Efficient Optical Waveguiding Enabled by Focused Proton Beam Writing in Nd:YCOB Crystal

Abstract

:1. Introduction

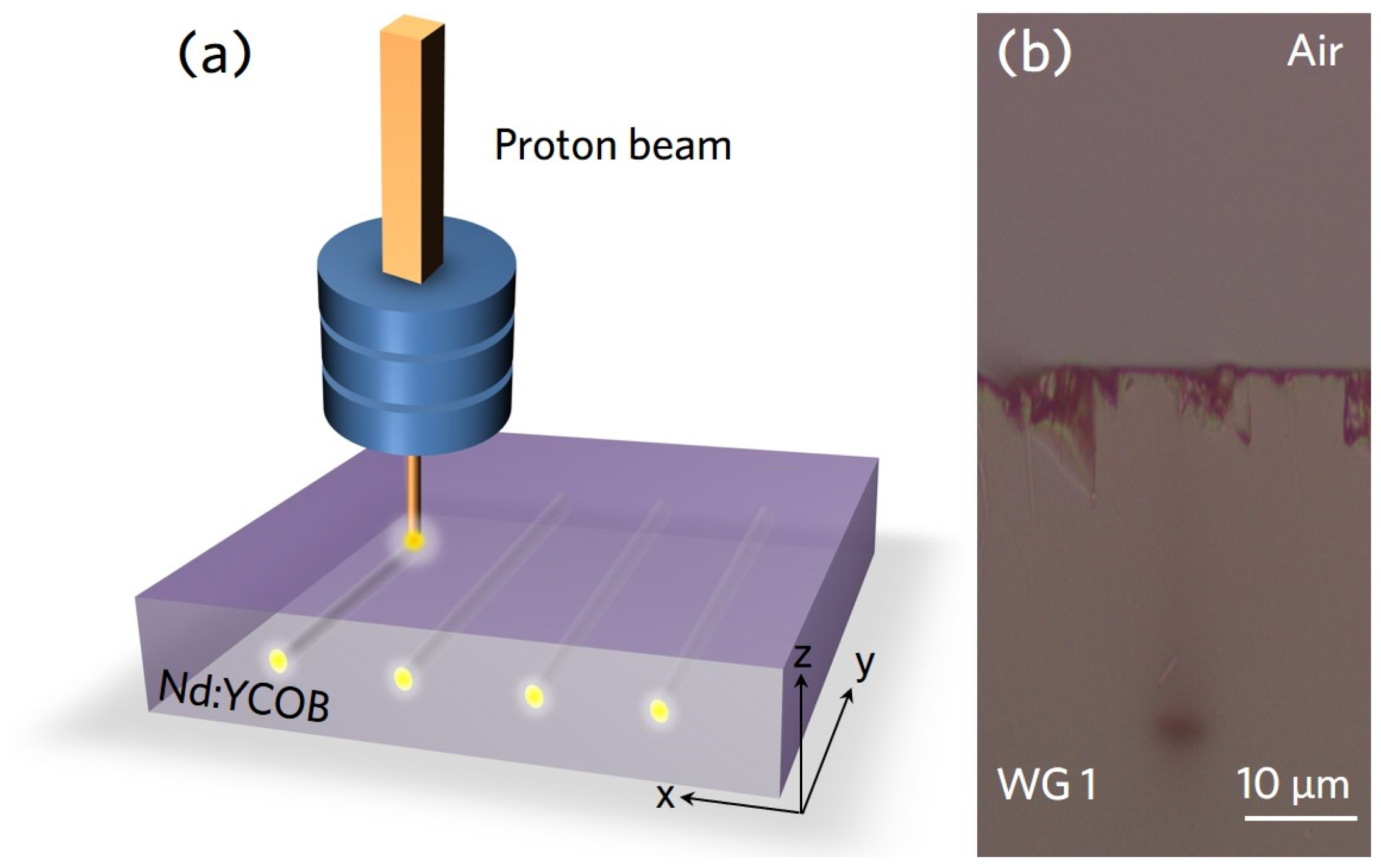

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Thylén, L.; Wosinski, L. Integrated photonics in the 21st century. Photonics Res. 2014, 2, 75–81. [Google Scholar] [CrossRef]

- Wolf, R.; Jia, Y.; Bonaus, S.; Werner, C.; Herr, S.; Breunig, I.; Buse, K.; Zappe, H. Quasi-phase-matched nonlinear optical frequency conversion in on-chip whispering galleries. Optica 2018, 5, 872–875. [Google Scholar] [CrossRef]

- Grivas, C. Optically pumped planar waveguide lasers, Part I: Fundamentals and fabrication techniques. Prog. Quantum Electron. 2011, 35, 159–239. [Google Scholar] [CrossRef] [Green Version]

- Grivas, C. Optically pumped planar waveguide lasers: Part II: Gain media, laser systems, and applications. Prog. Quantum Electron. 2016, 45, 3–160. [Google Scholar] [CrossRef]

- Jia, Y.; Wang, S.; Chen, F. Femtosecond laser direct writing of flexibly configured waveguide geometries in optical crystals: Fabrication and application. Opto-Electron. Adv. 2020, 3, 190042. [Google Scholar] [CrossRef]

- Jia, Y.; Wang, L.; Chen, F. Ion-cut lithium niobate on insulator technology: Recent advances and perspectives. Appl. Phys. Rev. 2021, 8, 011307. [Google Scholar] [CrossRef]

- Jia, Y.; Wu, J.; Sun, X.; Yan, X.; Xie, R.; Wang, L.; Chen, Y.; Chen, F. Integrated photonics based on rare-earth ion-doped thin-film lithium niobate. Laser Photonics Rev. 2022, 16, 2200059. [Google Scholar] [CrossRef]

- Jia, Y.; Chen, F. Compact solid-state waveguide lasers operating in the pulsed regime: A review. Chin. Opt. Lett. 2019, 17, 012302. [Google Scholar]

- Chen, F. Micro-and submicrometric waveguiding structures in optical crystals produced by ion beams for photonic applications. Laser Photonics Rev. 2012, 6, 622–640. [Google Scholar] [CrossRef]

- Chen, F.; Amekura, H.; Jia, Y. Ion Irradiation of Dielectrics for Photonic Applications; Springer-Nature: Singapore, 2020; pp. 1–290. [Google Scholar]

- Watt, F.; Breese, M.B.; Bettiol, A.A.; van Kan, J.A. Proton beam writing. Mater. Today 2007, 10, 20–29. [Google Scholar] [CrossRef]

- Sum, T.C.; Bettiol, A.A.; Van Kan, J.A.; Watt, F.; Pun, E.Y.B.; Tung, K.K. Proton beam writing of low-loss polymer optical waveguides. Appl. Phys. Lett. 2003, 83, 1707–1709. [Google Scholar] [CrossRef]

- Sum, T.C.; Bettiol, A.A.; Seng, H.L.; Rajta, I.; Van Kan, J.A.; Watt, F. Proton beam writing of passive waveguides in PMMA. Nucl. Instrum. Methods Phys. Res. Sect. B 2003, 210, 266–271. [Google Scholar] [CrossRef]

- Romanenko, O.; Havranek, V.; Mackova, A.; Davidkova, M.; Cutroneo, M.; Ponomarev, A.G.; Nagy, G.; Stammers, J.; Rajta, I. Performance and application of heavy ion nuclear microbeam facility at the Nuclear Physics Institute in Řež, Czech Republic. Rev. Sci. Instrum. 2019, 90, 013701. [Google Scholar] [CrossRef] [PubMed]

- Bányász, I.; Szilágyi, E.; Rajta, I.; Nagy, G.U.; Pelli, S.; Conti, G.N.; Berneschi, S.; Havránek, V.; Vosecek, V.; Nagy, N.; et al. Fabrication of low loss channel waveguide in tungsten-tellurite glass by 11 MeV carbon ion microbeam for telecom C band. Opt. Mater. X 2019, 4, 100035. [Google Scholar] [CrossRef]

- Bányász, I.; Rajta, I.; Nagy, G.U.; Khanh, N.Q.; Havránek, V.; Vosecek, V.; Fried, M.; Szabó, Z.; Veres, M.; Holomb, R.; et al. Characterisation of Channel Waveguides Fabricated in an Er3+-Doped Tellurite Glass Using Two Ion Beam Techniques. Chemosensors 2022, 10, 337. [Google Scholar] [CrossRef]

- Jin, H.; Turaga, S.P.; Vanga, S.K.; Bettiol, A.A. Single-mode light guiding in diamond waveguides directly written by a focused proton beam. Opt. Lett. 2018, 43, 2648–2651. [Google Scholar] [CrossRef] [PubMed]

- Yao, Y.; Dong, N.; Chen, F.; Vanga, S.K.; Bettiol, A.A. Proton beam writing of Nd: GGG crystals as new waveguide laser sources. Opt. Lett. 2011, 36, 4173–4175. [Google Scholar] [CrossRef]

- An, Q.; Cheng, C.; Vanga, S.K.; Bettiol, A.A.; Chen, F. Proton beam writing of chalcogenide glass: A new approach for fabrication of channel waveguides at telecommunication O and C bands. J. Light. Technol. 2014, 32, 3763–3767. [Google Scholar] [CrossRef]

- Wang, S.F.; Sang, L.F. Diode-pumped Nd: YCOB self-frequency-doubling green laser at 530 nm. Laser Phy. 2011, 21, 1347–1349. [Google Scholar] [CrossRef]

- Fang, Q.; Lu, D.; Yu, H.; Zhang, H.; Wang, J. Self-frequency-doubled vibronic yellow Yb: YCOB laser at the wavelength of 570 nm. Opt. Lett. 2016, 41, 1002–1005. [Google Scholar] [CrossRef]

- Khaled, F.; Loiseau, P.; Aka, G.; Gheorghe, L. Rise in power of Yb: YCOB for green light generation by self-frequency doubling. Opt. Lett. 2016, 41, 3607–3610. [Google Scholar] [CrossRef] [PubMed]

- Ren, Y.; Dong, N.; Jia, Y.; Pang, L.; Wang, Z.; Lu, Q.; Chen, F. Efficient laser emissions at 1.06 μm of swift heavy ion irradiated Nd: YCOB waveguides. Opt. Lett. 2011, 36, 4521–4523. [Google Scholar] [CrossRef] [PubMed]

- Ren, Y.; Jia, Y.; Dong, N.; Pang, L.; Wang, Z.; Lu, Q.; Chen, F. Guided-wave second harmonics in Nd: YCOB optical waveguides for integrated green lasers. Opt. Lett. 2012, 37, 244–246. [Google Scholar] [CrossRef] [PubMed]

- Ren, Y.; Chen, F.; Vázquez de Aldana, J.R. Near-infrared lasers and self-frequency-doubling in Nd: YCOB cladding waveguides. Opt. Express 2013, 21, 11562–11567. [Google Scholar] [CrossRef] [PubMed]

- Available online: http://www.srim.org/ (accessed on 1 October 2022).

- Siebenmorgen, J.; Petermann, K.; Huber, G.; Rademaker, K.; Nolte, S.; Tünnermann, A. Femtosecond laser written stress-induced Nd:Y3Al5O12 (Nd: YAG) channel waveguide laser. Appl. Phys. B 2009, 97, 251–255. [Google Scholar] [CrossRef]

- Saleh, B.E.A.; Teich, M.C. Fundamentals of Photonics, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2019; pp. 1–1370. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Yao, Y.; Liu, F.; Guan, J.; Lu, Q.; Jia, Y. Efficient Optical Waveguiding Enabled by Focused Proton Beam Writing in Nd:YCOB Crystal. Crystals 2022, 12, 1832. https://doi.org/10.3390/cryst12121832

Zhao X, Yao Y, Liu F, Guan J, Lu Q, Jia Y. Efficient Optical Waveguiding Enabled by Focused Proton Beam Writing in Nd:YCOB Crystal. Crystals. 2022; 12(12):1832. https://doi.org/10.3390/cryst12121832

Chicago/Turabian StyleZhao, Xingjuan, Yicun Yao, Fengqin Liu, Jing Guan, Qingming Lu, and Yuechen Jia. 2022. "Efficient Optical Waveguiding Enabled by Focused Proton Beam Writing in Nd:YCOB Crystal" Crystals 12, no. 12: 1832. https://doi.org/10.3390/cryst12121832

APA StyleZhao, X., Yao, Y., Liu, F., Guan, J., Lu, Q., & Jia, Y. (2022). Efficient Optical Waveguiding Enabled by Focused Proton Beam Writing in Nd:YCOB Crystal. Crystals, 12(12), 1832. https://doi.org/10.3390/cryst12121832