Phase Field Simulation Research on the Microstructural Evolution of Monocrystalline and Polycrystalline Silicon

Abstract

:1. Introduction

2. Phase Field Model

3. Determination and Simulation Calculation of Phase Field Parameters

3.1. Initial and Boundary Conditions

3.2. Material Physical Parameters

3.3. Numerical Calculation Method

4. Analysis of Simulation Results

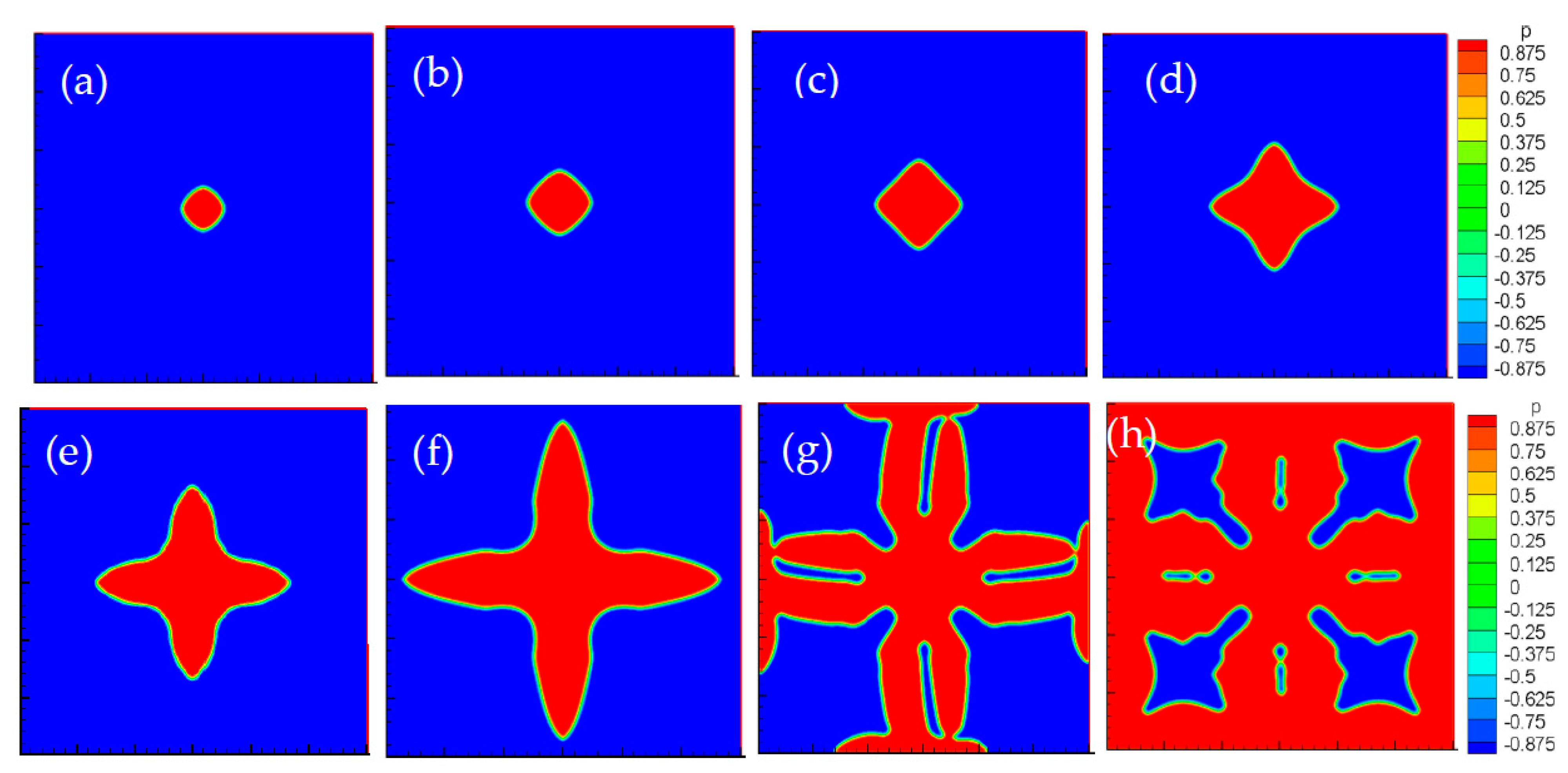

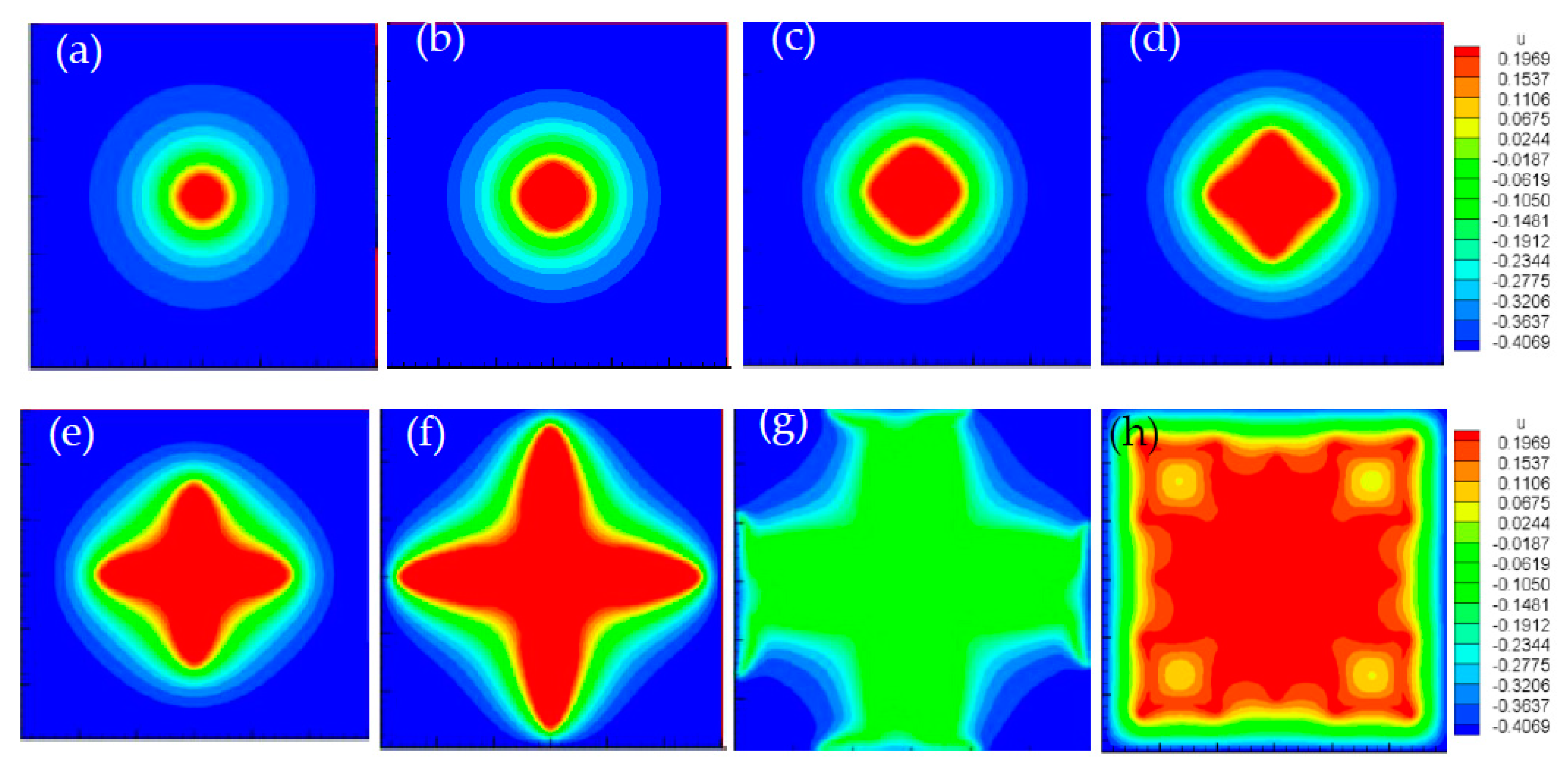

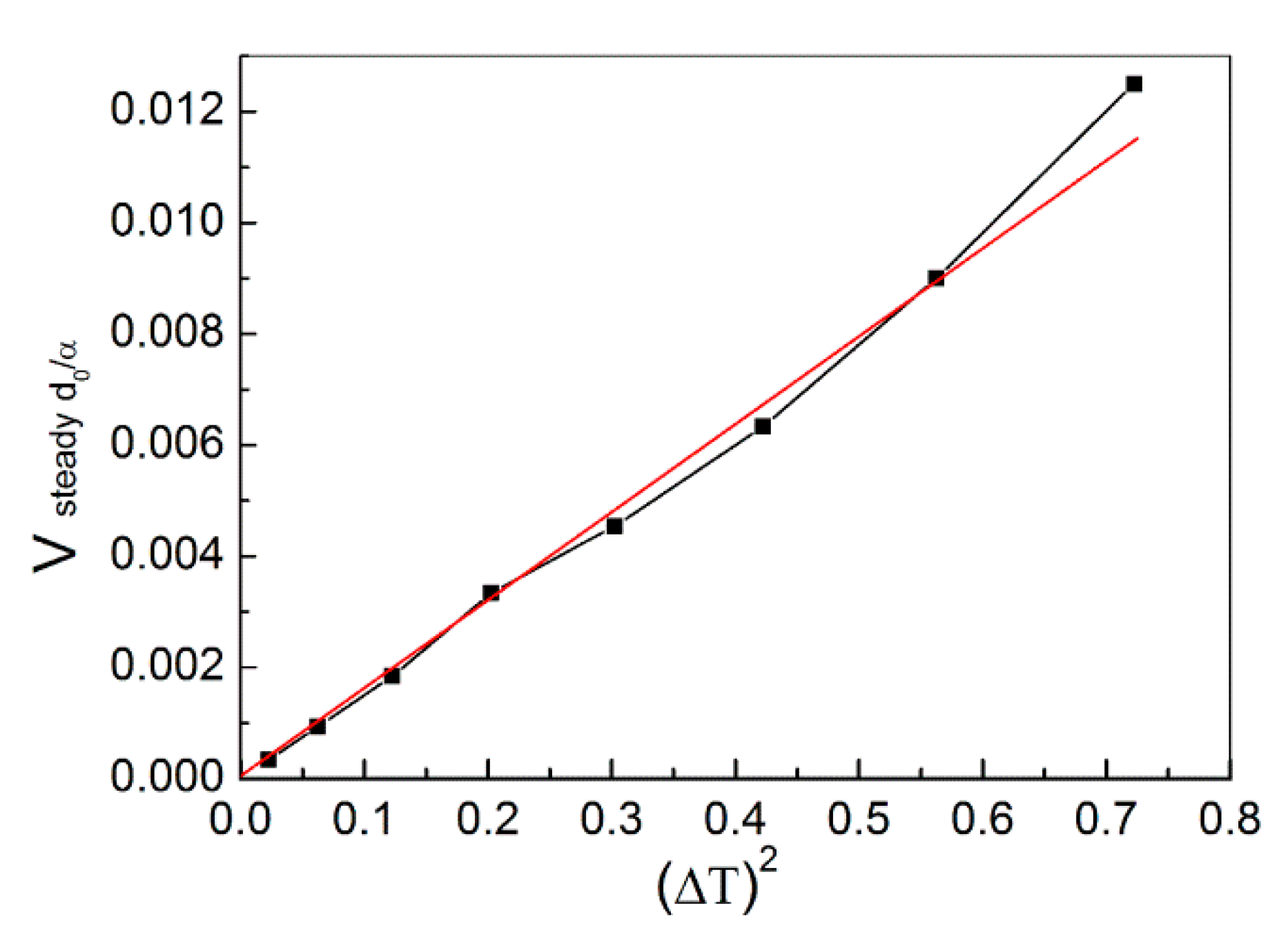

4.1. Influence of Undercooling Degree

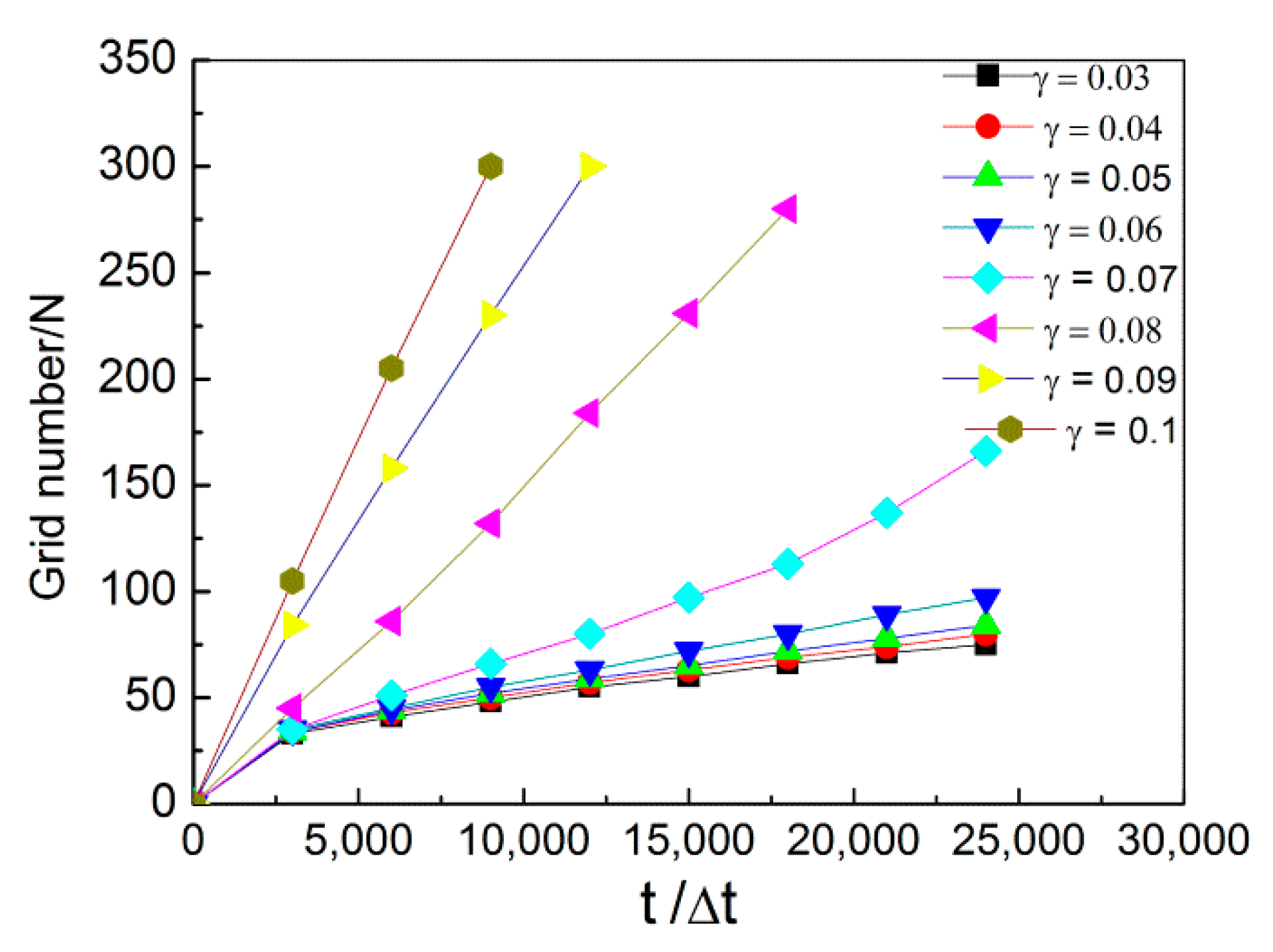

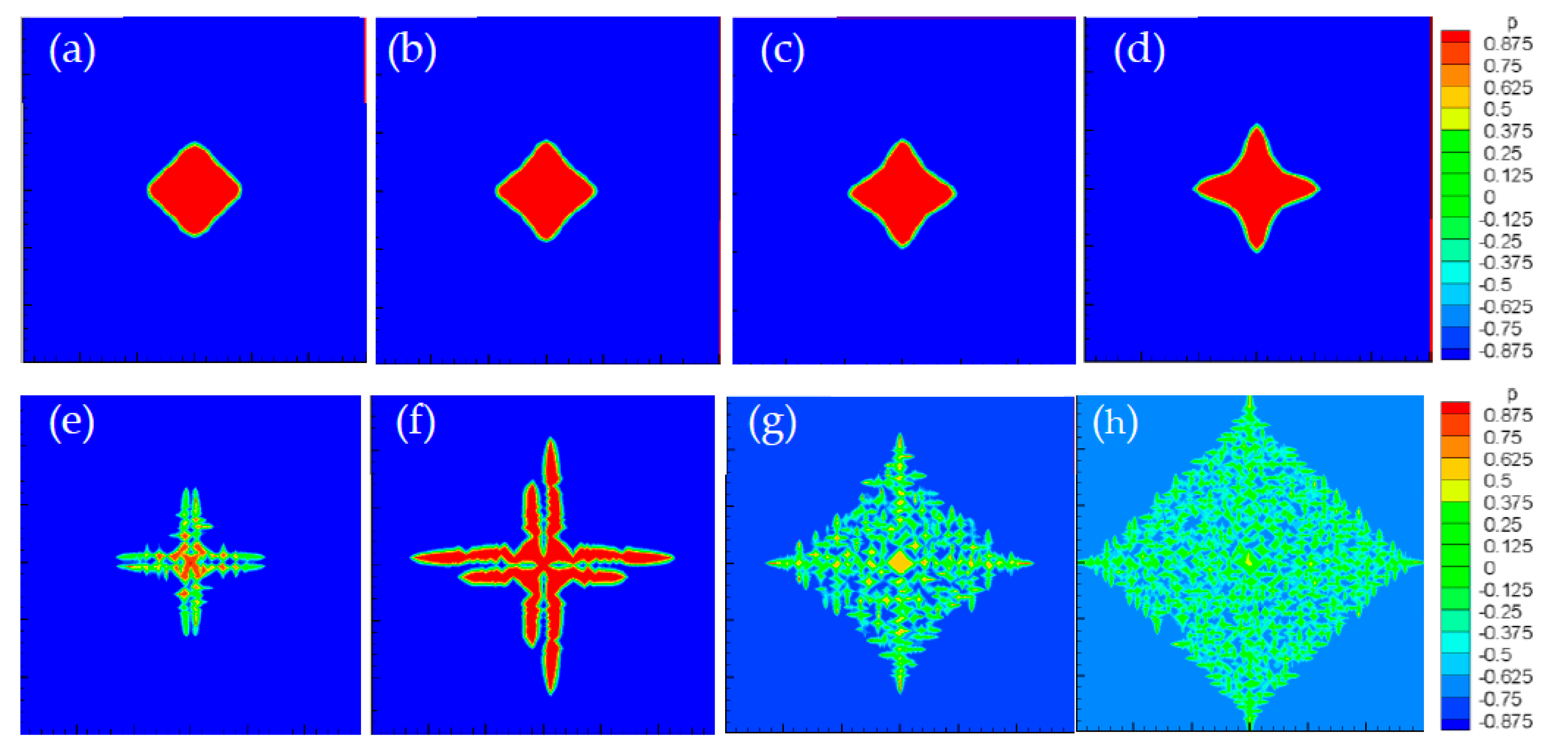

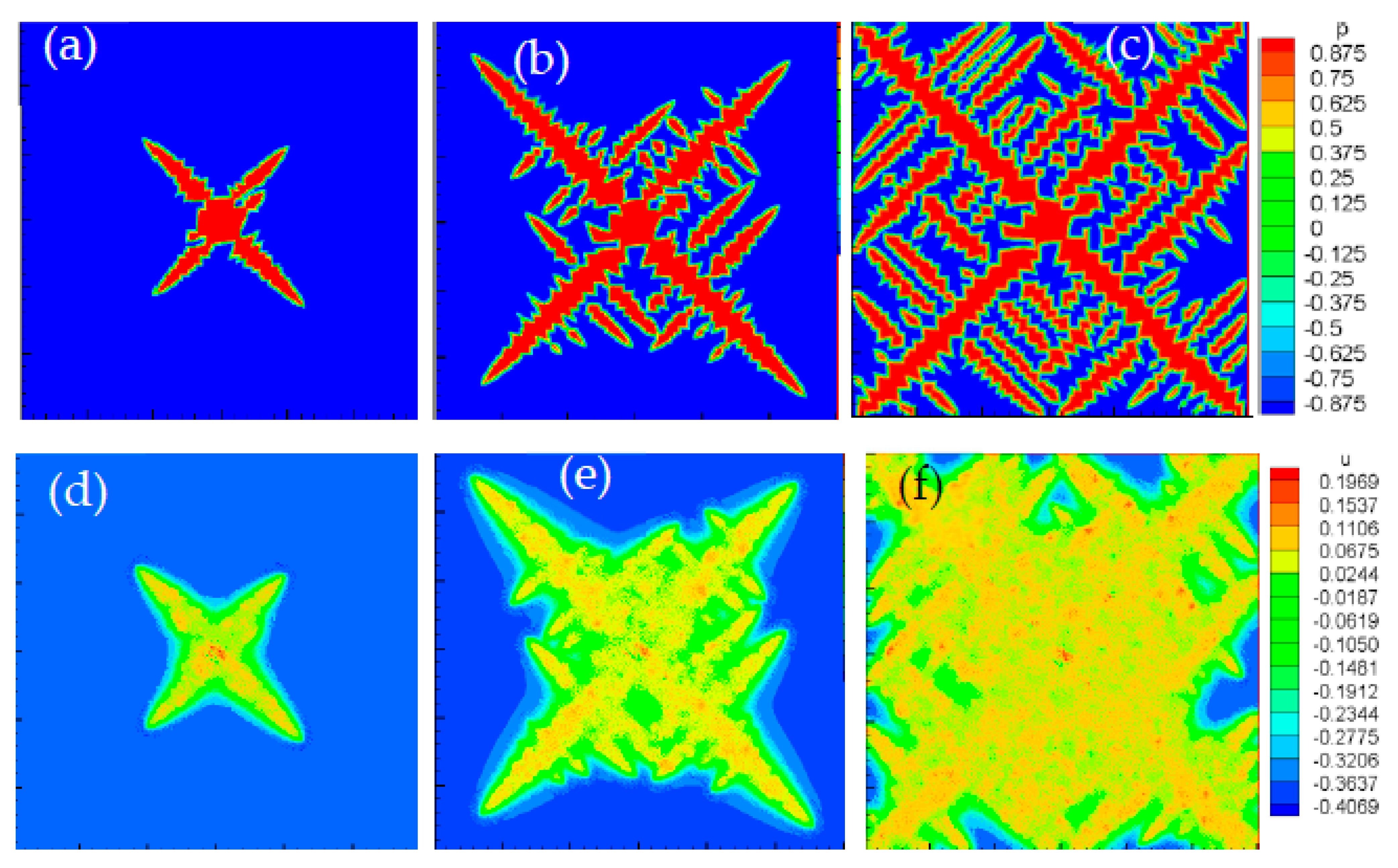

4.2. Influence of the Anisotropy Coefficient

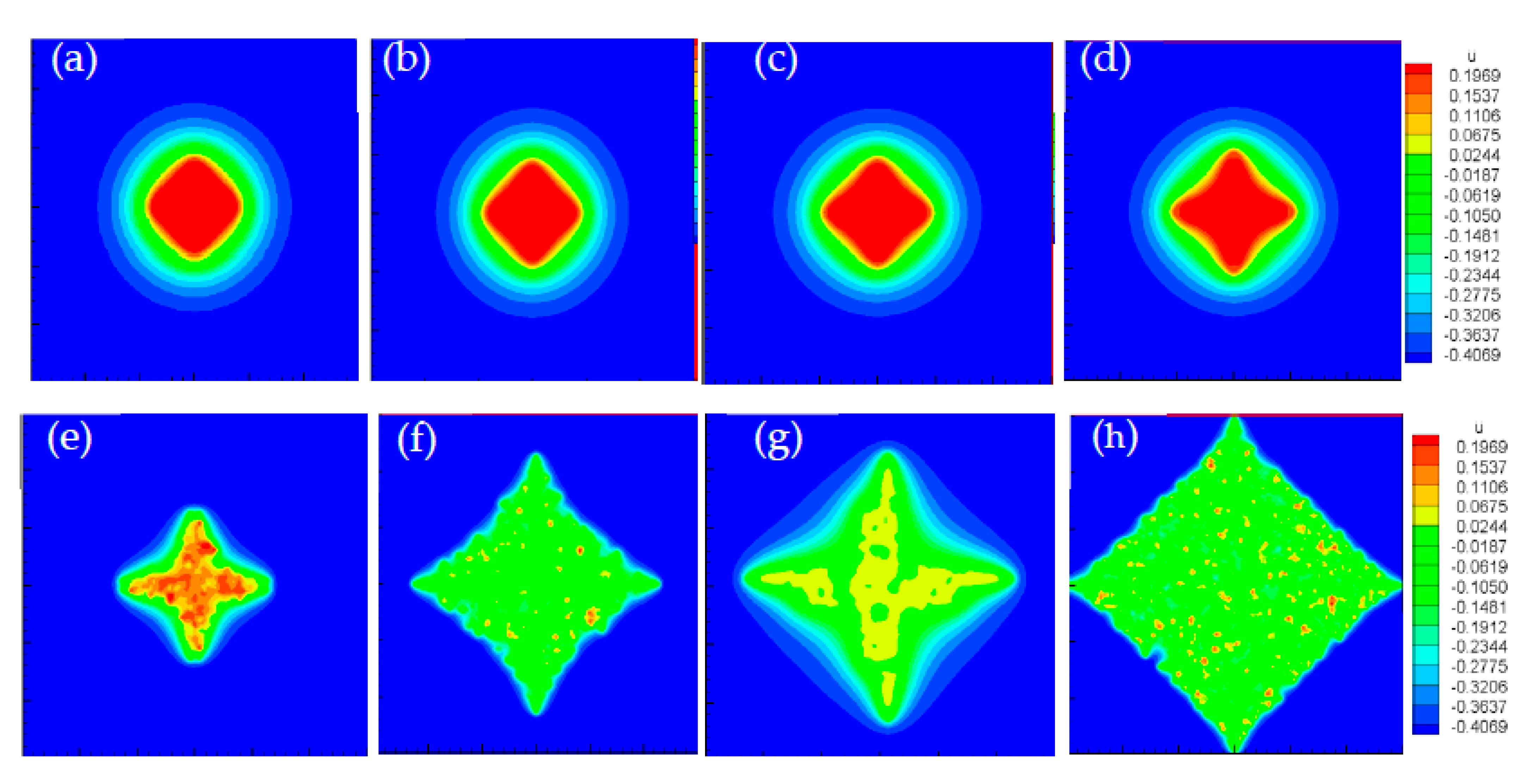

4.3. Selection of the Optimal Direction

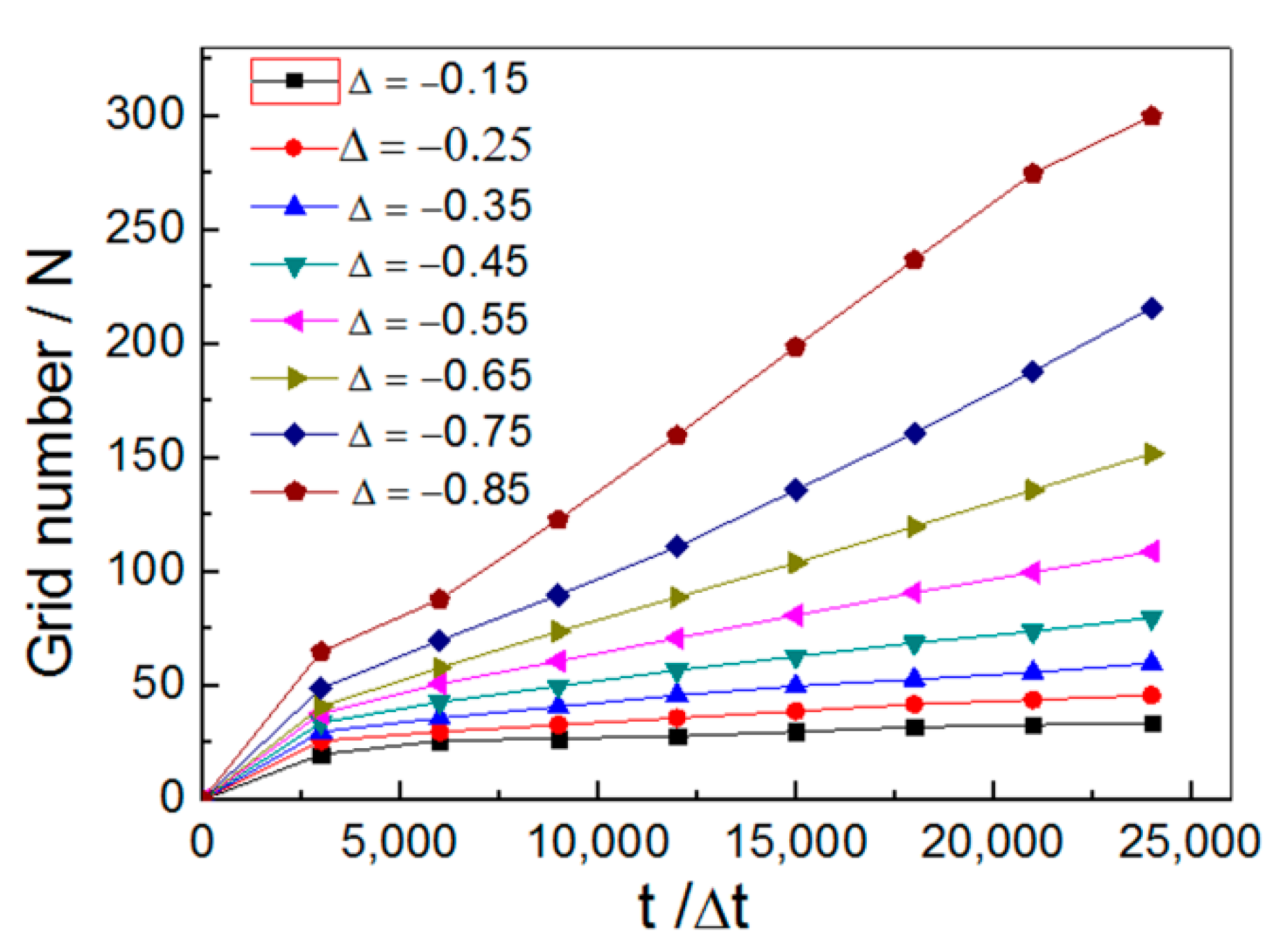

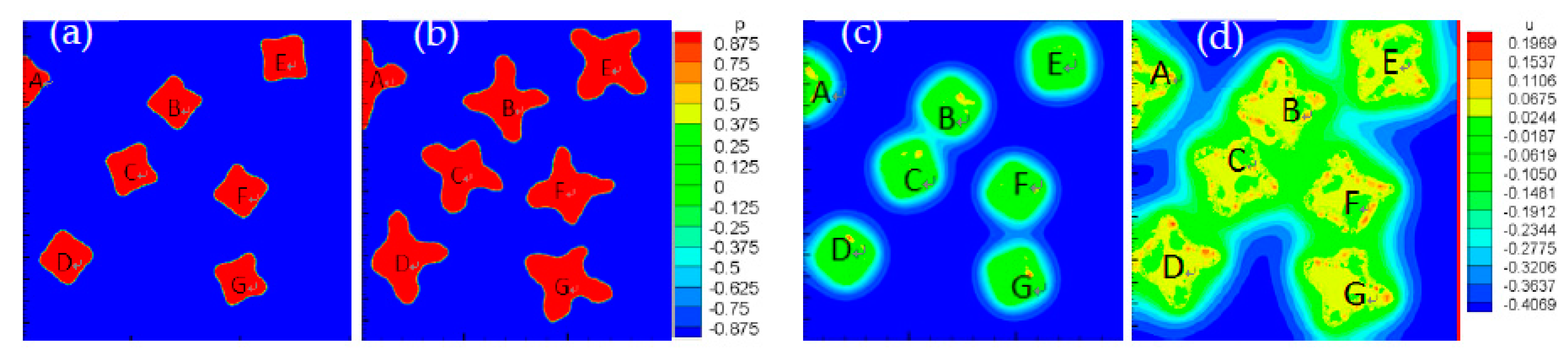

4.4. Multigrain Competitive Growth

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, W.J.; Wang, S.C. Status and prospect of distributed photovoltaic power generation in my country. J. Chin. Acad. Sci. 2016, 31, 165–172. [Google Scholar]

- Su, L.; Hao, Q.Y.; Xie, J.X. Research progress of quasi-single crystal silicon technology. Bull. Silic. 2012, 31, 603–609. [Google Scholar]

- Shi, B.C.; Li, K.; Kang, R.G. Technology status and development of casting polysilicon prepared by directional solidification method. Mater. Rev. 2014, 28, 183–187. [Google Scholar]

- Fujiwara, K.; Obinata, Y.; Ujihara, T. In-situ Observations of Melt Growth Behavior of Polycrystalline Silicon. J. Cryst. Growth 2004, 262, 124–129. [Google Scholar] [CrossRef]

- Fujiwara, K.; Pan, W.; Sawada, K. Directional Growth Method to Obtain High Quality Polycrystalline Silicon from Its Melt. J. Cryst. Growth 2006, 292, 282–285. [Google Scholar] [CrossRef]

- Nagashio, K.; Kuribayashi, K. Growth Mechanism of Twin- related and Twin- free Facet Si Dendrites. Acta Mater. 2005, 53, 3021–3029. [Google Scholar] [CrossRef]

- Aoyama, T.; Kuribayshi, K. Influence of undercooling on solid/liquidinterface morphology in semiconductors. Acta Mater. 2000, 48, 3739–3744. [Google Scholar] [CrossRef]

- Chen, P.; Tsai, Y.L.; Lan, C.W. Phase field modeling of growth competition of silicon grains. Acta Mater. 2008, 56, 4114–4122. [Google Scholar] [CrossRef]

- Boettinger, W.J.; Coriell, S.R.; Greer, A.L.; Karma, A.; Kurz, W.; Rappaz, M.; Trivedi, R. Solidification microstructures: Recent developments, future directions. Acta Mater. 2000, 48, 43–70. [Google Scholar] [CrossRef]

- Ode, M.; Kim, S.G.; Suzuki, T. Recent Advances in the Phase-Field Model for Solidification. ISIJ Int. 2001, 41, 1076–1082. [Google Scholar] [CrossRef]

- Granasy, L.; Borzsonyi, T.; Pusztai, T. Crystal nucleation and growth in binary phase-field theory. Phys. Rev. Lett. 2002, 237, 1813–1817. [Google Scholar]

- Granasy, L.; Borzsonyi, T.; Pusztai, T. Phase Field Theory of Heterogeneous Crystal Nucleation. Phys. Rev. Lett. 2007, 98, 035703. [Google Scholar] [CrossRef] [PubMed]

- Wendler, F.; Mennerich, C.; Nestler, B. A phase-field model for polycrystalline thin film growth. J. Cryst. Growth 2011, 327, 189–201. [Google Scholar] [CrossRef]

- Torabi, S.; Lowengrub, J.; Voigt, A.; Wise, S. A new phase-field model for strongly anisotropic systems. Proc. R. Soc. A Math. Phys. Eng. Sci. 2009, 465, 1337–1359. [Google Scholar] [CrossRef]

- Lin, H.K.; Lan, C.W. Three-Dimensional phase field modeling of silicon thin-film growth during directional solidification: Facet formation and grain competition. J. Cryst. Growth 2014, 401, 740–747. [Google Scholar] [CrossRef]

- Kasajima, H.; Nagano, E.; Suzuki, T. Phase-Field modeling for facet dendrite growth of silicon. Sci. Technol. Adv. Mater. 2003, 4, 553–557. [Google Scholar] [CrossRef]

- Suzuki, T.; Kim, S.G.; Kim, W.T. Two-Dimensional facet crystal growth of silicon from undercooled melt of Si-Ni alloy. Mater. Sci. Eng. A 2007, 449, 99–104. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, C.L.; Hao, L.M. Numerical simulation of facet dendrite growth. Trans. Nonferrous Met. Soc. China 2008, 18, 938–943. [Google Scholar] [CrossRef]

- Liu, B.Y.; Zhou, Y. Research on interface morphology evolution process of silicon materials using phase field method. Foundry Technol. 2016, 37, 2326–2330. [Google Scholar]

- Yuan, X.F.; Yang, Y.; Liu, F. Interface morphology evolution process of solidification for multicrystalline silicon using phase-field method. Sci. Technol. Eng. 2019, 19, 123–128. [Google Scholar]

- Zhao, D.P.; Jing, T.; Liu, B.C. Research progress of quasi-single crystal silicon technology. Acta Phys. 2003, 52, 1737–1742. [Google Scholar]

| Property | Value |

|---|---|

| Density ρ | 2570 kg/m3 |

| Melting point Tm | 1687 K |

| Thermal conductivity λ | 66.5 W/k·m |

| Kinematic viscosity μ | 8 × 10−4 Pa·s |

| Latent heat L | 1.587 × 106 J/kg |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, D.; Yang, X.; Wang, H.; Song, Q. Phase Field Simulation Research on the Microstructural Evolution of Monocrystalline and Polycrystalline Silicon. Crystals 2022, 12, 1271. https://doi.org/10.3390/cryst12091271

Zhang D, Yang X, Wang H, Song Q. Phase Field Simulation Research on the Microstructural Evolution of Monocrystalline and Polycrystalline Silicon. Crystals. 2022; 12(9):1271. https://doi.org/10.3390/cryst12091271

Chicago/Turabian StyleZhang, Dianxi, Xiufan Yang, Huaizhi Wang, and Qingjiang Song. 2022. "Phase Field Simulation Research on the Microstructural Evolution of Monocrystalline and Polycrystalline Silicon" Crystals 12, no. 9: 1271. https://doi.org/10.3390/cryst12091271

APA StyleZhang, D., Yang, X., Wang, H., & Song, Q. (2022). Phase Field Simulation Research on the Microstructural Evolution of Monocrystalline and Polycrystalline Silicon. Crystals, 12(9), 1271. https://doi.org/10.3390/cryst12091271