Engineering the Mechanics and Thermodynamics of Ti3AlC2, Hf3AlC2, Hf3GaC2, (ZrHf)3AlC2, and (ZrHf)4AlN3 MAX Phases via the Ab Initio Method

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| κ | Thermal conductivity |

| μ | Poisson ratio |

| Density | |

| σ | Electrical conductivity |

| Debye temperature | |

| Al | Aluminium |

| B | Bulk modulus/Boron |

| C | Carbon |

| CASTEP | Cambridge Serial Total Energy Package |

| Elastic stiffness constant | |

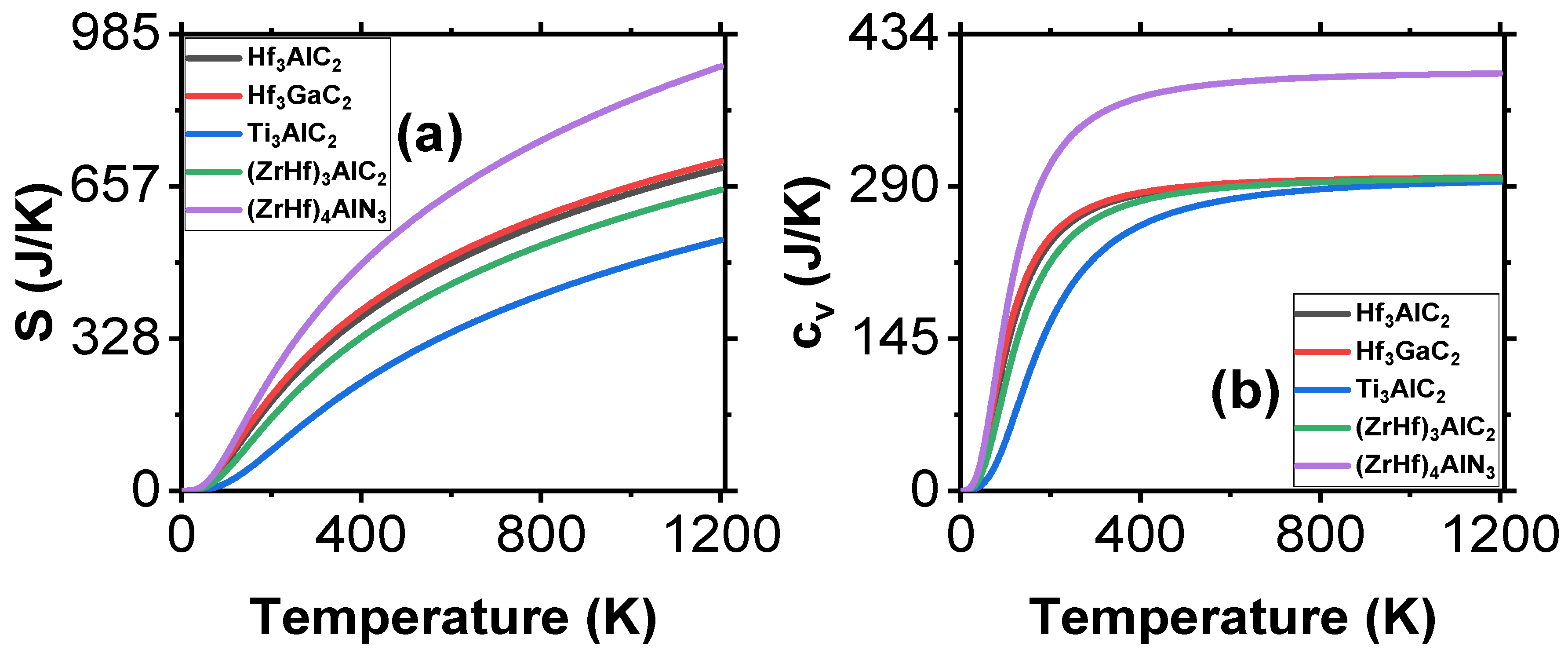

| Specific heat at constant volume | |

| E | Young’s modulus |

| G | Shear modulus |

| Hf | Hafnium |

| Ga | Gallium |

| Vickers hardness | |

| Ecut | Kinetic energy cut-off |

| GGA | Generalised Gradient Approximation |

| Boltzmann constant | |

| N | Nitrogen |

| n | Pugh’s modulus ratio |

| Avogadro’s number | |

| PBE | Perdew–Burke–Ernzerhof |

| S | Entropy |

| Ti | Titanium |

| Melting temperature | |

| , , | Mean, longitudinal, and transverse sound velocities, respectively |

| Zr | Zirconium |

References

- Zhang, Z.; Duan, X.; Jia, D.; Zhou, Y.; Zwaag, S. On the formation mechanisms and properties of MAX phases: A review. J. Eur. Ceram. Soc. 2021, 41, 3851–3878. [Google Scholar] [CrossRef]

- Shao, H.; Luo, S.; Descamps-Mandine, A.; Ge, K.; Lin, Z.; Taberna, P.; Gogotsi, Y.; Simon, P. Synthesis of MAX phase nanofibers and nanoflakes and the resulting MXenes. Adv. Sci. 2022, 10, 2205509. [Google Scholar] [CrossRef] [PubMed]

- Qureshi, M.; Ali, M.; Ma, X. Screen the thermomechanical and optical properties of the new ductile 314 MAX phase boride Zr3CdB4: A DFT insight. J. Alloys Compd. 2021, 877, 160248. [Google Scholar] [CrossRef]

- Khazaei, M.; Maleki, I.; Koshi, N.; Ranjbar, A.; Miao, N.; Wang, J.; Khaledialidusti, R.; Kühne, T.; Lee, S.; Bhattacharjee, S.; et al. Beyond metals: Theoretical discovery of semiconducting MAX phases and their potential application in thermoelectrics. Phys. Chem. Chem. Phys. PCCP 2024, 26, 18907–18917. [Google Scholar] [CrossRef] [PubMed]

- Fu, L.; Xia, W. MAX phases as nanolaminate materials: Chemical composition, microstructure, synthesis, properties, and applications. Adv. Eng. Mater. 2021, 23, 2001191. [Google Scholar] [CrossRef]

- Fisher, D.J. Mechanical Properties of MAX Phases; Materials Research Foundations: Millersille, PA, USA, 2021. [Google Scholar] [CrossRef]

- Alam, M.; Chowdhury, M.; Khandaker, T.; Hossain, M.; Islam, M.; Islam, M.; Hasan, M. Advancements in MAX phase materials: Structure, properties, and novel applications. RSC Adv. 2024, 14, 26995–27041. [Google Scholar] [CrossRef]

- Tan, Y.; Xia, Y.; Teng, Z.; Chen, C.; Zhou, X.; Zhang, H. Synthesis and enhanced mechanical properties of compositionally complex MAX phases. J. Eur. Ceram. Soc. 2021, 41, 4658–4665. [Google Scholar] [CrossRef]

- Kubitza, N.; Büchner, C.; Sinclair, J.; Snyder, R.; Birkel, C. Extending the chemistry of layered solids and nanosheets: Chemistry and structure of MAX phases, MAB phases and MXenes. ChemPlusChem 2023, 88, e202300214. [Google Scholar] [CrossRef]

- Zhao, Y.; Deng, S.; Liu, H.; Zhang, J.; Guo, Z.; Hou, H. First-principles investigation of pressure and temperature influence on structural, mechanical and thermodynamic properties of Ti3AC2 (A = Al and Si). Comput. Mater. Sci. 2018, 154, 365–370. [Google Scholar] [CrossRef]

- Sokol, M.; Natu, V.; Kota, S.; Barsoum, M. On the chemical diversity of the MAX phases. Trends Chem. 2019, 1, 210–223. [Google Scholar] [CrossRef]

- Ghafar, N.; Markom, A.; Rosol, A.; Zulkipli, N.; Omar, S.; Muhammad, A.; Haris, H.; Saad, I.; Harun, S. Q-switched pulse generation in Erbium-based with niobium aluminium carbide saturable absorber. J. Adv. Res. Micro Nano Eng. 2024, 19, 99–106. [Google Scholar] [CrossRef]

- Radhakrishnan, R.; Ramamoorthi, V.; Srinivasan, R. Experimental investigation on powder processing and its flow properties of AlSi10Mg alloy with niobium carbide for additive manufacturing. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2021, 236, 1421–1429. [Google Scholar] [CrossRef]

- Gurgel, M.; De Souza Baêta Júnior, E.; Da Silva Teixeira, R.; Nascimento, G.; De Sant’ Ana Oliveira, S.; Leite, D.; Moreira, L.; Brandão, L.; Paula, A. Microstructure and continuous cooling transformation of an Fe-7.1Al-0.7Mn-0.4C-0.3Nb Alloy. Metals 2022, 12, 1305. [Google Scholar] [CrossRef]

- Molochkova, O.; Petrochenko, E. Structural-phase state and properties of heat and wear resistant cast irons of Cr–Mn–Ni–Ti system additionally alloyed with Al and Nb. Ferr. Metall. Bull. Sci. Tech. Econ. Inf. 2024, 80, 12–20. [Google Scholar] [CrossRef]

- Zhang, Q.; Luo, J.; Wen, B.; Zhou, Y.; Chu, L.; Feng, Q.; Hu, C. Determination of new α-312 MAX phases of Zr3InC2 and Hf3InC2. J. Eur. Ceram. Soc. 2023, 43, 7228–7233. [Google Scholar] [CrossRef]

- Li, S.; Liu, Y.; Zhang, Y.; Wang, L.; Zhang, P.; Pan, L.; He, W.; Tian, W.; Sun, Z. The formation mechanism of Ti2InC by pressureless sintering and optimization of synthesis parameters. J. Aust. Ceram. Soc. 2021, 57, 911–917. [Google Scholar] [CrossRef]

- Cannavo, A.; Vacík, J.; Bakardjieva, S.; Kupčík, J.; Lavrentiev, V.; Ceccio, G.; Horak, P.; Němeček, J.; Calcagno, L. Effect of medium energy He+, Ne+ and Ar+ ion irradiation on the Hf-In-C thin film composites. Thin Solid Films. 2022, 743, 139052. [Google Scholar] [CrossRef]

- Sauceda, D.; Singh, P.; Fałkowski, A.; Chen, Y.; Doung, T.; Vazquez, G.; Radovic, M.; Arróyave, R. High-throughput reaction engineering to assess the oxidation stability of MAX phases. npj Comput. Mater. 2021, 7, 6. [Google Scholar] [CrossRef]

- Kohn, W.; Sham, L.J. Self-consistent equations including exchange and correlation effects. Phys. Rev. 1965, 140, A1133–A1138. [Google Scholar] [CrossRef]

- Giannozzi, P.; Baroni, S.; Bonini, N.; Calandra, M.; Car, R.; Cavazzoni, C.; Ceresoli, D.; Chiarotti, G.L.; Cococcioni, M.; Dabo, I. Quantum ESPRESSO: A modular and open-source software project for quantum simulations of materials. J. Phys. Condens. Matter 2009, 21, 395502. [Google Scholar] [CrossRef]

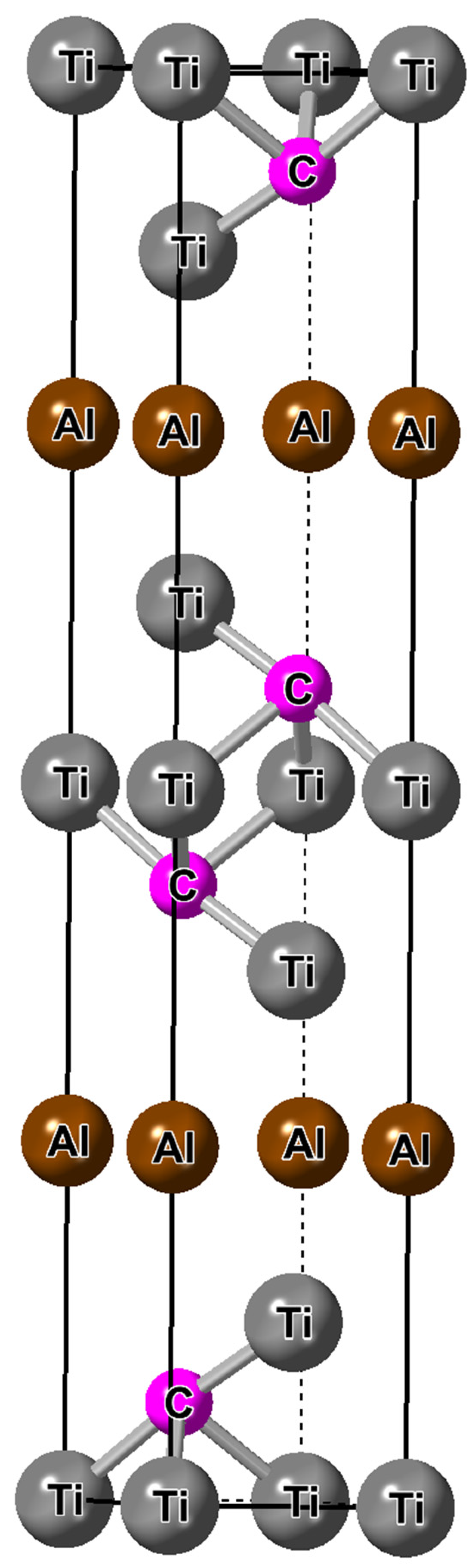

- Zhou, Y.C.; Wang, X.H.; Chen, S.Q.; Sun, Z.M. Electronic and structural properties of the layered ternary carbide Ti3AlC2. J. Mater. Chem. 2001, 11, 2335–2339. [Google Scholar] [CrossRef]

- Perdew, J.P.; Burke, K.; Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 1996, 77, 3865–3868. [Google Scholar] [CrossRef] [PubMed]

- Monkhorst, H.J.; Pack, J.D. Special points for Brillouin-zone integrations. Phys. Rev. B 1976, 13, 5188–5192. [Google Scholar] [CrossRef]

- Fletcher, R. Practical Methods of Optimization; Wiley: New York, NY, USA, 2000. [Google Scholar] [CrossRef]

- Emery, A.A.; Wolverton, C. High-throughput DFT calculations of formation energy, stability and oxygen vacancy formation energy of ABO3 perovskites. Sci. Data 2017, 4, 170153. [Google Scholar] [CrossRef]

- Ongwen, N.O.; Ogam, E.; Otunga, H.O. Ab initio study of elastic properties of orthorhombic cadmium stannate as a substrate for the manufacture of MEMS devices. Mater. Today Commun. 2021, 26, 101822. [Google Scholar] [CrossRef]

- Avery, P.; Wang, X.; Oses, C.; Gossett, E.; Proserpio, D.M.; Toher, C.; Curtarolo, S.; Zurek, E. Predicting superhard materials via a machine learning informed evolutionary structure search. Npj Comput. Mater. 2019, 5, 1–11. [Google Scholar] [CrossRef]

- Thakur, B.; Gong, X.; Dal Corso, A. Thermodynamic properties of rhodium: A first principles study. AIP Adv. 2024, 14, 045229. [Google Scholar] [CrossRef]

- Roknuzzaman, M.; Hadi, M.A.; Ali, M.A.; Hossain, M.M.; Jahan, N.; Uddin, M.M.; Alarco, J.A.; Ostrikov, K. First hafnium-based MAX phase in the 312 family, Hf3AlC2: A first-principles study. J. Alloys Compd. 2017, 727, 616–626. [Google Scholar] [CrossRef]

- Ongwen, N.O.; Ogam, E.; Fellah, Z.E.A.; Mageto, M.; Othieno, H.; Otunga, H. Thermal properties and pressure-dependent elastic constants of cadmium stannate as a substrate for MEMS: An ab initio study. Phys. B Condens. Matter 2023, 651, 414599. [Google Scholar] [CrossRef]

- Madsen JK, H.; Carrete, J.; Verstraete, M.J. BoltzTraP2, a program for interpolating band structures and calculating semi-classical transport coefficients. Comput. Phys. Commun. 2018, 231, 140–145. [Google Scholar] [CrossRef]

- Vovk, R.V.; Khadzhai, G.Y.; Prikhna, T.A.; Gevorkyan, E.S.; Kislitsa, M.V.; Soloviev, A.L.; Goulatis, I.L.; Chroneos, A. Charge and heat transfer of the Ti3AlC2 MAX phase. J. Mater. Sci. Mater. Electron. 2018, 29, 11478–11481. [Google Scholar] [CrossRef]

- Mebtouche, H.; Baraka, O.; Yakoubi, A.; Khenata, R.; Tahir, S.; Ahmed, R.; Naqib, S.; Bouhemadou, A.; Omran, S.; Wang, X. First-principles calculations of the structural, electronic, mechanical and thermodynamic properties of MAX phase Mon+1GeCn (n = 1–3) compounds. Mater. Today Commun. 2020, 25, 101420. [Google Scholar] [CrossRef]

- Azzouz-Rached, A.; Hadi, M.; Rached, H.; Hadji, T.; Rached, D.; Bouhemadou, A. Pressure effects on the structural, elastic, magnetic and thermodynamic properties of Mn2AlC and Mn2SiC MAX phases. J. Alloys Compd. 2021, 885, 160998. [Google Scholar] [CrossRef]

- Hadi, M.; Rayhan, M.; Naqib, S.; Chroneos, A.; Islam, A. Structural, elastic, thermal and lattice dynamic properties of new 321 MAX phases. Comput. Mater. Sci. 2019, 170, 109144. [Google Scholar] [CrossRef]

- Sun, Z. Progress in research and development on MAX phases: A family of layered ternary compounds. Int. Mater. Rev. 2011, 56, 143–166. [Google Scholar] [CrossRef]

- Zapata-Solvas, E.; Hadi, M.; Horlait, D.; Parfitt, D.; Thibaud, A.; Chroneos, A.; Lee, W. Synthesis and physical properties of (Zr1−x,Tix)3AlC2 MAX phases. J. Am. Ceram. Soc. 2017, 100, 3393–3401. [Google Scholar] [CrossRef]

- Gupta, S.; Barsoum, M. On the tribology of the MAX phases and their composites during dry sliding: A review. Wear 2011, 271, 1878–1894. [Google Scholar] [CrossRef]

- Hadi, M.A.; Roknuzzaman, M.; Nasir, M.T.; Monira, U.; Naqib, S.H.; Chroneos, A.; Islam, A.; Alarco, J.A.; Ostrikov, K. Effects of Al substitution by Si in Ti3AlC2 nanolaminate. Sci. Rep. 2021, 11, 3410. [Google Scholar] [CrossRef]

- Ho, J.C.; Hamdeh, H.H.; Barsoum, M.W.; El-Raghy, T. Low temperature heat capacities of Ti3Al1.1C1.8, Ti4AlN3, and Ti3SiC2. J. Appl. Phys. 1999, 86, 3609–3611. [Google Scholar] [CrossRef]

- Available online: https://www.indiamart.com/proddetail/ti3alc2-max-phase-titanium-aluminium-carbide-powder-19902128455.html (accessed on 4 June 2024).

- Khadzhai, G.Y.; Vovk, R.V.; Prichna, T.A.; Gevorkyan, E.S.; Kislitsa, M.V.; Solovjov, A.L. Electrical and thermal conductivity of the Ti3AlC2 MAX phase at low temperatures. Low Temp. Phys. 2018, 44, 451–452. [Google Scholar] [CrossRef]

- Qian, X.-K.; Li, Y.-B.; He, X.-D.; Chen, Y.-X.; Yun, S.-N. Electrical and thermal properties of Ti3AlC2 at high temperature. J. Ceram. Sci. Technol. 2011, 2, 155–158. [Google Scholar] [CrossRef]

- Oses, C.; Toher, C.; Curtarolo, S. High-entropy ceramics. Nat. Rev. Mater. 2020, 5, 295–309. [Google Scholar] [CrossRef]

- Lin, C.; Wen, H.; Lei, L.; Liu, S.; Ma, T.; Fan, B.; Wang, F. Heat generation quantification of high-specific-energy 21700 battery cell using average and variable specific heat capacities. Appl. Therm. Eng. 2020, 184, 116215. [Google Scholar] [CrossRef]

- Mo, Y.; Rulis, P.; Ching, W. Electronic structure and optical conductivities of 20 MAX-phase compounds. Phys. Rev. B 2012, 86, 165122. [Google Scholar] [CrossRef]

- Pazniak, A.; Bazhin, P.; Shchetinin, I.; Kolesnikov, E.; Prokopets, A.; Shplis, N.; Stolin, A.; Kuznetsov, D. Dense Ti3AlC2 based materials obtained by SHS-extrusion and compression methods. Ceram. Int. 2019, 45, 2020–2027. [Google Scholar] [CrossRef]

| Sample | |||||

|---|---|---|---|---|---|

| 3.270 (3.332 [30]) | 19.659 (19.690 [30]) | 6.011 (5.909 [30]) | 10,699 (10,288 [30]) | −4.825 | |

| 3.279 | 19.256 | 5.872 | 11,652 | −4.802 | |

| 3.077 (3.072 [33]) | 18.746 (18.547 [33]) | 6.092 | 4205 (4240 [33]) | −4.874 | |

| 3.319 | 19.951 | 6.011 | 6426 | −5.431 | |

| 3.190 | 24.857 | 7.792 | 10,546 | −13.90 |

| Sample | |||||

|---|---|---|---|---|---|

| 332.1 (347 [30]) | 75.9 (77 [30]) | 73.9 (80 [30]) | 284.7 (291 [30]) | 117.8 (127 [30]) | |

| 340.7 | 92.9 | 116.9 | 280.6 | 109.9 | |

| 342.9 (356.8 [10]) | 69.8 (70.2 [10]) | 73.4 (69.2 [10]) | 285.2 (329.7 [10]) | 113.2 (139.8 [10]) | |

| 307.1 | 82.6 | 128.4 | 248.3 | 94.7 | |

| 337.1 | 68.2 | 107.3 | 298.3 | 143.5 |

| Sample | ||||||

|---|---|---|---|---|---|---|

| 150.7 (162 [30]) | 122.3 (127 [30]) | 288.9 (302 [30]) | 0.181 (0.189 [30]) | 1.232 (1.282 [30]) | 4.710 (4.9 [30]) | |

| 156.2 | 119 | 284.7 | 0.196 | 1.313 | 4.461 | |

| 153.9 (162.1 [10]) | 122.8 (140.2 [10]) | 290.4 (326.4 [10]) | 0.185 | 1.253 | 4.631 | |

| 144.4 | 103.4 | 250.4 | 0.211 | 1.400 | 4.096 | |

| 183.6 | 118.7 | 293.4 | 0.234 | 1.547 | 4.061 |

| Sample | ||||||

|---|---|---|---|---|---|---|

| 448.3 (459.5 [30]) | 2077 | 145.6 | 135.0 | 1.84 | 12.61 | |

| 426.2 | 2097 | 154.5 | 136.1 | 1.53 | 11.54 | |

| 757.3 (680 [40]), (764 [41]) | 2111 (2100 [42]) | 82.5 | 111.2 (115 [10]) | 2.34 (1.7 [43]), (2.9 [44]) | 16.22 (16 [43]) | |

| 524.6 | 1947 | 126.9 | 129.5 | 2.22 | 17.46 | |

| 462.4 | 2112 | 191.2 | 178.2 | 1.77 | 11.54 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alruqi, A.B. Engineering the Mechanics and Thermodynamics of Ti3AlC2, Hf3AlC2, Hf3GaC2, (ZrHf)3AlC2, and (ZrHf)4AlN3 MAX Phases via the Ab Initio Method. Crystals 2025, 15, 87. https://doi.org/10.3390/cryst15010087

Alruqi AB. Engineering the Mechanics and Thermodynamics of Ti3AlC2, Hf3AlC2, Hf3GaC2, (ZrHf)3AlC2, and (ZrHf)4AlN3 MAX Phases via the Ab Initio Method. Crystals. 2025; 15(1):87. https://doi.org/10.3390/cryst15010087

Chicago/Turabian StyleAlruqi, Adel Bandar. 2025. "Engineering the Mechanics and Thermodynamics of Ti3AlC2, Hf3AlC2, Hf3GaC2, (ZrHf)3AlC2, and (ZrHf)4AlN3 MAX Phases via the Ab Initio Method" Crystals 15, no. 1: 87. https://doi.org/10.3390/cryst15010087

APA StyleAlruqi, A. B. (2025). Engineering the Mechanics and Thermodynamics of Ti3AlC2, Hf3AlC2, Hf3GaC2, (ZrHf)3AlC2, and (ZrHf)4AlN3 MAX Phases via the Ab Initio Method. Crystals, 15(1), 87. https://doi.org/10.3390/cryst15010087