The Effect of Microstructural Defects on High-Cycle Fatigue of Ti Grade 2 Manufactured by PBF-LB and Hydrostatic Extrusion

Abstract

:1. Introduction

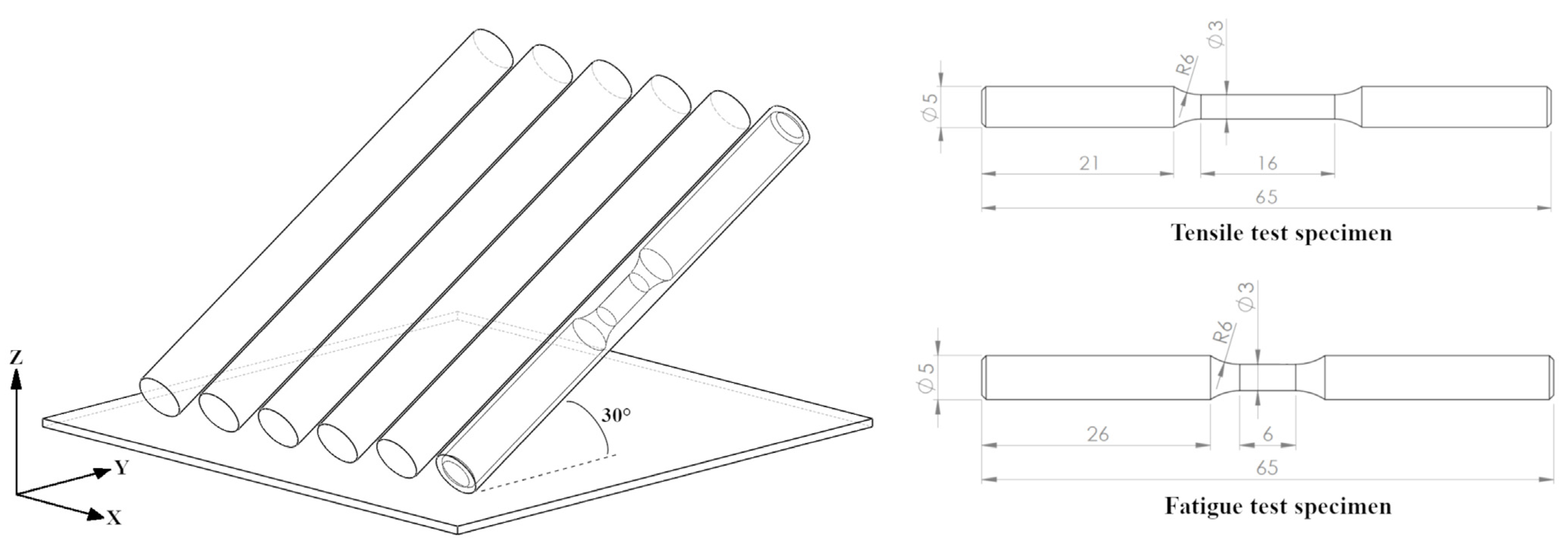

2. Materials and Methods

3. Results and Discussion

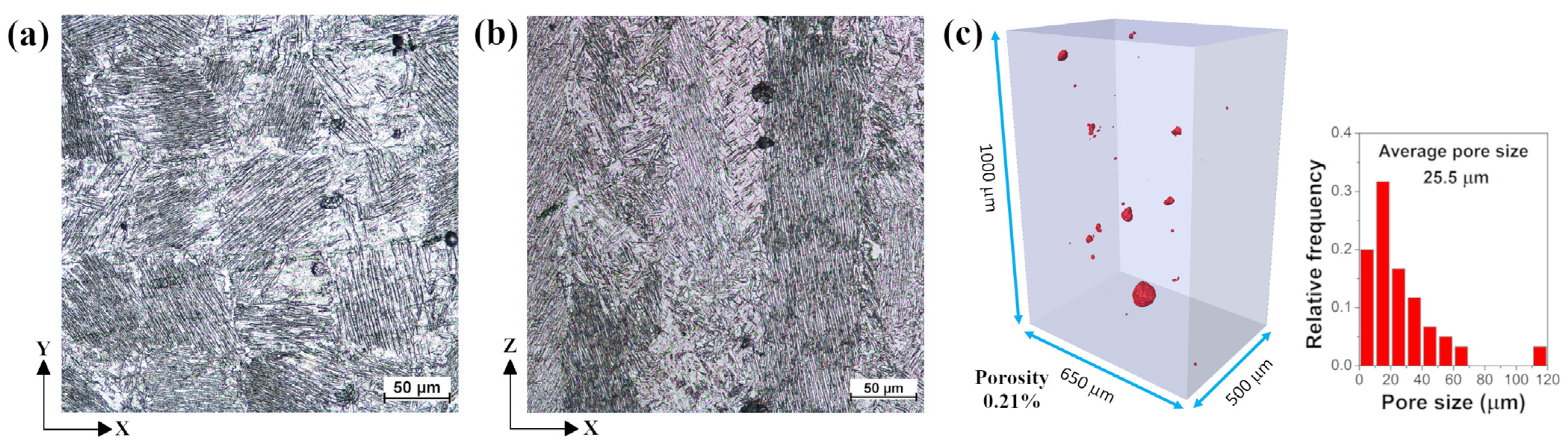

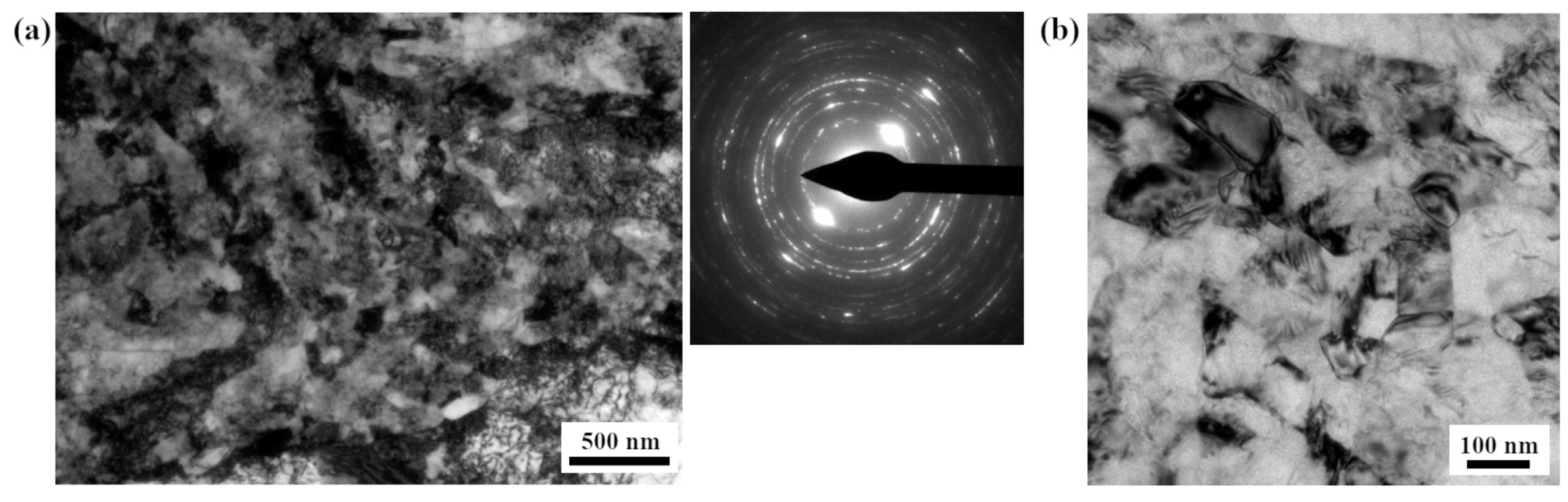

3.1. Microstructure and Tensile Properties of PBF-LB and UFG Ti Grade 2

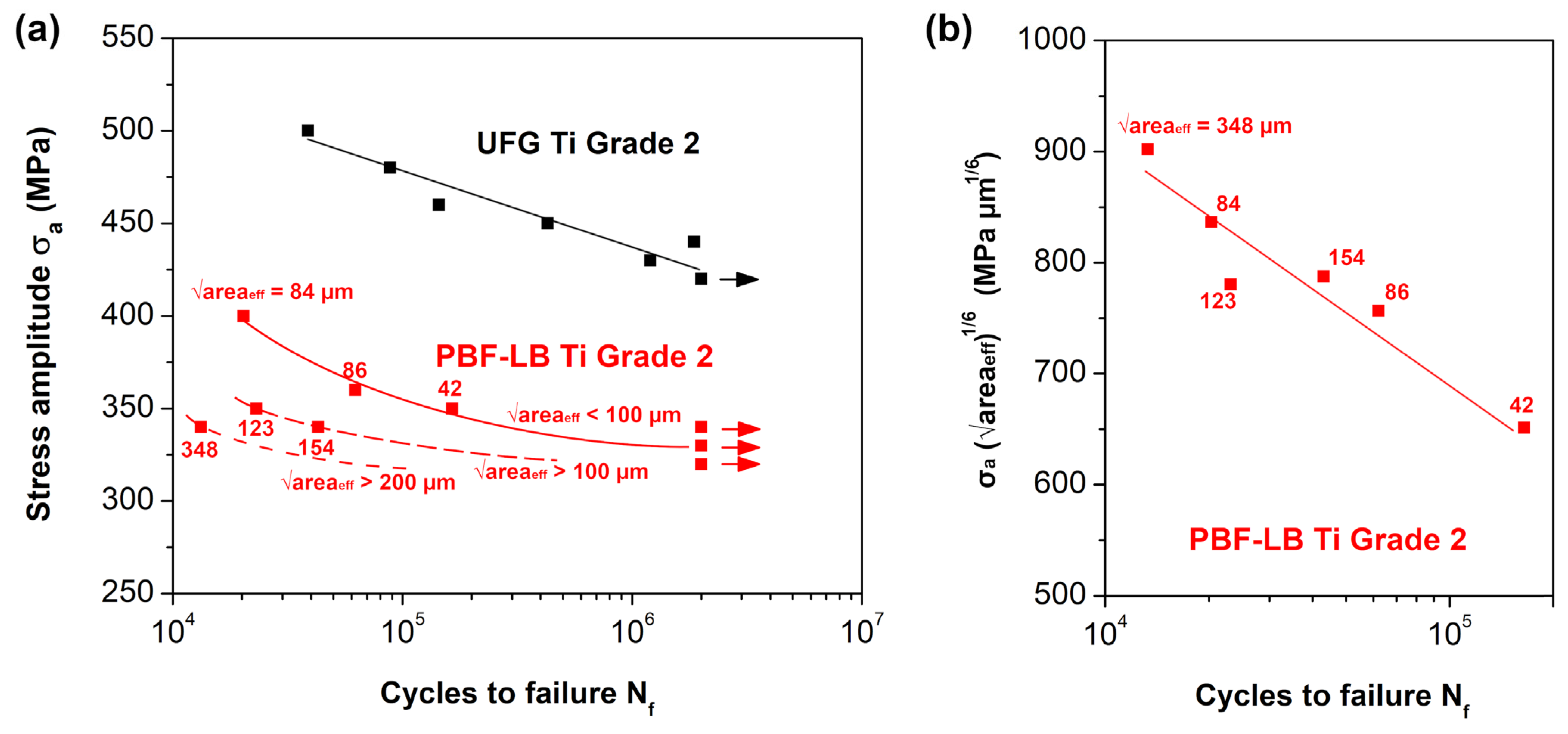

3.2. High-Cycle Fatigue Life and Crack Initiation Sites for the PBF-LB and UFG Ti Grade 2

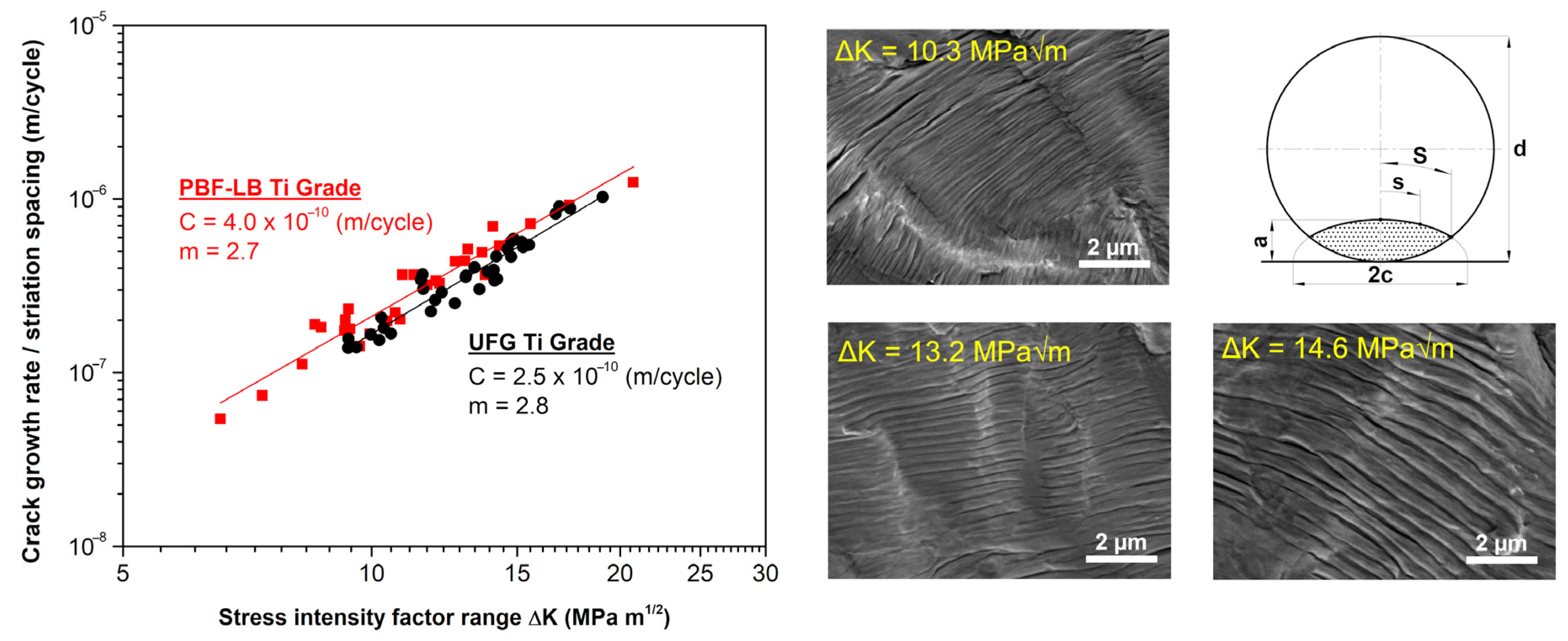

3.3. Fatigue Crack Growth Rate of PBF-LB and UFG Ti Grade 2

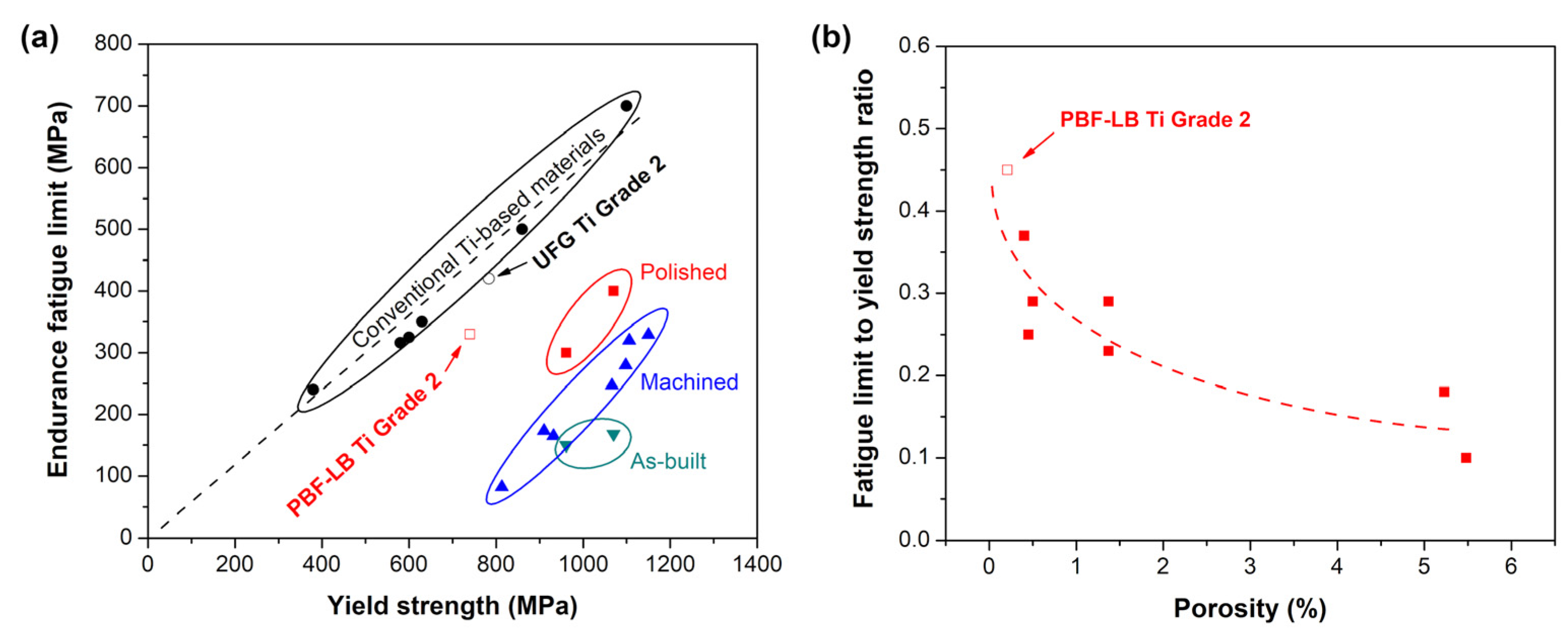

3.4. Effect of Manufacturing Defects on High-Cycle Fatigue of PBF-LB and UFG Ti Grade 2

4. Conclusions

- PBF-LB Ti Grade 2 consisted of typical columnar prior β grains with an acicular martensite α’ microstructure, while UFG Ti Grade 2 was mainly composed of fine, equiaxed α phase grains/subgrains with a size of 50–150 nm. What is important here is that a residual porosity of 0.21% was observed in the PBF-LB Ti Grade 2 by X-ray computed tomography.

- Despite having a similar yield strength, a significantly higher endurance fatigue limit was noticed for UFG Ti Grade 2 (420 MPa) compared to PBF-LB Ti Grade 2 (330 MPa). This resulted from the presence of manufacturing defects, such as pores and a lack of fusion zones. Fatigue cracks were initiated mainly at the lack of fusion zones, with the effective defect size √areaeff ranging from about 80 to 350 µm. When the √areaeff parameter increased, the high-cycle fatigue lifetime was reduced to a greater extent.

- Fatigue striation analysis showed that the fatigue crack propagation rate was not affected by manufacturing technology. The estimated values of Paris law constants were as follows: C = 4.0 × 10−10 m/cycle and m = 2.7 for PBF-LB and C = 2.5 × 10−10 m/cycle and m = 2.8 for UFG Ti Grade 2, which indicated their similar fatigue crack growth resistance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Levy, G.N.; Schindel, R.; Kruth, J.P. Rapid Manufacturing and Rapid Tooling with Layer Manufacturing (LM) Technologies, State of the Art and Future Perspectives. CIRP Ann. Manuf. Technol. 2003, 52, 589–609. [Google Scholar] [CrossRef]

- Kruth, J.-P.; Levy, G.; Klocke, F.; Childs, T.H.C. Consolidation phenomena in laser and powder-bed based layered manufacturing. CIRP Ann. Manuf. Technol. 2007, 56, 730–759. [Google Scholar] [CrossRef]

- Zhang, L.-C.; Attar, H. Selective Laser Melting of Titanium Alloys and Titanium Matrix Composites for Biomedical Applications: A Review. Adv. Eng. Mater. 2016, 18, 463–475. [Google Scholar] [CrossRef]

- Shipley, H.; McDonnell, D.; Culleton, M.; Coull, R.; Lupoi, R.; Donnell, G.O.; Trimble, D. Optimisation of process parameters to address fundamental challenges during selective laser melting of Ti-6Al-4V: A review. Int. J. Mach. Tools Manuf. 2018, 128, 1–20. [Google Scholar] [CrossRef]

- Gu, D.; Hagedorn, Y.-C.; Meiners, W.; Meng, G.; Santos Batista, R.J.; Wissenbach, K.; Poprawe, R. Densification behavior, microstructure evolution, and wear performance of selective laser melting processed commercially pure titanium. Acta Mater. 2012, 60, 3849–3860. [Google Scholar] [CrossRef]

- Attar, H.; Calin, M.; Zhang, L.C.; Scudino, S.; Eckert, J. Manufacture by selective laser melting and mechanical behavior of commercially pure titanium. Mater. Sci. Eng. A 2014, 593, 170–177. [Google Scholar] [CrossRef]

- Majchrowicz, K.; Pakieła, Z.; Moszczyńska, D.; Kurzynowski, T.; Chlebus, E. Hot Corrosion of Ti–Re Alloys Fabricated by Selective Laser Melting. Oxid. Met. 2017, 90, 83–96. [Google Scholar] [CrossRef] [Green Version]

- Wysocki, B.; Maj, P.; Krawczyńska, A.; Rożniatowski, K.; Zdunek, J.; Kurzydłowski, K.J.; Święszkowski, W. Microstructure and mechanical properties investigation of CP titanium processed by selective laser melting (SLM). J. Mater. Process. Technol. 2017, 241, 13–23. [Google Scholar] [CrossRef]

- Singh, D.D.; Mahender, T.; Reddy, A.R. Powder bed fusion process: A brief review. Mater. Today Proc. 2021, 46, 350–355. [Google Scholar] [CrossRef]

- Kaur, M.; Singh, K. Review on titanium and titanium based alloys as biomaterials for orthopaedic applications. Mater. Sci. Eng. C 2019, 102, 844–862. [Google Scholar] [CrossRef] [PubMed]

- Agius, D.; Kourousis, K.I.; Wallbrink, C. A Review of the As-Built SLM Ti-6Al-4V Mechanical Properties towards Achieving Fatigue Resistant Designs. Metals 2018, 8, 75. [Google Scholar] [CrossRef] [Green Version]

- Fotovvati, B.; Namdari, N.; Dehghanghadikolaei, A. Fatigue performance of selective laser melted Ti6Al4V components: State of the art. Mater. Res. Express 2019, 6, 012002. [Google Scholar] [CrossRef]

- Leuders, S.; Meiners, S.; Wu, L.; Taube, A.; Tröster, T.; Niendorf, T. Structural components manufactured by Selective Laser Melting and Investment Casting—Impact of the process route on the damage mechanism under cyclic loading. J. Mater. Process. Technol. 2017, 248, 130–142. [Google Scholar] [CrossRef]

- Rans, C.; Michielssen, J.; Walker, M.; Wang, W.; Hoen-Velterop, L. Beyond the orthogonal: On the influence of build orientation on fatigue crack growth in SLM Ti-6Al-4V. Int. J. Fatigue 2018, 116, 344–354. [Google Scholar] [CrossRef]

- Leuders, S.; Thöne, M.; Riemer, A.; Niendorf, T.; Tröster, T.; Richard, H.A.; Maier, H.J. On the mechanical behaviour of titanium alloy TiAl6V4 manufactured by selective laser melting: Fatigue resistance and crack growth performance. Int. J. Fatigue 2013, 48, 300–307. [Google Scholar] [CrossRef]

- Ali, H.; Ma, L.; Ghadbeigi, H.; Mumtaz, K. In-situ residual stress reduction, martensitic decomposition and mechanical properties enhancement through high temperature powder bed pre-heating of Selective Laser Melted Ti6Al4V. Mater. Sci. Eng. A 2017, 695, 211–220. [Google Scholar] [CrossRef]

- Syed, A.K.; Ahmad, B.; Guo, H.; Machry, T.; Eatock, D.; Meyer, J.; Fitzpatrick, M.E.; Zhang, X. An experimental study of residual stress and direction-dependence of fatigue crack growth behaviour in as-built and stress-relieved selective-laser-melted Ti6Al4V. Mater. Sci. Eng. A 2019, 755, 246–257. [Google Scholar] [CrossRef]

- Vayssette, B.; Saintier, N.; Brugger, C.; El May, M.; Pessard, E. Numerical modelling of surface roughness effect on the fatigue behavior of Ti-6Al-4V obtained by additive manufacturing. Int. J. Fatigue 2019, 123, 180–195. [Google Scholar] [CrossRef] [Green Version]

- Wycisk, E.; Solbach, A.; Siddique, S.; Herzog, D.; Walther, F.; Emmelmann, C. Effects of defects in laser additive manufactured Ti-6Al-4V on fatigue properties. Phys. Procedia 2014, 56, 371–378. [Google Scholar] [CrossRef] [Green Version]

- Rafi, H.K.; Starr, T.L.; Stucker, B.E. A comparison of the tensile, fatigue, and fracture behavior of Ti-6Al-4V and 15-5 PH stainless steel parts made by selective laser melting. Int. J. Adv. Manuf. Technol. 2013, 69, 1299–1309. [Google Scholar] [CrossRef]

- Liu, Q.C.; Elambasseril, J.; Sun, S.J.; Leary, M.; Brandt, M.; Sharp, P.K. The effect of manufacturing defects on the fatigue behaviour of Ti-6Al-4V specimens fabricated using selective laser melting. Adv. Mater. Res. 2014, 891–892, 1519–1524. [Google Scholar] [CrossRef]

- Walker, K.F.; Liu, Q.; Brandt, M. Evaluation of fatigue crack propagation behaviour in Ti-6Al-4V manufactured by selective laser melting. Int. J. Fatigue 2017, 104, 302–308. [Google Scholar] [CrossRef]

- Chastand, V.; Quaegebeur, P.; Maia, W.; Charkaluk, E. Comparative study of fatigue properties of Ti-6Al-4V specimens built by electron beam melting (EBM) and selective laser melting (SLM). Mater. Charact. 2018, 143, 76–81. [Google Scholar] [CrossRef]

- Estrin, Y.; Vinogradov, A. Fatigue behaviour of light alloys with ultrafine grain structure produced by severe plastic deformation: An overview. Int. J. Fatigue 2010, 32, 898–907. [Google Scholar] [CrossRef]

- Majchrowicz, K.; Pakieła, Z.; Giżyński, M.; Karny, M.; Kulczyk, M. High-cycle fatigue strength of ultrafine-grained 5483 Al-Mg alloy at low and elevated temperature in comparison to conventional coarse-grained Al alloys. Int. J. Fatigue 2018, 106, 81–91. [Google Scholar] [CrossRef]

- Elias, C.N.; Fernandes, D.J.; De Souza, F.M.; Monteiro, E.D.S.; Biasi, R.S. De Mechanical and clinical properties of titanium and titanium-based alloys (Ti G2, Ti G4 cold worked nanostructured and Ti G5) for biomedical applications. J. Mater. Res. Technol. 2019, 8, 1060–1069. [Google Scholar] [CrossRef]

- Sotniczuk, A.; Majchrowicz, K.; Kuczyńska-Zemła, D.; Pisarek, M.; Adamczyk-Cieślak, B.; Garbacz, H. Surface Properties and Mechanical Performance of Ti-Based Dental Materials: Comparative Effect of Valve Alloying Elements and Structural Defects. Metall. Mater. Trans. A 2022, 53, 225–239. [Google Scholar] [CrossRef]

- Shaqour, B.; Górecka, Ż.; Chmielewska, A.; Wysocki, B.; Heljak, M.; Gernaey, M.; Verleije, B.; Beyers, K.; Vervaet, C.; Choińska, E.; et al. Novel design for an additively manufactured nozzle to produce tubular scaffolds via fused filament fabrication. Addit. Manuf. 2022, 49, 102467. [Google Scholar] [CrossRef]

- Pisarek, M.; Ambroziak, R.; Hołdyński, M.; Roguska, A.; Majchrowicz, A.; Wysocki, B.; Kudelski, A. Nanofunctionalization of Additively Manufactured Titanium Substrates for Surface-Enhanced Raman Spectroscopy Measurements. Materials 2022, 15, 3108. [Google Scholar] [CrossRef] [PubMed]

- Chmielewska, A.; Wysocki, B.A.; Gadalińska, E.; MacDonald, E.; Adamczyk-Cieślak, B.; Dean, D.; Świeszkowski, W. Laser powder bed fusion (LPBF) of NiTi alloy using elemental powders: The influence of remelting on printability and microstructure. Rapid Prototyp. J. 2022, 28, 1845–1868. [Google Scholar] [CrossRef]

- Wysocki, B.; Idaszek, J.; Buhagiar, J.; Szlązak, K.; Brynk, T.; Kurzydłowski, K.J.; Święszkowski, W. The influence of chemical polishing of titanium scaffolds on their mechanical strength and in-vitro cell response. Mater. Sci. Eng. C 2019, 95, 428–439. [Google Scholar] [CrossRef]

- Skiba, J.; Kulczyk, M.; Przybysz-Gloc, S.; Skorupska, M.; Niczyporuk, K. The impact of severe plastic deformations obtained by hydrostatic extrusion on the machinability of ultrafine-grained Ti grade 2 intended for fasteners. Sci. Rep. 2022, 12, 16240. [Google Scholar] [CrossRef]

- Wejrzanowski, T.; Spychalski, W.L.; Różniatowski, K.; Kurzydłowski, K.J. Image Based Analysis of Complex Microstructures of Engineering Materials. Int. J. Appl. Math. Comput. Sci. 2008, 18, 33–39. [Google Scholar] [CrossRef]

- Majchrowicz, K.; Pakieła, Z.; Kamiński, J.; Płocińska, M.; Kurzynowski, T.; Chlebus, E. The Effect of Rhenium Addition on Microstructure and Corrosion Resistance of Inconel 718 Processed by Selective Laser Melting. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2018, 49, 6479–6489. [Google Scholar] [CrossRef] [Green Version]

- Wysocki, B.; Maj, P.; Sitek, R.; Buhagiar, J.; Kurzydłowski, K.J.; Świeszkowski, W. Laser and electron beam additive manufacturing methods of fabricating titanium bone implants. Appl. Sci. 2017, 7, 657. [Google Scholar] [CrossRef] [Green Version]

- Pachla, W.; Kulczyk, M.; Przybysz, S.; Skiba, J.; Wojciechowski, K.; Przybysz, M.; Topolski, K.; Sobolewski, A.; Charkiewicz, M. Effect of severe plastic deformation realized by hydrostatic extrusion and rotary swaging on the properties of CP Ti grade 2. J. Mater. Process. Technol. 2015, 221, 255–268. [Google Scholar] [CrossRef]

- Garbacz, H.; Pakieła, Z.; Kurzydłowski, K.J. Fatigue properties of nanocrystalline titanium. Rev. Adv. Mater. 2010, 25, 256–260. [Google Scholar]

- Majchrowicz, K.; Sotniczuk, A.; Adamczyk-Cieślak, B.; Chromiński, W.; Jóźwik, P.; Pakieła, Z.; Garbacz, H. The influence of microstructure and texture on the hardening by annealing effect in cold-rolled titanium. J. Alloys Compd. 2023, 948, 169791. [Google Scholar] [CrossRef]

- Ren, S.; Chen, Y.; Liu, T.; Qu, X. Effect of Build Orientation on Mechanical Properties and Microstructure of Ti-6Al-4V Manufactured by Selective Laser Melting. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2019, 50, 4388–4409. [Google Scholar] [CrossRef]

- Hasib, M.T.; Ostergaard, H.E.; Liu, Q.; Li, X.; Kruzic, J.J. Tensile and fatigue crack growth behavior of commercially pure titanium produced by laser powder bed fusion additive manufacturing. Addit. Manuf. 2021, 45, 102027. [Google Scholar] [CrossRef]

- Barbas, A.; Bonnet, A.S.; Lipinski, P.; Pesci, R.; Dubois, G. Development and mechanical characterization of porous titanium bone substitutes. J. Mech. Behav. Biomed. Mater. 2012, 9, 34–44. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Majchrowicz, K.; Pakieła, Z.; Brynk, T.; Romelczyk-Baishya, B.; Płocińska, M.; Kurzynowski, T.; Chlebus, E. Microstructure and mechanical properties of Ti-Re alloys manufactured by selective laser melting. Mater. Sci. Eng. A 2019, 765, 138290. [Google Scholar] [CrossRef]

- Mughrabi, H. Fatigue, an everlasting materials problem—Still en vogue. Procedia Eng. 2010, 2, 3–26. [Google Scholar] [CrossRef] [Green Version]

- Hu, Y.N.; Wu, S.C.; Withers, P.J.; Zhang, J.; Bao, H.Y.X.; Fu, Y.N.; Kang, G.Z. The effect of manufacturing defects on the fatigue life of selective laser melted Ti-6Al-4V structures. Mater. Des. 2020, 192, 108708. [Google Scholar] [CrossRef]

- Masuo, H.; Tanaka, Y.; Morokoshi, S.; Yagura, H.; Uchida, T.; Yamamoto, Y.; Murakami, Y. Influence of defects, surface roughness and HIP on the fatigue strength of Ti-6Al-4V manufactured by additive manufacturing. Int. J. Fatigue 2018, 117, 163–179. [Google Scholar] [CrossRef]

- Murakami, Y. Metal Fatigue: Effects of Small Defects and Nonmetallic Inclusions; Elsevier: Oxford, UK, 2002. [Google Scholar]

- Matsunaga, H.; Murakami, Y.; Kubota, M.; Lee, J.-H. Fatigue Strength of Ti-6Al-4V Alloys Containing Small Artificial Defects. Mater. Sci. Res. Int. 2003, 9, 263–269. [Google Scholar] [CrossRef]

- Shojima, K.; Weldle, S.; Okazaki, S.; Endo, M.; Eifler, D.; Balle, F. Nothc Effects in High Cycle Fatigue of Ti-6Al-4V. Mater. Sci. Forum 2013, 750, 232–235. [Google Scholar] [CrossRef]

- Guo, W.; Shen, H.; Li, H. Stress intensity factors for elliptical surface cracks in round bars with different stress concentration coefficient. Int. J. Fatigue 2003, 25, 733–741. [Google Scholar] [CrossRef]

- Cavaliere, P. Fatigue properties and crack behavior of ultra-fine and nanocrystalline pure metals. Int. J. Fatigue 2009, 31, 1476–1489. [Google Scholar] [CrossRef]

- Hanlon, T.; Tabachnikova, E.D.; Suresh, S. Fatigue behavior of nanocrystalline metals and alloys. Int. J. Fatigue 2005, 27, 1147–1158. [Google Scholar] [CrossRef]

- Xu, Z.W.; Liu, A.; Wang, X.S. The influence of building direction on the fatigue crack propagation behavior of Ti6Al4V alloy produced by selective laser melting. Mater. Sci. Eng. A 2019, 767, 138409. [Google Scholar] [CrossRef]

- Tao, J.; Hu, S.; Ji, L. Effect of micromorphology at the fatigue crack tip on the crack growth in electron beam welded Ti-6Al-4V joint. Mater. Charact. 2016, 120, 185–194. [Google Scholar] [CrossRef]

- Xu, W.; Sun, S.; Elambasseril, J.; Liu, Q.; Brandt, M.; Qian, M. Ti-6Al-4V Additively Manufactured by Selective Laser Melting with Superior Mechanical Properties. JOM 2015, 67, 668–673. [Google Scholar] [CrossRef]

- Dowling, N.E.; Calhoun, C.A.; Arcari, A. Mean stress effects in stress-life fatigue and the Walker equation. Fatigue Fract. Eng. Mater. Struct. 2009, 32, 163–179. [Google Scholar] [CrossRef]

- Kim, W.J.; Hyun, C.Y.; Kim, H.K. Fatigue strength of ultrafine-grained pure Ti after severe plastic deformation. Scr. Mater. 2006, 54, 1745–1750. [Google Scholar] [CrossRef]

- Gong, H.; Rafi, K.; Gu, H.; Janaki Ram, G.D.; Starr, T.; Stucker, B. Influence of defects on mechanical properties of Ti-6Al-4V components produced by selective laser melting and electron beam melting. Mater. Des. 2015, 86, 545–554. [Google Scholar] [CrossRef]

- Edwards, P.; Ramulu, M. Fatigue performance evaluation of selective laser melted Ti-6Al-4V. Mater. Sci. Eng. A 2014, 598, 327–337. [Google Scholar] [CrossRef]

| Material /Processing Method | Building Angle (°) | YS (MPa) | UTS (MPa) | A (%) | Reference |

|---|---|---|---|---|---|

| PBF-LB Ti Grade 2 | 30 | 740 ± 7 | 866 ± 6 | 29.9 ± 2.2 | This work |

| UFG Ti Grade 2 | - | 783 ± 8 | 888 ± 7 | 11.5 ± 0.8 | This work |

| Extrusion | - | 440 | 550 | 24 | [36] |

| Cold rolling | - | 380 | 460 | 26 | [24] |

| Cold rolling (ε = 2.3) | - | 600 | 798 | 16 | [38] |

| AM | 0 | 521 | 607 | 10.4 | [40] |

| 0 | 518 | 640 | 14.7 | [41] | |

| 0 | 669 | 732 | 14.5 | [42] | |

| 90 | 522 | 654 | 17.0 | [41] | |

| 90 | 555 | 757 | 19.5 | [6] | |

| 90 | 630 | 720 | 8.3 | [40] | |

| 90 | 659 | 719 | 13.5 | [42] |

| Material (Processing Method) | Building Angle (°) | C (m/Cycle) | m | Reference |

|---|---|---|---|---|

| PBF-LB Ti Grade 2 | 30 | 4.0 × 10−10 | 2.7 | This work |

| UFG Ti Grade 2 | - | 2.5 × 10−10 | 2.8 | This work |

| Ti Grade 2 (cold rolling) | - | 1.8 × 10−12 | 4.3 | [40] |

| - | 5.8 × 10−12 | 3.7 | [50] | |

| - | 7.9 × 10−12 | 3.9 | [40] | |

| Ti Grade 2 (ECAP) | - | 1.8 × 10−10 | 2.4 | [50] |

| Ti Grade 2 (AM) | 0 | 6.3 × 10−12 | 3.8 | [40] |

| 90 | 3.0 × 10−12 | 4.2 | [40] | |

| Ti-6Al-4V (AM) | 0 | 6.7 × 10−10 | 1.9 | [14] |

| 30 | 2.7 × 10−9 | 1.5 | [14] | |

| 45 | 3.2 × 10−9 | 1.5 | [14] | |

| 60 | 2.3 × 10−9 | 1.6 | [14] | |

| 90 | 9.7 × 10−10 | 1.8 | [14] | |

| 0 | 6.5 × 10−10 | 3.8 | [52] | |

| 45 | 5.0 × 10−9 | 3.2 | [52] | |

| 90 | 1.2 × 10−9 | 3.5 | [52] |

| Material (Processing Method) | YS (MPa) | Endurance Fatigue Limit (MPa) | Surface Finish | Porosity (%) | Reference |

|---|---|---|---|---|---|

| Ti Grade 2 (cold rolling) | 380 | 240 | - | - | [24] |

| Ti Grade 2 (ECAP) | 600 | 325 | - | - | [24] |

| Ti Grade 2 (ECAP) | 630 | 350 | - | - | [56] |

| Ti Grade 4 (ECAP) | 580 | 316 | - | - | [24] |

| Ti Grade 4 (ECAP + forging) | 860 | 500 | - | - | [24] |

| Ti-6Al-4V (solution treatment + ageing) | 1100 | 700 | - | - | [24] |

| Ti-6Al-4V (AM) | 813 | 82 | Machined | 5.48 | [57] |

| 910 | 173 | Machined | - | [58] | |

| 932 | 165 | Machined | 5.23 | [57] | |

| 961 | 150 | As-built | - | [23] | |

| 961 | 300 | Polished | - | [23] | |

| 1066 | 247 | Machined | 1.37 | [57] | |

| 1070 | 168 | As-built | 0.4 | [19] | |

| 1070 | 400 | Polished | 0.4 | [19] | |

| 1098 | 280 | Machined | 0.45 | [57] | |

| 1106 | 320 | Machined | 0.5 | [54] | |

| 1150 | 329 | Machined | 1.37 | [57] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Majchrowicz, K.; Chmielewska, A.; Wysocki, B.; Przybysz-Gloc, S.; Kulczyk, M.; Garbacz, H.; Pakieła, Z. The Effect of Microstructural Defects on High-Cycle Fatigue of Ti Grade 2 Manufactured by PBF-LB and Hydrostatic Extrusion. Crystals 2023, 13, 1250. https://doi.org/10.3390/cryst13081250

Majchrowicz K, Chmielewska A, Wysocki B, Przybysz-Gloc S, Kulczyk M, Garbacz H, Pakieła Z. The Effect of Microstructural Defects on High-Cycle Fatigue of Ti Grade 2 Manufactured by PBF-LB and Hydrostatic Extrusion. Crystals. 2023; 13(8):1250. https://doi.org/10.3390/cryst13081250

Chicago/Turabian StyleMajchrowicz, Kamil, Agnieszka Chmielewska, Bartłomiej Wysocki, Sylwia Przybysz-Gloc, Mariusz Kulczyk, Halina Garbacz, and Zbigniew Pakieła. 2023. "The Effect of Microstructural Defects on High-Cycle Fatigue of Ti Grade 2 Manufactured by PBF-LB and Hydrostatic Extrusion" Crystals 13, no. 8: 1250. https://doi.org/10.3390/cryst13081250

APA StyleMajchrowicz, K., Chmielewska, A., Wysocki, B., Przybysz-Gloc, S., Kulczyk, M., Garbacz, H., & Pakieła, Z. (2023). The Effect of Microstructural Defects on High-Cycle Fatigue of Ti Grade 2 Manufactured by PBF-LB and Hydrostatic Extrusion. Crystals, 13(8), 1250. https://doi.org/10.3390/cryst13081250