Filled Sb-Based Skutterudites from 1996–2022

Abstract

:1. Introduction

- (a)

- Partially or fully filling of skutterudites was a big step towards high ZTs. It was found that the maximum filling fraction increases with the type of filler, which roughly follows the sequence: rare earths, alkaline earths, alkaline metals. Of course, it is also affected by the radius, the valence and the electronegativity of the filler ions. Double and multiple filling (Table 1 and Table 2), due to different frequencies and masses of the fillers, enhances the phonon scattering and therefore reduces the thermal conductivity. As the filling fractions of the rare earths influence the carrier properties, lattice thermal conductivity will decrease but the power factor will remain (details are given in [5]).

- (b)

- Charge compensation (Table 1 and Table 2) is achieved by substituting Fe by Co, Fe by Ni or in rare cases Fe by Zn (p-type), or Co by Cr, Fe, Ni, Pd, or by using Fe/Ni substitution (n-type) to control the carrier concentration and positively influence the TE properties. These substitutions alter the nature of the conduction process from that of being substantially metallic to one with a more semiconducting character, leading to a reduction in the thermal conductivity. One has additionally to take into account the interplay between the electron doping via the filler atoms and the hole doping on the Co sites.

- (c)

- Doping at the Sb sites (Table 3), because these dopant atoms create a perturbation on the vibration of the Sb4-ring, introduces defects and therefore enhances the scattering of high-frequency phonons on electrons and impurities. This way the thermal conductivity can be reduced without affecting either the electrical resistivity or the Seebeck coefficient.

- (d)

- The possibility to enhance the Seebeck coefficient and concomitantly reduce the electrical resistivity and thermal conductivity is provided by dispersing micro- or, even better, nanoparticles within the bulk material to form nanocomposites. These “obstacles” disperse evenly at the grain boundaries of the skutterudite matrix and enhance interfacial scattering of the heat-carrying phonons in conjunction with point defect scattering and mixed valence scattering. This should reduce the thermal conductivity more than the electrical conductivity, and should increase the Seebeck coefficient by the energy filtering of the charge carriers or by quantum confinement, more than decreasing the electrical conductivity. One may also aim at precipitating nanoparticles within the matrix from supersaturated solutions. It is important to select particles which enhance the scattering of the heat-carrying phonons of different wavelengths and reduce thermal conductivity but do not disturb the charge carriers. A good overview of additives for unfilled and filled p- and n-type skutterudites is given in [22]. The variety of additives for filled Sb-based skutterudites in this work is shown in Table 3.

- (e)

- Ball-milling produces very fine, even nano-sized powders. Even though during the densification (e.g., hot-pressing or spark plasma sintering) some particle growth occurs, the reduced particle size decreases the mean free path of the phonons and thereby reduces the thermal conductivity. Although the electrical resistivity increases, the net effect is in most cases positive i.e., ZT is higher.

- (f)

- Severe plastic deformation (SPD) via high-pressure torsion (HPT) reduces the crystallite size and in parallel increases the quantity of lattice defects–mainly dislocations. This way the scattering of the heat-carrying phonons is enhanced, which reduces the thermal conductivity more than it enhances the electrical resistivity (the Seebeck coefficient remains untouched), resulting in higher ZTs. This method was applied on hot pressed samples as well as on cold pressed skutterudite powder, the latter technique saving a lot of energy and time on samples with 10 or 30 mm in diameter and a height of ~1 mm or ~8 mm.

2. Experimental Methods

3. Results and Discussion

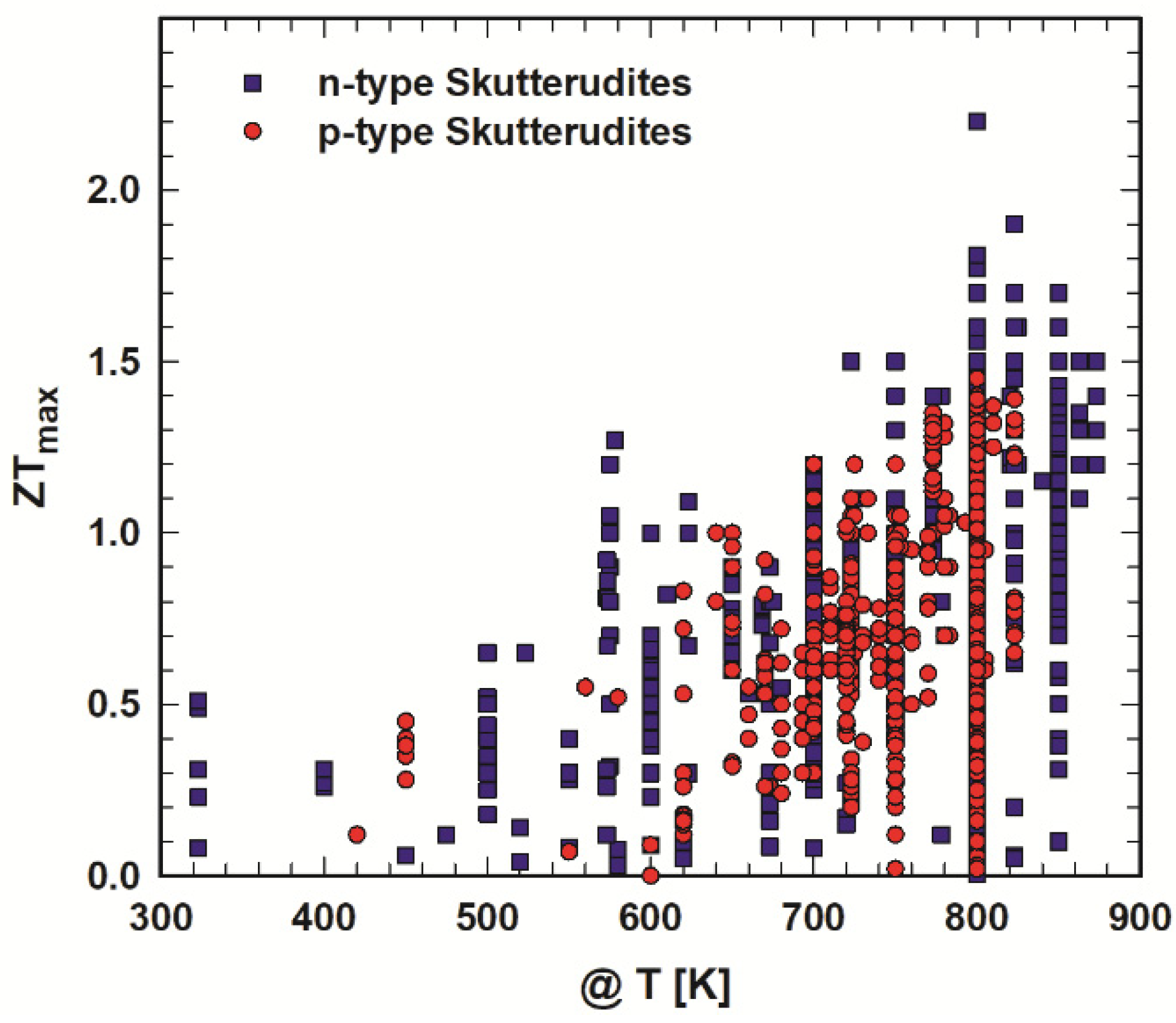

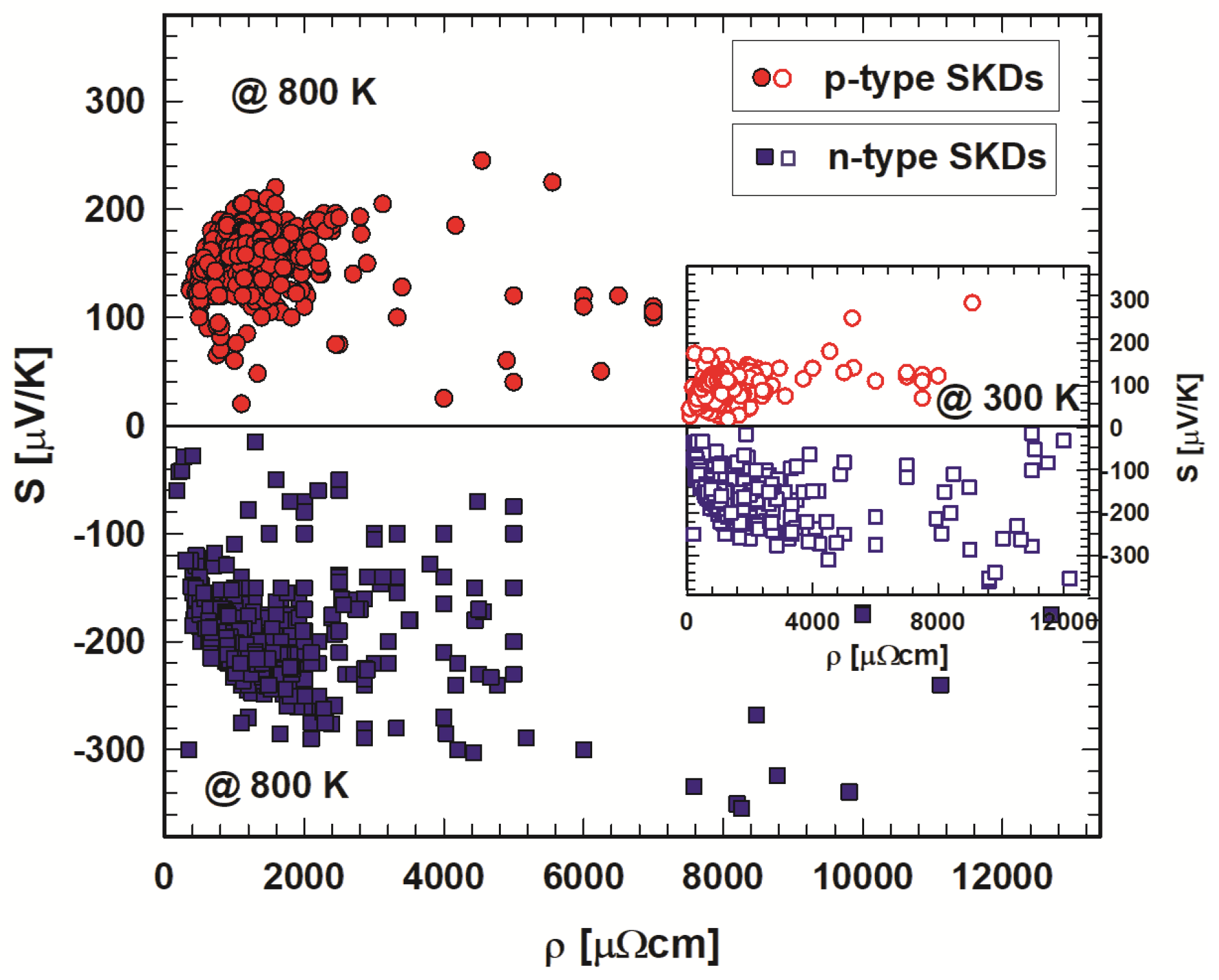

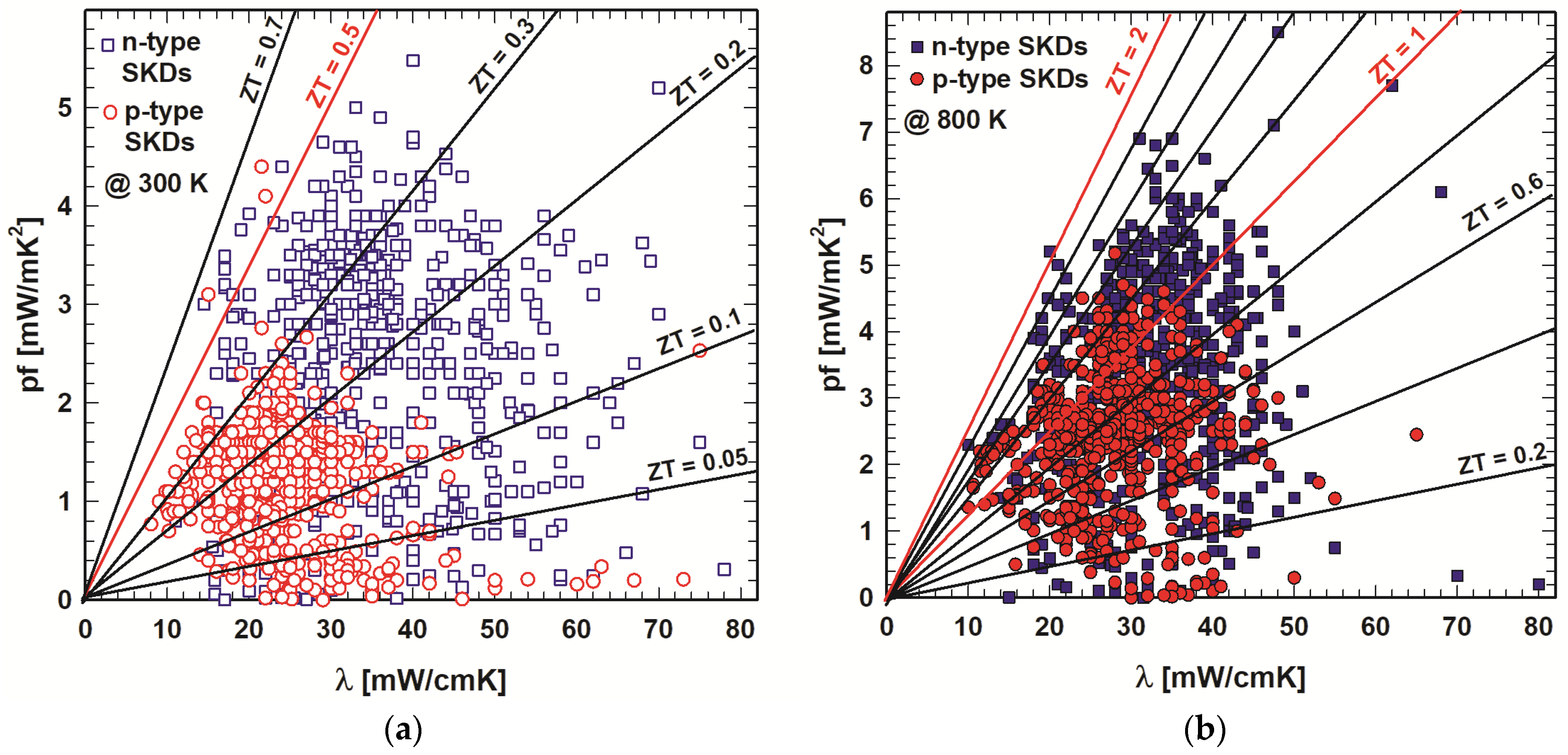

3.1. General Overview

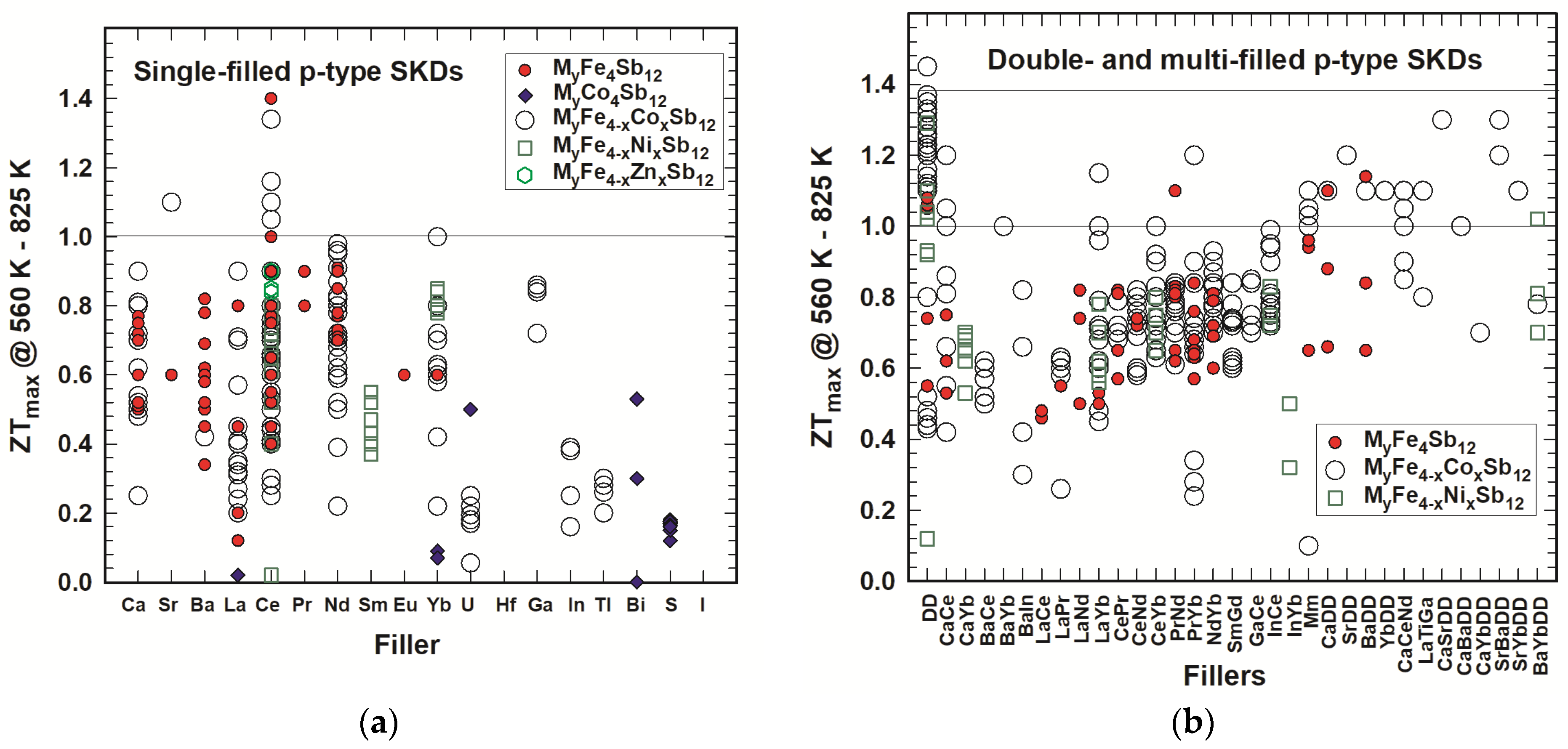

3.2. P-Type Skutterudites

3.2.1. Skutterudites MyCo4Sb12

| Fe4Sb12 Refs. | Fe/Ni Refs. | Fe/Co Refs. | Fe/Zn Refs. | Co4Sb12 Refs. | |

|---|---|---|---|---|---|

| Ca | [25,105,107,109] | - | [58,97,107,182,278] | - | - |

| Sr | [105] | - | [97] | - | - |

| Ba | [105,107,109,267] | - | [97,103,107] | - | - |

| La | [52,53,105] | - | [26,46,47,49,52,76,141] | - | [261] |

| Ce | [25,104,105,123,136,153,183,189,199,254] | [43,152,190,195] | [25,28,29,36,49,64,101,103,104,152,183,199,202,209,217,219,232,233,247,254,274] | 123 | - |

| Pr | [101,105,264] | - | - | - | - |

| Nd | [105,206,264] | - | [140,164,192,194,203,205,206,222,241,242] | - | - |

| Sm | - | [185] | - | - | - |

| Eu | [34,38,105] | - | [38] | - | - |

| Yb | [40,105,228,280] | - | [40,89,97,103,104,141,226,263] | - | [211,228] |

| U | - | - | [48] | - | [48] |

| Hf | [50] | - | - | - | - |

| Ga | - | - | [253] | - | - |

| In | - | - | [215] | - | [119] |

| Tl | - | - | [160] | - | [33] |

| Bi | - | - | - | - | [131] |

| S | - | - | - | - | [262] |

| I | - | - | - | - | [147] |

| Double-fillers | |||||

| DD | [95,107,109] | [95,122] | [95,97,106,107,120,134,151,173,174,220,239,276] | [95,122] | - |

| Ca, Ce | [156] | - | [58,156] | - | - |

| Ca, Yb | - | [62] | - | [62] | - |

| Ba, Ce | - | - | [103] | - | - |

| Ba, Yb | - | - | [163] | - | - |

| Ba, In | - | - | [124,139] | - | - |

| La, Ce | [272] | [167] | [49,169,187,219,272] | [167] | - |

| La, Pr | [230] | - | [207,230] | - | - |

| La, Nd | [178,249] | - | [178,249] | - | - |

| La, Yb | [250] | [168] | [141,250] | [168] | - |

| Ce, Pr | [225,231] | - | [225] | - | - |

| Ce, Nd | [130,224] | - | [103,130,224] | - | - |

| Ce, Yb | - | [196] | [89,103,219,266] | - | - |

| Pr, Nd | [177,204,264] | - | [177,204,264] | - | - |

| Pr, Yb | [176,223] | - | [176,223] | - | - |

| Nd, Yb | [205,242] | - | [193,205,242] | - | - |

| Sm, Gd | - | - | [246] | - | - |

| Ga, Ce | - | - | [253] | - | - |

| In, Ce | - | - | [209] | - | - |

| In, Yb | - | - | [179,212] | - | |

| Multi-fillers | |||||

| Mm | [101,107,109] | - | [101,107,162,233] | - | - |

| Ca, DD | [107] | - | [97,107] | - | - |

| Sr, DD | - | - | [97] | - | - |

| Ba, DD | [107] | - | [97,107] | - | - |

| Yb, DD | - | - | [97] | - | - |

| Ca, Ce, Nd | - | - | [161] | - | - |

| La, Ti, Ga | - | - | [218,237] | - | - |

| Ca, Sr, DD | - | - | [97] | - | - |

| Ca, Ba, DD | - | - | [97] | - | - |

| Ca, Yb, DD | - | - | [97] | - | - |

| Sr, Ba, DD | - | - | [97] | - | - |

| Sr, Yb, DD | - | - | [97] | - | - |

| Ba, Yb, DD | - | [122] | [97] | [122] | - |

3.2.2. Skutterudites MyFe4Sb12

3.2.3. P-Type Skutterudites with Fe/Co, Fe/Ni and Fe/Zn Substitution

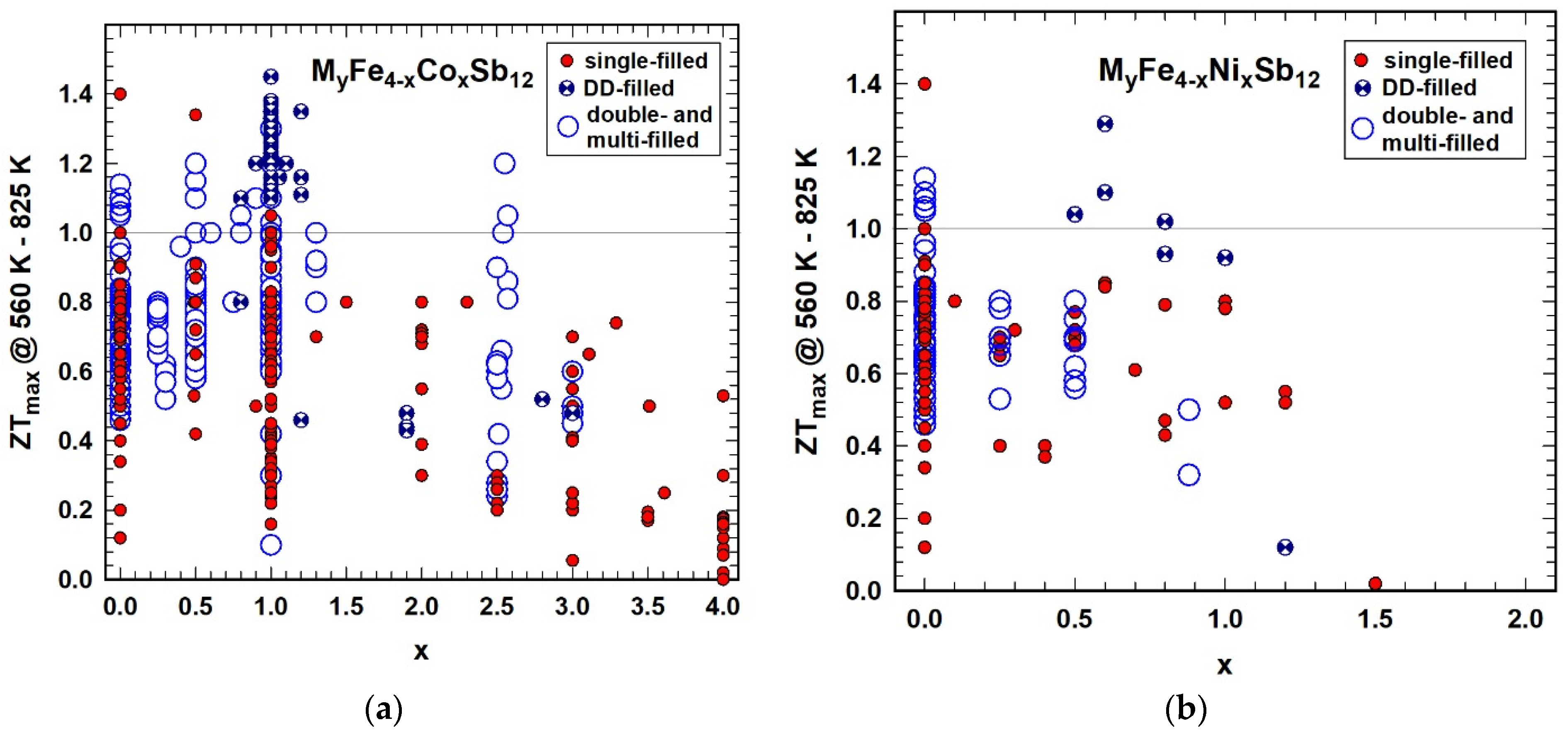

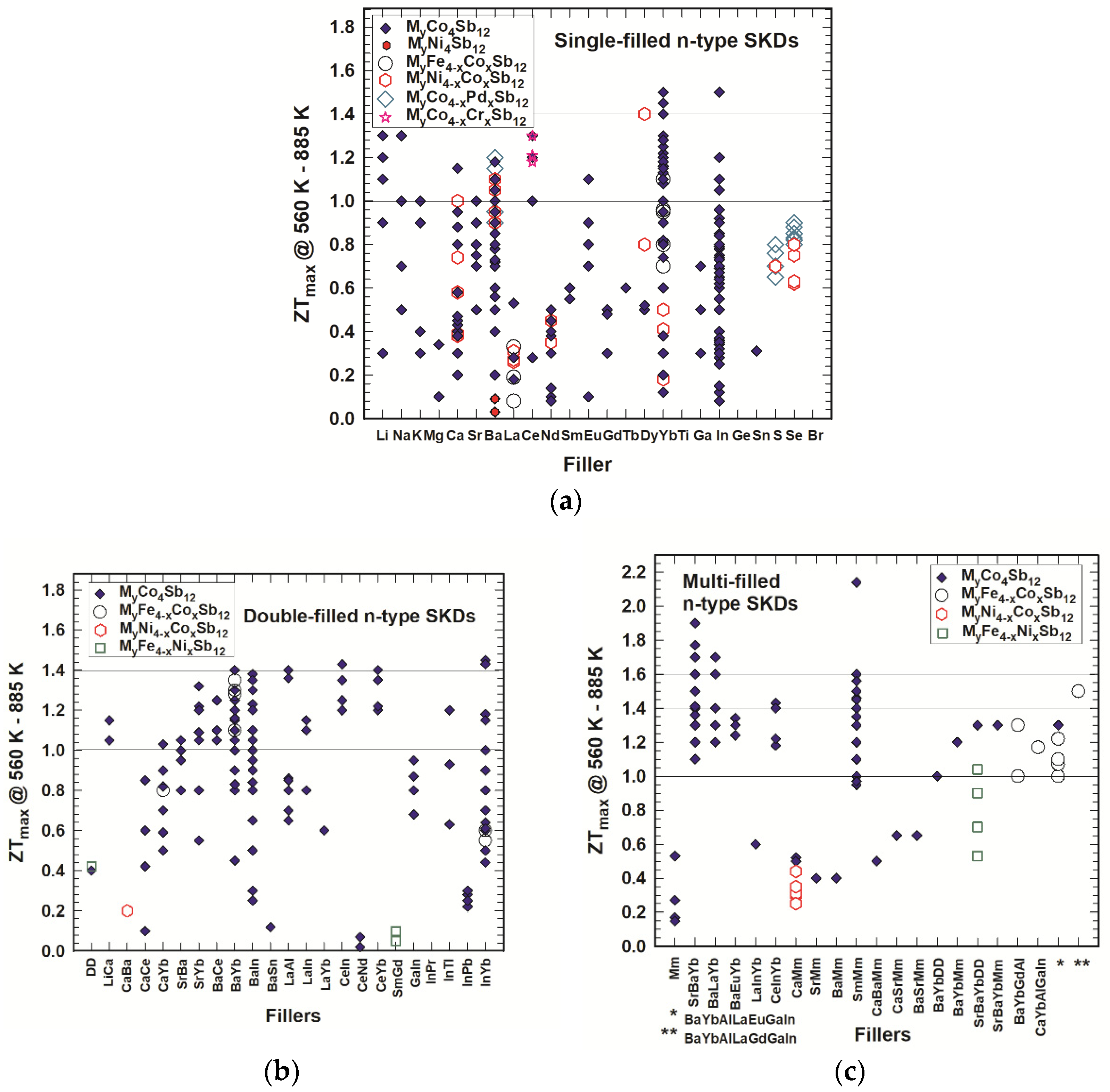

3.3. N-Type Skutterudites

3.3.1. Skutterudites MyCo4Sb12

| Filler(s) of N-Type SKDs | Co4Sb12 Refs. | Co/Cr Refs. | Fe/Co Refs. | Co/Ni Refs. | Co/Pd Refs. | Fe/Ni Refs. |

|---|---|---|---|---|---|---|

| Single-fillers | ||||||

| Li | [113,125,216] | - | - | - | - | - |

| Na | [83] | - | - | - | - | - |

| K | [57] | - | - | - | - | - |

| Mg | [138] | |||||

| Ca | [44,45,79,98,197,216] | - | - | [45] | - | - |

| Sr | [60,93] | - | - | - | - | - |

| Ba | [35,37,65,66,67,74,75,77,88,91,92,126,158,159,174,213,260,270] | - | - | [37,201,234] | [65] | [201] |

| La | [210,240] | - | [46] | [59,112] | - | - |

| Ce | [28,29,30,181,183,184,236] | [184] | [28] | - | - | - |

| Nd | [42,54,198,236] | - | - | [54] | - | - |

| Sm | [94,198] | - | - | - | - | - |

| Eu | [38,39,72] | - | [38] | - | - | - |

| Gd | [137,198] | - | - | - | - | - |

| Tb | [198] | - | - | - | - | - |

| Dy | [198,243] | - | - | [243] | - | - |

| Yb | [31,32,61,62,68,69,71,74,75,80,84,85,90,98,100,108,121,128,129,144,145,149,166,171,175,180,181,186,208,211,255,257,258,271] | - | [62,186] | [228] | - | [40] |

| Ti | [235] | - | - | - | - | - |

| Ga | [132] | - | - | - | - | - |

| In | [55,63,67,70,81,82,84,87,99,110,115,118,119,127,143,154,155,179,191,214,261] | - | - | - | - | - |

| Ge | [148] | - | - | - | - | - |

| Sn | [56,78] | - | - | - | - | - |

| S | [188,245,273] | - | - | [188] | [244] | - |

| Se | [188,227] | - | - | [277] | [248] | - |

| Br | 190 | - | - | - | - | - |

| Double-fillers | ||||||

| DD | [95] | - | - | - | - | [95] |

| Li, Ca | [216] | - | - | - | - | - |

| Ca, Ba | - | - | [96] | [96] | - | - |

| Ca, Ce | [79] | - | - | - | - | - |

| Ca, Yb | [98] | - | - | - | - | - |

| Sr, Ba | [93,108] | - | - | - | - | - |

| Sr, Yb | [51,91,93] | - | - | - | - | - |

| Ba, Ce | [77] | - | - | - | - | - |

| Ba, Yb | [74,75,91,135] | - | [142] | - | - | - |

| Ba, In | [67,92,127,157,252] | - | - | - | - | - |

| Ba, Sn | [159] | - | - | - | - | - |

| La, Al | [259] | - | - | - | - | - |

| La, In | [229] | - | - | - | - | - |

| La, Yb | [117] | - | - | - | - | - |

| Ce, In | [81,146] | - | - | - | - | - |

| Ce, Nd | [217] | - | - | - | - | - |

| Ce, Yb | [114] | - | - | - | - | - |

| Sm, Gd | - | - | - | - | - | [246] |

| Ga, In | [170] | - | - | - | - | - |

| In, Pr | [154] | - | - | - | - | - |

| In, Tl | [116] | - | - | - | - | - |

| In, Pb | [127] | - | - | - | - | - |

| In, Yb | [73,84,114,117,212] | - | - | - | - | - |

| Multi-fillers | ||||||

| Mm | [101,253] | - | - | - | - | - |

| Sr, Ba, Yb | [91,108,120,150,175] | - | - | - | - | - |

| Ba, La, Yb | [111,150] | - | - | - | - | - |

| Ba, Eu, Yb | [86] | - | - | - | - | - |

| La, In, Yb | [117] | - | - | - | - | - |

| Ce, In, Yb | [114,146] | - | - | - | - | - |

| Ca, Mm | [102] | - | - | [102] | - | - |

| Sr, Mm | [102] | - | - | [102] | - | - |

| Ba, Mm | [102] | - | - | - | - | - |

| Sm, Mm | [151,220,256,265,275] | - | - | - | - | - |

| Ca, Ba, Mm | [102] | - | - | - | - | - |

| Ca, Sr, Mm | [102] | - | - | - | - | - |

| Ba, Sr, Mm | [102] | - | - | - | - | - |

| Ba, Yb, DD | [150] | - | - | - | - | - |

| Ba, Yb, Mm | [150] | - | - | - | - | - |

| Sr, Ba, Yb, DD | [150] | - | - | - | - | [133] |

| Sr, Ba, Yb, Mm | [150] | - | - | - | - | - |

| Ba, Yb, Gd, Al | - | - | [200] | - | - | - |

| Ca, Yb, Al, Ga, In | - | - | [200,269] | - | - | - |

| Ba, Yb, Al, La, Gd, Ga, In | - | - | [200] | - | - | - |

| Ba, Yb, Al, La, Eu Ga, In | [269] | - | [200,268,269] | - | - | - |

| Additives | P-Type Refs. | N-Type Refs. |

|---|---|---|

| TiO2 | - | [88,158] |

| Cu2O | - | [159,220] |

| ZnO | - | [143] |

| MoO2 | [64] | - |

| WO | [64] | - |

| Al2O3 | - | [220] |

| Yb2O3 | - | [61,128,145] |

| La1.85Sr0.15CuO4 | [220] | [220] |

| Ni core shells | - | [165] |

| Ag | - | [126,172] |

| Al | - | [211] |

| CoSb3 | - | [71] |

| GaSb | - | [100,270] |

| InSb | - | [191,260,261,271] |

| Fe3Si | [200] | - |

| CoSi | - | [255] |

| PbTe | - | [143] |

| AgSbTe2 | - | [129,149] |

| InCo4Sb12 | - | [175] |

| Fe2.25Co0.075B | [220] | [220] |

| Ta0.8Zr0.2B | [220,238] | [220,238] |

| SiC | - | [257] |

| fullerene C60 | - | [66] |

| graphene | [237] | - |

| carbon fiber | [183] | - |

| MWCNT | [221] | [210] |

| Substitutions | ||

| Sb/Ga | - | [100,132] |

| Sb/Ge | [119,139,140,174,203,241] | [119] |

| Sb/Te | [189,190] | [56,63,70,78,188,235,245,252,273] |

| Sb/Sn | [164,174] | [41,201] |

| Sb/Se | - | [227,248] |

| Sb/TeGe | - | [179] |

3.3.2. N-Type Skutterudites with Co/Cr, Fe/Co, Ni/Co, Co/Pd and Fe/Ni Substitution

3.4. Substitutions and Additives

3.4.1. Sb Substituted by Ga, Ge, Sn, Se, Te, Ge + Te

3.4.2. Additives

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Oftedal, I. The crystal structure of skutterudite and smaltite-chloanthite. Z. Kristallogr. A 1928, 66, 517–546. [Google Scholar] [CrossRef]

- Jeitschko, W.; Braun, D. Thorium-containing pnictides with the LaFe4P12 structure, LaFe4P12 with filled CoAs3-type structure and isotypic lanthanoid–transition metal polyphosphides. Acta Crystallogr. 1977, 33, 3401–3406. [Google Scholar] [CrossRef]

- Slack, G. CRC Handbook of Thermoelectrics, 1st ed.; Rowe, M., Ed.; CRC Press: Boca Raton, FL, USA, 1995; p. 407. [Google Scholar]

- Rowe, D.M.; Bhandari, C.M. Modern Thermoelectrics, 1st ed.; Reston Publishing Company: Reston, VA, USA, 1983; pp. 1–157. [Google Scholar]

- Uher, C. Skutterudites: Prospective novel thermoelectrics. In Semiconductors and Semimetals; Elsevier: Amsterdam, The Netherlands, 2001; Volume 69, pp. 139–253. [Google Scholar]

- Rowe, D.M. Thermoelectrics Handbook Macro to Nano, 1st ed.; CRC Press: Boca Raton, FL, USA, 2006; pp. 1–1022. [Google Scholar]

- Snyder, G.J.; Toberer, E.S. Complex thermoelectric materials. Nature Mater. 2008, 7, 105–114. [Google Scholar] [CrossRef] [Green Version]

- Minnich, A.J.; Dresselhaus, M.S.; Ren, Z.F.; Chen, G. Bulk nanostructured thermoelectric materials: Current research and future prospects. Energy Environ. Sci. 2009, 2, 466–479. [Google Scholar] [CrossRef]

- Goldsmid, H.J. Introduction to Thermoelectricity, 2nd ed.; Springer Series in Materials Science; Springer: Berlin/Heidelberg, Germany, 2010; Volume 121, pp. 1–242. [Google Scholar]

- Gaultois, M.W.; Sparks, T.D.; Borg, C.K.H.; Seshadri, R.; Bonificio, W.D.; Clarke, D.R. Data-driven review of thermoelectric materials: Performance and resource considerations. Chem. Mater. 2013, 25, 2911–2920. [Google Scholar] [CrossRef] [Green Version]

- Kuomoto, K.; Mori, T. Thermoelectric Nanomaterials, 1st ed.; Springer Series in Materials Science; Springer: Berlin/Heidelberg, Germany, 2013; Volume 182, pp. 1–387. [Google Scholar]

- Schierning, G.; Chavez, R.; Schmechel, R.; Balke, B.; Rogl, G.; Rogl, P. Concepts for medium-high to high temperature thermoelectric heat-to-electricity conversion: A review of selected materials and basic considerations of module design. Transl. Mater. Res. 2015, 2, 025001. [Google Scholar] [CrossRef]

- Rull-Bravo, M.; Moure, A.; Fernández, J.F.; Martín-González, S. Skutterudites as thermoelectric material: Revisited. RSC Adv. 2015, 5, 41653. [Google Scholar] [CrossRef]

- Fitriani, R.; Ovik, B.D.; Long, M.C.; Barma, M.; Riaz, M.F.M.; Sabri, S.M.; Saidur, S.R. A review on nanostructures of high-temperature thermoelectric materials for waste heat recovery. Renew. Sustain. Energy Rev. 2016, 64, 635–659. [Google Scholar] [CrossRef]

- Rogl, G.; Rogl, P. Skutterudites, a most promising group of thermoelectric materials. In Current Opinion in Green and Sustainable Chemistry; Schorr, S., Ed.; Elsevier: Amsterdam, The Netherlands, 2017; Volume 4, pp. 50–57. [Google Scholar]

- Beretta, D.; Neophytou, N.; Hodges, J.M.; Kanatzidis, M.G.; Narducci, D.; Martin-Gonzalez, M.; Beekman, M.; Balke, B.; Tremel, G.W.; Zevalkink, A.; et al. Thermoelectrics: From history, a window to the future. Mater. Sci. Eng. R Rep. 2019, 138, 100501. [Google Scholar] [CrossRef]

- Hasan, M.N.; Wahid, H.; Nayan, N.; Mohamed, A.M.S. Inorganic thermoelectric materials: A review. Int. J. Energy Res. 2020, 44, 6170–6222. [Google Scholar] [CrossRef]

- Nandihalli, N.; Gregory, D.H.; Mori, T. Energy-saving pathways for thermoelectric nanomaterial synthesis: Hydrothermal/solvothermal, microwave-assisted, solution-based, and powder processing. Adv. Sci. 2022, 9, 2106052. [Google Scholar] [CrossRef] [PubMed]

- Rogl, G.; Rogl, P. High pressure torsion, a large-scale manufacturing tool for high ZT skutterudite thermoelectrics. Z. Anorg. Allg. Chem. 2022, 648, e202200044. [Google Scholar] [CrossRef]

- Rogl, G.; Grytsiv, A.; Bauer, E.; Rogl, P. Thermoelectric Sb-based skutterudites for medium temperatures. In Advanced Thermoelectrics: Materials, Contacts, Devices and Systems; Ren, Z., Lan, Y., Zhang, Q., Eds.; CRC Press: Boca Raton, FL, USA, 2018; pp. 193–230. [Google Scholar]

- Rogl, G.; Rogl, P. Skutterudites: Progress and Challenges. In Novel Thermoelectric Materials and Device Design Concepts; Skipidarov, S., Nikitin, M., Eds.; Springer Verlag: Berlin/Heidelberg, Germany, 2019; pp. 177–203. [Google Scholar]

- Rogl, G.; Rogl, P. How nanoparticles can change the figure of merit, ZT, and mechanical properties of skutterudites. Mater. Today Phys. 2017, 3, 48–69. [Google Scholar] [CrossRef]

- Freer, R.; Ekren, D.; Ghosh, T.; Biswas, K.; Qiu, P.; Wan, S.; Chen, L.; Han, S.; Fu, C.; Zhu, T.; et al. Key Properties of Inorganic Thermoelectric Materials—Tables. J. Phys. Energy 2022, 4, 022002. [Google Scholar] [CrossRef]

- Zhao, C.; Wang, M.; Liu, Z. Research progress on preparation methods of skutterudite. Inorganics 2022, 10, 106. [Google Scholar] [CrossRef]

- Kim, H.-S.; Gibbs, Z.M.; Tang, Y.; Wang, H.; Snyder, G.J. Characterization of Lorenz number with Seebeck coefficient measurement. APL Mater. 2015, 3, 041506. [Google Scholar] [CrossRef] [Green Version]

- Fleurial, J.-P.; Borshchevsky, A.; Morelli, D.T.; Meisner, G.P. High figure of merit in Ce-filled skutterudites. In Proceedings of the Fifteenth International Conference on Thermoelectrics, Pasadena, CA, USA, 30 November 1996; pp. 91–95. [Google Scholar]

- Sales, B.C.; Mandrus, D.; Williams, R.K. Filled skutterudite antimonides: A new class of thermoelectric materials. Science 1996, 272, 1325–1327. [Google Scholar] [CrossRef]

- Chen, B.; Xu, J.-H.; Uher, C.; Morelli, D.T.; Meisner, G.P.; Fleurial, J.P.; Caillat, T.; Borshchevsky, A. Low-temperature transport properties of the filled skutterudites CeFe4−xCoxSb12. Phys. Rev. B 1997, 55, 1476–1480. [Google Scholar] [CrossRef]

- Morelli, D.T.; Meisner, G.P.; Chen, B.; Hu, S.; Uher, C. Cerium filling and doping of cobalt triantimonide. Phys. Rev. B 1997, 56, 7376–7383. [Google Scholar] [CrossRef]

- Uher, C.; Chen, B.; Hu, S.; Morelli, D.T.; Meisner, G.P. Transport properties of partially-filled CeyCo4Sb12. Mat. Res. Soc. Symp. Proc. 1997, 478, 315–320. [Google Scholar] [CrossRef]

- Nolas, G.S.; Kaeser, M.; Littleton, I.V.R.T.; Tritt, T.M.; Johnson, D.C.; Sellinschegg, H.; Nelson, E. Partially-filled Skutterudites: Optimizing the thermoelectric properties. Mat. Res. Soc. Symp. Proc. 2000, 626, Z10.1.1–Z10.1.6. [Google Scholar] [CrossRef]

- Nolas, G.S.; Kaeser, M.; Littleton, I.V.R.T.; Tritt, T.M. High figure of merit in partially filled ytterbium skutterudite materials. Appl. Phys. Lett. 2000, 77, 1855–1857. [Google Scholar] [CrossRef]

- Sales, B.C.; Chakoumakos, B.C.; Mandrus, D. Thermoelectric properties of thallium-filled skutterudites. Phys. Rev. B 2000, 61, 2475–2481. [Google Scholar] [CrossRef]

- Bauer, E.; Berger, S.; Galli, M.; Michor, H.; Hilscher, G.; Paul, C.; Ni, B.; Abd-Elmeguid, M.; Tran, V.H.; Grytsiv, A.; et al. Crystal structure and physical properties of Eu0.83Fe4Sb12. Phys. Rev. B 2001, 63, 224414–224421. [Google Scholar] [CrossRef]

- Chen, L.D.; Kawahara, T.; Tang, X.F.; Goto, T.; Hirai, T.; Dyck, J.S.; Chen, W.; Uher, C. Anomalous barium filling fraction and n-type thermoelectric performance of BayCo4Sb12. J. Appl. Phys. 2001, 90, 1864–1868. [Google Scholar] [CrossRef]

- Tang, X.F.; Chen, L.D.; Goto, T.; Hirai, T.; Yuan, R.Z. Synthesis and thermoelectric properties of filled skutterudite compounds CeyFexCo4−xSb12 by solid state reaction. J. Mater. Sci. 2001, 36, 5435–5439. [Google Scholar] [CrossRef]

- Dyck, J.S.; Chen, W.; Uher, C.; Chen, L.; Tang, X.; Hirai, T. Thermoelectric properties of the n-type filled skutterudite Ba0.3Co4Sb12 doped with Ni. J. Appl. Phys. 2002, 91, 3698–3705. [Google Scholar] [CrossRef]

- Grytsiv, A.; Rogl, P.; Berger, S.t.; Paul, C.; Bauer, E.; Godart, C.; Ni, B.; Abd-Elmeguid, M.M.; Saccone, A.; Ferro, R.; et al. Structure and physical properties of the thermoelectric skutterudites EuyFe4−xCoxSb12. Phys. Rev. B 2002, 66, 094411. [Google Scholar] [CrossRef]

- Lamberton Jr, G.A.; Bhattacharya, S.; Littleton, I.V.R.T.; Kaeser, M.A.; Tedstrom, R.H.; Tritt, T.; Yang, M.J.; Nolas, G.S. High figure of merit in Eu-filled CoSb3-based skutterudites. Appl. Phys. Lett. 2002, 80, 598–600. [Google Scholar] [CrossRef]

- Bauer, E.; Berger, S.T.; Paul, C.h.; Michor, H.; Grytsiv, A.; Rogl, P. Effect of ionic valence and electronic correlations on the thermoelectric power in some filled skutterudites. Phys. B 2003, 328, 49–52. [Google Scholar] [CrossRef]

- Grytsiv, A.; Rogl, P.; Berger, S.; Paul, C.; Michor, H.; Bauer, E.; Hilscher, G.; Lottermoser, W.; Saccone, A.; Ferro, R.; et al. Novel thermoelectric skutterudites SnyNi4Sb12−xSnx. Phys. B 2003, 328, 71–73. [Google Scholar] [CrossRef]

- Kuznetsov, V.L.; Kuznetsova, L.A.; Rowe, D.M. Effect of partial void filling on the transport properties of NdxCo4Sb12 skutterudites. J. Phys. Condens. Matter 2003, 15, 5035–5048. [Google Scholar] [CrossRef]

- Viennois, R.; Girard, C.L.; Ravot, D.; Terki, F.; Charar, S.; Tedenac, J.C.; Paschen, S.; Bentien, A.; Steglich, F. Physical properties of the skutterudites (Ce,La)Fe4−xNixSb12. In Proceedings of the ICT’03: The Twenty-second International Conference on Thermoelectrics, La Grande Motte, France, 17–21 August 2003; pp. 60–63. [Google Scholar]

- Puyet, M.; Lenoir, B.; Dauscher, A.; Dehmas, M.; Stiewe, C.; Müller, E. High temperature transport properties of partially filled CaxCo4Sb12 skutterudites. J. Appl. Phys. 2004, 95, 4852–4855. [Google Scholar] [CrossRef]

- Puyet, M.; Lenoir, B.; Dauscher, A.; Scherrer, H.; Dehmas, M.; Hejtmanek, J.; Stiewe, C.; Müller, E. Effect of Ni in new skutterudite compounds CaxCo4Sb12. Mat. Res. Soc. Symp. Proc. 2004, 793, S4.1.1–S4.1.6. [Google Scholar] [CrossRef]

- Yang, L.; Wu, J.S.; Zhang, L.T. Synthesis of filled skutterudite compound La0.75Fe3CoSb12 by spark plasma sintering and effect of porosity on thermoelectric properties. J. Alloys Compd. 2004, 364, 83–88. [Google Scholar] [CrossRef]

- Yang, L.; Wu, J.S.; Zhang, L.T. Thermoelectric properties of some skutterudite compounds with different grain size. J. Alloys Compd. 2004, 375, 114–119. [Google Scholar] [CrossRef]

- Arita, Y.; Ogawa, T.; Kobayashi, H.; Iwasaki, K.; Matsui, T.; Nagasaki, T. Thermoelectric properties of uranium filled skutterudites Uy(FexCo4−x)Sb12. J. Nuclear Mater. 2005, 344, 79–83. [Google Scholar] [CrossRef]

- Lu, Q.M.; Zhang, J.X.; Zhang, X.; Liu, Y.Q.; Liu, D.M.; Zhou, M.L. Effects of double filling of La and Ce on thermoelectric properties of CemLanFeCo3Sb12 compounds by spark plasma sintering. J. Appl. Phys. 2005, 98, 106107. [Google Scholar] [CrossRef]

- Nolas, G.S.; Yoon, G.; Sellinschegg, H.; Smalley, A.; Johnson, D.C. Synthesis and transport properties of HfFe4Sb12. Appl. Phys. Lett. 2005, 86, 042111. [Google Scholar] [CrossRef]

- Bai, S.Q.; Zhao, X.Y.; Pei, Y.Z.; Chen, L.D.; Zhang, W.Q. Synthesis and thermoelectric properties of (Sr,Yb)yCo4Sb12 double filled skutterudites. In Proceedings of the 2006 25th International Conference on Thermoelectrics, Vienna, Austria, 6–10 August 2006; pp. 145–147. [Google Scholar]

- Bao, S.; Yang, J.; Peng, J.; Zhu, W.; Fan, X.; Song, X. Preparation and thermoelectric properties of LaxFeCo3Sb12 skutterudites by mechanical alloying and hot pressing. J. Alloys Compd. 2006, 421, 105–108. [Google Scholar] [CrossRef]

- Bao, S.; Yang, J.; Peng, J.; Zhu, W.; Fan, X.; Duan, X.; Peng, J. Preparation and thermoelectric properties of La filled skutterudites by mechanical alloying and hot pressing. Mater. Lett. 2006, 60, 2029–2032. [Google Scholar] [CrossRef]

- Da Ros, V.; Lenoir, B.; Dauscher, A.; Candolfi, C.; Bellouard, C.; Stiewe, C.; Müller, E.; Hejtmanek, J. Thermoelectric properties of NdxCo4−yNiySb12 skutterudite compounds. In Proceedings of the 2006 25th International Conference on Thermoelectrics, Vienna, Austria, 6–10 August 2006; pp. 155–158. [Google Scholar]

- He, T.; Chen, J.; Rosenfeld, H.D.; Subramanian, M.A. Thermoelectric properties of indium-filled skutterudites. Chem. Mater. 2006, 18, 759–762. [Google Scholar] [CrossRef]

- Mallik, R.C.; Jung, J.-Y.; Das, V.D.; Ur, S.-C.; Kim, I.-H. Thermoelectric properties of SnzCo4Sb12−yTey skutterudites. In Proceedings of the 2006 25th International Conference on Thermoelectrics, Vienna, Austria, 6–10 August 2006; pp. 431–434. [Google Scholar]

- Pei YZ: Chen, L.D.; Zhang, W.; Shi, X.; Bai, S.Q.; Zhao, X.Y.; Mei, Z.G.; Li, X.Y. Synthesis and thermoelectric properties of KyCo4Sb12. Appl. Phys. Lett. 2006, 89, 221107. [Google Scholar]

- Tang, X.; Li, H.; Zhang, Q.; Niino, N.; Goto, T. Synthesis and thermoelectric properties of double-atom-filled skutterudite compounds CamCenFexCo4−xSb12. J. Appl. Phys. 2006, 100, 123702. [Google Scholar] [CrossRef]

- Yang, J.; Chen, Y.; Zhu, W.; Peng, J.; Bao, S.; Fan, X.; Duan, X. Effect of La filling on thermoelectric properties of LaxCo3.6Ni0.4Sb12-filled skutterudite prepared by MA-HP method. J. Solid State Chem. 2006, 179, 212–216. [Google Scholar] [CrossRef]

- Zhao, X.Y.; Shi, X.; Chen, L.D.; Zhang, W.Q.; Pei, Y.Z. Synthesis and thermoelectric properties of Sr-filled skutterudite SryCo4Sb12. J. Appl. Phys. 2006, 99, 053711. [Google Scholar] [CrossRef]

- Zhao, X.Y.; Shi, X.; Chen, L.D.; Zhang, W.Q.; Bai, Y.Z.; Pei, Y.Z.; Li, X.Y.; Goto, T. Synthesis of YbyCo4Sb12/Yb2O3 composites and their thermoelectric properties. Appl. Phys. Lett. 2006, 89, 092121. [Google Scholar] [CrossRef]

- Guo, J.Q.; Geng, Y.; Ochi, H.K.; Kim, H.K.; Hyodo, K.; Kimura, K. Thermoelectric properties of (Yb,Ca)x(Co,Fe)4Sb12 skutterudites. In Proceedings of the 2007 26th International Conference on Thermoelectrics, Jeju, Korea, 3–5 June 2007; pp. 183–186. [Google Scholar]

- Jung, J.-Y.; Hong, S.-J.; You, S.-W.; Jeong, Y.-J.; Lee, J.-I.; Ur, S.-C.; Kim, I.-H. Thermoelectric properties of InzCo4Sb12−yTey skutterudites. In Proceedings of the 2007 26th International Conference on Thermoelectrics, Jeju, Korea, 3–5 June 2007; pp. 207–210. [Google Scholar]

- Katsuyama, S.; Okada, H. Synthesis of rare earth filled skutterudite with dispersed oxide particles by mechanical milling and SPS techniques and investigation of its thermoelectric properties. J. Jpn. Soc. Powder Metall. 2007, 54, 375–380. [Google Scholar] [CrossRef] [Green Version]

- Pei, Y.Z.; Chen, L.D.; Bai, S.Q.; Zhao, X.Y.; Li, X.Y. Effect of Pd substitution on thermoelectric properties of Ba0.32PdxCo4−xSb12. Scr. Mater. 2007, 56, 621–624. [Google Scholar] [CrossRef]

- Shi, X.; Chen, L.D.; Bai, S.Q.; Huang, X.Y.; Zhao, X.Y.; Yao, Q. Influence of fullerene dispersion on high temperature thermoelectric properties of BayCo4Sb12-based composites. J. Appl. Phys. 2007, 102, 103709. [Google Scholar] [CrossRef]

- Zhao, W.Y.; Dong, C.L.; Wei, P.; Guan, W.; Liu, L.S.; Zhai, P.C.; Tang, X.F.; Zhang, Q.J. Synthesis and high temperature transport properties of barium and indium double-filled skutterudites BaxInyCo4Sb12−z. J. Appl. Phys. 2007, 102, 113708. [Google Scholar] [CrossRef]

- Li, H.; Tang, X.; Su, X.; Zhang, Q. Preparation and thermoelectric properties of high-performance Sb additional Yb0.2Co4Sb12+y bulk materials with nanostructure. Appl. Phys. Lett. 2008, 92, 202114. [Google Scholar] [CrossRef]

- Li, H.; Tang, X.; Su, X.; Zhang, Q.; Uher, C. Rapid preparation method of bulk nanostructured Yb0.3Co4Sb12+y compounds and their improved thermoelectric performance. Appl. Phys. Lett. 2008, 93, 252109. [Google Scholar] [CrossRef] [Green Version]

- Mallik, R.C.; Jung, J.-Y.; Ur, S.-C.; Kim, I.-H. Thermoelectric properties of InzCo4Sb12 skutterudites. Metal Mater. Int. 2008, 14, 223–228. [Google Scholar] [CrossRef]

- Mi, J.L.; Zhao, X.B.; Zhu, T.J.; Tu, J.P. Thermoelectric properties of Yb0.15Co4Sb12 based nanocomposites with CoSb3 nano-inclusion. J. Phys. D Appl. Phys. 2008, 41, 205403. [Google Scholar] [CrossRef]

- Pei, Y.Z.; Bai, S.Q.; Zhao, X.Y.; Zhang, W.; Chen, L.D. Thermoelectric properties of EuyCo4Sb12 filled skutterudites. Solid State Sci. 2008, 10, 1422–1428. [Google Scholar] [CrossRef]

- Peng, J.Y.; Alboni, P.N.; Zhang, B.; Su, Z.; Holgate, T.; Gothard, N.; Tritt, T.M. Thermoelectric properties of (In,Yb) double-filled CoSb3 skutterudite. J. Appl. Phys. 2008, 104, 053710. [Google Scholar] [CrossRef]

- Shi, X.; Kong, H.; Li, C.-P.; Yang, J.; Salvador, J.R.; Wang, H.; Chen, L.; Zhang, W. Low thermal conductivity and high thermoelectric figure of merit in n-type BaxYbyCo4Sb12 double-filled skutterudites. Appl. Phys. Lett. 2008, 92, 182101. [Google Scholar] [CrossRef]

- Uher, C.; Shi, X.; Kong, H. Enhanced thermoelectric figure of merit in BaxYbyCo4Sb12 skutterudite. Mater. Res. Soc. Symp. Proc. 2008, 1044, U05–U09. [Google Scholar] [CrossRef]

- Bao, S.; Yang, J.; Zhu, W.; Fan, X.; Duan, X. Effect of processing parameters on formation and thermoelectric properties of La0.4FeCo3Sb12 skutterudite by MA–HP method. J. Alloys Compd. 2009, 476, 802–806. [Google Scholar] [CrossRef]

- Bai, S.Q.; Pei, Y.Z.; Chen, L.D.; Zhang, W.Q.; Zhao, X.Y.; Yang, J. Enhanced thermoelectric performance of dual-element-filled skutterudites BaxCeyCo4Sb12. Acta Mater. 2009, 57, 3135–3139. [Google Scholar] [CrossRef]

- Jung, J.-Y.; Ur, S.-C.; Kim, I.-H. Thermoelectric properties of SnzCo4Sb11.2Te0.8 skutterudites. J. Ceram. Proc. Res. 2009, 10, 158–161. [Google Scholar]

- Li, D.; Yang, K.; Hng, H.H.; Yan, Q.Y.; Ma, J.; Zhu, T.J.; Zhao, X.B. Synthesis and high temperature thermoelectric properties of calcium and cerium double-filled skutterudites Ca0.1CexCo4Sb12. J. Phys. D Appl. Phys. 2009, 42, 105408. [Google Scholar] [CrossRef]

- Li, H.; Tang, X.; Su, X.; Zhang, Q.; Uher, C. Nanostructured bulk YbxCo4Sb12 with high thermoelectric performance prepared by the rapid solidification method. J. Phys. D Appl. Phys. 2009, 42, 145409. [Google Scholar] [CrossRef]

- Li, H.; Tang, X.; Zhang, Q.; Uher, C. High performance InxCeyCo4Sb12 thermoelectric materials with in situ forming nanostructured InSb phase. Appl. Phys. Lett. 2009, 94, 102114. [Google Scholar] [CrossRef]

- Mallik, R.C.; Stiewe, C.; Karpinski, G.; Hassdorf, R.; Müller, E. Thermoelectric properties of Co4Sb12 skutterudite materials with partial In filling and excess In additions. J. Electron. Mater. 2009, 38, 1337–1343. [Google Scholar] [CrossRef]

- Pei, Y.Z.; Yang, J.; Chen, L.D.; Zhang, W.; Salvador, J.R.; Yang, J. Improving thermoelectric performance of caged compounds through light-element filling. Appl. Phys. Lett. 2009, 95, 042101. [Google Scholar] [CrossRef]

- Peng, J.; He, J.; Su, Z.; Alboni, P.N.; Zhu, S.; Tritt, T.M. High temperature thermoelectric properties of double-filled InxYbyCo4Sb12 skutterudites. J. Appl. Phys. 2009, 105, 084907. [Google Scholar] [CrossRef]

- Salvador, J.R.; Yang, J.; Shi, X.; Wang, H.; Wereszczak, A.A.; Kong, H.; Uher, C. Transport and mechanical properties of Yb-filled skutterudites. Phil. Mag. 2009, 89, 1517–1534. [Google Scholar] [CrossRef]

- Shi, X.; Salvador, J.R.; Yang, J.; Wang, H. Thermoelectric properties of n-type multi-filled skutterudites. J. Electron. Mater. 2009, 38, 930–933. [Google Scholar] [CrossRef]

- Wang, L.; Cai, K.F.; Wang, Y.Y.; Li, H.; Wang, H.F. Thermoelectric properties of indium-filled skutterudites prepared by combining solvothermal synthesis and melting. Appl. Phys. A 2009, 97, 841–845. [Google Scholar] [CrossRef]

- Xiong, Z.; Chen, X.; Zhao, X.; Bai, S.; Huang, L.; Chen, L. Effects of nano-TiO2 dispersion on the thermoelectric properties of filled skutterudite Ba0.22Co4Sb12. Solid State Sci. 2009, 11, 1612–1616. [Google Scholar] [CrossRef]

- Yang, K.; Cheng, H.; Hng, H.H.; Ma, J.; Mi, J.L.; Zhao, X.B.; Zhu, T.J.; Zhang, Y.B. Synthesis and thermoelectric properties of double-filled skutterudites CeyYb0.5−yFe1.5Co2.5Sb12. J. Alloys Compd. 2009, 467, 528–532. [Google Scholar] [CrossRef]

- Yang, J.; Hao, Q.; Wang, H.; Lan, Y.C.; He, Q.Y.; Minnich, A.; Wang, D.Z.; Harriman, J.A.; Varki, V.M.; Dresselhaus, M.S.; et al. Solubility study of Yb in n-type skutterudites YbxCo4Sb12 and their enhanced thermoelectric properties. Phys. Rev. B 2009, 80, 115329. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.; Grytsiv, A.; Rogl, P.; Bauer, E.; Zehetbauer, M. High thermoelectric performance of triple-filled n-type skutterudites (Sr,Ba,Yb)yCo4Sb12. J. Phys. D Appl. Phys. 2009, 42, 225405. [Google Scholar] [CrossRef]

- Zhao, W.; Wei, P.; Zhang, Q.; Dong, C.; Liu, L.; Tang, X. Enhanced thermoelectric performance in barium and indium double-filled skutterudite bulk materials via orbital hybridization induced by indium filler. J. Am. Chem. Soc. 2009, 131, 3713–3720. [Google Scholar] [CrossRef]

- Bai, S.Q.; Huang, X.Y.; Chen, L.D.; Zhang, W.; Zhao, X.Y.; Zhou, Y.F. Thermoelectric properties of n-type SrxMyCo4Sb12 (M = Yb, Ba) double-filled skutterudites. Appl. Phys. A 2010, 100, 1109–1114. [Google Scholar] [CrossRef]

- Jiang, Y.P.; Jia, X.P.; Su, T.C.; Dong, N.; Yu, F.R.; Tian, Y.J.; Guo, W.; Xu, H.W.; Deng, L.; Ma, H.A. Thermoelectric properties of SmxCo4Sb12 prepared by high pressure and high temperature. J. Alloys Compd. 2010, 493, 535–538. [Google Scholar] [CrossRef]

- Rogl, G.; Grytsiv, A.; Bauer, E.; Rogl, P.; Zehetbauer, M. Thermoelectric properties of novel skutterudites with didymium: DDy(Fe1−xCox)4Sb12 and DDy(Fe1−xNix)4Sb12. Intermetallics 2010, 18, 57–60. [Google Scholar] [CrossRef]

- Rogl, G.; Grytsiv, A.; Bauer, E.; Rogl, P.; Zehetbauer, M. Structural and physical properties of n–type skutterudite Ca0.07Ba0.23Co3.95Ni0.05Sb12. Intermetallics 2010, 18, 394–398. [Google Scholar] [CrossRef]

- Rogl, G.; Grytsiv, A.; Bauer, E.; Kerber, M.B.; Rogl, P.; Zehetbauer, M.; Puchegger, S. Multifilled nanocrystalline p-type didymium-skutterudites with ZT > 1.2. Intermetallics 2010, 18, 2435–2444. [Google Scholar] [CrossRef]

- Salvador, J.R.; Yang, R.; Wang, J.H.; Shi, X. Double-filled skutterudites of the type YbxCayCo4Sb12: Synthesis and properties. J. Appl. Phys. 2010, 107, 043705. [Google Scholar] [CrossRef]

- Sesselmann, A.; Hassdorf, R.; Zastrow, S.; Müller, E. High-temperature transport properties of indium added cobaltantimonide based skutterudites processed by current assisted short-term sintering. Adv. Sci. Technol. 2010, 74, 54–59. [Google Scholar]

- Xiong, Z.; Chen, X.; Huang, X.; Bai, S.; Chen, L. High thermoelectric performance of Yb0.26Co4Sb12/yGaSb nanocomposites originating from scattering electrons of low energy. Acta Mater. 2010, 58, 3995–4002. [Google Scholar] [CrossRef]

- Zhang, L.; Grytsiv, A.; Kerber, M.; Rogl, P.; Bauer, E.; Zehetbauer, M. Thermoelectric performance of mischmetal skutterudites MmyFe4−xCoxSb12 at elevated temperatures. J. Alloys Compd. 2010, 490, 19–25. [Google Scholar] [CrossRef]

- Zhang, L.; Melnychenko-Koblyuk, N.; Royanian, E.; Grytsiv, A.; Rogl, P.; Bauer, E. Influence of filler element and Ni-substitution on thermoelectric properties of multi-filled skutterudites. J. Alloys Compd. 2010, 504, 53–59. [Google Scholar] [CrossRef]

- Liu, R.; Yang, J.; Chen, X.; Shi, X.; Chen, L.; Uher, C. P-type skutterudites RxMyFe3CoSb12 (R, M = Ba, Ce, Nd, and Yb): Effectiveness of double-filling for the lattice thermal conductivity reduction. Intermetallics 2011, 19, 1747–1751. [Google Scholar] [CrossRef]

- Liu, R.; Qiu, P.; Chen, X.; Huang, X.; Chen, L. Composition optimization of p-type skutterudites CeyFexCo4−xSb12 and YbyFexCo4−xSb12. J. Mater. Res. 2011, 26, 1813–1819. [Google Scholar] [CrossRef]

- Qiu, P.; Yang, J.; Liu, R.; Shi, X.; Huang, X.; Snyder, G.J.; Zhang, W.; Chen, L. High-temperature electrical and thermal transport properties of fully filled skutterudites RFe4Sb12 (R = Ca, Sr, Ba, La, Ce, Pr, Nd, Eu, and Yb). J. Appl. Phys. 2011, 109, 063713. [Google Scholar] [CrossRef] [Green Version]

- Rogl, G.; Grytsiv, A.; Bauer, E.; Rogl, P.; Zehetbauer, M. Enhanced thermoelectric figure of merit in p-type DDy(Fe1−xCox)4Sb12. Solid State Phen. 2011, 170, 240–243. [Google Scholar] [CrossRef]

- Rogl, G.; Grytsiv, A.; Bauer, E.; Rogl, P.; Zehetbauer, M. A new generation of p-type didymium skutterudites with high ZT. Intermetallics 2011, 19, 546–555. [Google Scholar] [CrossRef]

- Rogl, G.; Grytsiv, A.; Melnychenko-Koblyuk, N.; Bauer, E.; Laumann, S.; Rogl, P. Compositional dependence of the thermoelectric properties of (SrxBaxYb1−2x)yCo4Sb12. J. Phys. Condens. Matter 2011, 23, 275601. [Google Scholar] [CrossRef] [PubMed]

- Rogl, G.; Zehetbauer, M.; Kerber, M.; Rogl, P.; Bauer, E. Impact of ball milling and high-pressure torsion on the microstructure and thermoelectric properties of p- and n-type Sb-based skutterudites. In Materials Science Forum; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2001; Volume 667, pp. 1089–1094. [Google Scholar]

- Sesselmann, A.; Dasgupta, T.; Kelm, K.; Müller, E. Transport properties and microstructure of indium-added cobalt–antimony-based skutterudites. J. Mater. Res. 2011, 26, 1820–1826. [Google Scholar] [CrossRef]

- Shi, X.; Yang, J.; Salvador, J.R.; Chi, M.; Cho, J.Y.; Wang, H.; Bai, S.; Yang, J.; Zhang, W.; Chen, L. Multiple-filled Skutterudites: High thermoelectric figure of merit through separately optimizing electrical and thermal transports. J. Am. Chem. Soc. 2011, 133, 7837–7846. [Google Scholar] [CrossRef]

- Yang, J.; Chen, Y.; Zhu, W.; Bao, S.; Fan, X.; Duan, X. Characterization and Thermoelectric Properties of La0.4Ni0.2Co3.8Sb12 filled skutterudite prepared by the MA-HP method. J. Am. Ceram. Soc. 2011, 94, 277–280. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, B.; Wang, L.-M.; Yu, D.; Liu, Z.; He, J.; Tian, Y. Great thermoelectric power factor enhancement of CoSb3 through the lightest metal element filling. Appl. Phys. Lett. 2011, 98, 072809. [Google Scholar] [CrossRef]

- Ballikaya, S.; Uzar, N.; Yildirim, S.; Salvador, J.R.; Uher, C. High thermoelectric performance of In, Yb, Ce multiple-filled CoSb3 based skutterudite compounds. J. Solid State Chem. 2012, 193, 31–35. [Google Scholar] [CrossRef]

- Eilertsen, J.; Rouvimov, S.; Subramanian, M.A. Rattler-seeded InSb nanoinclusions from metastable indium-filled In0.1Co4Sb12 skutterudites for high-performance thermoelectrics. Acta Mater. 2012, 60, 2178–2185. [Google Scholar] [CrossRef]

- Harnwunggmoung, A.; Kurosaki, K.; Kosuga, A.; Ishimaru, M.; Plirdpring, T.; Yimnirun, R.; Jutimoosik, J.; Rujirawat, S.; Ohishi, Y.; Muta HYamanaka, S. Enhancement of thermoelectric properties of CoSb3-based skutterudites by double filling of Tl and In. J. Appl. Phys. 2012, 112, 0435098. [Google Scholar] [CrossRef]

- Lee, J.-K.; Choi, S.-M.; Seo, W.-S.; Lim, Y.-S.; Lee, H.-L.; Kim, I.-H. Thermoelectric properties of spark plasma sintered InxYbyLa0.3−x−yCo4Sb12 skutterudite system. Renew. Energy 2012, 42, 36–40. [Google Scholar] [CrossRef]

- Li, G.; Kurosaki, K.; Ohishi, Y.; Muta, H.; Yamanaka, S. Thermoelectric properties of indium-added skutterudites InxCo4Sb12. J. Electron. Mater. 2012, 42, 1463–1468. [Google Scholar] [CrossRef]

- Mallik, R.C.; Mueller, E.; Kim, I.H. Thermoelectric properties of indium filled and germanium doped Co4Sb12 skutterudites. J. Appl. Phys. 2012, 111, 023708. [Google Scholar] [CrossRef]

- Rogl, G.; Setman, D.; Schafler, E.; Horky, J.; Kerber, M.; Zehetbauer, M.; Falmbigl, M.; Rogl, P.; Royanian, E.; Bauer, E. High pressure torsion, a new processing route for thermoelectrics of high ZTs by means of severe plastic deformation. Acta Mater. 2012, 60, 2146–2157. [Google Scholar] [CrossRef]

- Rogl, G.; Aabdin, Z.; Schafler, E.; Horky, J.; Setman, D.; Zehetbauer, M.; Kriegisch, M.; Eibl, O.; Grytsiv, A.; Royanian, E.; et al. Effect of HPT processing on the structure, thermoelectric and mechanical properties of Sr0.07Ba0.07Yb0.07Co4Sb12. J. Alloys Compd. 2012, 537, 183–189. [Google Scholar] [CrossRef]

- Rogl, G.; Grytsiv, A.; Falmbigl, M.; Bauer, E.; Rogl, P.; Zehetbauer, M.; Gelbstein, Y. Thermoelectric properties of p-type didymium (DD) based skutterudites DDy(Fe1−xNix)4Sb12 (0.13 ≤ x ≤ 0.25, 0.46 ≤ y ≤ 0.68). J. Alloys Compd. 2012, 537, 242–249. [Google Scholar] [CrossRef]

- Tan, G.; Wang, S.; Li, H.; Yan, Y.; Tang, X. Enhanced thermoelectric performance in zinc substituted p-type filled skutterudites CeFe4−xZnxSb12. J. Solid State Chem. 2012, 187, 316–322. [Google Scholar] [CrossRef]

- Yu, J.; Zhao, W.-Y.; Wie, P.; Tang, D.-G. Effects of excess Sb on thermoelectric properties of barium and indium double-filled iron-based p-type skutterudite materials. J. Electron. Mater. 2012, 41, 1414–1420. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, B.; Wang, L.-M.; Yu, D.; Yang, J.; Yu, F.; Liu, Z.; He, J.; Wen, B.; Tian, Y. High-pressure synthesis of phonon-glass electron-crystal featured thermoelectric LixCo4Sb12. Acta Mater. 2012, 60, 1246–1251. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, G.; Zhang, L.; Chi, H.; Su, X.; Sakamoto, J.; Uher, C. Enhanced thermoelectric properties of Ba-filled skutterudites by grain size reduction and Ag nanoparticle inclusion. J. Mater. Chem. 2012, 22, 2958–2964. [Google Scholar] [CrossRef]

- Deng, L.; Jia, X.P.; Ma, H.A.; Su, T.C.; Jie, K.; Guo, X. The thermoelectric properties of InxM0.2Co4Sb12 (M=Ba and Pb) double-filled skutterudites. Solid State Comm. 2013, 163, 15–18. [Google Scholar] [CrossRef]

- Ding, J.; Gu, H.; Qiu, P.; Chen, X.; Xiong, Z.; Zheng, Q.; Shi, X.; Chen, L. Creation of Yb2O3 nanoprecipitates through an oxidation process in bulk Yb-filled skutterudite. J. Electron. Mater. 2013, 42, 382–388. [Google Scholar] [CrossRef]

- Fu, L.; Yang, J.; Xiao, Y.; Peng, J.; Liu, M.; Luo, Y.; Li, G. AgSbTe2 nanoinclusion in Yb0.2Co4Sb12 for high performance thermoelectrics. Intermetallics 2013, 43, 79–84. [Google Scholar] [CrossRef]

- Jie, Q.; Wang, H.; Liu, W.; Wang, H.; Chen, G.; Ren, Z. Fast phase formation of double-filled p-type skutterudites by ball-milling and hot-pressing. Phys. Chem. Chem. Phys. 2013, 15, 6809–6816. [Google Scholar] [CrossRef] [PubMed]

- Mallik, R.C.; Anbalagan, R.; Raut, K.K.; Bali, A.; Royanian, E.; Bauer, E.; Rogl, G.; Rogl, P. Thermoelectric properties of Bi-added Co4Sb12 skutterudites. J. Phys.: Condens. Matter 2013, 25, 105701. [Google Scholar] [PubMed]

- Qiu, Y.; Xi, L.; Shi, X.; Qiu, P.; Zhang, W.; Chen, L.; Salvador, J.R.; Cho, J.Y.; Yang, J.; Chien, Y.; et al. Charge-compensated compound defects in Ga-containing thermoelectric skutterudites. Adv. Funct. Mater. 2013, 23, 3194–3203. [Google Scholar] [CrossRef] [Green Version]

- Rogl, G.; Grytsiv, A.; Royanian, E.; Heinrich, E.; Bauer, E.; Rogl, P.; Zehetbauer, M.; Falmbigl, M.; Puchegger, S.; Reinecker, M.; et al. New p- and n-type skutterudites with ZT > 1 and nearly identical thermal expansion and mechanical properties. Acta Mater. 2013, 61, 4066–4079. [Google Scholar] [CrossRef]

- Rogl, G.; Grytsiv, A.; Royanian, E.; Bauer, E.; Horky, J.; Setman, D.; Schafler, E.; Zehetbauer, M. Dependence of thermoelectric behavior on severe plastic deformation parameters: A case study on p-type skutterudite DD0.60Fe3CoSb12. Acta Mater. 2013, 61, 6778–6788. [Google Scholar] [CrossRef]

- Salvador, J.R.; Waldo, R.A.; Wong, C.A.; Tessema, M.; Brown, D.N.; Miller, D.J.; Wang, H.; Wereszczak, A.A.; Cai, W. Thermoelectric and mechanical properties of melt spun and spark plasma sintered n-type Yb- and Ba-filled skutterudites. Mater. Sci. Eng. B 2013, 178, 1087–1096. [Google Scholar] [CrossRef]

- Tan, G.; Liu, W.; Wang, S.; Yan, Y.; Li, H.; Tang, X.; Uher, C. Rapid preparation of CeFe4Sb12 skutterudite by melt spinning: Rich nanostructures and high thermoelectric performance. J. Mater. Chem. A 2013, 1, 12657–12668. [Google Scholar] [CrossRef]

- Yang, J.; Xu, B.; Zhang, L.; Liu, Y.; Yu, D.; Liu, Z.; He, J.; Tian, Y. Gadolinium filled CoSb3: High pressure synthesis and thermoelectric properties. Mater. Lett. 2013, 98, 171–173. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, L.; Liu, Y.; Chen, C.; Li, J.; Yu, D.; He, J.; Liu, Z.; Tian, Y.; Xu, B. Investigation of skutterudite MgyCo4Sb12: High pressure synthesis and thermoelectric properties. J. Appl. Phys. 2013, 113, 113703. [Google Scholar] [CrossRef]

- Yu, J.; Zhao, W.-Y.; Lei, B.; Tang, D.-G.; Zhang, Q.-J. Effects of Ge dopant on thermoelectric properties of barium and indium double-filled p-type skutterudites. J. Electron. Mater. 2013, 42, 1400–1405. [Google Scholar] [CrossRef]

- Zhang, L.; Duan, F.; Li, X.; Yan, X.; Hu, W.; Wang, L.; Liu, Z.; Tian, Y.; Xu, B. Intensive suppression of thermal conductivity in Nd0.6Fe2Co2Sb12−xGex through spontaneous precipitates. J. Appl. Phys. 2013, 114, 083715. [Google Scholar] [CrossRef]

- Zhou, L.; Qiu, P.; Uher, C.; Shi, X.; Chen, L. Thermoelectric properties of p-type YbxLayFe2.7Co1.3Sb12 double-filled skutterudites. Intermetallics 2013, 32, 209–213. [Google Scholar] [CrossRef]

- Ballikaya, S.; Uher, C. Enhanced thermoelectric performance of optimized Ba, Yb filled and Fe substituted skutterudite compounds. J. Alloys Compd. 2014, 585, 168–172. [Google Scholar] [CrossRef]

- Chubilleau, C.; Lenoir, B.; Candolfi, C.; Masschelein, P.; Dauscher, A.; Guilmeau, E.; Godart, C. Thermoelectric properties of In0.2Co4Sb12 skutterudites with embedded PbTe or ZnO nanoparticles. J. Alloys Compds. 2014, 589, 513–523. [Google Scholar] [CrossRef]

- Dahal, T.; Jie, Q.; Joshi, G.; Chen, S.; Guo, C.; Lan, Y.; Ren, Z. Thermoelectric property enhancement in Yb-doped n-type skutterudites YbxCo4Sb12. Acta Mater. 2014, 75, 316–321. [Google Scholar] [CrossRef]

- Ding, J.; Liu, R.-H.; Gu, H.; Chen, L.-D. Study on the high-temperature stability of YbyCo4Sb12/Yb2O3 composite thermoelectric material. J. Inorg. Mater. 2014, 29, 209–214. [Google Scholar] [CrossRef]

- Graff, J.; He, J.; Tritt, T.M. Qualifying the role of indium in the multiple-filled Ce0.1InxYb0.2Co4Sb12 skutterudite. Inorganics 2014, 2, 168–176. [Google Scholar] [CrossRef]

- Li, X.; Xu, B.; Zhang, L.; Duan, F.; Yan, X.; Yang, J.; Tian, Y. Synthesis of iodine filled CoSb3 with extremely low thermal conductivity. J. Alloys Compd. 2014, 615, 177–180. [Google Scholar] [CrossRef]

- Nolas, G.S.; Yang, J.; Takizawa, H. Transport properties of germanium-filled CoSb3. Appl. Phys. Lett. 2014, 84, 5210–5212. [Google Scholar] [CrossRef]

- Peng, J.; Fu, L.; Liu, Q.; Liu, M.; Yang, J.; Hitchcock, D.; Zhou, M.; He, J. A study of Yb0.2Co4Sb12–AgSbTe2 nanocomposites: Simultaneous enhancement of all three thermoelectric properties. J. Mater. Chem. A 2014, 2, 73–79. [Google Scholar] [CrossRef]

- Rogl, G.; Grytsiv, A.; Rogl, P.; Peranio, N.; Bauer, E.; Zehetbauer, M.; Eibl, O. n-Type skutterudites (R, Ba,Yb)yCo4Sb12 (R = Sr, La, Mm, DD, SrMm, SrDD) approaching ZT~2.0. Acta Mater. 2014, 63, 30–43. [Google Scholar] [CrossRef]

- Rogl, G.; Grytsiv, A.; Rogl, P.; Bauer, E.; Hochenhofer, M.R.; Mallik, R.C.; Anbalagan, R.; Schafler, E. Nanostructuring of p- and n-type skutterudites reaching figures of merit of approximately 1.3 and 1.6, respectively. Acta Mater. 2014, 76, 434–448. [Google Scholar] [CrossRef]

- Tan, G.J.; Wang, S.Y.; Tang, X.F. Thermoelectric performance optimization in p-type CeyFe3CoSb12 skutterudites. J. Electron. Mater. 2014, 43, 1712–1717. [Google Scholar] [CrossRef]

- Tan, G.; Zheng, Y.; Yan, Y.; Tang, X. Preparation and thermoelectric properties of p-type filled skutterudites CeyFe4−xNixSb12. J. Alloys Compd. 2014, 284, 216–221. [Google Scholar] [CrossRef]

- Tang, G.; Yang, W.; Xu, F.; He, Y. Synthesis and thermoelectric properties of In and Pr double-filled skutterudites InxPryCo4Sb12. J. Electron. Mater. 2014, 43, 435–438. [Google Scholar] [CrossRef]

- Tang, Y.; Qiu, Y.; Xi, L.; Shi, X.; Zhang, W.; Chen, L.; Tseng, S.; Chen, S.; Snyder, G.J. Phase diagram of In–Co–Sb system and thermoelectric properties of In-containing skutterudites. Energy Environ. Sci. 2014, 7, 812–819. [Google Scholar] [CrossRef] [Green Version]

- Yan, Y.G.; Wong-Ng, W.; Li, L.; Levin, I.; Kaduk, J.A.; Suchomel, M.R.; Sun, X.; Tan, G.J.; Tang, X.F. Structures and thermoelectric properties of double-filled (CaxCe1−x)Fe4Sb12 skutterudites. J. Solid State Chem. 2014, 218, 221–229. [Google Scholar] [CrossRef]

- Yu, J.; Thao, W.-Y.; Wie, P.; Zhu, W.-T.; Zhou, H.-Y.; Liu, Z.-Y.; Tang, D.-G.; Lei BZhang, Q.-J. Enhanced thermoelectric performance of (Ba, In) double-filled skutterudites via randomly arranged micropores. Appl. Phys. Lett. 2014, 104, 142104. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, G.; Guo, L.; Chi, H.; Wang, G.; Zhang, Q.; Chen, C.; Thompson, T.; Sakamoto, J.; Dravid, V.P.; et al. Hierarchically structured TiO2 for Ba-filled skutterudite with enhanced thermoelectric performance. J. Mater. Chem. A 2014, 2, 20629–20635. [Google Scholar] [CrossRef]

- Battabyal, M.; Priyadarshini, B.; Sivaprahasam, D.; Karthiselva, N.S.; Gopalan, R. The effect of Cu2O nanoparticle dispersion on the thermoelectric properties of n-type skutterudites. J. Phys. D Appl. Phys. 2015, 48, 455309. [Google Scholar] [CrossRef]

- Choi, S.; Kurosaki, K.; Yusufu, A.; Ohishi, Y.; Muta, H.; Yamanaka, S. Thermoelectric properties of p-type Tl-filled skutterudites: TlxFe1.5Co2.5Sb12. J. Electron. Mater. 2015, 44, 1743–1749. [Google Scholar] [CrossRef]

- Dahal, T.; Jie, Q.; Liu, W.; Dahal, K.; Guo, C.; Lan, Y. Effect of triple fillers in thermoelectric performance of p-type skutterudites. J. Alloys Compd. 2015, 623, 104–108. [Google Scholar] [CrossRef] [Green Version]

- Dahal, T.; Gahlawat, S.; Jie, Q.; Dahal, K.; Lan, Y.; White, K.; Ren, Z. Thermoelectric and mechanical properties on misch metal filled p-type skutterudites Mm0.9Fe4−xCoxSb12. J. Appl. Phys. 2015, 117, 055201. [Google Scholar] [CrossRef]

- Dong, Y.; Nolas, G.S.; Zeng, X.; Tritt, T.M. High temperature thermoelectric properties of BaxYbyFe3CoSb12 p-type skutterudites. J. Mater. Res. 2015, 30, 2558–2563. [Google Scholar] [CrossRef]

- Duan, F.; Zhang, L.; Dong, J.; Sakamoto, J.; Xu, B.; Li, X.; Tian, Y. Thermoelectric properties of Sn substituted p-type Nd filled skutterudites. J. Alloys Compd. 2015, 639, 68–73. [Google Scholar] [CrossRef]

- Fu, L.; Yang, J.; Peng, J.; Jiang, Q.; Xiao, Y.; Luo, Y.; Zhang, D.; Zhou, Z.; Zhang, M.; Cheng, Y.; et al. Enhancement of thermoelectric properties of Yb-filled skutterudites by an Ni-induced “core–shell” structure. J. Mater. Chem. A 2015, 3, 1010–1016. [Google Scholar] [CrossRef]

- Jeon, B.-J.; Shin, D.-K.; Kim, I.-H. Synthesis and thermoelectric properties of Ce1−zYbzFe4−xNixSb12 skutterudites. J. Electron. Mater. 2015, 44, 1388–1393. [Google Scholar] [CrossRef]

- Jeon, B.-J.; Shin, D.-K.; Kim, I.-H. Transport and thermoelectric properties of La1−zCezFe4−xNixSb12 skutterudites. J. Korean Phys. Soc. 2015, 66, 1862–1867. [Google Scholar] [CrossRef]

- Jeon, B.-J.; Shin, D.-K.; Kim, I.-H. Synthesis and thermoelectric properties of of La1−zYbzFe4−xNixSb12 skutterudites. J. Electron. Mater. 2015, 67, 1251–1256. [Google Scholar]

- Joo, G.-S.; Shin, D.-K.; Kim, I.-H. Thermoelectric properties of double filled p-type of La1−zCezFe4−xCoxSb12. J. Electron. Mater. 2015, 44, 1383–1387. [Google Scholar] [CrossRef]

- Kurosaki, K.; Choi, S.; Harnwunggmoung, A.; Ohishi, Y.; Muta, H.; Yamanaka, S. Thermoelectric properties of Ga and In double-filled CoSb3-based skutterudites. Materials 2015, 8, 1–9. [Google Scholar]

- Li, Y.; Qiu, P.; Xiong, Z.; Chen, J.; Nunna, R.; Shi, X.; Chen, L. Electrical and thermal transport properties of YbxCo4Sb12 filled skutterudites with ultrahigh carrier concentrations. AIP Adv. 2015, 5, 117239. [Google Scholar] [CrossRef] [Green Version]

- Peng, K.; Guo, L.; Wang, G.; Su, X.; Zhou, X.; Tang, X.; Uher, C. Optimization of Ag nanoparticles on thermoelectric performance of Ba-filled skutterudite. Sci. Adv. Mater. 2015, 7, 682–687. [Google Scholar] [CrossRef]

- Rogl, G.; Grytsiv, A.; Horky, J.; Bauer, E.; Horky, J.; Anbalagan, R.; Mallik, R.C.; Rogl, P.; Zehetbauer, M. Changes in microstructure and physical properties of skutterudites after severe plastic deformation. Phys. Chem. Chem. Phys. 2015, 17, 3715–3722. [Google Scholar] [CrossRef]

- Rogl, G.; Grytsiv, A.; Heinrich, P.; Bauer, E.; Kumar, P.; Peranio, N.; Eibl, O.; Horky, J.; Zehetbauer, M.; Rogl, P. New bulk p-type skutterudites DD0.7Fe2.7Co1.3Sb12−xXx (X = Ge, Sn) reaching ZT>1.3. Acta Mater. 2015, 9, 227–238. [Google Scholar] [CrossRef] [Green Version]

- Rogl, G.; Grytsiv, A.; Yubuta, K.; Puchegger, S.; Bauer, E.; Raju, C.; Mallik, R.C.; Rogl, P. In-doped multifilled n-type skutterudites with ZT = 1.8. Acta Mater. 2015, 95, 201–211. [Google Scholar] [CrossRef]

- Shin, D.-K.; Kim, I.-H. Transport and thermoelectric properties of double-filled Pr1−zYbzFe4−xCoxSb12 skutterudites. J. Korean Phys. Soc. 2015, 67, 1208–1213. [Google Scholar] [CrossRef]

- Shin, D.-K.; Kim, I.-H. Transport and thermoelectric properties of double-filled Pr1−zNdzFe4−xCoxSb12 skutterudites. J. Korean Phys. Soc. 2015, 66, 1879–1884. [Google Scholar] [CrossRef]

- Song, K.-M.; Shin, D.-K.; Kim, I.-H. Synthesis and thermoelectric properties of double-filled La1−zNdzFe4−xCoxSb12 skutterudites. J. Korean Phys. Soc. 2015, 67, 1597–1602. [Google Scholar] [CrossRef]

- Sun, H.; Jia, X.; Lv, P.; Deng, L.; Zhang, Y.; Sun, B.; Liu, B.; Kong, L.; Liu, H.; Ma, H. Rapid synthesis and thermoelectric properties of In0.1Co4Sb11Te0.8Ge0.2 alloys via high temperature and high pressure. Scr. Mater. 2015, 105, 38–41. [Google Scholar] [CrossRef]

- Tang, Y.; Chen, S.-W.; Snyder, G.J. Temperature dependent solubility of Yb in Yb-CoSb3 skutterudite and its effect on preparation, optimization and lifetime of thermoelectrics. J. Mater. 2015, 1, 75–84. [Google Scholar] [CrossRef] [Green Version]

- Tang, Y.; Hanus, R.; Chen, S.W.; Snyder, G.J. Solubility design leading to high figure of merit in low-cost Ce-CoSb3 skutterudites. Nat. Commun. 2015, 6, 7584. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Thompson, D.R.; Liu, C.; Yang, J.; Salvador, J.R.; Haddad, D.B.; Ellison, N.D.; Waldob, R.A.; Yang, J. Rare-earth free p-type filled skutterudites: Mechanisms for low thermal conductivity and effects of Fe/Co ratio on the band structure and charge transport. Acta Mater. 2015, 92, 152–162. [Google Scholar] [CrossRef]

- Wan, S.; Huang, X.; Qiu, P.; Bai, S.; Chen, L. The effect of short carbon fibers on the thermoelectric and mechanical properties of p-type CeFe4Sb12 skutterudite composites. Mater. Des. 2015, 67, 379–384. [Google Scholar] [CrossRef]

- Wang, S.; Yang, J.; Wu, L.; Wie, P.; Zhang, W.; Yang, J. On intensifying carrier impurity scattering to enhance thermoelectric performance in Cr-doped CeyCo4Sb12. Adv. Funct. Mater. 2015, 25, 6660. [Google Scholar] [CrossRef]

- Carlini, R.; Khan, A.U.; Ricciardi, R.; Mori, T.; Zanicchi, G. Synthesis, characterization and thermoelectric properties of Sm filled Fe4−xNixSb12 skutterudites. J. Alloys Compd. 2016, 655, 321–326. [Google Scholar] [CrossRef]

- Chen, Y.; Kawamura, Y.; Hayashi, J.; Sekine, C. Enhanced thermoelectric performance of optimized Yb-filled and Fe-substituted skutterudite compounds Yb0.6FexCo4−xSb12. Jap. J. Appl. Phys. 2016, 55, 04EJ02. [Google Scholar] [CrossRef] [Green Version]

- Dahal, T.; Kim, H.S.; Gahlawat, S.; Dahal, K.; Jie, Q.; Liu, W.; Lan, Y.; White, K.; Ren, Z. Transport and mechanical properties of the double-filled p-type skutterudites La0.68Ce0.22Fe4−xCoxSb12. Acta Mater. 2016, 117, 13–22. [Google Scholar] [CrossRef] [Green Version]

- Duan, B.; Yang, J.; Salvador, J.R.; He, Y.; Zhao, B.; Wang, S.; Wei, P.; Ohuchi, F.S.; Zhang, W.; Hermann, R.P.; et al. Electronegative guests in CoSb3. Energy Environ. Sci. 2016, 9, 2090–2098. [Google Scholar] [CrossRef]

- Fu, L.; Yang, J.; Jiang, Q.; Xiao, Y.; Luo, Y.; Zhang, D.; Zhou, Z. Thermoelectric performance enhancement of CeFe4Sb12 p-type skutterudite by disorder on the Sb4 rings induced by Te-doping and nanopores. J. Electron. Mater. 2016, 45, 1240–1244. [Google Scholar] [CrossRef]

- Fu, L.; Jiang, Q.; Yang, J.; Peng, J.; Xiao, Y.; Luo, Y.; Zhou, Z.; Zhang, D.; Zhou, Z. Enhancement of thermoelectric properties of Ce0.9Fe3.75Ni0.25Sb12 p-type skutterudite by tellurium addition. J. Mater. Chem. A 2016, 4, 16499–16506. [Google Scholar] [CrossRef]

- Gharleghi, A.; Hung, P.-C.; Lin, F.-H.; Liu, C.-J. Enhanced ZT of InxCo4Sb12−InSb nanocomposites fabricated by hydrothermal synthesis combined with solid−vapor reaction: A signature of phonon-glass and electron-crystal materials. ACS Appl. Mater. Interfaces 2016, 8, 35123–35131. [Google Scholar] [CrossRef]

- Guo, L.; Cai, Z.; Xu, X.; Peng, K.; Wang, G.; Wang, G.; Zhou, X. Raising the thermoelectric performance of Fe3CoSb12 skutterudites via Nd filling and in-situ nanostructuring. J. Nanosci. Nanotechnol. 2016, 16, 3841–3847. [Google Scholar] [CrossRef]

- Guo, L.; Wang, G.; Peng, K.; Yan, Y.; Tang, X.; Zeng, M.; Dai, J.; Wang, G.; Zhou, X. Melt spinning synthesis of p-type skutterudites: Drastically speed up the process of high performance thermoelectrics. Scr. Mater. 2016, 116, 26–30. [Google Scholar] [CrossRef]

- Guo, L.; Zhang, Y.; Zheng, Y.; Yao, W.; Wang, G.; Wang, G.; Zhou, X. Super-rapid preparation of nanostructured NdxFe3CoSb12 compounds and their improved thermoelectric performance. J. Electron. Mater. 2016, 45, 11271–11277. [Google Scholar] [CrossRef]

- Joo, G.-S.; Shin, D.-K.; Kim, I.-H. Synthesis and thermoelectric properties of p-type double filled Ce1−zYbzFe4−xCoxSb12 skutterudites. J. Electron. Mater. 2016, 45, 1251–1256. [Google Scholar] [CrossRef]

- Lee, W.-M.; Shin, D.-K.; Kim, I.-H. Thermoelectric and transport Properties of CezFe4−xNixSb12 skutterudites. J. Electron. Mater. 2016, 45, 1245–1250. [Google Scholar] [CrossRef]

- Li, X.; Zhang, Q.; Kang, Y.; Chen, C.; Zhang, L.; Yu, D.; Tian, Y.; Xu, B. High pressure synthesized Ca-filled CoSb3 skutterudites with enhanced thermoelectric properties. J. Alloys Compd. 2016, 677, 61–65. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Qiu, P.; Duan, H.; Chen, J.; Snyder, G.J.; Shi, X.; Iversen, B.B.; Chen, L. Enhanced thermoelectric performance in rare-earth filled-skutterudites. J. Mater. Chem. C 2016, 4, 4374–4379. [Google Scholar] [CrossRef]

- Liu, Y.; Li, X.; Zhang, Q.; Zhang, L.; Yu, D.; Xu, B.; Tian, Y. High pressure synthesis of p-type CeyFe4−xCoxSb12 skutterudites. Materials 2016, 9, 257. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Matsubara, M.; Asahi, R. Optimization of filler elements in CoSb3-based skutterudites for high-performance n-type thermoelectric materials. J. Electron. Mater. 2016, 45, 1669–1678. [Google Scholar] [CrossRef]

- Paschinger, W.; Rogl, G.; Grytsiv, A.; Michor, H.; Heinrich, P.R.; Müller, H.; Puchegger, S.; Klobes, B.; Hermann, R.P.; Reinecker, M.; et al. Ba-filled Ni-Sb-Sn based skutterudites with anomalously high lattice thermal conductivity. Dalton Trans. 2016, 45, 11071–11100. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sesselmann, A.; Skomedal, G.; Middleton, H.; Müller, E. The influence of synthesis procedure on the microstructure and thermoelectric properties of p-type skutterudite Ce0.6Fe2Co2Sb12. J. Electron. Mater. 2016, 45, 1397–1407. [Google Scholar] [CrossRef]

- Shaheen, N.; Shen, X.; Javed, M.S.; Zhan, H.; Guo, L.; Alsharafi, R.; Huang, T.; Lu, X.; Wang, G.; Zhou, X. High-temperature thermoelectric properties of Ge-substituted p-type Nd filled skutterudites. J. Electron. Mater. 2016, 45, 2958–2963. [Google Scholar] [CrossRef]

- Shin, D.-K.; Kim, I.-H. Thermoelectric properties of p-type partially double-filled (Pr1−zNdz)yFe4−xCoxSb12 skutterudites. J. Korean Phys. Soc. 2016, 69, 798–805. [Google Scholar] [CrossRef]

- Shin, D.-K.; Kim, I.-H.; Jang, K.-W.; Choi, S.-M. Charge transport and thermoelectric properties of double-filled (Nd1−zYbz)yFe4−xCoxSb12 skutterudites. J. Korean Phys. Soc. 2016, 68, 875–882. [Google Scholar] [CrossRef]

- Shin, D.-K.; Kim, I.-H. Electronic transport and thermoelectric properties of p-type NdzFe4−xCoxSb12 skutterudites. J. Electron. Mater. 2016, 45, 1234–1239. [Google Scholar] [CrossRef]

- Song, K.-M.; Shin, D.-K.; Kim, I.-H. Thermoelectric properties of p-type La1−zPrzFe4−xCoxSb12 skutterudites. J. Electron. Mater. 2016, 45, 1227–1233. [Google Scholar] [CrossRef]

- Wang, S.; Salvador, J.R.; Yang, J.; Wei, P.; Duan, B.; Yang, J. High-performance n-type YbxCo4Sb12: From partially filled skutterudites towards composite thermoelectrics. NPG Asia Mater. 2016, 8, e285. [Google Scholar] [CrossRef] [Green Version]

- Benyahia, M.; Vaney, J.B.; Leroy, E.; Rouleau, O.; Dauscher, A.; Lenoir, B.; Alleno, E. Thermoelectric properties in double-filled Ce0.3InyFe1.5Co2.5Sb12 p-type skutterudites. J. Alloys Compd. 2017, 696, 1031–1038. [Google Scholar] [CrossRef]

- Che, P.; Wang, B.; Sun, C.; Han, Y.; Li, W. Influence of multi-walled carbon nanotubes on the thermoelectric properties of La-filled CoSb3 skutterudite composites. J. Alloys Compd. 2017, 695, 1908–1912. [Google Scholar] [CrossRef] [Green Version]

- Elsheikh, M.H.; Sabri, M.F.M.; Said, S.M.; Miyazaki, Y.; Masjuki, H.H.; Shnawah, D.A.; Naito, S.; Bashir, M.B.A. Rapid preparation of bulk AlxYb0.25Co4Sb12 (x = 0, 0.1, 0.2, 0.3) skutterudite thermoelectric materials with high figure of merit ZT=1.36. J. Mater. Sci. 2017, 52, 5324–5332. [Google Scholar] [CrossRef]

- Hobbis, D.; Liu, Y.; Wei, K.; Tritt, T.M.; Nolas, G.S. High temperature transport properties of Yb and In double-filled p-type skutterudites. Crystals 2017, 7, 256. [Google Scholar] [CrossRef]

- Kang, Y.; Yu, F.; Chen, C.; Zhang, Q.; Sun, H.; Zhang, L.; Yu, D.; Tian, Y.; Xu, B. High pressure synthesis and thermoelectric properties of Ba-filled CoSb3 skutterudites. J. Mater. Sci. Mater. Electron. 2017, 28, 8771–8776. [Google Scholar] [CrossRef]

- Khovaylo, V.V.; Korolkov, T.A.; Voronin, A.I.; Gorshenkova, M.V.; Burkovc, A.T. Rapid preparation of InxCo4Sb12 with a record breaking ZT = 1.5: The role of the In overfilling fraction limit and Sb overstoichiometry. J. Mater. Chem. A 2017, 5, 3541–3546. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.; Kurosaki, K.; Choi, S.; Ohishi, Y.; Muta, H.; Yamanaka, S.; Takahashi, M.; Tanaka, J. Thermoelectric properties of InxFeCo3Sb12 consisting mainly of In-filled p-type skutterudites. Mater. Trans. 2017, 58, 1207–1211. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Kang, Y.; Chen, C.; Li, J.; Zhang, L.; Yu, F.; Yu, D.; Tian, Y.; Xua, B. Thermoelectric properties of high pressure synthesized lithium and calcium double-filled CoSb3. AIP Adv. 2017, 7, 015204. [Google Scholar] [CrossRef] [Green Version]

- Litvinova, K.I.; Voronin, A.I.; Gorshenkov, M.V.; Karpenkov Yu, D.; Novitskii, A.P.; Khovaylo, V.V. Thermoelectric properties of CexNdyCo4Sb12 skutterudites. Semiconductors 2017, 51, 928–931. [Google Scholar] [CrossRef]

- Peng, S.; Sun, J.; Cui, B.; Meng, X.; Qin, D.; Liu, Z.; Cai, W. Enhanced thermoelectric and mechanical properties of p-type skutterudites with in situ formed Fe3Si nanoprecipitate. Inorg. Chem. Front. 2017, 10, 1697–1703. [Google Scholar] [CrossRef]

- Prado-Gonjal, J.; Vaqueiro, P.; Nuttall, C.; Potter, R.; Powell, A.V. Enhancing the thermoelectric properties of single and double filled p-type skutterudites synthesized by an up-scaled ball-milling process. J. Alloys Compd. 2017, 695, 3598–3604. [Google Scholar] [CrossRef]

- Rogl, G.; Grytsiv, A.; Failamani, F.; Hochenhofer, M.; Bauer, E.; Rogl, P. Attempts to further enhance ZT in skutterudites via nano-composites. J. Alloys Compd. 2017, 695, 682–696. [Google Scholar] [CrossRef]

- Schmitz, A.; Schmid, C.; De Boor, J.; Müller, E. Dispersion of multi-walled carbon nanotubes in skutterudites and its effect on thermoelectric and mechanical properties. J. Nanosci. Nanotech. 2017, 17, 154–1554. [Google Scholar] [CrossRef]

- Shaheen, N.; Shen, X.; Javed, M.S.; Guo, L.; Zhang, A.; Lu, X.; Wang, G.; Zhou, X. Super-fast preparation of Nd-filled p-type skutterudite compounds with enhanced thermoelectric properties. Ceram. Int. 2017, 43, 7443–7447. [Google Scholar] [CrossRef]

- Shin, D.-K.; Kim, I.-H. Thermoelectric properties of partially double-filled (Pr1−zYbz)yFe4−xCoxSb12 skutterudites. J. Korean Phys. Soc. 2017, 70, 591–597. [Google Scholar] [CrossRef]

- Song, K.-M.; Shin, D.-K.; Kim, I.-H. Charge transport and thermoelectric properties of Ce1−zNdzFe4−xCoxSb12 skutterudites. J. Korean Phys. Soc. 2017, 70, 499–504. [Google Scholar] [CrossRef]

- Song, K.-M.; Shin, D.-K.; Jang, K.-W.; Choi, S.-M.; Lee, S.; Seo, W.-S.; Kim, I.-H. Sythesis and thermoelectric properties of Ce1−zPrzFe4−xCoxSb12 skutterudites. J. Electron. Mater. 2017, 46, 2634–2639. [Google Scholar] [CrossRef]

- Son, G.; Lee, K.H.; Choi, S.-M. Enhanced thermoelectric properties of melt-spun p-type Yb0.9Fe3CoSb12. J. Electron. Mater. 2017, 46, 2839–2843. [Google Scholar] [CrossRef]

- Wan, S.; Huang, X.; Qiu, P.; Shi, X.; Chen, L. Compound defects and thermoelectric properties of self-charge compensated skutterudites SeyCo4Sb12–xSex. ACS Appl. Mater. Inter. 2017, 9, 22713–22724. [Google Scholar] [CrossRef]

- Bashir, M.B.A.; Said, S.M.; Sabri, M.F.M.; Miyazaki, Y.; Shnawah, D.A.A.; Shimada, M.; Elsheikh, M.H. Enhancement of thermoelectric properties of Yb0.25Co4Sb12 skutterudites through Ni substitution. Sains Malays. 2018, 47, 181–187. [Google Scholar] [CrossRef]

- Bashir, M.B.A.; Said, S.M.; Sabri, M.F.M.; Miyazaki, Y.; Shnawah, D.A.A.; Shimada, M.; Salleh, M.F.M.; Mahmood, M.S.; Fitriani, F.; Elsheikh, M.H. In-filled La0.5Co4Sb12 skutterudite system with high thermoelectric figure of merit. J. Electron. Mater. 2018, 47, 2429–2438. [Google Scholar] [CrossRef]

- Cha, Y.-E.; Kim, I.-H. Charge transport and thermoelectric properties of (La1−zPrz)0.8Fe4−xCoxSb12 skutterudites. Korean J. Met. Mater. 2018, 56, 772–778. [Google Scholar] [CrossRef] [Green Version]

- Cha, Y.-E.; Shin, D.-K.; Kim, I.-H. Synthesis and thermoelectric properties of partially double-filled (Ce1−zPrz)0.8Fe4−xCoxSb12 skutterudites. J. Electron. Mater. 2018, 47, 3152–3158. [Google Scholar] [CrossRef]

- Kim, J.; Ohishi, Y.; Muta, H.; Kurosaki, K. Enhancement of thermoelectric properties of p-type single-filled skutterudites CexFeyCo4−ySb12 by tuning the Ce and Fe content. AIP Adv. 2018, 8, 105104. [Google Scholar] [CrossRef]

- Kogut, I.u.; Nichkalo, S.; Ohorodniichuk, V.; Dauscher, A.; Candolfi, C.; Masschelein, P.; Jacquot, A.; Lenoir, B. Nanostructure features, phase relationships and thermoelectric properties of melt-spun and spark-plasma-sintered skutterudites. Acta Phys. Pol. 2018, 133, 879–883. [Google Scholar] [CrossRef]

- Kong, L.; Jia, X.; Zhang, Y.; Sun, B.; Liu, B.; Liu, H.; Wang, C.; Liu, B.; Chen, J.; Ma, H. N-type Ba0.3Ni0.15Co3.85Sb12 skutterudite: High pressure processing technique and thermoelectric properties. J. Alloys Compd. 2018, 734, 36–42. [Google Scholar] [CrossRef]

- Lei, Y.; Gao, W.; Li, Y.; Wan, R.; Chen, W.; Zheng, R.; Ma, L.; Zhou, H. Structure and thermoelectric performance of Ti-filled and Te-doped skutterudite TixCo4Sb11.5Te0.5 bulks fabricated by combination of microwave synthesis and spark plasma sintering. Mater. Lett. 2018, 233, 166–169. [Google Scholar] [CrossRef]

- Mona, Y.; Hayashi, J.; Kawamura, Y.; Kihou, K.; Nishiate, H.; Lee, C.-H.; Sekine, C. Thermoelectric properties of partially filled skutterudites RxCo4Sb12 (R = Ce and Nd) synthesized under high pressures. Jap. J. Appl. Phys. 2018, 57, 125506. [Google Scholar] [CrossRef]

- Qin, D.; Liu, Y.; Meng, X.; Cui, B.; Qi, Y.; Cai, W.; Sui, J. Graphene-enhanced thermoelectric properties of p-type skutterudites. Chin. Phys. B 2018, 27, 048402. [Google Scholar] [CrossRef]

- Rogl, G.; Grytsiv, A.; Puchegger, S.; Soprunyuk, V.; Schranz, W.; Yan, X.; Bauer, E.; Rogl, P. Nanostructuring as a tool to adjust thermal expansion in high ZT. Acta Mater. 2018, 145, 359–368. [Google Scholar] [CrossRef]

- Rogl, G.; Grytsiv, A.; Anbalagan, R.; Bursik, J.; Kerber, M.; Schafler, E.; Zehetbauer, M.; Bauer, E.; Rogl, P. Direct SPD-processing to achieve high-ZT skutterudites. Acta Mater. 2018, 159, 352–363. [Google Scholar] [CrossRef]

- Serrano-Sánchez, F.; Prado-Gonjal, J.; Nemes, N.M.; Biskup, N.; Varela, M.; Dura, O.J.; Martínez, J.L.; Fernández-Díaz, M.T.; Fauth, F.; Alonso, J.A. Low thermal conductivity in La-filled cobalt antimonide skutterudites with inhomogeneous filling factor prepared under high-pressure conditions. J. Mater. Chem. 2018, 6, 118–126. [Google Scholar] [CrossRef] [Green Version]

- Shaheen, N.; Javed, M.S.; Shah, H.U.; Hussain, S.; Ashfaq, M.; Raza, R.; Saleem, M.; Zhou, X. Enhanced thermoelectric properties in Ge-doped and single-filled skutterudites prepared by unique melt-spinning method. Ceram. Internat. 2018, 44, 12610–12614. [Google Scholar] [CrossRef]

- Shin, D.-K.; Jang, K.-W.; Choi, S.-M.; Lee, S.; Seo, W.-S.; Kim, I.-H. Charge transport and thermoelectric properties of (Nd1−zYbz)yFe4−xCoxSb12 skutterudites. J. Electron. Mater. 2018, 47, 3143–3151. [Google Scholar] [CrossRef]

- Trivedi, V.; Battabyal, M.; Balasubramanian, P.; Muralikrishna, G.M.; Jain, P.K.; Gopalan, R. Microstructure and doping effect on the enhancement of the thermoelectric properties of Ni doped Dy filled CoSb3 skutterudites. Sustain. Energy Fuels 2018, 2, 2687–2697. [Google Scholar] [CrossRef]

- Wan, S.; Qiu, P.; Huang, X.; Song, Q.; Bai, S.; Shi, X.; Chen, L. Synthesis and thermoelectric properties of charge-compensated SyPdxCo4−xSb12 skutterudites. ACS Appl. Mater. Interfaces 2018, 10, 625–634. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Duan, B.; Bai, G.; Li, J.; Yu, Y.; Yang, H.; Chen, G.; Zhai, P. Beneficial effect of S filling on thermoelectric properties of SxCo4Sb11.2Te0.8 skutterudite. J. Electron. Mater. 2018, 47, 3061–3066. [Google Scholar] [CrossRef]

- Artini, C.; Carlini, R.; Spotorno, R.; Failamani, F.; Mori, T.; Mele, P. Structural properties and thermoelectric performance of the double-filled skutterudite (Sm,Gd)y(FexNi1−x)4Sb12. Materials 2019, 12, 2451. [Google Scholar] [CrossRef] [Green Version]

- Bae, S.H.; Lee, K.H.; Choi, S.-M. Effective role of filling fraction control in p-type CexFe3CoSb12 skutterudite thermoelectric materials. Intermetallics 2019, 105, 44–47. [Google Scholar] [CrossRef]

- Bao, X.; Wu, Z.; Xie, H. Enhanced thermoelectric properties of CoSb3-based skutterudites by filling Se as electronegative element. Mater. Res. Express 2019, 6, 025511. [Google Scholar] [CrossRef]

- Cha, Y.-E.; Kim, I.-H. Synthesis and thermoelectric properties of (La1−zNdz)0.8Fe4−xCoxSb12 skutterudites. Korean J. Met. Mater. 2019, 57, 366–373. [Google Scholar] [CrossRef] [Green Version]

- Cha, Y.-E.; Kim, I.-H. Synthesis and thermoelectric properties of partially double-filled skutterudites (La1−zYbz)0.8Fe4−xCoxSb12. Korean J. Met. Mater. 2019, 57, 801–807. [Google Scholar] [CrossRef]

- Gainza, J.; Serrano-Sanchez, F.; Prado-Gonjal, J.; Nemes, N.M.; Biskup, N.; Dura, O.J.; Martınez, J.L.; Fauth, F.J.; Alonso, A. Substantial thermal conductivity reduction in mischmetal skutterudites MmxCo4Sb12 prepared under high-pressure conditions, due to uneven distribution of the rare-earth elements. J. Mater. Chem. C 2019, 7, 4124–4131. [Google Scholar] [CrossRef] [Green Version]

- Han, X.; Wang, L.B.; Li, D.N.; Deng, L.; Jia, X.P.; Ma, H.A. Effects of pressure and ions doping on the optimization of double filled CoSb3 thermoelectric materials. Mater. Lett. 2019, 237, 49–52. [Google Scholar] [CrossRef]

- Kim, J.; Ohishi, Y.; Muta, H.; Kurosaki, K. Enhanced thermoelectric properties of Ga and Ce double-filled p-type skutterudites. Mater. Trans. 2019, 60, 1078–1082. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Zhu, W.; Nie, X.; Zhao, W. Effects of sintering temperature on microstructure and thermoelectric properties of Ce-filled Fe4Sb12 skutterudites. J. Mater. Sci. Mater. Electron. 2019, 30, 12493–12499. [Google Scholar] [CrossRef]

- Qin, D.; Wu, H.; Cai, S.; Zhu, J.; Cui, B.; Yin, L.; Qin, H.; Shi, W.; Zhang, Y.; Zhang, Q.; et al. Enhanced thermoelectric and mechanical properties in Yb0.3Co4Sb12 with in situ formed CoSi nanoprecipitates. Adv. Energy Mater. 2019, 9, 1902435. [Google Scholar] [CrossRef]

- Rogl, G.; Yubuta, K.; Kerber, M.; Grytsiv, A.; Zehetbauer, M.; Bauer, E.; Rogl, P. Sustainable and simple processing technique for n-type skutterudites with high ZT and their analysis. Acta Mater. 2019, 173, 9–19. [Google Scholar] [CrossRef]

- Zhou, Z.; Li, J.; Fan, Y.; Zhang, Q.; Lu, X.; Fan, S.; Kikuchi, K.; Nomura, N.; Kawasaki, A.; Wang, L.; et al. Uniform dispersion of SiC in Yb-filled skutterudite nanocomposites with high thermoelectric and mechanical performance. Scr. Mater. 2019, 162, 166–171. [Google Scholar] [CrossRef]

- Alleno, E.; Benyahia, M.; Vaney, J.B.; Provost, K.; Paul-Boncour, V.; Monnier, J.; Dauscher, A.; Lenoir, B. High thermoelectric figure of merit in well optimized YbyCo4Sb12. J. Mater. Chem. C 2020, 8, 17034–17044. [Google Scholar] [CrossRef]

- Bashir, M.B.A.; Sabri, M.F.M.; Said, S.M.; Miyazaki, Y.; Badruddin, I.A.; Shnawah, D.A.A.; Salih, E.Y.; Abushousha, S.; Elsheikh, M.H. Enhancement of thermoelectric properties of Co4Sb12 skutterudite by Al and La double filling. J. Solid State Chem. 2020, 284, 121205. [Google Scholar] [CrossRef]

- Ghosh, S.; Shankar, G.; Karati, A.; Werbach, K.; Rogl, G.; Rogl, P.; Bauer, E.; Murty, B.S.; Suwas, S.; Mallik, R.C. Enhanced thermoelectric performance in the Ba0.3Co4Sb12/InSb nano-composite originating from the minimum possible thermal conductivity. ACS Appl. Mater. Interfaces 2020, 12, 48729. [Google Scholar] [CrossRef]

- Ghosh, S.; Valiyaveettil, S.M.; Shankar, G.; Maity, T.; Murty, B.S.; Chen, K.H.; Biswas, K.; Suwas, S.; Mallik, R.C. Enhanced thermoelectric properties of In-filled Co4Sb12. with InSb nanoinclusions. ACS Appl. Energy Mater. 2020, 3, 635–646. [Google Scholar] [CrossRef] [Green Version]

- Ghosh, S.; Raut, K.K.; Ramakrishnan, A.; Chen, K.-H.; Hong, S.-J.; Mallik, R.C. Thermoelectric properties of p-type filled skutterudites SxCo4Sb12. AIP Conf. Proc. 2020, 2265, 030606. [Google Scholar]

- Lee, K.H.; Bae, S.H.; Choi, S.-M. Phase formation behavior and thermoelectric transport properties of p-type YbxFe3CoSb12 prepared by melt spinning and spark plasma sintering. Materials 2020, 13, 87. [Google Scholar] [CrossRef]

- Limbu, N.; Ram, M.; Joshi, H.; Saxena, A.; Bin Omran, S.; Khenata, R.; Shankar, A. Enhanced electronic and thermoelectric properties of p-type doped filled skutterudites RFe4Sb12 (R = Pr, Nd). J. Appl. Phys. 2020, 128, 145104. [Google Scholar] [CrossRef]

- Rogl, G.; Ghosh, S.; Renk, O.; Yubuta, K.; Grytsiv, A.; Schafler, E.; Zehetbauer, M.; Mallik, R.C.; Bauer, E.; Rogl, P. HPT production of large bulk skutterudites. J. Alloys Compd. 2020, 854, 156678. [Google Scholar] [CrossRef]

- Woo, H.Y.; Son, G.; Lee, K.-M.; Choi, S.-M. Thermal conductivity reduction by tuning the rattler fraction in a p-type CeyYb1−yFe3CoSb12 double-filled skutterudite. J. Korean Phys. Soc. 2020, 77, 667–672. [Google Scholar] [CrossRef]

- Yu, J.; Zhu, W.; Zhao, W.; Luo, Q.; Liu, Z.; Chen, H. Rapid fabrication of pure p-type filled skutterudites with enhanced thermoelectric properties via a reactive liquid-phase sintering. J. Mater. Sci. 2020, 55, 7432–7440. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, X.; Lu, Q.; He, P.; Lin, T.; Geng, H. Investigation of melt-spinning speed on the property of Yb0.2Ba0.1Al0.1Ga0.1In0.1La0.05Eu0.05Co3.75Fe0.25Sb12 skutterudites. Mater. Lett. 2020, 260, 126960. [Google Scholar] [CrossRef]

- Zhang, S.; Xu, S.; Gao, H.; Lu, Q.; Lin, T.; He, P.; Geng, H. Characterization of multiple-filled skutterudites with high thermoelectric performance. J. Alloys Compd. 2020, 814, 152272. [Google Scholar] [CrossRef]

- Ghosh, S.; Shankar, G.; Karati, A.; Rogl, G.; Rogl, P.; Bauer, E.; Murty, B.S.; Suwas, S.; Mallik, R.C. Thermoelectric properties enhancement of Ba0.2Co4Sb12 through dispersion of GaSb inclusions. Phys. B Condens. Matter 2021, 606, 412440. [Google Scholar] [CrossRef]

- Ghosh, S.; Tippireddy, S.; Shankar, G.; Karati, A.; Rogl, G.; Rogl, P.; Bauer, E.; Malladi, S.R.K.; Murty, B.S.; Suwas, S.; et al. Dispersion of InSb nanoparticles producing significant improvement in thermoelectric performance of Yb-filled Co4Sb12. J. Alloys Compd. 2021, 880, 160532. [Google Scholar] [CrossRef]

- Jang, K.-W.; Cha, Y.-E.; Cho, D.-Y.; Kim, S.; Seo, W.-S.; Lee, K.H.; Kim, I.-H. Effects of charge compensation on the thermoelectric properties of (La1−zCez)0.8Fe4−xCoxSb12 skutterudites. Korean J. Met. Mater. 2021, 59, 239–246. [Google Scholar] [CrossRef]

- Jin, D.; Ruan, Z.; Duan, B.; Li, J.; Zhai, P.; Yang, H.; Wang, H.; Li, G.; Zhou, L. Rapid preparation of high-performance S0.4Co4Sb11.2Te0.8 skutterudites with a highly porous structure. J. Eur. Ceram. Soc. 2021, 41, 4484–4489. [Google Scholar] [CrossRef]

- Li, X.-G.; Liu, W.-D.; Li, S.-M.; Li, D.; Zhu, J.X.; Feng, Z.-Y.; Yang, B.; Zhong, H.; Shi, X.-L.; Chen, Z.-G. Ce filling limit and its influence on thermoelectric performance of Fe3CoSb12-based skutterudite grown by a temperature gradient zone melting method. Materials 2021, 14, 6810. [Google Scholar] [CrossRef] [PubMed]

- Rogl, G.; Ghosh, S.; Renk, O.; Yubuta, K.; Grytsiv, A.; Schafler, E.; Zehetbauer, M.; Mallik, R.C.; Bauer, E.; Rogl, P. Influence of shear strain on HPT-processed n-type skutterudites yielding ZT~2.1. J. Alloys Compd. 2021, 8545, 157409. [Google Scholar] [CrossRef]

- Rogl, G.; Renk, O.; Ghosh, S.; Mallik, R.C.; Grytsiv, A.; Bursik, J.; Schafler, E.; Tuomisto, F.; Bauer, E.; Rogl, P.F. Properties of HPT-processed large bulks of p-type skutterudite DD0.7Fe3CoSb12 with high ZT > 1.3. ACS Appl. Energy Mater. 2021, 4, 4831–4844. [Google Scholar] [CrossRef]

- Wang, B.; Fang, D.; Yi, W.; Zhao, S.; Li, J.; Li, J.; Zhao, Y.; Jin, H. Synthesis and thermoelectric performance of Ni0.3Co3.7Sb12 skutterudite filled with electronegative guest Se. Ceram. Int. 2021, 47, 17753–17759. [Google Scholar] [CrossRef]