Low Cycle Fatigue Crack Damage Behavior of TC21 Titanium Alloy with Basketweave Microstructure

Abstract

:1. Introduction

2. Materials and Methods

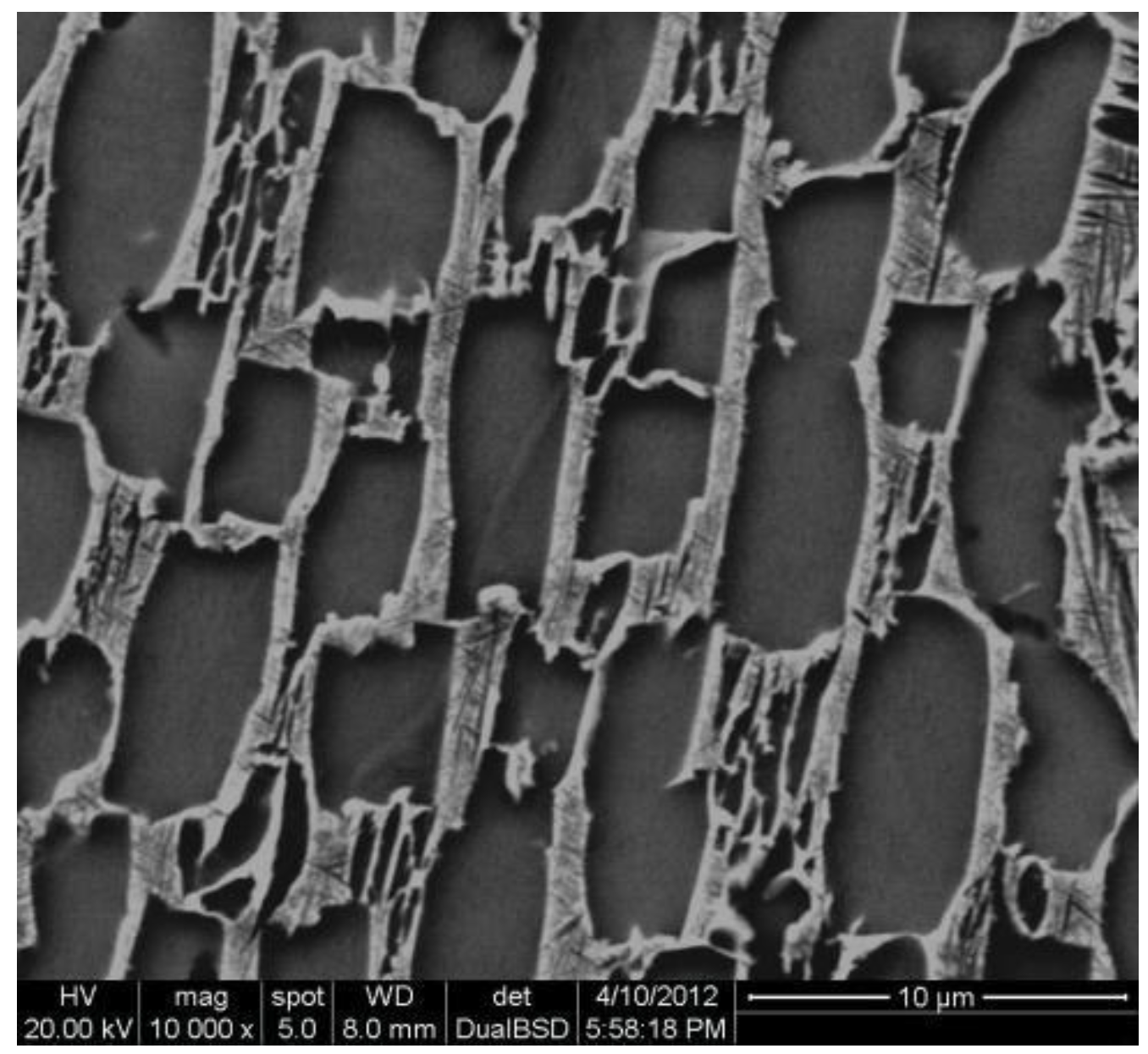

2.1. Materials

2.2. Surface Treatment

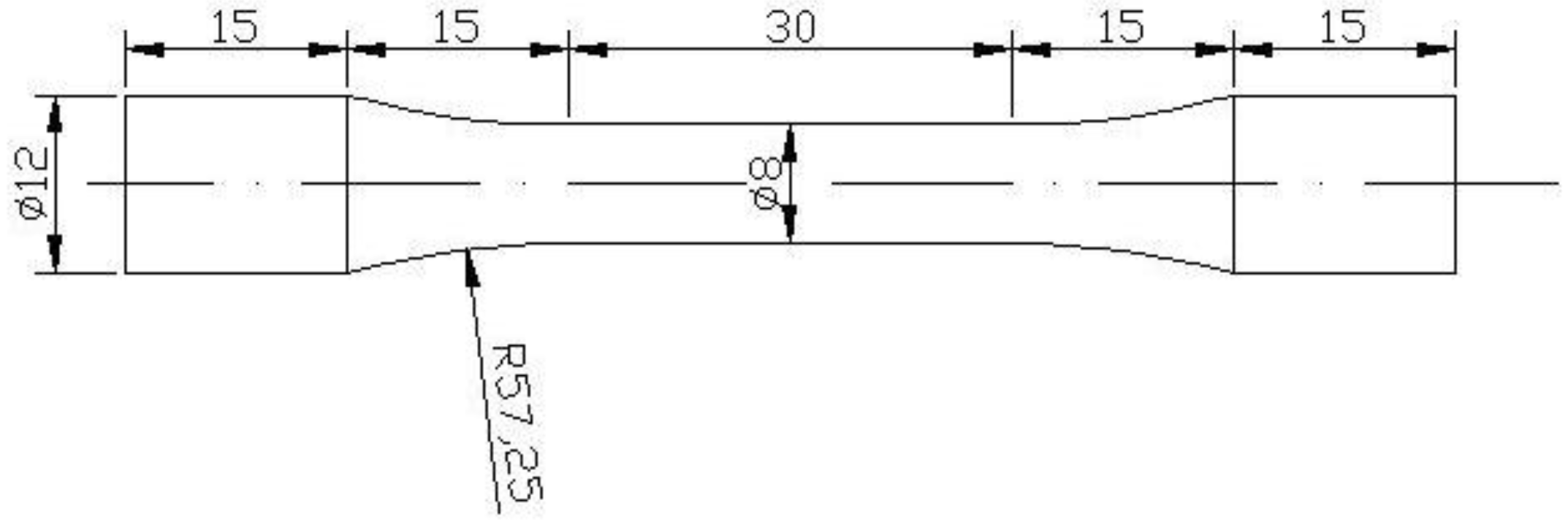

2.3. Low Cycle Fatigue

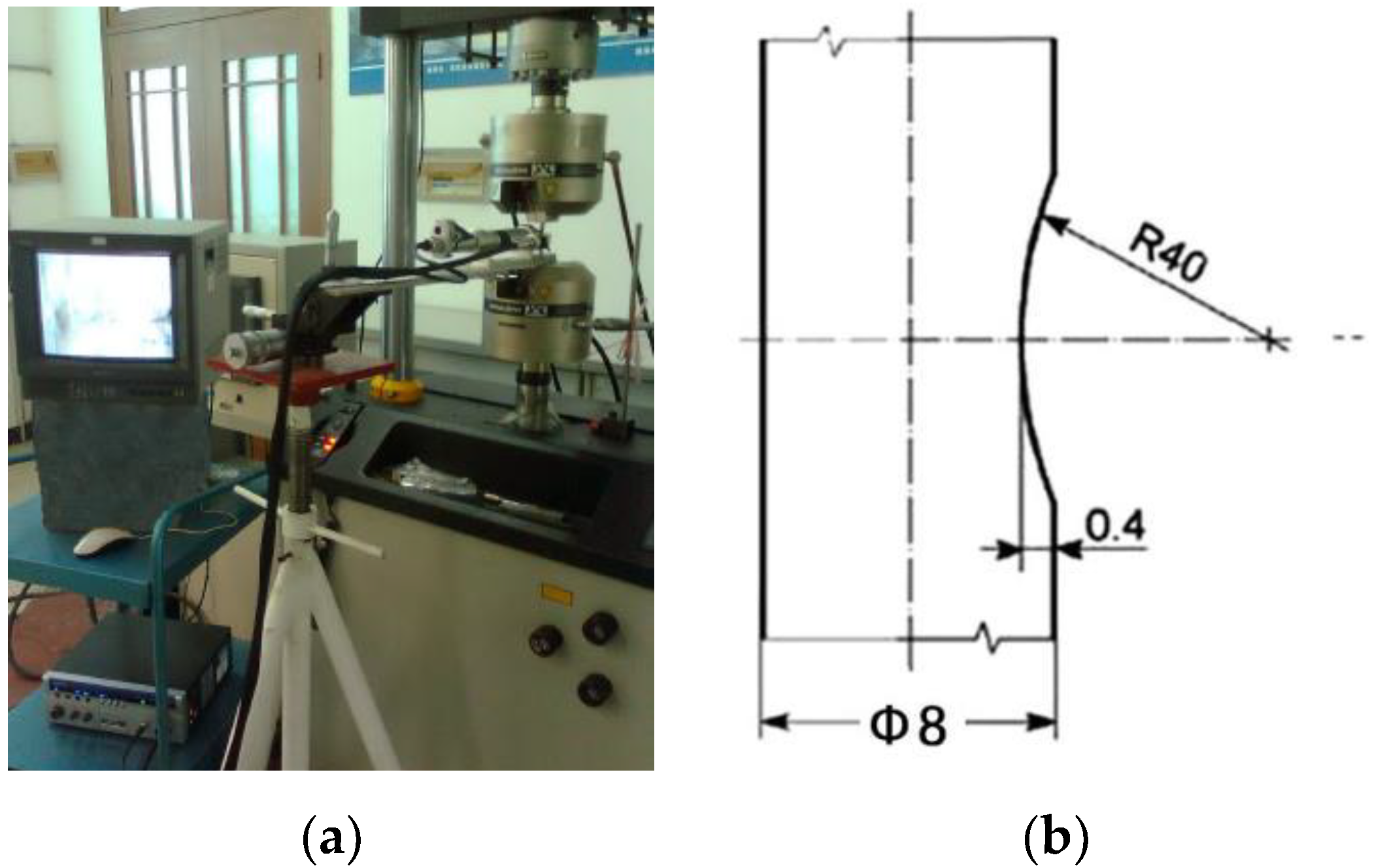

2.4. On Line Monitoring of Fatigue Crack Initiation and Propagation

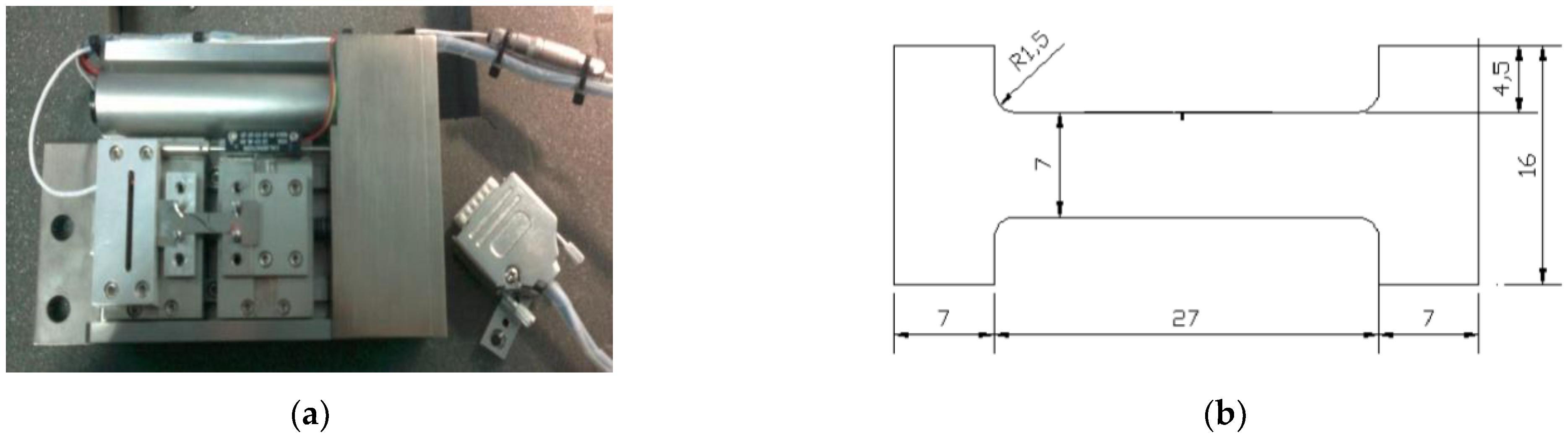

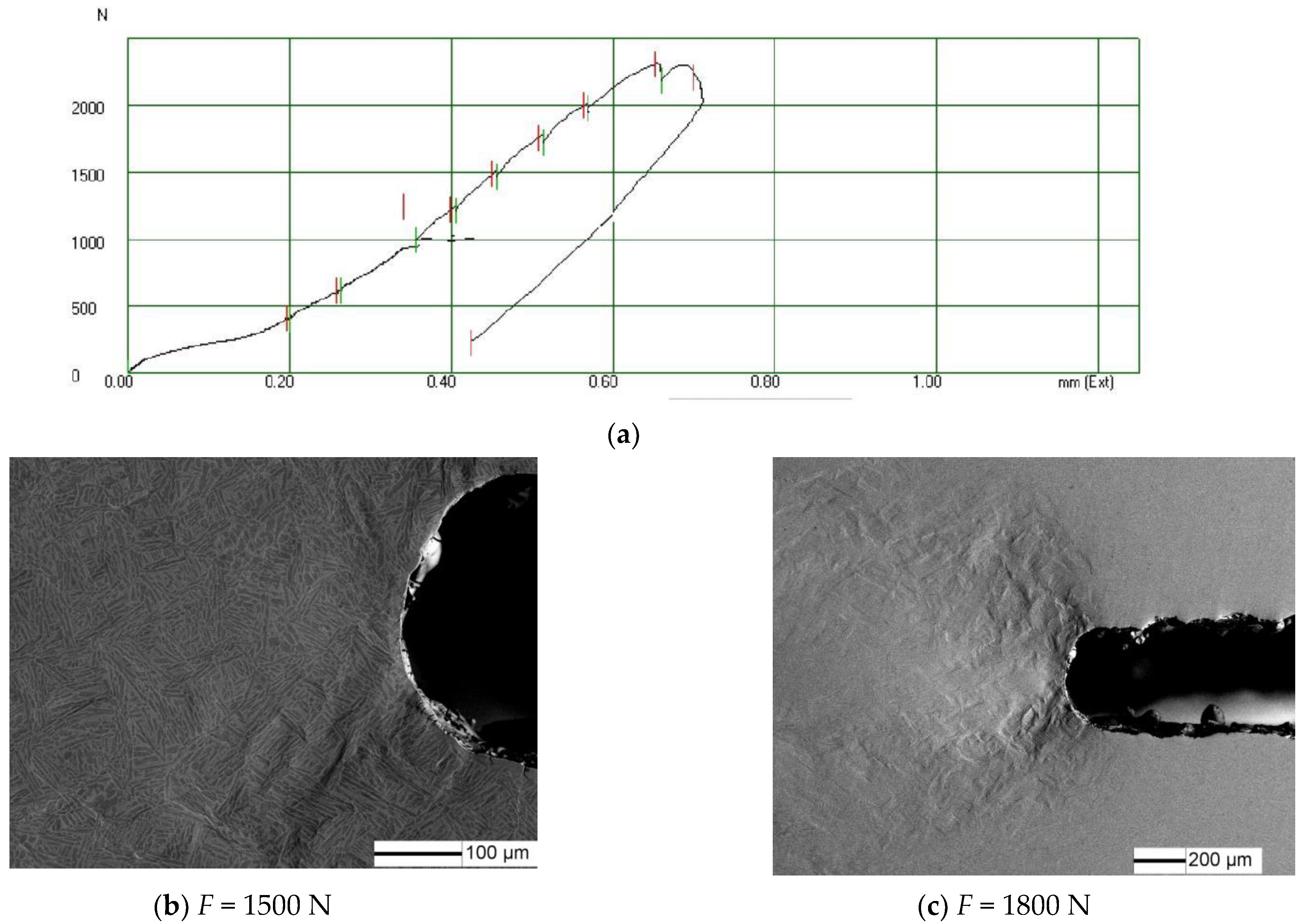

2.5. In Situ SEM Fatigue Test

3. Results and Discussion

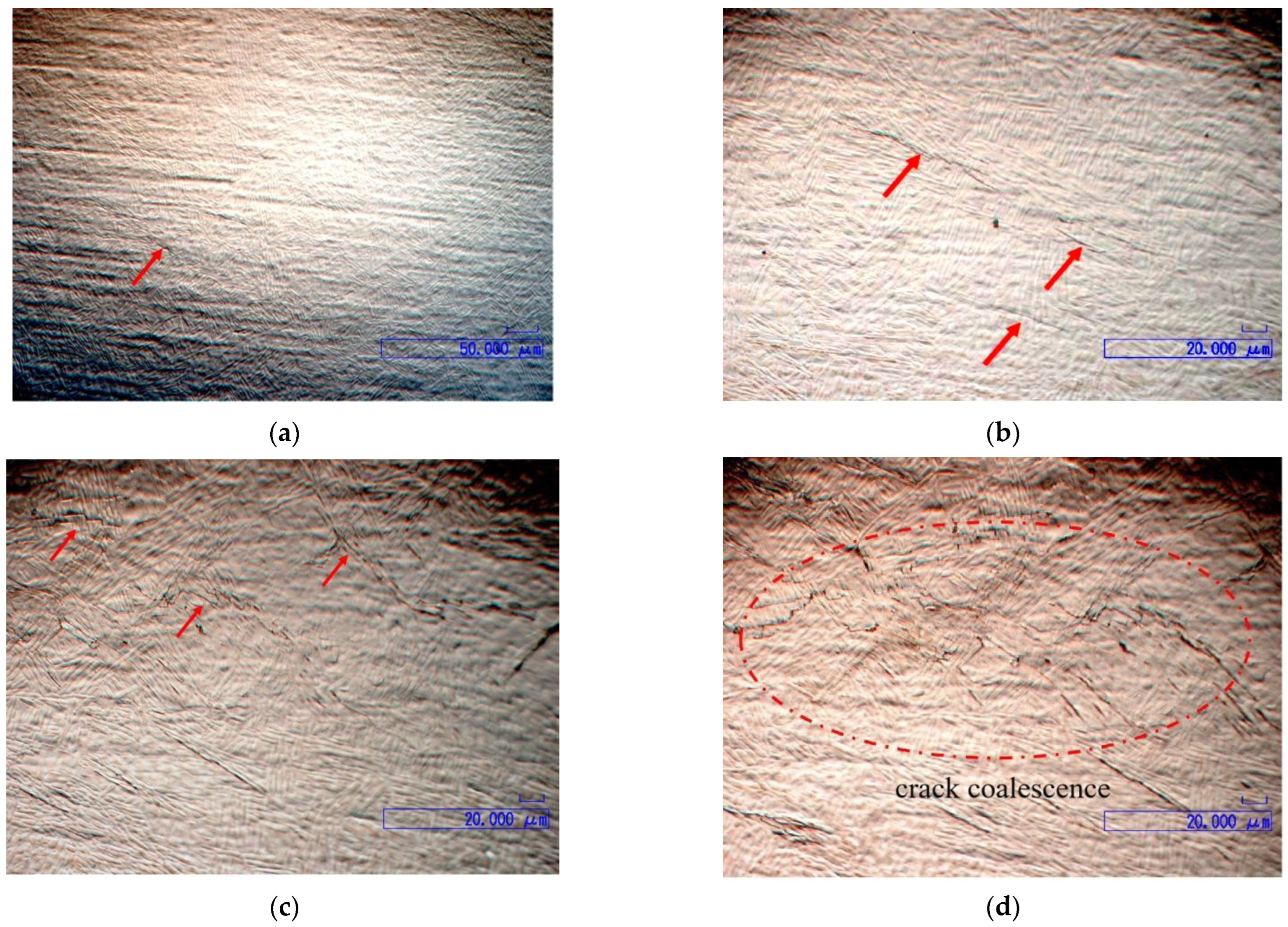

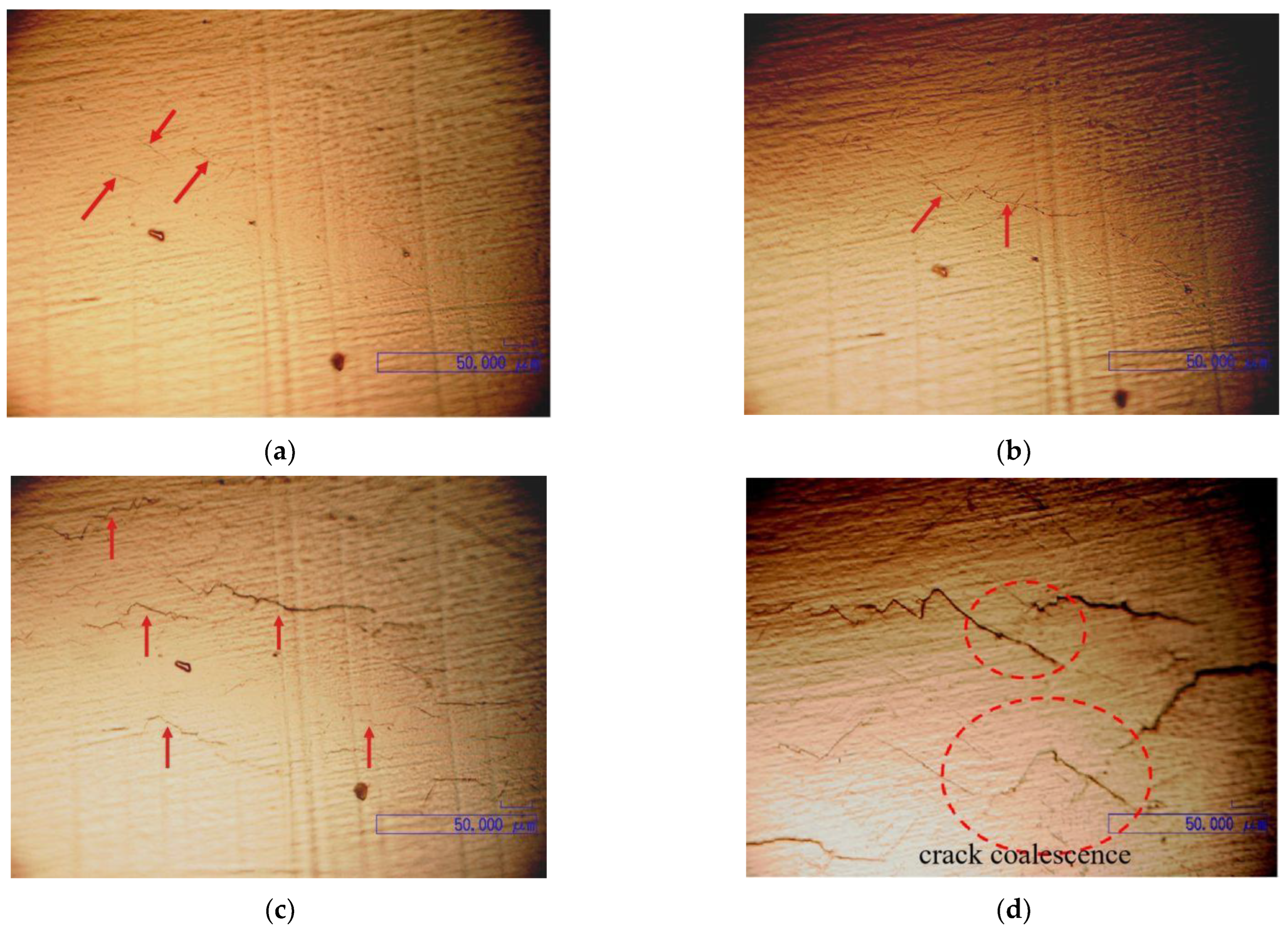

3.1. Evolution of Low Cycle Fatigue Crack on Cylindrical Specimens

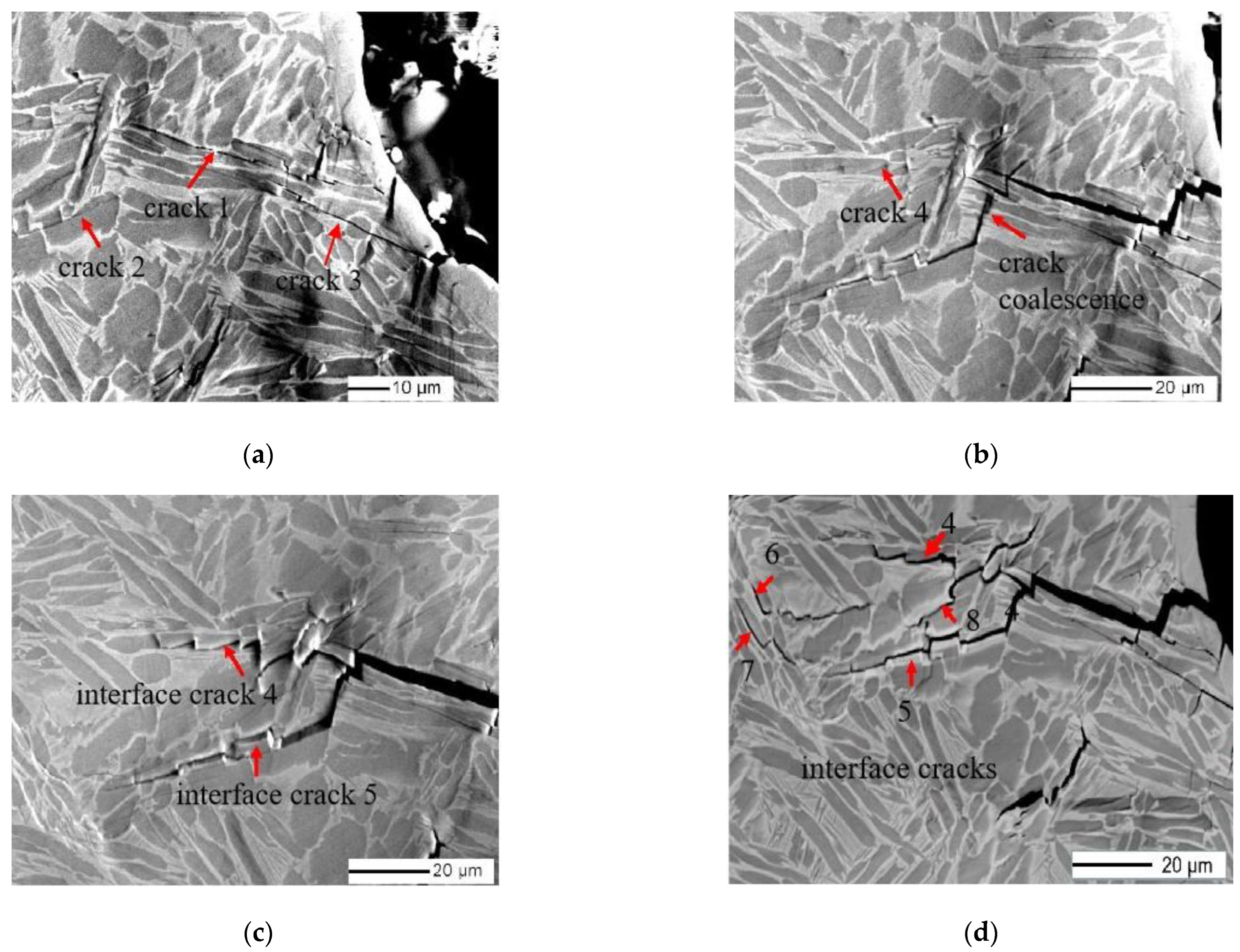

3.2. In-Situ SEM Fatigue Observation and Fatigue Small Crack Propagation Mechanism

3.3. Low Cycle Fatigue Damage Evolution

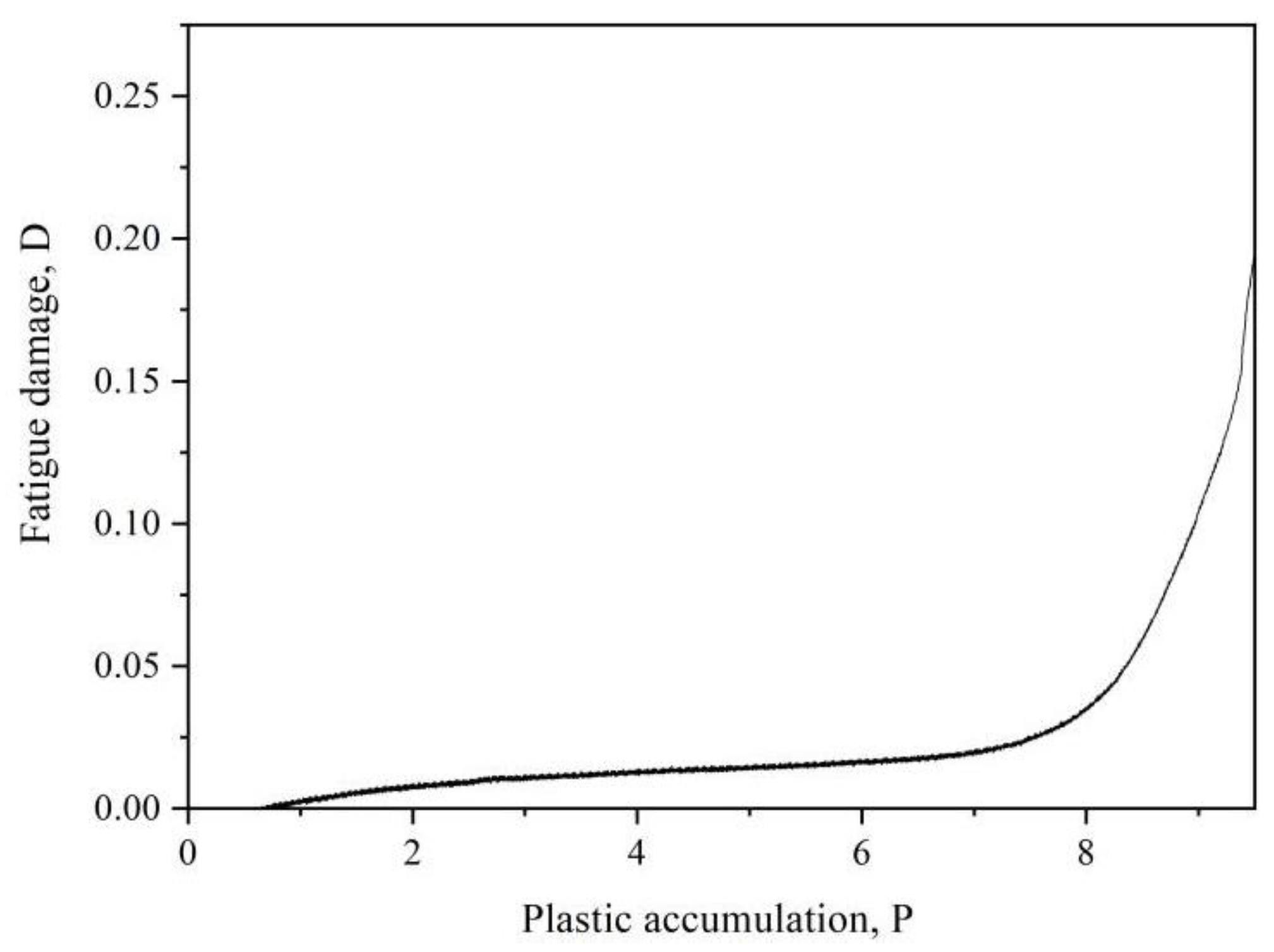

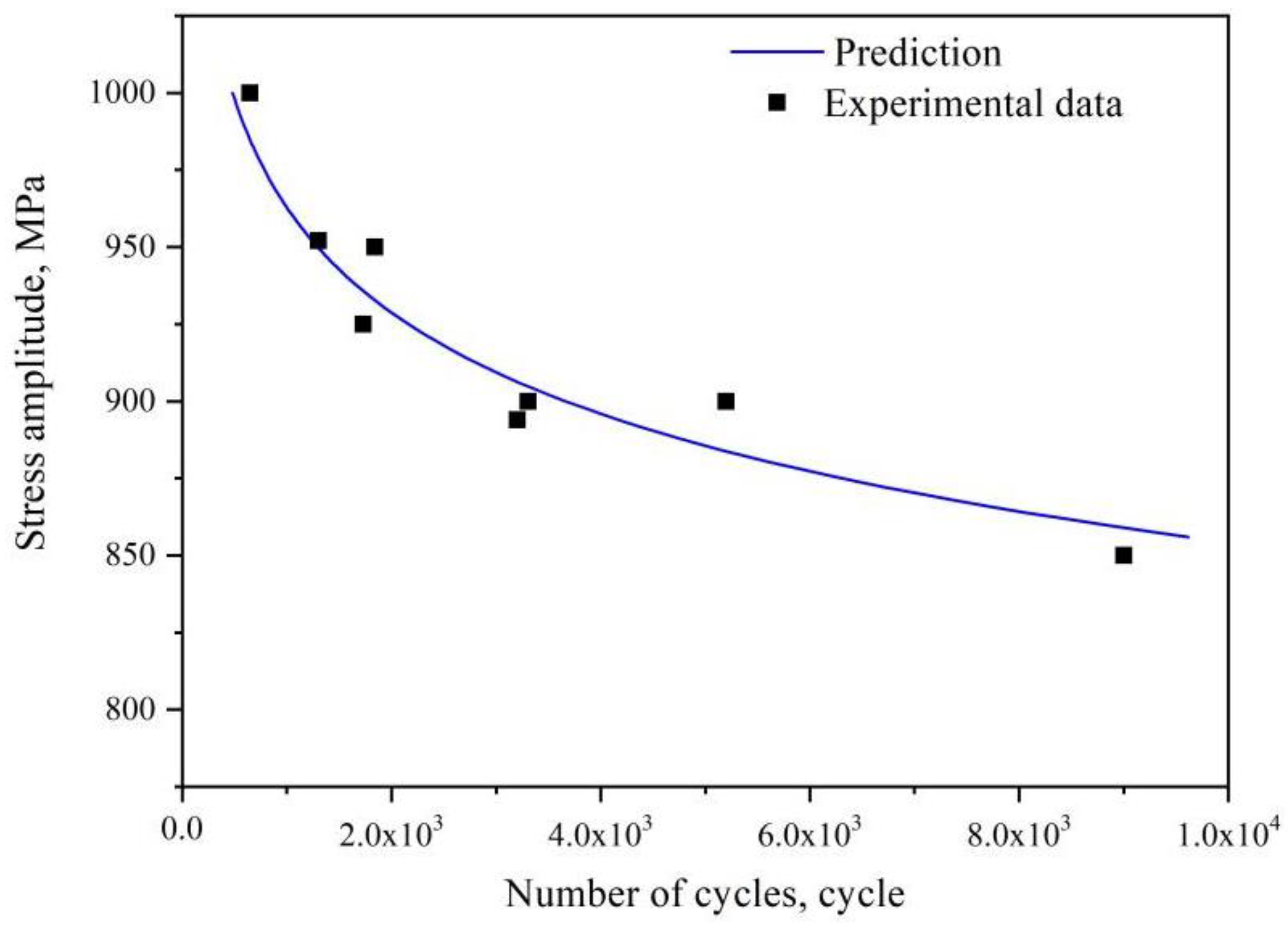

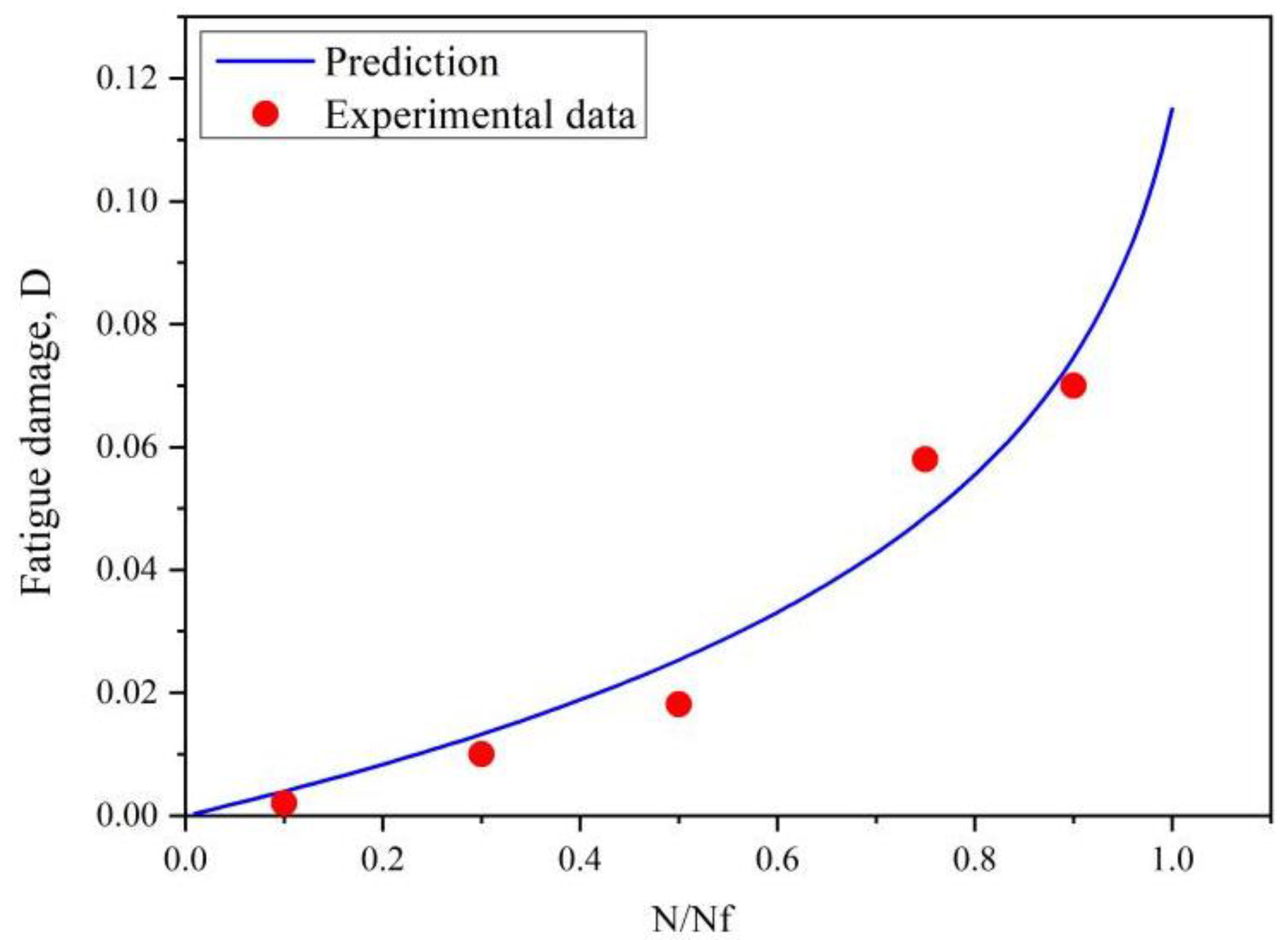

3.3.1. Low Cycle Fatigue Damage Model

- (1)

- The damage changes little during one cycle, and the damage variable D can be approximately regarded as a constant;

- (2)

- When the damage limit Dc was small, and the damage variable D was much small, so the change of cyclic stress between different cycles can be ignored.

3.3.2. Fatigue Damage Parameters

3.3.3. Fatigue Damage Model Verification and Discussion

4. Conclusions

- (1)

- Low cycle fatigue of TC21 titanium alloy with basketweave microstructure presented multi-cracks initiation mode, and the cracks propagated through the crack coalescence.

- (2)

- Under the stress amplitude slightly higher than the yield strength, fatigue microcracks propagated through slip bands due to the large plastic deformation; However, fatigue microcracks tended to propagate along the αL/β interface at relatively low stress amplitude.

- (3)

- Based on Lemaitre damage theory, low cycle fatigue damage model was established to analyze the fatigue damage process, which was consistent with the experimental data. When the maximum stress exceeded yield stress, fatigue damage increased sharply and fatigue life decreased significantly.

Author Contributions

Funding

Conflicts of Interest

References

- Zhao, Q.; Sun, Q.; Xin, S.; Chen, Y.; Wu, C.; Wang, H.; Xu, J.; Wan, M.; Zeng, W.; Zhao, Y. High-strength titanium alloys for aerospace engineering applications: A review on melting-forging process. Mater. Sci. Eng. A 2022, 845, 143260. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, D.; Zhong, B. Constitutive and damage modelling of selective laser melted Ti-6Al-4V lattice structure subjected to low cycle fatigue. Int. J. Fatigue 2022, 159, 106800. [Google Scholar] [CrossRef]

- Xu, Z.; Huang, C.; Wan, M.; Tan, C.; Zhao, Y.; Ji, S.; Zeng, W. Influence of microstructure on strain controlled low cycle fatigue crack initiation and propagation of Ti-55531 alloy. Int. J. Fatigue 2022, 156, 106678. [Google Scholar] [CrossRef]

- Helstroffer, A.; Hémery, S.; Andrieu, S.; Villechaise, P. Low cycle fatigue crack initiation in Ti-5Al-5Mo-5V-3Cr in relation to local crystallographic orientations. Mater. Lett. 2020, 276, 128198. [Google Scholar] [CrossRef]

- Joseph, S.; Bantounas, I.; Lindley, T.C. Slip transfer and deformation structures resulting from the low cycle fatigue of near-alpha titanium alloy Ti-6242Si. Int. J. Plast. 2018, 100, 90–103. [Google Scholar] [CrossRef]

- Gao, P.F.; Lei, Z.N.; Li, Y.K.; Zhan, M. Low-cycle fatigue behavior and property of TA15 titanium alloy with trimodal microstructure. Mater. Sci. Eng. A 2018, 736, 1–11. [Google Scholar] [CrossRef]

- Ren, J.; Wang, Q.; Zhang, B.; Yang, D.; Lu, X.; Zhang, X.; Zhang, X.; Hu, J. Influence of microstructure on fatigue crack growth behavior of Ti–6Al–3Nb–2Zr–1Mo alloy: Bimodal vs. lamellar structures. Intermetallics 2021, 130, 107058. [Google Scholar] [CrossRef]

- Li, S.; Xiong, B.; Hui, S. Comparison of the fatigue and fracture of Ti-6Al-2Zr-1Mo-1V with lamellar and bimodal microstructures. Mater. Sci. Eng. A 2007, 460, 140–145. [Google Scholar] [CrossRef]

- Xu, Z.; Huang, C.; Tan, C.; Wan, M.; Zhao, Y.; Ye, J.; Zeng, W. Influence of microstructure on cyclic deformation response and micromechanics of Ti-55531 alloy. Mater. Sci. Eng. A 2021, 803, 140505. [Google Scholar] [CrossRef]

- Sen, M.; Suman, S.; Mukherjee, S. Low cycle fatigue behavior and deformation mechanism of different microstructures in Ti-5Al-5Mo-5V-3Cr alloy. Int. J. Fatigue 2021, 148, 106238. [Google Scholar] [CrossRef]

- Anoushe, A.S.; Zarei-Hanzaki, A.; Abedi, H.R.; Barabi, A.; Huang, C.; Berto, F. On the microstructure evolution during isothermal low cycle fatigue of β-annealed Ti-6242S titanium alloy: Internal damage mechanism, substructure development and early globularization. Int. J. Fatigue 2018, 116, 592–601. [Google Scholar]

- Tan, C.; Sun, Q.; Xiao, L.; Zhao, Y.; Sun, J. Cyclic deformation and microcrack initiation during stress controlled high cycle fatigue of a titanium alloy. Mater. Sci. Eng. A 2018, 711, 212–222. [Google Scholar]

- Shao, H.; Zhao, Y.; Ge, P.; Zeng, W. Crack initiation and mechanical properties of TC21 titanium alloy with equiaxed microstructure. Mater. Sci. Eng. A 2013, 586, 215–222. [Google Scholar]

- Briffod, F.; Bleuset, A.; Shiraiwa, T.; Enoki, M. Effect of crystallographic orientation and geometrical compatibility on fatigue crack initiation and propagation in rolled Ti-6Al-4V alloy. Acta Mater. 2019, 177, 56–67. [Google Scholar]

- Sun, B.; Li, Z. A multi-scale damage model for fatigue accumulation due to short cracks nucleation and growth. Eng. Fract. Mech. 2014, 127, 280–295. [Google Scholar]

- Pang, K.; Yuan, H. Assessment of three-dimensional multi-crack propagation for fatigue life Prediction. Int. J. Pres. Ves. Pip. 2022, 198, 104660. [Google Scholar]

- Xiao, H.; Song, T.; Jia, B.; Lu, X. Uncertainty analysis of MSD crack propagation based on polynomial chaos expansion. Theor. Appl. Fract. Mech. 2022, 120, 103390. [Google Scholar]

- Tang, J.; Hu, W.; Meng, Q.; Sun, L.; Zhan, Z. A novel two-scale damage model for fatigue damage analysis of transition region between high- and low-cycle fatigue. Int. J. Fatigue 2017, 105, 208–218. [Google Scholar]

- Nie, B.; Song, Y.; Huang, X.; Qi, H.; Zhao, Z.; Chen, D. Low Cycle fatigue behavior of TC21 titanium alloy with bi-Lamellar basketweave microstructure. Crystals 2022, 12, 796. [Google Scholar]

- Zhu, S.; Hao, Y.; Liao, D. Probabilistic modeling and simulation of multiple surface crack propagation and coalescence. Appl. Math. Model. 2020, 78, 383–398. [Google Scholar]

- Briffod, F.; Bleuset, A.; Shiraiwa, T.; Enoki, M.; Emura, S. Effect of macrozones on fatigue crack initiation and propagation mechanisms in a forged Ti-6Al-4V alloy under fully-reversed condition. Materialia 2022, 22, 101401. [Google Scholar]

- Wang, X.; Zhao, Y.; Wang, L.; Wei, L.; He, J.; Guan, X. In-situ SEM investigation and modeling of small crack growth behavior of additively manufactured titanium alloy. Int. J. Fatigue 2021, 149, 106303. [Google Scholar]

- Koga, N.; Sakamaki, Y.; Kaseya, A.; Umezawa, O.; Nakata, H.; Toyoda, S. Visualization of strain distribution around fatigue crack developed by low cycle fatigue test in high-strength steels using digital image correlation method for replica films. Mater. Charact. 2022, 185, 111731. [Google Scholar]

- Xie, Y.; Gong, M.; Luo, Z.; Li, Q.; Gao, M.; Wang, F.; Zeng, X.; Wang, G. Effect of microstructure on short fatigue crack growth of wire arc addictive manufactured Ti-6Al-4V. Mater. Charact. 2021, 177, 111183. [Google Scholar]

- Lemaitre, J.; Desmorat, R. Engineering Damage Mechanics: Ductile, Creep, Fatigue and Brittle Failures; Springer: Dordrecht, The Netherlands, 2006. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nie, B.; Liu, S.; Huang, X.; Qi, H.; Shi, B.; Zhao, Z.; Chen, D. Low Cycle Fatigue Crack Damage Behavior of TC21 Titanium Alloy with Basketweave Microstructure. Crystals 2022, 12, 1211. https://doi.org/10.3390/cryst12091211

Nie B, Liu S, Huang X, Qi H, Shi B, Zhao Z, Chen D. Low Cycle Fatigue Crack Damage Behavior of TC21 Titanium Alloy with Basketweave Microstructure. Crystals. 2022; 12(9):1211. https://doi.org/10.3390/cryst12091211

Chicago/Turabian StyleNie, Baohua, Shuai Liu, Xianyi Huang, Haiying Qi, Binqing Shi, Zihua Zhao, and Dongchu Chen. 2022. "Low Cycle Fatigue Crack Damage Behavior of TC21 Titanium Alloy with Basketweave Microstructure" Crystals 12, no. 9: 1211. https://doi.org/10.3390/cryst12091211

APA StyleNie, B., Liu, S., Huang, X., Qi, H., Shi, B., Zhao, Z., & Chen, D. (2022). Low Cycle Fatigue Crack Damage Behavior of TC21 Titanium Alloy with Basketweave Microstructure. Crystals, 12(9), 1211. https://doi.org/10.3390/cryst12091211