Effect of Samarium on the Properties of Hot-Extruded Mg–Y–Gd–Zr Alloys

Abstract

:1. Introduction

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

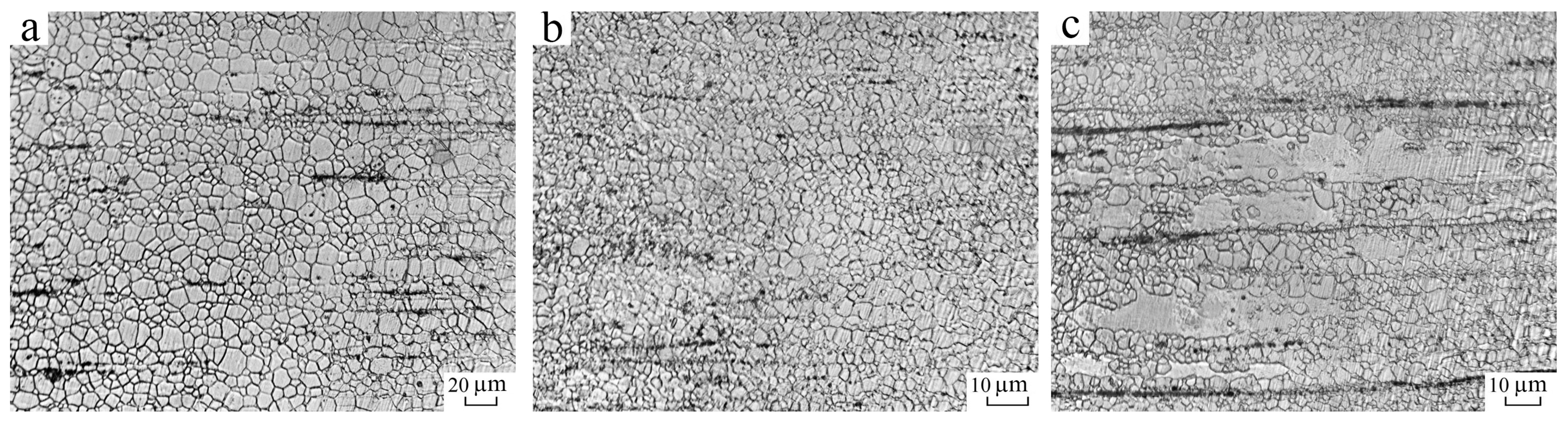

- In Mg–Y–Gd–Zr alloys with the addition of samarium 1.7–2.5% and without it, dynamic recrystallization occurs during hot extrusion. Depending on the content of samarium and its ratio to the content of yttrium and gadolinium, recrystallization proceeds differently. With an increase in the samarium content, the microstructure of the alloys changes from completely recrystallized to partially recrystallized with the presence of elongated deformed grains. At the same time, a finer recrystallized grains (up to ~3 μm) are formed in the structure of hot-extruded alloys with samarium than in an alloy without samarium.

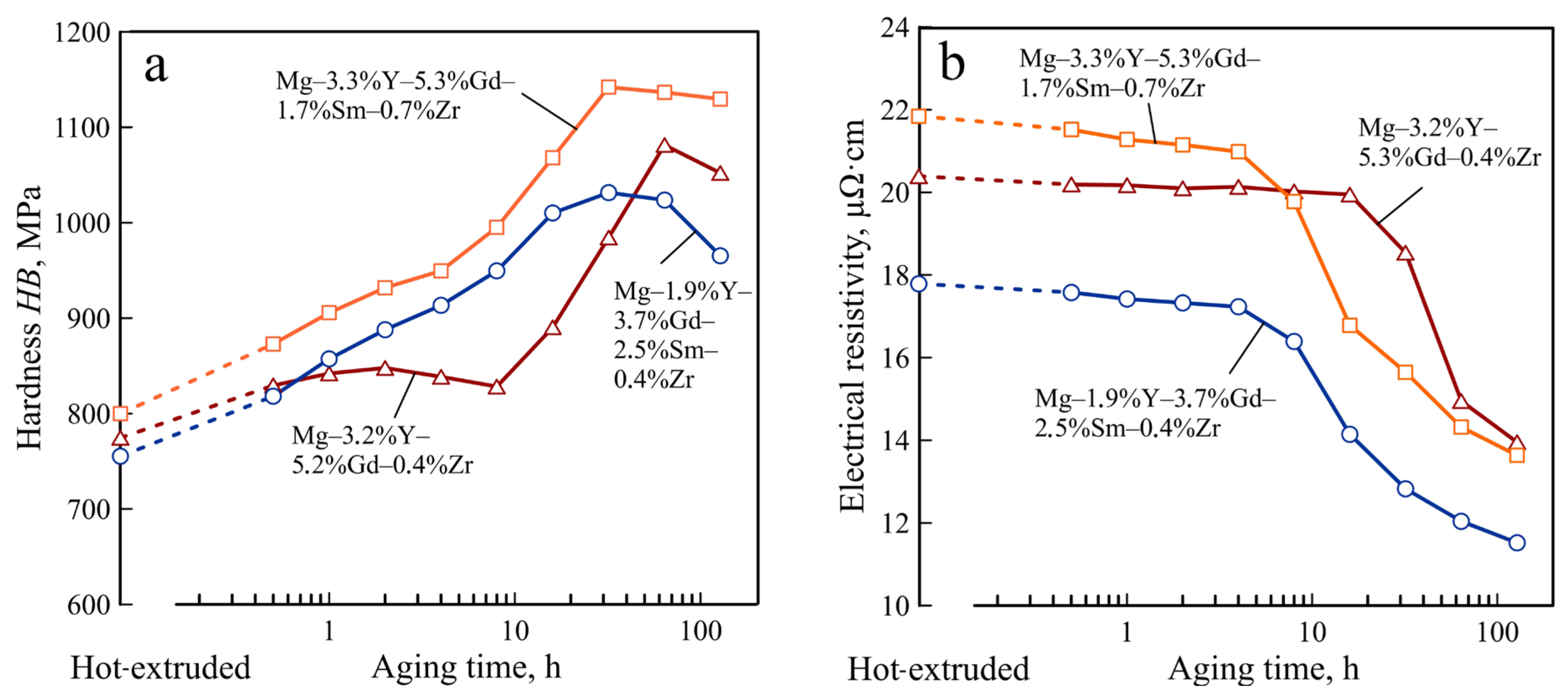

- Hot-extruded Mg–Y–Gd–Sm–Zr alloys are additionally strengthened after isothermal aging at 200 °C due to the decomposition of the supersaturated magnesium solid solution. Samarium accelerates the decomposition of the Mg solid solution of the Mg-Y–Gd–Zr alloys after hot extrusion, thereby reducing the duration of the heat treatment by aging required to achieve greatest hardening.

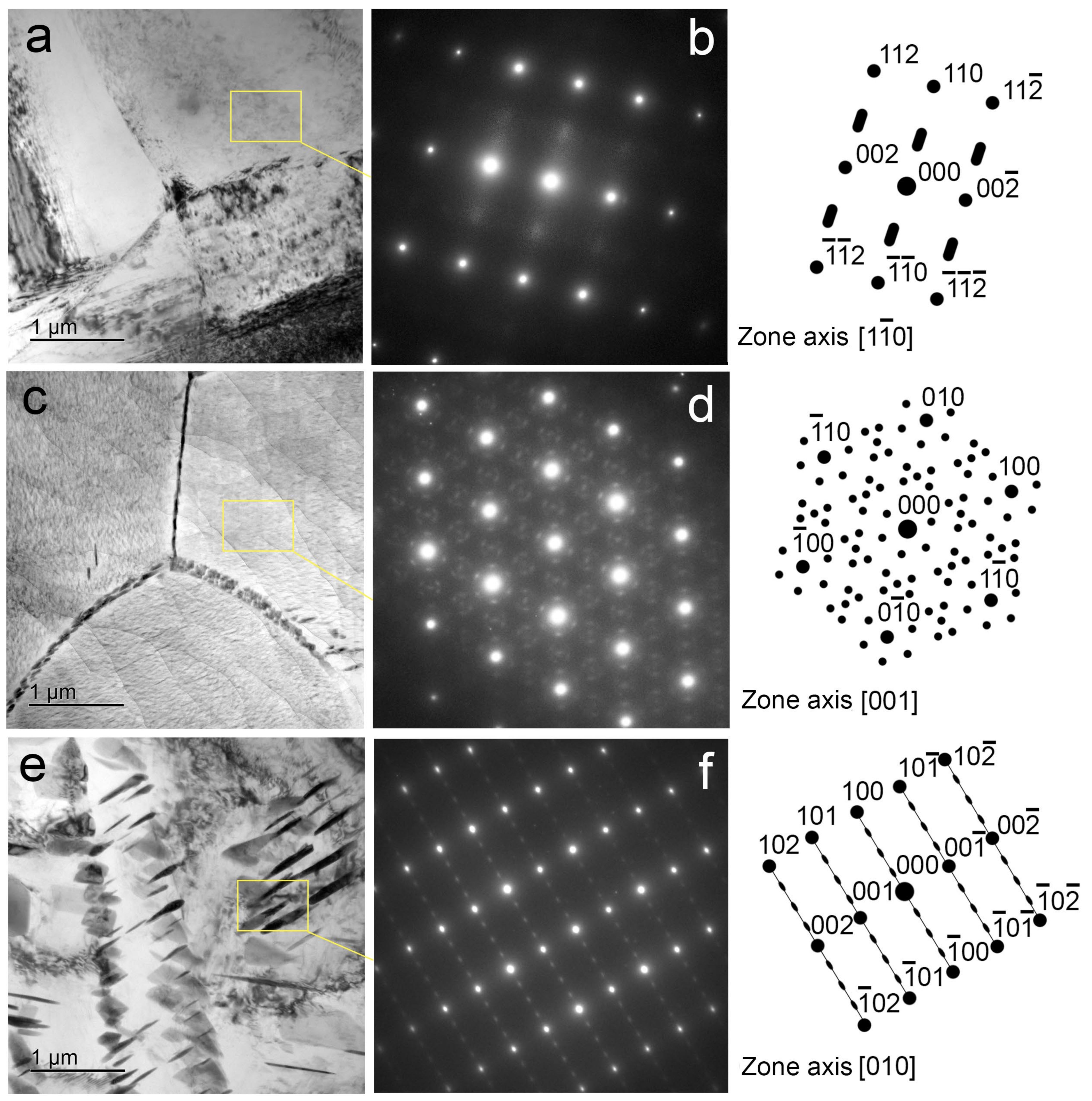

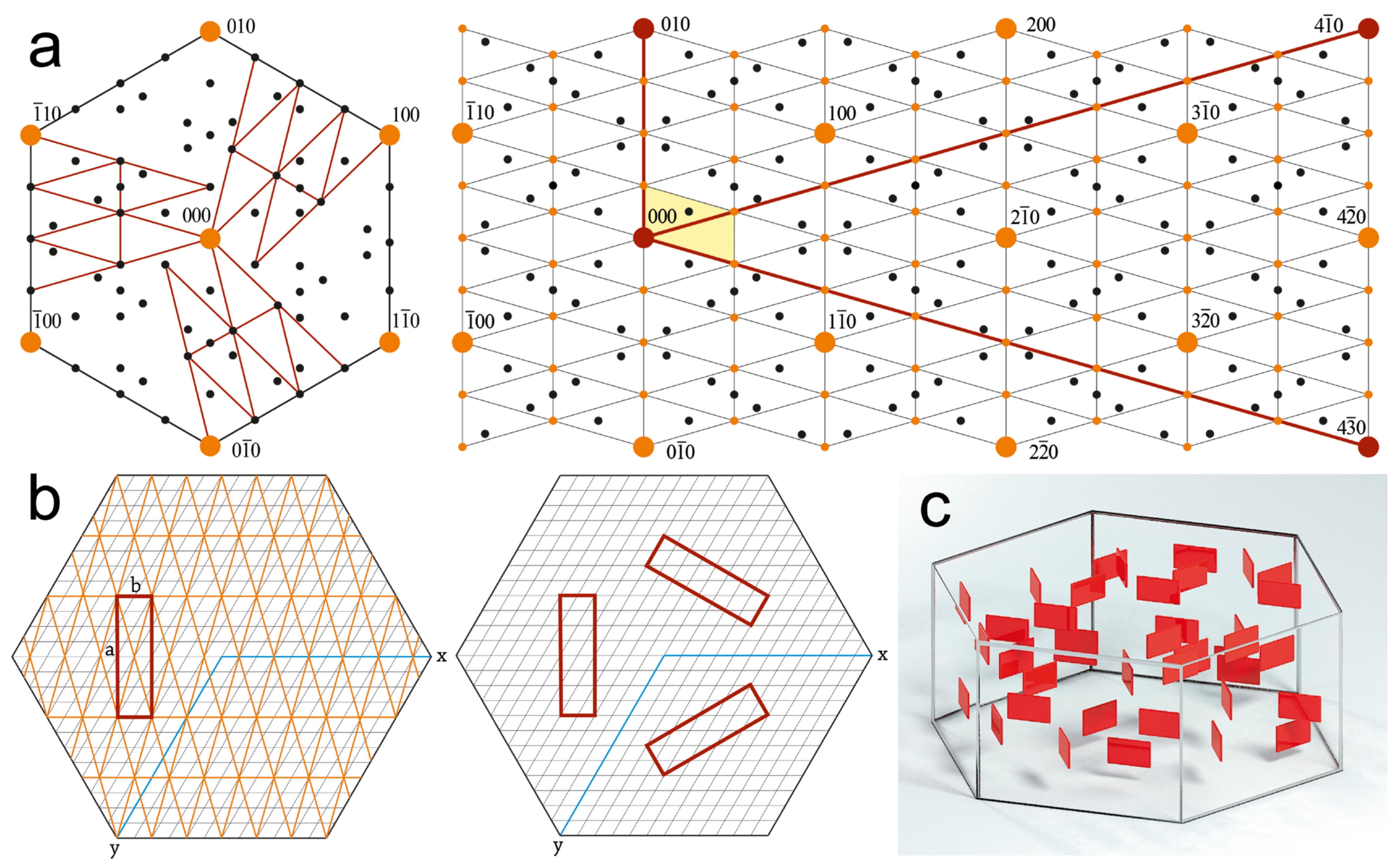

- Strengthening of hot-extruded Mg–Y–Gd–Sm–Zr alloys during aging is due to the formation of a metastable orthorhombic phase β’ in the structure of plate-shaped precipitates, which is coherently bound to the crystal lattice of the magnesium solid solution. It is oriented with respect to the magnesium matrix in three symmetrical ways with the symmetry axis coinciding with the hexagonal axis of the crystal lattice of the Mg solid solution, and is arranged in large planes along the (110) planes of Mg perpendicular to its basal plane.

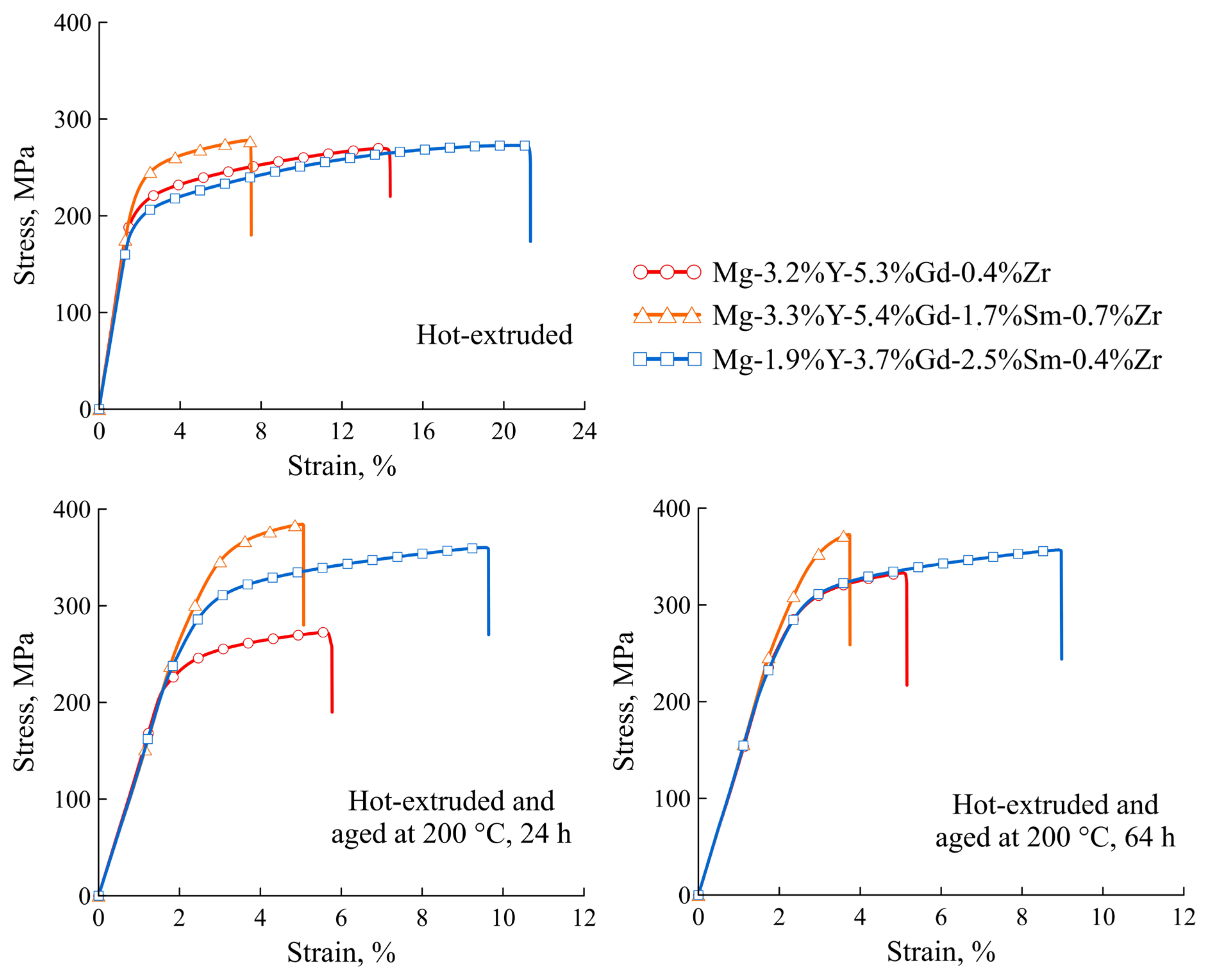

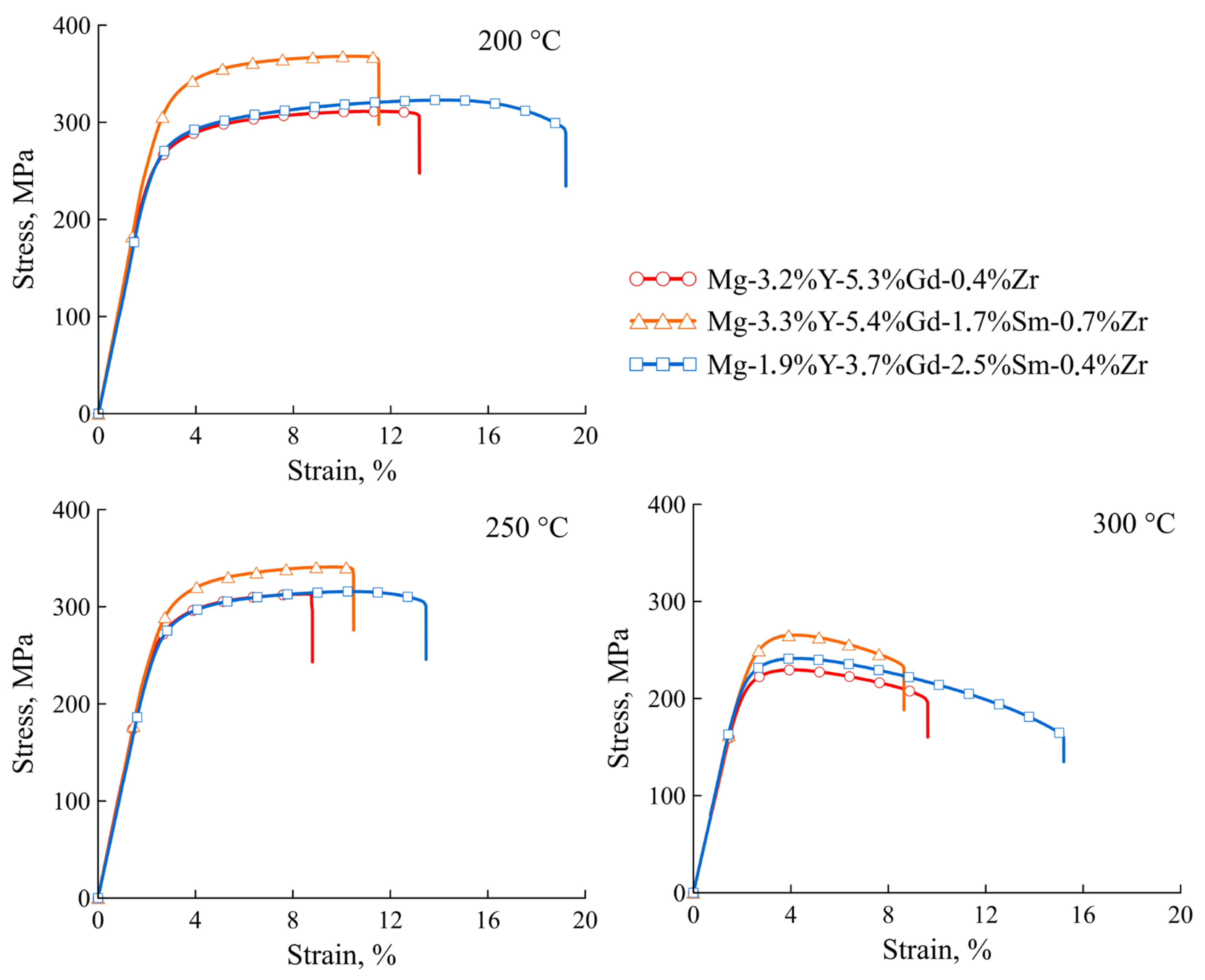

- The addition of 1.7% samarium to the alloy with ~3% yttrium and ~5% gadolinium increases its strength properties at room temperature only after additional hardening aging and significantly reduces its ductility. However, the mechanical properties of the alloy are high at elevated temperatures of 200–300 °C. The addition of 2.5% samarium to the alloy with ~2% yttrium and ~4% gadolinium provides high mechanical characteristics up to 300 °C with a lower content of expensive REEs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, Y.Q.; Li, F.; Kang, F.W.; Du, H.Q.; Chen, Z.Y. Recent research and advances in extrusion forming of magnesium alloys: A review. J. Alloys Compd. 2023, 953, 170080. [Google Scholar] [CrossRef]

- Liu, B.; Yang, J.; Zhang, X.; Yang, Q.; Zhang, J.; Li, X. Development and application of magnesium alloy parts for automotive OEMs: A review. J. Magnes. Alloy. 2023, 11, 15–47. [Google Scholar] [CrossRef]

- Volkova, E.F.; Akinina, M.V.; Mostyaev, I.V.; Duyunova, V.A.; Alikhanyan, A.A. New studies in the field of alloying and deformation of modern magnesium alloys. Review. Russ. Metall. Met. 2022, 3, 191–199. [Google Scholar] [CrossRef]

- You, S.; Huang, Y.; Kainer, K.U.; Hort, N. Recent research and developments on wrought magnesium alloys. J. Magnes. Alloys 2017, 5, 239–253. [Google Scholar] [CrossRef]

- Rokhlin, L.L. Magnesium Alloys Containing Rare Earth Metals: Structure and Properties, 1st ed.; Taylor & Francis Group: London, UK, 2003; 256p. [Google Scholar] [CrossRef]

- Mordike, B.L.; Ebert, T. Magnesium: Properties-applications-potential. Mater. Sci. Eng. A 2001, 302, 37–45. [Google Scholar] [CrossRef]

- He, M.; Chen, L.; Yin, M.; Xu, S.; Liang, Z. Review on magnesium and magnesium-based alloys as biomaterials for bone immobilization. J. Mater. Res. Technol. 2023, 23, 4396–4419. [Google Scholar] [CrossRef]

- Deng, Y.; Yan, H.; Li, Q.; Chen, J.; Xia, W.; Su, B.; Wu, M.; Yu, Y.; Song, M. Enhancing strength and ductility of low RE content Mg–Gd–Y–Zr alloy via a novel thermomechanical treatment based on multi-directional forging. J. Alloys Compd. 2023, 958, 170535. [Google Scholar] [CrossRef]

- Li, W.; Shen, Y.; Shen, J.; Shen, D.; Liu, X.; Zheng, Y.; Yeung, K.W.K.; Guan, S.; Kulyasova, O.B.; Valiev, R.Z. In vitro and in vivo studies on pure Mg, Mg–1Ca and Mg–2Sr alloys processed by equal channel angular pressing. Nano Mater. Sci. 2020, 2, 96–108. [Google Scholar] [CrossRef]

- Elambharathi, B.; Dharani Kumar, S.; Dhanoop, V.U.; Dinakar, S.; Rajumar, S.; Sharma, S.; Kumar, V.; Li, C.; Eldin, E.M.T.; Wojciechowski, S. Novel insights on different treatment of magnesium alloys: A critical review. Heliyon 2022, 11, e11712. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, A.; Li, C.; Xie, H.; Jiang, B.; Dong, Z.; Jin, P.; Pan, F. Recent advances of high strength Mg-RE alloys: Alloy development, forming and application. J. Mater. Res. Technol. 2023, 26, 2919–2940. [Google Scholar] [CrossRef]

- Mirzadeh, H. Grain refinement of magnesium alloys by dynamic recrystallization (DRX): A review. J. Mater. Res. Technol 2023, 25, 7050–7077. [Google Scholar] [CrossRef]

- Calado, L.M.; Carmezim, M.J.; Montemor, M.F. Rare Earth Based Magnesium Alloys—A Review on WE Series. Front. Mater. 2022, 8. [Google Scholar] [CrossRef]

- Lü, Z.; Zhou, J.; Sun, Z.; Chen, R.S. Effect of rare earth elements on the structures and mechanical properties of magnesium alloys. Chin. Sci. Bull. 2013, 58, 816–820. [Google Scholar] [CrossRef]

- Rokhlin, L.L. Structure and properties of alloys of the Mg-REM system. Met. Sci. Heat Treat. 2006, 48, 487–490. [Google Scholar] [CrossRef]

- Dong, J.; Lin, T.; Shao, H.; Wang, H.; Wang, X.; Song, K.; Li, Q. Advances in degradation behavior of biomedical magnesium alloys: A review. J. Alloys Compd. 2022, 908, 164600. [Google Scholar] [CrossRef]

- Lei, B.; Wang, C.; Jiang, B.; Bai, S.; Dong, Z.; Qian, X.; He, C.; Xu, J.; Yang, H.; Wang, Q.; et al. Role of Y on the microstructure and mechanical properties of Mg–Gd–Zr alloy. Mater. Sci. Eng. A 2022, 861, 144371. [Google Scholar] [CrossRef]

- Ren, X.; An, X.; Ni, S.; Huang, Y.; Song, M. Formation of nanocrystalline grain structure in an Mg–Gd–Y–Zr alloy processed by high-pressure torsion. Mater. Charact. 2022, 191, 112088. [Google Scholar] [CrossRef]

- Zhao, S.; Xu, Y.; Geng, C.; Lin, X.; Tang, Q.; Dong, Y. High temperature mechanical properties and strain hardening mechanism of directionally solidified Mg–Gd–Y alloy. Mater. Sci. Eng. A 2022, 833, 142337. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Y.; Ni, C.; Fang, Y.; Yu, X.; Zhang, P. Effect of Gd content on microstructure and dynamic mechanical properties of solution-treated Mg–xGd–3Y–0.5Zr alloy. T. Nonferr. Metal. Soc. 2022, 32, 2177–2189. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, Q.; Chen, X.; Zhao, J.; Bao, J.; Chen, Z. Dynamic precipitation and recrystallization mechanism during hot compression of Mg–Gd–Y–Zr alloy. J. Mater. Res. Technol. 2021, 15, 37–51. [Google Scholar] [CrossRef]

- Li, J.; Dong, Z.; Yi, X.; Wu, D.; Chen, R. Twin evolution in cast Mg–Gd–Y alloys and its dependence on aging heat treatment. J. Magnes. Alloy. 2021, in press. [Google Scholar] [CrossRef]

- Liu, J.; Sun, J.; Chen, Q.; Lu, L.; Zhao, Y. Study on Microstructure and Mechanical Property in Mg–Gd–Y Alloy by Secondary Extrusion Process. Crystals 2021, 11, 939. [Google Scholar] [CrossRef]

- Wang, B.; Tang, B.; You, C.; Wan, Y.; Gao, Y.; Chen, Z.; Lu, L.; Liu, C.; Wang, J. Dislocation arrays, precipitate bands and free zones in forged Mg–Gd–Y–Zr alloy. Mater. Sci. Eng. A 2020, 775, 138789. [Google Scholar] [CrossRef]

- Yu, S.; Wan, Y.; Liu, C.; Wang, J. Age-hardening and age-softening in nanocrystalline Mg–Gd–Y–Zr alloy. Mater. Charact. 2019, 156, 109841. [Google Scholar] [CrossRef]

- Dobatkin, S.V.; Rokhlin, L.L.; Lukyanova, E.A.; Dobatkina, T.V.; Tabachkova, N.Y.; Murashkin, M.Y. Structure and mechanical properties of the Mg–Y–Gd–Zr alloy after high pressure torsion. Mater. Sci. Eng. A 2016, 667, 217–223. [Google Scholar] [CrossRef]

- Lukyanova, E.A.; Rokhlin, L.L.; Dobatkina, T.V.; Nikitina, N.I.; Tabachkova, N.Y. Reversion after Ageing in an Mg–Y–Gd–Zr Alloy. J. Alloys Compd. 2015, 635, 173–179. [Google Scholar] [CrossRef]

- He, S.M.; Zeng, X.Q.; Peng, L.M.; Gao, X.Q.; Nie, J.F.; Ding, W.J. Precipitation in a Mg–10Gd–3Y–0.4 Zr (wt.%) alloy during isothermal ageing at 250 C. J. Alloys Compd. 2006, 421, 309–313. [Google Scholar] [CrossRef]

- Drits, M.E.; Rokhlin, L.L.; Nikitina, N.I.; Gur’ev, I.I.; Miklina, N.V.; Dianova, T.M.; Vlasova, T.A.; Siulina, N.A.; Al’tman, M.B.; Bljablin, A.A.; et al. Magnesium-Base Alloy. Patent SU 1010880 A1, 20 October 1997. [Google Scholar]

- Rokhlin, L.L.; Dobatkina, T.V.; Nikitina, N.I.; Tarytina, I.E. A study of properties of high-strength magnesium alloy of the Mg–Y–Gd–Zr system. Met. Sci. Heat Treat. 2011, 52, 588–591. [Google Scholar] [CrossRef]

- Drits, M.E.; Rokhlin, L.L.; Abrukina, N.P. Mechanical properties of binary alloys of the Mg-Sm system. Met. Sci. Heat Treat. 1985, 27, 508–510. [Google Scholar] [CrossRef]

- Yuan, M.; He, C.; Dong, Z.; Jiang, B.; Song, B.; Guo, N.; Liu, T.; Guo, S.; Pan, F. Effect of Sm addition on the microstructure and mechanical properties of Mg–xSm–0.4Zr alloys. J. Mater. Res. Technol. 2023, 23, 4814–4827. [Google Scholar] [CrossRef]

- Rokhlin, L.L.; Luk’yanova, E.A.; Dobatkina, T.V.; Alad’ev, N.A.; Korol’kova, I.G. Phase equilibria in Mg–Y–Gd–Sm alloys. Russ. Metall. Met. 2012, 9, 802–807. [Google Scholar] [CrossRef]

- Luk’yanova, E.A.; Rokhlin, L.L.; Dobatkina, T.V.; Korol’kova, I.G. Samarium solubility in an yttrium- and gadolinium-containing magnesium-based solid solution. Russ. Metall. Met. 2012, 7, 625–629. [Google Scholar] [CrossRef]

- Yan, L.; Li, Q.; Zhu, L.; Chen, X.; Yang, L.; Chen, J.; Li, W. Investigation of hot extruded GW84 alloy on high temperature tensile properties and microstructure evolution. J. Mater. Res. Technol. 2021, 13, 408–416. [Google Scholar] [CrossRef]

- Chen, X.; Li, Q.; Zhou, Y.; Chen, P. Creep behavior and creep mechanism of Mg–Gd–Y–Sm–Zr alloy. Vacuum 2023, 212, 112009. [Google Scholar] [CrossRef]

- Rokhlin, L.L.; Dobatkina, T.V.; Tarytina, I.E.; Luk’yanova, E.A.; Ovchinnikova, O.A. Effect of samarium on the strength properties of Mg–Y–Gd–Zr Alloys. Russ. Metall. 2021, 3, 267–271. [Google Scholar] [CrossRef]

- Pang, H.; Li, Q.; Chen, X.; Chen, P.; Li, X.; Tan, J. Hot deformation behavior and microstructure evolution of Mg–Gd–Y(–Sm)–Zr alloys. J. Alloys Compd. 2022, 920, 165937. [Google Scholar] [CrossRef]

- Pei, Y.; Yuan, M.; Wei, E.; Teng, B. Effects of Sm element addition on the workability and microstructure evolution of Mg–Gd–Y–Zr alloy during hot deformation. Mater. Des. 2023, 230, 111962. [Google Scholar] [CrossRef]

- Nie, J.F. Precipitation and hardening in magnesium alloys. Metall. Mater. Trans. A 2012, 43, 3891–3939. [Google Scholar] [CrossRef]

| Alloy Composition | Hot Extrusion | Hot Extrusion + Aging 200 °C, 24 h | Hot Extrusion + Aging 200 °C, 64 h | ||||||

|---|---|---|---|---|---|---|---|---|---|

| UTS, MPa | YS, MPa | EL, % | UTS, MPa | YS, MPa | EL, % | UTS, MPa | YS, MPa | EL, % | |

| Mg–3.2%Y–5.3%Gd–0.4%Zr | 270 ± 4 | 194 ± 2 | 12.2 ± 2.3 | 273 ± 2 | 228 ± 1 | 3.5 ± 0.2 | 333 ± 7 | 278 ± 3 | 2.5 ± 0.9 |

| Mg–3.3%Y–5.4%Gd–1.7%Sm–0.7%Zr | 278 ± 7 | 223 ± 5 | 5.2 ± 1.2 | 386 ± 6 | 331 ± 3 | 1.9 ± 0.6 | 372 ± 1 | 331 ± 1 | 1.0 ± 0.1 |

| Mg–1.9%Y–3.7%Gd–2.5%Sm–0.4%Zr | 273 ± 1 | 186 ± 3 | 18.9 ± 1.2 | 360 ± 6 | 276 ± 6 | 6.6 ± 0.7 | 357 ± 1 | 272 ± 2 | 6.1 ± 0.3 |

| Alloy Composition | T = 200 °C | T = 250 °C | T = 300 °C | ||||||

|---|---|---|---|---|---|---|---|---|---|

| UTS, MPa | YS, MPa | EL, % | UTS, MPa | YS, MPa | EL, % | UTS, MPa | YS, MPa | EL, % | |

| Mg–3.2%Y–5.3%Gd–0.4%Zr | 312 ± 1 | 252 ± 8 | 8.9 ± 2.2 | 313 ± 1 | 255 ± 6 | 6.0 ± 1.4 | 230 ± 10 | 202 ± 5 | 7.6 ± 0.3 |

| Mg–3.3%Y–5.4%Gd–1.7%Sm–0.7%Zr | 368 ± 5 | 292 ± 10 | 8.5 ± 1.1 | 341 ± 2 | 269 ± 7 | 7.6 ± 0.6 | 266 ± 2 | 277 ± 6 | 6.4 ± 0.1 |

| Mg–1.9%Y–3.7%Gd-2.5%Sm–0.4%Zr | 323 ± 3 | 257 ± 2 | 16.5 ± 0.9 | 316 ± 2 | 258 ± 8 | 10.6 ± 0.5 | 241 ± 1 | 211 ± 1 | 13.6 ± 1.3 |

| Alloy | Test Temperature, °C | UTS, MPa | YS, MPa | EL, % | Source |

|---|---|---|---|---|---|

| Mg–8%Gd–4%Y–1%Sm–0.5%Zr Hot extrusion + aging | 20 | – | – | – | [35] |

| 200 | 376 | 325 | 4 | ||

| 250 | 393 | 345 | 6,2 | ||

| 300 | 354 | 300 | 10 | ||

| Mg–11%Gd–2%Y–3%Sm–0.5%Zr As-cast | 20 | 252 | 201 | 2.4 | [36] |

| 200 | 303 | 237 | 3.4 | ||

| 250 | 319 | 246 | 4 | ||

| 300 | 273 | 212 | 4.7 | ||

| Mg–5.5%Y–5.5%Gd–3%Sm–0.7%Zr As-cast + aging | 20 | 339 | 234 | 1.1 | [37] |

| 200 | – | – | – | ||

| 250 | 304 | 224 | 0.8 | ||

| 300 | – | – | – | ||

| Mg–7.5%Y–7.5%Gd–5%Sm–0.7%Zr As-cast + aging | 20 | 290 | 285 | 0.1 | |

| 200 | – | – | – | ||

| 250 | 285 | 282 | 0.1 | ||

| 300 | – | – | – | ||

| Mg–3.3%Y–5.4%Gd–1.7%Sm–0.7%Zr Hot extrusion + aging | 20 | 386 | 331 | 1.9 | present study |

| 200 | 368 | 292 | 8.5 | ||

| 250 | 356 | 315 | 7.8 | ||

| 300 | 266 | 277 | 6.4 | ||

| Mg–1.9%Y–3.7%Gd–2.5%Sm–0.4%Zr Hot extrusion + aging | 20 | 360 | 276 | 6.6 | |

| 200 | 323 | 257 | 16.5 | ||

| 250 | 316 | 258 | 10.6 | ||

| 300 | 241 | 211 | 13.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lukyanova, E.; Martynenko, N.; Rybalchenko, O.; Dobatkina, T.; Tarytina, I.; Tabachkova, N.; Rybalchenko, G.; Andreeva, N.; Dobatkin, S. Effect of Samarium on the Properties of Hot-Extruded Mg–Y–Gd–Zr Alloys. Crystals 2023, 13, 1443. https://doi.org/10.3390/cryst13101443

Lukyanova E, Martynenko N, Rybalchenko O, Dobatkina T, Tarytina I, Tabachkova N, Rybalchenko G, Andreeva N, Dobatkin S. Effect of Samarium on the Properties of Hot-Extruded Mg–Y–Gd–Zr Alloys. Crystals. 2023; 13(10):1443. https://doi.org/10.3390/cryst13101443

Chicago/Turabian StyleLukyanova, Elena, Natalia Martynenko, Olga Rybalchenko, Tatiana Dobatkina, Irina Tarytina, Natalia Tabachkova, Georgy Rybalchenko, Nadezhda Andreeva, and Sergey Dobatkin. 2023. "Effect of Samarium on the Properties of Hot-Extruded Mg–Y–Gd–Zr Alloys" Crystals 13, no. 10: 1443. https://doi.org/10.3390/cryst13101443

APA StyleLukyanova, E., Martynenko, N., Rybalchenko, O., Dobatkina, T., Tarytina, I., Tabachkova, N., Rybalchenko, G., Andreeva, N., & Dobatkin, S. (2023). Effect of Samarium on the Properties of Hot-Extruded Mg–Y–Gd–Zr Alloys. Crystals, 13(10), 1443. https://doi.org/10.3390/cryst13101443