Effects of Nitrogen Content and Strain Rate on the Tensile Behavior of High-Nitrogen and Nickel-Free Austenitic Stainless Steel

Abstract

1. Introduction

2. Experimental Procedures

3. Results

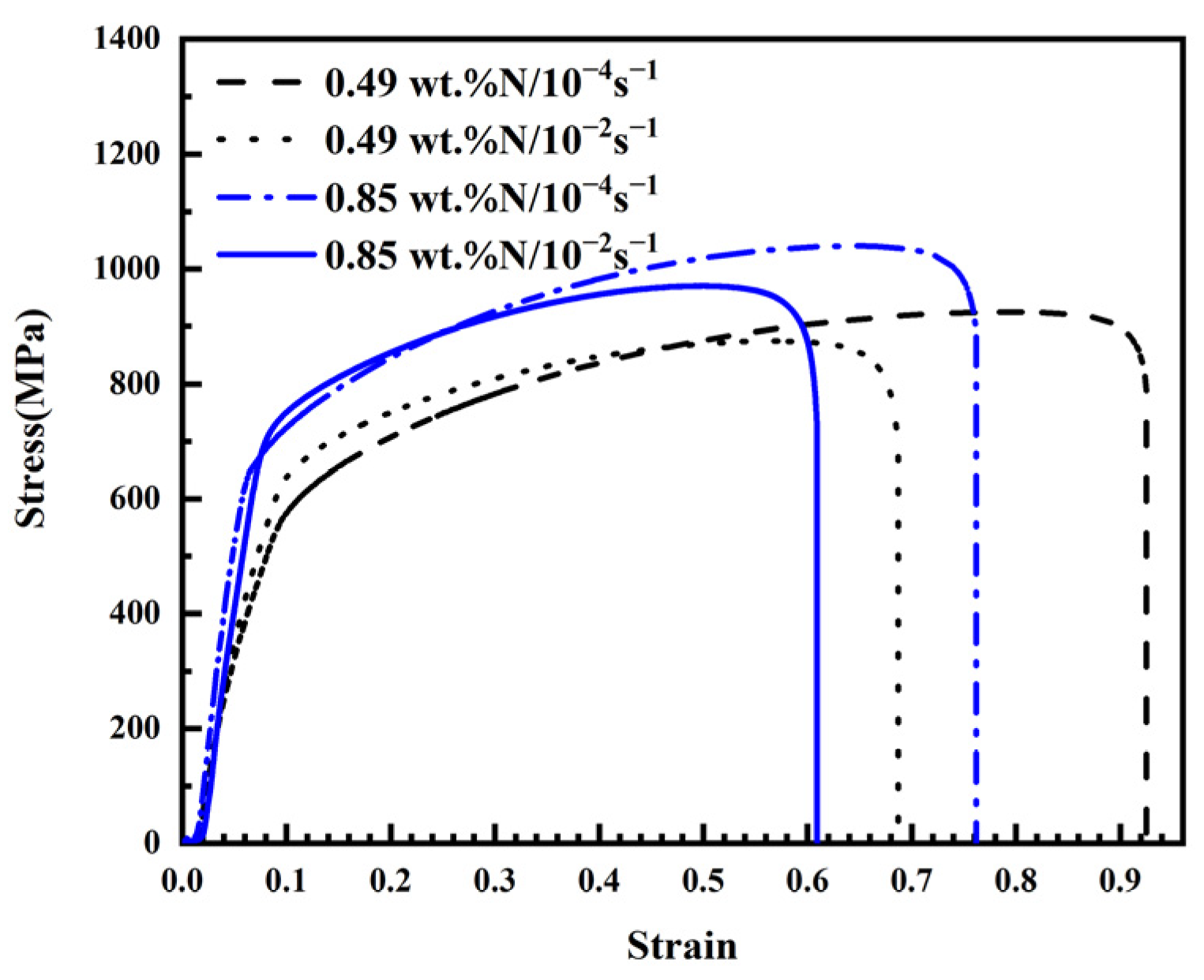

3.1. Mechanical Properties

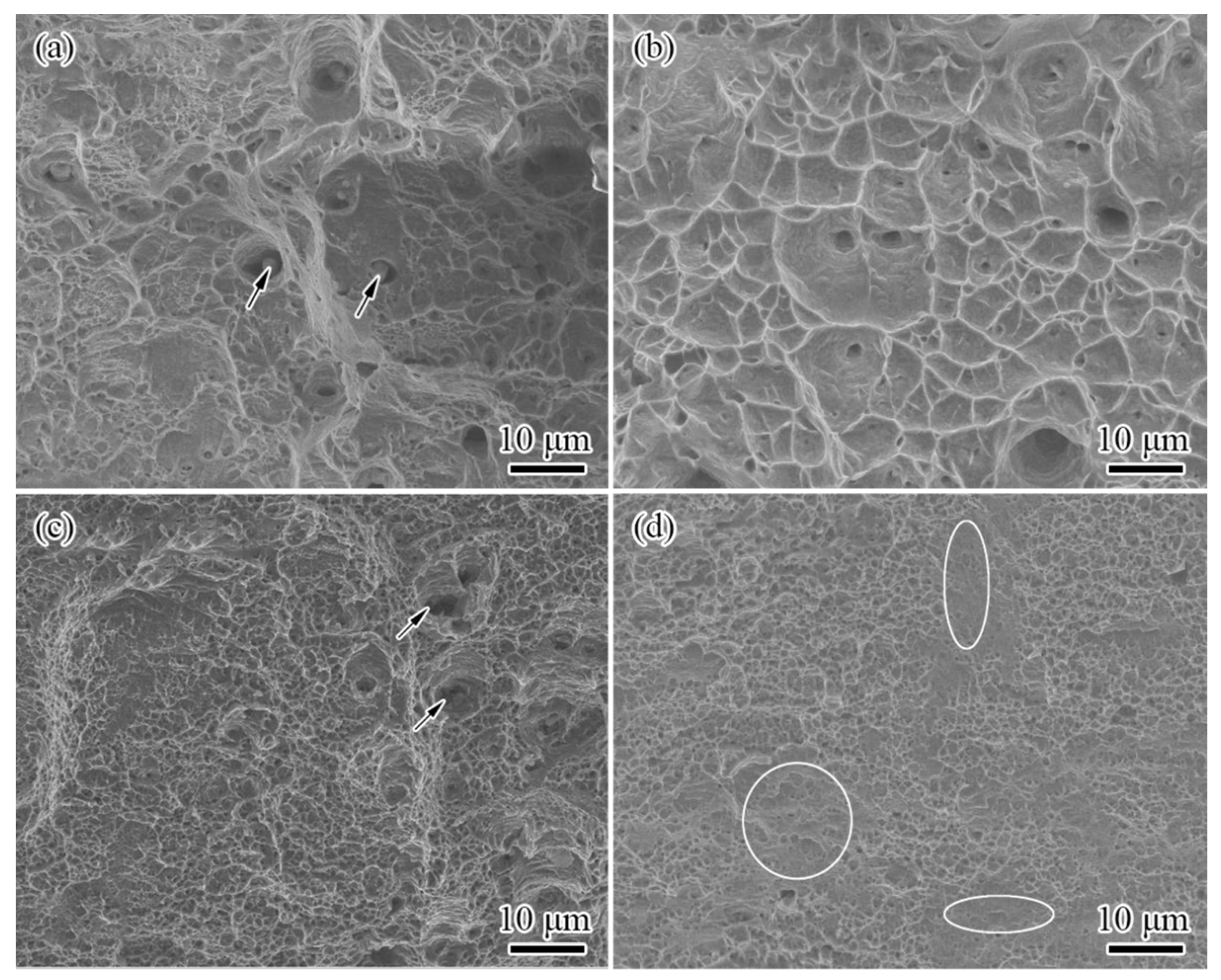

3.2. Fracture Surface Features

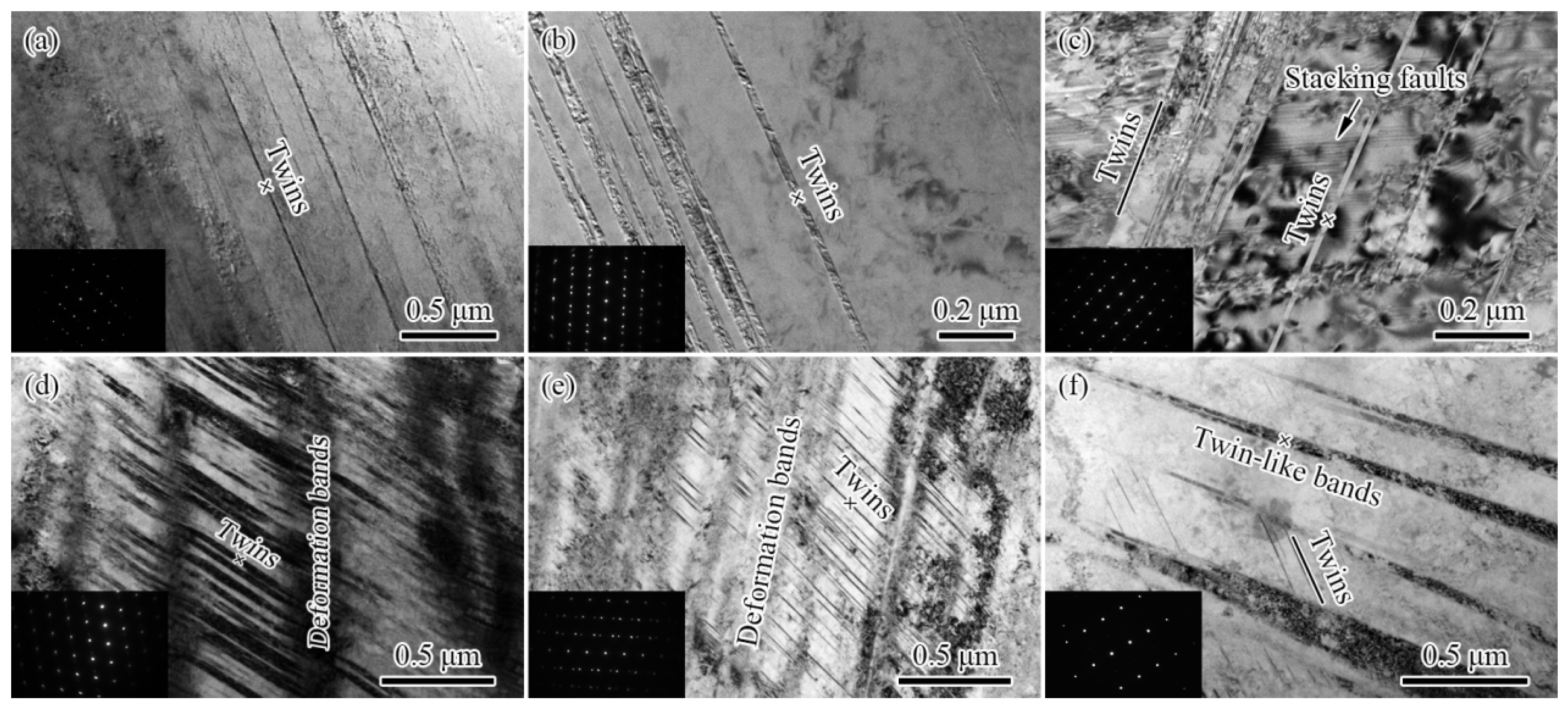

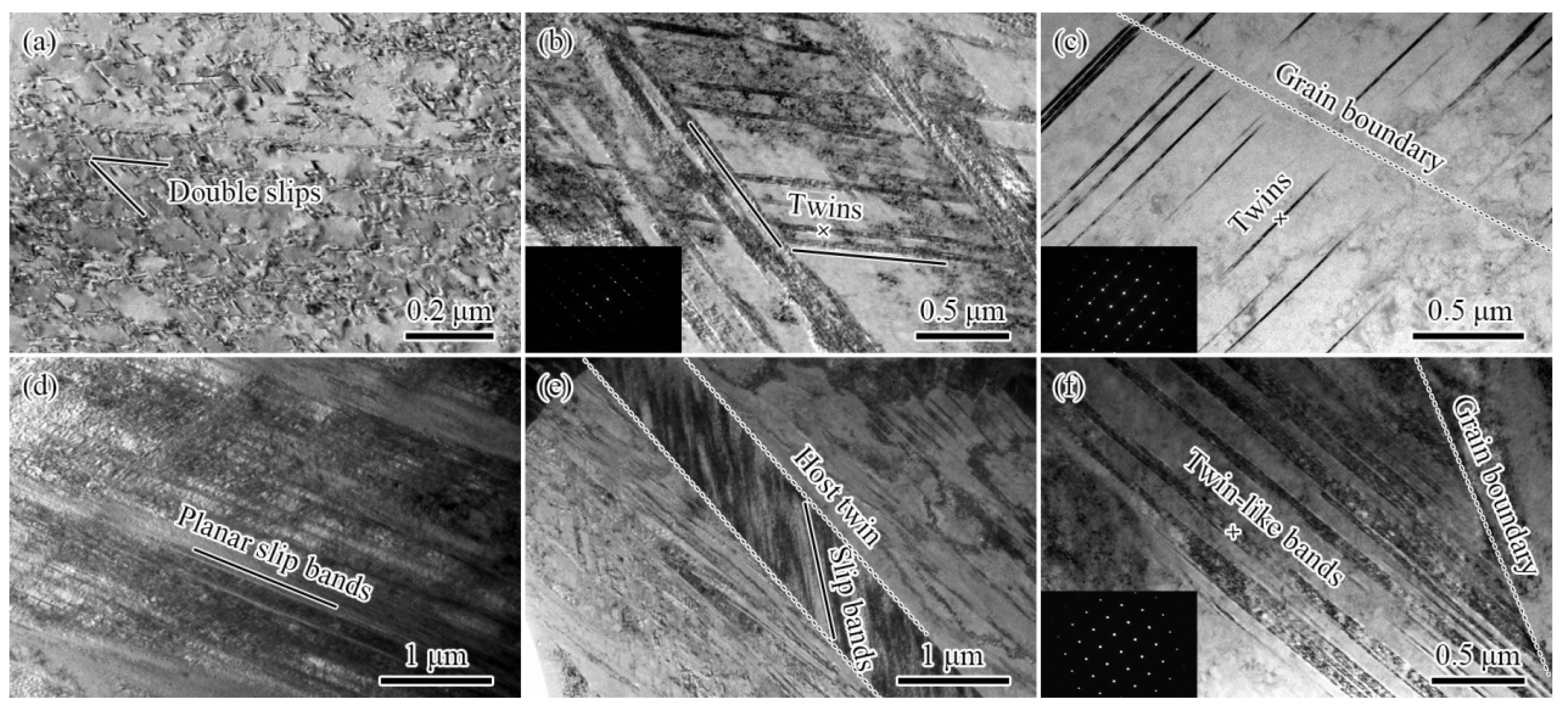

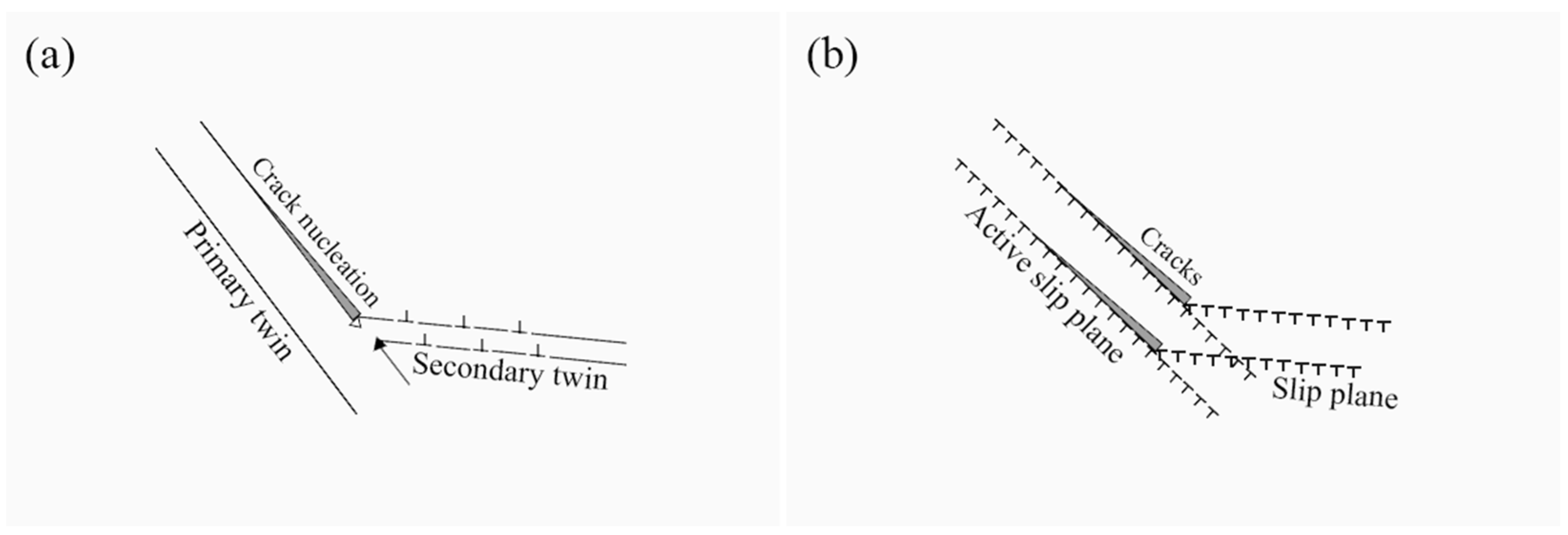

3.3. Deformation Microstructures

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ma, T.; Wan, P.; Cui, Y.; Zhang, G.; Li, J.; Liu, J.; Ren, Y.; Yang, K.; Lu, L. Cytocompatibility of High Nitrogen Nickel-Free Stainless Steel for Orthopedic Implants. J. Mater. Sci. Technol. 2012, 28, 647–653. [Google Scholar] [CrossRef]

- Yuan, J.P.; Li, W.; Chen, S.X.; Lu, H.X. Research and development of high nitrogen nickel-free austenitic stainless steel. Foundry 2012, 61, 1308–1312. (In Chinese) [Google Scholar]

- Shi, F.; Gao, R.H.; Guan, X.J.; Liu, C.M.; Li, X.W. Application of grain boundary engineering to improve intergranular corro-sion resistance in a Fe–Cr–Mn–Mo–N high-nitrogen and nickel-free austenitic stainless steel. Acta Metall. Sin. (Engl. Lett.) 2020, 33, 789–798. [Google Scholar] [CrossRef]

- Kim, J.-K.; Kwon, M.-H.; De Cooman, B.C. On the deformation twinning mechanisms in twinning-induced plasticity steel. Acta Mater. 2017, 141, 444–455. [Google Scholar] [CrossRef]

- Li, H.; Jiang, Z.; Feng, H.; Zhang, S.; Li, L.; Han, P.; Misra, R.; Li, J. Microstructure, mechanical and corrosion properties of friction stir welded high nitrogen nickel-free austenitic stainless steel. Mater. Des. 2015, 84, 291–299. [Google Scholar] [CrossRef]

- Shi, F.; Tian, P.; Jia, N.; Ye, Z.; Qi, Y.; Liu, C.; Li, X. Improving intergranular corrosion resistance in a nickel-free and manganese-bearing high-nitrogen austenitic stainless steel through grain boundary character distribution optimization. Corros. Sci. 2016, 107, 49–59. [Google Scholar] [CrossRef]

- Simmons, J. Overview: High-nitrogen alloying of stainless steels. Mater. Sci. Eng. A 1996, 207, 159–169. [Google Scholar] [CrossRef]

- Yoon, Y.-S.; Ha, H.-Y.; Lee, T.-H.; Kim, S. Effect of N and C on stress corrosion cracking susceptibility of austenitic Fe18Cr10Mn-based stainless steels. Corros. Sci. 2014, 80, 28–36. [Google Scholar] [CrossRef]

- Simmons, J. Strain hardening and plastic flow properties of nitrogen-alloyed Fe-17Cr-(8–10)Mn-5Ni austenitic stainless steels. Acta Mater. 1997, 45, 2467–2475. [Google Scholar] [CrossRef]

- Müllner, P.; Solenthaler, C.; Uggowitzer, P.; Speidel, M. On the effect of nitrogen on the dislocation structure of austenitic stainless steel. Mater. Sci. Eng. A 1993, 164, 164–169. [Google Scholar] [CrossRef]

- Dai, Q.; Yuan, Z.; Chen, X.; Chen, K. High-cycle fatigue behavior of high-nitrogen austenitic stainless steel. Mater. Sci. Eng. A 2009, 517, 257–260. [Google Scholar] [CrossRef]

- Raj, B.; Mudali, U.K. Materials development and corrosion problems in nuclear fuel reprocessing plants. Prog. Nucl. Energy 2006, 48, 283–313. [Google Scholar] [CrossRef]

- Uggowitzer, P.; Magdowski, R.; Speidel, M.O. High Nitrogen Steels. Nickel Free High Nitrogen Austenitic Steels. ISIJ Int. 1996, 36, 901–908. [Google Scholar] [CrossRef]

- Lo, K.H.; Shek, C.H.; Lai, J.K.L. Recent developments in stainless steels. Mater. Sci. Eng. R Rep. 2009, 65, 39–104. [Google Scholar] [CrossRef]

- Baba, H.; Kodama, T.; Katada, Y. Role of nitrogen on the corrosion behavior of austenitic stainless steels. Corros. Sci. 2002, 44, 2393–2407. [Google Scholar] [CrossRef]

- Masumura, T.; Tsuchiyama, T. Effect of Carbon and Nitrogen on Work-hardening Behavior in Metastable Austenitic Stainless Steel. ISIJ Int. 2021, 61, 617–624. [Google Scholar] [CrossRef]

- Byrnes, M.; Grujicic, M.; Owen, W. Nitrogen strengthening of a stable austenitic stainless steel. Acta Met. 1987, 35, 1853–1862. [Google Scholar] [CrossRef]

- Soussan, A.; Degallaix, S.; Magnin, T. Work-hardening behaviour of nitrogen-alloyed austenitic stainless steels. Mater. Sci. Eng. A 1991, 142, 169–176. [Google Scholar] [CrossRef]

- Wang, S.T.; Yang, K.; Shan, Y.Y.; Li, L.F. Effect of Cold Deformation on Microstructure and Mechanical Behavior of High Nitrogen Austenitic Stainless Steel. Acta Metall. Sin. 2007, 43, 713–718. [Google Scholar]

- Shin, J.-H.; Lee, J.-W. Effects of twin intersection on the tensile behavior in high nitrogen austenitic stainless steel. Mater. Charact. 2014, 91, 19–25. [Google Scholar] [CrossRef]

- Sun, S.C.; Mu, J.W.; Jiang, Z.H.; Ji, C.T.; Lian, J.S.; Jiang, Q. Effect of cold rolling on tensile properties and microstructure of high nitrogen alloyed austenitic steel. Mater. Sci. Technol. 2013, 30, 146–151. [Google Scholar] [CrossRef]

- Saller, G.; Spiradek-Hahn, K.; Scheu, C.; Clemens, H. Microstructural evolution of Cr–Mn–N austenitic steels during cold work hardening. Mater. Sci. Eng. A 2006, 427, 246–254. [Google Scholar] [CrossRef]

- Shao, C.W.; Shi, F.; Guo, W.W.; Li, X.W. Plastic deformation and damage behaviors of Fe-18Cr-18Mn-0.63 N high-nitrogen austenitic stainless steel under uniaxial tension and compression. Mater. Trans. 2015, 56, 46–53. [Google Scholar] [CrossRef]

- Xiao, G.H.; Tao, N.R.; Lu, K. Effects of strain, strain rate and temperature on deformation twinning in a Cu–Zn alloy. Scr. Mater. 2008, 59, 975–978. [Google Scholar] [CrossRef]

- Jin, Z.; Bieler, T.R. An in-situ observation of mechanical twin nucleation and propagation in TiAl. Philos. Mag. A 1995, 71, 925–947. [Google Scholar] [CrossRef]

- Wang, Z.; Han, D.; Li, X. Competitive effect of stacking fault energy and short-range clustering on the plastic deformation behavior of Cu-Ni alloys. Mater. Sci. Eng. A 2017, 679, 484–492. [Google Scholar] [CrossRef]

- Karaman, I.; Sehitoglu, H.; Maier, H.; Chumlyakov, Y. Competing mechanisms and modeling of deformation in austenitic stainless steel single crystals with and without nitrogen. Acta Mater. 2001, 49, 3919–3933. [Google Scholar] [CrossRef]

- Gavriljuk, V.; Petrov, Y.; Shanina, B. Effect of nitrogen on the electron structure and stacking fault energy in austenitic steels. Scr. Mater. 2006, 55, 537–540. [Google Scholar] [CrossRef]

- Byun, T. On the stress dependence of partial dislocation separation and deformation microstructure in austenitic stainless steels. Acta Mater. 2003, 51, 3063–3071. [Google Scholar] [CrossRef]

- Lee, T.-H.; Oh, C.-S.; Kim, S.-J.; Takaki, S. Deformation twinning in high-nitrogen austenitic stainless steel. Acta Mater. 2007, 55, 3649–3662. [Google Scholar] [CrossRef]

- Singh, S.R.; Howe, J.M. Effect of Ta on twinning in TiAl. Scr. Metall. Mater. 1991, 25, 485–490. [Google Scholar] [CrossRef]

- Singh, S.; Howe, J.M. Studies on the deformation behaviour of interfaces in (γ + α2) titanium aluminide by high-resolution transmission electron microscopy. Philos. Mag. Lett. 1992, 65, 233–241. [Google Scholar] [CrossRef]

- Mandal, S.; Bhaduri, A.K.; Sarma, V.S. Role of Twinning on Dynamic Recrystallization and Microstructure During Moderate to High Strain Rate Hot Deformation of a Ti-Modified Austenitic Stainless Steel. Met. Mater. Trans. A 2012, 43, 2056–2068. [Google Scholar] [CrossRef]

- Xu, M.Z.; Wang, L.J.; Wang, J.J.; Liu, C.M. Effect of nitrogen on plastic rheological behavior of New nickel-free High nitrogen austenitic Stainless Steel. J. Mater. Metall. 2011, 10, 132–135. [Google Scholar]

- Grujicic, M. Embedded-atom/Monte Carlo study of short-range order in nitrogen strengthened Fe-Ni-Cr austenite. Mater. Sci. Eng. A 1994, 177, 233–241. [Google Scholar] [CrossRef]

- Wang, W.; Chen, S.M.; Yan, W.; Zhao, L.J.; Shan, Y.Y.; Yang, K. Effect of Nitrogen on Microstructure of Cold Deformed High Nitrogen Austenitic Stainless Steel. J. Mater. Heat Treat. 2010, 31, 59–65. [Google Scholar]

- Kim, J.M.; Kim, S.J.; Kang, J.H. Effects of short-range ordering and stacking fault energy on tensile behavior of nitro-gen-containing austenitic stainless steels. Mater. Sci. Eng. A 2022, 836, 142730. [Google Scholar] [CrossRef]

- Gerold, V.; Karnthaler, H. On the origin of planar slip in F.C.C. alloys. Acta Met. 1989, 37, 2177–2183. [Google Scholar] [CrossRef]

- Saenarjhan, N.; Kang, J.-H.; Kim, S.-J. Effects of carbon and nitrogen on austenite stability and tensile deformation behavior of 15Cr-15Mn-4Ni based austenitic stainless steels. Mater. Sci. Eng. A 2018, 742, 608–616. [Google Scholar] [CrossRef]

- Han, D.; Zhang, Y.; Li, X. A crucial impact of short-range ordering on the cyclic deformation and damage behavior of face-centered cubic alloys: A case study on Cu-Mn alloys. Acta Mater. 2020, 205, 116559. [Google Scholar] [CrossRef]

- Werner, E. Solid solution and grain size hardening of nitrogen-alloyed austenitic steels. Mater. Sci. Eng. A 1988, 101, 93–98. [Google Scholar]

- Blewitt, T.H.; Coltman, R.R.; Redman, J.K. Low-Temperature Deformation of Copper Single Crystals. J. Appl. Phys. 1957, 28, 651–660. [Google Scholar] [CrossRef]

- Li, H.-B.; Jiang, Z.-H.; Shen, M.-H.; You, X.-M. High Nitrogen Austenitic Stainless Steels Manufactured by Nitrogen Gas Alloying and Adding Nitrided Ferroalloys. J. Iron Steel Res. Int. 2007, 14, 63–68. [Google Scholar] [CrossRef]

- Müllner, P. On the ductile to brittle transition in austenitic steel. Mater. Sci. Eng. A 1997, 234–236, 94–97. [Google Scholar] [CrossRef]

- Tomota, Y.; Xia, Y.; Inoue, K. Mechanism of low temperature brittle fracture in high nitrogen bearing austenitic steels. Acta Mater. 1998, 46, 1577–1587. [Google Scholar] [CrossRef]

| Cr | Mn | Mo | N | C | Fe | |

|---|---|---|---|---|---|---|

| Fe-19Cr-16Mn-2Mo-0.49N | 19.30 | 15.96 | 2.25 | 0.49 | 0.011 | Balanced |

| Fe-18Cr-16Mn-2Mo-0.85N | 18.36 | 16.52 | 2.32 | 0.85 | 0.023 | Balanced |

| Sample | Strain Rate, s−1 | Rm, MPa | Rp0.2, MPa | δ, % |

|---|---|---|---|---|

| Fe-19Cr-16Mn2Mo-0.49N | 10−4 | 930 ± 10.1 | 541 ± 3.3 | 66.86 ± 2.18 |

| 10−2 | 882 ± 13.6 | 559 ± 10.6 | 50.98 ± 1.85 | |

| Fe-18Cr-16Mn-2Mo-0.85N | 10−4 | 1037 ± 7.3 | 642 ± 6.5 | 58.01 ± 1.70 |

| 10−2 | 985 ± 17.5 | 718 ± 8.2 | 47.18 ± 1.56 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, F.; Zhang, X.; Li, T.; Guan, X.; Li, X.; Liu, C. Effects of Nitrogen Content and Strain Rate on the Tensile Behavior of High-Nitrogen and Nickel-Free Austenitic Stainless Steel. Crystals 2023, 13, 129. https://doi.org/10.3390/cryst13010129

Shi F, Zhang X, Li T, Guan X, Li X, Liu C. Effects of Nitrogen Content and Strain Rate on the Tensile Behavior of High-Nitrogen and Nickel-Free Austenitic Stainless Steel. Crystals. 2023; 13(1):129. https://doi.org/10.3390/cryst13010129

Chicago/Turabian StyleShi, Feng, Xinyue Zhang, Tianzeng Li, Xianjun Guan, Xiaowu Li, and Chunming Liu. 2023. "Effects of Nitrogen Content and Strain Rate on the Tensile Behavior of High-Nitrogen and Nickel-Free Austenitic Stainless Steel" Crystals 13, no. 1: 129. https://doi.org/10.3390/cryst13010129

APA StyleShi, F., Zhang, X., Li, T., Guan, X., Li, X., & Liu, C. (2023). Effects of Nitrogen Content and Strain Rate on the Tensile Behavior of High-Nitrogen and Nickel-Free Austenitic Stainless Steel. Crystals, 13(1), 129. https://doi.org/10.3390/cryst13010129