Optimization of Process Parameters and Microscopic Morphology of Multi-Walled Carbon Nanotubes/PEEK Films Using the Vacuum Suction Filtration Method

Abstract

1. Introduction

2. Materials and Methods

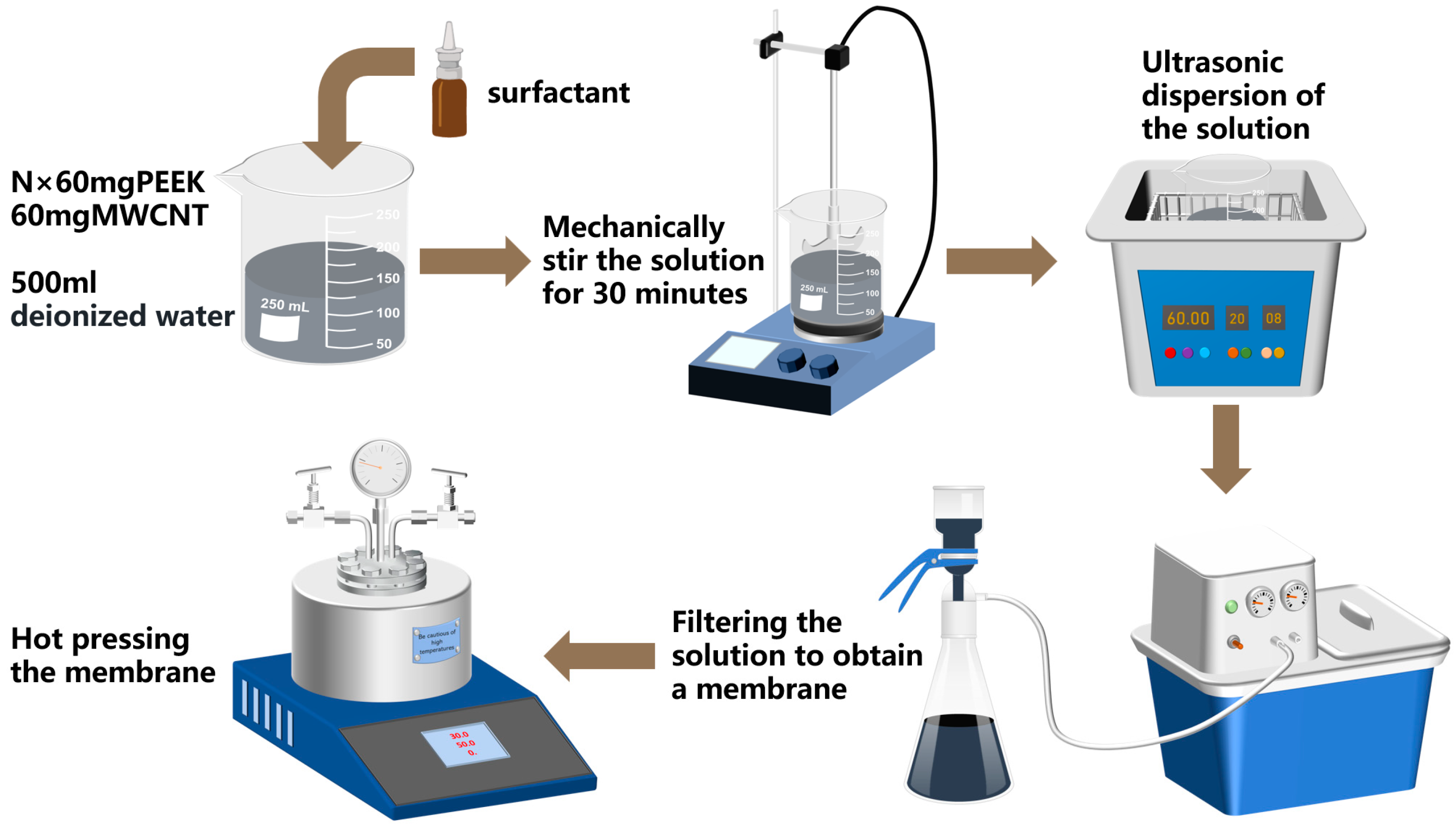

2.1. Preparation of MWCNTs/PEEK Composite Films

2.1.1. Materials

2.1.2. Preparation Processes

2.2. Performance Characterization Methods

3. Microscopic Morphology and Mechanical Performance of MWCNTs/PEEK Composite Films

3.1. Mechanical Performance of MWCNTs/PEEK Composite Films

3.2. Microscopic Morphology of the MWCNTs/PEEK Film

4. Response Surface Methodology to Optimize Optimal Parameters

4.1. Analysis of the Fitted Model

4.2. Analysis of Fitting Results

4.3. Prediction of Optimal Process Parameters and Experimental Validation

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Moghadam, H.Z.; Faghidian, S.A.; Jamal-Omidi, M. Agglomeration effects of carbon nanotube on residual stresses in polymer nano composite using experimental and analytical method. Mater. Res. Express 2019, 6, 035009. [Google Scholar] [CrossRef]

- Alharbi, T.M.D. Continuous flow laser-induced unzipping of multiwalled carbon nanotubes. J. Taibah Univ. Sci. 2024, 18, 2310885. [Google Scholar] [CrossRef]

- Kim, Y.; Lee, J.; Park, S. Effect of ambient plasma treatment on single-walled carbon nanotubes-based epoxy/fabrics for improving fracture toughness and electromagnetic shielding effectiveness. Compos. Part A Appl. Sci. Manuf. 2021, 148, 106456. [Google Scholar] [CrossRef]

- Zhu, S.; Qian, Y.; Hassan, E.A.M.; Shi, R.; Yang, L.; Cao, H.; Zhou, J.; Ge, D.; Yu, M. Enhanced interfacial interactions by PEEK—grafting and coupling of acylated CNT for GF/PEEK composites. Compos. Commun. 2020, 18, 43–48. [Google Scholar] [CrossRef]

- Zhang, J.; Jiang, D.; Peng, H.; Qin, F. Enhanced mechanical and electrical properties of carbon nanotube buckypaper by in situ cross-linking. Carbon 2013, 63, 125–132. [Google Scholar] [CrossRef]

- Ni, X.; Furtado, C.; Kalfon-Cohen, E.; Zhou, Y.; Valdes, G.A.; Hank, T.J.; Camanho, P.P.; Wardle, B.L. Static and fatigue interlaminar shear reinforcement in aligned carbon nanotube-reinforced hierarchical advanced composites. Compos. Part A Appl. Sci. Manuf. 2019, 120, 106–115. [Google Scholar] [CrossRef]

- Jin, Z.; Sun, S.; Liu, M.; Joshi, S.C.; Han, Z.; Zheng, Z.; Qiang, G. Forming method, crystallinity, and mechanical performance of buckypaper/carbon fiber/polyether ether ketone multi-scale thermoplastic composites. High. Perform. Polym. 2024, 36, 119–129. [Google Scholar] [CrossRef]

- Gao, X.; Huang, Z.; Zhou, H.; Li, D.; Li, Y.; Wang, Y. Higher mechanical performances of CF/PEEK composite laminates via reducing interlayer porosity based on the affinity of functional s-PEEK. Polym. Compos. 2019, 40, 3749–3757. [Google Scholar] [CrossRef]

- Jin, Z.; Han, Z.; Chang, C.; Sun, S.; Fu, H. Review of methods for enhancing interlaminar mechanical properties of fiber-reinforced thermoplastic composites: Interfacial modification, nano-filling and forming technology. Compos. Sci. Technol. 2022, 228, 109660. [Google Scholar] [CrossRef]

- Wang, X.; Huang, Z.; Lai, M.; Jiang, L.; Zhang, Y.; Zhou, H. Highly enhancing the interfacial strength of CF/PEEK composites by introducing PAIK onto diazonium functionalized carbon fibers. Appl. Surf. Sci. 2020, 510, 145400. [Google Scholar] [CrossRef]

- Wang, Z.; Liang, Z.Y.; Wang, B.; Zhang, C.; Kramer, L. Processing and property investigation of single-walled carbon nanotube (SWNT) buckypaper/epoxy resin matrix nanocomposites. Compos. Part A Appl. Sci. Manuf. 2004, 35, 1225–1232. [Google Scholar] [CrossRef]

- Kubo, M.; Kadomura, H.; Shimada, M. In-flight coating of multi-walled carbon nanotubes. Mater. Lett. 2015, 155, 114–117. [Google Scholar] [CrossRef]

- Chen, C.; Li, Y.; Yu, T. Interlaminar toughening in flax fiber—reinforced composites interleaved with carbon nanotube buckypaper. J. Reinf. Plast. Comp. 2014, 33, 1859–1868. [Google Scholar] [CrossRef]

- Coelho, P.G.; Guedes, J.M.; Rodrigues, H.C. Multiscale topology optimization of bi-material laminated composite structures. Compos. Struct. 2015, 132, 495–505. [Google Scholar] [CrossRef]

- Zhang, C.; Duan, Y.; Xiao, H.; Wang, B.; Xin, Z.; Liu, G.; Wang, F.; Cui, W. Preparation of MWCNTs/CF/PEEK multi-scale composites with good mechanical and electrical conductivity by a two-step process of AFP and out-of-autoclave tempering. Compos. Part C Open Access 2022, 9, 100321. [Google Scholar] [CrossRef]

- Lin, Y.J.; Qin, S.; Han, B.; Gao, C.; Zhang, S.L. Preparation of poly (ether ether ketone) based composite with high electrical conductivity, good mechanical properties and thermal stability. High. Perform. Polym. 2017, 29, 205–210. [Google Scholar] [CrossRef]

- Cao, Z.; Qiu, L.; Yang, Y.; Chen, Y.; Liu, X. The surface modifications of multi-walled carbon nanotubes for multi-walled carbon nanotube/poly (ether ether ketone) composites. Appl. Surf. Sci. 2015, 353, 873–881. [Google Scholar] [CrossRef]

- Jin, Z.; Han, Z.; Liu, X.; Sun, S.; Fu, H. The interlaminar performance of carbon fiber reinforced polyetheretherketone composites reinforced by doped buckypaper. Mater. Lett. 2022, 321, 132426. [Google Scholar] [CrossRef]

- Ren, T.; Zhu, G.; Zhang, C. Improvement of the interfacial properties of CF/PEEK composites by introducing aminated polyphenylene sulphide (PPS-NH 2) as a sizing agent. Polym. Compos. 2022, 43, 8890–8903. [Google Scholar] [CrossRef]

- Coleman, J.N.; Blau, W.J.; Dalton, A.B.; Muñoz, E.; Collins, S.; Kim, B.G.; Razal, J.; Selvidge, M.; Vieiro, G.; Baughman, R.H. Improving the mechanical properties of single-walled carbon nanotube sheets by intercalation of polymeric adhesives. Appl. Phys. Lett. 2003, 82, 1682–1684. [Google Scholar] [CrossRef]

- Zhang, J.; Jiang, D. Influence of geometries of multi-walled carbon nanotubes on the pore structures of Buckypaper. Compos. Part A Appl. Sci. Manuf. 2012, 43, 469–474. [Google Scholar] [CrossRef]

- GB/T 1499-2005; Steel for the Reinforcement of Concrete. China Standards Press: Beijing, China, 2005.

- Jin, Z.; Sun, S.; Joshi, S.C.; Han, Z.; Fu, H. A chemically modified MWCNT/PEEK multiscale thermoplastic composites: Forming, mechanical performance, and application. Polym. Compos. 2023. [Google Scholar] [CrossRef]

| Group | Pore Size of Filter Paper | Time | Mass Ratio |

|---|---|---|---|

| 1 | 0.45 μm | 3 h | 1:1 |

| 2 | 0.45 μm | 6 h | 1:8 |

| 3 | 0.45 μm | 9 h | 1:4 |

| 4 | 0.8 μm | 3 h | 1:8 |

| 5 | 0.8 μm | 6 h | 1:4 |

| 6 | 0.8 μm | 9 h | 1:1 |

| 7 | 1.2 μm | 3 h | 1:4 |

| 8 | 1.2 μm | 6 h | 1:1 |

| 9 | 1.2 μm | 9 h | 1:8 |

| Group | Tensile Strength | Elastic Modulus | Elongation at Break |

|---|---|---|---|

| 1 | 31.0181 MPa | 952.6326 MPa | 3.14 |

| 2 | 61.944 MPa | 2128.4348 MPa | 4.22 |

| 3 | 43.4245 MPa | 2136.6987 MPa | 2.32 |

| 4 | 38.5375 MPa | 1848.165 MPa | 2.30 |

| 5 | 45.7498 MPa | 1913.6859 MPa | 2.92 |

| 6 | 27.7818 MPa | 1484.7015 MPa | 2.20 |

| 7 | 37.544 MPa | 2162.805 MPa | 3.49 |

| 8 | 28.5746 MPa | 1300.84915 MPa | 3.05 |

| 9 | 28.8517 MPa | 2005.1019 MPa | 1.40 |

| Source | Sequential p-Value | Adjusted R2 | Predicted R2 |

|---|---|---|---|

| Linear | 0.1623 | 0.2252 | −0.8350 |

| 2FI | 0.0126 | 0.7865 | −1.8202 |

| Quadratic | <0.0001 | 0.9999 | −2.6730 |

| Source | Sequential p-Value | Adjusted R2 | Predicted R2 |

|---|---|---|---|

| Linear | 0.8646 | −0.2336 | −2.1906 |

| 2FI | 0.0515 | 0.4465 | −6.0720 |

| Quadratic | <0.0001 | 0.9999 | −6.5487 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, M.; Fu, H.; Yu, S.; Jin, Z.; Han, Z.; Sun, S. Optimization of Process Parameters and Microscopic Morphology of Multi-Walled Carbon Nanotubes/PEEK Films Using the Vacuum Suction Filtration Method. Crystals 2024, 14, 561. https://doi.org/10.3390/cryst14060561

Liu M, Fu H, Yu S, Jin Z, Han Z, Sun S. Optimization of Process Parameters and Microscopic Morphology of Multi-Walled Carbon Nanotubes/PEEK Films Using the Vacuum Suction Filtration Method. Crystals. 2024; 14(6):561. https://doi.org/10.3390/cryst14060561

Chicago/Turabian StyleLiu, Mingyu, Hongya Fu, Songsong Yu, Ziang Jin, Zhenyu Han, and Shouzheng Sun. 2024. "Optimization of Process Parameters and Microscopic Morphology of Multi-Walled Carbon Nanotubes/PEEK Films Using the Vacuum Suction Filtration Method" Crystals 14, no. 6: 561. https://doi.org/10.3390/cryst14060561

APA StyleLiu, M., Fu, H., Yu, S., Jin, Z., Han, Z., & Sun, S. (2024). Optimization of Process Parameters and Microscopic Morphology of Multi-Walled Carbon Nanotubes/PEEK Films Using the Vacuum Suction Filtration Method. Crystals, 14(6), 561. https://doi.org/10.3390/cryst14060561