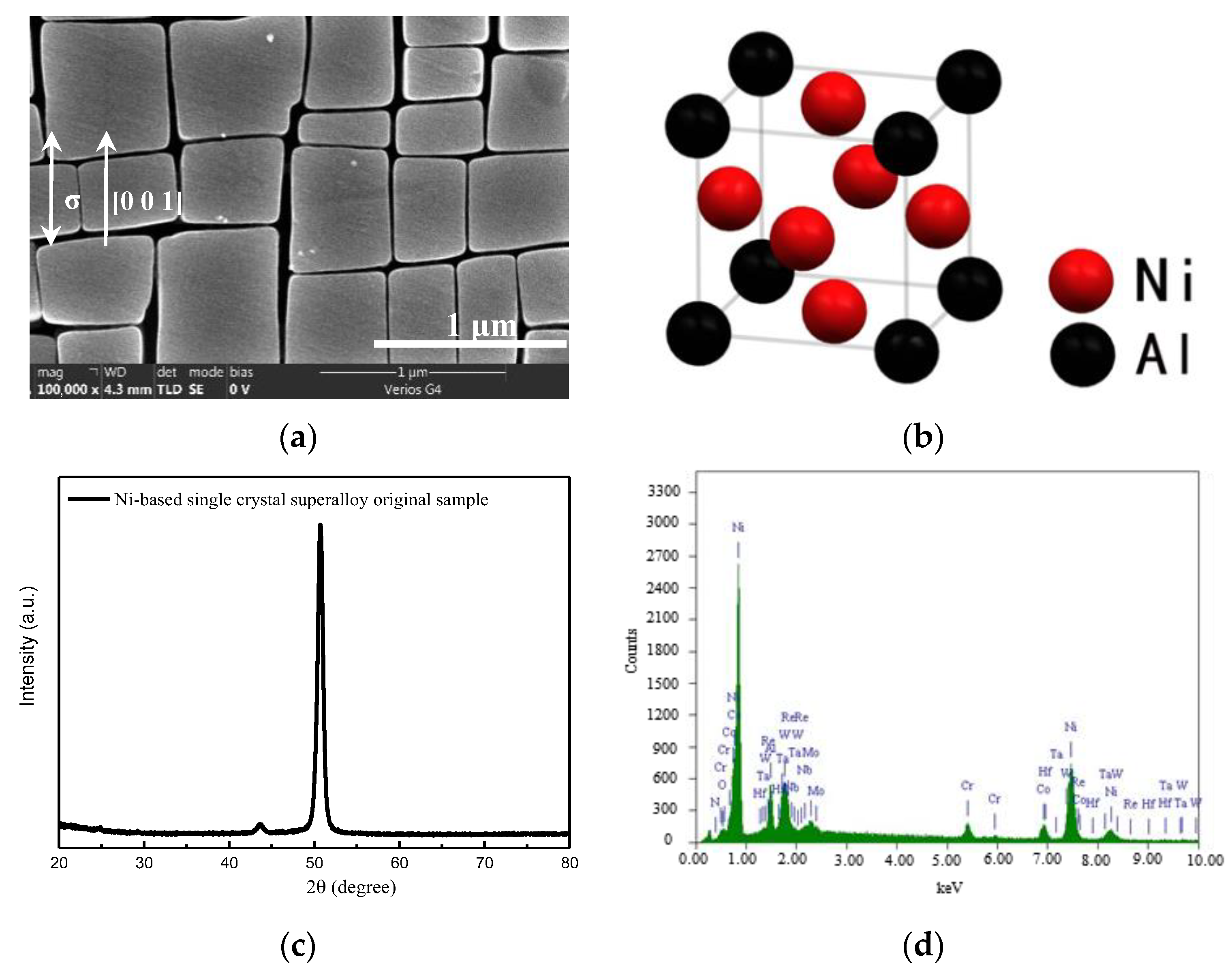

3.1. Effect of Size on Creep of Ni-Based Single Crystals

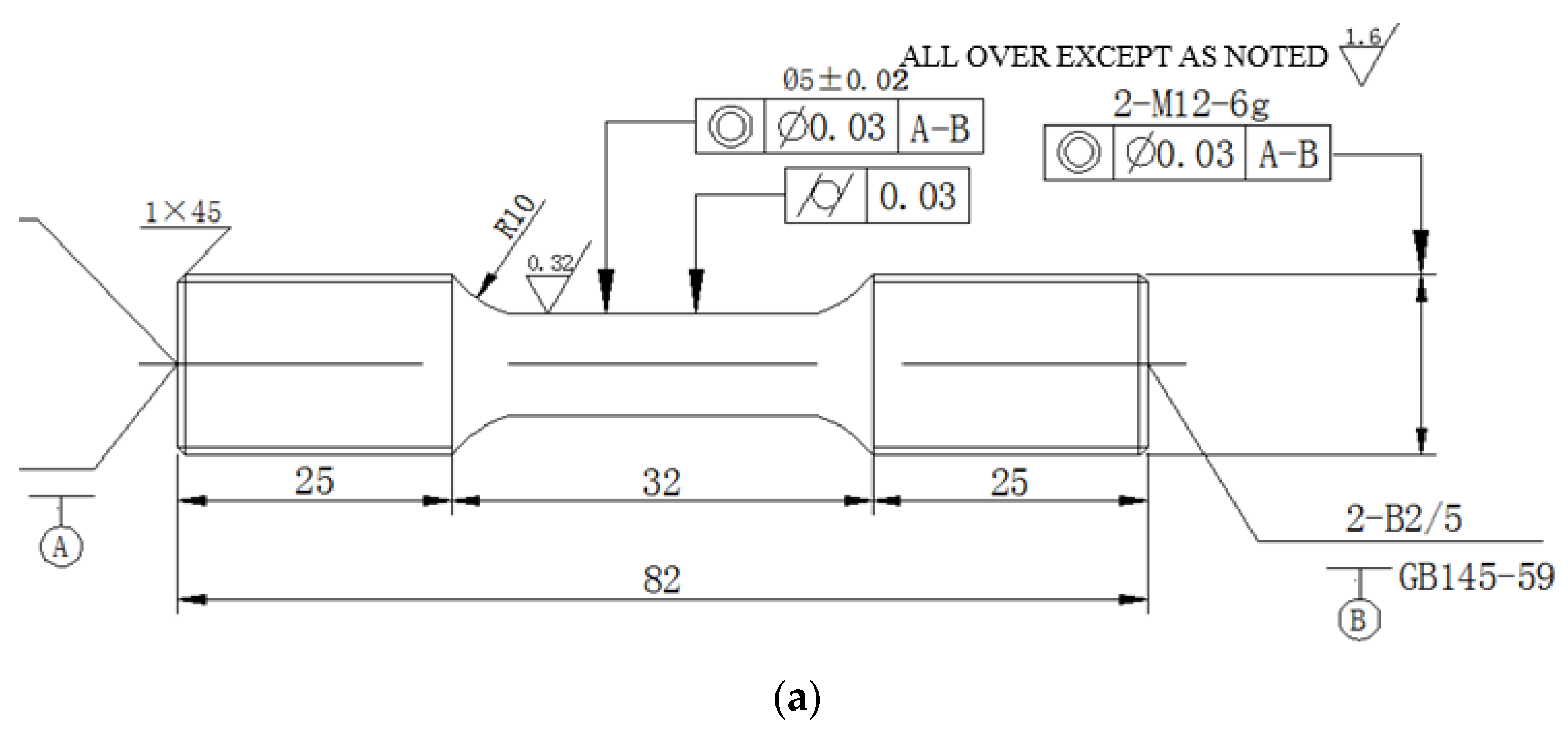

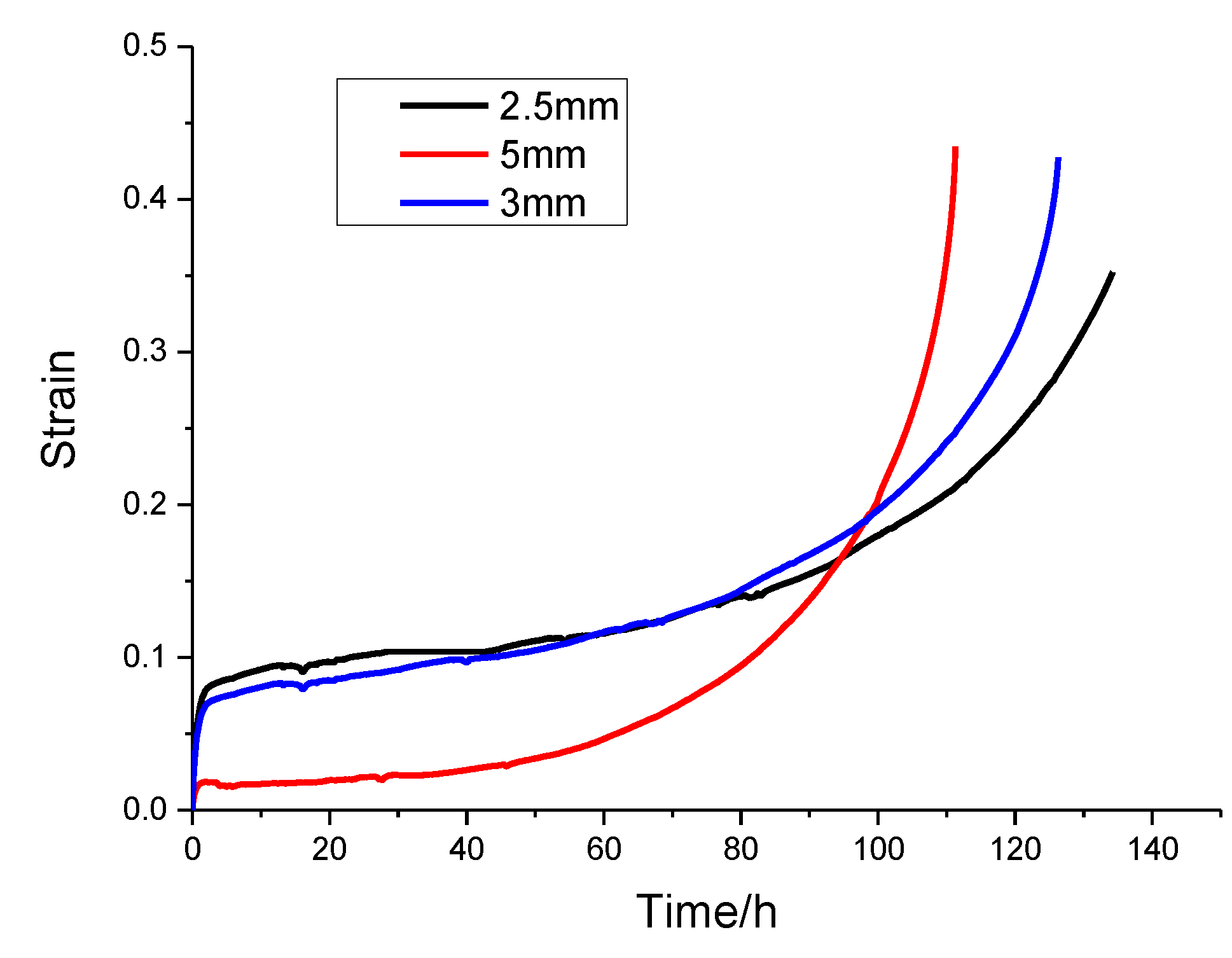

High-temperature creep tests were conducted on specimens of domestic second-generation single-crystal superalloys of different diameters (2.5, 3, and 5 mm) at 980 °C and 300 MPa. The test conditions and methods were kept the same, and only the specimen diameters were varied. The creep test results, including creep life, creep fracture strain, and cross-sectional shrinkage, are listed in

Table 2.

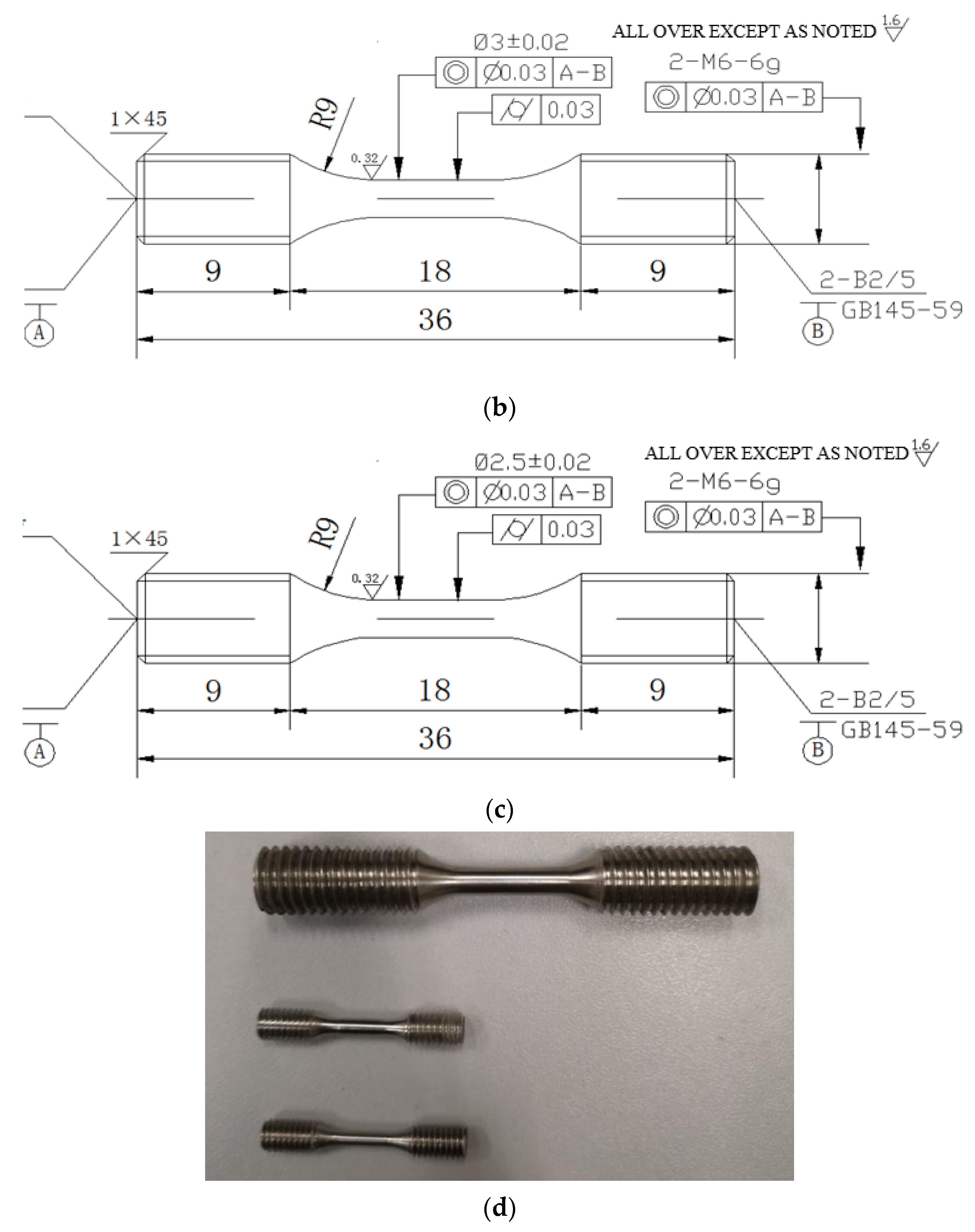

From the test results (

Table 2 and

Figure 3), it can be seen that the miniature specimen exhibits the longest creep life for constant temperature stress, i.e., 980 °C/300 MPa. All dimensions were tested in triplicate. For the specimen with a diameter of 2.5 mm, the creep life is 139.22 h, 134.19 h, and 132.34 h, respectively, with little difference. The strains at break are 36.4%, 35.2%, and 42.2%, respectively, and the strain at break of A3 is larger. The fracture shrinkage rates are 26.1%, 24.8%, and 25.5%, respectively, with a small difference; for the specimen with a diameter of 3.0 mm, the creep life is 122.93 h, 125.42 h, and 128.66 h, respectively. The strains at break are 43.3%, 42.7%, and 38.9%, respectively, and the strain at break of B3 is smaller. The fracture shrinkage rates are 25.6%, 25.3%, and 24.4%, respectively, and the difference is small; for the specimen with a diameter of 5.0 mm, the creep life is 108.33 h, 111.27 h, and 109.51 h, respectively. The strains at break are 44.6%, 43.4%, and 43.8%, respectively. The fracture shrinkage rates are 24.7%, 26.4%, and 23.9%, respectively, and the fracture shrinkage rate of C2 is larger. To sum up, in general, the difference between the test results is small and within the acceptable range.

The average creep life was found to be approximately 125.67 h, whereas the average creep life of the 5 mm specimen was approximately 109.7 h. The maximum difference in creep life between the three specimens was 25.55 h, indicating a clear correlation between the size of the specimen and its creep life under these test conditions. Overall, the smaller the specimen size, the longer its creep life. It was also observed that at this temperature stress, the average strain at fracture of the 2.5-, 3- and 5-mm specimens was approximately 37.9%, 41. 6%, and 43.9%, respectively. This result indicated that the larger the size of the specimen, the larger the creep fracture strain. In general, the size of the specimen had no significant effect on the creep fracture strain. After calculating the average shrinkage rate of each specimen after creep, it was found that there was no significant difference in the shrinkage rate of the three different sizes of round bar specimens, which were all approximately 25%, and obvious necking occurred.

It can be seen from

Figure 4 above that the creep curves of all three specimen sizes show exponential growth at the same temperature stress (980 °C/300 MPa). The analysis shows that the specimen with a diameter of 2.5 mm exhibits three obvious stages of creep deformation, first presenting a typical initial creep stage, also called the deceleration creep stage. In this stage, an obvious hardening of the creep process occurs, the creep strain is generated instantaneously with the loading of the stress, and the creep strain rate decreases dramatically until it reaches a minimum value. This stage was very short, lasting approximately 1.5 h, before rapidly entering the second stage of creep. The second stage is the steady-state creep stage, in which the creep rate remained stable and can be approximated as a straight line with a gradient of approximately 3.86 × 10

−3/h. This stage lasted approximately 120 h, accounting for 88% of the total creep life, but the strain only increased by ~0.18. Subsequently, the third stage of creep was entered with a higher creep rate and shorter time, also known as the accelerated creep stage.

The creep strain rate increased monotonically, with strain increasing to a maximum value of 35.2%, at which point the specimen showed damage failure. By analyzing the creep curve for a diameter of 3 mm, it was found that the behavior was still in agreement with standard creep characteristics. The same short deceleration creep stage was observed, quickly followed by the stable second stage. This second stage involved ~115 h of slow, uniform growth, accounting for 90% of the total creep time. In the very short third stage, the creep strain rate was found to change dramatically in a sharp upward trend and finally increased to 42.7% at the point of fracture. Analysis of the 5-mm creep curve diameter shows that the creep strain in the first 5 mm of the third stage is significantly smaller than the other two sizes tested. Moreover, there is no obvious first stage, meaning direct entry into the second stage, when the creep rate is very slow and smooth, with a rate of approximately 2.41 × 10−3/h. The total time spent in this stage was ~99 h, accounting for 89% of the total creep time. When entering the third stage, the creep strain increased significantly from 18% in the second stage to 43.4%, i.e., by a factor of almost 2.4. The creep strain rate also showed a sharp increase, which finally led to the fracture of the specimen.

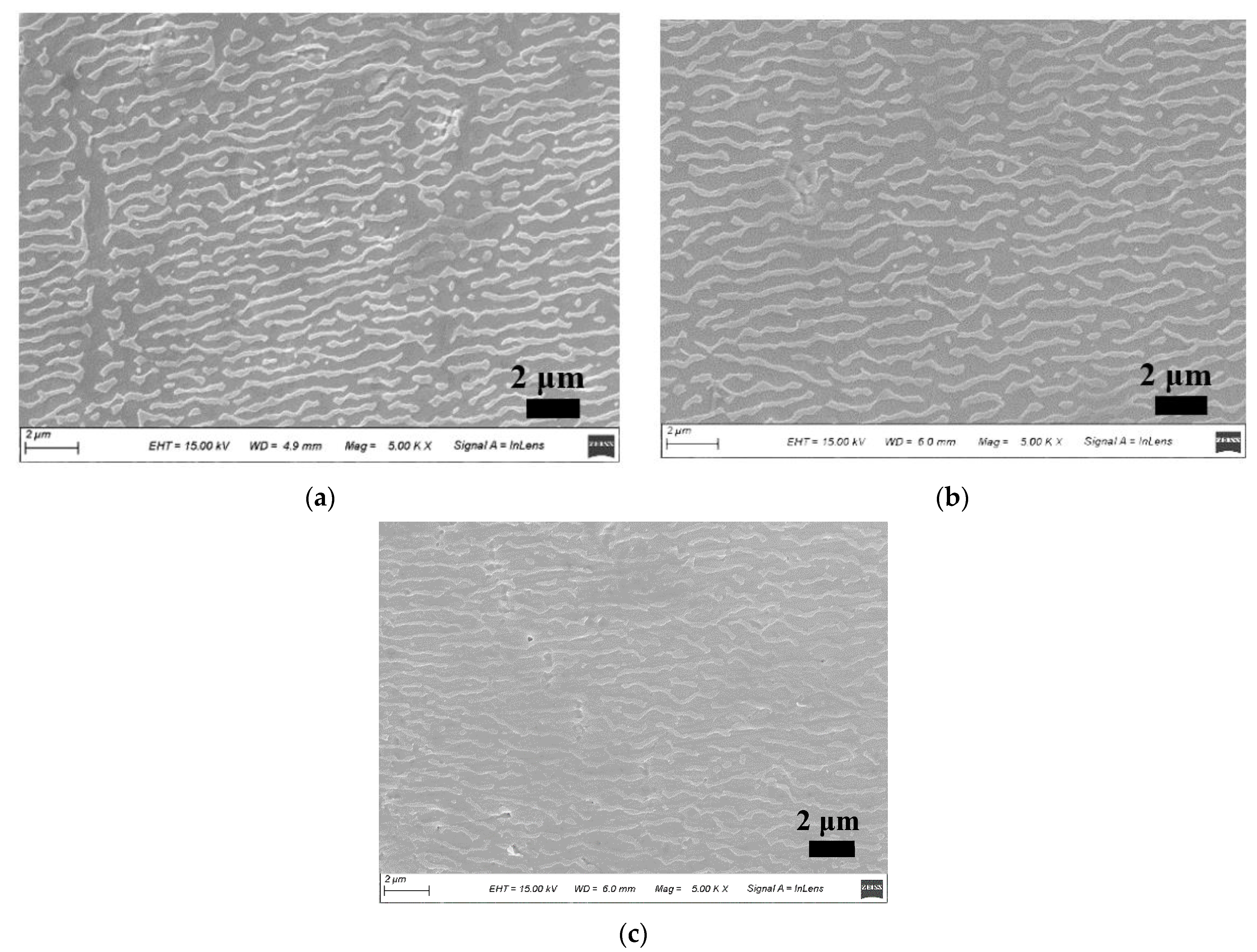

Figure 5 shows the microstructural morphology of round bar specimens with diameters of 2.5, 3, and 5 mm near the point of high-temperature creep fracture at 980 °C/300 MPa.

Figure 5a shows the microstructural morphology of the 2.5-mm diameter specimen, where the initial cubic γ phase evolves into a slender strip-like raft structure in the horizontal direction after creep (i.e., the classical “N” type raft structure). At this point, the γ matrix phase channels in the vertical direction were found to almost completely disappear and those in the horizontal direction fused, forming a single piece with increasing width. The two adjacent γ phases in the horizontal direction were further elongated and thickened in the horizontal direction owing to the disappearance of the matrix phase between them, and the γ′ phases fused on meeting. After approximately 134 h of creep, a small part of the raft-like structure fractured into fragments. The creeping raft-like structure gradually lost its ability to resist deformation and appeared to be delaminated, which finally manifested as macroscopic damage and destruction of the alloy material.

Figure 5b shows the SEM images of the 3-mm creep specimen, from which it can be seen that a creep rafting phenomenon is also evident; however, the coarsening length of the γ phase in the horizontal direction is larger than that of the former. Although the changes in microstructure were similar, the creep time of the specimen was approximately 125 h. The occurrence of the raft shape also accompanies creep fracture, but the degree is much weaker than that of the former, and there are only a few scattered raft disintegration structures.

Figure 5c shows the microstructure of a standard specimen with a diameter of 5 mm under the same test conditions. The creep life of this specimen was approximately 111 h. Compared with the first two microstructure images, the extension size of the γ phase along the horizontal direction increased. Furthermore, the connection formed a complete raft-shaped strip structure with almost no interruption, and the reinforced phases were connected in bunches and strips. There was no fragmented structure observed, indicating that the raft shape had not yet formed. Other defects are also visible, such as inclusion cracks, which are often responsible for creep damage and lead to a significantly shorter creep life and faster damage.

Figure 5 shows that, for specimens of different sizes, the microscopic morphology after creep rupture is the key to dominating the creep behavior. For the sample with a diameter of 2.5 mm (

Figure 5a), the strengthening phase γ’ did not completely connect into a plate shape, and the degree of rafting is small. The channel of the matrix phase γ is narrow, and its life is longer. For the sample with a diameter of 5.0 mm (

Figure 5c), the strengthening phase has a high degree of rafting, which has been approximately completely connected into a plate shape. The width of the matrix phase γ channel is wider and there are obvious holes, which accelerate the creeping, Therefore, larger size specimens have shorter creep life.

These results indicate that under the given conditions at 980 °C, the creep life of Ni-based single crystal alloys decreases with increasing specimen size. This, in turn, leads to the difference in the presence and shape of rafts for each size specimen. Thus, it can be concluded that the size of the specimen is closely related to the morphology and microstructure of the alloy, and more closely related to the creep persistence performance.

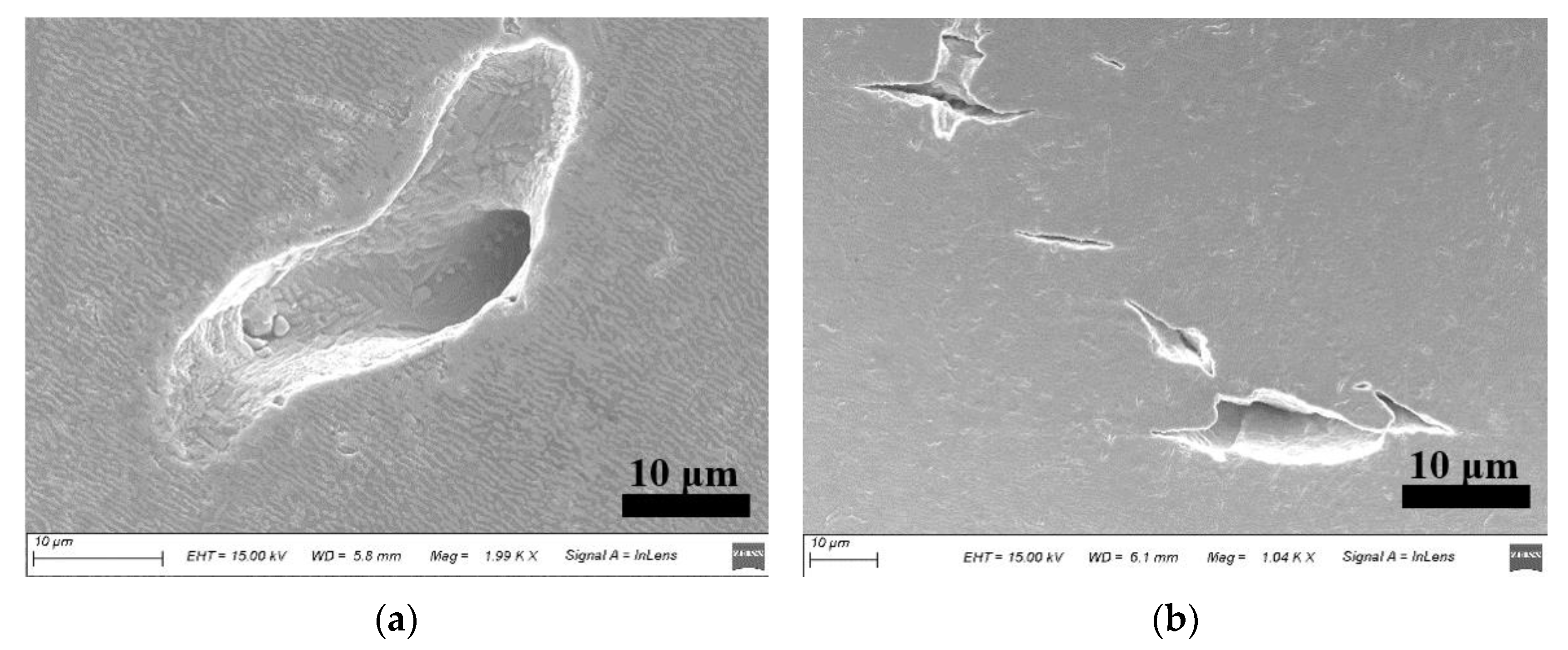

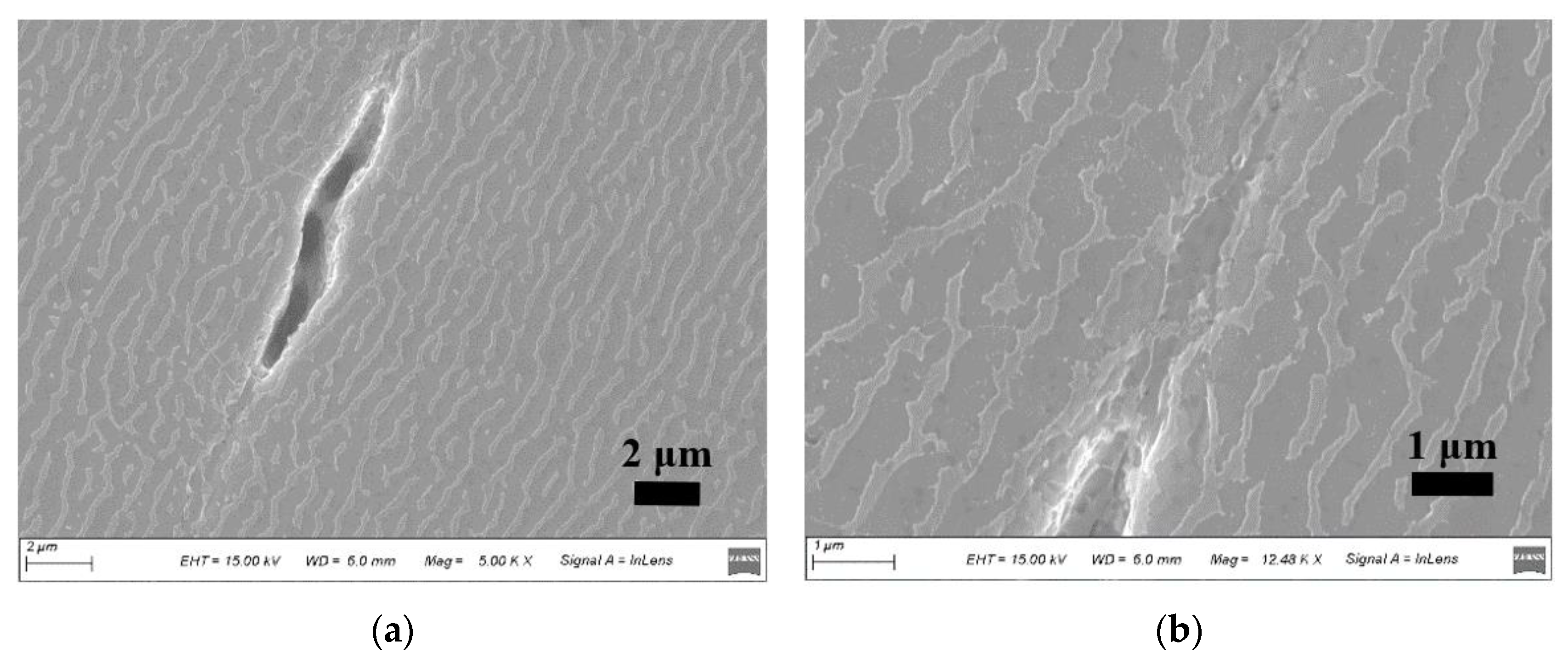

SEM was used to observe the microstructural morphology around the creep fracture of the superalloy at 980 °C/300 MPa, where a large number of crack sources could be seen. A large, elliptical hole defect can be seen in

Figure 6a, and the γ phase near this region has been oriented and coarsened to form a thinly striped raft-like structure, i.e., an “N”-shaped raft. The presence of the hole defect interrupts the continuity of the γ phase, resulting in the raft-like γ phase around the hole being significantly distorted. The hole was identified as a casting defect in the material that severely disrupted the continuity of the tissue and thus affected the creep life of the Ni-based superalloy. Similarly, many defects can be seen in

Figure 6b, including cracks, inclusions, and holes. Casting defects are one of the most important influencers of creep life. Microdefects gradually expand and extend with creep, leading to a decrease in the effective bearing area of the specimen and an increase in the actual stress in the cross-section, which eventually leads to creep fracture.

Figure 7 shows that after a long period of high-temperature creep testing, the surface of the Ni-based alloy underwent severe oxidation, and a thick oxide layer with bright white color was formed on the surface of the specimen. A large number of pores and cracks were observed near the oxide layer, causing a reduction in the finite cross-sectional area. However, the deformation resistance of the oxides (for example, Al

2O

3) in the oxide layer is not equal to that of the base alloy, and the deformation rate of the oxide layer is smaller. The uncoordinated deformation during creep causes cracks in the oxide layer, which in turn results in the fracture of the Ni-based single crystal and leads to a reduction in creep life.

In summary, it can be concluded that under the same test conditions, the smaller the size of the specimen, the longer its creep life. In addition to the errors caused by the test process, such as the error of the testing machine, test operation, dispersion of test data, dimension processing, and the analysis of the causes of such differences in test results from the perspective of creep damage, there are two main influencing factors. First, the casting defects of the material itself, including cracks, holes, and inclusions, cause a reduction in the effective bearing area during creep and eventually lead to specimen fracture. The 2.5-mm specimen, owing to its smaller volume and surface area, benefits from a reduced effective bearing area caused by the volume of the high-stress area. The possibility of defects or weak points is reduced, which in turn leads to the creep life of this specimen being extended. The second is the loss of the effective cross-sectional area due to oxidative corrosion on the specimen surface, leading to creep fracture due to the incompatible deformation of the oxide layer and the base alloy. Compared to standard specimens, miniature specimens are smaller in size, volume, and surface area, and have a smaller area for oxidation loss defects; therefore, in general, the smaller the specimen size, the longer the creep life.

3.2. Creep Process of Ni-Based Single Crystals at 980 °C/300 MPa

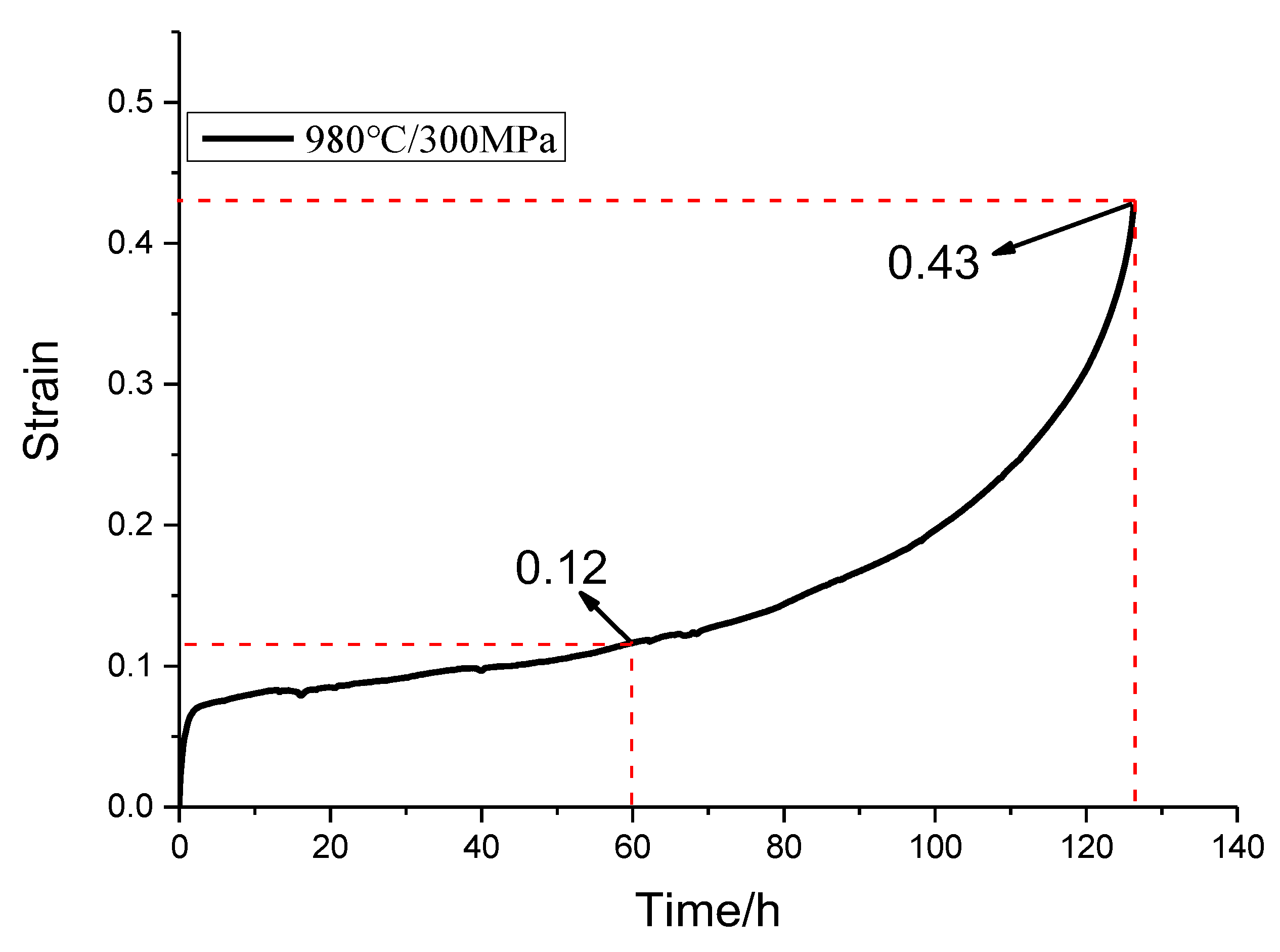

Creep interruption tests for periods of 30, 60, and 90 h and complete tests up to the point of fracture were carried out on Ni-based single-crystal superalloy specimens at 980 °C/300 MPa. These specimens were [001] oriented round bars with a diameter of 3 mm, whose full creep life curves are shown in

Figure 8. The creep deformation is characteristically divided into three stages. In the first stage, the creep deformation rate decreased rapidly for a short time, typical of the creep deceleration stage. Contrast analysis of this creep process showed that this stage, the process of hardening and recovery of softening in a smooth state, accounts for a large percentage of the overall creep life. This is followed by a rapid transition to the second stage of creep. During the second stage, the creep strain grew smoothly and slowly, and the creep rate remained almost constant. At a creep time of 60 h, the creep strain was only 0.12. Finally, the third stage of creep was entered, which is the accelerated creep stage. At this point, the creep rate and creep strain suddenly and rapidly increased. The fracture occurred at approximately 125 h, at which point the strain reached 0.43. This additional value was relatively large, which finally led to the failure and destruction of the specimen.

Numerous studies have shown that the excellent properties of Ni-based single-crystal high-temperature alloys arise from their unique crystal structure, which changes during the creep process. To study the evolution of the microstructure during creep, the morphology of the specimens was observed and analyzed by scanning electron microscopy (SEM) for different periods of creep: 30, 60, and 90 h, and the final fracture moment.

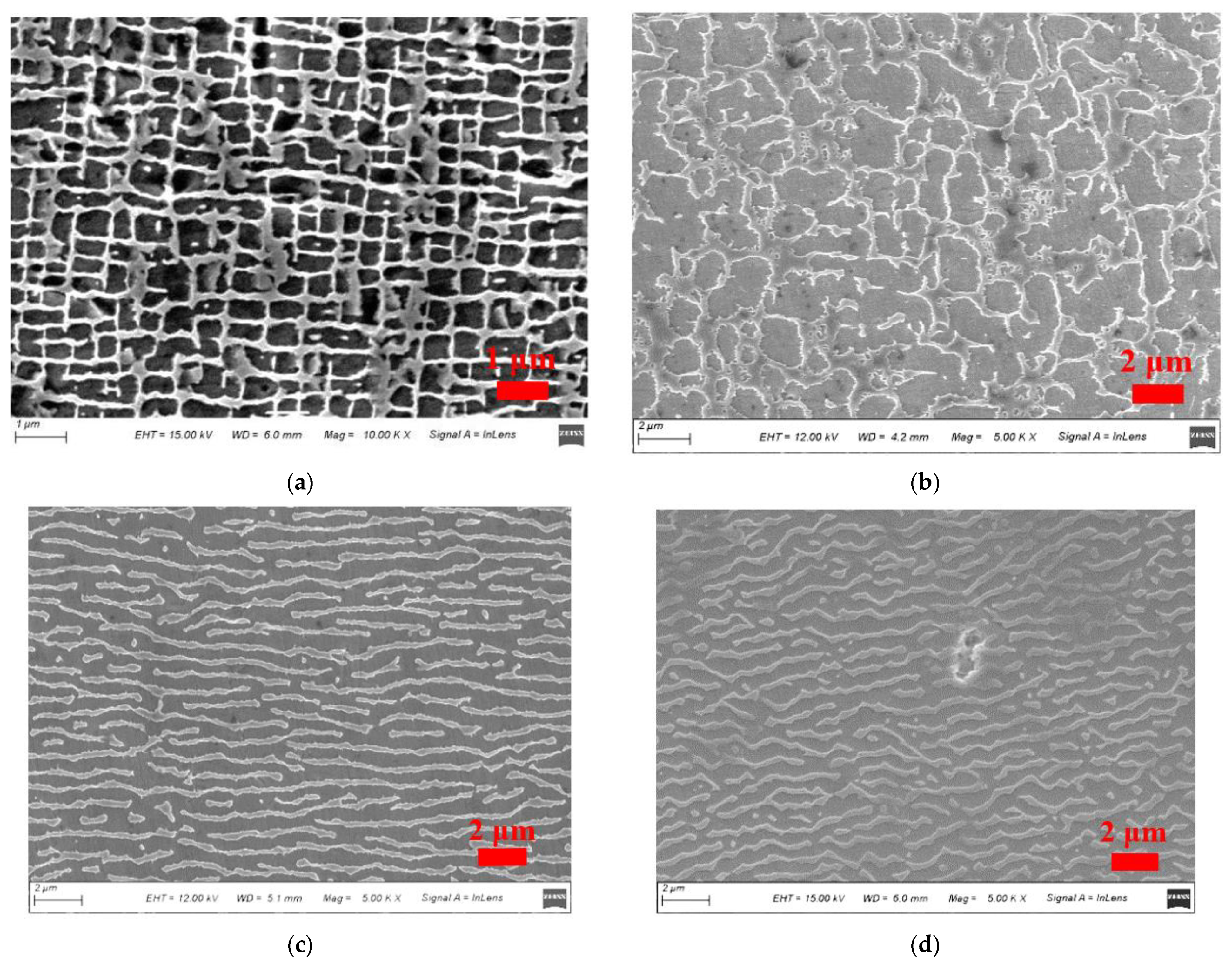

Figure 9 shows the microstructure morphology of the Ni-based single-crystal superalloy at different time points during creep at 980 °C/300 MPa test conditions.

Figure 9a shows the microstructure morphology at the beginning of the second stage of creep—that is, the steady-state creep stage. It can be seen that the γ phase starts to change shape at this time; it is no longer the original uniform co-grid of the γ phase, and the initial raft shape occurs. The two γ-reinforced phases that are partially adjacent to each other are interconnected and show a trend of directional coarsening along the horizontal axis. Although the reinforced phase γ maintains a block-like structure, its grain size gradually increases, and the matrix phase passages start to widen. At this time, the size of the reinforced phase γ was approximately 0.5–0.6 µm.

Figure 9b shows the microstructure of the superalloy during the middle stage of steady-state creep at 60 h. The two-phase structure is clearly deformed, the matrix phase channel in the horizontal direction slowly thicker, and the matrix channel in the vertical direction gradually became thinner or disappeared completely. The grain size of the γ′ phase has grown to 1.2–1.4 µm, and the surrounding cubic γ′ phase is passivated and has become round and elliptical. The position of the γ phase is disordered, and a raft-like structure was observed.

When the creep enters the end of the steady-state phase at 90 h, as shown in

Figure 9c, the degree of deformation of the two γ/γ′ phases intensifies and significant rafting can be seen to have occurred. The two γ′ phases fuse together, join to form a strip, and continue to grow in the horizontal direction. The matrix channels in the vertical direction have completely disappeared, and the coarsening of the matrix phase channels in the horizontal direction has continued to expand severely, forming a typical “N”-type raft structure. From the above analysis, it can be seen that when the specimen was in the steady-state creep stage, the creep strain and creep rate were very low, and the microstructure indicated that the initial rafting phenomenon was not very obvious. Only the outcrop and γ phase morphology did not change significantly, meaning that good creep performance can be maintained for a long period of time. While rafting was observed in the middle of the steady-state creep stage, the width of the reinforced phase morphology and the matrix phase changed significantly; at the end of the steady-state stage, the γ phase coarsened to form a plate, the rafting phenomenon was complete, and the third stage of creep was about to be entered. As shown in

Figure 9d, the microstructure of the specimen at the point of fracture was a partially fractured γ phase raft-like strip structure, in which there were many scattered points. The matrix phase channel almost entirely disappeared.

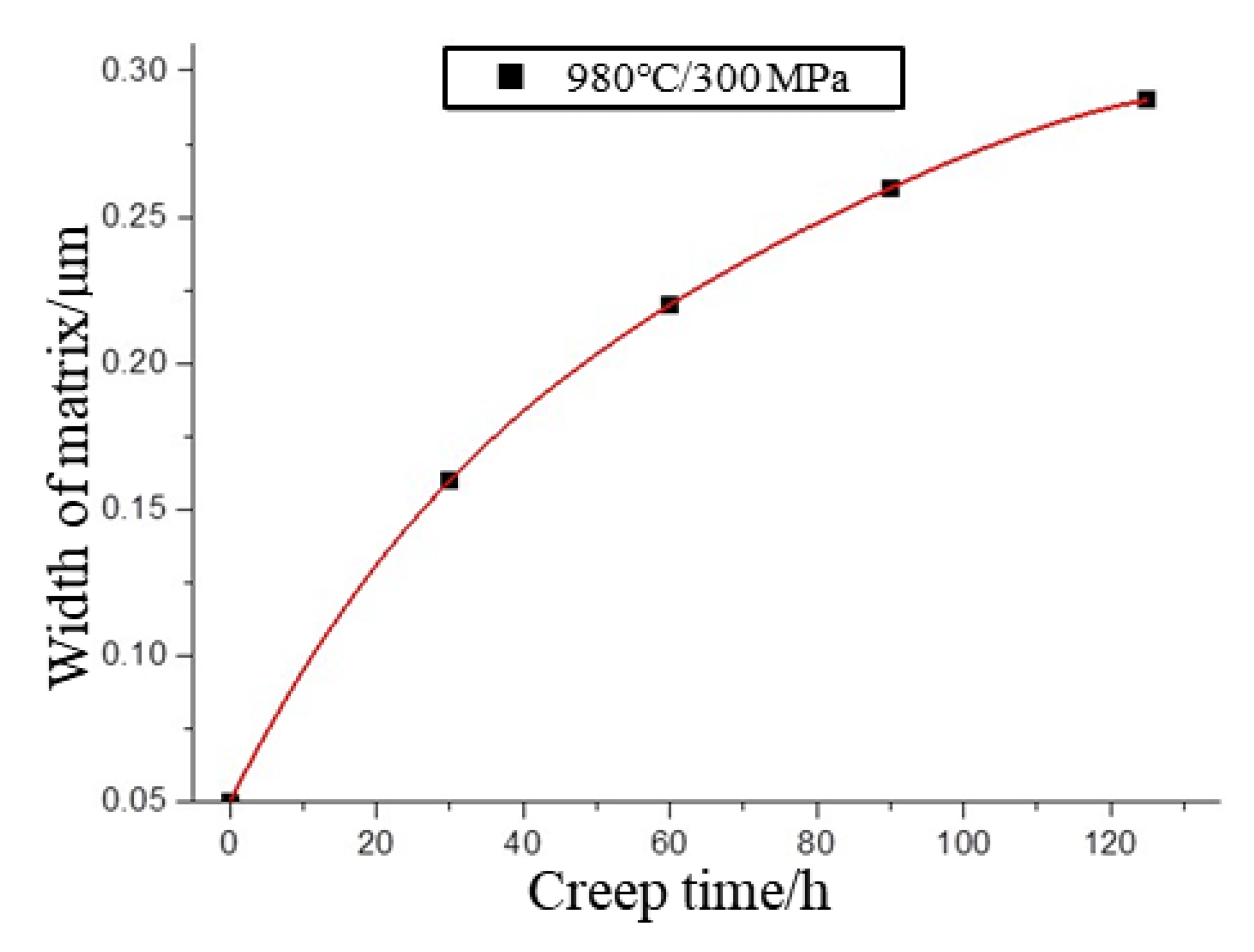

The above analysis shows that the width of the γ-phase channel continuously increases with the extent of creep during the high-temperature creep process. The γ-phase channel widths in the microstructural diagrams of the specimens for each process were statistically calculated using ImageJ image processing software. The statistical results showed that the sample values of the γ-phase channel widths at different creep moments obeyed a log-normal distribution. The γ-phase channel widths under tensile creep at 980 °C/300 MPa were fitted according to the mean value combined with the data processing software results, as shown in

Figure 10. It can be observed that the rate of change of matrix phase width is fastest at the early creep stage, and this rate of increase slows down significantly in the middle and late creep stages with the appearance and completion of rafting. The analysis of the curves shows that the width of the matrix phase channel during creep exhibits a fast and then slow overall evolution.

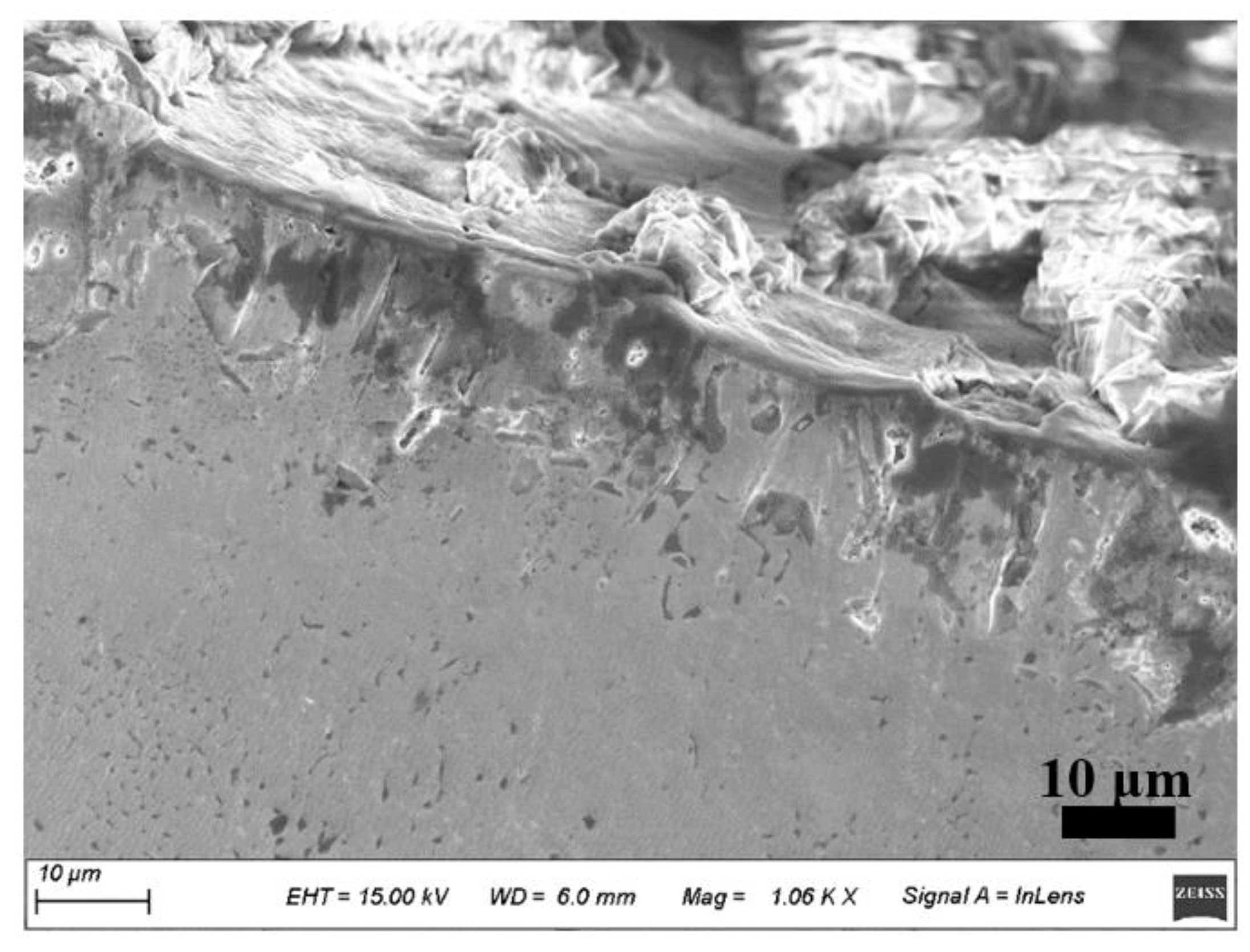

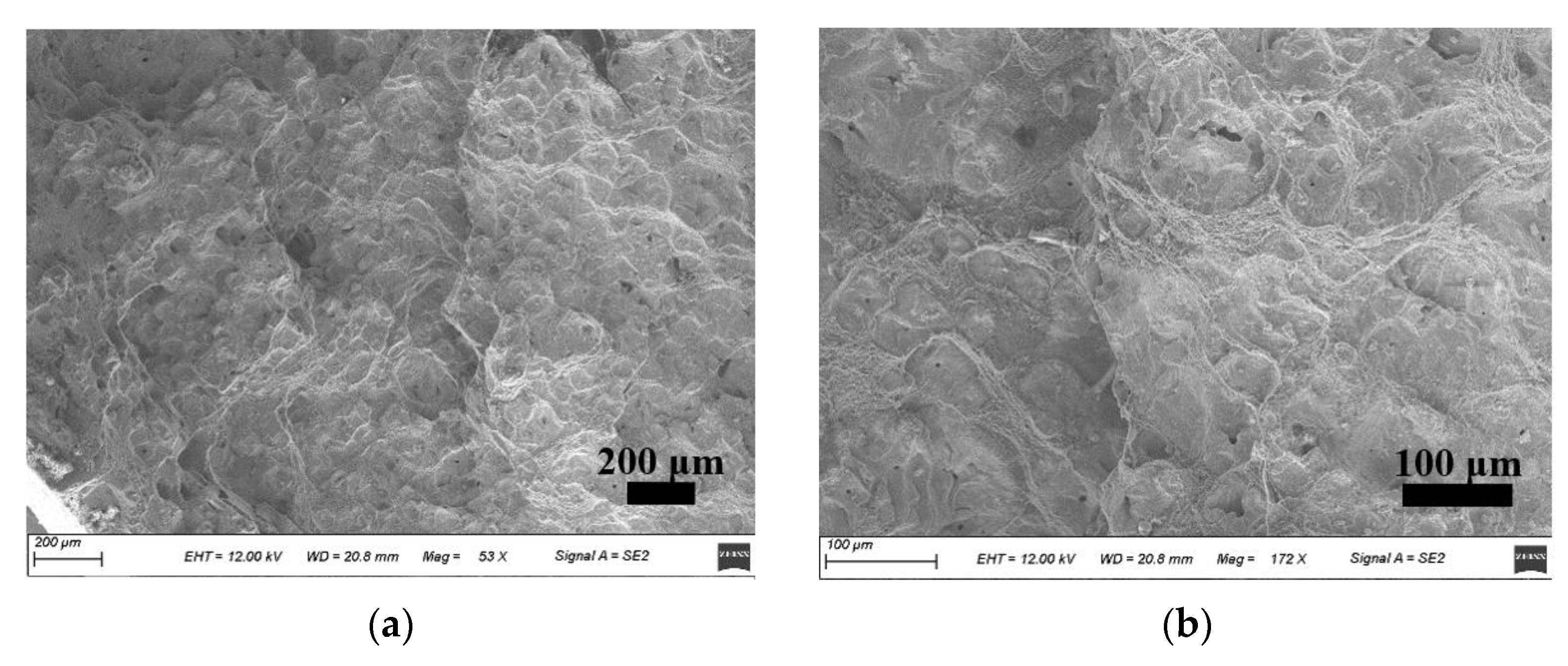

The creep fracture of the specimen at 980 °C/300 MPa is shown in

Figure 11. The low-magnification morphology of the creep fracture of the material is shown in

Figure 11a, where the fracture surface is relatively rough and oxidation is more severe. The deformation mechanism is mainly a diffusion creep mechanism with the directional diffusion of atoms and vacancies. This can be seen more clearly in the high-magnification image in

Figure 11b: there is obvious creep cavitation in the fracture area with a large number of tough nests of different sizes. The center of these tough nests is often accompanied by many small holes, which are generally thought to be the source of crack budding, leading to creeping damage. Cracks sprout from the defect at the hole and expand radially, sometimes also causing the appearance of secondary cracks. The material collapses from the inside and finally shows the fracture pattern of holes and tough nests.

During high-temperature creep, a large number of dislocations slip or climb up the alloy matrix. Some dislocations shear into the reinforced phase, resulting in many holes near the interface between the matrix and reinforcing phases. This causes cracks to sprout and extend to form tough nests. Oxygen is able to enter from the holes and tough nests and subsequently react with Ni, Al, and other elements during oxidation, destroying the microstructure of the alloy and thus reducing its creep resistance. The cracks connect and extend towards each other, gradually forming tearing ribs in the direction of maximum shear stress, and finally, macroscopic fracture occurs in the late creep stage.

The microstructure morphology near the point of creep fracture of the Ni-based single-crystal superalloy was observed using SEM, and a large number of crack sources were found in the creep fracture region of the specimen. As shown in

Figure 12a, the cracks were formed by the expansion of the original casting defects or initial microcracks during creep. Their expansion direction was perpendicular to the direction of the tensile axis, and the crack length was approximately 11.3 µm. At this point, the γ/γ phase exhibited an “N”-type raft structure. The γ phase striped raft structure was partially fractured, with many scattered points, and the matrix phase passages almost entirely disappeared. The rafting phenomenon was clearly present.

Figure 12b shows the local enlargement of the crack tip, which is small in size and has a large stress concentration. The raft-like γ phase in this region is violently deformed with a large degree of tilting, the orientation of the raft-like γ phase is more disordered, and some small cracks exist in the region surrounding the crack.