A Microstructural and Compositional Study of ε-Fe2O3 Crystals in the Hare’s Fur Jian Ware

Abstract

:1. Introduction

2. Materials and Methods

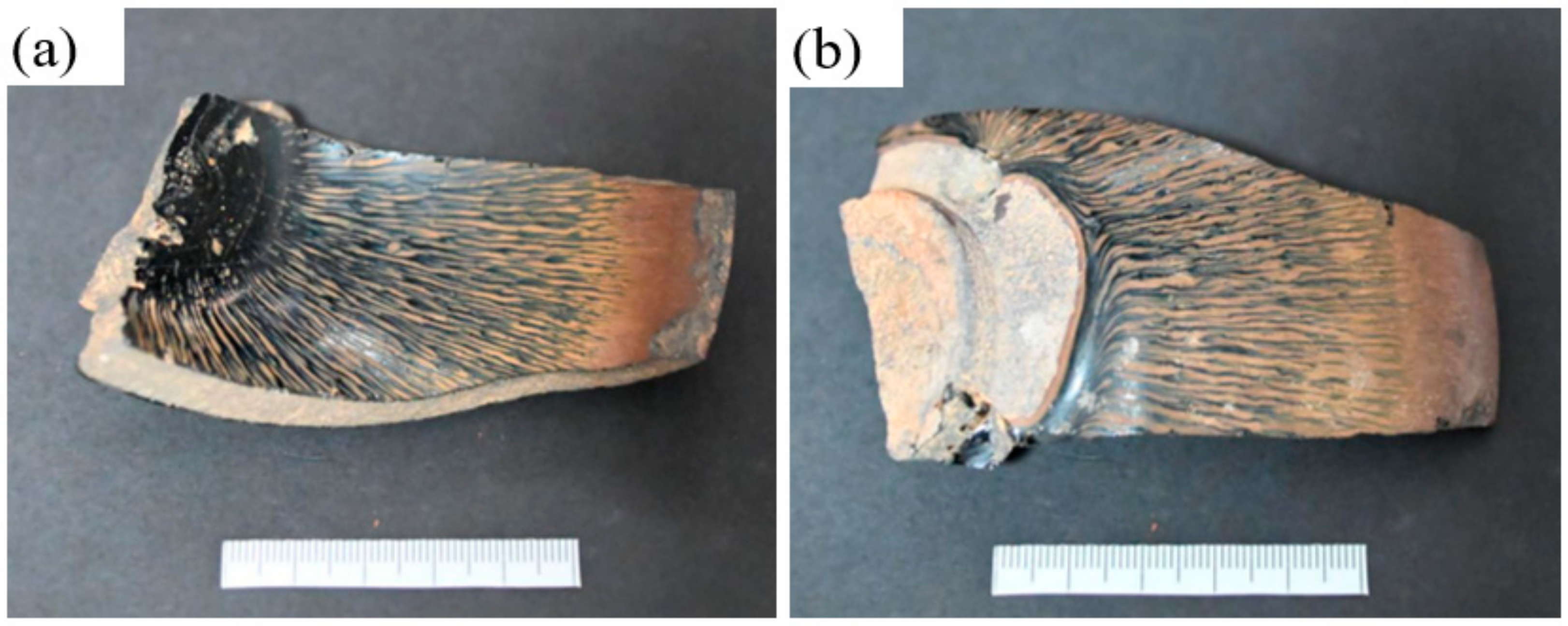

2.1. Sample Preparation

2.2. Characterization Techniques

3. Results

3.1. Chemical Composition

3.2. Microstructure Analysis by OM

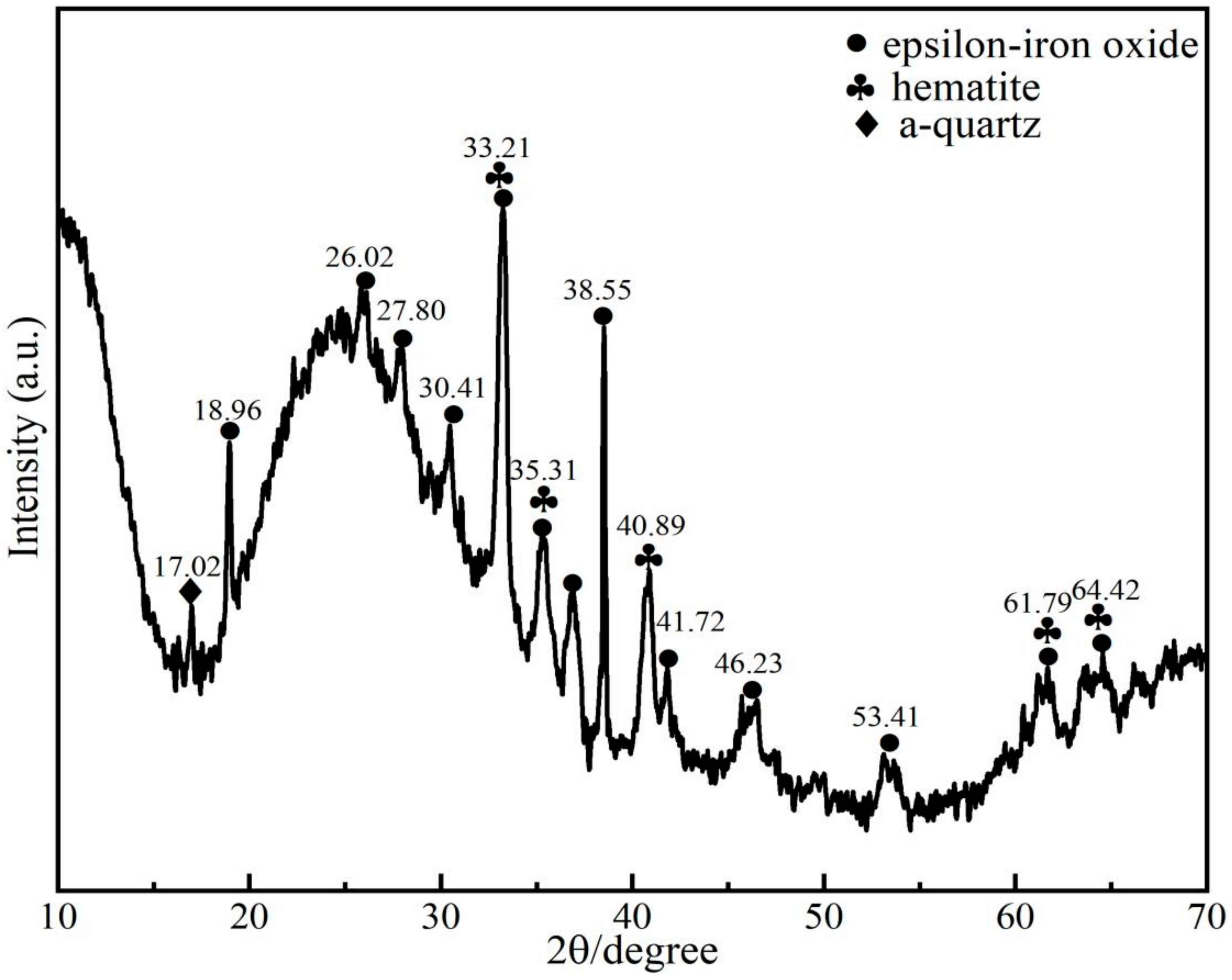

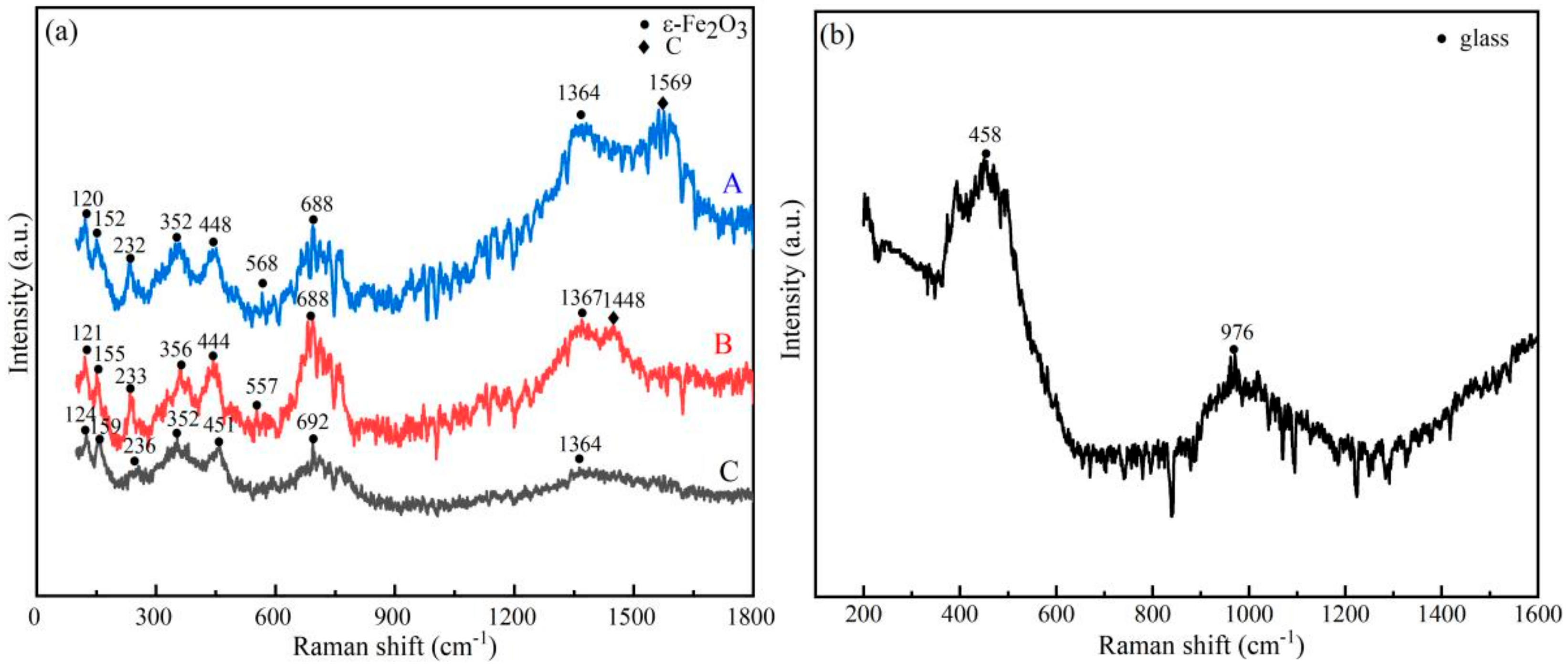

3.3. Phase Analysis by XRD and RS

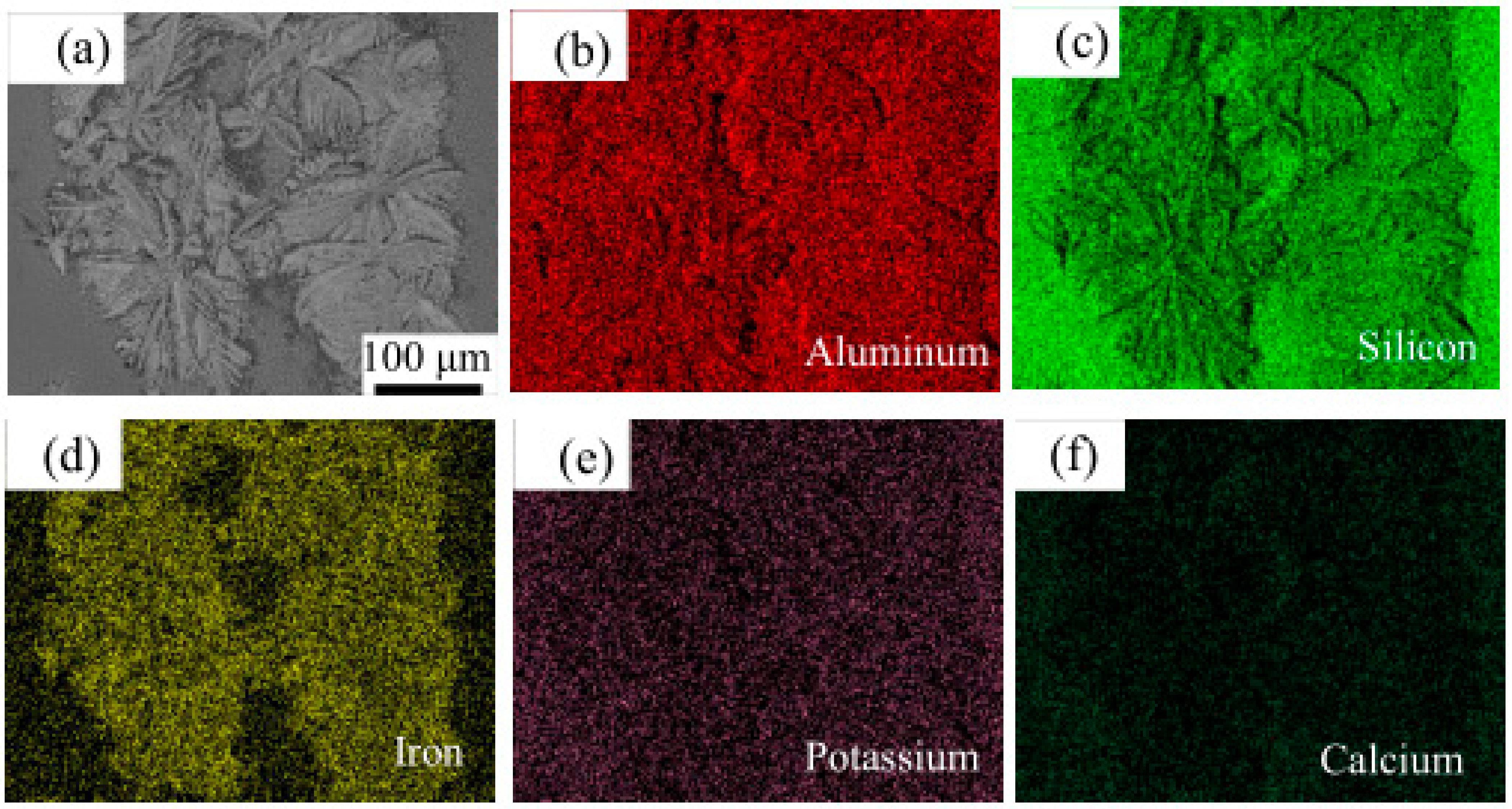

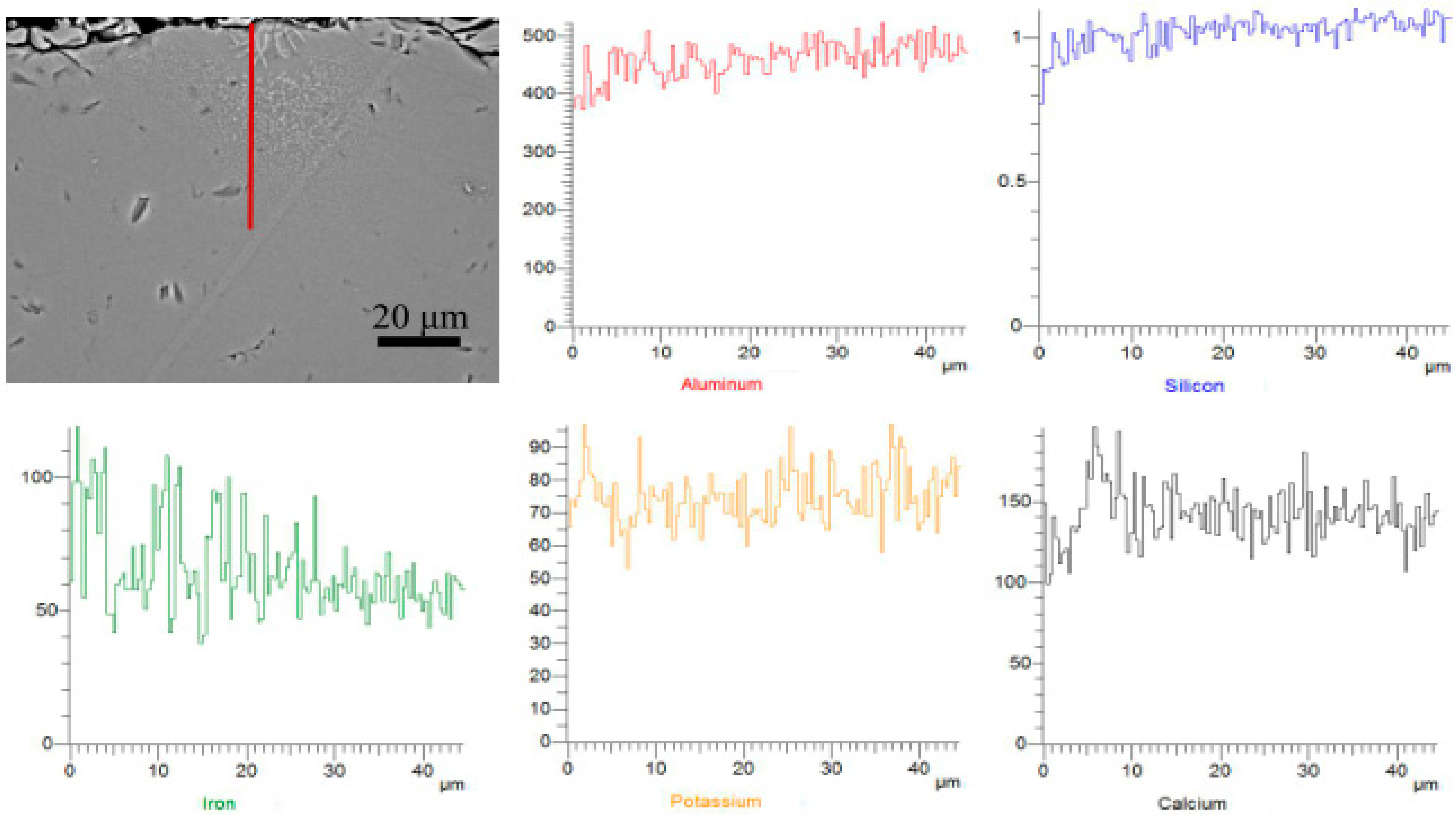

3.4. Microstructure Analysis by SEM–EDS

4. Discussion

5. Conclusions

- The main constituents of the HF glaze were alumina (10.61–16.43 wt.%), silica (62.20–77.07 wt.%), calcium (3.85–6.97 wt.%), and iron oxide (4.10–8.35 wt.%). Minor elements such as sodium, potassium, and calcium existed as flux. The formation of HF patterns in the glaze occurred as a result of phase separation between melted glaze and crystallized iron oxides.

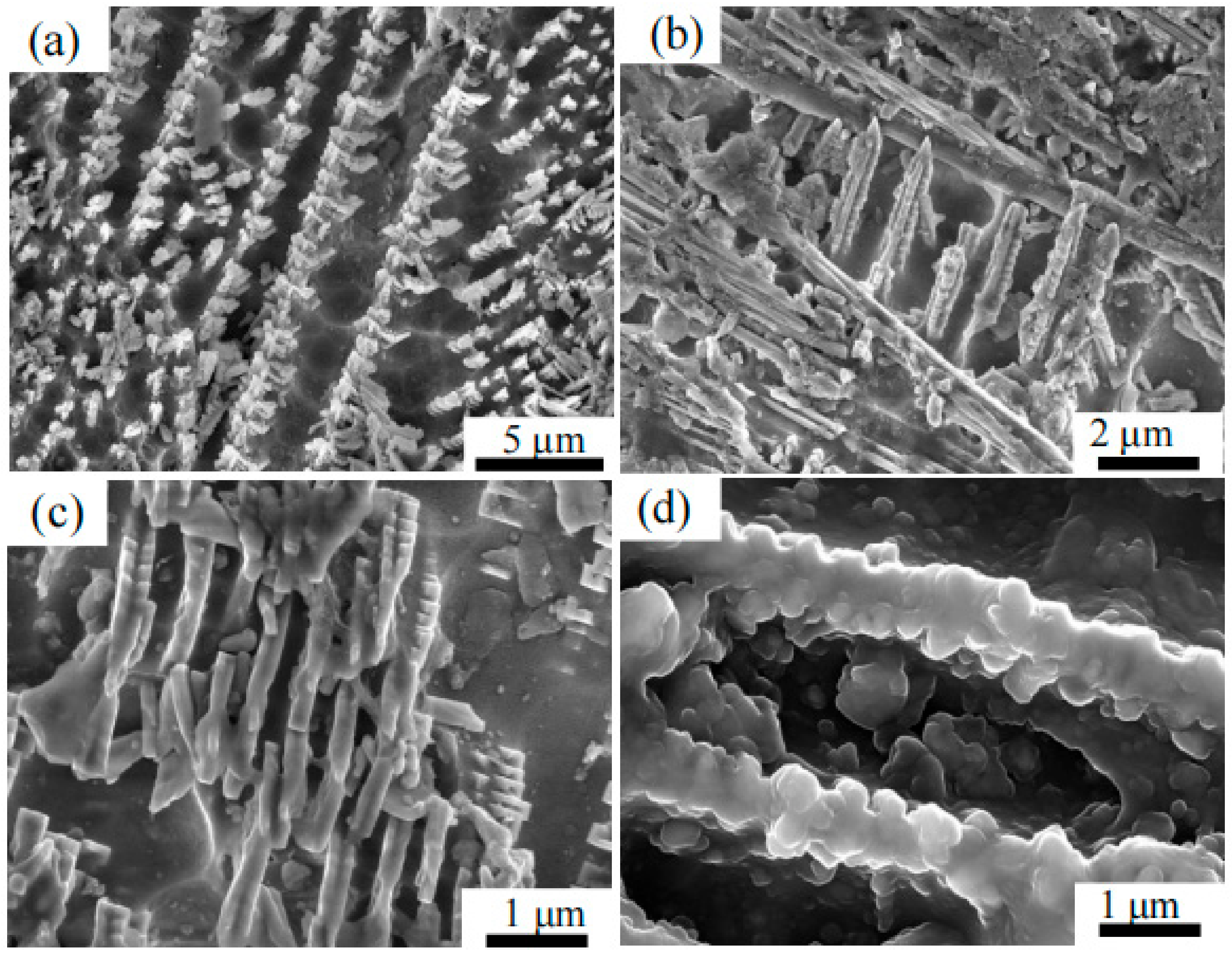

- There were three types of ε-Fe2O3 crystals in the glaze surface: One consisted of well-grown leaf-like or dendritic-like structure, with highly ordered branches at micrometers scales; one comprised flower-like clusters accompanied by branches radiating from the center, petals growing along the branches, and needles on both sides of the petals; the last type entailed a honeycomb structure tightly packed with plentiful spherical or irregular-shaped particles. In addition, ε-Fe2O3 crystals in the cross-section of the glaze showed a gradient distribution.

- At first, the nucleation seeds were formed and gradually grew into plentiful spherical or irregular-shaped particles. Then, these particles started to crystallize to form a two-dimensional plane structure, such as a flower-shaped structure with the primary branches formed radially. As the reaction time increased, more main branches such as secondary branches emerged and grew. The longer branches quickly grew preferentially in certain directions and some began to diverge. Tertiary branches grew with the accumulated particles attached to them, following the above processes. Eventually, highly differentiated or well-defined hierarchical structures were formed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, X.; Chen, S.; Huang, R. A study on Song dynasty Jian bowl. China Ceram. 1983, 2, 61–69. (In Chinese) [Google Scholar]

- Huang, R.; Chen, X.; Chen, S. A high resolution electron microscopic investigation on the imitative glaze of Yaobian Tenmoku in Southern Song Dynasty. China Ceram. 1988, 1, 17–21. (In Chinese) [Google Scholar]

- Li, X.; Lu, J.; Yu, X. Imitation of ancient black-glazed Jian bowls (Yohen Tenmoku): Fabrication and characterization. Ceram. Int. 2016, 42, 15269–15273. [Google Scholar] [CrossRef]

- Xu, C.; Li, W.; Lu, X. Unveiling the science behind the tea bowls from the Jizhou kiln. Part I. Chemical compositions and the two-layer glazing technique. Ceram. Int. 2018, 44, 8540–8549. [Google Scholar]

- Li, W.; Zhang, W.; Lu, X. Chemical compositions and microstructures of hare’s fur black-glazed porcelains from Jian kiln, Jizhou kiln and Yaozhou kiln sites. J. Build. Mater. 2011, 14, 329–334. (In Chinese) [Google Scholar]

- Wu, B.; Zhao, W.; Ren, X.; Liu, X.; Li, B.; Feng, S.; Feng, X.; Zhao, H. Firing process and colouring mechanism of black glaze and brown glaze porcelains from the Yuan and Ming dynasties from the Qingliang Temple kiln in Baofeng, Henan, China. Ceram. Int. 2021, 47, 32817–32827. [Google Scholar] [CrossRef]

- Zhang, A. Scientific research on Jianzhan in Song Dynasty. Ceramics 2021, 5, 157–158. [Google Scholar]

- Chen, N. Taking the Hare’s fur glazed bowls as an example, discussing the firing process of Jian wares. Orient. Collect. 2020, 6, 48–50. (In Chinese) [Google Scholar]

- Chen, X.; Sun, J. Discussion on the peculiarity of oil spot national treasure Tenmoku Wares Jian of spot through the research results of the rare sherds. J. Ceram. 1995, 1, 26. [Google Scholar]

- Dejoie, C.; Sciau, P.; Li, W. Learning from the past: Rare ε-Fe2O3 in the ancient black-glazed Jian (Tenmoku) wares. Sci. Rep. 2014, 4, 4941. [Google Scholar] [CrossRef] [Green Version]

- Gich, M.; Frontera, C.; Roig, A. Magnetoelectric coupling in ε-Fe2O3 nanoparticles. Nanotechnology 2006, 17, 687–691. [Google Scholar] [CrossRef] [Green Version]

- Knížek, K.; Pashchenko, M.; Levinský, P. Spin seebeck effect in ε-Fe2O3 thin films with high coercive field. J. Appl. Phys. 2018, 124, 213904. [Google Scholar] [CrossRef]

- Ding, Y.; Morber, J.; Snyder, R. Nanowire structural evolution from Fe3O4 to ε-Fe2O3. Adv. Funct. Mater. 2007, 17, 1172–1178. [Google Scholar] [CrossRef]

- Tuček, J.; Zbořil, R.; Namai, A. ε-Fe2O3: An advanced nanomaterial exhibiting giant coercive field, millimeter-wave ferromagnetic resonance, and magnetoelectric coupling. Chem. Mater. 2010, 22, 6483–6505. [Google Scholar] [CrossRef]

- Kusano, Y.; Fujii, T.; Takada, J. Epitaxial growth of ε-Fe2O3 on mullite found through studies on a traditional Japanese stoneware. Chem. Mater. 2008, 20, 151–156. [Google Scholar] [CrossRef]

- Guan, M.; Kang, B.; Wei, X. The microstructure of multicolor hare’s fur glaze: The correlation between morphological and compositional characteristics and glaze color. Herit. Sci. 2021, 9, 21. [Google Scholar] [CrossRef]

- Chen, X.; Li, W.; Xu, C. Angle dependence of Jian bowl color and its coloring mechanism. J. Eur. Ceram. Soc. 2022, 42, 693–706. [Google Scholar] [CrossRef]

- Hoo, Q.; Liang, Y.; Yan, X. Millimeter-sized flower-like clusters composed of mullite and ε-Fe2O3 on the Hare’s Fur Jian Ware. J. Eur. Ceram. Soc. 2020, 40, 4340–4347. [Google Scholar] [CrossRef]

- Franci, G.; Akkas, T.; Yildirim, S. Characterization of a Jian-like sherd with the optical microscope, confocal Raman, wavelength-dispersive X-ray fluorescence, and portable XRF spectrometers. J. Raman Spectrosc. 2020, 51, 1343–1352. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Y.; Zhang, M. Three-dimensional microstructure of ε-Fe2O3 crystals in ancient Chinese sauce glaze porcelain revealed by focused ion beam scanning electron microscopy. Anal. Chem. 2019, 91, 13054–13061. [Google Scholar] [CrossRef]

- Wang, M.; Wang, T.; Wang, F. Raman study of rusty oil spotted glaze produced in Linfen kilns (Shanxi province, AD 1115–1368). J. Raman Spectrosc. 2021, 8, 1–11. [Google Scholar] [CrossRef]

- Xu, Y.; Qin, Y.; Ding, F. Characterization of the rare oil spot glazed bowl excavated from the Xiao kiln site of north China. Ceram. Int. 2017, 43, 8636–8642. [Google Scholar] [CrossRef]

- Xu, C.; Li, W.; Lu, X. Unveiling the science behind the tea bowls from the Jizhou kiln. Part II. Microstructures and the coloring mechanism. Ceram. Int. 2018, 44, 19461–19473. [Google Scholar]

- Wen, R.; Wang, D.; Wang, L. The colouring mechanism of the brown glaze porcelain of the Yaozhou Kiln in the Northern Song Dynasty. Ceram. Int. 2019, 45, 10589–10595. [Google Scholar] [CrossRef]

- Zhong, D.; Guo, M.; Liu, Y. Nondestructive analysis of iron rich porcelains excavated from Qingliangsi Site in Baofeng Country, Henan Province. Spectrosc. Spectr. Anal. 2019, 1, 172–179. (In Chinese) [Google Scholar]

- Liu, Z.; Jia, C.; Li, L. The morphology and structure of crystals in Qing Dynasty purple-gold glaze excavated from the Forbidden City. J. Am. Ceram. Soc. 2018, 101, 5229–5240. [Google Scholar] [CrossRef]

- Liu, S.; Li, Q. Characterization of some ancient glass vessels fragments found in Xinjiang, China, using a portable energy dispersive XRF spectrometer. X-ray Spectrom. 2011, 40, 364–375. [Google Scholar] [CrossRef]

- Liu, S.; Li, Q.; Gan, F. Silk Road glass in Xinjiang, China: Chemical compositional analysis and interpretation using a high-resolution portable XRF spectrometer. J. Archaeol. Sci. 2012, 39, 2128–2142. [Google Scholar] [CrossRef]

- Tantrakarn, K.; Kato, N.; Hokura, A. Archaeological analysis of Roman glass excavated from Zadar, Croatia, by a newly developed portable XRF spectrometer for glass. X-ray Spectrom. 2009, 38, 121–127. [Google Scholar] [CrossRef]

- Ma, Q.; Pollard, A.M.; Jiang, J. Evaluation of quantitative XRF analysis applied to determine cobalt sources in Chinese Blue-and-White porcelain. Archaeometry 2021, 63, 194–203. [Google Scholar] [CrossRef]

- Min, Y. The Development of Ancient Iron-Based Glaze and Its Impact; Jingdezhen Ceramic Institute: Jingdezhen, China, 2009. (In Chinese) [Google Scholar]

- Li, W.; Luo, H.; Li, J. Studies on the microstructure of the black-glazed bowl sherds excavated from the Jian kiln site of ancient China. Ceram. Int. 2008, 34, 1473–1480. [Google Scholar] [CrossRef]

- Liu, Z.W.; Zhang, Z.G.; Li, H.; Wu, W.; Hua, J.J.; Cheng, G.F.; Lin, C.C. Microstructure Characteristics of the Black-Glazed Shreds Excavated from the Qingliangsi Kiln. Key Eng. Mater. 2011, 492, 112–117. [Google Scholar] [CrossRef]

- Libor, M.; Jiri, T.; Radek, Z. Polymorphous Transformations of Nanometric Iron (III) Oxide: A Review. Chem. Mater. 2011, 23, 3255–3272. [Google Scholar]

- López-Sánchez, J.; Serrano, A.; Del Campo, A.; Abuín, M.; Rodríguez de La Fuente, O.; Carmona, N. Sol-gel synthesis and micro-raman characterization of ε-Fe2O3 micro- and nanoparticles. Chem. Mater. 2016, 28, 511–518. [Google Scholar] [CrossRef]

- Mukherjee, S.; Garg, A.; Gupta, R. Probing magnetoelastic coupling and structural changes in magnetoelectric gallium ferrite. J. Phys.-Condens. Matter 2011, 23, 445403. [Google Scholar] [CrossRef] [Green Version]

- Puech, P.; Kandara, M.; Paredes, G.; Moulin, L.; Weiss-Hortala, E.; Kundu, A.; Monthioux, M. Analyzing the Raman Spectra of Graphenic Carbon Materials from Kerogens to Nanotubes: What Type of Information Can Be Extracted from Defect Bands? C-J. Carbon Res. 2019, 5, 69. [Google Scholar] [CrossRef] [Green Version]

- Spoto, S.; Paladini, G.; Caridi, F. Multi-Technique Diagnostic Analysis of Plasters and Mortars from the Church of the Annunciation (Tortorici, Sicily). Materials 2022, 15, 958. [Google Scholar] [CrossRef] [PubMed]

- Forestier, H.; Guiot-Guillain, G. New ferromagnetic variety of ferric oxide. C. R. Acad. Sci. 1934, 199, 720. [Google Scholar]

- Tronc, E.; Chaneác, C.; Jolivet, J. Structural and magnetic characterization of ε-Fe2O3. J. Solid State Chem. 1998, 139, 93–104. [Google Scholar] [CrossRef]

- Jin, J.; Ohkoshi, S.; Hashimoto, K. Giant coercive field of nanometer-sized iron oxide. Adv. Mater. 2004, 16, 48–51. [Google Scholar] [CrossRef]

- Shi, P.; Wang, F.; Zhu, J. Effect of phase separation on the Jian ware blue colored glaze with iron oxide. Ceram. Int. 2018, 44, 16407–16413. [Google Scholar] [CrossRef]

- Zhang, W.; Zheng, N.; Li, W. Scientific study of high-iron crystallization glaze. China Ceram. 2010, 46, 20–25. (In Chinese) [Google Scholar]

- Lahlil, S.; Xu, J.; Li, W. Influence of manufacturing parameters on the crackling process of ancient Chinese glazed ceramics. J. Cult. Herit. 2015, 16, 401–412. [Google Scholar] [CrossRef]

- Li, M.; Li, W.; Lu, X. Controllable preparation and decorative effect of iron-based crystalline glazes. J. Chin. Ceram. Soc. 2020, 48, 1134–1144. [Google Scholar]

| SiO2 | Al2O3 | Fe2O3 | Na2O | K2O | CaO | MgO | TiO | MnO | P2O5 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Hare’s fur glaze | 62.20 | 16.43 | 8.35 | N.D. | 3.02 | 6.97 | 1.79 | 0.58 | 0.58 | 0.07 |

| Black glaze | 77.07 | 10.61 | 4.10 | N.D. | 2.06 | 3.85 | 1.54 | 0.36 | 0.36 | 0.06 |

| Body | 66.32 | 18.50 | 10.04 | 1.41 | 2.49 | 0.11 | 0.51 | 0.62 | 0.08 | 0.01 |

| Elements | wt.% | ||||

|---|---|---|---|---|---|

| Point A | Point B | Point C | Point D | Point E | |

| O | 45.561 | 40.111 | 47.512 | 46.446 | 47.784 |

| Al | 8.722 | 6.293 | 7.790 | 10.726 | 11.193 |

| Si | 30.281 | 8.538 | 14.130 | 18.063 | 21.998 |

| K | 3.651 | 1.102 | 1.584 | 2.134 | 2.150 |

| Ca | 4.203 | 0.785 | 1.016 | 1.725 | 1.609 |

| Fe | 5.994 | 41.569 | 26.598 | 19.716 | 13.851 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tao, S.; Liu, S.; Yuan, Y.; Dong, J.; Li, Q. A Microstructural and Compositional Study of ε-Fe2O3 Crystals in the Hare’s Fur Jian Ware. Crystals 2022, 12, 367. https://doi.org/10.3390/cryst12030367

Tao S, Liu S, Yuan Y, Dong J, Li Q. A Microstructural and Compositional Study of ε-Fe2O3 Crystals in the Hare’s Fur Jian Ware. Crystals. 2022; 12(3):367. https://doi.org/10.3390/cryst12030367

Chicago/Turabian StyleTao, Shiqian, Song Liu, Yimeng Yuan, Junqing Dong, and Qinghui Li. 2022. "A Microstructural and Compositional Study of ε-Fe2O3 Crystals in the Hare’s Fur Jian Ware" Crystals 12, no. 3: 367. https://doi.org/10.3390/cryst12030367

APA StyleTao, S., Liu, S., Yuan, Y., Dong, J., & Li, Q. (2022). A Microstructural and Compositional Study of ε-Fe2O3 Crystals in the Hare’s Fur Jian Ware. Crystals, 12(3), 367. https://doi.org/10.3390/cryst12030367