Microstructure and Mechanical Properties of Laser Narrow-Gap Multi-Pass Weld 20 mm-Thick Ti-6Al-4V Alloy with Different Filling Layers

Abstract

:1. Introduction

2. Materials and Experimental Methods

2.1. Materials

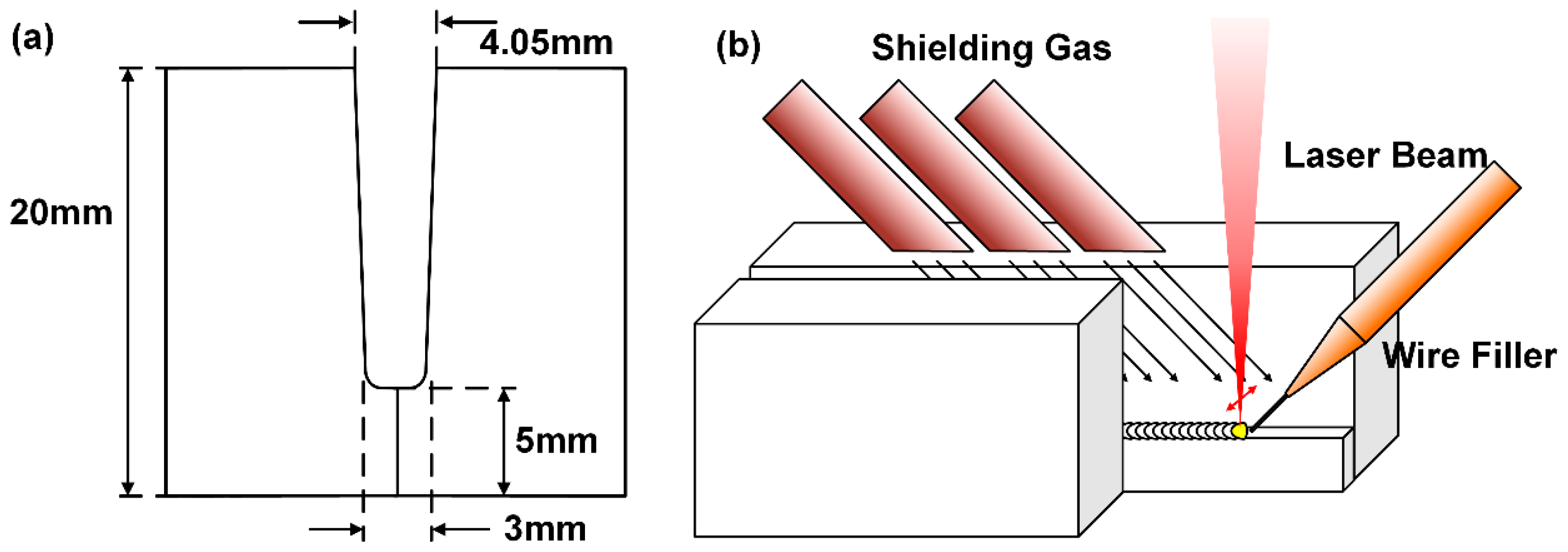

2.2. Experimental Method

2.3. Microstructure Observation

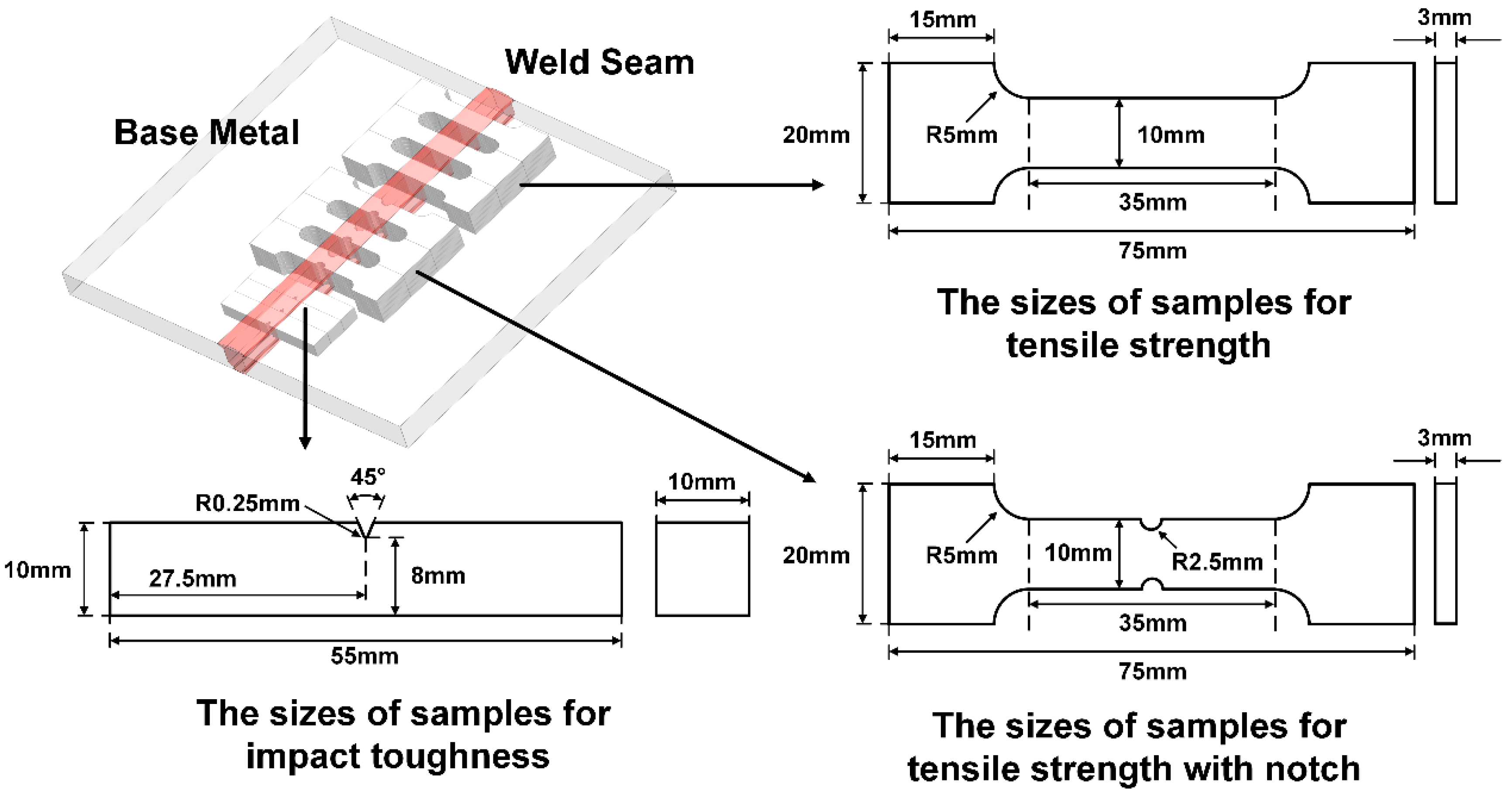

2.4. Test of the Mechanical Properties

3. Results and Discussion

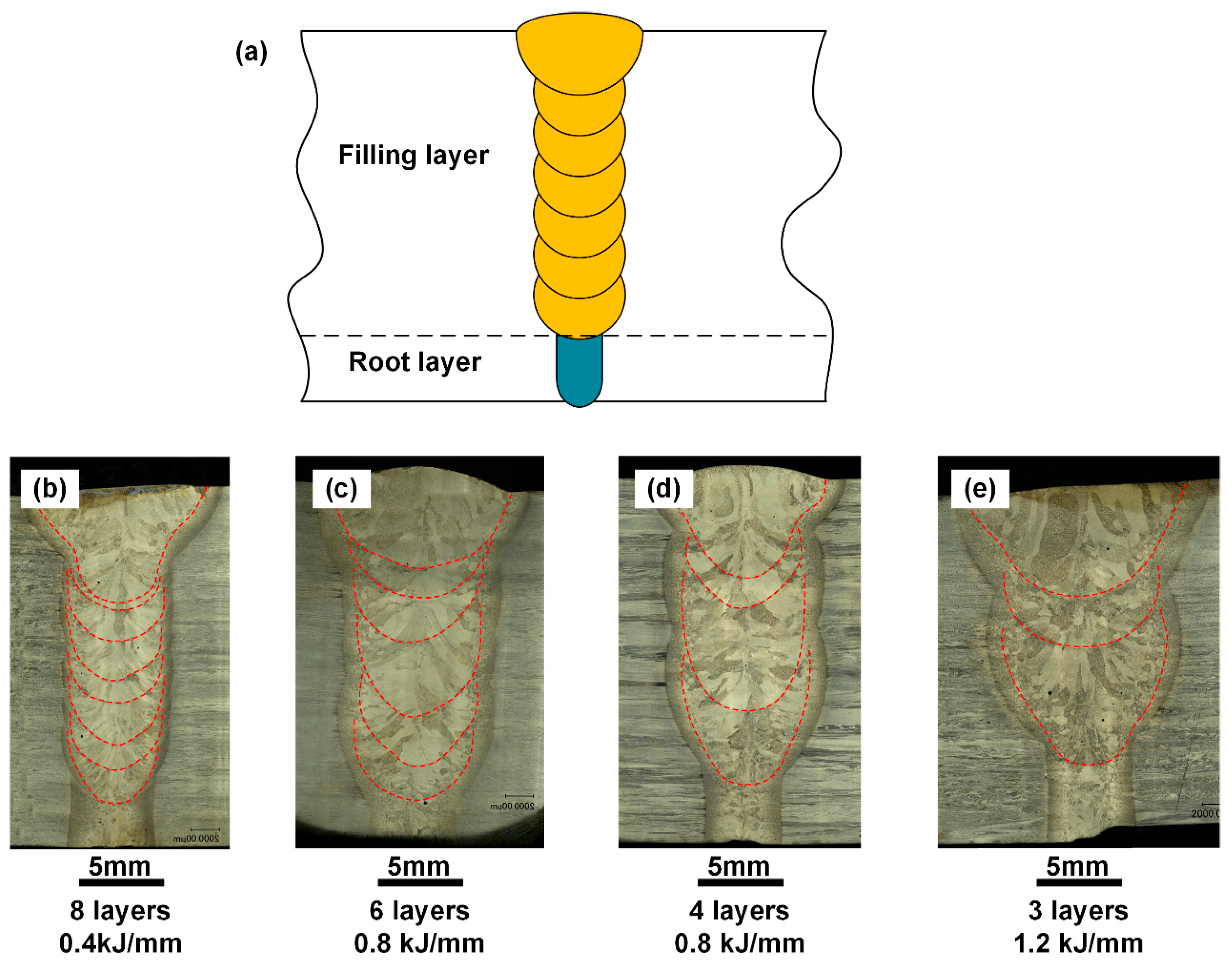

3.1. Paraments and Weld Formation

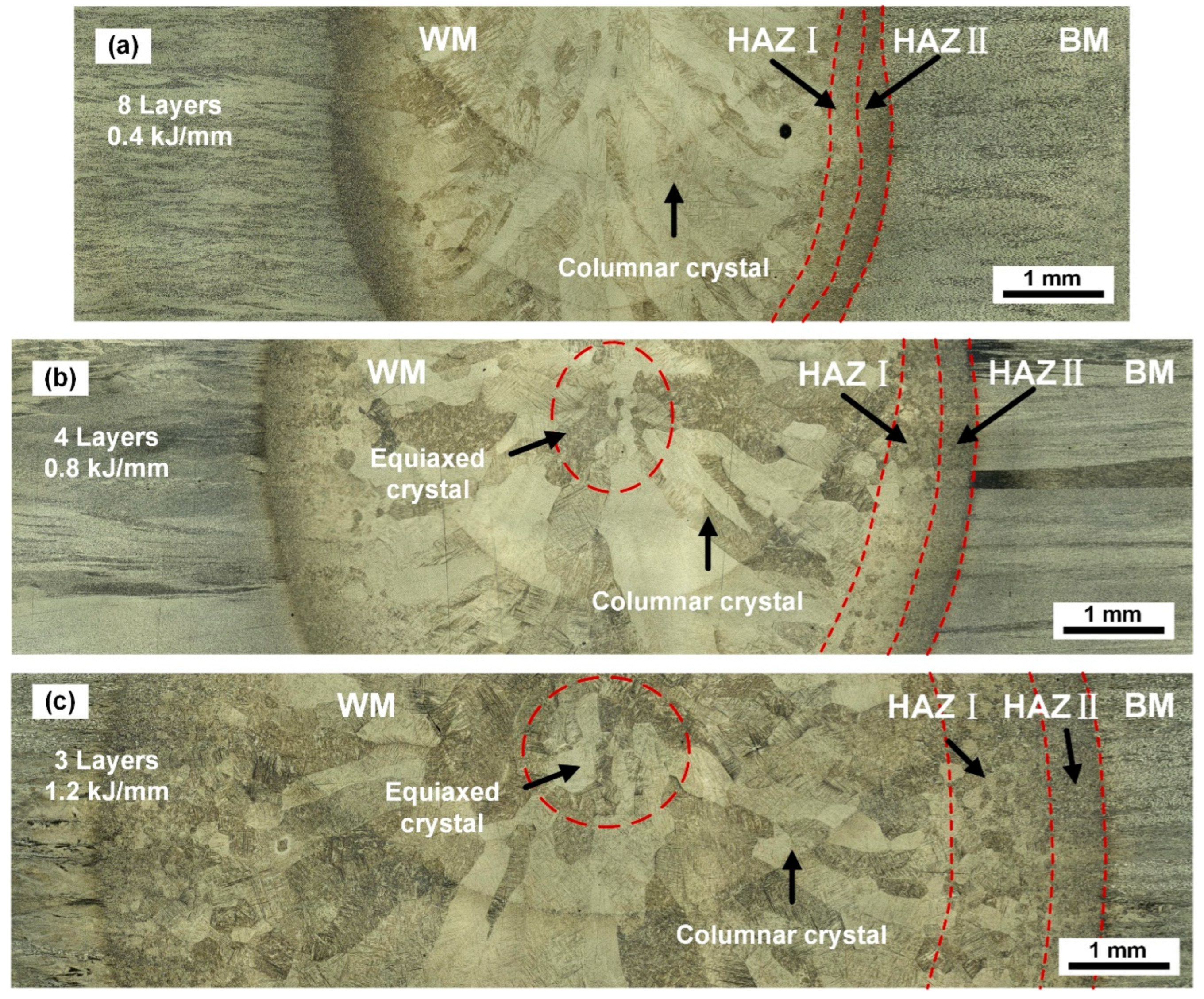

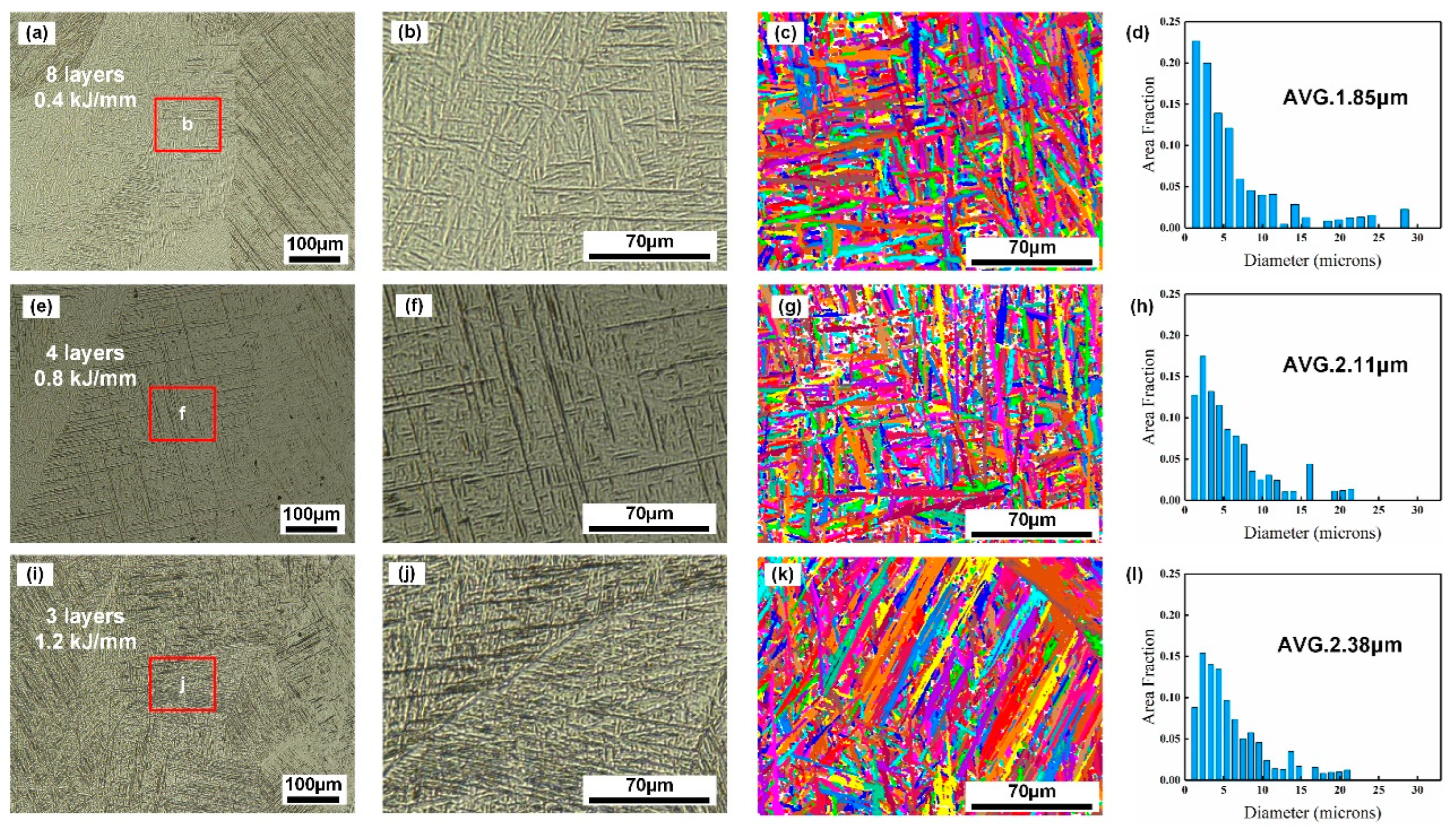

3.2. Microstructure of Different Specimens

3.3. The Weld Joint Mechanical Properties

3.3.1. Microhardness

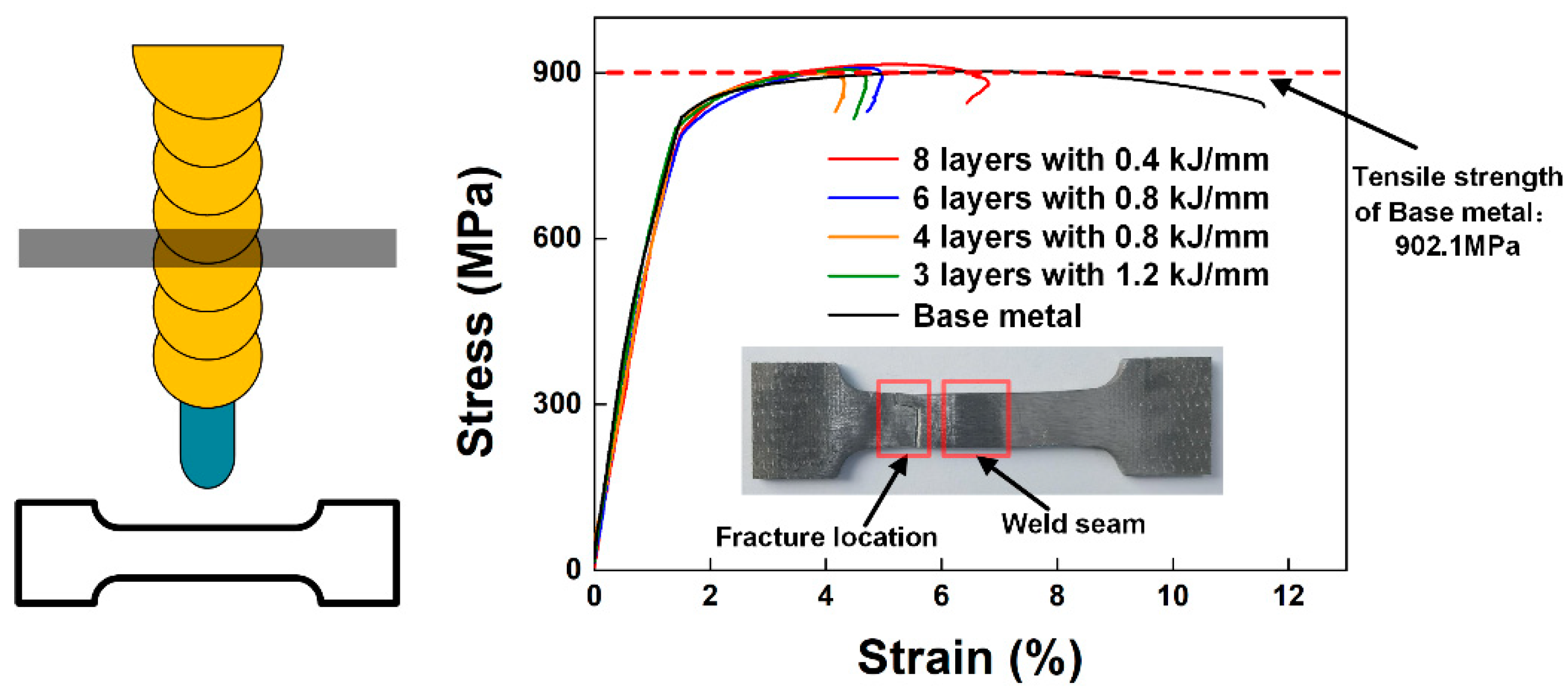

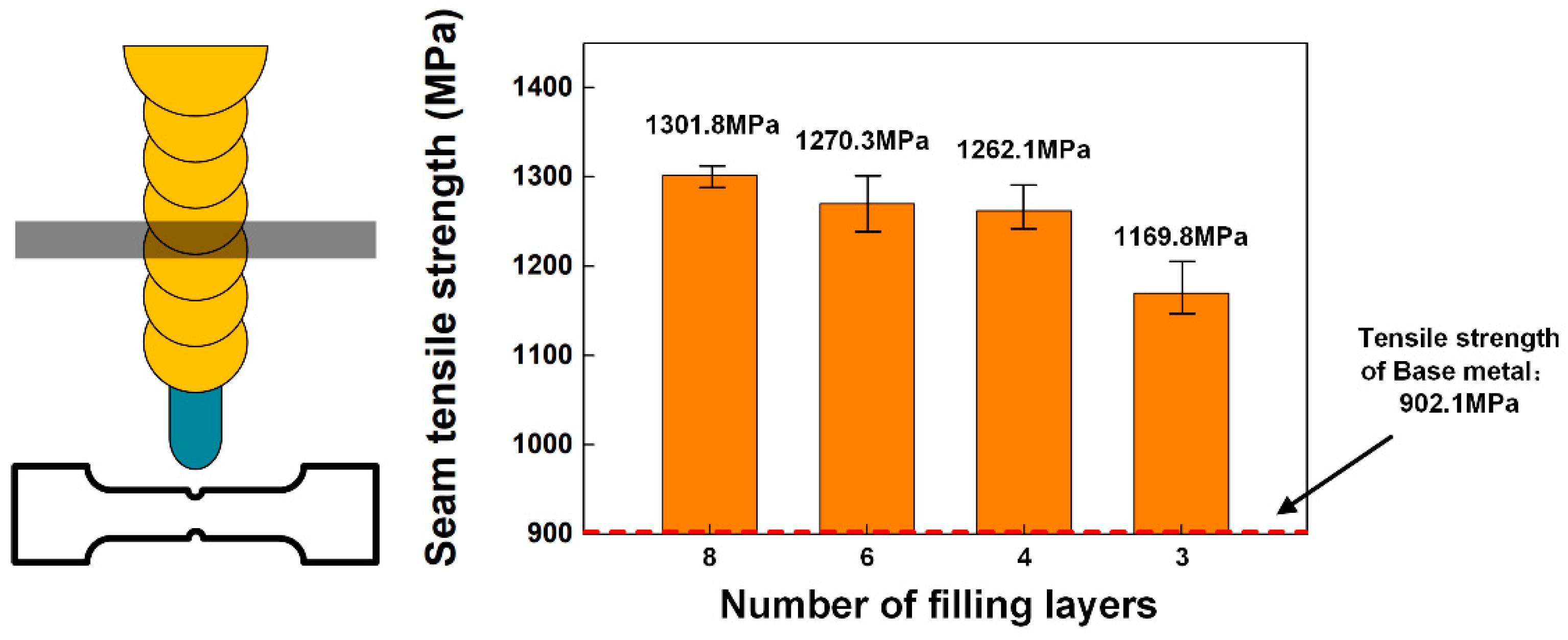

3.3.2. Tensile Strength

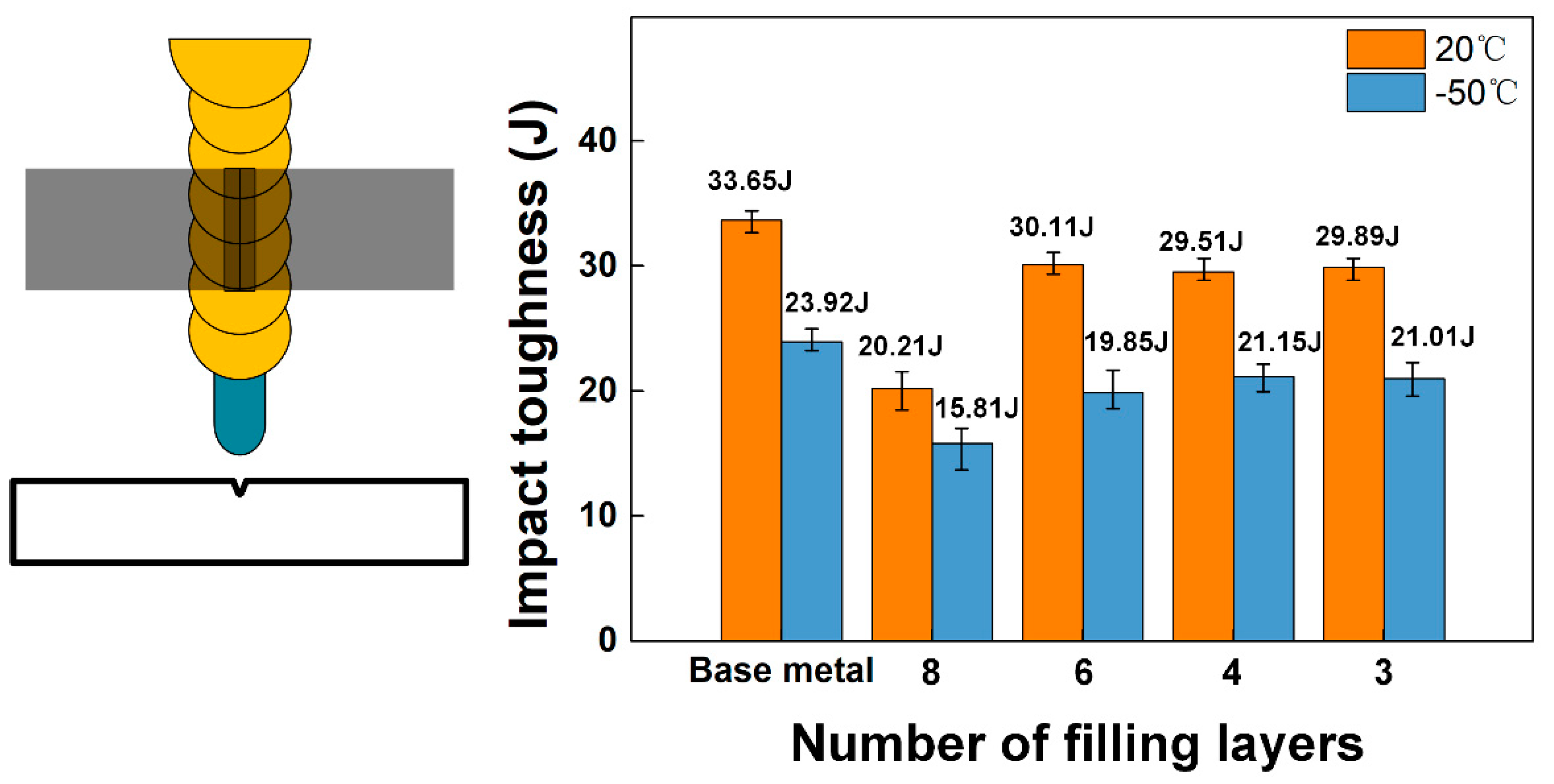

3.3.3. Impact Toughness

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lu, J.Z.; Lu, H.; Xu, X.; Yao, J.; Cai, J.; Luo, K. High-performance integrated additive manufacturing with laser shock peening-induced microstructural evolution and improvement in mechanical properties of Ti6Al4V alloy components. Int. J. Mach. Tools Manuf. 2020, 148, 14. [Google Scholar] [CrossRef]

- Calamaz, M.; Coupard, D.; Girot, F. A new material model for 2D numerical simulation of serrated chip formation when machining titanium alloy Ti-6Al-4V. Int. J. Mach. Tools Manuf. 2008, 48, 275–288. [Google Scholar] [CrossRef] [Green Version]

- Kawahito, Y.; Wang, H.; Katayama, S.; Sumimori, D. Ultra high power (100 kW) fiber laser welding of steel. Opt. Lett. 2018, 43, 4667–4670. [Google Scholar] [CrossRef] [PubMed]

- Jian, L.A.; Long, J.; Zhang, L.J.; Ning, J.; Ma, Z.X.; Zang, S.L. Zoning study on the fatigue crack propagation behaviors of a double-sided electron beam welded joint of TC4 titanium alloy with the thickness of 140 mm. Int. J. Fatigue 2021, 146, 106145. [Google Scholar]

- Bayley, C.J.; Mantei, A. Influence of Weld Heat Input on the Fracture and Metallurgy of HSLA-65. Can. Metall. Q. 2009, 48, 311–316. [Google Scholar] [CrossRef]

- Viano, D.M.; Ahmed, N.U.; Schumann, G.O. Influence of heat input and travel speed on microstructure and mechanical properties of double tandem submerged arc high strength low alloy steel weldments. Sci. Technol. Weld. Join. 2000, 5, 26–34. [Google Scholar] [CrossRef]

- Zhang, C.G.; Lu, P.; Hu, X.; Song, X. Effect of buffer layer and notch location on fatigue behavior in welded high-strength low-alloy. J. Mater. Process.Technol. 2012, 212, 2091–2101. [Google Scholar] [CrossRef]

- Guo, Y.; Chiu, Y.; Attallah, M.M.; Li, H.; Bray, S.; Bowen, P. Characterization of Dissimilar Linear Friction Welds of α-β Titanium Alloys. J. Mater. Eng. Perform. 2012, 21, 770–776. [Google Scholar] [CrossRef]

- Prikhodko, S.V.; Savvakin, D.G.; Markovsky, P.E.; Stasuk, O.O.; Penney, J.; Shirzadi, A.A.; Davies, P.D.; Davies, H.M. Diffusion bonding of TiC or TiB reinforced Ti–6Al–4V matrix composites to conventional Ti–6Al–4V alloy. Sci. Technol. Weld. Join. 2020, 25, 518–524. [Google Scholar] [CrossRef]

- Ma, T.J.; Chen, X.; Li, W.Y. Effect of Process Parameters on Welding Variables during Linear Friction Welding of Ti-6Al-4V Alloy. Adv. Mater. Res. 2011, 314, 979–983. [Google Scholar] [CrossRef]

- Dittrich, D.; Schedewy, R.; Brenner, B.; Standfuß, J. Laser-multi-pass-narrow-gap-welding of hot crack sensitive thick aluminum plates. In Proceedings of the 7th International WLT Conference on Lasers in Manufacturing (LiM), Munich, Germany, 13–16 May 2013; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Elmesalamy, A.; Francis, J.A.; Li, L. A comparison of residual stresses in multi pass narrow gap laser welds and gas-tungsten arc welds in AISI 316L stainless steel. Int. J. Press. Vessel. Pip. 2014, 113, 49–59. [Google Scholar] [CrossRef]

- Zhang, X.D.; Ashida, E.; Tarasawa, S.; Anma, Y.; Okada, M.; Katayama, S.; Mizutani, M. Welding of thick stainless steel plates up to 50 mm with high brightness lasers. J. Laser Appl. 2011, 23, 7. [Google Scholar] [CrossRef]

- Feng, J.C.; Rathod, D.W.; Roy, M.J.; Francis, J.A.; Guo, W.; Irvine, N.M.; Vasileiou, A.N.; Sun, Y.L.; Smith, M.C.; Li, L. An evaluation of multipass narrow gap laser welding as a candidate process for the manufacture of nuclear pressure vessels. Int. J. Press. Vessel. Pip. 2017, 157, 43–50. [Google Scholar] [CrossRef] [Green Version]

- Sun, J.H.; Ren, W.; Nie, P.; Huang, J.; Zhang, K.; Li, Z. Study on the weldability, microstructure and mechanical properties of thick Inconel 617 plate using narrow gap laser welding method. Mater. Des. 2019, 175, 13. [Google Scholar] [CrossRef]

- Wu, S.K.; Zhang, J.; Yang, J.; Lu, J.; Liao, H.; Wang, X. Investigation on microstructure and properties of narrow-gap laser welding on reduced activation ferritic/martensitic steel CLF-1 with a thickness of 35 mm. J. Nucl. Mater. 2018, 503, 66–74. [Google Scholar] [CrossRef]

- Cui, B.; Zhang, H.; Zhao, C.; Shao, T. Microstructure and Mechanical Properties of TC4 Titanium Alloy Joint by Ultra-narrow Gap Laser Welding. Mater. Rev. 2018. [Google Scholar]

- Liu, J.Z.; Zhan, X.; Gao, Z.; Yan, T.; Zhou, Z. Microstructure and stress distribution of TC4 titanium alloy joint using laser-multi-pass-narrow-gap welding. Int. J. Adv. Manuf. Technol. 2020, 108, 3725–3735. [Google Scholar] [CrossRef]

- Dewangan, S. Effect of heat treatment into tensile strength, hardness and microstructural attributes of TIG welded Ti-6Al-4V titanium alloy. Aust. J. Mech. Eng. 2022, 1–10, (ahead-of-print). [Google Scholar] [CrossRef]

- Guo, W.; Li, L.; Dong, S.; Crowther, D.; Thompson, A. Comparison of microstructure and mechanical properties of ultra-narrow gap laser and gas-metal-arc welded S960 high strength steel. Opt. Lasers Eng. 2017, 91, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Lehto, P.; Remes, H. EBSD characterisation of grain size distribution and grain sub-structures for ferritic steel weld metals. Weld. World 2022, 66, 363–377. [Google Scholar] [CrossRef]

- Cui, C.Y.; Cui, X.G.; Ren, X.D.; Liu, T.T.; Hu, J.D.; Wang, Y.M. Microstructure and microhardness of fiber laser butt welded joint of stainless steel plates. Mater. Des. 2013, 49, 761–765. [Google Scholar] [CrossRef]

- Zhang, H.; Li, J.; Ma, P.; Xiong, J.; Zhang, F. Study on microstructure and impact toughness of TC4 titanium alloy diffusion bonding joint. Vacuum 2018, 152, 272–277. [Google Scholar] [CrossRef]

- Shi, X.; Zeng, W.; Sun, Y.; Han, Y.; Zhao, Y. Study on the Hot Processing Parameters-Impact Toughness Correlation of Ti-6Al-4V Alloy. J. Mater. Eng. Perform. 2016, 25, 1741–1748. [Google Scholar] [CrossRef]

| Chemical Constituents (%) | Mechanical Properties | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Al | V | Fe | C | N | H | O | Ti | σb (Mpa) | δ (%) |

| 6 | 4 | 0.3 | 0.1 | 0.05 | 0.015 | 0.2 | Bal | 895 | 10 |

| Sample | Filling Layers | Line Energy | Weld Speed | Wire Speed |

|---|---|---|---|---|

| 1 | 8 | 0.4 kJ/mm | 0.6 m/min | 3 m/min |

| 2 | 5 | 0.8 kJ/mm | 0.3 m/min | 3 m/min |

| 3 | 4 | 0.8 kJ/mm | 0.3 m/min | 4.5 m/min |

| 4 | 3 | 1.2 kJ/mm | 0.2 m/min | 4 m/min |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, S.; Li, L.; Si, C.; Gong, J.; Tao, W. Microstructure and Mechanical Properties of Laser Narrow-Gap Multi-Pass Weld 20 mm-Thick Ti-6Al-4V Alloy with Different Filling Layers. Crystals 2022, 12, 977. https://doi.org/10.3390/cryst12070977

Meng S, Li L, Si C, Gong J, Tao W. Microstructure and Mechanical Properties of Laser Narrow-Gap Multi-Pass Weld 20 mm-Thick Ti-6Al-4V Alloy with Different Filling Layers. Crystals. 2022; 12(7):977. https://doi.org/10.3390/cryst12070977

Chicago/Turabian StyleMeng, Shenghao, Liqun Li, Changjian Si, Jianfeng Gong, and Wang Tao. 2022. "Microstructure and Mechanical Properties of Laser Narrow-Gap Multi-Pass Weld 20 mm-Thick Ti-6Al-4V Alloy with Different Filling Layers" Crystals 12, no. 7: 977. https://doi.org/10.3390/cryst12070977

APA StyleMeng, S., Li, L., Si, C., Gong, J., & Tao, W. (2022). Microstructure and Mechanical Properties of Laser Narrow-Gap Multi-Pass Weld 20 mm-Thick Ti-6Al-4V Alloy with Different Filling Layers. Crystals, 12(7), 977. https://doi.org/10.3390/cryst12070977