Study of Gas Swelling Processes under Irradiation with Protons and He2+ Ions in Li4SiO4–Li2TiO3 Ceramics

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

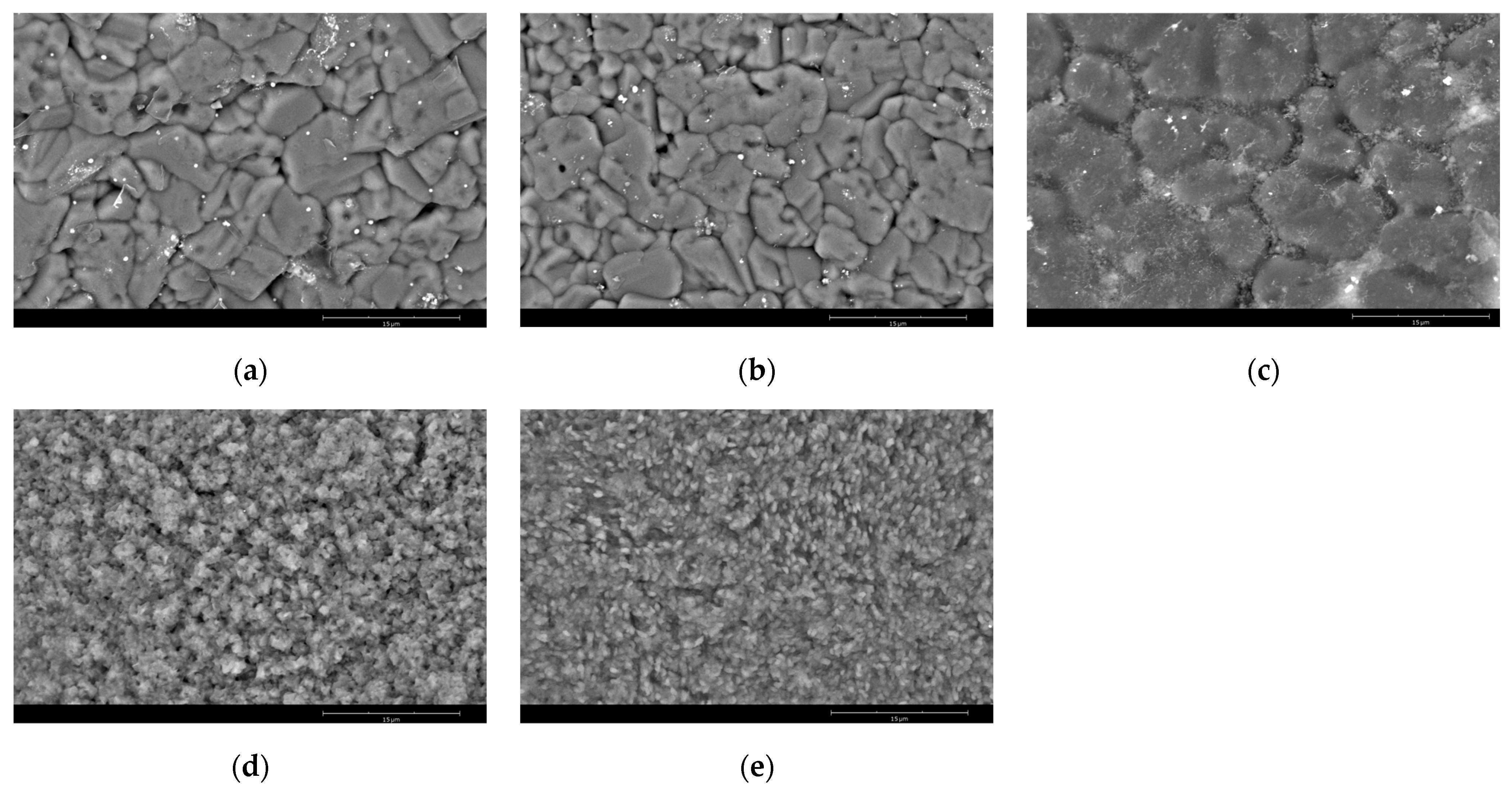

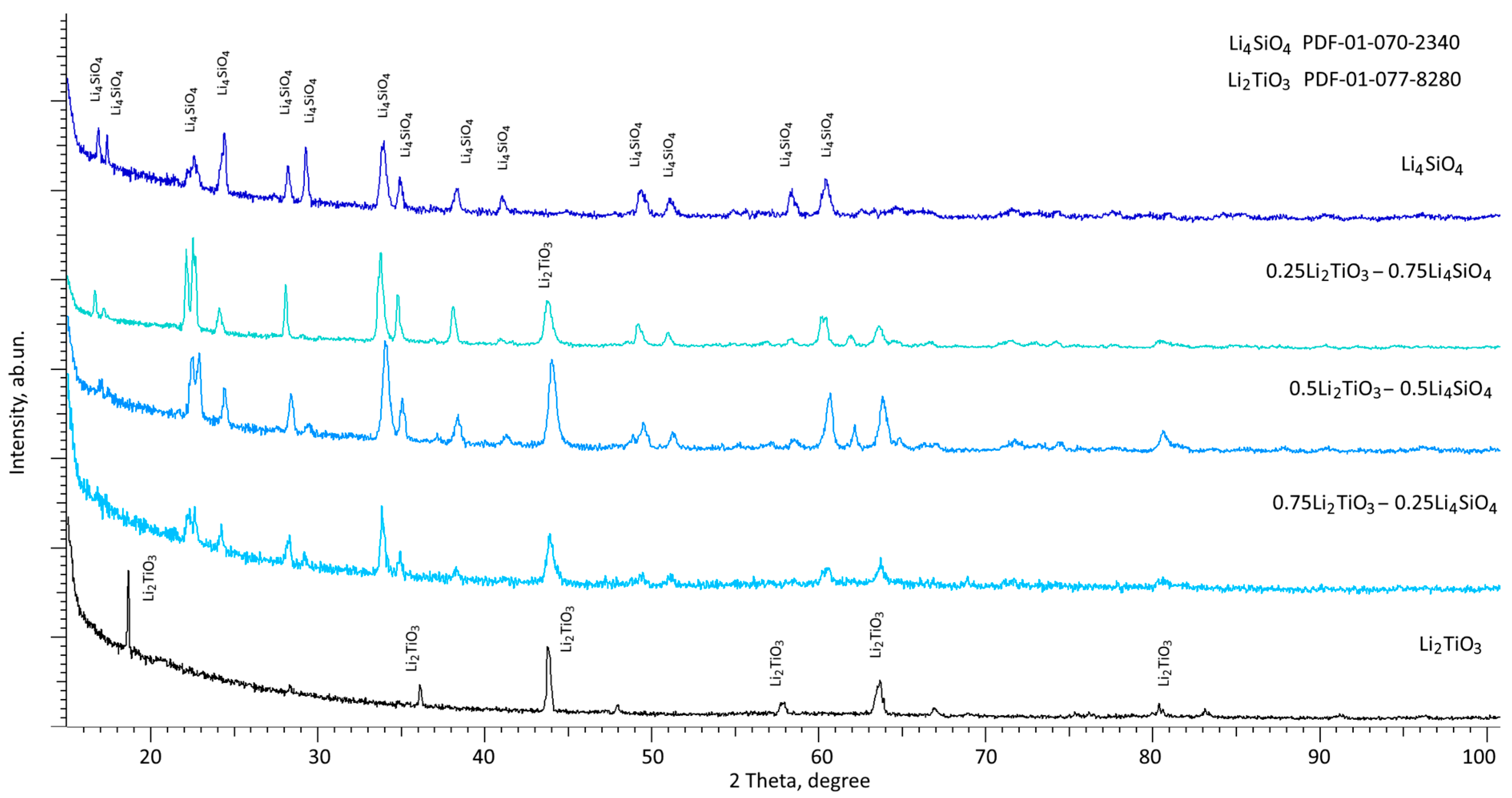

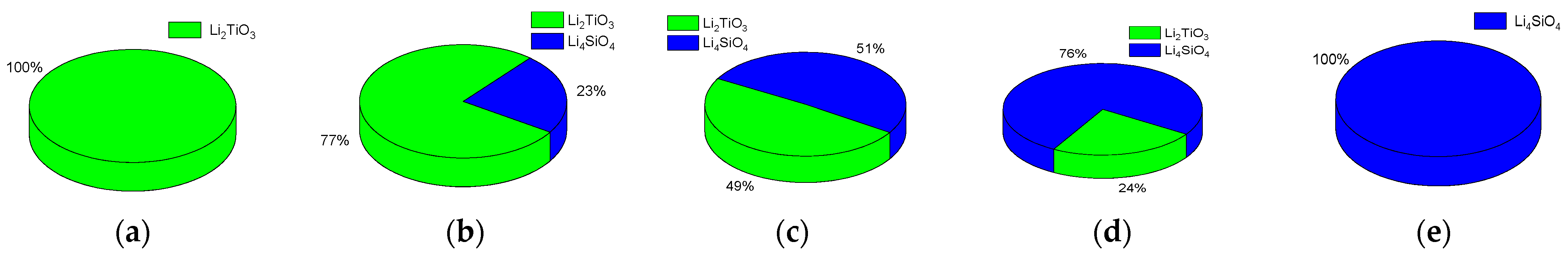

3.1. Characterization of Initial Samples Obtained Using Mechanical-Chemical Mixing and Subsequent Thermal Annealing

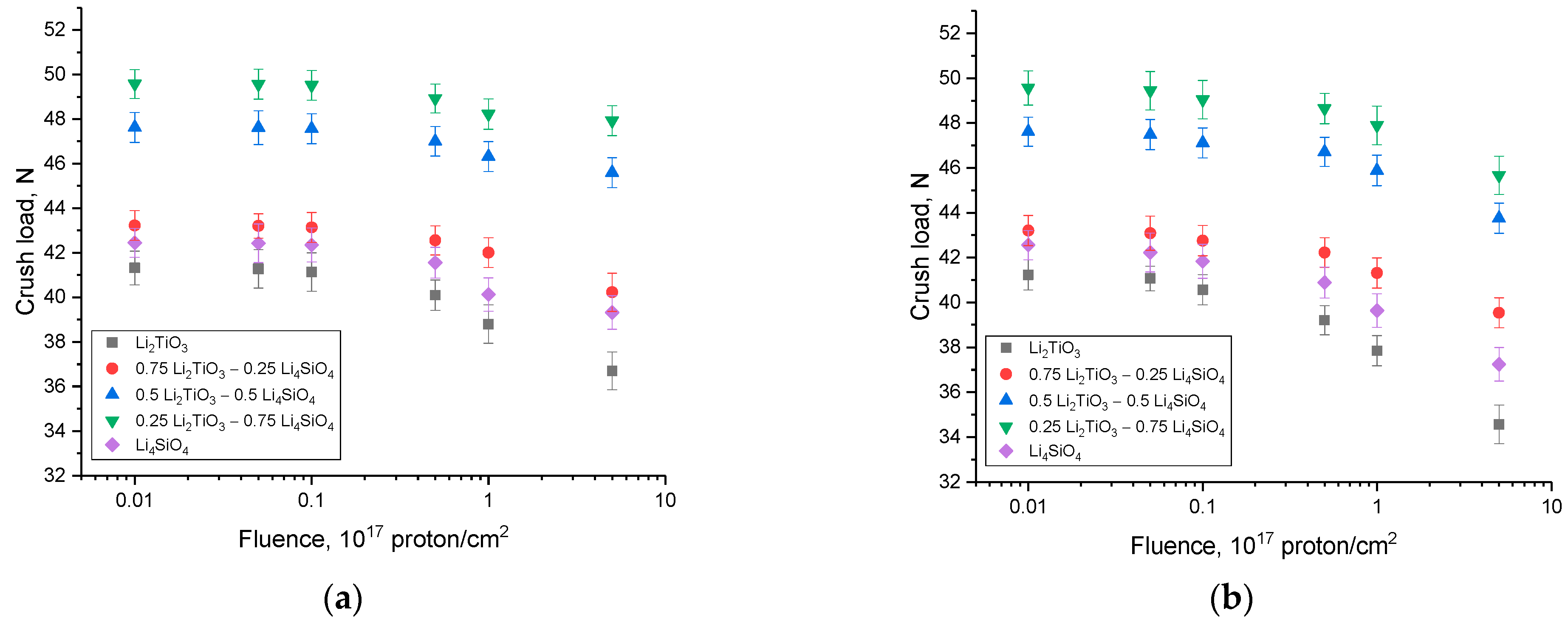

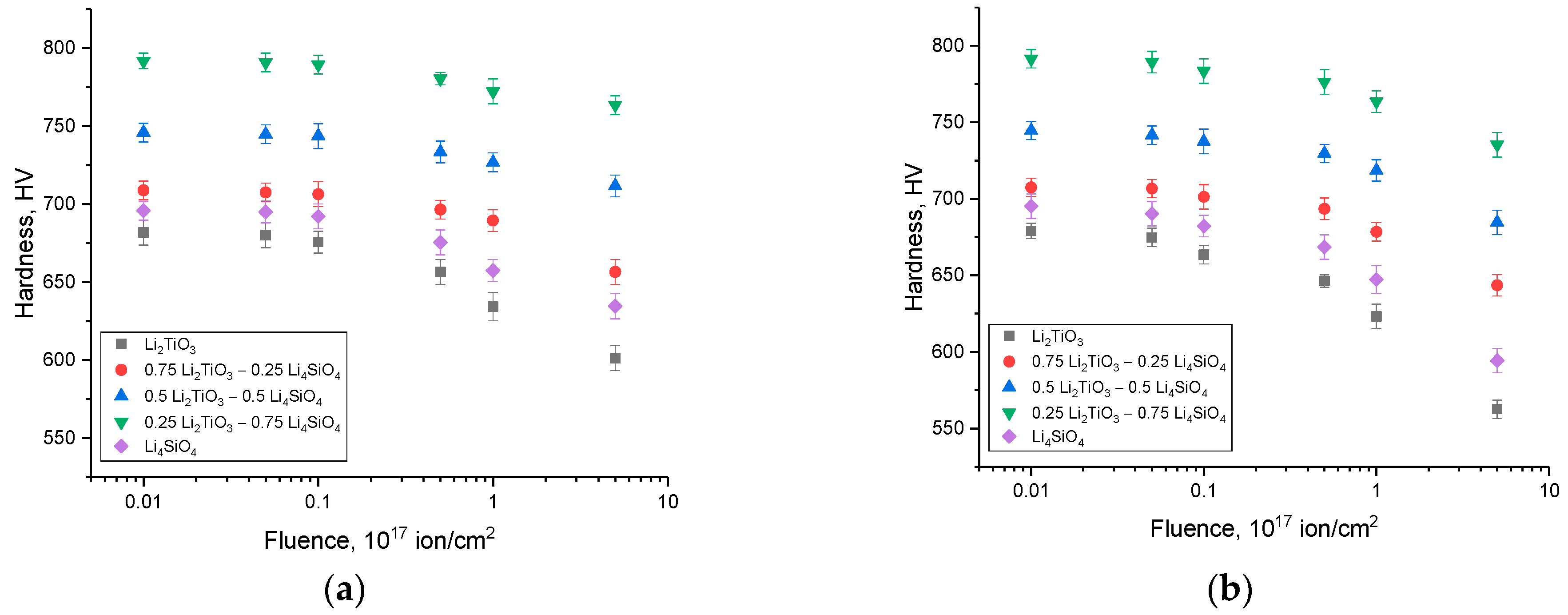

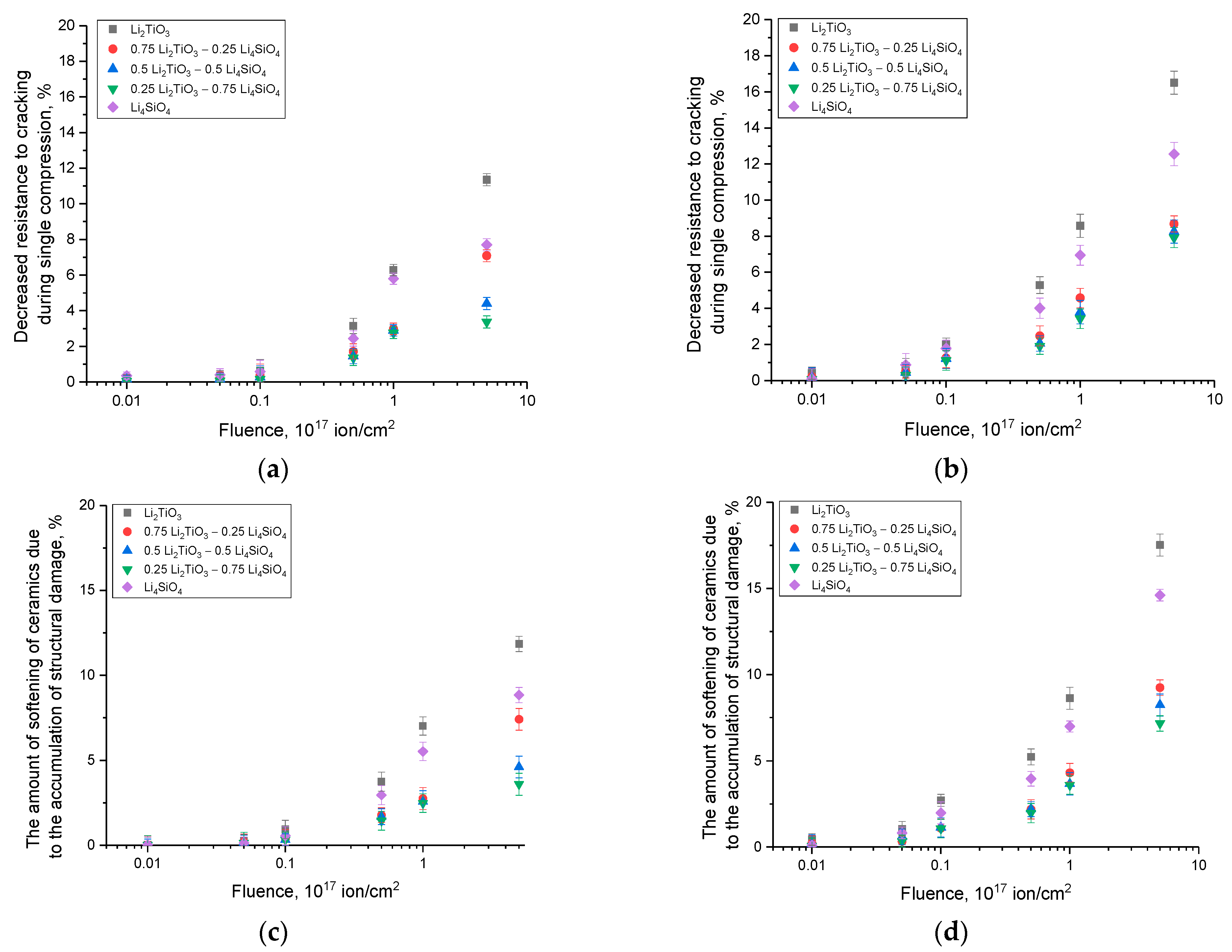

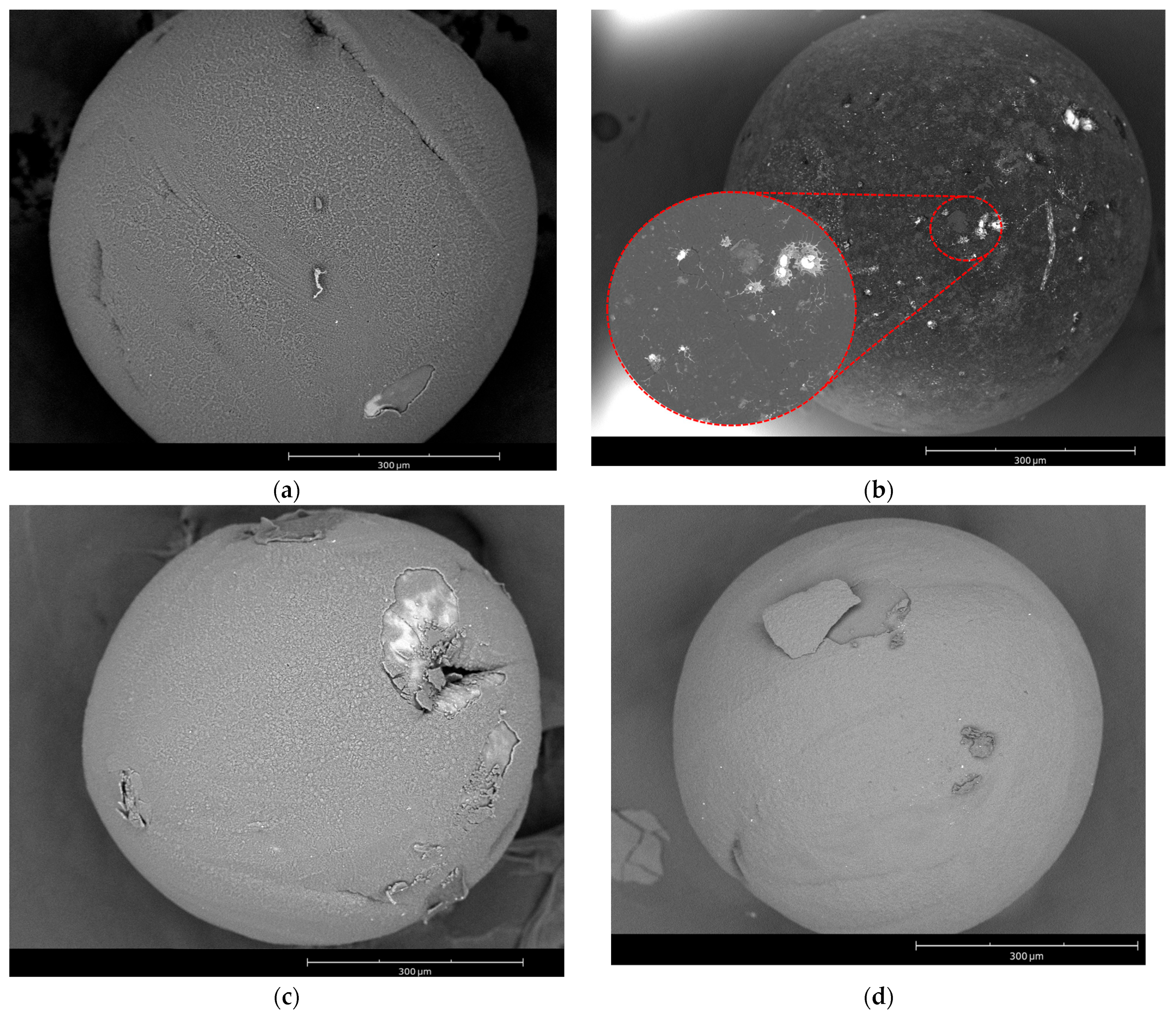

3.2. Study of the Influence of Hardening Factors at Variation of Composition of xLi4SiO4–(1−x)Li2TiO3 Ceramics on Radiation-Induced Swelling at Helium and Hydrogen Accumulation in the Near-Surface Layer

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tan, G.; Hu, X.; Cai, L.; Xue, H.; Oya, Y.; Zhang, Y. Study on the chemical compatibility between Li2TiO3 ceramic pebbles and diverse advanced structural materials. Int. J. Appl. Ceram. Technol. 2023, 20, 2562–2575. [Google Scholar] [CrossRef]

- Rao, G.J.; Mazumder, R.; Bhattacharyya, S.; Chaudhuri, P. Fabrication and characterization of Li4SiO4-Li2TiO3 composite ceramic pebbles using extrusion and spherodization technique. J. Eur. Ceram. Soc. 2018, 38, 5174–5183. [Google Scholar]

- Tan, G.; Hu, X.; Cai, L.; Xue, H.; Yang, X.; Zhang, Y. Mass fabrication of Li2TiO3–Li4SiO4 ceramic pebbles with high strength by facile centrifugal granulation method. J. Am. Ceram. Soc. 2023, 106, 4304–4320. [Google Scholar] [CrossRef]

- Chikada, T.; Kolb, M.H.; Fujita, H.; Nakamura, K.; Kimura, K.; Rasinski, M.; Knitter, R. Compatibility of tritium permeation barrier coatings with ceramic breeder pebbles. Corros. Sci. 2021, 182, 109288. [Google Scholar] [CrossRef]

- Gaisina, E.; Gaisin, R.; Leys, J.; Knitter, R.; Aktaa, J.; Walter, M. Comparative analysis of low cycle fatigue behavior of pre-corroded standard and sub-sized EUROFER97 specimens exposed to ceramic breeder environment. Nucl. Mater. Energy 2023, 36, 101497. [Google Scholar] [CrossRef]

- Guo, H.; Wang, H.; Chen, R.; Huang, Z.; Gong, Y.; Zeng, Y.; Lu, T. Low-cost fabrication of Li2TiO3 tritium breeding ceramic pebbles via low-temperature solid-state precursor method. Ceram. Int. 2019, 45, 17114–17119. [Google Scholar] [CrossRef]

- Chen, R.; Katayama, K.; Ipponsugi, A.; Guo, H.; Lu, T.; Feng, W. Effects of water adsorption on tritium release behavior of Li4TiO4 and Li4TiO4-Li2TiO3 core-shell structure breeding ceramics. Fusion Eng. Des. 2023, 187, 113374. [Google Scholar] [CrossRef]

- Gong, Y.; Liu, L.; Qi, J.; Yang, M.; Li, J.; Wang, H.; Lu, T. A comprehensive study on Li4Si1−xTixO4 ceramics for advanced tritium breeders. J. Adv. Ceram. 2020, 9, 629–640. [Google Scholar] [CrossRef]

- Yamamoto, R.; Katayama, K.; Hoshino, T.; Takeishi, T.; Fukada, S. Li mass loss from Li2TiO3 with excess Li pebbles fabricated by optimized sintering condition. Fusion Eng. Des. 2017, 124, 787–791. [Google Scholar] [CrossRef]

- Xiang, K.; Li, S.; Li, Y.; Wang, H.; Xiang, R.; He, X. Firing properties and corrosion resistance of mullite-Al2TiO5 saggar materials. Int. J. Appl. Ceram. Technol. 2023, 20, 1928–1938. [Google Scholar] [CrossRef]

- Xu, K.; Qi, C.; Wang, B. Recent Progress in Research of Solid Tritium Breeder Materials Li2TiO3: A Review. Coatings 2022, 12, 1053. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D.; Beresnev, V.M.; Smyrnova, K.V.; Kravchenko, Y.O.; Zukowski, P.V.; Bondarenko, G.G. The influence of nitrogen pressure on the fabrication of the two-phase superhard nanocomposite (TiZrNbAlYCr)N coatings. Mater. Lett. 2018, 211, 316–318. [Google Scholar] [CrossRef]

- Pogrebnjak, A.; Ivashchenko, V.; Maksakova, O.; Buranich, V.; Konarski, P.; Bondariev, V.; Koltunowicz, T.N. Comparative measurements and analysis of the mechanical and electrical properties of Ti-Zr-C nanocomposite: Role of stoichiometry. Measurement 2021, 176, 109223. [Google Scholar] [CrossRef]

- Bagdasaryan, A.A.; Pshyk, A.V.; Coy, L.E.; Kempiński, M.; Pogrebnjak, A.D.; Beresnev, V.M.; Jurga, S. Structural and mechanical characterization of (TiZrNbHfTa)N/WN multilayered nitride coatings. Mater. Lett. 2018, 229, 364–367. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D.; Kong, C.H.; Webster, R.F.; Tilley, R.D.; Takeda, Y.; Oyoshi, K.; Konarski, P. Antibacterial effect of Au implantation in ductile nanocomposite multilayer (TiAlSiY)N/CrN coatings. ACS Appl. Mater. Interfaces 2019, 11, 48540–48550. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D.; Webster, R.F.; Tilley, R.D.; Buranich, V.V.; Ivashchenko, V.I.; Takeda, Y.; Budzynski, P. Formation of Si-rich interfaces by radiation-induced diffusion and microsegregation in CrN/ZrN nanolayer coating. ACS Appl. Mater. Interfaces 2021, 13, 16928–16938. [Google Scholar] [CrossRef]

- Leys, J.M.; Zarins, A.; Cipa, J.; Baumane, L.; Kizane, G.; Knitter, R. Radiation-induced effects in neutron-and electron-irradiated lithium silicate ceramic breeder pebbles. J. Nucl. Mater. 2020, 540, 152347. [Google Scholar] [CrossRef]

- Cho, H.; Burgeson, I.E.; Adami, S.R.; Sinkov, S.I. Isotope-specific analysis of neutron-irradiated lithium aluminate ceramics by nuclear magnetic resonance spectroscopy. J. Am. Ceram. Soc. 2020, 103, 7291–7298. [Google Scholar] [CrossRef]

- Heuser, J.M.; Zarins, A.; Baumane, L.; Kizane, G.; Knitter, R. Radiation stability of long-term annealed bi-phasic advanced ceramic breeder pebbles. Fusion Eng. Des. 2019, 138, 395–399. [Google Scholar] [CrossRef]

- Daghbouj, N.; Sen, H.S.; Callisti, M.; Vronka, M.; Karlik, M.; Duchoň, J.; Polcar, T. Revealing nanoscale strain mechanisms in ion-irradiated multilayers. Acta Mater. 2022, 229, 117807. [Google Scholar] [CrossRef]

- Daghbouj, N.; Sen, H.S.; Čížek, J.; Lorinčík, J.; Karlík, M.; Callisti, M.; Polcar, T. Characterizing heavy ions-irradiated Zr/Nb: Structure and mechanical properties. Mater. Des. 2022, 219, 110732. [Google Scholar] [CrossRef]

- Daghbouj, N.; AlMotasem, A.T.; Vesely, J.; Li, B.S.; Sen, H.S.; Karlik, M.; Polcar, T. Microstructure evolution of iron precipitates in (Fe, He)-irradiated 6H-SiC: A combined TEM and multiscale modeling. J. Nucl. Mater. 2023, 584, 154543. [Google Scholar] [CrossRef]

- Nir-El, Y.; Katz, V.; Haddad, J.; Eliezer, D. Determination of structure and composition in ceramics and aerospace materials by neutron radiography. Nondestruct. Test. Eval. 1994, 11, 149–153. [Google Scholar] [CrossRef]

- Laadel, N.E.; El Mansori, M.; Kang, N.; Marlin, S.; Boussant-Roux, Y. Permeation barriers for hydrogen embrittlement prevention in metals—A review on mechanisms, materials suitability and efficiency. Int. J. Hydrogen Energy 2022, 47, 32707–32731. [Google Scholar] [CrossRef]

- Pint, B.A.; DeVan, J.H.; DiStefano, J.R. Temperature limits on the compatibility of insulating ceramics in lithium. J. Nucl. Mater. 2002, 307, 1344–1350. [Google Scholar] [CrossRef]

- Lu, Y.; Xu, K.; Ye, M.; Lei, M.; Mao, S.; Liu, X. Neutronics Analysis of Helium Cooled Ceramic Breeder Blanket with S-shaped Lithium Zone and Cooling Plate for CFETR. IEEE Trans. Plasma Sci. 2018, 46, 1471–1476. [Google Scholar] [CrossRef]

- Mishra, B.; Olson, D.L. Corrosion of refractory alloys in molten lithium and lithium chloride. Int. J. 2002, 22, 369–388. [Google Scholar] [CrossRef]

- Chen, R.; Shi, Q.; Yang, M.; Shi, Y.; Wang, H.; Dang, C.; Lu, T. Microstructure and phase evolution of Li4TiO4 ceramics pebbles prepared from a nanostructured precursor powder synthesized by hydrothermal method. J. Nucl. Mater. 2018, 508, 434–439. [Google Scholar] [CrossRef]

- Hoshino, T. Pebble fabrication of super advanced tritium breeders using a solid solution of Li2+xTiO3+y with Li2ZrO3. Nucl. Mater. Energy 2016, 9, 221–226. [Google Scholar] [CrossRef]

- Tan, G.; Xu, D.; Tu, W.; Gu, H.; Ren, Y.; Hu, X.; Zhang, Y. Low-temperature synthesis of Li2TiO3 tritium breeder ceramic pebbles by water controlled-release solvothermal process. Adv. Powder Technol. 2021, 32, 1983–1991. [Google Scholar] [CrossRef]

- Kozlovskiy, A.; Shlimas, D.I.; Zdorovets, M.V.; Moskina, A.; Pankratov, V.; Popov, A.I. Study of the Effect of Two Phases in Li4SiO4–Li2SiO3 Ceramics on the Strength and Thermophysical Parameters. Nanomaterials 2022, 12, 3682. [Google Scholar] [CrossRef] [PubMed]

- Zhai, Y.; Hu, J.; Duan, Y.; Wang, K.; Zhang, W. Characterization of tritium breeding ceramic pebbles prepared by melt spraying. J. Eur. Ceram. Soc. 2020, 40, 1602–1612. [Google Scholar] [CrossRef]

- Tan, G.; Song, S.; Hu, X.; Cai, L.; Li, Y.; Zhang, Y. Efficient fabrication of high strength Li2TiO3 ceramic pebbles via improved rolling ball method assisted by sesbania gum binder. Ceram. Int. 2021, 47, 26978–26990. [Google Scholar] [CrossRef]

- Wang, H.; Qi, J.; Guo, H.; Chen, R.; Yang, M.; Gong, Y.; Lu, T. Influence of helium ion radiation on the nano-grained Li2TiO3 ceramic for tritium breeding. Ceram. Int. 2021, 47, 28357–28366. [Google Scholar] [CrossRef]

- Tynyshbayeva, K.M.; Kadyrzhanov, K.K.; Kozlovskiy, A.L.; Kuldeyev, Y.I.; Uglov, V.; Zdorovets, M.V. Study of helium swelling and embrittlement mechanisms in SiC ceramics. Crystals 2022, 12, 239. [Google Scholar] [CrossRef]

- Kislitsin, S.B.; Ryskulov, A.E.; Kozlovskiy, A.L.; Ivanov, I.A.; Uglov, V.V.; Zdorovets, M.V. Degradation processes and helium swelling in beryllium oxide. Surf. Coat. Technol. 2020, 386, 125498. [Google Scholar] [CrossRef]

- Shlimas, D.I.; Kozlovskiy, A.L.; Syzdykov, A.K.; Borgekov, D.B.; Zdorovets, M.V. Study of Resistance to Helium Swelling of Lithium-Containing Ceramics under High-Temperature Irradiation. Crystals 2021, 11, 1350. [Google Scholar] [CrossRef]

- Gong, Y.; Yang, M.; Feng, L.; Shi, Q.; Shi, Y.; Xiang, X.; Huang, W. Fabrication of attractive Li4SiO4 pebbles with modified powders synthesized via surfactant-assisted hydrothermal method. Ceram. Int. 2016, 42, 10014–10020. [Google Scholar] [CrossRef]

- Evans, J.H.; Van Veen, A. Gas release processes for high concentrations of helium bubbles in metals. J. Nucl. Mater. 1996, 233, 1179–1183. [Google Scholar] [CrossRef]

- Evans, J.H.; Foreman, A.J.E. Some implications of anisotropic self-interstitial diffusion on void swelling in metals. J. Nucl. Mater. 1985, 137, 1–6. [Google Scholar] [CrossRef]

- Evans, J.H. A mechanism of surface blistering on metals irradiated with helium ions. J. Nucl. Mater. 1976, 61, 1–7. [Google Scholar] [CrossRef]

| Parameter | Component Ratio of xLi4SiO4–(1−x)Li2TiO3 Ceramics | ||||

|---|---|---|---|---|---|

| 0 M | 0.25 M | 0.5 M | 0.75 M | 1 M | |

| Density, g/cm3 | 3.33 ± 0.12 | 3.11 ± 0.14 | 2.85 ± 0.11 | 2.62 ± 0.09 | 2.32 ± 0.13 |

| Porosity, % | 2.91 ± 0.06 | 1.92 ± 0.11 | 1.73 ± 0.13 | 0.72 ± 0.05 | 2.52 ± 0.14 |

| Parameter | Component Ratio of xLi4SiO4–(1−x)Li2TiO3 Ceramics | ||||

|---|---|---|---|---|---|

| 0 M | 0.25 M | 0.5 M | 0.75 M | 1 M | |

| Li2TiO3 * | a = 5.0360 Å, | a = 5.0251Å, | a = 5.0507 Å, | a = 5.0401 Å, | |

| b = 8.8008 Å, | b = 8.7750 Å, | b = 8.7405 Å, | b = 8.7835 Å, | ||

| c = 9.7137 Å, | c = 9.7193 Å, | c = 9.6585 Å, | c = 9.7060 Å, | ||

| β = 99.792°, | β = 99.615°. | β = 95.147°. | β = 99.832° | ||

| Li4SiO4 ** | - | a = 11.5345 Å, | a = 11.5006 Å, | a = 11.4872 Å, | a = 11.4985 Å, |

| b = 6.0948 Å, | b = 6.0947 Å, | b = 6.0876 Å, | b = 6.1007 Å, | ||

| c = 16.5567 Å, | c = 16.5667 Å, | c = 16.5537 Å, | c = 16.58952 Å, | ||

| β = 98.567° | β = 98.567° | β = 98.993° | β = 99.285° | ||

| Parameter | Component Ratio of xLi4SiO4–(1−x)Li2TiO3 Ceramics | ||||

|---|---|---|---|---|---|

| 0 M | 0.25 M | 0.5 M | 0.75 M | 1 M | |

| Hardening factor, % * | - | 4.6 | 15.2 | 19.8 | 2.9 |

| Crack resistance increase, % * | - | 3.9 | 9.4 | 16.1 | 2.1 |

| Dislocation density, 109 cm−2 | 0.0016 | 0.0022 | 0.0048 | 0.057 | 0.164 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kenzhina, I.E.; Kozlovskiy, A.L.; Chikhray, Y.; Kulsartov, T.; Zaurbekova, Z.; Begentayev, M.; Askerbekov, S. Study of Gas Swelling Processes under Irradiation with Protons and He2+ Ions in Li4SiO4–Li2TiO3 Ceramics. Crystals 2023, 13, 1526. https://doi.org/10.3390/cryst13101526

Kenzhina IE, Kozlovskiy AL, Chikhray Y, Kulsartov T, Zaurbekova Z, Begentayev M, Askerbekov S. Study of Gas Swelling Processes under Irradiation with Protons and He2+ Ions in Li4SiO4–Li2TiO3 Ceramics. Crystals. 2023; 13(10):1526. https://doi.org/10.3390/cryst13101526

Chicago/Turabian StyleKenzhina, Inesh E., Artem L. Kozlovskiy, Yevgen Chikhray, Timur Kulsartov, Zhanna Zaurbekova, Meiram Begentayev, and Saulet Askerbekov. 2023. "Study of Gas Swelling Processes under Irradiation with Protons and He2+ Ions in Li4SiO4–Li2TiO3 Ceramics" Crystals 13, no. 10: 1526. https://doi.org/10.3390/cryst13101526

APA StyleKenzhina, I. E., Kozlovskiy, A. L., Chikhray, Y., Kulsartov, T., Zaurbekova, Z., Begentayev, M., & Askerbekov, S. (2023). Study of Gas Swelling Processes under Irradiation with Protons and He2+ Ions in Li4SiO4–Li2TiO3 Ceramics. Crystals, 13(10), 1526. https://doi.org/10.3390/cryst13101526