Abstract

In this paper, the compression behavior of a triply minimal periodic surface (Shwartz Diamond) fabricated by selective laser melting (SLM) under different loading rates was studied. A quasi-static strain rate of 2.22 × 10−3/s was tested using a universal testing machine, and a strain rate of 650/s was tested by Hopkinson pressure bar (SHPB). The results showed that the yield stress of all structures increased under dynamic load, and the DIF of sheet structure was higher than that of the skeleton structure, among which the DIF of GSHD was the largest and most sensitive to strain rate. However, the normalized SEA of USHD was the highest.

1. Introduction

With the increasing maturity of additive manufacturing technology, lattice structures with a triply periodic minimal surface (TPMS) can be fabricated to further their applications in lightweight [1], filtration [2], energy absorption [3], and Bio-implants [4]. Researchers usually use selective laser melting (SLM) and electron beam melting (EBM) to prepare lattice structures, including truss structures [5,6,7,8] and TPMS structures [9,10,11,12] due to their high fabrication accuracy. TPMS structures have a clean mathematical representation and a very convenient gradient design process. Their advantages are having a continuous topology that can avoid stress concentration and have good mechanical properties, and having a surface with zero mean curvature that is similar to natural structures (e.g., porous bone) and thus excellent bionic properties. The commonly used TPMS structures such as Primitive, Diamond and Gyroid structures have attracted researchers’ interest. Researchers have found that the gradient structure exhibited superior energy absorption capacity, larger strain before densification, and significantly different deformation behavior compared to the uniform structure. Yang et al. [13] investigated the effect of loading direction on the compressive properties of gradient Gyroid structures and developed a mathematical model to predict the mechanical properties of gradient structures. The gradient skeletal Gyroid structure had a greater initial densification strain, and the energy absorption was greater than that of the uniform skeletal structure. Additionally, the deformation behavior of the gradient structure changed with a changing loading direction. Liu et al. [9] investigated the deformation behavior of gradient cell-size Diamond and Gyroid, and the results showed that 45 shear damage occurred first to the larger cell. Zhang et al. [14] investigated energy absorption characteristics and established energy absorption diagrams of three 316L sheet TPMS structures under compressive loading using experiments and finite element simulations. The results showed that Diamond structures exhibited better mechanical properties and energy-absorption capabilities. Therefore, it was necessary to study the mechanical behavior and deformation mechanism of gradient sheet with a Diamond structure.

The dynamic compression behavior of porous materials was very important when they were used for energy absorption, intrusion resistance and blast protection [15]. The dynamic compression behavior of foams has been thoroughly investigated by researchers. Deshpande et al. [16] investigated the high strain rate compression behavior of two foams (Alulight and Duocel) and showed that the platform stress and densification strain were independent of the strain rate but were sensitive to the relative density. However, the results of ALPORAS aluminum foam showed a high strain-rate sensitivity for platform stresses. Duarte et al. [17] reduced the high dispersion of mechanical properties caused by structural defects by adding a skin to the aluminum foam surface and found that the foam density and pore size distribution have a significant effect on the mechanical properties of the foam cubes. Mukai et al. [18] showed that the yield stress of ALPORAS aluminum foam exhibited significant strain rate sensitivity and the per-unit volume energy absorption was 50% higher at high strain rates than at quasi-static rates. Ozdemir et al. [19] showed that the lattice structure was able to diffuse the impact load and reduce the peak impact stress in time. Novak et al. [10] investigated four common 316L uniform sheet TPMS structures and found that the platform stress of Diamond structure was the largest under quasi-static and dynamic loading. However, strain rate hardening caused an increase in platform stress and specific energy absorption. Yin et al. [20] investigated the crushing behavior of four 316L sheet TPMS structures under dynamic loading using experiments and finite element simulations, and the results showed that the specific energy absorption, average crushing force, and peak crushing force of all structures increased with the increase in shell thickness. TPMS structures had a continuous surface, which was accompanied by energy absorption during surface deformation and therefore had superior energy absorption performance.

Steel is one of the most widely used metallic materials due to its superior mechanical properties, such as corrosion resistance, compression hardening and high strain rate sensitivity. Park et al.’s results [21,22] showed that ellipsoidal pores inside the foam led to anisotropy of stainless steel foam, the yield strength of foam steel was sensitive to strain rate at higher strain rates, and the corrugation of cell walls in foam steel changed the dependence on the density. A study by Zong et al. [23] showed that the impact toughness of SLM-prepared 316L stainless steel cross-section was 62.69% higher than that of the longitudinal section due to lower tough-brittle transition temperature by grain refinement perpendicular to the building direction. A study by Cao et al. [24] showed that the SLM-prepared rhombic dodecahedron 316L lattice structure had a higher compressive strength, platform stress and specific energy. Additionally, the mechanical properties had a certain dependence on the strain rate. The porous structure might be subjected to impact load or explosion load, and the mechanical behavior and deformation behavior under a dynamic load were more complex. However, the dynamic compression characteristics of TPMS structures manufactured by additive manufacturing were less studied. Additionally, the reason for stress enhancement and deformation mechanism of TPMS structures under dynamic load was not clear, especially for skeleton-based TPMS and gradient TPMS structures. Therefore, it was necessary to study the properties of skeleton-based TPMS and gradient TPMS structures under dynamic loading.

Therefore, this paper discusses the mechanical properties of SLM-manufactured 316L gradient sheet Diamond (GSHD), gradient skeletal Diamond (GSKD), uniform sheet Diamond (USHD), and uniform skeletal Diamond (USKD) structures under nominal strain rates ranging from 2.22 × 10−3/s to 650/s. Additionally, dynamic performance was tested using the split Hopkinson pressure bar (SHPB).

2. Materials and Methods

2.1. TPMS Lattice Structure Design

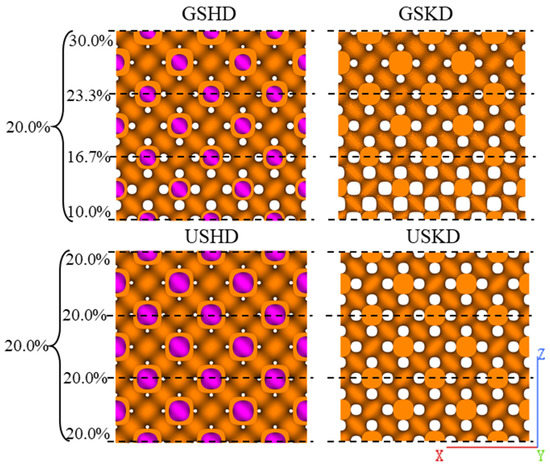

In this work, we used MATLAB 2019a, which has strong programming and plotting capabilities, to generate Diamond-equivalent surface cells described by mathematical expressions as shown in Equation (1). The STL format of the solid model can be generated in Materialise magic 22.0 by complementing, thickening, intersecting, and aggregating the Diamond equivalent surface. We designed a total of four structures, namely uniform sheet diamond (USHD) structure, uniform skeletal diamond (USKD) structure, gradient sheet diamond (GSHD) structure, and gradient skeletal diamond (GSKD) structure, as shown in Figure 1. USHD and USKD structures were composed of 5 mm × 5 mm × 5 mm unit cells arrayed three times in x-, y-, and z-directions to obtain the total structure size. The relative density of GSHD and GSKD unit cells varied uniformly in the z-direction, and GSHD and GSKD structures with relative density ranging from 30% at the top to 10% at the bottom were designed. GSHD is obtained by subtracting USKD with a relative density of 10% from GSKD with a relative density of 40–20%, and USHD is obtained by subtracting USKD with relative density of 40% from USKD with relative density of 20%. In order to keep the relative densities of the four structures consistent, the relative densities of uniform sheet diamond (USHD) and uniform skeletal diamond (USKD) were both 20%.

where C is the value of the equation controlling the position of the equivalence surface, and , , and are the unit length values in the x-, y-, and z-directions, respectively.

Figure 1.

Front view of the four designed Diamond structures.

2.2. Diamond Structure Prepared by SLM

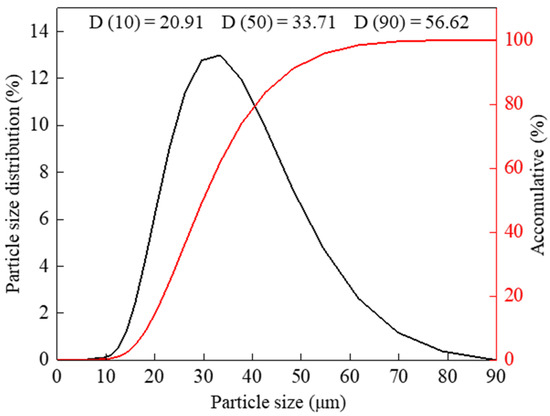

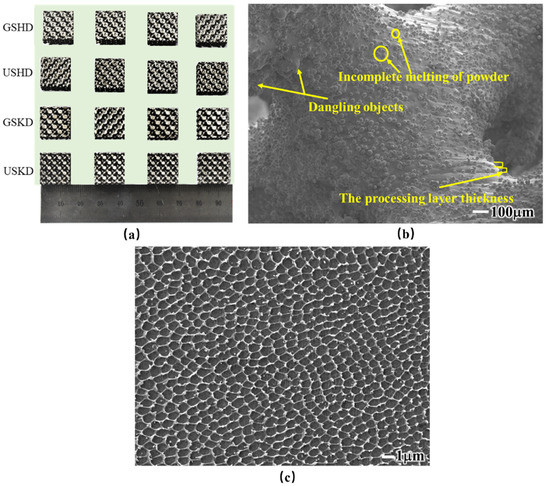

Diamond lattice structure samples were prepared from 316L powder of AVIMETAL AM. The chemical composition of 316L powder is shown in Table 1. As analyzed by Mastersizzer (S3500, Microtrac, Osaka, Japan), its particle size distribution ranged from 20.91 µm (D10) to 56.62 µm (D90), with an average particle size of 33.71 µm, as shown in Figure 2. Samples of 316L of Diamond porous structures were fabricated by EP-M150 (E-PLUS 3D, Beijing, China) in a building chamber of Φ150 × 150 mm2. The SLM system was equipped with a maximum power of 500 W water-cooled fiber laser with a beam diameter of 70 µm. The specimens were manufactured on 304 substrates. The SLM process parameters were as follows: laser power 185 W, layer thickness 30 µm, hatch forming 110, hatch type rotation 10°–352°–19°–344°–31°–326°–43°–315°, and scanning speed 620 mm/s. The SLM process was carried out in high-purity argon gas to avoid oxygen contamination (O2 ≤ 100 ppm). These parameters were given by the equipment manufacturer to obtain the highest density and low concentration of surface defects (e.g., spherification). Subsequently, the fabricated samples, shown in Figure 3a, were removed from the substrate by electric discharge machining (EDM) followed by ultrasonic cleaning with pure ethanol to remove the powder from the sample pores and impurities left on the sample surface after EDM cutting. A SU5000 (Hitachi, Tokyo, Japan) SEM was used to characterize the microstructure of the 316L Diamond structure. Figure 3b shows the front view of a strut node, in which incomplete melting of powder and significant step effect were evident. This was mainly caused by the rapid transition of the Diamond structure at the node. The microstructure of GSKD structure contained honeycombed grains with a size of about 1 μm, as shown in Figure 3c. In general, the smaller the grain size, the higher the strength of the material. Therefore, the strength of the Diamond structure prepared this time was relatively high.

Table 1.

Chemical composition of 316L.

Figure 2.

316L powders particle size distribution.

Figure 3.

(a) Samples of Diamond lattice structures manufactured by SLM; SEM images of SLM-manufactured GSKD structure: (b) the microscopic structure of the upper surface; (c) the front view of a strut node.

2.3. Mechanical Properties Experiments

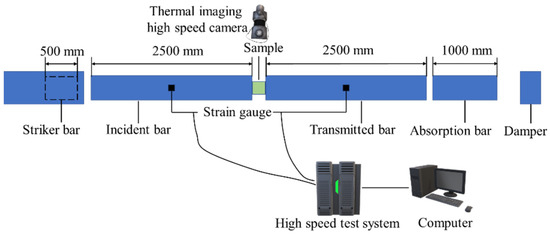

Uniaxial compression tests were carried out on CMT5101 Electronic Universal Testing Machine (MTS, Eden Prairie, USA) at room temperature with a speed of 2 mm/min. Additionally, the loading direction was opposite to the construction direction. The dynamic compression test was performed using a split Hopkinson compression bar as shown in Figure 4. The lengths of the bullet, incident rod, transmission rod, and absorption rod used in this test were 500 mm, 2500 mm, 2500 mm, and 1000 mm, respectively, all with a diameter of 37 mm. The two strain gauges used to collect and output signals were located at 1250 mm from the test-incident–rod interface and the projection-rod–sample interface, respectively, as shown in Figure 4. Additionally, the construction direction of the sample was opposite to the impact direction. The strain gauges collected the incident stress wave and the transmission wave signal. The signals were processed and amplified by the dynamic strain test device and then recorded and displayed on the computer. The mechanical properties of the impacted dotted structure were measured at strain rate of 650/s. The relevant mechanical derivation was as follows.

where and are the obtained reflected and transmitted waves, respectively. , , and are the modulus of elasticity, cross-sectional area and wave velocity (5050 m/s) of the steel rod, respectively. and are the initial surface area and length of the specimen, respectively.

Figure 4.

Schematic diagram of the separated Hopkinson compression bar.

According to the standard IOS 13314:2011, the yield strength was the stress corresponding to 0.2% plastic deformation in the quasi-static experiments, and the dynamic experiments all show significant yielding with the initial peak stress as the yield strength. The energy absorption capacity of the structure was assessed using the specific energy absorption (SEA) [20,25,26], which is defined as follows.

where is the energy absorbed per unit volume, is the density of the 316L stainless steel, is the stress, and is the strain.

3. Results and Discussion

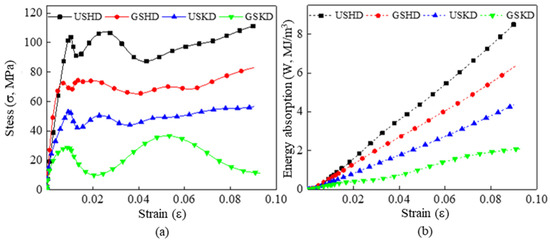

In order to reduce the effect of signal fluctuations, the stress–strain curves at nominal strain rates of 650/s were obtained by smoothing the obtained incident wave with 170 points, as shown in Figure 5. Unfortunately, the densification of the lattice structures was not seen due to the low dynamic loading speed.

Figure 5.

(a) Stress–strain and (b) strain–energy absorption curves under a strain rate of 650/s.

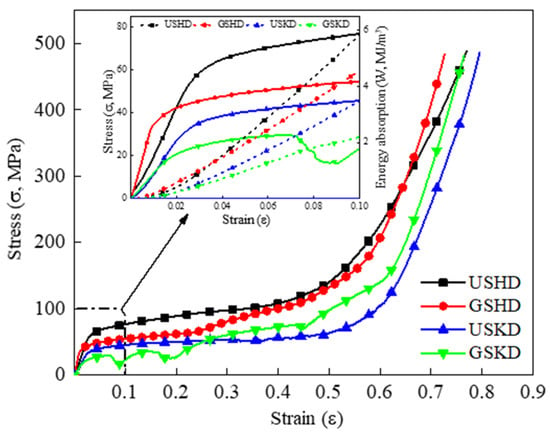

It can be seen from Figure 5 and Figure 6 that, at nominal strain rates of 650/s, all four structures exhibited significant yielding and stress drop, while under quasi-static loading, only the GSKD structure experienced a stress drop. This might be due to the strain rate effect of the structure. The strain-hardening properties of the 316L substrate led to an overall rise in stress after a stress drop. In the work of Li et al. [25], the Gyroid structure also showed a stress drop in the SHPB experiment. Saremian et al. [27] suggest that the reflection of stress waves within the cell structure caused slight fluctuations after the stress drop. The energy absorption–strain curve under dynamic load was closer to a straight line, excluding a GSKD structure. However, the energy absorption–strain curve under quasi-static load was closer to a parabola. This might be mainly caused by strain rate effect.

Figure 6.

Stress–strain and energy absorption-strain curves under a strain rate of 2.22 × 10−3/s.

Wang [28] defined a dimensionless parameter-stress drop factor to quantify the degree of stress drop, i.e., , where is the interpolation of the initial stress peak and valley and is the initial stress peak. The corresponding stress drop factors of the dotted structure under different velocity loading can be obtained in Table 2, and it can be clearly seen that the GSHD structure had the smallest stress drop factor of 0.06 and the GSKD structure had the largest of 0.65. This was mainly due to the fact that the GSKD had the lowest relative density, where the deformation occurred first and was more difficult to contact with the adjacent parts’ site.

Table 2.

Stress drop factor and dynamic increase factor of the lattice structures.

There were four main reasons recognized by researchers for strain rate sensitivity [29,30]: the sensitivity of the matrix material itself to strain rate, the local deformation of the structure, inertial effects, the action of gases within the closed-cell foam, and the magnitude of the strain rate. Dynamic increase factor (DIF, the ratio of the difference between dynamic and static collapse strength to static collapse strength) was one of the important parameters to measure whether the material was sensitive to strain rate. The Dynamic increase factor of the four structures are given in Table 2, and it can be clearly seen that the GSHD structure had the largest value of stress enhancement factor (0.98) and the highest sensitivity to strain rate. Similarly, the GSKD structure has the lowest sensitivity to strain rate. This was mainly due to the different material distribution characteristics of the four structures and unique stress-distribution law. A study by Yin et al. [20] showed that the shell thickness had a significant effect on the performance of TPMS structures under dynamic loading. In addition, the air in our added protective casing contributed to the strain rate sensitivity of the structure.

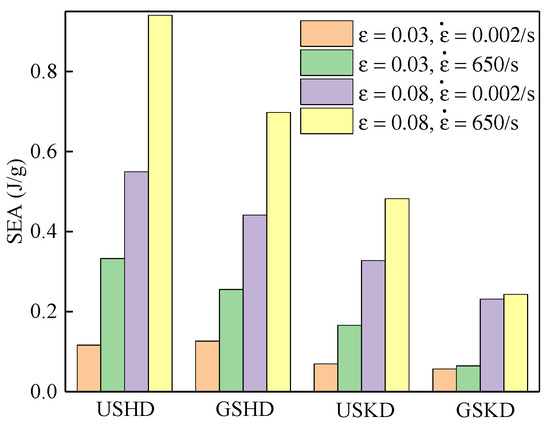

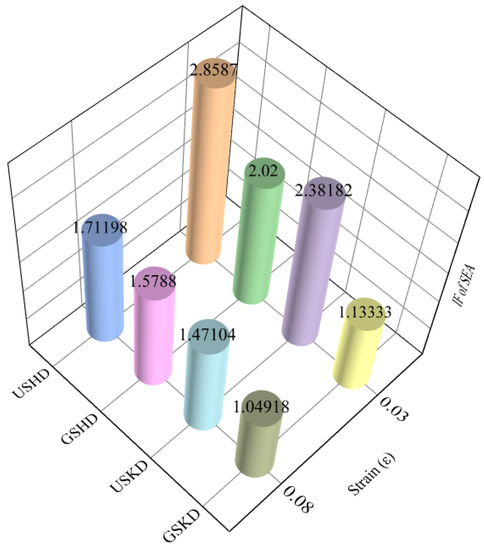

Previous studies have shown that TPMS structures exhibit excellent performance in terms of energy absorption. The results of Novak et al. [10] showed that sheet Diamond structures of the same relative density exhibit the highest energy absorption due to their extremely high plateau stress. In our quasi-static experiments, the SEA of the USHD structure was 5.42 J/g. However, the initial densification strain was not reached due to the short loading time of the SHPB experiment. We analyzed the energy absorption of the four structures at ε = 0.03 and ε = 0.08, as shown in Figure 7. Interestingly, the SEA of USHD was lower than that of GSHD at quasi-static loading at ε = 0.03; however, the opposite result was exhibited under dynamic loading. This was mainly due to the stress fluctuations under dynamic loading. As shown in Figure 8, all SEAs are normalized by corresponding quasi-static SEAs. The normalized SEA of the USHD structure was the largest, and that of GSKD was the smallest. This was mainly due to the higher stresses in the USHD structure.

Figure 7.

Specific energy absorption of the four structures at ε = 0.03 and ε = 0.08.

Figure 8.

SEA after normalization of four structures.

4. Conclusions

In this paper, four Diamond lattice structures with different material distributions were prepared using a selective laser melting technique. The mechanical behavior of gradient structure under quasi-static and dynamic loads was studied and compared with that of uniform structure. The following conclusions were made.

- When the strain rate was 650/s, all structures showed a stress drop, and the stress drop factor of GSKD structure was the largest, mainly because the relative density of GSKD at the beginning of deformation was the lowest and it took a long time to contact the adjacent parts.

- At nominal strain rates of 650/s, the DIF of sheet structures was higher than that of the skeleton structure, and the DIF of GSHD structure was the largest, reaching 0.98, which was the most sensitive to strain rate. Additionally, the USHD structure showed the best energy absorption capability.

- After the corresponding static SEA normalization, SEA showed different rules at ε = 0.03 and ε = 0.08, which was mainly caused by the different structural stiffness.

Author Contributions

Conceptualization, Q.M. and Z.L.; methodology, J.L.; formal analysis, J.L.; investigation, Q.M. and Z.L.; writing—original draft preparation, Q.M. and J.L.; writing—review and editing, Q.M. and Z.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (Grant No. 51905497, No. 52075502) and the Support Program for Young Academic Leaders of North University of China (No. QX201902).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Li, D.; Liao, W.; Dai, N.; Dong, G.; Tang, Y. Optimal design and modeling of gyroid-based functionally graded cellular structures for additive manufacturing. Comput.-Aided Des. 2018, 104, 87–99. [Google Scholar] [CrossRef]

- Wei, Q.; Li, H.; Liu, G.; He, Y.; Wang, Y.; Tan, Y.E.; Wang, D.; Peng, X.; Yang, G.; Tsubaki, N. Metal 3D printing technology for functional integration of catalytic system. Nat. Commun. 2020, 11, 4098. [Google Scholar] [CrossRef] [PubMed]

- Andrew, J.J.; Schneider, J.; Ubaid, J.; Velmurugan, R.; Gupta, N.K.; Kumar, S. Energy absorption characteristics of additively manufactured plate-lattices under low- velocity impact loading. Int. J. Impact Eng. 2021, 149, 103768. [Google Scholar] [CrossRef]

- Alzahrani, M.; Choi, S.K.; Rosen, D.W. Design of truss-like cellular structures using relative density mapping method. Mater. Des. 2015, 85, 349–360. [Google Scholar] [CrossRef] [Green Version]

- Li, P. Constitutive and failure behaviour in selective laser melted stainless steel for microlattice structures. Mater. Sci. Eng. 2015, 622, 114–120. [Google Scholar] [CrossRef]

- Cheng, X.Y.; Li, S.J.; Murr, L.E.; Zhang, Z.B.; Hao, Y.L.; Yang, R.; Medina, F.; Wicker, R.B. Compression deformation behavior of Ti-6Al-4V alloy with cellular structures fabricated by electron beam melting. J. Mech. Behav. Biomed. Mater. 2012, 16, 153–162. [Google Scholar] [CrossRef]

- Isaenkova, M.G.; Yudin, A.V.; Rubanov, A.E.; Osintsev, A.V.; Degadnikova, L.A. Deformation behavior modelling of lattice structures manufactured by a selective laser melting of 316L steel powder. J. Mater. Res. Technol. 2020, 9, 15177–15184. [Google Scholar] [CrossRef]

- Smith, M.; Guan, Z.; Cantwell, W.J. Finite element modelling of the compressive response of lattice structures manufactured using the selective laser melting technique. Int. J. Mech. Sci. 2013, 67, 28–41. [Google Scholar] [CrossRef]

- Liu, F.; Mao, Z.; Zhang, P.; Zhang, D.Z.; Jiang, J.; Ma, Z. Functionally graded porous scaffolds in multiple patterns: New design method, physical and mechanical properties. Mater. Des. 2018, 160, 849–860. [Google Scholar] [CrossRef]

- Novak, N.; Al-Ketan, O.; Krstulović-Opara, L.; Rowshan, R.; Abu Al-Rub, R.K.; Vesenjak, M.; Ren, Z. Quasi-static and dynamic compressive behaviour of sheet TPMS cellular structures. Compos. Struct. 2021, 266, 113801. [Google Scholar] [CrossRef]

- Santos, J.; Pires, T.; Gouveia, B.P.; Castro, A.P.G.; Fernandes, P.R. On the permeability of TPMS scaffolds. J. Mech. Behav. Biomed. Mater. 2020, 110, 103932. [Google Scholar] [CrossRef] [PubMed]

- Yan, C.; Hao, L.; Hussein, A.; Bubb, S.L.; Young, P.; Raymont, D. Evaluation of light-weight AlSi10Mg periodic cellular lattice structures fabricated via direct metal laser sintering. J. Mater. Process. Technol. 2014, 214, 856–864. [Google Scholar] [CrossRef]

- Yang, L.; Mertens, R.; Ferrucci, M.; Yan, C.; Shi, Y.; Yang, S. Continuous graded Gyroid cellular structures fabricated by selective laser melting: Design, manufacturing and mechanical properties. Mater. Des. 2019, 162, 394–404. [Google Scholar] [CrossRef]

- Zhang, L.; Feih, S.; Daynes, S.; Chang, S.; Wang, M.Y.; Wei, J.; Lu, W.F. Energy absorption characteristics of metallic triply periodic minimal surface sheet structures under compressive loading. Addit. Manuf. 2018, 23, 505–515. [Google Scholar] [CrossRef]

- Merrett, R.P.; Langdon, G.S.; Theobald, M.D. The blast and impact loading of aluminium foam. Mater. Des. 2013, 44, 311–319. [Google Scholar] [CrossRef]

- Deshpande, V.S.; Fleck, N.A. High strain rate compressive behaviour of aluminium alloy foams. Int. J. Impact Eng. 2000, 24, 277–298. [Google Scholar] [CrossRef] [Green Version]

- Duarte, I.; Vesenjak, M.; Krstulović-Opara, L. Variation of quasi-static and dynamic compressive properties in a single aluminium foam block. Mater. Sci. Eng. 2014, 616, 171–182. [Google Scholar] [CrossRef]

- Mukai, T.; Kanahashi, H.; Miyoshi, T.; Mabuchi, M.; Nieh, T.G.; Higashi, K. Experimental study of energy absorption in a closed-celled aluminum foam under dynamic loading. Scr. Mater. 1999, 40, 921–927. [Google Scholar] [CrossRef]

- Ozdemir, Z.; Hernandez-Nava, E.; Tyas, A.; Warren, J.A.; Fay, S.D.; Goodall, R.; Todd, I.; Askes, H. Energy absorption in lattice structures in dynamics: Experiments. Int. J. Impact Eng. 2016, 89, 49–61. [Google Scholar] [CrossRef] [Green Version]

- Yin, H.; Liu, Z.; Dai, J.; Wen, G.; Zhang, C. Crushing behavior and optimization of sheet-based 3D periodic cellular structures. Compos. Part B Eng. 2020, 182, 107565. [Google Scholar] [CrossRef]

- Park, C.; Nutt, S.R. Strain rate sensitivity and defects in steel foam. Mater. Sci. Eng. 2002, 323, 358–366. [Google Scholar] [CrossRef]

- Park, C.; Nutt, S.R. Anisotropy and strain localization in steel foam. Mater. Sci. Eng. 2001, 299, 68–74. [Google Scholar] [CrossRef]

- Zong, X.; Liu, W.; Yang, Y.; Zhang, S.; Chen, Z. Anisotropy in microstructure and impact toughness of 316L austenitic stainless steel produced by melting. Rare Metal Mater. Eng. 2020, 49, 4031–4040. [Google Scholar]

- Cao, X.; Xiao, D.; Li, Y.; Wen, W.; Zhao, T.; Chen, Z.; Jiang, Y.; Fang, D. Dynamic compressive behavior of a modified additively manufactured rhombic dodecahedron 316L stainless steel lattice structure. Thin-Walled Struct. 2020, 148, 106586. [Google Scholar] [CrossRef]

- Li, X.; Xiao, L.; Song, W. Compressive behavior of selective laser melting printed Gyroid structures under dynamic loading. Addit. Manuf. 2021, 46, 102054. [Google Scholar] [CrossRef]

- Bai, L.; Zhang, J.; Xiong, Y.; Chen, X.; Sun, Y.; Gong, C.; Pu, H.; Wu, X.; Luo, J. Influence of unit cell pose on the mechanical properties of Ti6Al4V lattice structures manufactured by selective laser melting. Addit. Manuf. 2020, 34, 101222. [Google Scholar] [CrossRef]

- Saremian, R.; Badrossamay, M.; Foroozmehr, E.; Kadkhodaei, M.; Forooghi, F. Experimental and numerical investigation on lattice structures fabricated by selective laser melting process under quasi-static and dynamic loadings. Int. J. Adv. Manuf. Technol. 2021, 112, 2815–2836. [Google Scholar] [CrossRef]

- Wang, P.F. Study on Dynamic Mechanical Response and Temperature Dependence of Porous Metals. Ph.D. Thesis, University of Science and Technology of China, Hefei, China, 2012. [Google Scholar]

- Zhao, H.; Elnasri, I.; Abdennadher, S. An experimental study on the behaviour under impact loading of metallic cellular materials. Int. J. Mech. Sci. 2005, 47, 757–774. [Google Scholar] [CrossRef]

- Atturan, U.A.; Nandam, S.H.; Murty, B.S.; Sankaran, S. Deformation behaviour of in-situ TiB2 reinforced A357 aluminium alloy composite foams under compressive and impact loading. Mater. Sci. Eng. 2017, 684, 178–185. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).