Efficient Adsorption Removal of Tetrabromobisphenol A from Water by Using a Magnetic Composite Fe3O4/GO/ZIF-67

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals and Reagents

2.2. Experimental Instruments

2.3. Preparation of Magnetic Material Fe3O4/GO

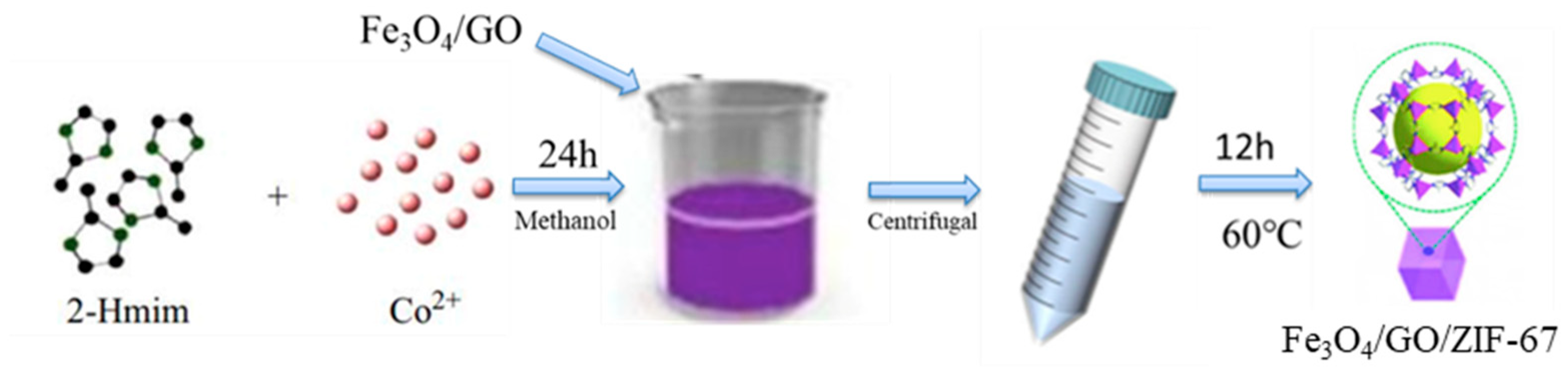

2.4. Preparation of Fe3O4/GO/ZIF-67

2.5. Adsorption Performance of Fe3O4/GO/ZIF-67

3. Results and Discussion

3.1. Synthesis of Fe3O4/GO/ZIF-67

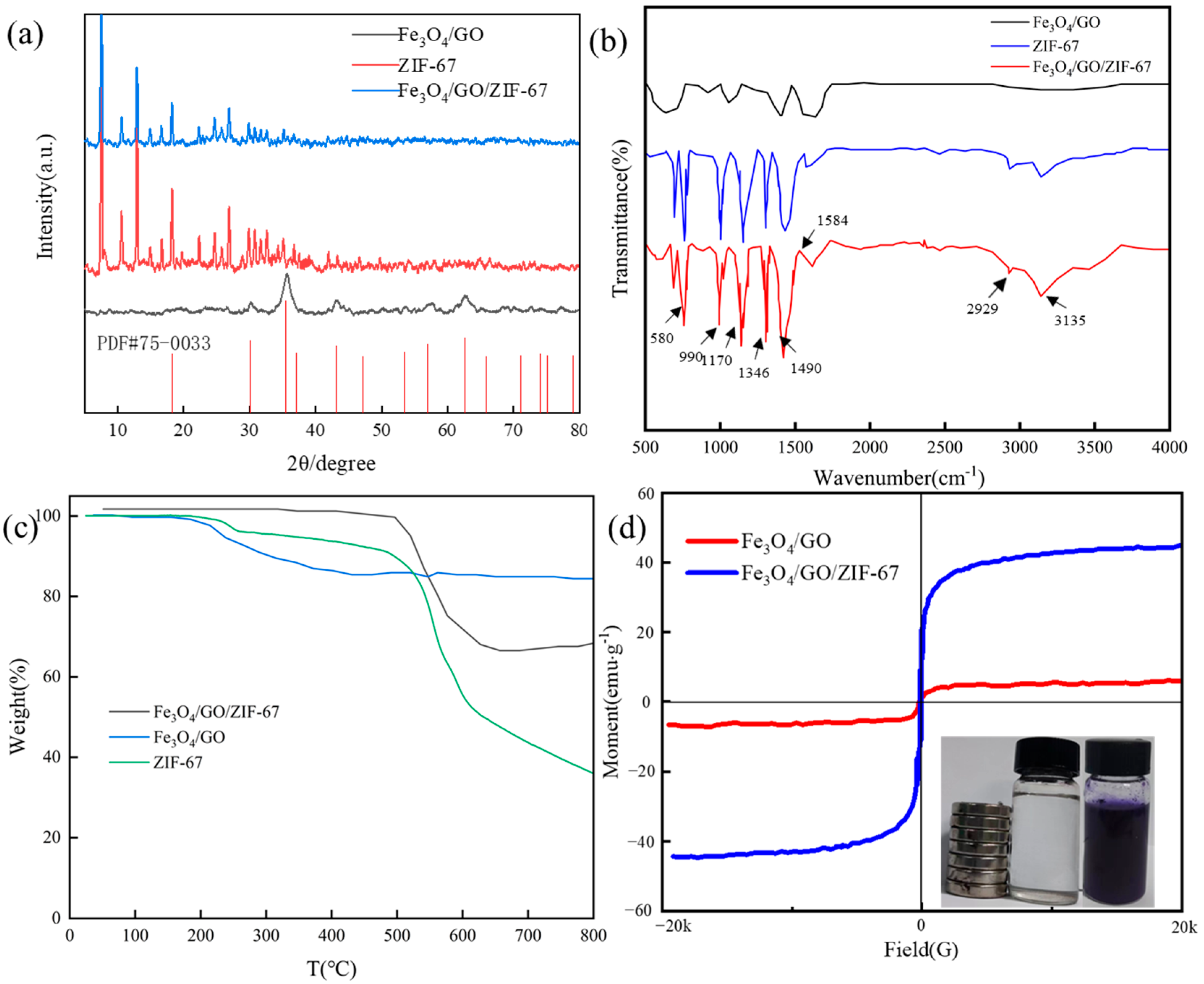

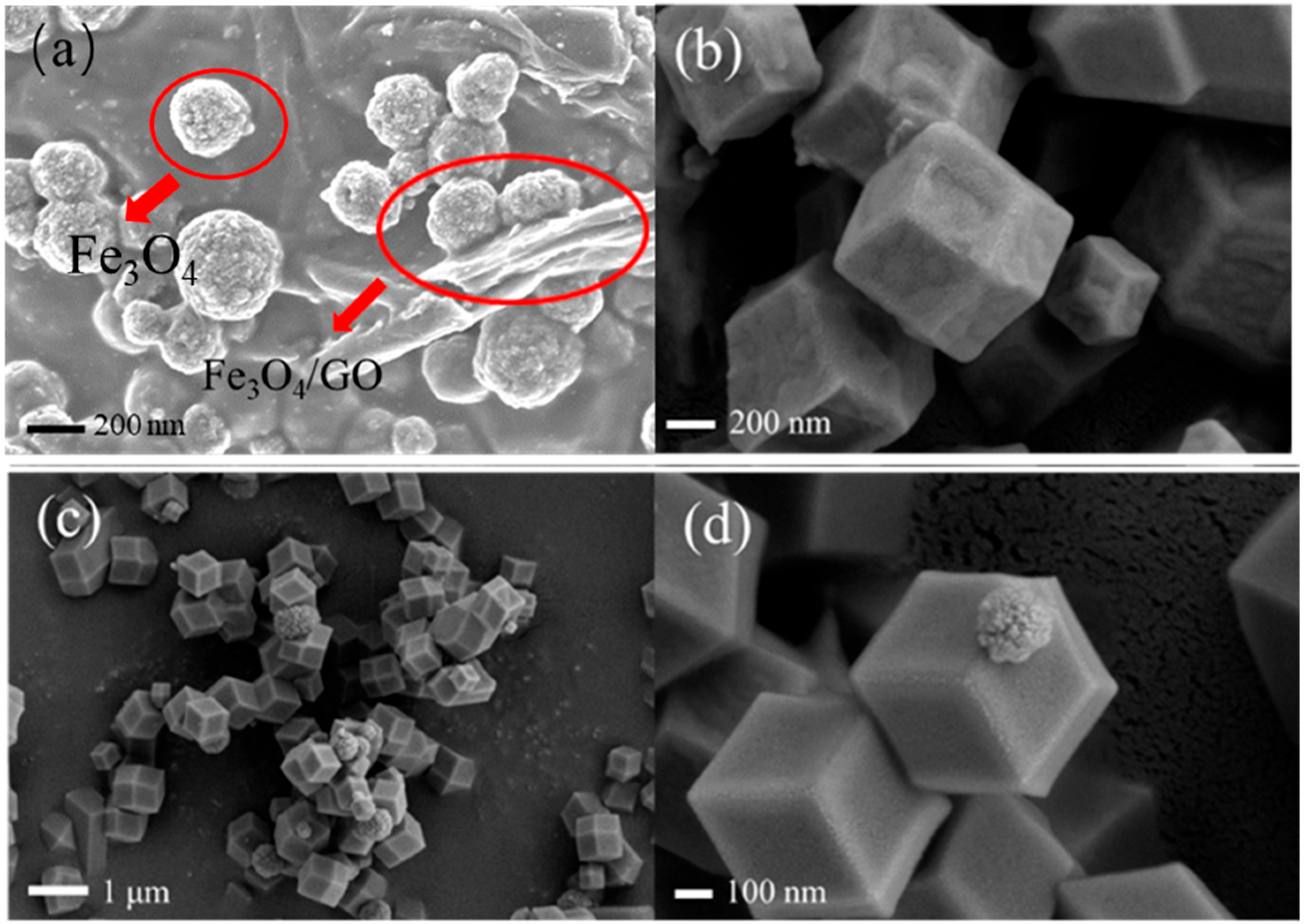

3.2. Characterization

3.3. Factors Affecting the Adsorption of TBBPA by Fe3O4/GO/ZIF-67

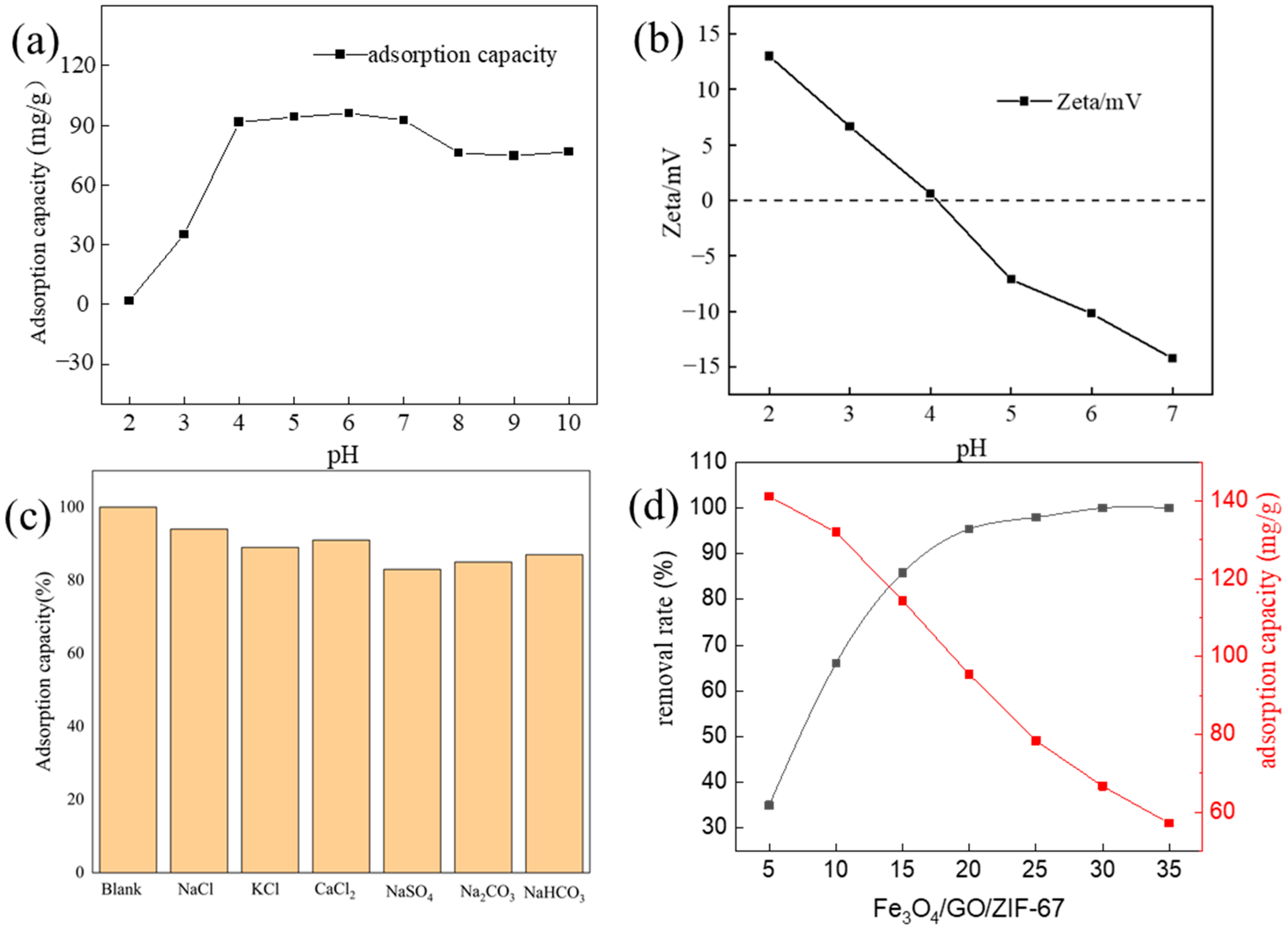

3.3.1. Effects of pH and Ionic Strengths

3.3.2. Effects of Adsorbent Dosage

3.4. Kinetic Adsorption and Isotherms

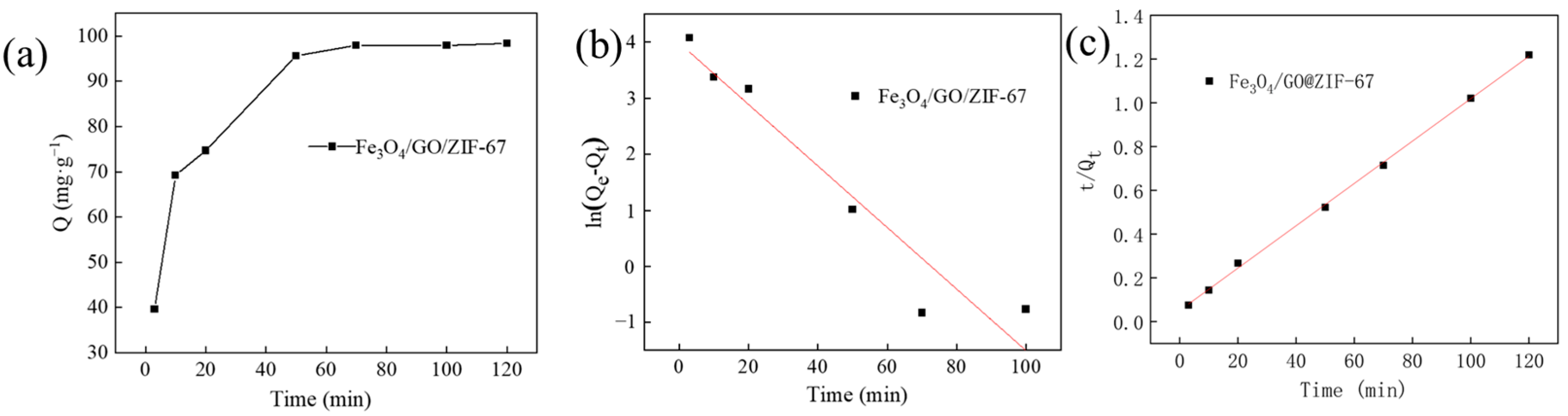

3.4.1. Adsorption Kinetics

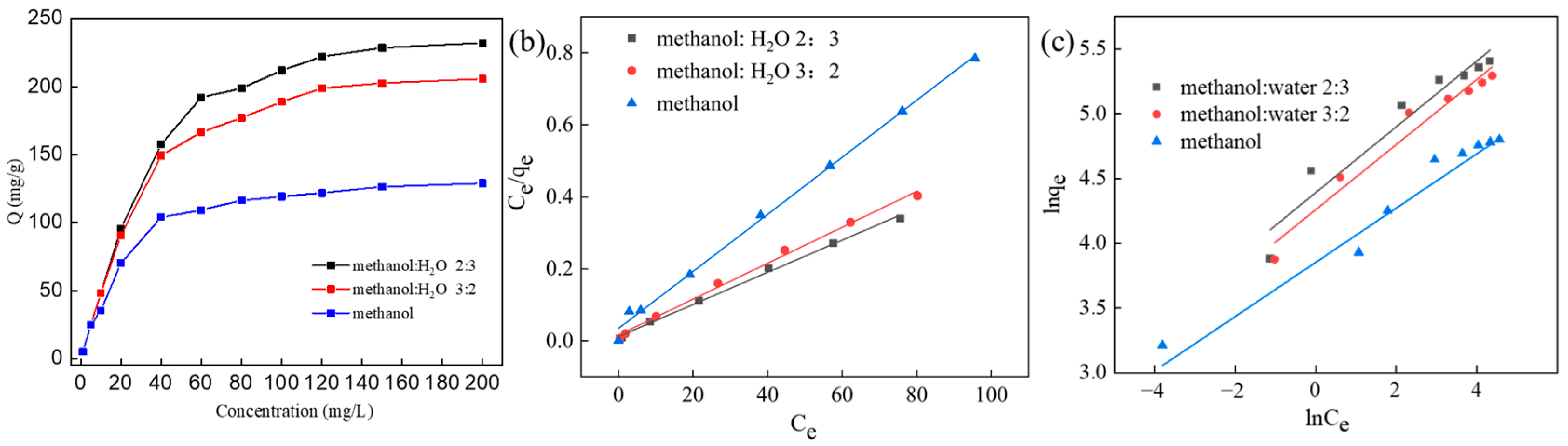

3.4.2. Adsorption Isotherm Study

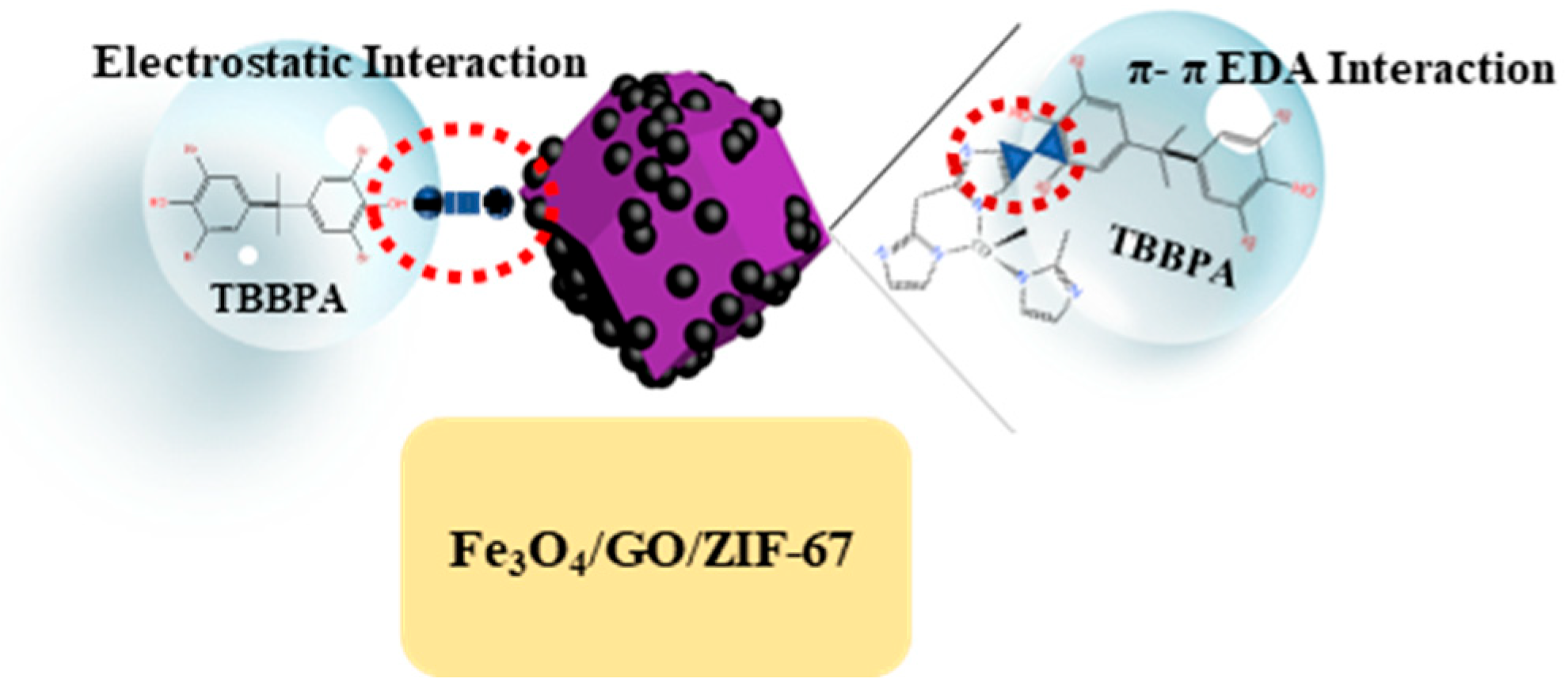

3.5. Possible Adsorption Mechanism

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- de Wit, C.A.; Alaee, M.; Muir, D.C.G. Levels and Trends of Brominated Flame Retardants in the Arctic. Chemosphere 2006, 64, 209–233. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.; Li, J.; Yan, S.; Zhang, W.; Li, Y.; Han, D. A Review of Status of Tetrabromobisphenol A (TBBPA) in China. Chemosphere 2016, 148, 8–20. [Google Scholar] [CrossRef] [PubMed]

- Rosal, R.; Rodríguez, A.; Perdigón-Melón, J.A.; Petre, A.; García-Calvo, E.; Gómez, M.J.; Agüera, A.; Fernández-Alba, A.R. Occurrence of Emerging Pollutants in Urban Wastewater and Their Removal through Biological Treatment Followed by Ozonation. Water Res. 2010, 44, 578–588. [Google Scholar] [CrossRef] [PubMed]

- Oberg, O.; Warman, K. Distribution and Levels of Brominated Flame Retardants in Sewage Sludge. Chemosphere 2002, 48, 805–809. [Google Scholar] [CrossRef] [PubMed]

- Labadie, P.; Tlili, K.; Alliot, F.; Bourges, C.; Desportes, A.; Chevreuil, M. Development of Analytical Procedures for Trace-Level Determination of Polybrominated Diphenyl Ethers and Tetrabromobisphenol A in River Water and Sediment. Anal. Bioanal. Chem. 2010, 396, 865–875. [Google Scholar] [CrossRef] [PubMed]

- Harrad, S.; Abdallah, M.A.E.; Rose, N.L.; Turner, S.D.; Davidson, T.A. Current-Use Brominated Flame Retardants in Water, Sediment, and Fish from English Lakes. Environ. Sci. Technol. 2009, 43, 9077–9083. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, S.; Su, X.; Xu, J.; Nie, G.; Zhang, Y.; He, Y.; Yu, S. Synthesis and Characterization of Ag-Loaded p-Type TiO2 for Adsorption and Photocatalytic Degradation of Tetrabromobisphenol A. Water Environ. Res. 2020, 92, 713–721. [Google Scholar] [CrossRef] [PubMed]

- Gu, H.; Lou, H.; Tian, J.; Liu, S.; Tang, Y. Reproducible Magnetic Carbon Nanocomposites Derived from Polystyrene with Superior Tetrabromobisphenol A Adsorption Performance. J. Mater. Chem. A Mater. 2016, 4, 10174–10185. [Google Scholar] [CrossRef]

- Peng, H.; Pan, B.; Wu, M.; Liu, R.; Zhang, D.; Wu, D.; Xing, B. Adsorption of Ofloxacin on Carbon Nanotubes: Solubility, PH and Cosolvent Effects. J. Hazard. Mater. 2012, 211–212, 342–348. [Google Scholar] [CrossRef]

- Fang, L.; Xu, L.; Li, J.; Huang, L.Z. Copper Nanoparticles/Graphene Modified Green Rusts for Debromination of Tetrabromobisphenol A: Enhanced Galvanic Effect, Electron Transfer and Adsorption. Sci. Total Environ. 2019, 683, 275–283. [Google Scholar] [CrossRef]

- Ji, L.; Bai, X.; Zhou, L.; Shi, H.; Chen, W.; Hua, Z. One-Pot Preparation of Graphene Oxide Magnetic Nanocomposites for the Removal of Tetrabromobisphenol A. Front. Environ. Sci. Eng. 2013, 7, 442–450. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, L.; Akiyama, K.; Bingham, P.A.; Zhou, Y.; Kubuki, S. Self-Assembly of Nanosheet-Supported Fe-MOF Heterocrystals as a Reusable Catalyst for Boosting Advanced Oxidation Performance via Radical and Nonradical Pathways. ACS Appl. Mater. Interfaces 2021, 13, 22694–22707. [Google Scholar] [CrossRef]

- Gnanasekaran, G.; Arthanareeswaran, G.; Mok, Y.S. A High-Flux Metal-Organic Framework Membrane (PSF/MIL-100 (Fe)) for the Removal of Microplastics Adsorbing Dye Contaminants from Textile Wastewater. Sep. Purif. Technol. 2021, 277, 119655. [Google Scholar] [CrossRef]

- Liang, Y.; Zhang, Q.; Li, S.; Fei, J.; Zhou, J.; Shan, S.; Li, Z.; Li, H.; Chen, S. Highly Efficient Removal of Quinolones by Using the Easily Reusable MOF Derived-Carbon. J. Hazard. Mater. 2022, 423, 127181. [Google Scholar] [CrossRef]

- Zhou, T.; Zhao, X.; Xu, Y.; Tao, Y.; Luo, D.; Hu, L.; Jing, T.; Zhou, Y.; Wang, P.; Mei, S. Electrochemical Determination of Tetrabromobisphenol A in Water Samples Based on a Carbon Nanotubes@zeolitic Imidazole Framework-67 Modified Electrode. RSC Adv. 2020, 10, 2123–2132. [Google Scholar] [CrossRef]

- Xie, L.; Liu, D.; Huang, H.; Yang, Q.; Zhong, C. Efficient Capture of Nitrobenzene from Waste Water Using Metal-Organic Frameworks. Chem. Eng. J. 2014, 246, 142–149. [Google Scholar] [CrossRef]

- Yang, S.; Hai, F.I.; Nghiem, L.D.; Nguyen, L.N.; Roddick, F.; Price, W.E. Removal of Bisphenol A and Diclofenac by a Novel Fungal Membrane Bioreactor Operated under Non-Sterile Conditions. Int. Biodeterior. Biodegrad. 2013, 85, 483–490. [Google Scholar] [CrossRef]

- Saint-Louis, R.; Pelletier, E. LC-ESI-MS-MS Method for the Analysis of Tetrabromobisphenol A in Sediment and Sewage Sludge. Analyst 2004, 129, 724–730. [Google Scholar] [CrossRef]

- Ji, Y.; Kong, D.; Lu, J.; Jin, H.; Kang, F.; Yin, X.; Zhou, Q. Cobalt Catalyzed Peroxymonosulfate Oxidation of Tetrabromobisphenol A: Kinetics, Reaction Pathways, and Formation of Brominated by-Products. J. Hazard. Mater. 2016, 313, 229–237. [Google Scholar] [CrossRef]

- Li, L.; Liu, X.L.; Geng, H.Y.; Hu, B.; Song, G.W.; Xu, Z.S. A MOF/Graphite Oxide Hybrid (MOF: HKUST-1) Material for the Adsorption of Methylene Blue from Aqueous Solution. J. Mater. Chem. A Mater. 2013, 1, 10292–10299. [Google Scholar] [CrossRef]

- Jun, B.M.; Hwang, H.S.; Heo, J.; Han, J.; Jang, M.; Sohn, J.; Park, C.M.; Yoon, Y. Removal of Selected Endocrine-Disrupting Compounds Using Al-Based Metal Organic Framework: Performance and Mechanism of Competitive Adsorption. J. Ind. Eng. Chem. 2019, 79, 345–352. [Google Scholar] [CrossRef]

- Watanabe, I.; Kashimoto, T.; Tatsukawa, R. Identification of the Flame Retardant TetrabromobisphenoI-A in the River Sediment and the Mussel Collected in Osaka; Springer-Verlag New York Inc.: New York, NY, USA, 1983; Volume 31. [Google Scholar]

- De Wit, C.A.; Sverige. Naturvårdsverket. In Brominated Flame Retardants; Swedish Environmental Protection Agency (Naturvårdsverket): Stockholm, Sweden, 2000; ISBN 9162050656. [Google Scholar]

- Minna, L.; Sun, P.; Wu, Q.; Liu, D.; Zhou, L. Core-Shell Magnetic Metal-Organic Framework Molecularly Imprinted Nanospheres for Specific Adsorption of Tetrabromobisphenol A from Water. Environ. Sci. Nano 2018, 5, 2651–2662. [Google Scholar]

- Zhou, T.; Tao, Y.; Xu, Y.; Luo, D.; Hu, L.; Feng, J.; Jing, T.; Zhou, Y.; Mei, S. Facile Preparation of Magnetic Carbon Nanotubes@ZIF-67 for Rapid Removal of Tetrabromobisphenol A from Water Sample. Environ. Sci. Pollut. Res. 2018, 25, 35602–35613. [Google Scholar] [CrossRef]

- Zhou, T.; Feng, Y.; Zhou, L.; Tao, Y.; Luo, D.; Jing, T.; Shen, X.; Zhou, Y.; Mei, S. Selective and Sensitive Detection of Tetrabromobisphenol-A in Water Samples by Molecularly Imprinted Electrochemical Sensor. Sens. Actuators B Chem. 2016, 236, 153–162. [Google Scholar] [CrossRef]

- Marcuello, C.; Chambel, L.; Rodrigues, M.S.; Ferreira, L.P.; Cruz, M.M. Magnetotactic Bacteria: Magnetism Beyond Magnetosomes. IEEE Trans. Nanobiosci. 2018, 17, 555–559. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Ma, X.; Liao, H.; Liang, Z.; Li, F.; Tian, J.; Ling, D. Artificially Engineered Cubic Iron Oxide Nanoparticles as a High-Performance Magnetic Particle Imaging Tracer for Stem Cell Tracking. ACS Nano 2020, 14, 2053–2062. [Google Scholar] [CrossRef] [PubMed]

- Zheng, J.; Lin, Z.; Lin, G.; Yang, H.; Zhang, L. Preparation of Magnetic Metal-Organic Framework Nanocomposites for Highly Specific Separation of Histidine-Rich Proteins. J. Mater. Chem. B 2015, 3, 2185–2191. [Google Scholar] [CrossRef]

- Li, X.; Pillai, S.C.; Wei, L.; Liu, Z.; Huang, L.; Huang, Q.; Jia, X.; Hou, D.; Song, H.; Wang, H. Facile Synthesis of Polyoxometalate-Modified Metal Organic Frameworks for Eliminating Tetrabromobisphenol-A from Water. J. Hazard. Mater. 2020, 399, 122946. [Google Scholar] [CrossRef]

- Lastovina, T.A.; Budnyk, A.P. A Review of Methods for Extraction, Removal, and Stimulated Degradation of Microplastics. J. Water Process Eng. 2021, 43, 102209. [Google Scholar] [CrossRef]

| Adsorbent | Specific Surface Area (m2·g−1) | Hole Capacity (cm3·g−1) | Aperture (nm) |

|---|---|---|---|

| ZIF-67 | 2196 | 0.72 | 1.32 |

| Fe3O4/GO/ZIF-67 | 1912 | 0.63 | 1.31 |

| CTBBPA (mg·L−1) | qexp (mg·g−1) | Model | Rate Constant | qe (mg·g−1) | R2 |

|---|---|---|---|---|---|

| 20 | 98.39 | Pseudo-first-order dynamic model | K1 (min−1) 0.0549 | 63.4 | 0.910 |

| Pseudo-second-order dynamic model | K2 (g·mg−1·min−1) 0.0018 | 103 | 0.999 |

| Adsorbent | qmax (mg·g−1) | Ref. |

|---|---|---|

| PWA@Cu-BTC | 3.65 | [30] |

| Fe3O4@ZIF-8 | 81.00 | [31] |

| Fe3O4@ZIF-8@MIP | 117.60 | |

| MCNT@ZIF-67 | 83.23 | [25] |

| GO | 115.77 | [7] |

| Fe3O4/GO/ZIF-67 | 232.00 | This paper |

| Solvents | qexp (mg·g−1) | Model | Parameter 1 | Parameter 2 | R2 |

|---|---|---|---|---|---|

| Methanol–water 2:3 Methanol–water 3:2 Pure methanol | 222.15 198.97 121.8 | Langmuir model | qmax (mg·g−1) | KL (L·mg−1) | |

| 224 | 0.3827 | 0.9963 | |||

| 200 | 0.3129 | 0.9949 | |||

| 126 | 0.2309 | 0.9961 | |||

| Freundlich model | KF (mg·g−1)/(mg·L−1)−n | n | |||

| 80.9 | 3.94 | 0.9200 | |||

| 70.9 | 3.99 | 0.9528 | |||

| 47.2 | 4.78 | 0.8587 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Ji, J.; Shan, S.; Chen, S.; Li, H.; Xu, Q.; Liang, Y. Efficient Adsorption Removal of Tetrabromobisphenol A from Water by Using a Magnetic Composite Fe3O4/GO/ZIF-67. Crystals 2024, 14, 508. https://doi.org/10.3390/cryst14060508

Li S, Ji J, Shan S, Chen S, Li H, Xu Q, Liang Y. Efficient Adsorption Removal of Tetrabromobisphenol A from Water by Using a Magnetic Composite Fe3O4/GO/ZIF-67. Crystals. 2024; 14(6):508. https://doi.org/10.3390/cryst14060508

Chicago/Turabian StyleLi, Sumei, Jian Ji, Saisai Shan, Sha Chen, Hanbing Li, Qian Xu, and Yixuan Liang. 2024. "Efficient Adsorption Removal of Tetrabromobisphenol A from Water by Using a Magnetic Composite Fe3O4/GO/ZIF-67" Crystals 14, no. 6: 508. https://doi.org/10.3390/cryst14060508

APA StyleLi, S., Ji, J., Shan, S., Chen, S., Li, H., Xu, Q., & Liang, Y. (2024). Efficient Adsorption Removal of Tetrabromobisphenol A from Water by Using a Magnetic Composite Fe3O4/GO/ZIF-67. Crystals, 14(6), 508. https://doi.org/10.3390/cryst14060508