Characterization of Mn-Doped PIN-PMN-PT Single Crystal Grown by Continuous-Feeding Bridgman Method

Abstract

:1. Introduction

2. Materials and Methods

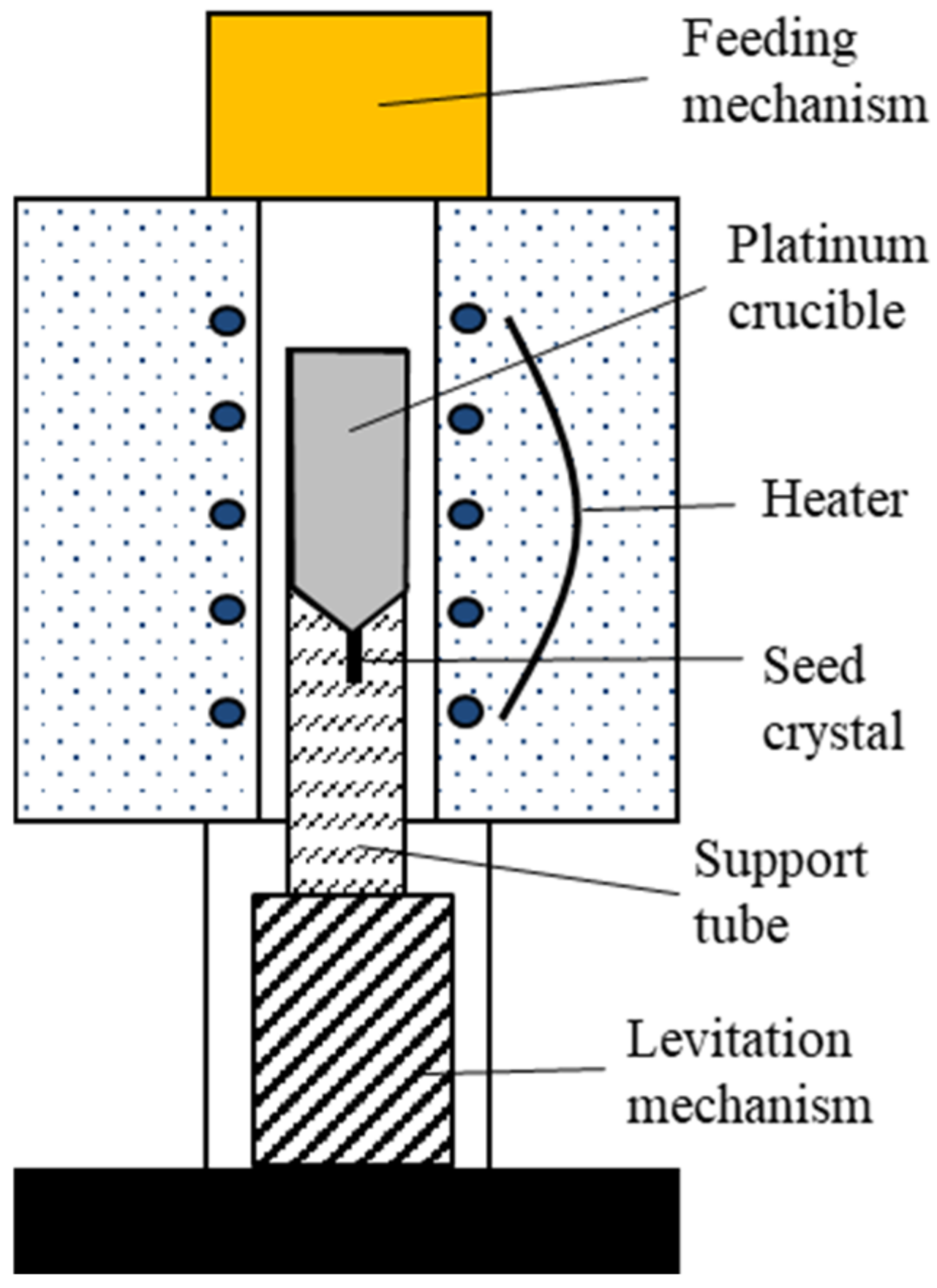

2.1. Crystal Growth

2.2. Characterization

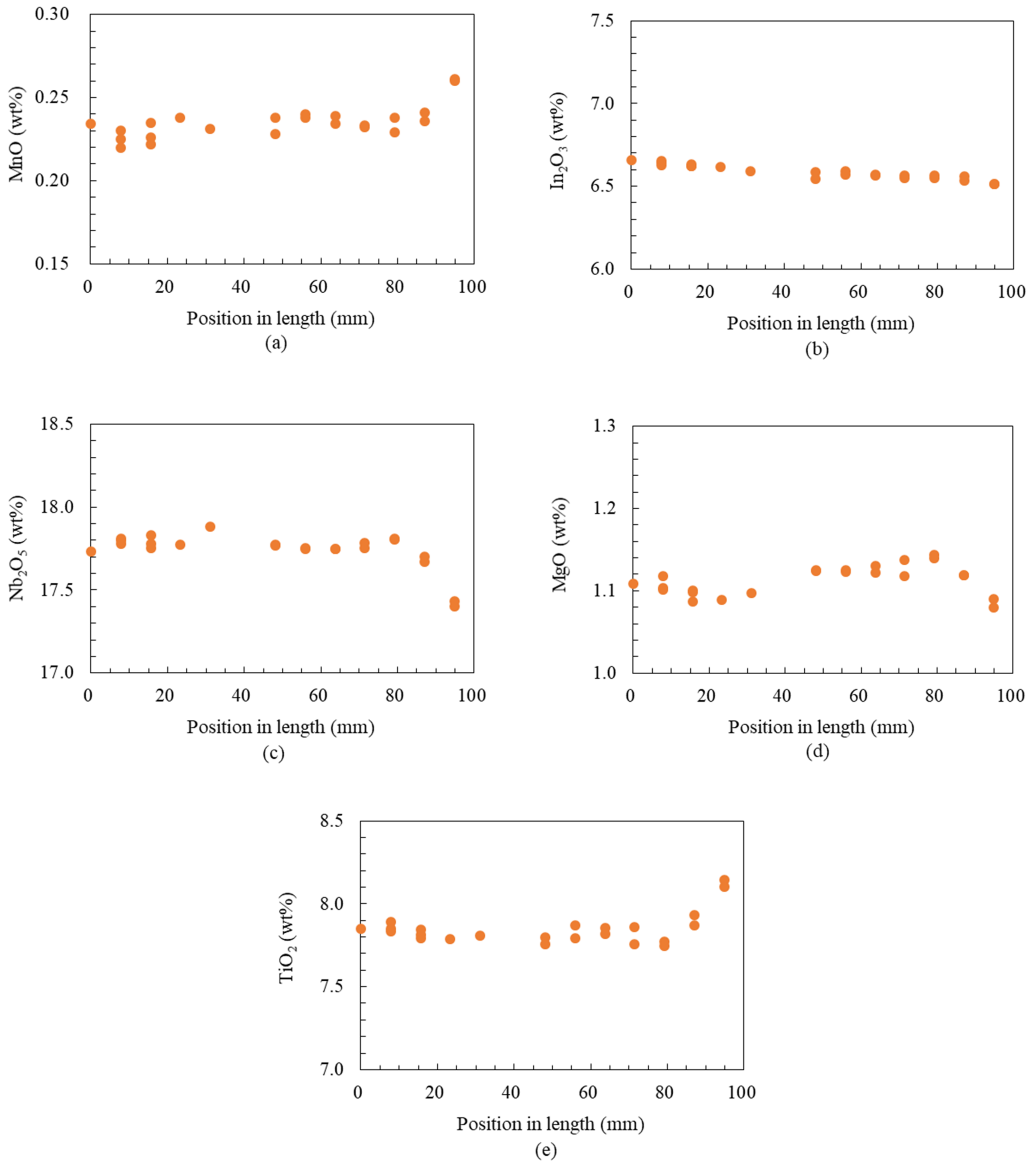

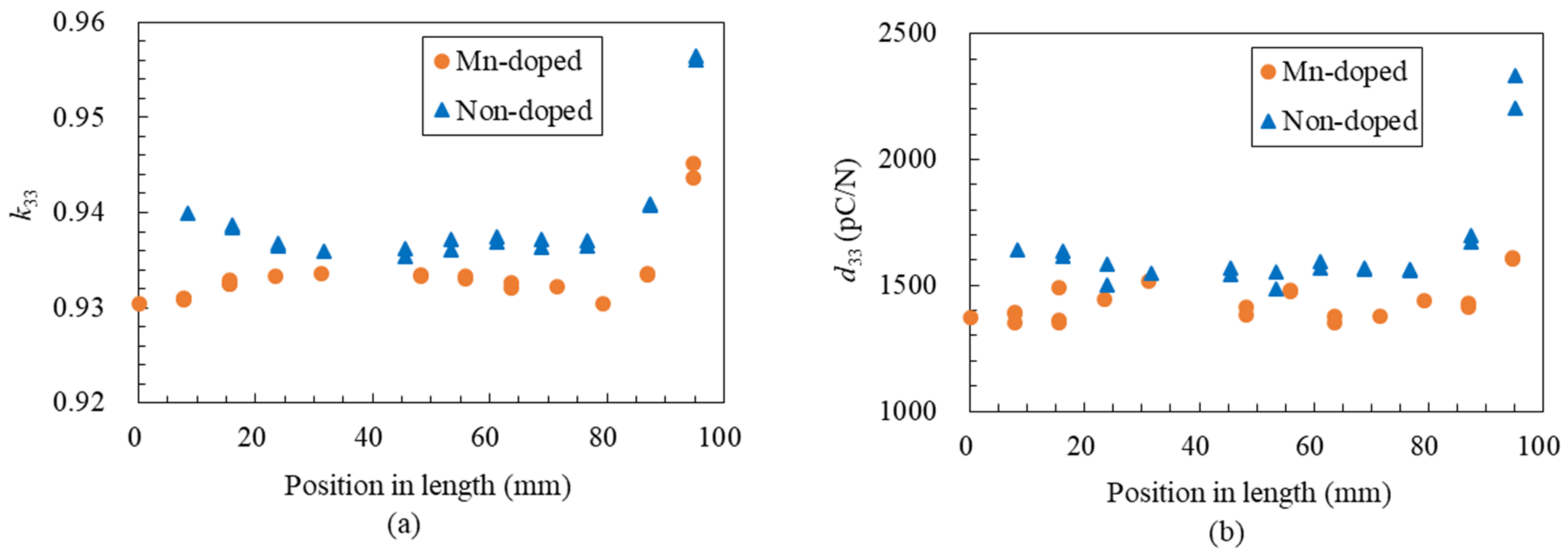

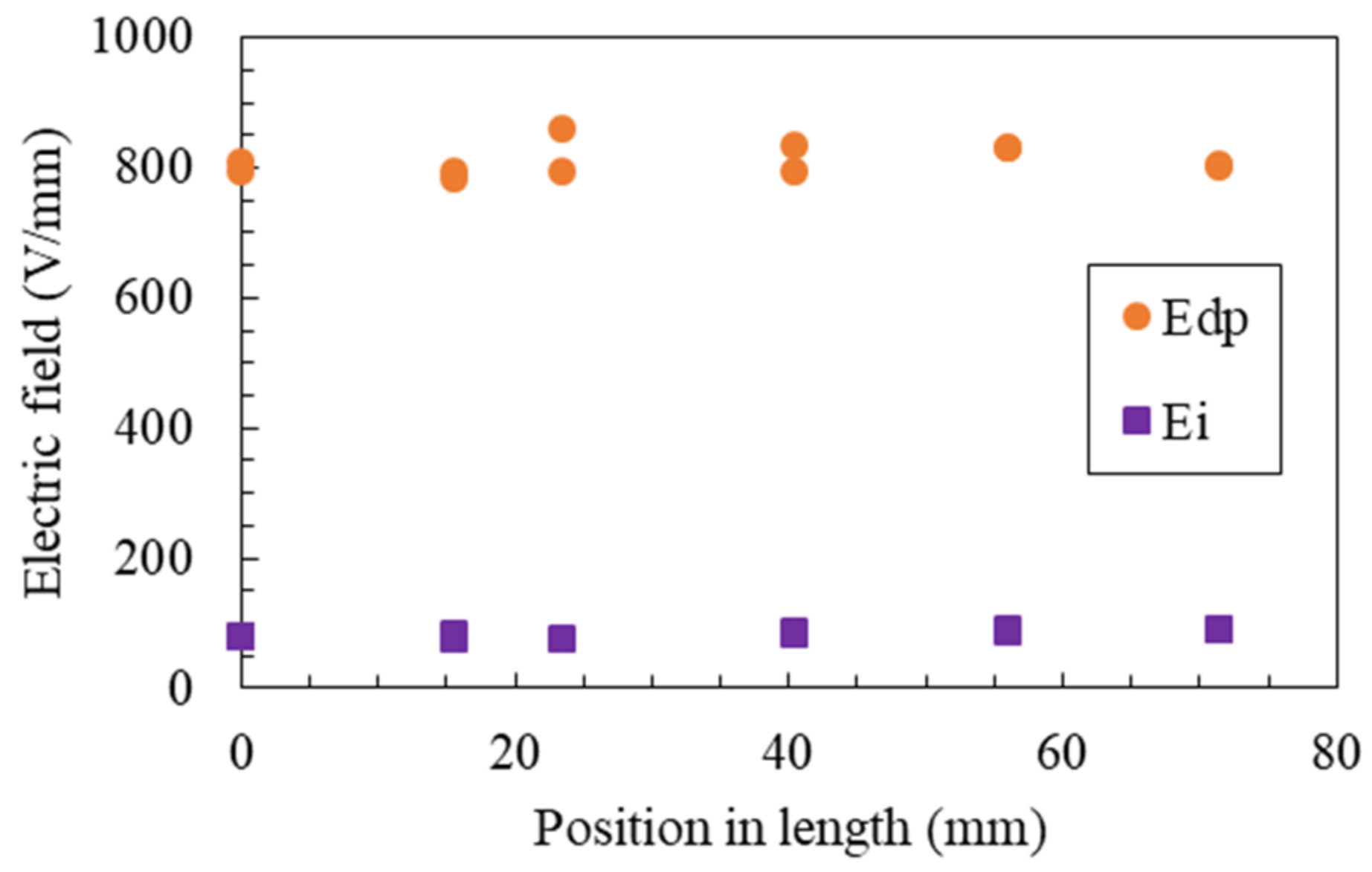

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Park, S.E.; Shrout, T.R. Ultrahigh strain and piezoelectric behavior in relaxor based ferroelectric single crystals. J. Appl. Phys. 1997, 82, 1804. [Google Scholar] [CrossRef]

- Hosono, Y.; Yamashita, Y.; Sakamoto, H.; Ichinose, N. Growth of Single Crystals of High-Curie-Temperature Pb(In1/2Nb1/2)O3–Pb(Mg1/3Nb2/3)O3–PbTiO3 Ternary Systems near Morphotropic Phase Boundary. Jpn. J. Appl. Phys. 2003, 42, 5681. [Google Scholar] [CrossRef]

- Luo, J.; Hackenberger, W.S.; Zhang, S.; Shrout, T.R. The Progress Update of Relaxor Piezoelectric Single Crystals. In Proceedings of the 2009 IEEE International Ultrasonics Symposium, Rome, Italy, 20–23 September 2009; pp. 968–971. [Google Scholar]

- Luo, H.; Xu, G.; Xu, H.; Wang, P.; Yin, Z. Compositional Homogeneity and Electrical Properties of Lead Magnesium Niobate Titanate Single Crystals Grown by a Modified Bridgman Technique. Jpn. J. Appl. Phys. 2000, 39, 5581–5585. [Google Scholar] [CrossRef]

- Zawilski, K.T.; Custodio, M.C.; DeMattei, R.C.; Lee, S.G.; Monteiro, R.G.; Odagawa, H.; Feigelson, R.S. Segregation during the vertical Bridgman growth of lead magnesium niobate–lead titanate single crystals. J. Cryst. Growth 2003, 258, 353–367. [Google Scholar] [CrossRef]

- Tian, J.; Han, P.; Huang, X.; Pan, H.; Carroll, J.F., III; Payne, D.A. Improved stability for piezoelectric crystals grown in the lead indium niobate–lead magnesium niobate–lead titanate system. Appl. Phys. Lett. 2007, 91, 222903. [Google Scholar] [CrossRef]

- Tian, J.; Han, P. Crystal growth and property characterization for PIN–PMN–PT ternary piezoelectric crystals. J. Adv. Dielectr. 2014, 4, 1350027. [Google Scholar] [CrossRef]

- Echizenya, K.; Matsushita, M. Continuous feed growth and characterization of PMN-PT single crystals. In Proceedings of the 2011 IEEE International Ultrasonics Symposium, Orlando, FL, USA, 18–21 October 2011; pp. 1813–1816. [Google Scholar] [CrossRef]

- Echizenya, K.; Nakamura, K. Piezoelectric single crystals grown by continuous feeding growth method. In Proceedings of the 17th US-Japan Seminar on Dielectric and Piezoelectric Ceramics, Matsumoto, Japan, 15–18 November 2015; pp. 227–230. [Google Scholar]

- Echizenya, K.; Nakamura, K.; Mizuno, K. PMN-PT and PIN-PMN-PT single crystals grown by continuous-feeding Bridgman method. J. Cryst. Growth 2020, 531, 125364. [Google Scholar] [CrossRef]

- Baasandorj, L.; Chen, Z. Recent Developments on Relaxor-PbTiO3 Ferroelectric Crystals. Crystals 2022, 12, 56. [Google Scholar] [CrossRef]

- Zhang, S.; Li, F.; Sherlock, N.P.; Luo, J.; Shrout, T.R. Recent developments on high Curie temperature PIN–PMN–PT ferroelectric crystals. J. Cryst. Growth 2011, 318, 846–850. [Google Scholar] [CrossRef] [PubMed]

- Luo, N.; Zhang, S.; Li, Q.; Yan, Q.; Zhang, Y.; Ansell, T.; Luo, J.; ShroutL, T.R. Crystallographic dependence of internal bias in domain engineered Mn-doped relaxor-PbTiO3 single crystals. J. Mater. Chem. C 2016, 4, 4568. [Google Scholar] [CrossRef]

- Zheng, L.; Sahul, R.; Zhang, S.; Jiang, W.; Li, S.; Cao, W. Orientation dependence of piezoelectric properties and mechanical quality factors of 0.27Pb(In1/2Nb1/2)O3-0.46Pb(Mg1/3Nb2/3)O3-0.27PbTiO3:Mn single crystals. J. Appl. Phys. 2013, 114, 104105. [Google Scholar] [CrossRef]

- Zheng, L.; Yang, L.; Li, Y.; Lu, X.; Huo, D.; Lü, W.; Zhang, R.; Yang, B.; Cao, W. Origin of Improvement in Mechanical Quality Factor in Acceptor-Doped Relaxor-Based Ferroelectric Single Crystals. Phys. Rev. Appl. 2018, 9, 064028. [Google Scholar] [CrossRef]

| Compound | MnO | Pb3O4 | InNbO4 | MgNb2O6 | TiO2 |

|---|---|---|---|---|---|

| Mixing ratio (wt%) | 0.2 | 68.4 | 12.8 | 11.3 | 7.3 |

| Single Crystal | Mn:PIN-PMN-PT | PIN-PMN-PT |

|---|---|---|

| ε33T/ε0 | 3530 | 4480 |

| tan δ (%) | 0.5 | 0.5 |

| k33 | 0.93 | 0.94 |

| d33 (pC/N) | 1480 | 1590 |

| Ed (V/mm) | 830 | 610 |

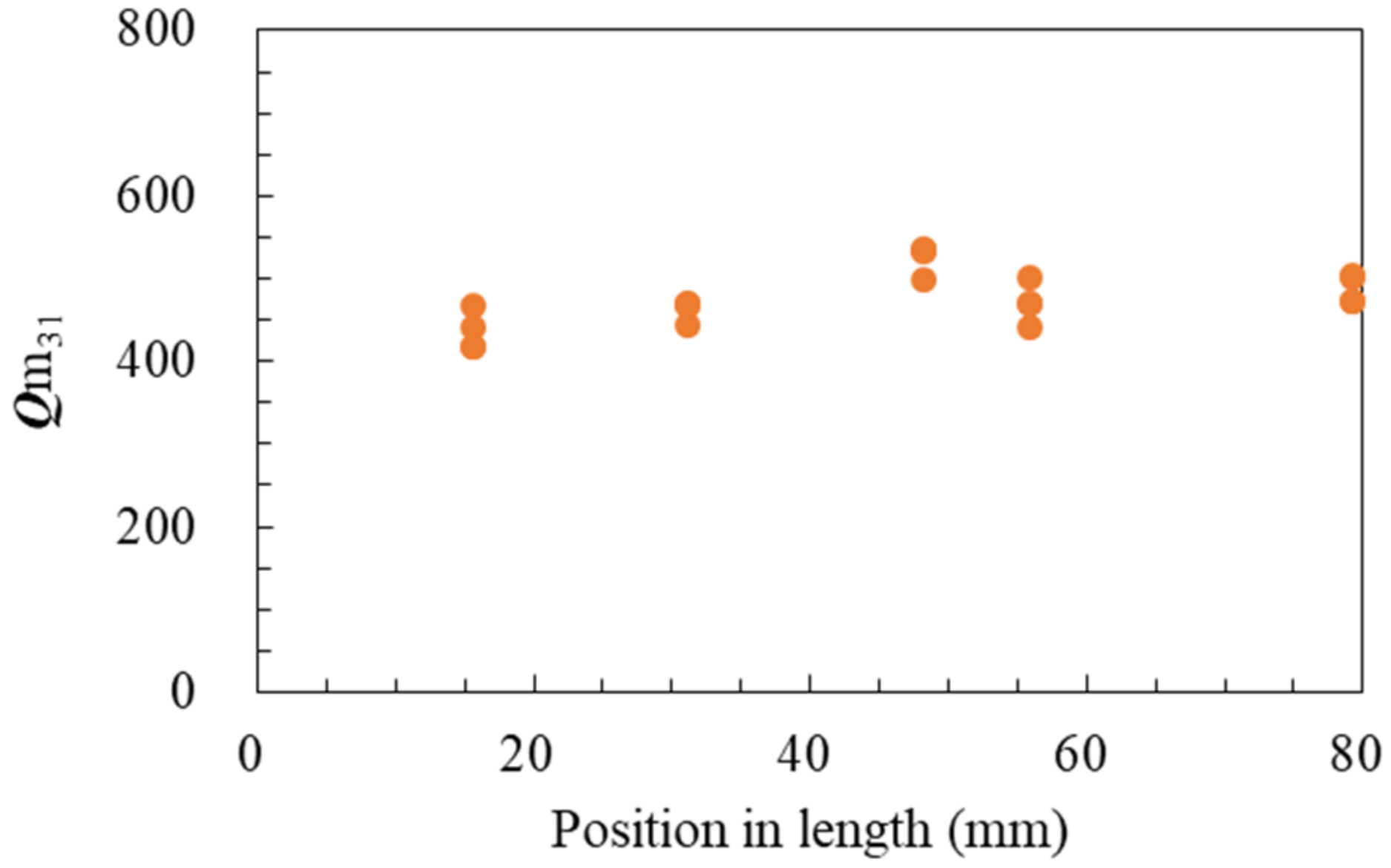

| Qm31 | 470 | 140 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Echizenya, K.; Noda, N.; Noro, H. Characterization of Mn-Doped PIN-PMN-PT Single Crystal Grown by Continuous-Feeding Bridgman Method. Crystals 2022, 12, 1183. https://doi.org/10.3390/cryst12091183

Echizenya K, Noda N, Noro H. Characterization of Mn-Doped PIN-PMN-PT Single Crystal Grown by Continuous-Feeding Bridgman Method. Crystals. 2022; 12(9):1183. https://doi.org/10.3390/cryst12091183

Chicago/Turabian StyleEchizenya, Kazuhiko, Naoki Noda, and Hisato Noro. 2022. "Characterization of Mn-Doped PIN-PMN-PT Single Crystal Grown by Continuous-Feeding Bridgman Method" Crystals 12, no. 9: 1183. https://doi.org/10.3390/cryst12091183

APA StyleEchizenya, K., Noda, N., & Noro, H. (2022). Characterization of Mn-Doped PIN-PMN-PT Single Crystal Grown by Continuous-Feeding Bridgman Method. Crystals, 12(9), 1183. https://doi.org/10.3390/cryst12091183