Abstract

Porous copper films used in current collectors have been shown to improve the stability of Li-ion batteries. They can be applied in Si-based photodiodes, sensors or as microradiators. Their fabrication, however, remains a challenge. In this work, we report on the direct deposition of porous copper films using magnetron sputtering in regular chamber geometry. We show how by using appropriate process gases and substrate temperatures, it is possible to control the morphology of the deposited films. In particular, the optimization of the argon to oxygen flow ratios and flow values leads to small porosification of the deposited copper films. Further, heating the substrate during deposition enables the growth of pore sizes into mesoporous and macroporous ranges. This approach is scalable, and since it does not require glancing angle deposition enables the easy coverage of large surfaces with uniformly porous films.

1. Introduction

Porous materials have been attracting significant research attention due to their developed surfaces, beneficial for applications involving the surface absorption of various molecules and light, e.g., in sensors [1,2,3,4], white coatings [5], energy storage [6,7], molecular sieving [8] and catalysis [9,10], as well as for heat dissipation [11,12] or lightweight construction [13,14]. The porosity scales range from individual Å to centimeters, depending on the application. It has been always difficult to fabricate such materials. While porous compounds may be formed through specific synthesis conditions, leading to the creation of, e.g., zeolites [15] or metal–organic frameworks [16], in which the appropriate crystallization of the different constituents of the compound enables porosity, porous monoelemental materials, and particularly metals, cannot be made in similar ways. On a large scale, porous metal materials are made using foaming—bubbling a gas through a melted metal and then cooling it down to retain the porous structure [17,18]. On the micro-to-nano scale, foaming is impractical, since it results in a jet of nanoparticles instead of a solid material. For that, thin films have been developed, where the substrate serves as the solid frame for the porous metal deposited using, e.g., electrodeposition [19], or etched by anodic etching [20] or chemical dealloying [21].

Copper is one of the technologically relevant metals due to its very large thermal and electrical conductivity, making porous copper films interesting for both thermal management as well as advanced electrodes for energy storage. There are reports on the electrodeposition of porous copper films, taking advantage of the hydrogen bubbles forming at the growth electrode (similar to foaming) [22,23,24]; however, this approach requires wet processing and a conducting substrate. Porous copper films have also been created by depositing a mixture of copper and aluminum and dealloying the latter by bathing in a NaOH solution to create voids [25]. While the deposition itself is performed using sputtering—a clean, large-area, vacuum-based method—the dealloying requires corrosive chemicals and is not compatible with all materials. Sputtering itself is a potentially appealing technique for large-scale applications and has been shown to enable the direct deposition of porous materials; however, in an embodiment requiring a very specific geometry—glancing angle of incidence deposition with a rotating substrate—making larger-scale coatings is impractical [26,27]. We have previously shown that it is possible to overcome this obstacle by utilizing reactive deposition with minute amounts of oxygen in a conventional chamber geometry. This way, we demonstrated that it was possible to directly deposit porous zinc [28,29] and magnesium [30] films. With the current communication, we propose an innovative general blueprint for the growth of porous films of metals using magnetron sputtering on any thermally stable substrate, not requiring wet processing, by exploring porous copper growth and discussing its mechanism with regard to Zn and Mg.

2. Materials and Methods

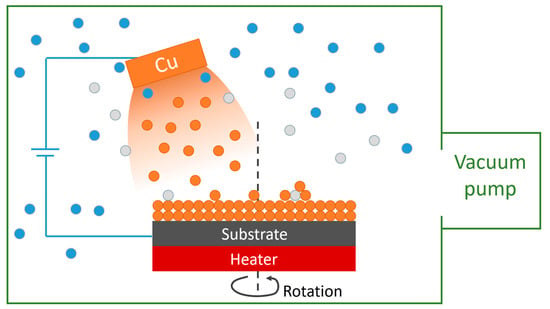

The deposition took place in a Gamma 1000C (Surrey Nanosystems, Newhaven, UK) reactor in confocal magnetron geometry. The substrates used were cleaned Si (111) and the substrates were rotated during deposition. We use one magnetron with a 99.99% pure Zn target 3″ in diameter as the source. The magnetron was supplied with 80 W DC power. The Ar and O2 gases were 99.9999% pure. A schematic of the sputtering chamber is presented in Figure 1.

Figure 1.

Schematic of the sputtering setup. A Cu source, called a ‘target’ is sputtered in a vacuum chamber when argon gas is introduced into it (dark blue dots) and ionized under the voltage applied between the target and substrate. The ionized gas hits the target and ejects the material into the chamber, including on the substrate on which it is coated. The addition of a reactive gas such as oxygen (pale grey dots) enables changes in the growth of the material, either by oxidizing or by influencing the nucleation of the grains. The substrate is rotated during deposition about its axis and may be heated to modify the film growth conditions.

We explored several Ar:O2 flow ratios while maintaining the same total pressure of 0.4 Pa using a Baratron-controlled throttle valve in front of the cryo-pump, similarly to our previous experiments on porous Zn, where we used Ar:O2 flow ratios of 10:1 and 10:2 [28,29]. In the current experiment focused on copper, we used ratios of 10:1 and 10:2 and also 15:1, 20:1 and 25:1, which were chosen based on the observed properties of the films deposited with 10:1 and 10:2 ratios. For each ratio, different flow values were tested, with the complete list of their values shown in Table 1.

Table 1.

List of Cu films deposited at room temperature. All were deposited at 0.4 Pa and 80 W DC power.

As discussed in the later sections, copper, unlike Zn, proved not to form porous films readily at room temperature; therefore, we explored the growth of the films for selected parameters with an increased substrate temperature up to 800 °C, which proved to be the necessary step for achieving porous Cu films and controlling their morphology. The base vacuum in all cases before film growth was of the order of 10−5 Pa. For the discussion of these results and their comparison with the Zn system better understood by us, we also prepared porous Zn samples deposited at elevated temperatures with the following process parameters: 0.4 Pa, 3 sccm Ar, 0.6 sccm O2 and 80 W DC power. Finally, to validate the proposed general blueprint, Al porous films were obtained using elevated temperature deposition for 6 sccm Ar, 0.3 sccm O2, 0.4 Pa and 80 W DC power.

All films underwent structural investigation by means of X-ray diffraction (XRD) in a Bragg–Brentano geometry using a Panalytical Empyrean with a Cu anode. Scanning Electron Microscope (SEM) images of the cross-sections and top surface of the films were taken using Zeiss Gemini and Transmission Electron Microscope (TEM) images of selected crystallites with their surface oxide passivation in high-resolution mode. In addition, elemental maps and selected area electron diffraction patterns (SEAD) were taken using a JEM 2100 (JEOL, Tokyo, Japan).

To determine the stability of the nanostructured films in aqueous environments, we chose to apply a microbiotic analysis, since copper and its oxides are known to be bacteriostatic. The dissolution and diffusion of copper ions in the agar with bacterial colonies is visible through the appearance of zones of inoculation close to the sample edges, which can be used to determine the material stability; if there is a large zone, a significant part of the material has dissolved. Therefore, we prepared small pieces (close to 5 mm × 5 mm) of the films deposited at elevated temperatures and placed them on the surface of MH agar containing a standardized bacterial suspension (0.5 McF; Escherichia coli ATCC 25922). The samples underwent overnight incubation at 35 °C. Post-incubation, a visual inspection was conducted to assess the inhibition of bacterial growth around the samples.

3. Results

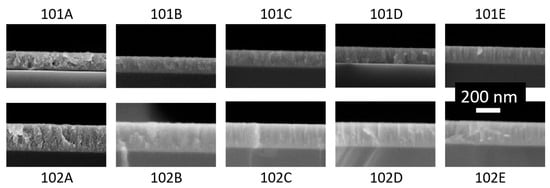

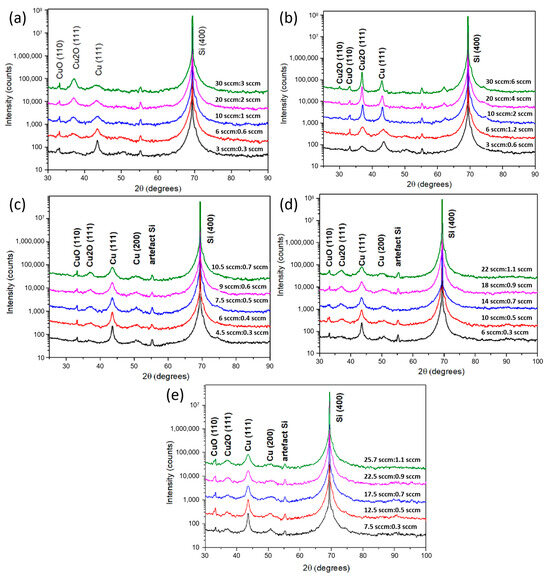

We started the investigations by depositing Cu using sputtering at 10:1 and 10:2 flow ratios of argon to oxygen without substrate heating. We made two batches of samples, as seen in Table 1. All the films that were grown under these conditions were, however, not porous columnar ones, with no evident changes in the film morphologies for different flow ratios or flow values (see Figure 2), and their XRD patterns showed that with increasing oxygen content, the Cu (111) line became less resolved and a Cu2O (111) line appeared to be more evident (see Figure 3a,b). In the XRD patterns, the Cu2O peaks were significantly more pronounced for the 10:2 flow ratios (Figure 3b) than for the 10:1 ones (Figure 3a), and also more pronounced, with an increase in the oxygen flow values within a batch.

Figure 2.

SEM cross-section images of the samples deposited at 10:1 and 10:2 Ar:O2 ratios. For sample names, please consult Table 1.

Figure 3.

XRD patterns of the samples deposited at room temperature in the flow ratios 10:1 (a), 10:2 (b), 15:1 (c), 20:1 (d) and 25:1 (e).

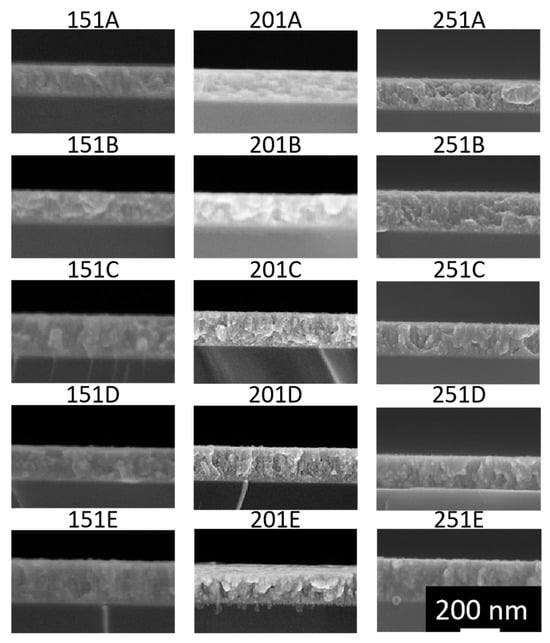

From the known porous Zn deposition processes, we know that the growth mechanism for the porous films is based on the initiation of new nucleation centers on the growing film by a minute amount of oxygen, lowering the Zn adatom mobility on the growth front and yielding many nanoscale grains, and by self-shadowing from the growing grains, leading to the creation of voids [29]. Therefore, in an effort to grow porous copper, we chose to explore further the conditions where the gas flow ratios would be less oxygen-rich, i.e., 15:1, 20:1 and 25:1 Ar:O2. Having prepared batches of samples for all such ratios (see Table 1), we found that the most promising material was deposited at the ratio 20:1, with 18 sccm Ar and 0.9 sccm O2. In terms of their XRD patterns, they exhibited no variability between all samples in these process conditions, showing that the process parameter space leads to no majority changes of the material, with a dominating Cu (111) peak and weaker, broader Cu2O (111) and Cu (002) peaks. For all the samples, the Cu (111) peak was the narrowest and highest for the samples deposited at the lowest flow values, and it decreased in intensity with increasing flow values; however, no differences between the batches could be seen. Based on the SEM analysis, these films deposited at these conditions showed many very small grains, as we would expect for the nucleation mechanism to occur, but there were too few voids to call this material a porous film (see Figure 4). From a careful examination of the images, it was concluded that the most clearly defined nanoscale pores were visible for the sample 201D, which was chosen for further optimization.

Figure 4.

SEM cross-section images of the samples deposited at 15:1, 20:1 and 25:1 Ar:O2 ratios. For sample names, please consult Table 1.

The parameters that which could still be changed were as follows: total pressure, magnetron power and substrate temperature. Power would controls the flux of the in-coming material and thus the stream of adatoms arriving at the growth front. The sSubstrate temperature would modifiesy the mobility of the adatoms at the growth front. While fFor nonreactive metal deposition, the temperature is expected to help in forming dense and smooth films. In, our experiments with the deposition of porous Mg [30], where the addition of substrate heating caused extended nanowire growth in the Mg film, showed it was shown that in the reactive deposition case, the mechanism is not as clear. Increasing the deposition pressure only lowered the growth rates dramat-ically and therefore was not explored. Changes in sputtering power from 40 to 200 W DC did not result in much change into the morphology of the films, only making them thicker (see Figure S1 in the Supplementary Materials), which is reflected in the in-creased intensity of the Cu (111) and the appearance of the Cu (200) peaks in the XRD patterns of the films deposited at increased power (see Figure S2). Additionally, in these samples, the intensity of the Cu2O (111) peak remaineds unchanged even with the increase inof the film thickness, hinting that its origin is surface native oxidation at the surface taking place after the removal of the material from the sputtering chamber. For the temperature optimization step, we therefore remained at 80 W sputtering power and changed the substrate temperature.

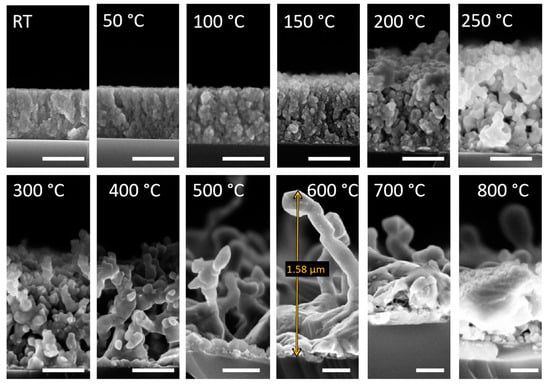

The increased temperature enabled the development of the film morphology, as evidenced by the SEM cross- section images in Figure 5. The films deposited at both RT and 50 °C had very small grains (diameters < 10 nm) and very small pores < 5 nm in size. However, we saw clearly the onset of morphology changes at 100 °C. At this tem-perature, the grain sizes increased to around 10 nm and the top surface became less smooth. The pores were slightly larger, with maximum sizes around 10 nm. Further increases in temperature to 150, 200 and 250 °C expanded the films and increased the maximum observed pore sizes to 30, 47 and 50 nm, respectively. Interestingly, the crystallite sizes also increased, as shown in Table 2. With the temperature increasing further, to 300 °C, we observed an opening of the morphology and the formation of nanocorals; similar to the case of zinc, the pore sizes increased to 60 nm and then to 112 nm for 400 °C and the crystal sizes followed. With further increases in temperature to 500 °C and 600 °C, the morphology turned to a one with less dense but longer single nanowires with an increasingly thicker substrate-bound layer. At 700 °C, the morphology started to collapse; —the nanowires were much shorter, and at 800 °C, only a thick, rough but nonporous film was left at the substrate.

Figure 5.

SEM cross-section images of the samples deposited at 18 sccm Ar:0.9 sccm O2 for various temperatures. The white horizontal bars denote 200 nm for each image.

Table 2.

Lattice parameters determined from XRD Cu (200) peak position, different from the bulk Cu lattice parameter = 3.61491 Å and crystallite/pore sizes determined from SEM images for the samples deposited with increasing temperature for 18 sccm Ar:0.9 sccm O2.

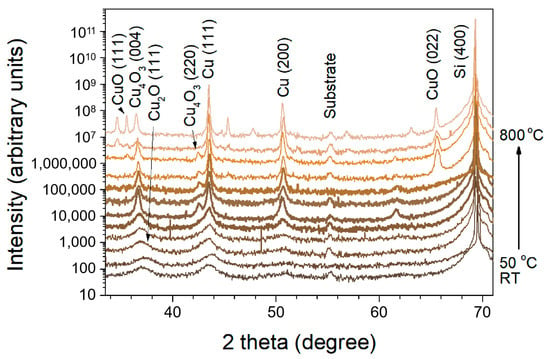

As for the XRD, in all cases the Cu (111) and Cu (200) peaks are visible, however the Cu (200) peak is significantly broader and smaller. Both of these peaks become narrower with the increase in the deposition temperature showing an improvement of the crystallinity of the Cu. The determination of the lattice constants from the position of these peaks, corrected to the d-spacing of the Si (400) peak is included in Table 2, and show that the Cu is slightly compressed in relation to the lattice constant of 3.61491 Å reported for bulk Cu [31], as is often the case for sputter deposited films, and also that there are no monotonous changes in the lattice parameters with the increase in the deposition temperature. In addition to the Cu peaks, there are several others, related to copper oxides (see Figure 6).

Figure 6.

XRD patterns of the samples deposited at 18 sccm Ar:0.9 sccm O2 for various temperatures. The thicker lines are drawn for the samples deposited between 200 and 400 °C, where the porous growth mode is observed.

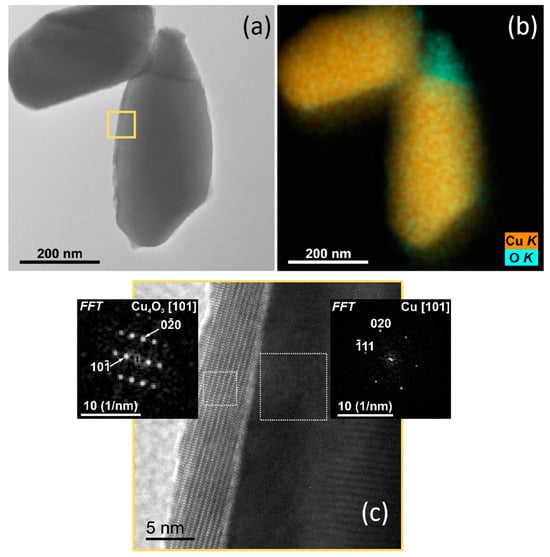

The Cu2O (111) peak appears to be shifting into smaller 2θ values, indicating an increase in the interlayer spacing of the oxide. The material that has larger interlayer distance is Cu3O4. The reason why the oxide moves from the low-oxygen content Cu2O to Cu3O4 is related to the increasing diffusivity and solubility of oxygen in copper with increasing temperature. This is also why for the highest temperatures, additional peaks from CuO appear, showing that even more oxygen reacted with the copper. The presence of Cu3O4 is further confirmed in the TEM imaging of the sample grown at 300 °C (see Figure 7), applied to determine the location of the oxide in the films. From the TEM imaging, we see that the nanocrystallites are copper in their bulk with a thin surface layer. Fast Fourier transform (FFT) shows that the surface layer is in fact Cu3O4 and that the grains are Cu.

Figure 7.

TEM images of the individual nanocrystals of the sample deposited at 300 °C. (a) Overview image with the frame showing the zoomed in area in (c). (b) Elemental mapping of the crystallites. (c) High-resolution image of the surface oxide on the Cu crystallite zoomed in from the yellow box in (a). Localized FFT profiles of the areas in white boxes show that the oxide is Cu4O3 and the grain is Cu.

The achieved tailoring of the film morphology and nanopore sizes enables the application of the films fabricated using this technique to a variety of areas. First, nanoporous Cu films made by Ti-Cu compound sputtering and chemical Ti dealloying with pore sizes in the range of 30–50 nm can serve as efficient Surface-enhanced Raman Spectroscopy (SERS) platforms [32]. Porous films created by dealloying Al-Cu compounds have been achieved with pore sizes above 50 nm for efficient solar steam generation [33]. In other works, porous Cu was also created by dealloying, with pore sizes larger than 100 nm improving the performance of current collectors in Li-ion batteries, inhibiting Li-dendrite formation and providing better long-term cycling stability [25]. In the same pore size range, electrodeposited porous copper can be used as a CO2 reduction catalyst [34]. For all of these, our approach would prove simpler than the current solutions, as it is a one-step approach and enables more precise tuning of the pore sizes.

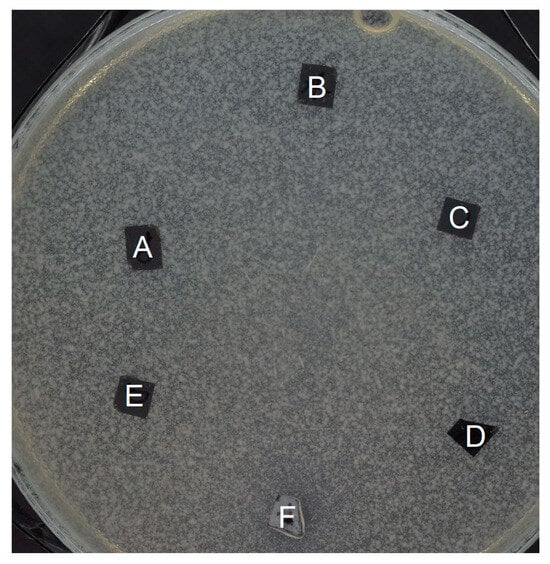

Finally, the stability of the nanostructures in aqueous media was proven using microbial stability testing with E. coli. Since it is known that the dissolution of Cu to its ionic form is needed for the antimicrobial effect to take place [35], the observation of an inhibition zone around the incubated samples may be treated as a measure to see how the development of the porosity and opening of the morphology would influence the dissolution of the copper. This is significantly easier than measuring the concentration of Cu ions in a solute in any other way. Since for a smooth Cu film, as the one deposited at room temperature, the available surface is low and the diffusion may take place very slowly, but for a highly developed film, the surface is high, which might enable a high degree of solution and more ions for diffusion, it was valid to verify the stability of the films. We tested the samples deposited at RT and temperatures of 50–300 °C. As seen in Figure 8, none of the tested samples exhibited any sort of inhibition zones, proving that the dissolution of copper does not take place, even from nanostructured features. This might be explained by the fact that the surfaces of the copper are protected by an oxide film, which inhibits the Cu dissolution. This result shows the need for a reduction in the material grown this way prior to use requiring the direct contact of the metallic copper with the external environment, such as steam generation.

Figure 8.

Optical image of the nanostructured Cu samples on the E. coli-loaded agar: A—RT, B—50 °C, C—100 °C, E—150 °C, D—200 °C and F—300 °C.

4. Discussion on the Growth Mechanism for Porous Metals

4.1. Insight from Known Zn and Mg Systems

When discussing the potential mechanism of porous metal growth using sputtering, many factors have to be taken into consideration. First, the affinity of the metal to oxygen may play a role, since it is the oxygen that in our previous work on Zn governed the nucleation of new crystallites. Its minute but non-negligible presence is needed to form porous Zn and Mg. From the current experiments, it is evident that for Cu the same is true, as deposition with low oxygen content results in uniform films. In all cases, when too much oxygen is added, the resulting films are oxides instead of porous metals. We found experimentally that overcoming 1 sccm O2 for Mg, 2 sccm O2 for Zn and 6 sccm O2 for Cu with 10 sccm of Ar in all cases leads to the formation of uniform metal oxide films. These limiting oxygen flow values are in the same order as the reactivity of these metals. The reactivity, however, seems only to limit the maximum amount of oxygen, which disables the porous growth mode.

A second important parameter is the substrate temperature during the deposition of the films. In the growth of porous Cu films, it is a key parameter, as we showed in the previous section. To compare the Cu with Zn (m.p. = 419.5 °C, b.p. = 907 °C), we made additional samples of porous Zn deposited at elevated temperatures. While the porous structures were observed already at RT, an increase in substrate temperature to 100 °C results in the growth of elongated features in the porous films, continuing up to 200 °C, at which temperature the morphology collapses (see Figure S3); similar behavior was observed in the case of Zn whisker growth at elevated temperatures [36]. Although the origin of whisker growth from Zn coatings is still debated in the literature [36], this behavior is similar to the one we observed when depositing on hot enough substrates, meaning that the addition of temperature causes the protrusions to form in more elongated forms. Furthermore, at 250 °C and more, there is no Zn deposited film visible on the substrate (see Figure S3). The low pressure in the chamber decreases the temperature needed for the evaporation of the Zn from that observed in atmospheric pressure, in line with the ideal gas law [37]. What is also important, in the XRD of the Zn deposited at higher temperatures, no dominating peaks related to ZnO could be seen, showing that the amount of oxygen is not enough to cause a conversion to ZnO (see Figure S4). For Mg (m.p. = 650 °C, b.p. = 1090 °C), the same situation took place, with first elongated features forming above 100 °C with no film visible after deposition at 400 °C. For Mg, there was oxidation of some of the nanostructures at 300 °C. The temperatures at which we observed no deposition for these two materials are much lower than their respective atmospheric boiling points, in line with the expectation from the ideal gas law that these values would be lower when operating under much lower pressures, such as 0.4 Pa in the chamber during deposition.

4.2. Proposed Mechanism for Cu

For Cu (m.p. = 1084.62 °C, b.p. = 2562 °C), the boiling point temperature is much higher than for Zn and Mg, and we did not reach in our experiment the state where no Cu was deposited on the substrate; however, the behavior of the morphology for lower temperatures was similar to that observed for Zn and Mg in the sense that at some temperature porous growth was observed, followed by whisker-like growth and then a collapse of the protrusions. However, at low temperatures we observed a dense, uniform film, which was not seen either for Zn or for Mg. We can correlate this behavior with the orders of magnitude lower vapor pressure (v.p.) of Cu (6 × 10−49 Pa) than for Mg (6 × 10−16 Pa) or Zn (1 × 10−14 Pa) at room temperature [38]. These observations allow the hypothesis that the temperature increase during the growth of porous films allows an increase in the mobility of the incoming species at the growth front and, since the deposited material and the growth front are both the same metal after an initial layer is formed, the v.p. of the metal used would be the measure of mobility of the adatoms on its surface.

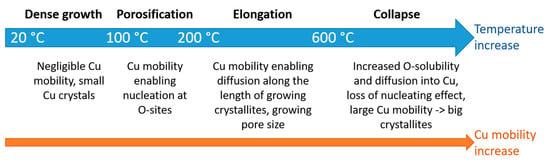

Discussing in terms of mobility, at a temperature leading to dense film growth, Cu mobility is limited, and the incoming adatoms moving along the growth front can move until they find an energetically favorable position to form bonds, which will most likely be next to an adsorbed oxygen atom due to the high copper reactivity with oxygen, as discussed previously (see Figure S5). This will lead to many local nucleation sites and small crystallites growing. Increasing the temperature yields increased Cu mobility, which enables the Cu adatoms to diffuse past the closest oxygen-induced nucleation site and move along the growing crystallites, although still at relatively small distances, leading to a visible porosification between 100 °C and 200 °C. At a further increase in temperature, the Cu adatoms arriving at the substrate have even more increased mobility, enabling further diffusion [39] and yielding longer crystallites and larger pores. Above 600 °C, the solubility of oxygen in copper is high enough [40] that the incoming oxygen molecules and atoms do not stick to the surface of the copper but instead dissolve in the growing material, leading to both the formation of oxides and a disappearance of the nucleation sites, which in turn allows the highly mobile Cu adatoms to find geometrical low energy sites and grow more flat films, yielding a collapse of the porous morphology (see Figure 9).

Figure 9.

Proposed growth zones for the porous Cu as a function of substrate temperature.

Looking for a numeric threshold for the effect, the v.p. for Cu at the onset of porosification at 100 °C becomes 5 × 10−36 Pa and increases to 1.5 × 10−22 Pa at 250 °C where the Zn-like porous films form. Since we are not able to lower the substrate temperature below RT during sputtering, we cannot say what kind of threshold v.p. is needed for porous Zn film formation or if it is a universal value. We know that the order of v.p. as seen for Zn at RT, i.e., 1 × 10−14 Pa, is achievable for Cu at 410 °C, at which temperature the morphology of the Cu is more sparse than for Zn at RT. Since the modelled particle fluxes from the sputtering of both targets are similar in magnitude, the only remaining difference is in the metal reactivity, leading to the conclusion that the lower reactivity of Cu to oxygen leads to fewer nucleation sites than for Zn, yielding a sparser morphology at the same vapor pressure of the material. It has to be noted that in these considerations, we did not take into account the Thornton zone model [41], since the growth mode that it leads to is porous or voided films at 0.4 Pa; in that model, it would be observed at below −22 °C for Cu and −150 °C for Zn, which is not in line with our observations. The Thornton zone model, however, does not take into account the reactive aspect of the deposition and the onset of new nucleation sites coming from oxygen contamination.

4.3. A General Blueprint for Porous Growth of Metal Films

Based on the experimental data, we can argue that the onset of the nucleation of the porous films is dependent on the vapor pressure dependence on temperature of the metals deposited. For some metals, such as Zn and Mg, at RT the vapor pressure is already high enough that it leads to enough mobility of the incoming species for them to find low-energy sites at the oxygen-initiated nucleation centers, leading to the formation of new grains. For metals with generally lower v.p., the temperature needs to be increased to achieve this kind of mobility, enabling the growth of porous structures. It is crucial, however, not to increase the temperature too much, as otherwise the growth will shift to whisker-like growth of the nanostructures. Based on the data for Zn, Mg and Cu, we could suggest that when choosing a deposition temperature for new materials aiming to obtain similarly porous structures, one should start with temperatures yielding a v.p. of at least around 10−22 Pa. Care has to be taken to remember that such very low values are burdened with significant uncertainty, and these temperature values should be regarded as approximate, not exact process parameters; however, still such a benchmark enables the assessment of the possibility of growing porous films at technologically available temperatures. For example, based on these predictions, we can say that Al, which has a v.p. trend very close to Cu, should be able to be grown into a porous film. It is possible that deposition onto a substrate kept at 200 °C results in a similarly porous structure, while RT deposition under the same conditions gives a columnar film (see Figure S6). On the other hand, materials such as Ta would require temperatures above the capabilities of our system—well above 800 °C.

Using the v.p. calculator from Technische Universität Wien [38], we prepared a table of temperatures for different elements with temperatures required to reach a v.p. of 10−22 Pa as a suggested starting point for future research endeavors in the deposition of porous metal films using magnetron sputtering (see Table 3). It can be seen that only Zn, Mg and Yb have low enough temperatures to achieve porous growth already at RT, and Pb is very close to RT, which taking into account the degree of uncertainty may enable porous Pb growth at RT. It has to be noted, however, that apart from the temperature, appropriate oxygen flow has to be selected to induce new nucleation centers but also not to oxidize the metals. As mentioned earlier, the oxygen flow values follow the general trend of the reactivity series with the following maximum non-oxidizing values: 1 sccm O2 for Mg, 2 sccm O2 for Zn and 6 sccm O2 for Cu with 10 sccm of Ar. Therefore, the target oxygen flow values for new elements should be estimated with regard to the position of the new elements on the reactivity series with regard to Mg, Zn and Cu.

Table 3.

Temperatures needed to achieve vapor pressure of 10−22 Pa for selected metallic elements. Data source: TU Wien [38].

5. Conclusions

In this report, we presented the growth of porous Cu films by magnetron sputtering using an appropriate selection of reactive sputter parameters and substrate temperatures. We showed that at temperatures higher than 100 °C, a porous morphology of the Cu film is achievable with tailored pore sizes from several nm to over 120 nm and open porosity, which simplifies the material preparation for various applications, such as SERS platforms, solar steam generation or Li-ion batteries, where the nanoporosity offers improved performance over non-nanostructured materials. By comparing with other porous films grown by magnetron sputtering at elevated temperatures, namely Zn and Mg, we were able to determine that the role of temperature is crucial in achieving porosity through the increased mobility of metal adatoms and that the presence of oxygen contaminants in the sputtering atmosphere is key to the formation of nucleation centers for the porous growth. By controlling the temperature, we can control the diffusion length of the incoming adatoms and thus the porosity. Based on copper, we discussed the following four growth zones: (I) dense metallic films, (II) porous coral-like growth, (III) elongated crystallite growth, (IV) the collapse of morphology. We found that the onset of the porous growth may correlate with a high enough vapor pressure of the deposited metal at a given substrate temperature and proposed a blueprint for the high-temperature reactive sputter deposition of porous metallic films using other metals, enabling the development of a single-step fabrication of porous films of Mn, Ag, Fe, Ni, Ti, Au, Pt, Zr, Hf and other metals.

Supplementary Materials

The following supporting information can be downloaded at https://www.mdpi.com/article/10.3390/cryst14110965/s1, Figure S1. SEM cross-section images of Cu films deposited at 18 sccm Ar, 0.9 sccm O2, 0.4 Pa, RT and varied DC power of 40 W (a), 80 W (b), 120 W (c), 160 W (d) and 200 W (e); Figure S2. XRD patterns of the Cu films deposited with varied power; Figure S3. SEM cross-section morphologies of porous films deposited at different temperatures under 80 W DC power, 3 sccm Ar, 0.6 sccm O2 and 0.4 Pa total pressure; Figure S4. XRD patterns of porous Zn films deposited at elevated temperatures; Figure S5. Schematic growth modes for porous metals (dark circles represent metal atoms, light circles represent oxygen atoms). (a) In a low-mobility scenario, the metallic adatom is free to move along the growth front, i.e., on surface of the metal on which was already deposited, and it will more likely attach to an already bonded oxygen atom (site A) than to an oxygen-free surface (site B). (b) The oxygen site serves as a nucleation site, since the new incoming metal atoms will diffuse to it, bond to it and then form kinks—low-energy sites that are favorable for new atoms to bond with (sites C). (c) In a high-temperature scenario, the diffusion along the growing crystals is favorable due to increased mobility. The creation of additional kink-like sites (sites C) will take place; however, the crystallite will mostly grow away from the substrate, not along it; Figure S6. SEM cross-section morphologies of aluminum films deposited at different temperatures under 80 W DC power, 6 sccm Ar, 0.3 sccm O2 and 0.4 Pa total pressure.

Author Contributions

Conceptualization, M.A.B., M.W., B.S.-M. and P.K.; methodology, M.A.B., M.W. and P.K.; formal analysis, M.A.B., M.W., B.S.-M. and P.K.; investigation, P.B., J.Z. and P.K.; resources, R.Z. and P.K.; data curation, M.A.B., M.W., P.B., J.Z. and P.K.; writing—original draft preparation, M.A.B. and B.S.-M.; writing—review and editing, M.A.B.; visualization, M.A.B., P.B., J.Z., M.W. and P.K.; supervision, M.A.B.; project administration, M.A.B.; funding acquisition, M.A.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Science Centre, Poland, grant number UMO-2020/39/D/ST5/01474.

Data Availability Statement

Data are contained within the article or Supplementary Material.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Hung, C.M.; Van Duy, L.; Thanh Le, D.T.; Nguyen, H.; Van Duy, N.; Hoa, N.D. ZnO Coral-like Nanoplates Decorated with Pd Nanoparticles for Enhanced VOC Gas Sensing. J. Sci. Adv. Mater. Devices 2021, 6, 453–461. [Google Scholar] [CrossRef]

- Ramírez-González, F.; García-Salgado, G.; Rosendo, E.; Díaz, T.; Nieto-Caballero, F.; Coyopol, A.; Romano, R.; Luna, A.; Monfil, K.; Gastellou, E. Porous Silicon Gas Sensors: The Role of the Layer Thickness and the Silicon Conductivity. Sensors 2020, 20, 4942. [Google Scholar] [CrossRef] [PubMed]

- Davoodi, E.; Montazerian, H.; Haghniaz, R.; Rashidi, A.; Ahadian, S.; Sheikhi, A.; Chen, J.; Khademhosseini, A.; Milani, A.S.; Hoorfar, M.; et al. 3D-Printed Ultra-Robust Surface-Doped Porous Silicone Sensors for Wearable Biomonitoring. ACS Nano 2020, 14, 1520–1532. [Google Scholar] [CrossRef]

- Campbell, M.G.; Dincă, M. Metal–Organic Frameworks as Active Materials in Electronic Sensor Devices. Sensors 2017, 17, 1108. [Google Scholar] [CrossRef] [PubMed]

- Yu, S.; Chen, J.; Gomard, G.; Hölscher, H.; Lemmer, U. Recent Progress in Light-Scattering Porous Polymers and Their Applications. Adv. Opt. Mater. 2023, 11, 2203134. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, S.; Shao, Y.; Wu, Y.; Sun, C.; Huo, Q.; Zhang, B.; Hu, H.; Hao, X. One-Step Fabrication of Porous GaN Crystal Membrane and Its Application in Energy Storage. Sci. Rep. 2017, 7, srep44063. [Google Scholar] [CrossRef]

- Feng, D.; Lei, T.; Lukatskaya, M.R.; Park, J.; Huang, Z.; Lee, M.; Shaw, L.; Chen, S.; Yakovenko, A.A.; Kulkarni, A.; et al. Robust and Conductive Two-Dimensional Metal-Organic Frameworks with Exceptionally High Volumetric and Areal Capacitance. Nat. Energy 2018, 3, 30–36. [Google Scholar] [CrossRef]

- Ahmad, S.; Siddiqi, W.A.; Ahmad, S. Sustainable Nanocomposite Porous Absorbent and Membrane Sieves: Definition, Classification, History, Properties, Synthesis, Applications, and Future Prospects. J. Environ. Chem. Eng. 2023, 11, 109367. [Google Scholar] [CrossRef]

- Wang, C.; Wang, W. Advances in Porous Organic Catalysis. Acta Chim. Sin. 2015, 73, 498–529. [Google Scholar] [CrossRef]

- Chen, Y.Z.; Zhang, R.; Jiao, L.; Jiang, H.L. Metal–Organic Framework-Derived Porous Materials for Catalysis. Coord. Chem. Rev. 2018, 362, 1–23. [Google Scholar] [CrossRef]

- Du, H.; Lu, D.; Qi, J.; Shen, Y.; Yin, L.; Wang, Y.; Zheng, Z.; Xiong, T. Heat Dissipation Performance of Porous Copper with Elongated Cylindrical Pores. J. Mater. Sci. Technol. 2014, 30, 934–938. [Google Scholar] [CrossRef]

- Chen, M.; Pang, D.; Yan, H. Highly Solar Reflectance and Infrared Transparent Porous Coating for Non-Contact Heat Dissipations. iScience 2022, 25, 104726. [Google Scholar] [CrossRef]

- Lo, T.Y.; Cui, H.Z. Effect of Porous Lightweight Aggregate on Strength of Concrete. Mater. Lett. 2004, 58, 916–919. [Google Scholar] [CrossRef]

- Sun, Y.; Chu, Y.; Wu, W.; Xiao, H. Nanocellulose-Based Lightweight Porous Materials: A Review. Carbohydr. Polym. 2021, 255, 117489. [Google Scholar] [CrossRef]

- Xu, H.; Wu, P. New Progress in Zeolite Synthesis and Catalysis. Natl. Sci. Rev. 2022, 9, nwac045. [Google Scholar] [CrossRef]

- Xie, L.S.; Skorupskii, G.; Dincǎ, M. Electrically Conductive Metal-Organic Frameworks. Chem. Rev. 2020, 120, 8536–8580. [Google Scholar] [CrossRef]

- Behymer, N.; Morsi, K. Review: Closed-Cell Metallic Foams Produced via Powder Metallurgy. Metals 2023, 13, 959. [Google Scholar] [CrossRef]

- Ru, J.; Kong, B.; Liu, Y.; Wang, X.; Fan, T.; Zhang, D. Microstructure and Sound Absorption of Porous Copper Prepared by Resin Curing and Foaming Method. Mater. Lett. 2015, 139, 318–321. [Google Scholar] [CrossRef]

- Tian, Q.; Guo, X. Manufacturing Microporous Foam Zinc Materials with High Porosity by Electrodeposition. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2011, 26, 843–846. [Google Scholar] [CrossRef]

- Kern, P.; Veh, J.; Michler, J. New Developments in Through-Mask Electrochemical Micromachining of Titanium. J. Micromechanics Microengineering 2007, 17, 1168–1177. [Google Scholar] [CrossRef]

- Gan, Y.X.; Zhang, Y.; Gan, J.B. Nanoporous Metals Processed by Dealloying and Their Applications. AIMS Mater. Sci. 2018, 5, 1141–1183. [Google Scholar] [CrossRef]

- Li, Y.; Jia, W.Z.; Song, Y.Y.; Xia, X.H. Superhydrophobicity of 3D Porous Copper Films Prepared Using the Hydrogen Bubble Dynamic Template. Chem. Mater. 2007, 19, 5758–5764. [Google Scholar] [CrossRef]

- Niu, J.; Liu, X.; Xia, K.; Xu, L.; Xu, Y.; Fang, X.; Lu, W. Effect of Electrodeposition Parameters on the Morphology of Three-Dimensional Porous Copper Foams. Int. J. Electrochem. Sci. 2015, 10, 7331–7340. [Google Scholar] [CrossRef]

- Wang, N.; Hu, W.C.; Lu, Y.H.; Deng, Y.F.; Wan, X.B.; Zhang, Y.W.; Du, K.; Zhang, L. Role of Surfactants in Construction of Porous Copper Film by Electrodeposition Approach. Trans. Inst. Met. Finish. 2011, 89, 261–267. [Google Scholar] [CrossRef]

- Shi, Y.; Wang, Z.; Gao, H.; Niu, J.; Ma, W.; Qin, J.; Peng, Z.; Zhang, Z. A Self-Supported, Three-Dimensional Porous Copper Film as a Current Collector for Advanced Lithium Metal Batteries. J. Mater. Chem. A 2019, 7, 1092–1098. [Google Scholar] [CrossRef]

- Bairagi, S.; Järrendahl, K.; Eriksson, F.; Hultman, L.; Birch, J.; Hsiao, C.L. Glancing Angle Deposition and Growth Mechanism of Inclined AlN Nanostructures Using Reactive Magnetron Sputtering. Coatings 2020, 10, 768. [Google Scholar] [CrossRef]

- Hawkeye, M.M.; Brett, M.J. Glancing Angle Deposition: Fabrication, Properties, and Applications of Micro- and Nanostructured Thin Films. J. Vac. Sci. Technol. A Vacuum Surfaces Film. 2007, 25, 1317. [Google Scholar] [CrossRef]

- Borysiewicz, M.A.; Dynowska, E.; Kolkovsky, V.; Dyczewski, J.; Wielgus, M.; Kamińska, E.; Piotrowska, A. From Porous to Dense Thin ZnO Films through Reactive DC Sputter Deposition onto Si (100) Substrates. Phys. Status Solidi Appl. Mater. Sci. 2012, 209, 2463–2469. [Google Scholar] [CrossRef]

- Masłyk, M.; Borysiewicz, M.A.; Wzorek, M.; Wojciechowski, T.; Kwoka, M.; Kamińska, E. Influence of Absolute Argon and Oxygen Flow Values at a Constant Ratio on the Growth of Zn/ZnO Nanostructures Obtained by DC Reactive Magnetron Sputtering. Appl. Surf. Sci. 2016, 389, 287–293. [Google Scholar] [CrossRef]

- Borysiewicz, M.A.; Barańczyk, P.; Wójcicka, A.; Zawadzki, J.; Wzorek, M.; Zybała, R. Mg Nanostructures with Controlled Dominant C-Plane or m-Plane Facets by DC Magnetron Sputter Depositio. arXiv 2024, arXiv:2402.03298. [Google Scholar] [CrossRef]

- Straumanis, M.E.; Yu, L.S. Lattice Parameters, Densities, Expansion Coefficients and Perfection of Structure of Cu and of Cu–In α Phase. Acta Crystallogr. Sect. A 1969, 25, 676–682. [Google Scholar] [CrossRef]

- Diao, F.; Xiao, X.; Luo, B.; Sun, H.; Ding, F.; Ci, L.; Si, P. Two-Step Fabrication of Nanoporous Copper Films with Tunable Morphology for SERS Application. Appl. Surf. Sci. 2018, 427, 1271–1279. [Google Scholar] [CrossRef]

- Yu, B.; Wang, Y.; Zhang, Y.; Zhang, Z. Self-Supporting Nanoporous Copper Film with High Porosity and Broadband Light Absorption for Efficient Solar Steam Generation. Nano-Micro Lett. 2023, 15, 94. [Google Scholar] [CrossRef]

- Hoang, T.T.H.; Ma, S.; Gold, J.I.; Kenis, P.J.A.; Gewirth, A.A. Nanoporous Copper Films by Additive-Controlled Electrodeposition: CO2 Reduction Catalysis. ACS Catal. 2017, 7, 3313–3321. [Google Scholar] [CrossRef]

- Bastos, C.A.P.; Faria, N.; Wills, J.; Malmberg, P.; Scheers, N.; Rees, P.; Powell, J.J. Copper Nanoparticles Have Negligible Direct Antibacterial Impact. NanoImpact 2020, 17, 100192. [Google Scholar] [CrossRef]

- Wu, L.; Ashworth, M.A.; Wilcox, G.D. Zinc Whisker Growth from Electroplated Finishes—A Review. Trans. Inst. Met. Finish. 2015, 93, 1–8. [Google Scholar] [CrossRef]

- Clapeyron, É. Mémoire Sur La Puissance Motrice de La Chaleur. J. l’ Ec. Polytech. 1834, 14, 153–190. [Google Scholar]

- Schmid, M. Vapor Pressure Calculator. Available online: https://www2.iap.tuwien.ac.at/www/surface/vapor_pressure (accessed on 31 October 2024).

- Wulfhekel, W.; Lipkin, N.N.; Kliewer, J.; Rosenfeld, G.; Jorritsma, L.C.; Poelsema, B.; Comsa, G. Conventional and Manipulated Growth of Cu/Cu(111). Surf. Sci. 1996, 348, 227–242. [Google Scholar] [CrossRef][Green Version]

- Narula, M.L.; Tare, V.B.; Worrell, W.L. Diffusivity and Solubility of Oxygen in Solid Copper Using Potentiostatic and Potentiometric Techniques. Metall. Trans. B 1983, 14, 673–677. [Google Scholar] [CrossRef]

- Mahieu, S.; Ghekiere, P.; Depla, D.; De Gryse, R. Biaxial Alignment in Sputter Deposited Thin Films. Thin Solid Films 2006, 515, 1229–1249. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).