Study on the Surface Morphology of Micro-Particles and the Oxide Layer on Silicon Carbide Crystal Using Nanosecond Green Laser Cleaning Assisted with Airflow

Abstract

:1. Introduction

2. Machining Principle of Laser Cleaning Assisted with Gas and Numerical Simulation

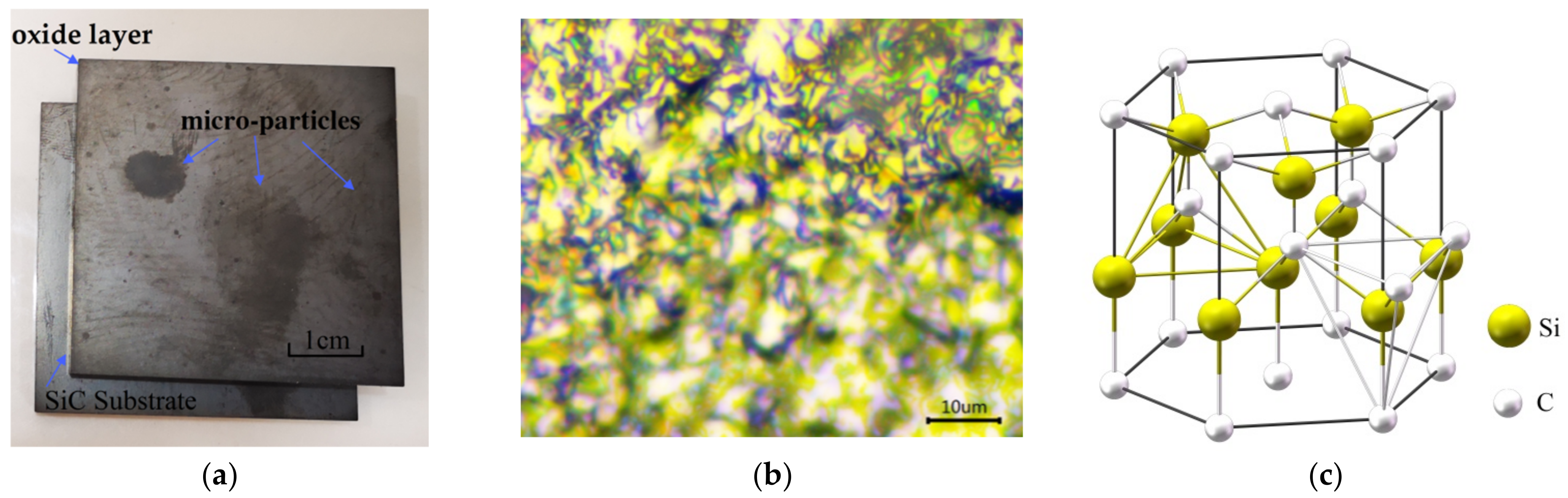

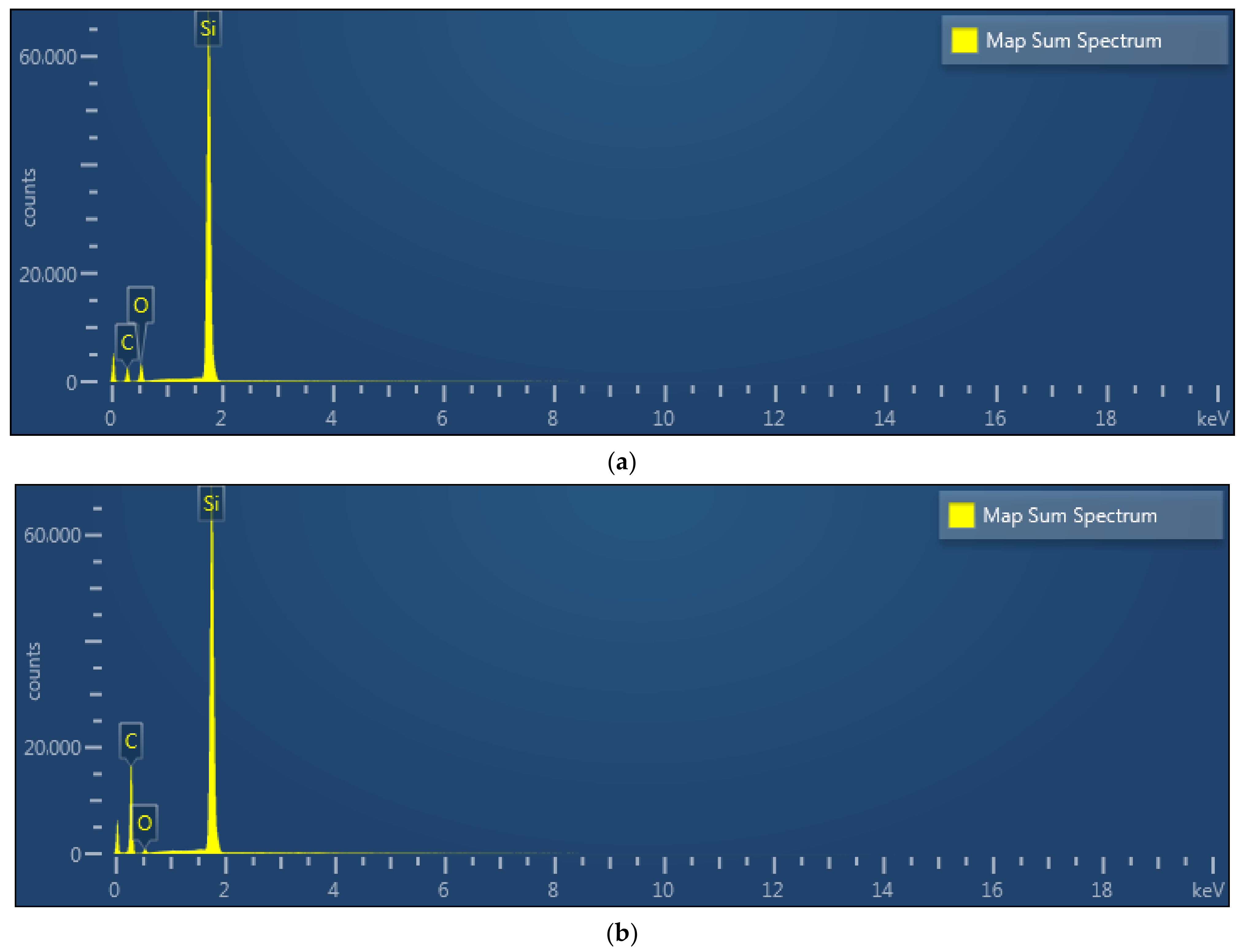

2.1. Silicon Carbide (SiC) Single-Crystal Material

2.2. Principles of Laser Cleaning Assisted by Airflow

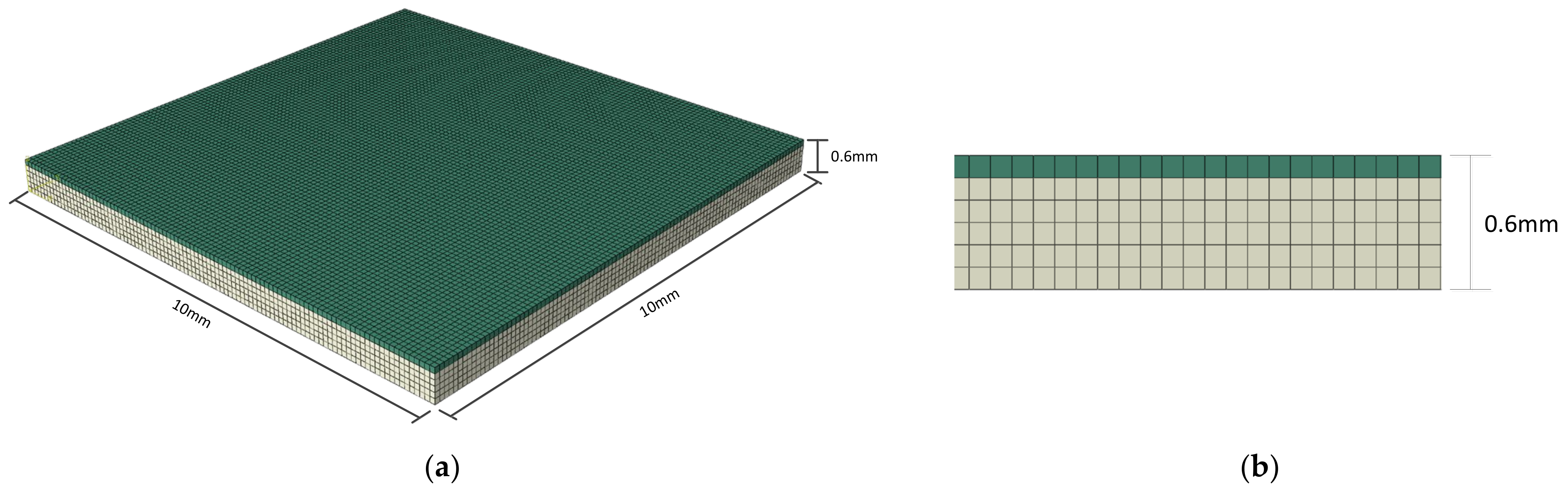

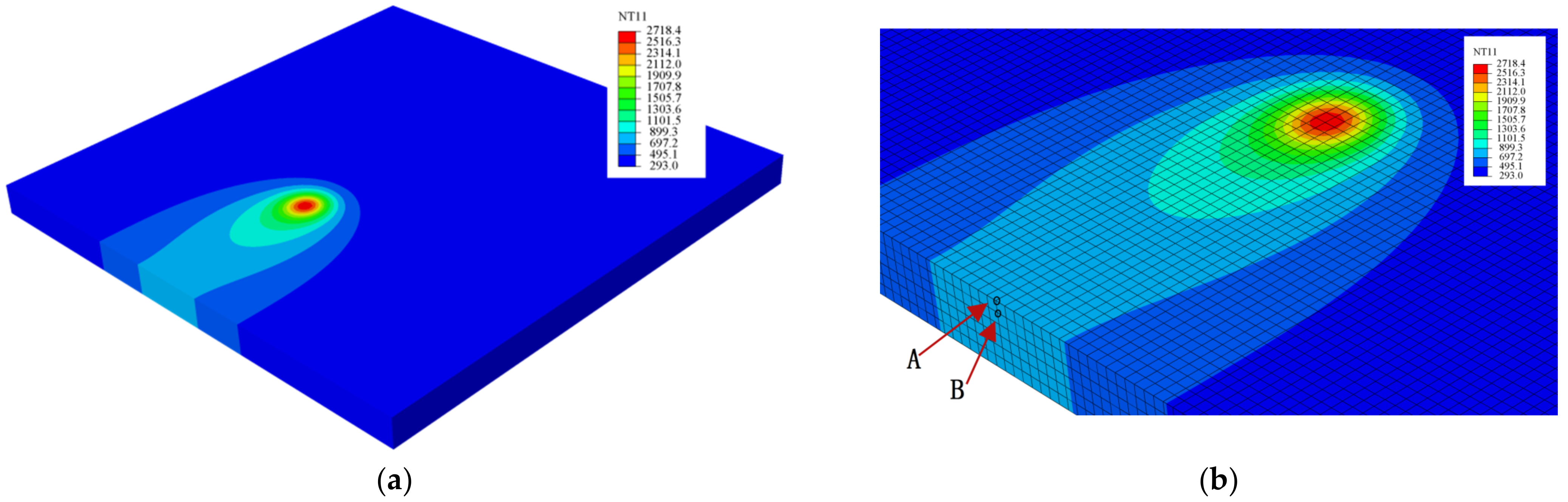

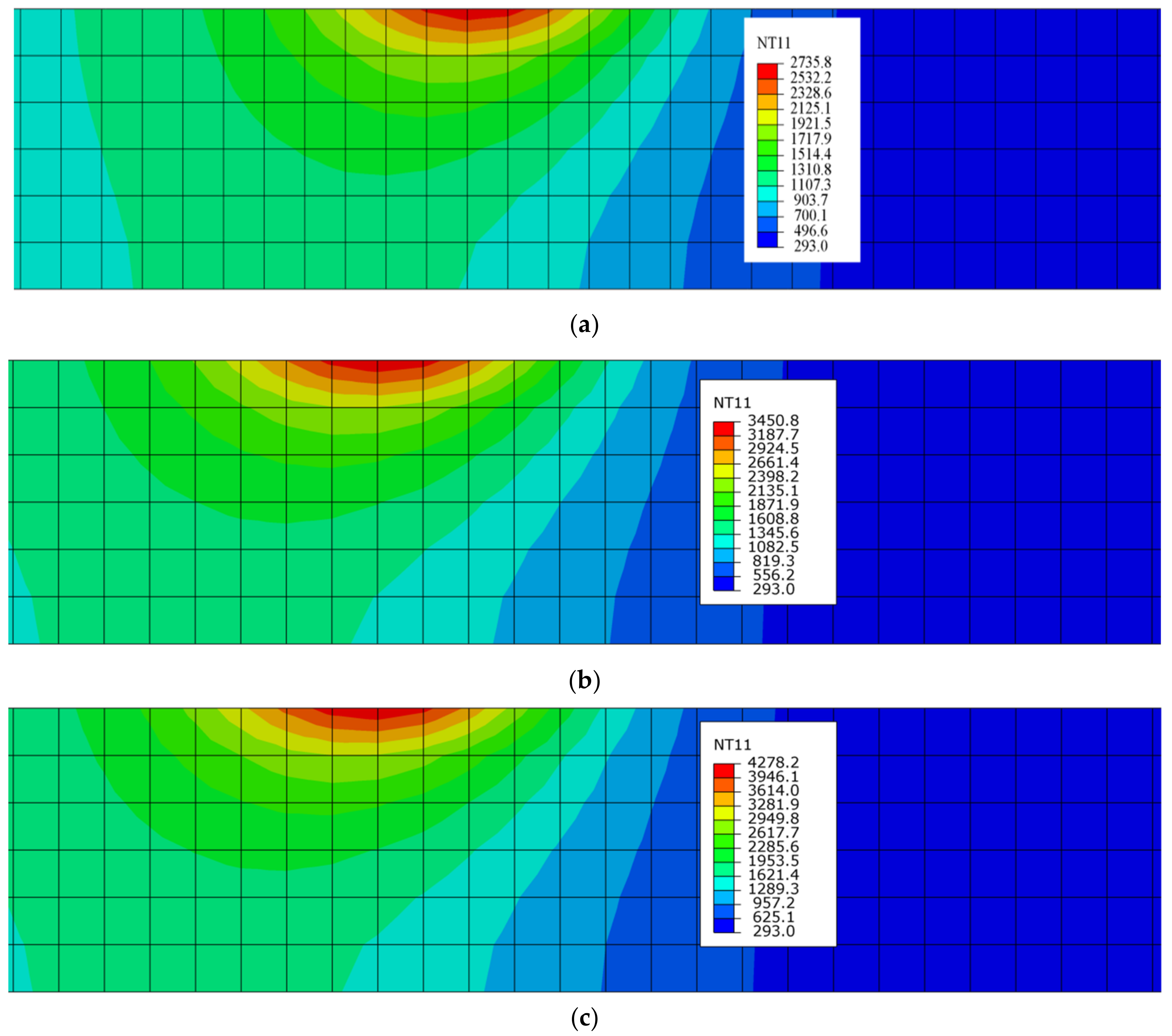

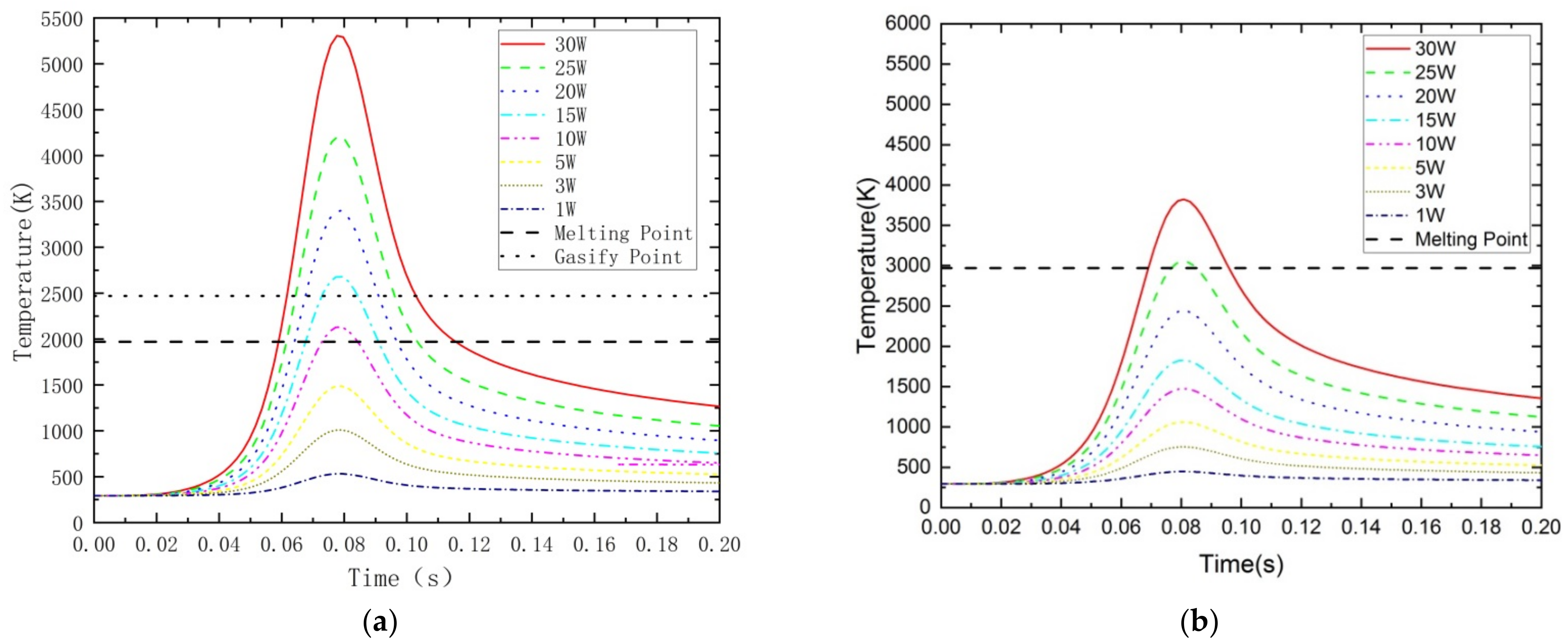

2.3. Temperature Simulation and Analysis

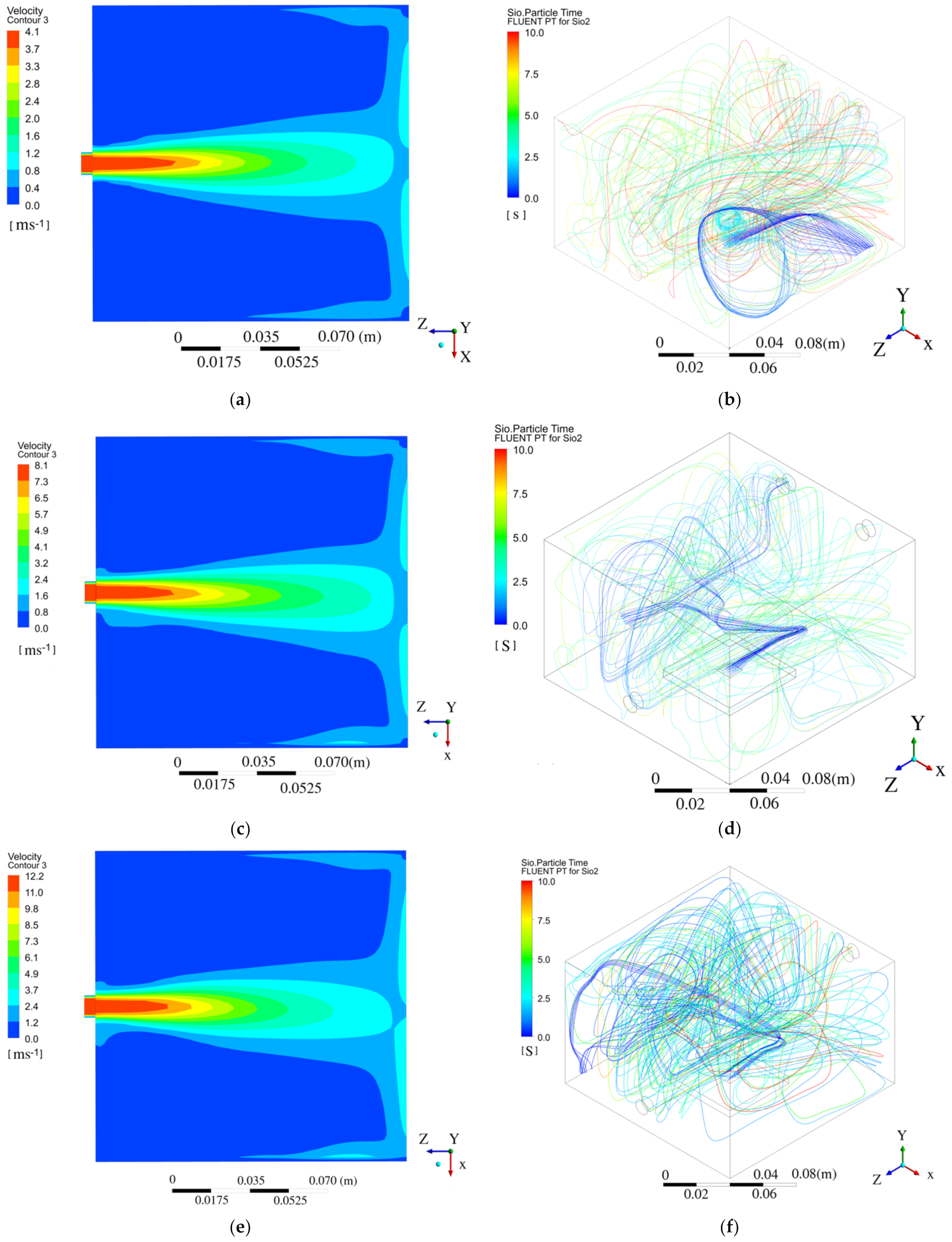

2.4. Dust Particle Simulation

3. Experimental Equipment and Method

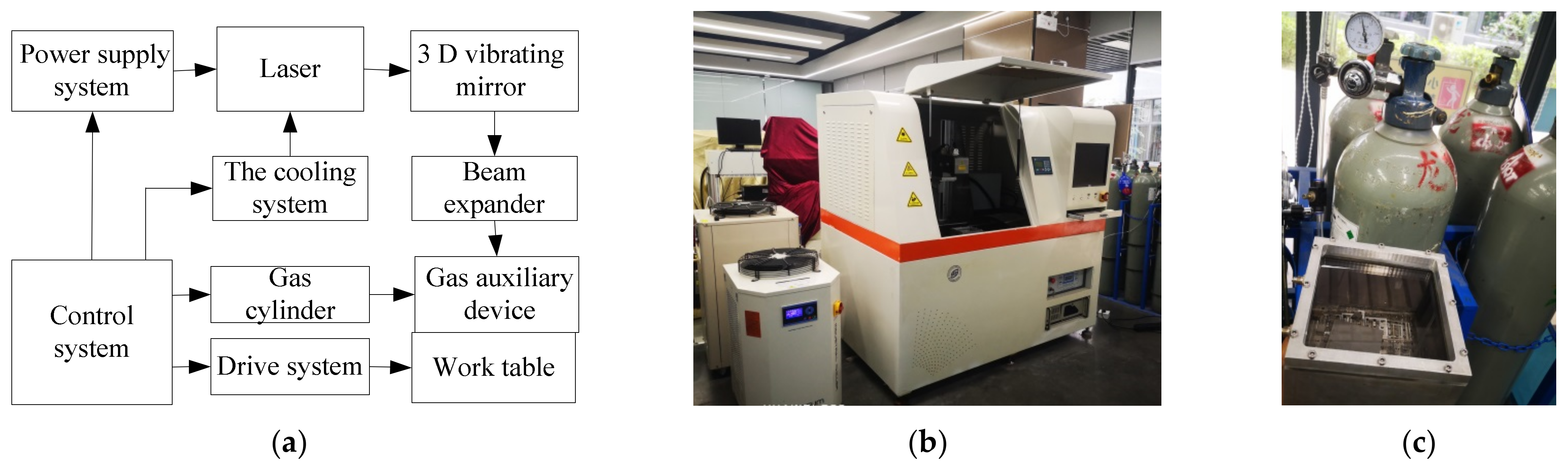

3.1. Experimental Equipment

3.2. Test Materials, Laser Cleaning Parameters, and Methods

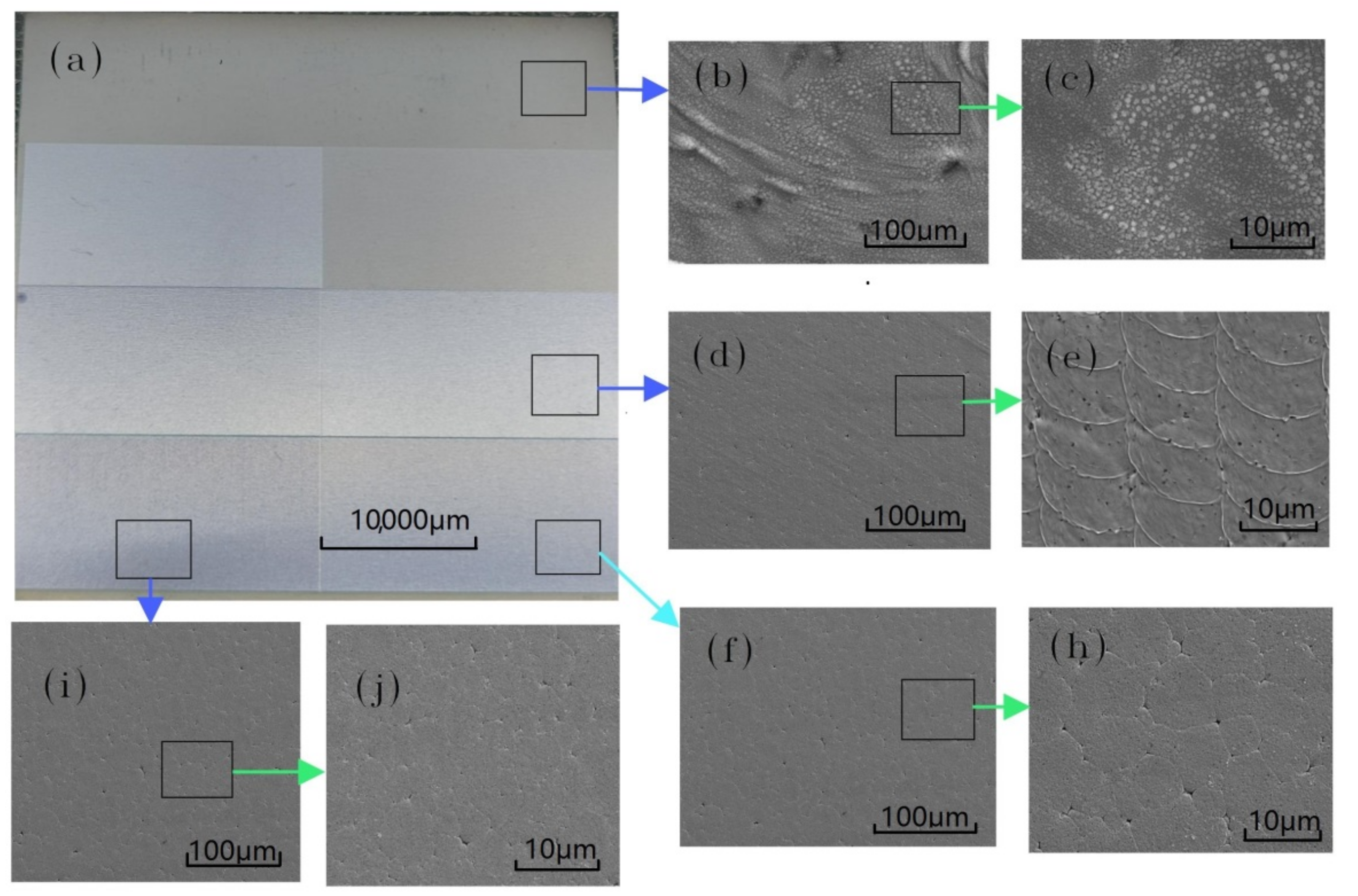

4. Results and Discussion

4.1. Influence of the Laser Cleaning

4.2. Test for Laser Cleaning

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chowdhury, E.H.; Rahman, M.H.; Hong, S. Tensile strength and fracture mechanics of two-dimensional nanocrystalline silicon carbide. Comput. Mater. Sci. 2021, 197, 110580. [Google Scholar] [CrossRef]

- Huang, D.; Tan, R.; Liu, L.; Ye, C.; Zhu, S.; Fan, Z.; Zhang, P.; Wu, H.; Han, F.; Liu, H.; et al. Preparation and properties of the three-dimensional highly thermal conductive carbon/carbon-silicon carbide composite using the mesophase-pitch-based carbon fibers and pyrocarbon as thermal diffusion channels. J. Eur. Ceram. Soc. 2021, 41, 4438–4446. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, C.; Song, M.; Chen, X.; Xia, W. Simple synthesis of ultrafine amorphous silicon carbide nanoparticles by atmospheric plasmas. Mater. Lett. 2021, 299, 130072. [Google Scholar] [CrossRef]

- Pan, Y.; Zhao, Q.; Guo, B.; Long, Y. High-efficiency machining of silicon carbide Fresnel micro-structure based on improved laser scanning contour ablation method with continuously variable federate- ScienceDirect. Ceram. Int. 2020, 47, 4062–4075. [Google Scholar] [CrossRef]

- Tam, A.C.; Park, H.K.; Grigoropoulos, C.P. Laser cleaning of surface contaminants. Appl. Surf. Sci. 1998, 127–129, 721–725. [Google Scholar] [CrossRef]

- Klein, S.; Fekrsanati, F.; Hildenhagen, J.; Dickmann, K.; Uphoff, H.; Marakis, Y.; Zafiropulos, V. Discoloration of marble during laser cleaning by Nd: YAG laser wavelengths. Appl. Surf. Sci. 2001, 171, 242–251. [Google Scholar] [CrossRef]

- Zheng, Y.W.; Luk’Yanchuk, B.S.; Lu, Y.F.; Song, W.D.; Mai, Z.H. Dry laser cleaning of particles from solid substrates: Experiments and theory. J. Appl. Phys. 2001, 90, 2135–2142. [Google Scholar] [CrossRef] [Green Version]

- Fieret, J.; Batta, N.; Lu, Y.; Wang, X.; Shi, J.; Thompson, D.W.; Doerr, D.W.; Alexander, D.R. Monitoring steam laser cleaning using optical probe techniques. Proc. SPIE 2005, 5713, 436–445. [Google Scholar]

- Allcock, D.T.C.; Guidoni, L.; Harty, T.P.; Ballance, C.J.; Blain, M.G.; Steane, A.M.; Lucas, D.M. Reduction of heating rate in a microfabricated ion trap by pulsed-laser cleaning. New J. Phys. 2011, 13, 814–823. [Google Scholar] [CrossRef]

- Samolik, S.; Walczak, M.; Plotek, M.; Sarzynski, A.; Pluska, I.; Marczak, J. Investigation into the removal of graffiti on mineral supports: Comparison of nano-second Nd: YAG laser cleaning with traditional mechanical and chemical methods. Stud. Conserv. 2015, 60, 58–64. [Google Scholar] [CrossRef] [Green Version]

- Kelley, J.D.; Hovis, F.E. A Thermal detachment mechanism for particle removal from surfaces by pulsed laser irradiation. Microelectron. Eng. 1993, 20, 159–170. [Google Scholar] [CrossRef]

- Kanazawa, Y.; Sawada, A.; Zhao, W.; Jarupoonphol, W.; Takai, M. Wavelength dependence of UV laser cleaning for silicon field emitter arrays. Jpn. J. Appl. Phys. 2003, 42, 196–197. [Google Scholar] [CrossRef]

- Jette, A.N.; Benson, R.C. Modeling of pulsed-laser cleaning of metal optical surfaces at cryogenic temperatures. J. Appl. Phys. 1994, 75, 3130–3141. [Google Scholar] [CrossRef]

- Zapka, W.; Ziemlich, W.; Leung, W.P.; Tam, A.C. Laser cleaning: Laser-induced removal of particles from surfaces. Adv. Funct. Mater. 2010, 2, 63–70. [Google Scholar] [CrossRef]

- Harris, C.D.; Shen, N.; Rubenchik, A.M.; Demos, S.G.; Matthews, M.J. Characterization of laser-induced plasmas associated with energetic laser cleaning of metal particles on fused silica surfaces. Opt. Lett. 2015, 40, 5212. [Google Scholar] [CrossRef]

- Kim, J.E.; Han, M.S.; Kim, J.D. Removal characteristics of shop-primer paint by laser energy density in Q-switching fiber laser cleaning. Mod. Phys. Lett. B 2020, 34, 2040042. [Google Scholar] [CrossRef]

- Lu, Y.F.; Zheng, Y.W.; Song, W.D. Laser induced removal of spherical particles from silicon wafers. J. Appl. Phys. 2000, 87, 1534–1539. [Google Scholar] [CrossRef]

- Lu, Y.F.; Zheng, Y.W. Characterization of ejected particles during laser cleaning. J. Appl. Phys. 2000, 87, 549–552. [Google Scholar] [CrossRef]

- Ling, X.; Wang, G.; Zhang, C. Investigation of laser cleaning on bronze cultural relics. Laser Phys. 2016, 26, 055603. [Google Scholar] [CrossRef]

- Wang, F.; Ai, S.; Wang, Q.; Cheng, Y.; Huang, H.; Cai, C.; Xie, D.; Chen, H.; Hu, W. Effect of narrow pulse width laser cleaning on corrosion resistance of A5083-H111 aluminum alloy. Anti-Corrosion Methods Mater. 2021, 68, 192–201. [Google Scholar] [CrossRef]

- Kumar, A.; Biswas, D. Particulate size and shape effects in laser cleaning of heavy metal oxide loose contamination off clad surface. Opt. Laser Technol. 2018, 106, 286–293. [Google Scholar] [CrossRef]

- Guo, L.; Li, Y.; Geng, S.; Wang, C.; Jiang, P. Numerical and experimental analysis for morphology evolution of 6061 aluminum alloy during nanosecond pulsed laser cleaning. Surf. Coat. Technol. 2022, 432, 128056. [Google Scholar] [CrossRef]

- Zheng, Y.W.; Lu, Y.F.; Song, W.D. Angular effect in laser removal of spherical silica particles from silicon wafers. J. Appl. Phys. 2001, 90, 59–63. [Google Scholar] [CrossRef]

- Leiderer, P.; Mosbacher, M.; Döbler, V.; Schilling, A.; Yavas, O.; Luk’Yanchuk, B.S.; Boneberg, J. Steam laser cleaning of silicon surfaces: Laser-induced gas bubble nucleation and efficiency measurements. In Laser Cleaning; Luk’Yanchuk, B., Ed.; World Scientific Publishing Co. Pte. Ltd.: Singapore, 2002; pp. 255–310. [Google Scholar]

- Wan, Z.; Yang, X.; Xia, G.; Li, D.; Liu, W.; Cheng, J.; Wang, S. Effect of laser power on cleaning mechanism and surface properties. Appl. Opt. 2020, 59, 9482–9490. [Google Scholar] [CrossRef] [PubMed]

- Kennedy, C.; Vest, M.; Cooper, M.; Wess, T.J. Laser cleaning of parchment: Structural, thermal and biochemical studies into the effect of wavelength and fluence. Appl. Surf. Sci. 2004, 227, 151–163. [Google Scholar] [CrossRef]

- Lee, J.M.; Watkins, K.G. Removal of small particles on silicon wafer by laser-induced airborne plasma shock waves. J. Appl. Phys. 2001, 89, 6496–6500. [Google Scholar] [CrossRef]

- Siano, S.; Salimbeni, R. Advances in Laser Cleaning of Artwork and Objects of Historical Interest: The Optimized Pulse Duration Approach. Am. Chem. Soc. 2010, 43, 739–750. [Google Scholar] [CrossRef]

- Kim, J.E.; Kim, J.D. A study on the removal of paint and oxide layer on the steel surface by laser beam scanning method. Int. J. Mod. Phys. B 2021, 35, 2140006. [Google Scholar] [CrossRef]

- Chen, T.; Wang, W.; Tao, T.; Pan, A.; Mei, X. Multi-scale micro-nano structures prepared by laser cleaning assisted laser ablation for broadband ultralow reflectivity silicon surfaces in ambient air. Appl. Surf. Sci. 2020, 509, 145182. [Google Scholar] [CrossRef]

- Zhang, S.; Yan, Q.; Lin, J.; Zhang, Q.; Lu, Y.; Yao, J.; Fan, L. Elimination of blind zone in nanoparticle removal on silicon wafers using a double-beam laser shockwave cleaning process. Appl. Surf. Sci. 2020, 539, 148057. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, W.; Zhang, D.; Tian, Z.; Sun, X.; Wei, Z. Experimental investigations into cleaning mechanism of ship shell plant surface involved in dry laser cleaning by controlling laser power. Appl. Phys. A-Mater. Sci. Process. 2020, 11, 886. [Google Scholar]

- Zhu, G.; Xu, Z.; Jin, Y.; Chen, X.; Yang, L.; Xu, J.; Shan, D.; Chen, Y.; Guo, B. Mechanism and application of laser cleaning: A review. Opt. Lasers Eng. 2022, 2022, 107130. [Google Scholar] [CrossRef]

- Ye, Y.; Yuan, X.; Xiang, X.; Cheng, X.; Miao, X. Laser cleaning of particle and grease contaminations on the surface of optics. Opt.-Int. J. Light Electron. Opt. 2012, 123, 1056–1060. [Google Scholar] [CrossRef]

- Milles, S.; Soldera, M.; Kuntze, T.; Lasagni, A.F. Characterization of self-cleaning properties on superhydrophobic aluminum surfaces fabricated by direct laser writing and direct laser interference patterning. Appl. Surf. Sci. 2020, 525, 146518. [Google Scholar] [CrossRef]

- Chen, E.Y.; Renner, P.; Lee, K.; Guo, B.; Liang, H. Effects of humidity on dust particle removal during solar panel cleaning. Surf. Topogr. Metrol. Prop. 2022, 10, 015003. [Google Scholar] [CrossRef]

- Ding, K.; Zhou, K.; Feng, G.; Han, J.; Xie, N.; Huang, Z.; Zhou, G. Mechanism and conditions for laser cleaning of micro and nanoparticles on the surface of transparent substrate. Vacuum 2022, 200, 110987. [Google Scholar] [CrossRef]

- Ghalamdaran, S.; Parvin, P.; Torkamany, M.J.; Zadeh, J.S. Two-dimensional simulation of laser ablation with 235 nanosecond pulses. J. Laser Appl. 2014, 26, 012009. [Google Scholar] [CrossRef]

- Ye, Y.; Yuan, X.; Xiang, X.; Dai, W.; Chen, M.; Miao, X.; Lv, H.; Wang, H.; Zheng, W. Laser plasma shockwave cleaning of SiO2 particles on gold film. Opt. Lasers Eng. 2010, 49, 536–541. [Google Scholar] [CrossRef]

- Yan, J.; Sakai, S.; Isogai, H.; Izunome, K. Characterization of microparticles and oxide layers generated by laser irradiation of diamond-machined silicon wafers. Semicond. Sci. Technol. Semicond 2011, 26, 025006. [Google Scholar] [CrossRef] [Green Version]

- Yan, J.; Takayama, N. Micro and Nanoscale Laser Processing of Hard Brittle Materials; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar]

- Yan, J.W.; Asami, T.; Harada, H.; Kuriyagawa, T. Crystallographic effect on subsurface damage formation in silicon microcutting. CIRP Ann. 2012, 61, 131–134. [Google Scholar] [CrossRef]

- Patankar, N.; Joseph, D. Modeling and numerical simulation of particulate flows by the Eulerian–Lagrangian approach. Int. J. Multiph. Flow 2001, 27, 1659–1684. [Google Scholar] [CrossRef] [Green Version]

- Miyato, N. Particle flux and particle density source due to gyro-center heat source. Phys. Plasmas 2021, 28, 062304. [Google Scholar] [CrossRef]

- Chen, G.; Qiao, J. Femtosecond-laser-enabled simultaneous figuring and finishing of glass with a subnanometer optical surface. Opt. Lett. 2022, 47, 3860–3863. [Google Scholar] [CrossRef] [PubMed]

- Sahoo, P.K.; Feng, T.; Qiao, J. Dynamic pulse propagation modelling for predictive femtosecond-laser-microbonding of transparent materials. Opt. Express 2020, 28, 31103–31118. [Google Scholar] [CrossRef] [PubMed]

- Xiao, H.; Zhang, W.; Zhou, Y.; Liu, M.; Zhou, G. A Numerical Simulation and Experimental Study on the Ultrafast Double-Laser Precision Cutting of Sapphire Materials. Crystals 2022, 12, 867. [Google Scholar] [CrossRef]

- Hsu, S.C.; Lin, J. Removal mechanisms of micro-scale particles by surface wave in laser cleaning. Opt. Laser Technol. 2006, 38, 544–551. [Google Scholar] [CrossRef]

- Berthonneau, J.; Parent, P.; Grauby, O.; Ferry, D.; Laffon, C.; Colombini, A.; Courtois, B.; Bromblet, P. Yellowing of laser-cleaned artworks: Formation of residual hydrocarbon compounds after Nd:YAG laser cleaning of gypsum plates covered by lamp black. J. Cult. Herit. 2019, 39, 57–65. [Google Scholar] [CrossRef]

- Xu, J.; Wu, C.; Zhang, X.; Gao, F.; Yu, T.; Yuan, X. Influence of parameters of a laser cleaning soil rust layer on the surface of ceramic artifacts. Appl. Opt. 2019, 58, 2725–2730. [Google Scholar] [CrossRef]

- Ge, J.; Ge, J.; Liu, H.; Yang, S.; Lan, J. Laser Cleaning Surface Roughness Estimation Using Enhanced GLCM Feature and IPSO-SVR. Photonics 2022, 9, 510. [Google Scholar] [CrossRef]

- Chen, L.; Su, Y.; Zhang, J.; Zhang, H.; Fan, B.; Shao, G.; Zhong, M.; Wang, C.-A. Nanosecond Laser Cleaning Method to Reduce the Surface Inert Layer and Activate the Garnet Electrolyte for a Solid-State Li Metal Battery. ACS Appl. Mater. Interfaces 2021, 13, 37082–37090. [Google Scholar] [CrossRef]

- Huang, L.Q.; Zhu, Q.Z.; Gao, M.C.; Qin, F.W.; Wang, D.J. Cleaning of SiC surfaces by low temperature ECR microwave hydrogen plasma. Appl. Surf. Sci. A J. Devoted Prop. Interfaces Relat. Synth. Behav. Mater. 2011, 257, 10172–10176. [Google Scholar] [CrossRef]

- Zhao, H.; Qiao, Y.L.; Zhang, Q.; Du, X.; Zang, Y.; Liu, X.; Han, B.Y. Study on the characteristics and mechanism of pulsed laser cleaning of polyacrylate resin coating on aluminum alloy substrates. Appl. Opt. 2020, 59, 7053–7065. [Google Scholar] [CrossRef]

| Test Materials | Composition | Melting Point | Boiling Point | Specific Gravity |

|---|---|---|---|---|

| SiC Substrate | SiC | 2827 °C | 3500 °C | 3.2 g/cm3 |

| Oxide layer on surface | SiO2 | 1723 ± 5 °C | 2230 °C | 2.2 g/cm3 |

| Parameters | Numerical Value of SiC | Numerical Value of Microparticle on the Surface(SiO2) |

|---|---|---|

| Conductivity | 16.7 W/(M·K) | 0.27 W/(m K) |

| Density | 3200 Kg/(m3) | 2400 Kg/(m3) |

| Specific heat | 472.27 J/(Kg·K) | 700 J/(Kg·K) |

| Expansion coefficient | 4.5 × 10−6 K−1 | 0.5 × 10−6 K−1 |

| Laser power 20, 25, 30 W; scanning speed, 1500 mm/s; pulse width, 25 ns | ||

| Factor Name | Optimized Value or Feature | |||||

|---|---|---|---|---|---|---|

| Laser power (W) | 5 | 10 | 15 | 20 | 25 | 30 |

| Scanning speed (mm/s) | 300 | 600 | 900 | 1200 | 1500 | 1800 |

| Pressure of the auxiliary gas | 0.15 Mpa; 0.2 Mpa; 0.25 Mpa | |||||

| Cleaning Parameters | Wavelength: 532 nm; spot size of the laser beam: 0.8 ± 0.2 mm; hatch: 0.03 mm | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, H.; Du, C.; Zhang, S.; Zhu, Y. Study on the Surface Morphology of Micro-Particles and the Oxide Layer on Silicon Carbide Crystal Using Nanosecond Green Laser Cleaning Assisted with Airflow. Crystals 2022, 12, 1788. https://doi.org/10.3390/cryst12121788

Xiao H, Du C, Zhang S, Zhu Y. Study on the Surface Morphology of Micro-Particles and the Oxide Layer on Silicon Carbide Crystal Using Nanosecond Green Laser Cleaning Assisted with Airflow. Crystals. 2022; 12(12):1788. https://doi.org/10.3390/cryst12121788

Chicago/Turabian StyleXiao, Haibing, Chenlin Du, Songling Zhang, and Yixin Zhu. 2022. "Study on the Surface Morphology of Micro-Particles and the Oxide Layer on Silicon Carbide Crystal Using Nanosecond Green Laser Cleaning Assisted with Airflow" Crystals 12, no. 12: 1788. https://doi.org/10.3390/cryst12121788

APA StyleXiao, H., Du, C., Zhang, S., & Zhu, Y. (2022). Study on the Surface Morphology of Micro-Particles and the Oxide Layer on Silicon Carbide Crystal Using Nanosecond Green Laser Cleaning Assisted with Airflow. Crystals, 12(12), 1788. https://doi.org/10.3390/cryst12121788