).

- Zhang, X.; Luo, T.; Liu, S.; Zheng, Z.; Wang, J.; Zheng, K.; Wang, S.; Chen, H. Microstructure and Corrosion Behavior of Fe-Based Austenite-Containing Composite Coatings Using Supersonic Plasma Spraying. Coatings 2023, 13, 694. [Google Scholar] [CrossRef]

- Lee, C.-Y.; Lin, T.-J.; Sheu, H.-H.; Lee, H.-B. A study on corrosion and corrosion-wear behavior of Fe-based amorphous alloy coating prepared by high velocity oxygen fuel method. J. Mater. Res. Technol. 2021, 15, 4880–4895. [Google Scholar] [CrossRef]

- Umanskyi, O.P.; Storozhenko, M.S.; Baglyuk, G.A.; Melnyk, O.V.; Brazhevsky, V.P.; Chernyshov, O.O.; Terentiev, O.E.; Gubin, Y.V.; Kostenko, O.D.; Martsenyuk, I.S. Structure and wear resistance of plasma-sprayed NiCrBSiC–TiCrC composite powder coatings. Powder Metall. Met. Ceram. 2020, 59, 434–444. [Google Scholar] [CrossRef]

- Abderrahmane, A.; Gaceb, M.; Cheikh, M.; LE Roux, S. Wear Behavior and Microstructure of Thermally Sprayed NiCrBSiFeC and Composite NiCrBSiFeC-WC(Co) Coatings. Mater. Sci. 2021, 27, 175–183. [Google Scholar] [CrossRef]

- Kazamer, N.; Vălean, P.; Pascal, D.-T.; Muntean, R.; Mărginean, G.; Șerban, V.-A. Development, optimization, and characterization of NiCrBSi-TiB2 flame-sprayed vacuum fused coatings. Surf. Coat. Technol. 2021, 406, 126747. [Google Scholar] [CrossRef]

- Monção, F.C.; Caliari, F.R.; Freitas, F.E.; Couto, A.A.; Augusto, A.; Lima, C.R.C.; Massi, M. Wear Resistance Evaluation of Self-Fluxing Nickel-Based Coating Deposited on AISI 4340 Steel by Atmospheric Plasma Spray. Metals 2024, 14, 532. [Google Scholar] [CrossRef]

- Shieh, Y.-H.; Wang, J.-T.; Shih, H.C.; Wu, S.-T. Allowing and post-heat treatment of thermal sprayed coatings of self-fluxing alloys. Surf. Coat. Technol. 1993, 58, 73–78. [Google Scholar] [CrossRef]

- Cha, S.C.; Gudenau, H.W.; Bayer, G.T. Comparison of corrosion behaviour of thermal sprayed and diffusion-coated materials. Mater. Corros. 2002, 53, 195–205. [Google Scholar] [CrossRef]

- Mahesh, C. Multiscale abinitio simulation of Ni-based alloys: Real-space distribution of atoms in γ + γ’ phase. Comp. Mater. Sci. 2015, 108, 192–204. [Google Scholar]

- Gagandeep, S.; Manpreet, K.; Rohit, U. Wear and friction behavior of NiCrBSi coatings at elevated temperatures. J. Therm. Spray Technol. 2019, 28, 1081–1102. [Google Scholar]

- Afsous, M.; Shafyei, A.; Soltani, M.; Eskandari, A. Characterization and evaluation of tribological properties of NiCrBSi–Gr composite coatings deposited on stainless steel 420 by HVOF. J. Therm. Spray Technol. 2020, 29, 773–788. [Google Scholar] [CrossRef]

- Tang, L.; Kang, J.; He, P.-F.; Ding, S.-Y.; Chen, S.-Y.; Liu, M.; Xiong, Y.-C.; Ma, G.Z.; Wang, H. Effects of spraying conditions on the microstructure and properties of NiCrBSi coatings prepared by internal rotating plasma spraying. Surf. Coat. Technol. 2019, 374, 625–633. [Google Scholar] [CrossRef]

- García, A.; Fern’andez, M.R.; Cuetos, J.M.; Gonz’alez, R.; Ortiz, A.; Cadenas, M. Study of the sliding wear and friction behavior of WC + NiCrBSi laser cladding coatings as a function of actual concentration of WC reinforcement particles in ball-on-disk test. Tribol. Lett. 2016, 63, 41. [Google Scholar] [CrossRef]

- Guo, C.; Zhou, J.; Chen, J.; Zhao, J.; Yu, Y.; Zhou, H. High temperature wear resistance of laser cladding NiCrBSi and NiCrBSi/WC-Ni composite coatings. Wear 2011, 270, 492–498. [Google Scholar] [CrossRef]

- Xiao, J.-K.; Wu, Y.-Q.; Zhang, W.; Chen, J.; Wei, X.-L.; Zhang, C. Microstructure, wear and corrosion behaviors of plasma sprayed NiCrBSi-Zr coating. Surf. Coat. Technol. 2019, 360, 172–180. [Google Scholar] [CrossRef]

- Gonzalez, R.; Garcia, M.A.; Penuelas, I.; Cadenas, M.; del Rocio Fernandez, M.; Hernandez Battez, A.; Felgueroso, D. Microstructural Study of NiCrBSi Coatings Obtained by Different Processes. Wear 2007, 263, 619–624. Available online: http://www.sciencedirect.com/science/article/pii/S0043164807004061 (accessed on 25 September 2025). [CrossRef]

- Li, Q.; Zhang, D.; Lei, T.; Chen, C.; Chen, W. Compari son of laser-clad and furnace-melted Ni-based alloy microstruc tures. Surf. Coat. Technol. 2001, 137, 122–135. Available online: http://www.sciencedirect.com/science/article/pii/S0257897200007325 (accessed on 29 September 2025). [CrossRef]

- Navas, C.; Colaco, R.; de Damborenea, J.; Vilar, R. Abrasive Wear Behaviour of Laser Clad and Flame Sprayed melted NiCrBSi Coatings. Surf. Coat. Technol. 2006, 200, 6854–6862. [Google Scholar] [CrossRef]

- Kim, H.-J.; Hwang, S.-Y.; Lee, C.-H.; Juvanon, P. Assessment of Wear Performance of Flame Sprayed and Fused Ni-based Coatings. Surf. Coat. Technol. 2003, 172, 262–269. [Google Scholar] [CrossRef]

- Hemmati, I.; Rao, J.C.; Ocelík, V.; De Hosson, J.T.M. Electron Microscopy Characterization of Ni-Cr-B-Si-C Laser Deposited Coatings. Microsc. Microanal. 2013, 19, 120–131. [Google Scholar] [CrossRef]

- ASTM A108; Standard Specification for Steel Bar, Carbon and Alloy, Cold-Finished. ASTM International: West Conshohocken, PA, USA, 2024.

- ISO/TR 26946:2011; Standard Method for Porosity Measurement of Thermally Sprayed Coatings. International Organization for Standardization: Geneva, Switzerland, 2011.

- Górka, J.; Lont, A.; Poloczek, T. The Microstructure and Properties of Laser Cladded Ni Based Self Fluxing Alloy Coatings Reinforced by TiC Particles. Coatings 2025, 15, 527. [Google Scholar] [CrossRef]

- Buitkenov, D.; Rakhadilov, B.; Nabioldina, A.; Mukazhanov, Y.; Adilkanova, M.; Raisov, N. Investigation of Structural Phase, Mechanical, and Tribological Characteristics of Layer Gradient Heat-Protective Coatings Obtained by the Detonation Spraying Method. Materials 2024, 17, 5253. [Google Scholar] [CrossRef]

- Sagdoldina, Z.; Baizhan, D.; Sulyubayeva, L.; Berdimuratov, N.; Buitkenov, D.; Bolatov, S. Effect of Electrofriction Treatment on Microstructure, Corrosion Resistance and Wear Resistance of Cladding Coatings. Coatings 2024, 14, 1433. [Google Scholar] [CrossRef]

- ASTM C633-15(2020); Standard Test Method for Adhesion or Cohesion Strength of Thermal Spray Coatings. ASTM International: West Conshohocken, PA, USA, 2020.

- ISO 19403-2:2024; Paints and Varnishes—Wettability—Part 2: Determination of Surface Free Energy of Solid Surfaces by Measuring the Contact Angle. International Organization for Standardization: Geneva, Switzerland, 2024.

- ISO 6507-1:2018; Metallic Materials—Vickers Hardness Test—Part 1: Test Method. International Organization for Standardization: Geneva, Switzerland, 2018.

- Wang, Y.; Stella, J.; Darut, G.; Poirier, T.; Liao, H.; Planche, M.-P. APS prepared NiCrBSi-YSZ composite coatings for protection against cavitation erosion. J. Alloys Compd. 2017, 699, 1095–1103. [Google Scholar] [CrossRef]

- Serres, N.; Hlawka, F.; Costil, S.; Langlade, C.; Machi, F. Microstructure and Environmental Assessment of Metallic NiCrBSi Coatings Manufactured via Hybrid Plasma Spray Process. Surf. Coat. Technol. 2010, 205, 1039–1046. [Google Scholar] [CrossRef]

- Muzamil, M.; Iqbal, S.A.; Anwar, M.N.; Samiuddin, M.; Yang, J.; Raza, M.A. Wear Behavior assessment of new wire-arc additively manufactured surfaces on AA6061 and AA5086 alloys through multi-walled carbon nanotubes and Ni particles inducement. Coatings 2024, 14, 429. [Google Scholar] [CrossRef]

- Miguel, J.M.; Guilemany, J.M.; Vizcaino, S. Tribological study of NiCrBSi coating obtained by different processes. Tribol. Int. 2003, 36, 181–187. [Google Scholar] [CrossRef]

- Baydoun, S.; Moul-El-Ksour, F.Z.; Fouvry, S.; Guillonneau, G.; Pereira, J.C.; Santos, F.; Rocchi, J. Tribological investigation of new self-fluxing nickel alloys for high temperature application: The effect of silicon distribution on glaze layer formation. Wear 2025, 564, 205631. [Google Scholar] [CrossRef]

- Chen, T.; Wu, F.; Wang, H.; Liu, D. Laser cladding in-situ Ti(C,N) particles reinforced Ni-based composite coatings modified with CeO2 nanoparticles. Metals 2018, 8, 601. [Google Scholar] [CrossRef]

- Huang, J.; Wu, J.; Yu, J.; Xu, Y.; Yan, J.; Li, J. Evaluation of Adhesion Strength of Thermally Sprayed Coatings: Limitations of the ASTM C633 Standard and Alternative Testing Approaches. Materials 2024, 17, 5069. [Google Scholar] [CrossRef]

- Rakhadilov, B.; Buitkenov, D.; Sagdoldina, Z.; Idrisheva, Z.; Zhamanbayeva, M.; Kakimzhanov, D. Preparation and Characterization of NiCr/NiCr-Al2O3/Al2O3 Multilayer Gradient Coatings by Gas Detonation Spraying. Coatings 2021, 11, 1524. [Google Scholar] [CrossRef]

- Houdková, Š.; Smazalová, E.; Vostřák, M.; Schubert, J. Properties of NiCrBSi coating, as sprayed and remelted by different technologies. Surf. Coat. Technol. 2014, 253, 14–26. [Google Scholar] [CrossRef]

- Rakhadilov, B.; Pogrebnjak, A.; Zhuldyz, S.; Buitkenov, D.; Beresnev, V.; Mukhamedova, A. Effect of Bilayer Thickness and Bias Potential on the Structure and Properties of (TiZr/Nb)N Multilayer Coatings as a Result of Arc-PVD Deposition. Materials 2022, 15, 7696. [Google Scholar] [CrossRef]

- Rakhadilov, B.; Sulyubayeva, L.; Maulet, M.; Sagdoldina, Z.; Buitkenov, D.; Issova, A. Investigation of High-Temperature Oxidation of Homogeneous and Gradient Ni-Cr-Al Coatings Obtained by Detonation Spraying. Coatings 2024, 14, 11. [Google Scholar] [CrossRef]

- Dzhurinskiy, D.; Babu, A.; Pathak, P.; Elkin, A.; Dautov, S.; Shornikov, P. Microstructure and wear properties of atmospheric plasma-sprayed Cr3C2-NiCr composite coatings. Surf. Coat. Technol. 2021, 428, 127904. [Google Scholar] [CrossRef]

- Meiirbekov, M.; Ismailov, M.; Kenzhegulov, A.; Mustafa, L.; Tashmukhanbetova, I. Study of the effect of combined reinforcement and modification of epoxy resin with rubbers on the impact strength of carbon fiber-reinforced plastic. Eurasian J. Phys. Funct. Mater. 2024, 8, 3. [Google Scholar] [CrossRef]

- Rojacz, H.; Zikin, A.; Mozelt, C.; Winkelmann, H.; Badisch, E. High temperature corrosion studies of cermet particle reinforced NiCrBSi hardfacings. Surf. Coat. Technol. 2013, 222, 90–96. [Google Scholar] [CrossRef]

- Bakhytuly, N.; Kenzhegulov, A.K.; Nurtanto, M.; Aliev, A.E.; Kuldeev, E.l. Microstructure and tribological study of TiAICN and TiTaCN coatings. Complex Use Miner. Resour. 2023, 327, 99–110. [Google Scholar] [CrossRef]

- González, R.; García, M.A.; Peñuelas, I.; Cadenas, M.; Fernández, M.D.R.; Battez, A.H. Microstructural study of NiCrBSi coatings obtained by differ ent processes. Wear 2007, 263, 619–624. [Google Scholar] [CrossRef]

- Fernández, E.; Cadenas, M.; González, R.; Navas, C.; Fernández, R.; De Damborenea, J. Wear behaviour of laser clad NiCrBSi coating. Wear 2005, 259, 870–875. [Google Scholar] [CrossRef]

- Hemmati, I. Evolution of microstructure and properties in laser cladding of a Ni-Cr–B–Si hardfacing alloy. Surf. Eff. Contact Mech. 2011, 71, 287–296. [Google Scholar] [CrossRef]

- Hemmati, I.; Ocelík, V.; De Hosson, J.T.M. Dilution effects in laser cladding of Ni Cr–B–Si–C hardfacing alloys. Mater. Lett. 2012, 84, 69–72. [Google Scholar] [CrossRef]

- Rakhadilov, B.; Kakimzhanov, D.; Baizhan, D.; Muslimanova, G.; Pazylbek, S.; Zhurerova, L. Comparative Study of Structures and Properties of Detonation Coatings with α-Al2O3 and γ-Al2O3 Main Phases. Coatings 2021, 11, 1566. [Google Scholar] [CrossRef]

| Steel Grade | C | Cu | Mn | As | Ni | P | S | Si | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 1045 | 0.47 | 0.28 | 0.78 | 0.07 | 0.20 | 0.035 | 0.040 | 0.27 | 97.85 |

| Operation gas | Oxygen | 25 NLPM |

| Acetylene | 15 NLPM | |

| Powder carrier gas | Air | 37 NLPM |

| Spraying distance | 200 mm | |

| Spray time | 30 s | |

| Samples | Adhesion Strength, MPa | Microhardness, HV0.05 | Wettability, ° | Friction Coefficient | Roughness, μm |

|---|---|---|---|---|---|

| SF1 | 18 | 528.7 ± 2.3 | 53.152 | 0.648 ± 0.070 | 31.860 ± 0.290 |

| SF2 | 27 | 771.6 ± 4.6 | 79.875 | 0.173 ± 0.050 | 14.915 ± 0.047 |

| SF3 | 34 | 922.4 ± 5.7 | 89.603 | 0.138 ± 0.003 | 13.388 ± 0.016 |

| Sample Name | Sample Wear Rate [mm3/(N·m)] |

|---|---|

| SF1 | 0.001694 ± 0.000085 |

| SF2 | 4.102 × 10−6 ± 0.205 × 10−5 |

| SF3 | 3.458 × 10−6 ± 0.173 × 10−6 |

| Samples | Initial AISI 1045 Steel | SF1 | SF2 | SF3 |

|---|---|---|---|---|

| Icorr (A) | 0.69218 | 0.42371 | 0.39466 | 0.38963 |

| icorr (A/cm2) | 0.881757962 | 0.539757962 | 0.502751592 | 0.496343949 |

| CR (mm/a) | 0.0100873122 | 0.006174832 | 0.005751479 | 0.005678175 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Buitkenov, D.; Raisov, N.; Alimbekuly, T.; Alibekova, B. Study of the Tribological Properties of Self-Fluxing Nickel-Based Coatings Obtained by Gas-Flame Spraying. Crystals 2025, 15, 862. https://doi.org/10.3390/cryst15100862

Buitkenov D, Raisov N, Alimbekuly T, Alibekova B. Study of the Tribological Properties of Self-Fluxing Nickel-Based Coatings Obtained by Gas-Flame Spraying. Crystals. 2025; 15(10):862. https://doi.org/10.3390/cryst15100862

Chicago/Turabian StyleBuitkenov, Dastan, Nurmakhanbet Raisov, Temirlan Alimbekuly, and Balym Alibekova. 2025. "Study of the Tribological Properties of Self-Fluxing Nickel-Based Coatings Obtained by Gas-Flame Spraying" Crystals 15, no. 10: 862. https://doi.org/10.3390/cryst15100862

APA StyleBuitkenov, D., Raisov, N., Alimbekuly, T., & Alibekova, B. (2025). Study of the Tribological Properties of Self-Fluxing Nickel-Based Coatings Obtained by Gas-Flame Spraying. Crystals, 15(10), 862. https://doi.org/10.3390/cryst15100862