Design of Tunable Liquid Crystal Lenses with a Parabolic Phase Profile

Abstract

1. Introduction

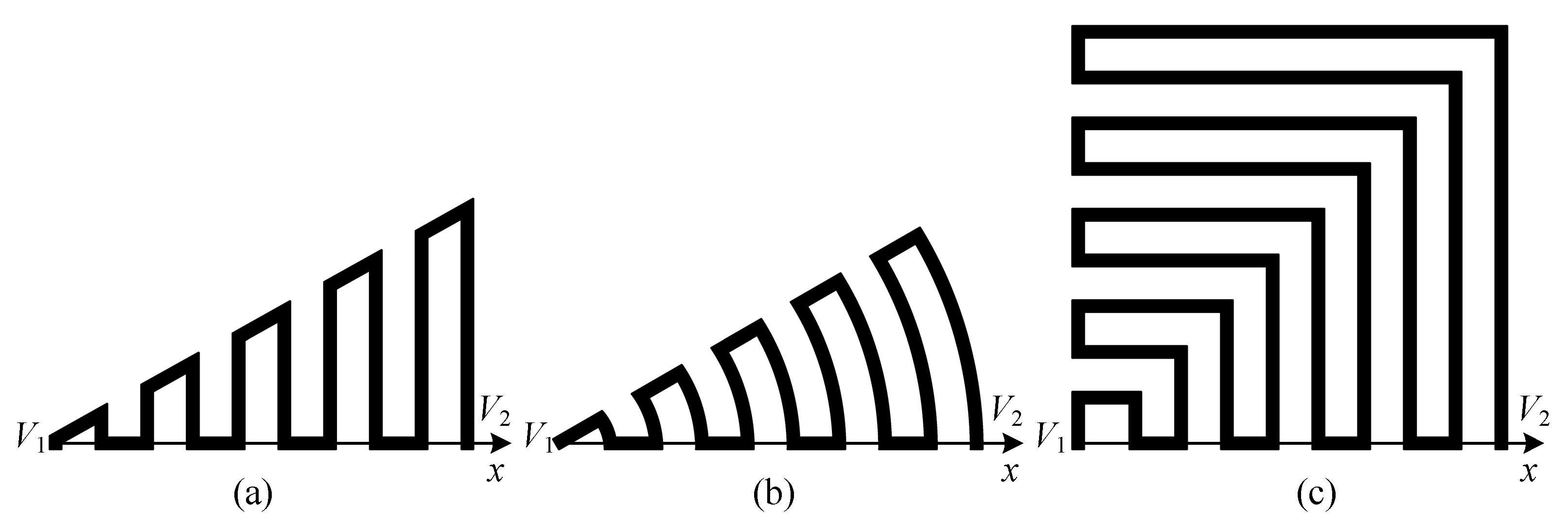

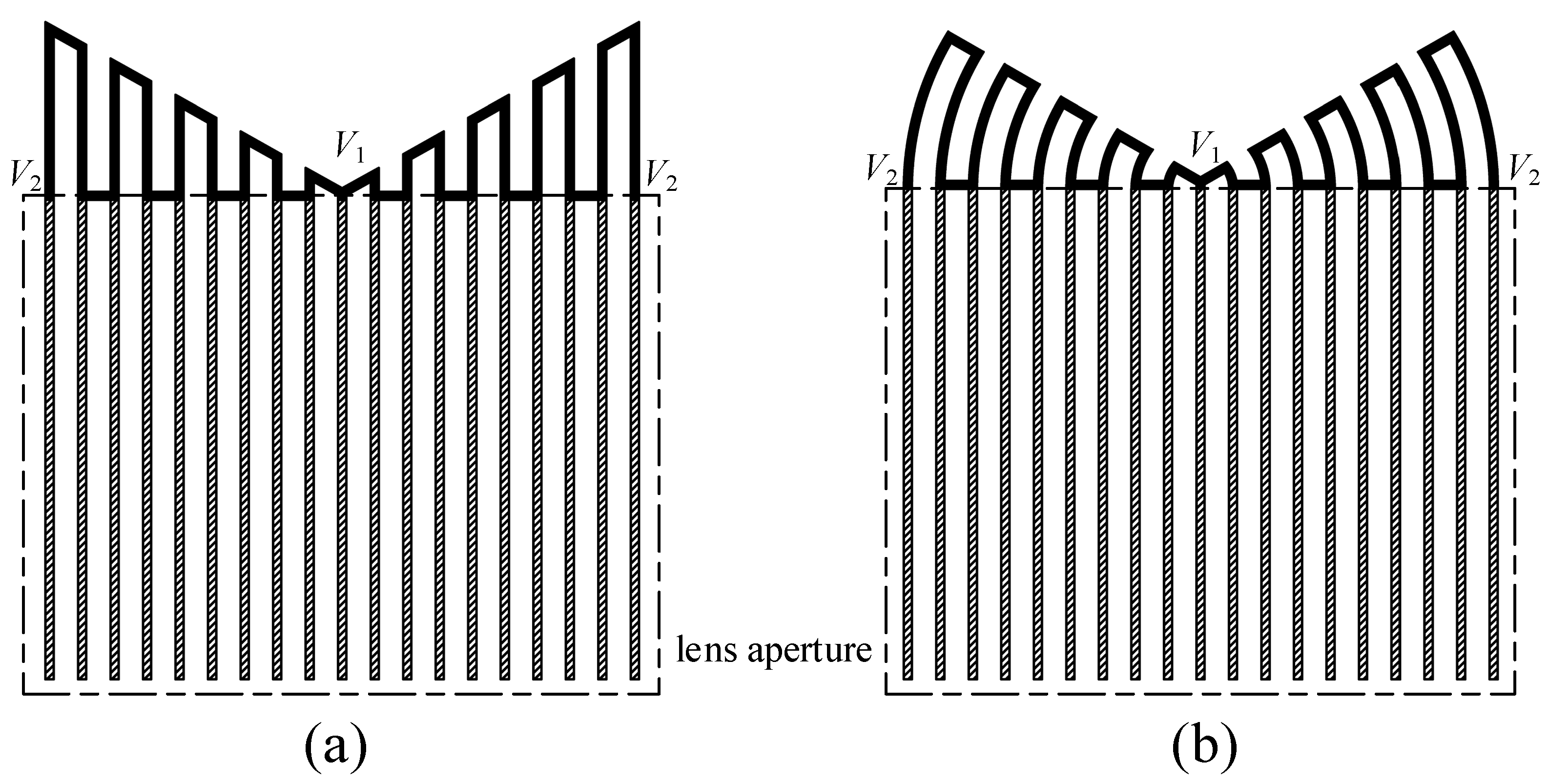

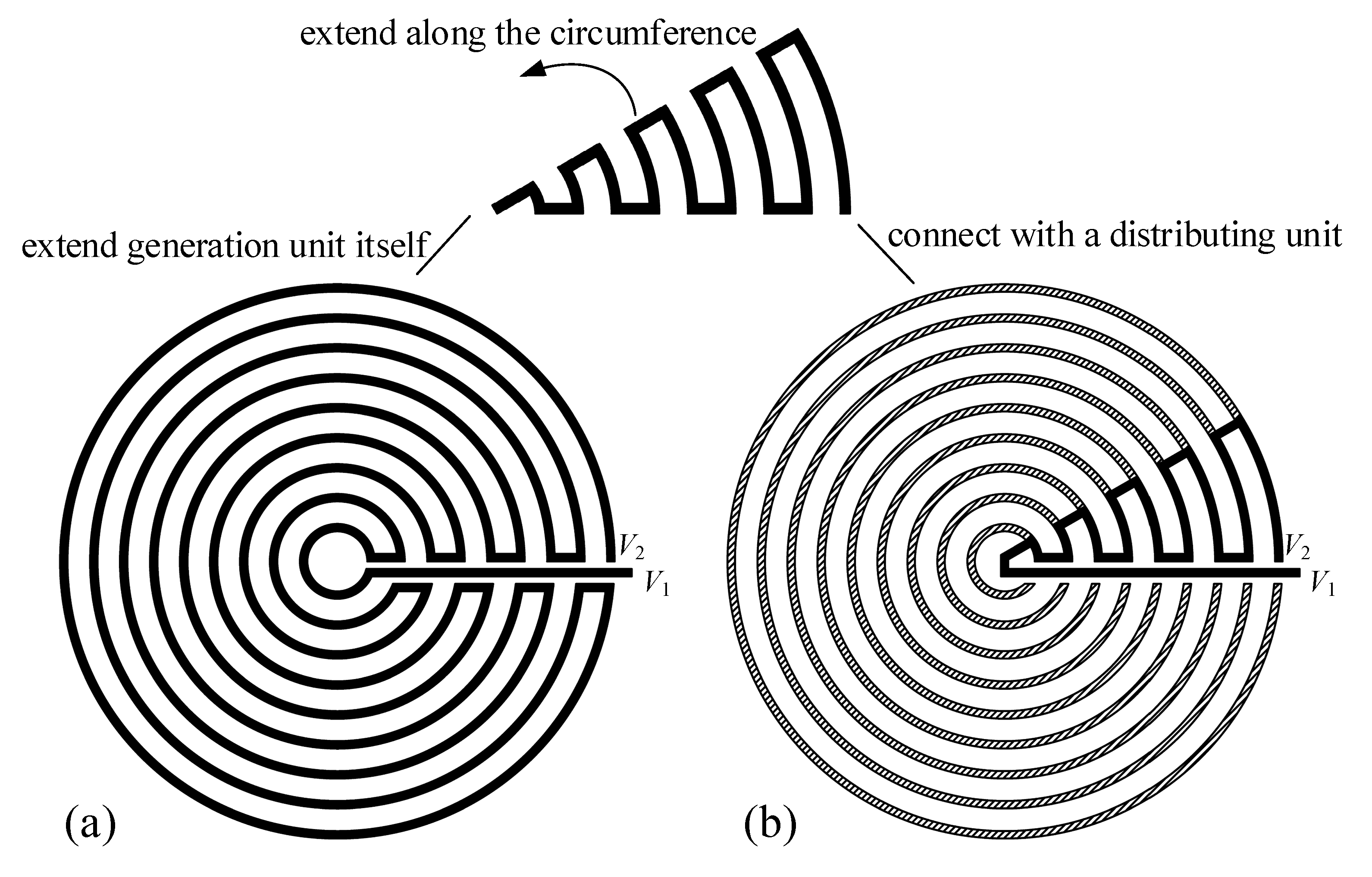

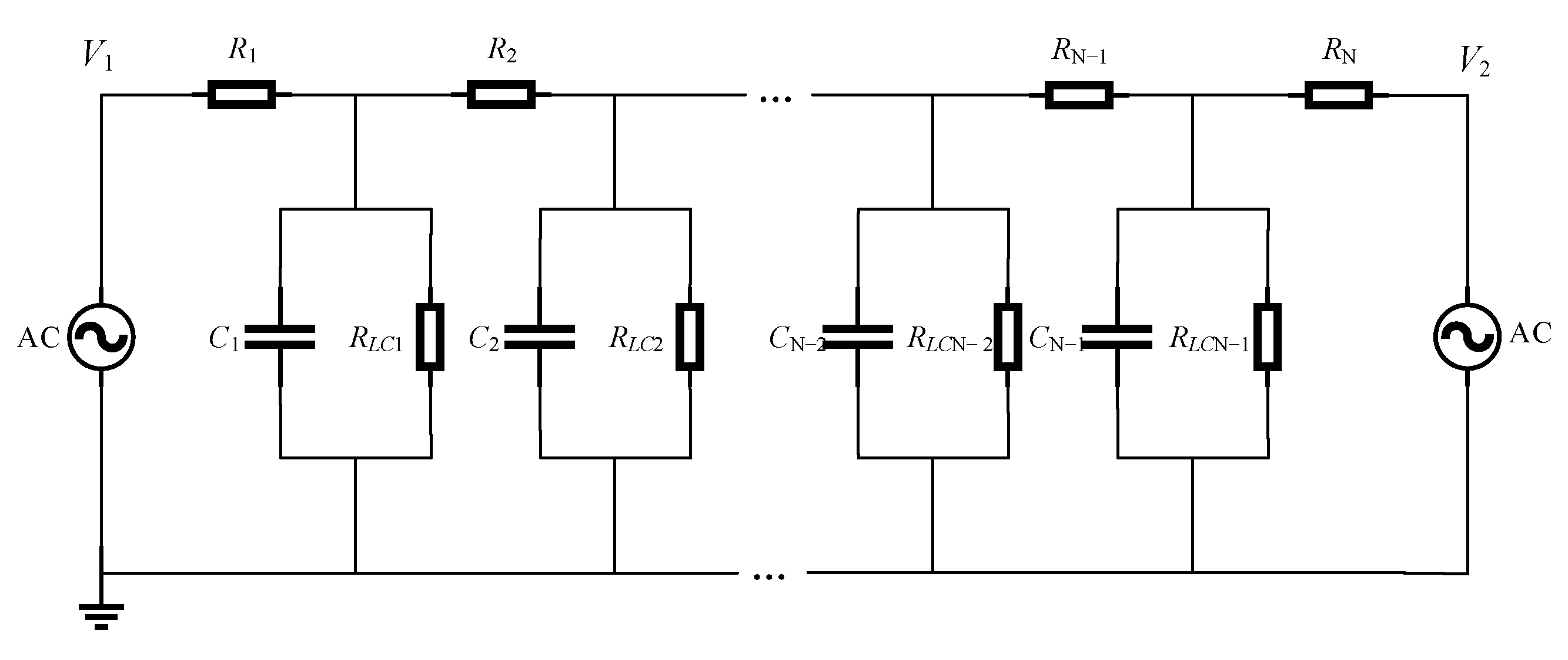

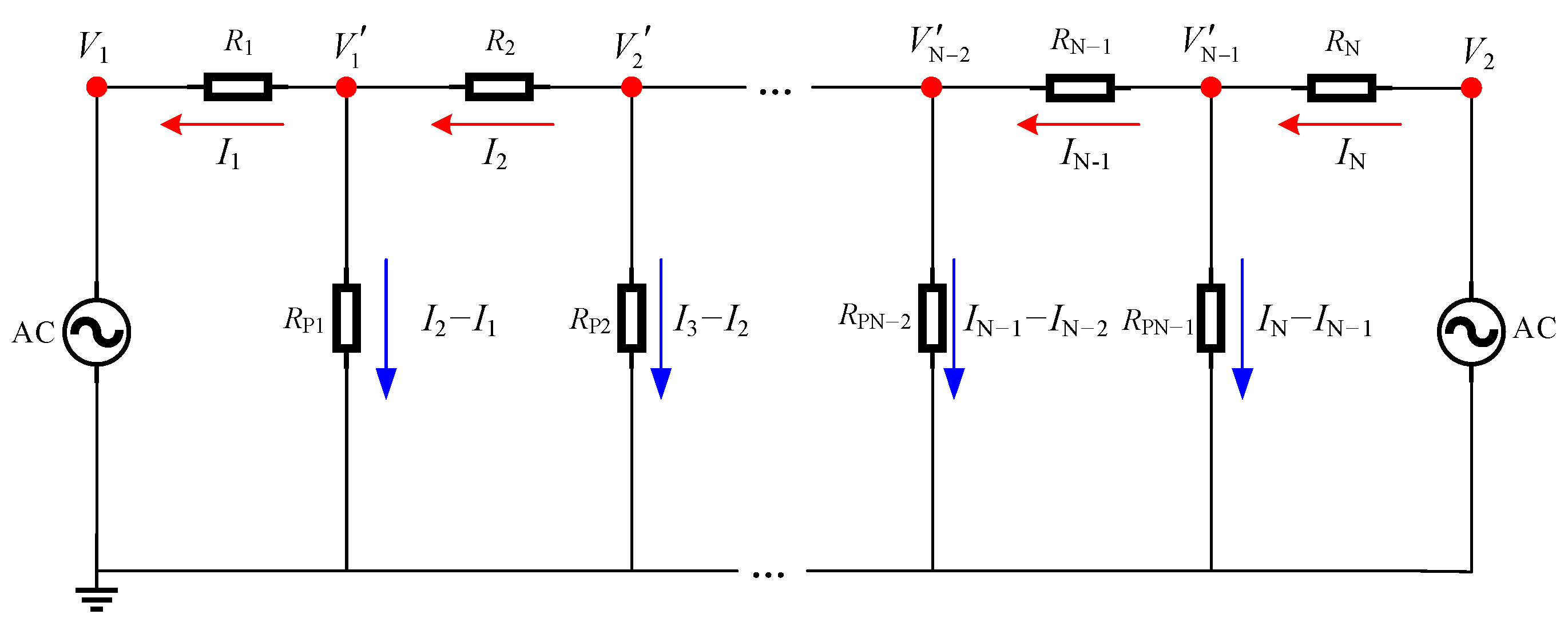

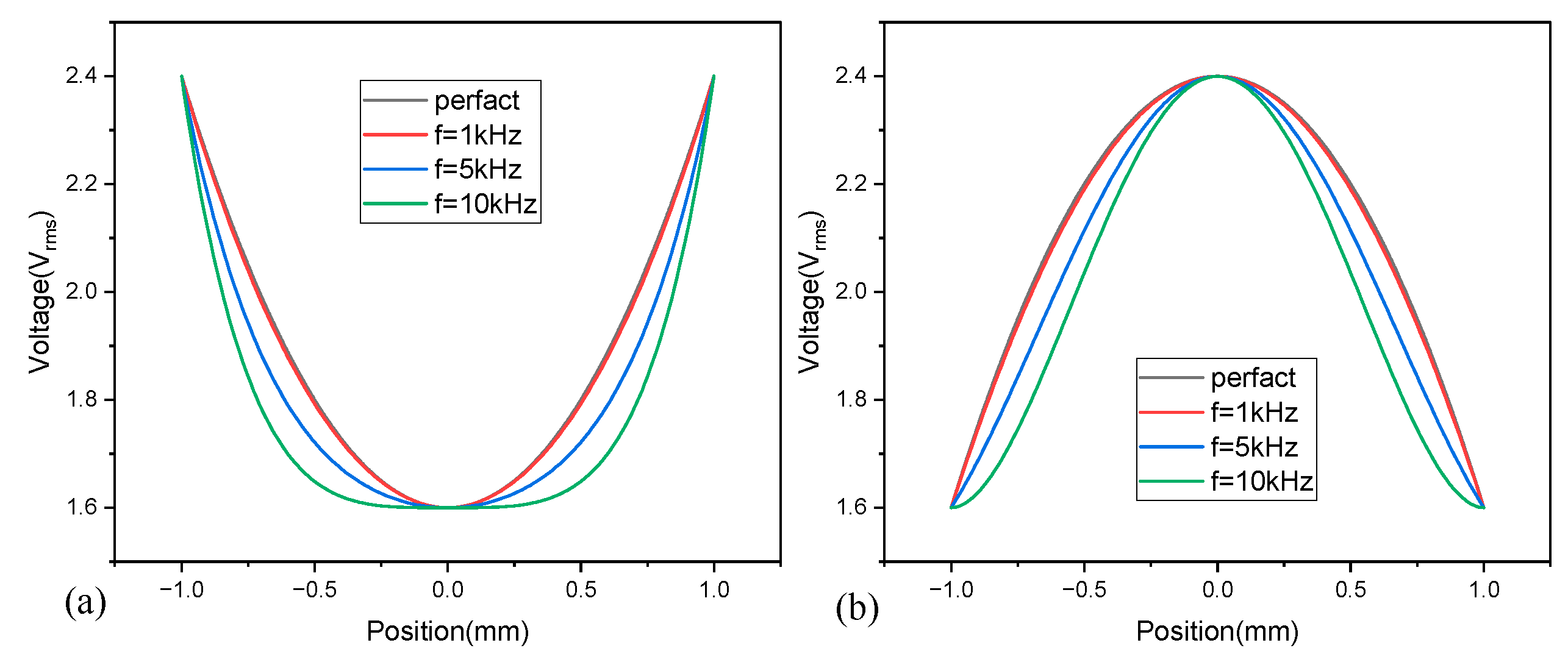

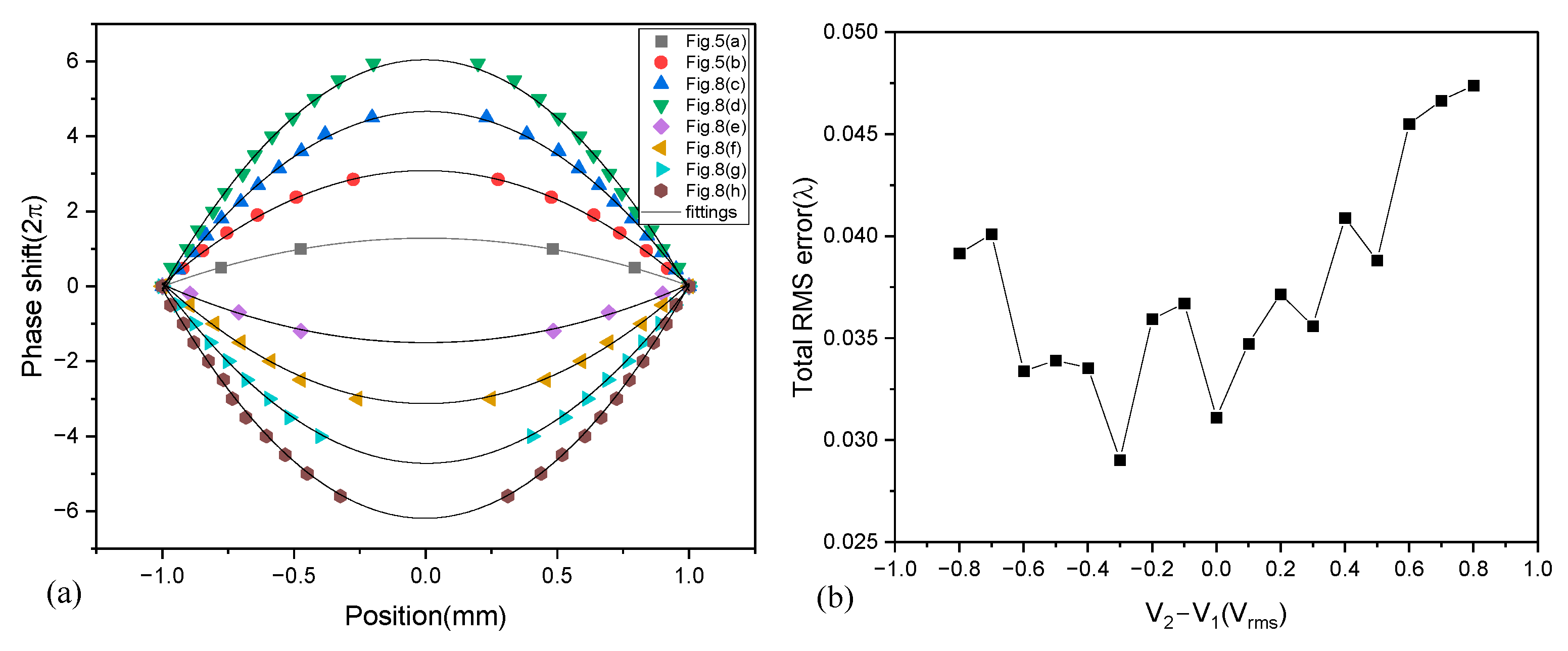

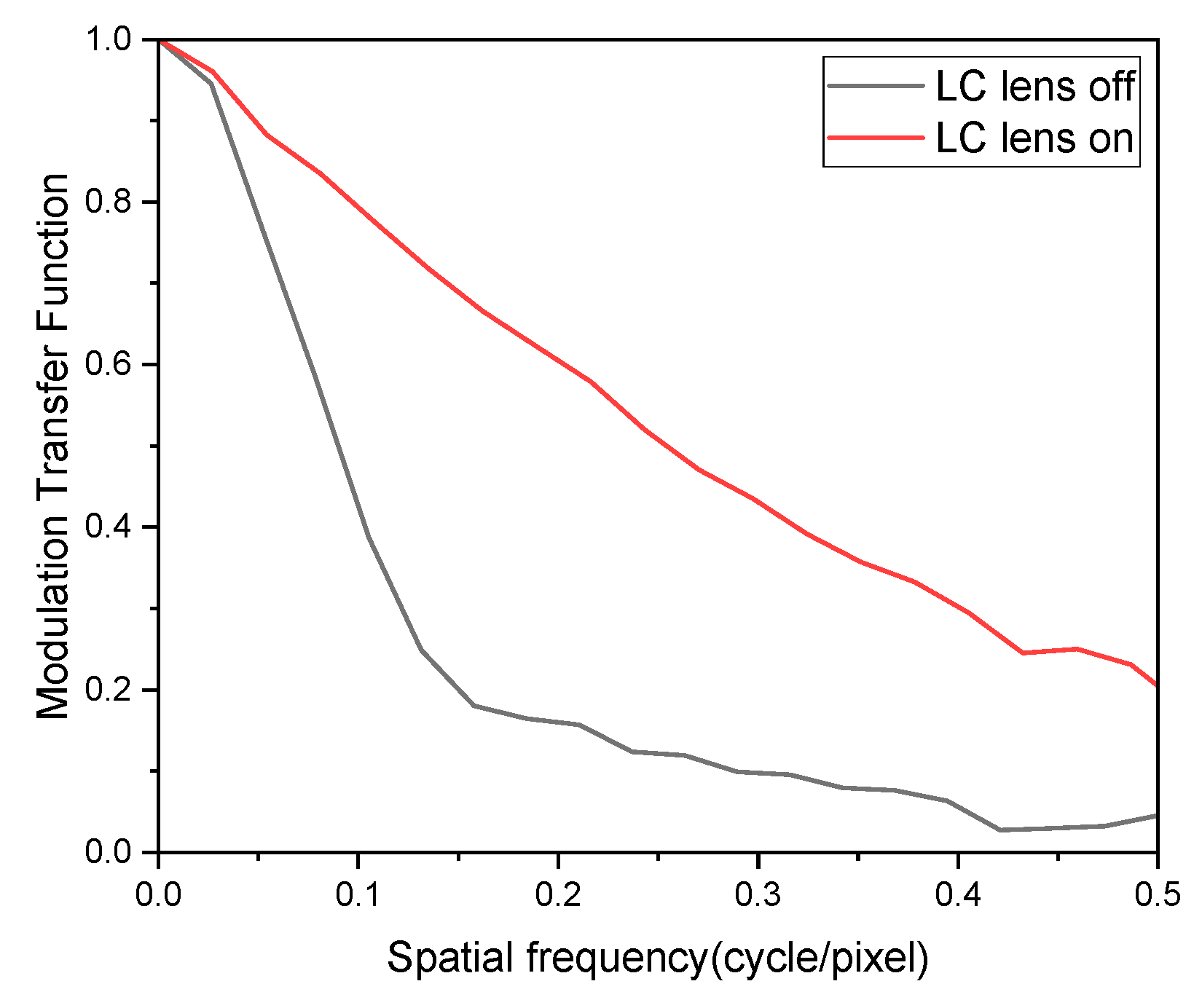

2. Principle

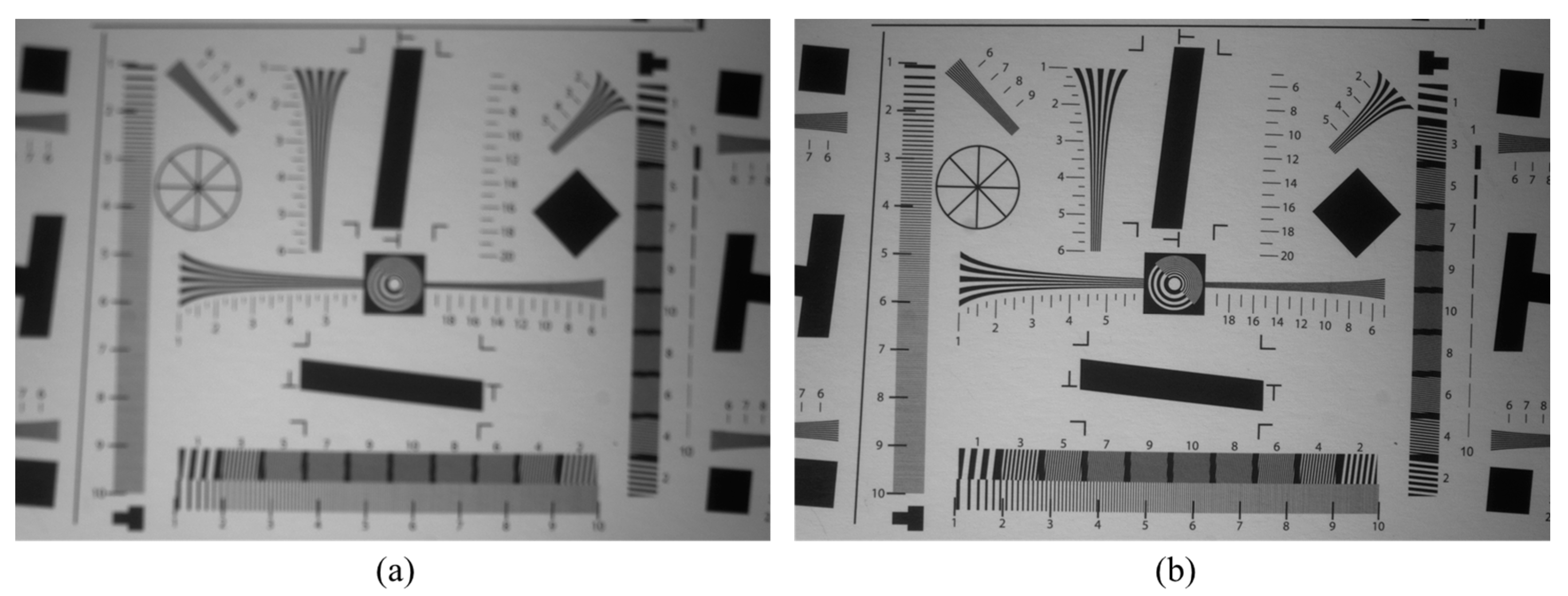

3. Experiments and Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kumar, A.; Singh, D.P.; Singh, G. Recent progress and future perspectives on carbon-nanomaterial-dispersed liquid crystal composites. J. Phys. D Appl. Phys. 2021, 55, 083002. [Google Scholar] [CrossRef]

- Khoo, I.C. Nonlinear optics of liquid crystalline materials. Phys. Rep. 2009, 471, 221–267. [Google Scholar] [CrossRef]

- Choudhary, A.; Singh, G.; Biradar, A.M. Advances in gold nanoparticle–liquid crystal composites. Nanoscale 2014, 6, 7743–7756. [Google Scholar] [CrossRef] [PubMed]

- Singh, G.; Fisch, M.; Kumar, S. Emissivity and electrooptical properties of semiconducting quantum dots/rods and liquid crystal composites: A review. Rep. Prog. Phys. 2016, 79, 056502. [Google Scholar] [CrossRef] [PubMed]

- Singh, G. Recent advances on cadmium free quantum dots-liquid crystal nanocomposites. Appl. Mater. Today 2020, 21, 100840. [Google Scholar] [CrossRef]

- Sato, S. Liquid-Crystal Lens-Cells with Variable Focal Length. Jpn. J. Appl. Phys. 1979, 18, 1679–1684. [Google Scholar] [CrossRef]

- Ye, M.; Sato, S. Liquid crystal lens with focus movable along and off axis. Opt. Commun. 2003, 225, 277–280. [Google Scholar] [CrossRef]

- Pishnyak, O.; Sato, S.; Lavrentovich, O.D. Electrically tunable lens based on a dual-frequency nematic liquid crystal. Appl. Opt. 2006, 45, 4576–4582. [Google Scholar] [CrossRef]

- Lin, Y.-H.; Chen, H.-S.; Lin, H.-C.; Tsou, Y.-S.; Hsu, H.-K.; Li, W.-Y. Polarizer-free and fast response microlens arrays using polymer-stabilized blue phase liquid crystals. Appl. Phys. Lett. 2010, 96, 113505. [Google Scholar] [CrossRef]

- Lin, H.-C.; Lin, Y.-H. An Electrically Tunable Focusing Pico-Projector Adopting a Liquid Crystal Lens. Jpn. J. Appl. Phys. 2010, 49, 102502. [Google Scholar] [CrossRef]

- Ren, H.; Xu, S.; Wu, S.-T. Polymer-stabilized liquid crystal microlens array with large dynamic range and fast response time. Opt. Lett. 2013, 38, 3144–3147. [Google Scholar] [CrossRef] [PubMed]

- Kawamura, M.; Nakamura, K.; Sato, S. Liquid-crystal micro-lens array with two-divided and tetragonally hole-patterned electrodes. Opt. Express 2013, 21, 26520–26526. [Google Scholar] [CrossRef] [PubMed]

- Algorri, J.F.; Urruchi, V.; García-Cámara, B.; Sánchez-Pena, J.M. Liquid Crystal Lensacons, Logarithmic and Linear Axicons. Materials 2014, 7, 2593–2604. [Google Scholar] [CrossRef] [PubMed]

- Algorri, J.F.; del Pozo, V.U.; Sanchez-Pena, J.M.; Oton, J.M. An Autostereoscopic Device for Mobile Applications Based on a Liquid Crystal Microlens Array and an OLED Display. J. Disp. Technol. 2014, 10, 713–720. [Google Scholar] [CrossRef]

- Chang, Y.-C.; Jen, T.-H.; Ting, C.-H.; Huang, Y.-P. High-resistance liquid-crystal lens array for rotaTable 2D/3D autostereoscopic display. Opt. Express 2014, 22, 2714–2724. [Google Scholar] [CrossRef] [PubMed]

- Shibuya, G.; Yoshida, H.; Ozaki, M. High-speed driving of liquid crystal lens with weakly conductive thin films and voltage booster. Appl. Opt. 2015, 54, 8145–8151. [Google Scholar] [CrossRef]

- Algorri, J.F.; Urruchi, V.; Bennis, N.; Sanchez-Pena, J.M.; Oton, J.M. Cylindrical Liquid Crystal Microlens Array With Rotary Optical Power and Tunable Focal Length. IEEE Electron Device Lett. 2015, 36, 582–584. [Google Scholar] [CrossRef]

- Zhang, Y.; Weng, X.; Liu, P.; Wu, C.; Sun, L.; Yan, Q.; Zhou, X.; Guo, T. Electrically high-resistance liquid crystal micro-lens arrays with high performances for integral imaging 3D display. Opt. Commun. 2020, 462, 125299. [Google Scholar] [CrossRef]

- Ye, M.; Sato, S. Optical Properties of Liquid Crystal Lens of Any Size. Jpn. J. Appl. Phys. 2002, 41, L571–L573. [Google Scholar] [CrossRef]

- Ye, M.; Wang, B.; Sato, S. Driving of Liquid Crystal Lens without Disclination Occurring by Applying In-Plane Electric Field. Jpn. J. Appl. Phys. 2003, 42, 5086–5089. [Google Scholar] [CrossRef]

- Wang, B.; Ye, M.; Sato, S. Liquid crystal lens with focal length variable from negative to positive values. IEEE Photonics Technol. Lett. 2005, 18, 79–81. [Google Scholar] [CrossRef]

- Ye, M.; Wang, B.; Kawamura, M.; Sato, S. Fast switching between negative and positive power of liquid crystal lens. Electron. Lett. 2007, 43, 474–476. [Google Scholar] [CrossRef]

- Lin, H.-C.; Lin, Y.-H. A fast response and large electrically tunable-focusing imaging system based on switching of two modes of a liquid crystal lens. Appl. Phys. Lett. 2010, 97, 063505. [Google Scholar] [CrossRef]

- Lin, H.-C.; Chen, M.-S.; Lin, Y.-H. A Review of Electrically Tunable Focusing Liquid Crystal Lenses. Trans. Electr. Electron. Mater. 2011, 12, 234–240. [Google Scholar] [CrossRef]

- Lin, Y.-H.; Wang, Y.-J.; Reshetnyak, V. Liquid crystal lenses with tunable focal length. Liq. Cryst. Rev. 2017, 5, 111–143. [Google Scholar] [CrossRef]

- Naumov, A.F.; Loktev, M.Y.; Guralnik, I.R.; Vdovin, G. Liquid-crystal adaptive lenses with modal control. Opt. Lett. 1998, 23, 992–994. [Google Scholar] [CrossRef]

- Naumov, A.F.; Love, G.D.; Loktev, M.Y.; Vladimirov, F.L. Control optimization of spherical modal liquid crystal lenses. Opt. Express 1999, 4, 344–352. [Google Scholar] [CrossRef]

- Ye, M.; Wang, B.; Sato, S. Realization of liquid crystal lens of large aperture and low driving voltages using thin layer of weakly conductive material. Opt. Express 2008, 16, 4302–4308. [Google Scholar] [CrossRef]

- Kotova, S.P.; Patlan, V.V.; Samagin, S.A. Tunable liquid-crystal focusing device. 1. Theory. Quantum Electron. 2011, 41, 58–64. [Google Scholar] [CrossRef]

- Kotova, S.P.; Patlan, V.V.; Samagin, S.A. Tunable liquid-crystal focusing device. 2. Experiment. Quantum Electron. 2011, 41, 65–70. [Google Scholar] [CrossRef]

- Algorri, J.F.; Morawiak, P.; Zografopoulos, D.C.; Bennis, N.; Spadlo, A.; Rodriguez-Cobo, L.; Jaroszewicz, L.R.; Sanchez-Pena, J.M.; Lopez-Higuera, J.M. Multifunctional light beam control device by stimuli-responsive liquid crystal micro-grating structures. Sci. Rep. 2020, 10, 13806. [Google Scholar] [CrossRef] [PubMed]

- Algorri, J.F.; Morawiak, P.; Bennis, N.; Zografopoulos, D.C.; Urruchi, V.; Rodriguez-Cobo, L.; Jaroszewicz, L.R.; Sanchez-Pena, J.M.; Lopez-Higuera, J.M. Positive-negative tunable liquid crystal lenses based on a microstructured transmission line. Sci. Rep. 2020, 10, 10153. [Google Scholar] [CrossRef] [PubMed]

- Algorri, J.F.; Morawiak, P.; Zografopoulos, D.C.; Bennis, N.; Spadlo, A.; Rodriguez-Cobo, L.; Jaroszewicz, L.R.; Sanchez-Pena, J.M.; Lopez-Higuera, J.M. Cylindrical and Powell Liquid Crystal Lenses With Positive-Negative Optical Power. IEEE Photonics Technol. Lett. 2020, 32, 1057–1060. [Google Scholar] [CrossRef]

- Bennis, N.; Jankowski, T.; Morawiak, P.; Spadlo, A.; Zografopoulos, D.C.; Sánchez-Pena, J.M.; López-Higuera, J.M.; Algorri, J.F. Aspherical liquid crystal lenses based on a variable transmission electrode. Opt. Express 2022, 30, 12237–12247. [Google Scholar] [CrossRef] [PubMed]

- Algorri, J.; Zografopoulos, D.; Rodríguez-Cobo, L.; Sánchez-Pena, J.; López-Higuera, J. Engineering Aspheric Liquid Crystal Lenses by Using the Transmission Electrode Technique. Crystals 2020, 10, 835. [Google Scholar] [CrossRef]

- Pusenkova, A.; Sova, O.; Galstian, T. Electrically variable liquid crystal lens with spiral electrode. Opt. Commun. 2021, 508, 127783. [Google Scholar] [CrossRef]

- Stevens, J.; Galstian, T. Electrically tunable liquid crystal lens with a serpentine electrode design. Opt. Lett. 2022, 47, 910–912. [Google Scholar] [CrossRef]

- Wang, B.; Ye, M.; Honma, M.; Nose, T.; Sato, S. Liquid Crystal Lens with Spherical Electrode. Jpn. J. Appl. Phys. 2002, 41, L1232–L1233. [Google Scholar] [CrossRef]

- Lin, C.-H.; Chen, C.-H.; Chiang, R.-H.; Jiang, I.-M.; Kuo, C.-T.; Huang, C.-Y. Dual-Frequency Liquid-Crystal Lenses Based on a Surface-Relief Dielectric Structure on an Electrode. IEEE Photonics Technol. Lett. 2011, 23, 1875–1877. [Google Scholar] [CrossRef]

- Wang, B.; Ye, M.; Sato, S. Lens of electrically controllable focal length made by a glass lens and liquid-crystal layers. Appl. Opt. 2004, 43, 3420–3425. [Google Scholar] [CrossRef]

- Ren, H.; Fan, Y.-H.; Gauza, S.; Wu, S.-T. Tunable-focus flat liquid crystal spherical lens. Appl. Phys. Lett. 2004, 84, 4789–4791. [Google Scholar] [CrossRef]

- Ren, H.; Wu, S.-T. Adaptive liquid crystal lens with large focal length tunability. Opt. Express 2006, 14, 11292–11298. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.-P.; Chen, C.-W.; Shen, T.-C. High resolution autostereoscopic 3D display with scanning multi-electrode driving liquid crystal (MeD-LC) Lens. In 2009 SID International Symposium Digest of Technical Papers, Vol XL, Books I–III; Society for Information Display: San Jose, CA, USA, 2009; pp. 336–339. [Google Scholar]

- Beeckman, J.; Yang, T.-H.; Nys, I.; George, J.P.; Lin, T.-H.; Neyts, K. Multi-electrode tunable liquid crystal lenses with one lithography step. Opt. Lett. 2018, 43, 271–274. [Google Scholar] [CrossRef] [PubMed]

- Shen, T.; Zheng, J.; Shen, C.; Wang, X.; Liu, Y. One-dimensional straight-stripe-electrode tunable self-focusing cylindrical liquid crystal lens to realize the achromatic function in time domain. Optik 2022, 260, 168962. [Google Scholar] [CrossRef]

- Li, L.; Bryant, D.; Bos, P.J. Liquid crystal lens with concentric electrodes and inter-electrode resistors. Liq. Cryst. Rev. 2014, 2, 130–154. [Google Scholar] [CrossRef]

- Feng, W.; Liu, Z.; Ye, M. Positive-negative tunable cylindrical liquid crystal lenses. Optik 2022, 266, 169613. [Google Scholar] [CrossRef]

- Feng, W.; Ye, M. Positive-Negative Tunable Liquid Crystal Lens of Rectangular Aperture. IEEE Photonics Technol. Lett. 2022, 34, 795–798. [Google Scholar] [CrossRef]

- Feng, W.; Liu, Z.; Ye, M. Liquid crystal lens array with positive and negative focal lengths. Opt. Express 2022, 30, 28941. [Google Scholar] [CrossRef]

- Feng, W.; Liu, Z.Q.; Xu, L.; Li, H.; Ye, M. A design method of high-performance liquid crystal lens. Acta Opt. Sin. 2023, 43, 0223001. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, W.; Liu, Z.; Liu, H.; Ye, M. Design of Tunable Liquid Crystal Lenses with a Parabolic Phase Profile. Crystals 2023, 13, 8. https://doi.org/10.3390/cryst13010008

Feng W, Liu Z, Liu H, Ye M. Design of Tunable Liquid Crystal Lenses with a Parabolic Phase Profile. Crystals. 2023; 13(1):8. https://doi.org/10.3390/cryst13010008

Chicago/Turabian StyleFeng, Wenbin, Zhiqiang Liu, Hao Liu, and Mao Ye. 2023. "Design of Tunable Liquid Crystal Lenses with a Parabolic Phase Profile" Crystals 13, no. 1: 8. https://doi.org/10.3390/cryst13010008

APA StyleFeng, W., Liu, Z., Liu, H., & Ye, M. (2023). Design of Tunable Liquid Crystal Lenses with a Parabolic Phase Profile. Crystals, 13(1), 8. https://doi.org/10.3390/cryst13010008