Abstract

To further determine the brittle-to-ductile transition temperature, the microstructures and mechanical properties of typical forged β-solidifying Ti-42Al-5Mn (TiAlMn) and Ti-43Al-4Nb-1Mo-0.5B (TNM) alloys were studied. The results show that the microstructures of both heat-treated alloys consist of γ/α2 lamellar colony, equiaxed γ phase, and β0 phase. In addition, the globular α2 phase appears in the TNM alloy. The yield strength of TiAlMn alloy increases gradually with the testing temperature, whereas a significant drop from 605 MPa to 469 MPa occurs between 650 °C and 700 °C. In contrast, the TNM alloy exhibits a declining trend with the increasing testing temperature, and a remarkable reduction is observed in the temperature range of 700 °C–750 °C. Moreover, the fracture mode transition from transcrystalline cleavage to intercrystalline with increasing testing temperature was applied to the auxiliary judgment of brittle-to-ductile transition. As a result, the brittle-to-ductile transition temperatures of TiAlMn alloy and TNM alloy are about 650 °C–700 °C and 700 °C–750 °C, which may provide a reference for service temperature range of both alloys.

1. Introduction

With the rapid development of the aviation and aerospace industry, the traditional high-temperature structural materials, such as Ni-based superalloy with high density and titanium alloy with insufficient high-temperature strength, have been gradually difficult to meet the technical requirements of advanced aircraft [1,2,3]. Nowadays, TiAl alloy is considered as one of the most promising light-weight alloys for high-temperature applications in the aviation industry due to the unique combination of low density, high specific strength, and excellent resistance to oxidation and corrosion [4,5,6,7,8,9,10,11,12]. The forged β-solidifying TiAl alloys possess adequately balanced mechanical properties via conventional manufacturing routes and heat-treatments due to an enlarged processing window [13,14]. A typical Ti-42Al-5Mn (named TiAlMn) alloy exhibits the advantages of low cost and great deformability [15,16,17]. Another representative alloy, the so-called TNM alloy, has a nominal composition of Ti-(42–44)Al-(3–5)Nb-1Mo-(0.1–1)B. The microstructure consists of α2/γ lamellar colonies surrounded by β0 phase and γ grains, which provides sufficient ductility at room temperature and adequate creep strength at high temperatures [18,19,20]. Nevertheless, the service temperature ranges of both alloys have not been determined clearly.

The yield strength at high temperatures is an important application parameter for TiAl alloys. With the increasing testing temperature, the deformation behavior of TiAl alloys shows a transition from brittle to ductile, which can be reflected by a remarkable decrease in the yield strength and a change in the fracture mode from cleavage to intergranular fracture [21,22,23]. Correspondingly, the brittle-to-ductile transition temperature can provide a reference for service temperature of TiAl alloys [24]. Researchers have studied the microstructure dependence of the brittle-to-ductile transition temperature of TiAl alloys by tensile tests [25,26,27,28]. Lin et al. [29] reported that after adding 1 at.% B into the Ti-47Al-2Mn-2Nb alloy, the brittle-to-ductile transition temperature decreased due to the microstructure refinement. Kim et al. [30] found that the brittle-to-ductile transition temperature of a fully lamellar microstructure was higher than that of a duplex microstructure. Although previous researches have reported the mechanical properties and fracture behavior of TiAlMn alloys and TNM alloys as a function of testing temperature, the brittle-to-ductile transition temperatures of both alloys are still evaluated within a large temperature range of 700 °C–800 °C [15,23,24,31,32,33].

Considering TiAl alloys with nearly fully lamellar or duplex microstructures exhibit preferable comprehensive mechanical properties, the purpose of this paper is to further determine the brittle-to-ductile transition temperature of forged β-solidifying TiAlMn alloy with a nearly fully lamellar microstructure and TNM alloy with a duplex microstructure. Hence, in this work, the microstructures and mechanical properties of Ti-42Al-5Mn alloy and Ti-43Al-4Nb-1Mo-0.5B alloy were systematically studied by X-ray diffraction (XRD), scanning electron microscope (SEM) equipped with energy dispersive spectrometer (EDS) and electronic tensile testing machine. Various characterizations were conducted to clarify the microstructural evolution and mechanical properties to obtain the brittle-to-ductile transition temperatures. These results may provide a reference for the service temperature ranges of both alloys.

2. Materials and Methods

2.1. Alloys Preparation

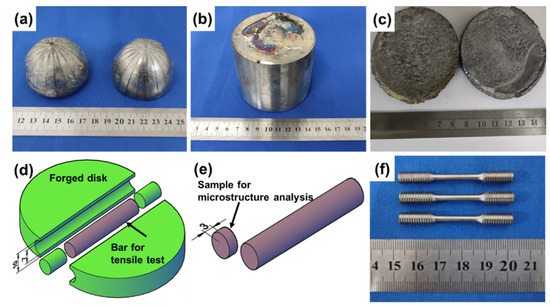

In this work, the nominal composition (atomic fraction, %) of the β-solidifying TiAlMn alloy and TNM alloy were Ti-42Al-5Mn and Ti-43Al-4Nb-1Mo-0.5B. The TiAlMn alloy ingots shown in Figure 1 were prepared using high-purity raw materials (99.999% Ti, 99.99% Al, 99.8% Mn) in a vacuum water-cooled copper crucible induction melting furnace. The cylinders with Φ40 mm × 30 mm were cut from the TiAlMn alloy ingots and then heated at 1300 °C for 20 min before free forging. The cylinders experienced two-pass hot-deformation with 30~40% reduction per pass, and were finally forged into disks with the thickness of 10 mm. The deformed TNM alloy with 50 mm × 50 mm × 90 mm was provided by Northwest Institute for Non-ferrous Metal Research. The TNM ingots were prepared by means of vacuum arc melting using commercially pure materials. The total amount of interstitial impurities (O, H, C, N, Fe) was well below 4000 atomic ppm. The TNM alloy ingots were treated by hot isostatic pressing at 1250 °C for 4 h under an argon pressure of 160 MPa. Then the TNM alloy experienced six-pass forging with ~25% reduction per pass at 1150 °C. The forging speed was 0.3 mm/s. The tensile strength and ductility of the forged TNM at 25 °C reach 556 MPa and 0.79%.

Figure 1.

The processing samples of TiAlMn alloy: (a) ingots, (b) canned-forging specimens, (c) forged disks, (d) sampling position for tensile tests, (e) sampling position for microstructure analysis, (f) tensile specimens.

2.2. Heat Treatments

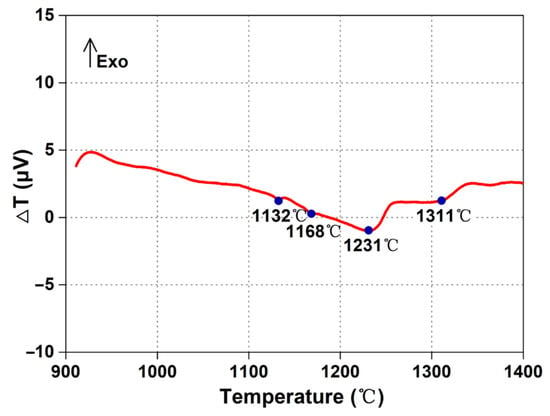

The differential thermal analysis (DTA) tests were conducted to obtain the phase transition temperatures of the TiAlMn alloy. The DTA specimens (Φ3 mm × 2 mm) of the TiAlMn alloy were cut from the as-cast ingot and ground to remove the oxide scale. They were tested by the SETSYS Evolution 18 machine in an alumina crucible with a heating rate of 10 °C/min referred to Ref. [17]. Figure 2 shows that there are four endothermic peaks in the DTA curve, which suggests that the relevant phase transition temperatures of Tβ, Tγsolv, Tβ→β0/α→α2, and Teut, were 1311 °C, 1231 °C, 1168 °C, and 1132 °C, respectively. W. Wallgram et al. [34] found that the Tα and Teut of TNM alloy were 1265 °C and 1115 °C. In order to obtain a nearly fully lamellar microstructure, the solid solution temperature of TiAlMn alloy was selected in the β + α phase region. On the other hand, the solid solution treatments of TNM alloy were conducted in the β + α + γ phase region to gain a duplex microstructure. Overall, the experimental conditions for the alloys are provided in Table 1. The TiAlMn alloy experienced the solid solution process at 1280 °C for 30 min followed by air cooling, and different aging processes, i.e., 850 °C/3 h, 850 °C/6 h, 950 °C/3 h, 950 °C/6 h, named as HT1, HT2, HT3, HT4, respectively, followed by furnace cooling. The TNM alloy experienced the solid solution process at 1230 °C for 1 h followed by air cooling, and the different aging processes, i.e., 850 °C/6 h, 950 °C/6 h, named as HT5, HT6, respectively, followed by furnace cooling. The heat treatments were performed by the KSL-1400X furnace (±1 °C).

Figure 2.

The DTA results of Ti42Al5Mn alloy showing the phase transformation temperatures.

Table 1.

Summary of heat treatments performed on the as-forged TiAlMn and TNM alloys.

2.3. Microstructure Analysis

The X-ray diffraction tests were performed on a Bruker-AXS D8 Advance diffractometer with CuKα1 radiation to identify the phases in the alloys. The metallographic specimens were cut from the same position of the samples as shown in Figure 1, then mechanically ground and polished in standard routines. The experimental samples were etched using 5 mL HNO3 + 5 mL HF + 90 mL distilled water for 10 s. After etching, the microstructures were observed using a Leica DM4M metallurgical microscope (OM). The variations in microstructure and fracture behavior of the alloys were characterized by FEI Quanta 250F field emission environmental scanning electron microscope in the back scattered electron (BSE) mode. The energy dispersive spectrometer was used to analyze the compositions of phases.

2.4. Mechanical Testing

The tensile samples with a gauge section of Φ3 mm × 15 mm were cut from the middle sections of the disks referred to Refs. [5,35]. The tensile tests were performed at 25 °C, 600 °C, 650 °C, 700 °C, 750 °C, and 800 °C at a constant strain rate of about 1 × 10−4 s−1 on an Instron 5982 electronic universal testing machine. In the high-temperature tensile tests, the samples were preheated at the test temperatures for about 20 min before loading. At least three samples of each group were tested to ensure the accuracy of the experiments.

3. Results and Discussion

3.1. Microstructures of As-Forged Alloys

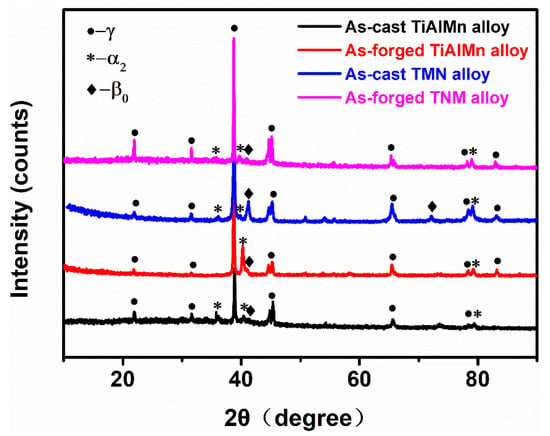

Figure 3 shows the XRD patterns of as-cast and as-forged TiAlMn and TNM alloys. The results manifest that the γ, α2, and β0 phases are identified in the as-cast and as-forged TiAlMn and TNM alloys. Like other TiAl structural materials, both alloys are based on the γ (TiAl) phase with the tetragonal L10 structure and the α2 (Ti3Al) phase with the hexagonal D019 structure [36]. Meanwhile, the appearance of the β0 phase with the bcc B2 structure in the as-cast TiAlMn alloy and TNM alloy is favorable to improving the high-temperature deformation capacity.

Figure 3.

XRD patterns of as-cast and as-forged TiAlMn and TNM alloys.

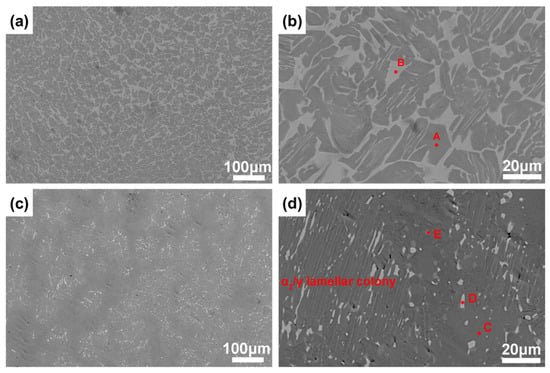

Figure 4 presents the microstructures of as-forged TiAlMn and TNM alloys. The phases were labelled and identified by EDS, and their specific compositions are given in Table 2. As can be seen in Figure 4a,b, the TiAlMn alloy shows a near-γ microstructure. The equiaxed γ phase (Label A) with an average size of 30–45 μm is homogeneously distributed, while the β0 phase (Label B) with uneven size and irregular morphology displays netlike distribution. The inapparent α2/γ lamellar structure shows a band-shaped distribution. After forging in the (β + α) two-phase region, the TiAlMn alloy experienced air cooling, and the insufficient phase transition of α → α2/γ resulted in the unobvious morphological feature of the α2/γ lamellar colony. Table 2 displays that the Al tends to enrich in the γ phase. The Mn content in γ and β0 phases increases in turn, and the Mn helps to improve β phase stability [37]. In Figure 4c,d, a typical duplex microstructure, including 20–30 μm equiaxed γ (Label C) and 100–150 μm α2/γ lamellar colony, is found in the as-forged TNM alloy. Meanwhile, the β0 phase (Label D) locates at the boundary and interior of the α2/γ lamellar colony. The β0 phase is obviously refined and exhibits uniform distribution with respect to the as-forged TiAlMn alloy. The Mo and Nb with a small diffusion coefficient segregate in the high-temperature β phase, and the β0 phase is formed by the ordering transformation [38,39]. Moreover, the globular α2 phase (Label E) can be detected in the equiaxed γ phase, which differs from the lath α2 phase in the α2/γ colony.

Figure 4.

The SEM-BSE photos of as-forged TiAlMn and TNM alloys: (a,b) TiAlMn alloy, (c,d) TNM alloy.

Table 2.

Compositions at different positions in Figure 4 identified by EDS.

3.2. Mechanical Properties of As-Forged Alloys

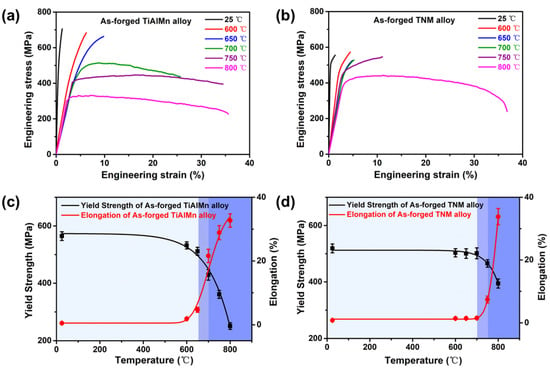

Figure 5 shows the engineering stress–strain curves of as-forged TiAlMn alloy and TNM alloy as a function of the testing temperature. The results of the tensile properties, i.e., ultimate tensile strength (UTS), yield strength (YS), and elongation (EL) at room and high temperatures, based on three samples for each chemical composition, are summarized. There is a general tendency toward a decrease in YS and an increase in EL with increasing temperature, which may be attributed to the domination of thermally activated dislocation movement [40,41,42].

Figure 5.

The tensile properties of as-forged TiAlMn alloy and TNM alloy: (a,b) the engineering stress–strain curves at different temperatures, (a) TiAlMn alloy, (b) TNM alloy; (c,d) the tensile properties as a function of the testing temperature, (c) TiAlMn alloy, (d) TNM alloy.

The UTS, YS, and EL of as-forged TiAlMn alloy and TNM alloy at 25 °C reach 706 MPa, 565 MPa, 0.5%, and 556 MPa, 519 MPa, 0.8%, respectively. The YS of as-forged TiAlMn alloy shows a slight decrease with the increasing temperature below 650 °C. The substantial change of YS and EL between 650 °C and 700 °C indicates that the brittle-to-ductile transition temperature of as-forged TiAlMn alloy is in this temperature range. The YS and EL of as-forged TNM alloy almost keep unchanged below 700 °C. However, the YS remarkably decreases to 465 MPa and the EL increases to 7.4% when the temperature rises to 750 °C, which suggests that the brittle-to-ductile transition temperature of the as-forged TNM alloy is between 700 °C and 750 °C.

3.3. Microstructures of Heat-Treated Alloys

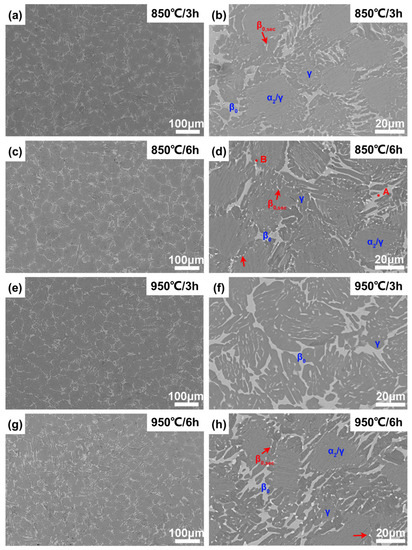

Figure 6 shows the microstructures of TiAlMn alloy after the corresponding heat treatments. It can be found that the microstructure consisting of the γ/α2 lamellar colony, γ phase, and β0 phase is generated after aging at 850 °C. The morphologies of α2/γ lamellar colony and γ phase show no evident change with increasing aging time at 850 °C. It is noteworthy that the fine particle phase (red arrows) is observed at the boundary of the α2/γ lamellar colony. Compared with β0 (12.64%), a greater amount of Mn (28.76%) is enriched in the fine particle phase as shown in Table 3. The Mn-rich phase precipitating during aging treatment is similar to the primary β0 phase, which is defined as β0,sec. These findings are consistent with the results of previous works [43,44]. The precipitation of the β0,sec may be attributed to the decomposition and dissolution of α2/γ lamellar. The dissolution of the α2/γ colony via discontinuous precipitation is evident, which is due to the fact that the initial material state is not in thermodynamic equilibrium [45]. This precipitation reaction, emanating from the colony boundary, is mostly triggered by the energy stored in the material by the large interfacial area through the formation of the nano-lamellar structure and concomitant coherency stresses [46]. Recently, this reaction can be understood as a recrystallization process [47]. The volume fraction of β0,sec phase increases with the prolonging aging time at 850 °C. As the aging temperature increases from 850 °C to 950 °C, the β0,sec phase coarsens obviously and its volume fraction increases after aging for 6 h. It can be seen that the γ phase also obviously grows with the increased aging temperature.

Figure 6.

The SEM-BSE photos of TiAlMn alloy after different aging treatments: (a,b) HT1, (c,d) HT2, (e,f) HT3, (g,h) HT4.

Table 3.

Compositions at different positions in Figure 6 identified by EDS.

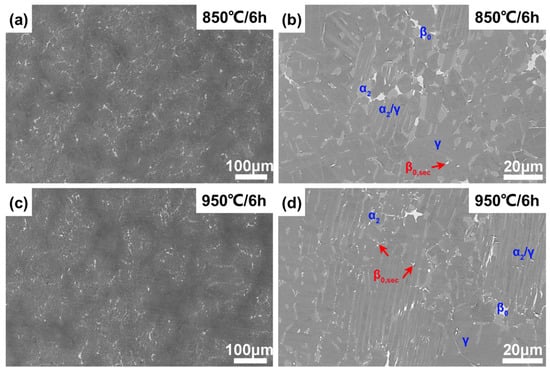

Figure 7 shows the microstructures of TNM alloy after different heat treatments. The heat-treated TNM alloy still displays a typical duplex microstructure like the as-forged state. The α2/γ lamellar colony is surrounded by equiaxed γ, globular α2, and blocky β0 phase after aging treatments. Compared with the as-forged state, the volume fraction of the β0 phase decreases obviously, while the volume fraction of the α2/γ lamellar colony increases. As the aging temperature increases, the proportion of α2/γ lamellar colony shows a declining trend, and its average size tends to increase to some extent. In contrast, the equiaxed γ changes in reverse. It is notable that the average size of the α2/γ lamellar colony in heat-treated TNM alloy is larger than that in heat-treated TiAlMn alloy. Owing to the low solution treatment temperature in the β + α + γ phase region, only partial α2/γ lamellar colony dissolves in TiAlMn alloy. The residual part coarsens at high temperatures and remains at ambient temperature [48,49]. The β0,sec also appears at the boundary or in the interior of α2/γ lamellar colony in the heat-treated TNM alloy.

Figure 7.

The SEM-BSE photos of TNM alloy after different aging treatments: (a,b) HT5, (c,d) HT6.

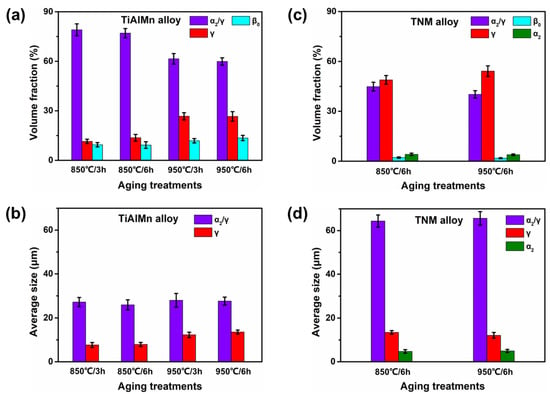

To reveal the morphological characteristics of phases after heat treatments, at least ten SEM pictures for each condition were statistically analyzed. Since the β0 phase with irregular shape displays a netlike distribution along the boundary of α2/γ lamellar colony and γ grain, only the quantitative statistics of volume fraction were conducted. Figure 8 shows the volume fraction and average size of the phases in the TiAlMn alloy and TNM alloy after different aging treatments. As shown in Figure 8, the average size of the α2/γ lamellar colony is about 27 μm in the TiAlMn alloy after aging at 850 °C for 3 h. With the increase of aging time at 850 °C, the volume fraction of the α2/γ lamellar colony gradually decreases, while its size almost remains unchanged. As the aging temperature increases from 850 °C to 950 °C, the average size of the α2/γ lamellar colony shows no significant fluctuation, but its volume fraction decreases from ~80% to ~60%. The higher temperature is favorable to the α2/γ → β0 reaction, which leads to the more dissolution of partial α2/γ lamellar. However, this reaction occurred in the interior or at the boundary of the α2/γ lamellar colony, which has little influence on the size of α2/γ lamellar colony [50]. The morphology of γ is sensitive to the parameters of heat treatments. The volume fraction of the γ phase increases from 8.8% to 13.7% with the aging time increasing from 3 h to 6 h at 850 °C. As the aging temperature increases from 850 °C to 950 °C, the γ phase coarsens gradually and its average size and volume fraction increase from 8 μm and 13.7% to 13 μm and 26.0% after aging for 6 h. The temperature has a great effect on the volume fraction and morphology of β0. When the aging temperature increases from 850 °C to 950 °C, the proportion of the β0 phase increases from 9.3% to 13.5% after aging for 6 h. This is related to the α2/γ → β0 reaction in the α2/γ lamellar colony, and the volume fraction of β0 increases as the reaction proceeds.

Figure 8.

The statistical results of volume fraction and average size of the phases in the TiAlMn alloy and TNM alloy after different aging treatments: (a,c) volume fraction of phases, (b,d) average size of phases.

The average size of the α2/γ lamellar colony is about 64 μm in the TNM alloy after aging at 850 °C for 6 h. The temperature has little effect on the size of the α2/γ lamellar colony. However, the volume fraction of α2/γ lamellar colony is reduced from 44.8% to 40.2% with aging temperature increasing from 850 °C to 950 °C. The reason for the variation of α2/γ lamellar colony in the TNM alloy is similar to that in the TiAlMn alloy after aging treatments at different temperatures. The proportion of γ phase increases with increasing the aging temperature. The average size of globular α2 shows little change and its volume fraction decreases slightly with increasing the aging temperature. At higher temperatures, the residual α2 is transformed into the α2/γ lamellar.

3.4. Mechanical Properties of Heat-Treated Alloys

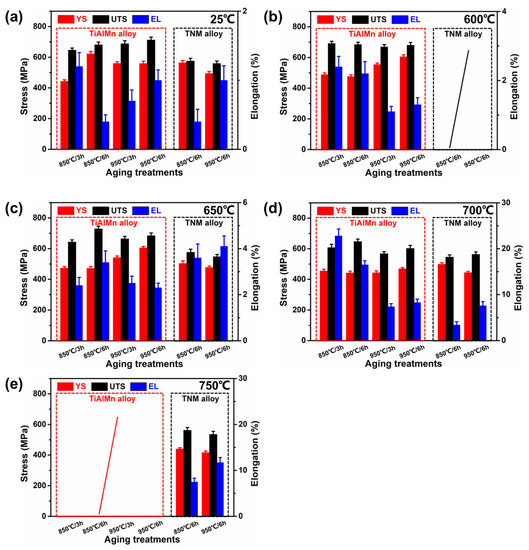

Since the brittle-to-ductile transition temperatures of the as-forged TiAlMn alloy and TNM alloy are about 650 °C–700 °C and 700 °C–750 °C, the tensile tests of heat-treated TiAlMn alloy were performed at 25 °C, 600 °C, 650 °C, and 700 °C at first, while that of the heat-treated TNM alloy were performed at 25 °C, 650 °C, 700 °C, and 750 °C. Figure 9 shows the typical tensile properties of the heat-treated TiAlMn alloy and TNM alloy as a function of the testing temperature. The results are summarized in Table 4. It turns out that the YS of heat-treated TiAlMn alloy increases at first and then decreases, but the EL increases throughout. In comparison with the TiAlMn alloy aged at 850 °C, the TiAlMn alloy aged at 950 °C exhibits superior yield strength above 600 °C. This is the result of the larger volume fraction of β0 phase in the TiAlMn alloy aged at 950 °C. In addition, the more precipitation of the β0,sec phase at the boundary of α2/γ lamellar, which can pin the grain boundary at high temperature [20,51]. Furthermore, the UTS and YS of TiAlMn alloys increase with prolonging the aging time at 950 °C, which is attributed to the increased volume fraction of the β0 and β0,sec phases. After 1280 °C/30 min/AC + 950 °C/6 h/FC heat treatment, the TiAlMn alloy exhibits the optimal tensile properties at elevated temperatures. Although, the YS, and EL of this alloy at room temperature are only 559 MPa and 1.0%, respectively. However, its YS and EL increase to 605 MPa and 2.3% when the testing temperature rises to 650 °C. The anomalous yield behavior is closely related to the cross slip between 1/2 screw dislocation and [101] superdislocation in the γ phase. Since the cross slip is a thermal activation process, it increases exponentially with the increase of temperature. The reduction of the distance between the pinning points strengthens the pinning effect on dislocation [52,53]. Moreover, for the intermetallic compounds with B2 structure, the dislocation mobility is intensified with the increase of temperature, and the pinning effect of immobile thermally activated vacancies on dislocations is enhanced gradually [54]. The yield strength of the β0 phase increases with the increase of testing temperature. As a result, the YS of heat-treated TiAlMn alloy at 650 °C is enhanced compared with that at 25 °C.

Figure 9.

The tensile properties of the TiAlMn alloy and TNM alloy after different aging treatments as a function of the testing temperature: (a) 25 °C, (b) 600 °C, (c) 650 °C, (d) 700 °C, (e) 750 °C.

Table 4.

Summary of the tensile properties of the heat-treated TiAlMn alloy and TNM alloy at different temperatures in Figure 9.

There is a general tendency toward a decrease in UTS and YS and an increase in EL with increasing aging temperature in TNM alloy. When the aging temperature increases from 850 °C to 950 °C, the UTS and YS of TNM alloy at ambient temperature decrease from 575 MPa and 564 MPa to 559 MPa and 494 MPa, while the EL increases from 0.4% to 1.0%. Besides, the high-temperature YS of TNM alloy aged at 850 °C is superior to that aged at 950 °C. The α2/γ lamellar colony is one of the main strengthening structures in TiAl alloy, and can especially enhance the elevated temperature strength of TNM alloy [55]. After aging at a higher temperature, the volume fraction of the α2/γ lamellar colony decreases, which is detrimental to the high-temperature mechanical properties. The TNM alloy after aging at 850 °C for 6 h possesses the YS of 498 MPa and the plasticity of 3.4% at 700 °C. In comparison with the as-forged state samples, the TNM alloy aged at 850 °C shows no advantage in aspects of tensile strength at high temperatures. Although the volume fraction of the α2/γ lamellar colony increases after 1230 °C/1 h/AC + 850 °C/6 h/FC heat treatment, the average size of the α2/γ lamellar colony is refined from ~126 μm to ~64 μm. Generally, the microstructure refinement is detrimental to the high-temperature strength due to the grain boundary migration and sliding. Moreover, the α phase is incompletely transformed into the α2/γ lamellar colony. The remaining globular α2 cannot make a sufficient contribution to elevated strength in contrast to the α2/γ lamellar colony. Consequently, the tensile strength of as-forged TNM alloy after heat treatments shows no obvious improvement.

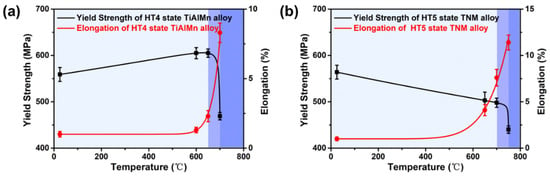

Figure 10 illustrates the tensile properties of heat-treated TiAlMn alloy and TNM alloy as a function of the testing temperature. It can be observed that the yield strength of HT4 state TiAlMn alloy increases gradually with the testing temperature below 650 °C. However, the yield strength drops sharply and the elongation increases significantly between 650 °C and 700 °C, which indicates that the brittle-to-ductile transition temperature of HT4 state TiAlMn alloy is in this temperature range. On the other hand, the yield strength of HT5 state TNM alloy decreases with the increasing testing temperature. Notably, the yield strength drops remarkably and the elongation increases obviously between 700 °C and 750 °C, which suggests that the brittle-to-ductile transition temperature of HT5 state TNM alloy is between 700 °C and 750 °C.

Figure 10.

The optimal tensile properties of the heat-treated TiAlMn alloy and TNM alloy as a function of the testing temperature: (a) HT4 state TiAlMn alloy, (b) HT5 state TNM alloy.

Compared with the as-forged alloys as shown in Figure 5c,d, the brittle-to-ductile transition temperatures of both alloys are almost unchanged after heat treatments. The mechanical properties of TiAl alloys are known to be largely dependent on the microstructures. The plastic γ phase exists in the TiAlMn alloy and TNM alloy before and after heat treatments. When the temperature is higher than the critical temperature, the dislocation locking caused by cross slip is unlocked and the dislocation movement is restarted in the γ phase due to the enhanced thermal activation [56]. Accordingly, the yield strength of TiAlMn alloy decreases remarkably in the temperature range of 650 °C–700 °C. Nevertheless, the solid solution of Nb and Mo elements in the γ phase can block the dislocation movement, which enhances the stability of γ phase in the TNM alloy [57]. In addition, the average size of α2/γ lamellar colony in the TNM alloy is larger than that in TiAlMn alloy as shown in Figure 8, and the lamellar colony with greater size can help improve the high-temperature performances [58]. Therefore, the yield strength of TNM alloy decreases slowly until 700 °C–750 °C, and the softening behavior of TNM alloy is postponed compared with TiAlMn alloy.

3.5. Fracture Surfaces Characterizations

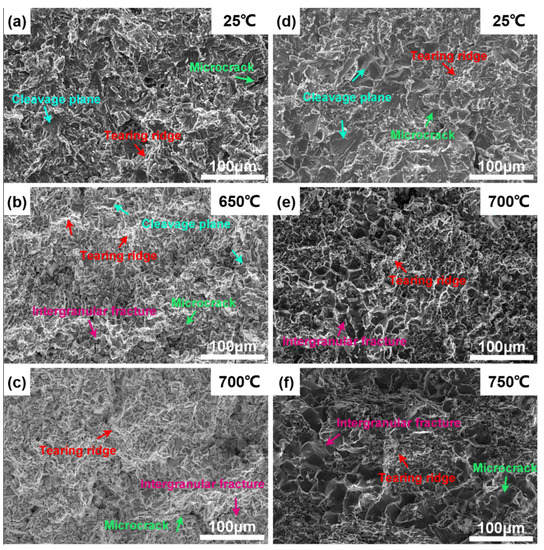

To better understand the failure modes of the HT4 state TiAlMn alloy and HT5 state TNM alloy at ambient and elevated temperatures, the fracture surfaces of tested alloys were examined using SEM. Figure 11 shows the corresponding fracture surfaces of the tensile specimens at different temperatures. The failure of TiAlMn alloy is dominated by the transcrystalline cleavage fracture at ambient temperature. It can be observed that the fracture surface of TiAlMn alloy exhibits many cleavage planes (blue arrow) separated by tearing ridges (red arrow) at 25 °C. The intergranular fracture feature companied with several small cleavage planes and many tearing ridges emerges on the fracture surface at 650 °C. At higher temperatures, more tearing ridges appear on the fracture surfaces especially at 700 °C, which proves the improved ductility. Similarly, a large number of cleavage planes (blue arrow) together with several tearing ridges (red arrow) occur on the fracture surface of TNM alloy at 25 °C, which indicates the brittle fracture. The intercrystalline fracture feature appears on the fracture surface of TNM alloy at 700 °C. The fracture surface of TNM alloy at 750 °C is dominated by the intercrystalline fracture with plenty of tearing ridges. The change of fracture modes suggests that the brittle-to-ductile deformation transition occurred with the increasing testing temperature. These results agree well with the aforementioned results of the mechanical performances.

Figure 11.

SEM micrographs of fracture surfaces on the tensile specimens of the HT4 state TiAlMn alloy and HT5 state TNM alloy: (a–c) The fracture surfaces of HT4 state TiAlMn alloy at different temperatures; (d–f) the fracture surfaces of HT5 state TNM alloy at different temperatures.

4. Conclusions

To further determine the brittle-to-ductile deformation transition temperature, the microstructures and mechanical properties of forged β-solidifying TiAlMn (Ti-42Al-5Mn) alloy and TNM (Ti-43Al-4Nb-1Mo-0.5B) alloy were investigated. The following conclusions can be drawn:

- (1)

- The heat-treated TiAlMn alloy with a nearly fully lamellar microstructure and the heat-treated TiAlMn with a duplex microstructure, are composed of γ/α2 lamellar colony, equiaxed γ phase, and β0 phase. Moreover, the globular α2 phase appears in the TNM alloy.

- (2)

- After 1280 °C/30 min/AC + 950 °C/6 h/FC heat treatment, the yield strength of TiAlMn alloy increases gradually with the testing temperature, then significantly drops from 605 MPa to 469 MPa in the temperature range of 650 °C–700 °C. After 1230 °C/1 h/AC + 850 °C/6 h/FC heat treatment, the yield strength of TNM alloy decreases gradually with the increasing testing temperature, and remarkably drops from 498 MPa to 440 MPa between 700 °C and 750 °C.

- (3)

- A typical brittle fracture is dominating at ambient temperature, then the fracture mode is changed from transcrystalline cleavage to intercrystalline fracture with the increasing testing temperature.

- (4)

- The brittle-to-ductile transition temperature of TiAlMn alloy and TNM alloy are about 650 °C–700 °C and 700 °C–750 °C.

Author Contributions

H.X. and X.S. designed and supervised the project. B.T. and W.S. synthesized the alloy samples and performed testing experiments. X.S. and H.Q. analyzed the data. X.S., P.L. and B.T. wrote this paper. X.S., P.L., H.Q., R.H. and C.F. revised this paper. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (Grant No. 52201125), the Natural Science Foundation of the Jiangsu Higher Education Institutions of China (Grant No. 22KJD430002), the Natural Science Foundation of Jiangsu Province (Grant No. BK20212009 and BK20220961), and the China Postdoctoral Science Foundation (Grant No. 2021M691582).

Data Availability Statement

Data available on request.

Conflicts of Interest

The authors declare no competing interest.

References

- Dimiduk, D.M. Gamma titanium aluminide alloys—An assessment within the competition of aerospace structural materials. Mater. Sci. Eng. A 1999, 263, 281–288. [Google Scholar] [CrossRef]

- Appel, F.; Brossmann, U.; Christoph, U.; Eggert, S.; Paul, J.D.H. Recent progress in the development of gamma titanium aluminide alloys. Adv. Eng. Mater. 2010, 2, 699–720. [Google Scholar] [CrossRef]

- Clemens, H.; Mayer, S. Design, processing, microstructure, properties, and applications of advanced intermetallic TiAl alloys. Adv. Eng. Mater. 2013, 15, 191–215. [Google Scholar] [CrossRef]

- Yamaguchi, M.; Inui, H.; Ito, K. High-temperature structural intermetallics. Acta Mater. 2000, 48, 307–322. [Google Scholar] [CrossRef]

- Chen, G.; Peng, Y.B.; Zheng, G.; Qi, Z.X.; Wang, M.Z.; Yu, H.C.; Dong, C.L.; Liu, C.T. Polysynthetic twinned TiAl single crystals for high temperature applications. Nat. Mater. 2016, 15, 876–881. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.P.; Qi, Z.X.; Zhang, H.T.; Chen, G.; Lu, Y.; Sun, B.A.; Liu, C.T. Microscale mechanical properties of ultra-high-strength polysynthetic TiAl-Ti3Al single crystals. Mater. Sci. Eng. A 2018, 732, 14–20. [Google Scholar] [CrossRef]

- Chen, Y.; Cao, Y.D.; Qi, Z.X.; Chen, G. Increasing high-temperature fatigue resistance of polysynthetic twinned TiAl single crystal by plastic strain delocalization. J. Mater. Sci. Technol. 2021, 93, 53–59. [Google Scholar] [CrossRef]

- Genc, O.; Unal, R. Development of gamma titanium aluminide (γ-TiAl) alloys: A review. J. Alloys Compd. 2022, 929, 167262. [Google Scholar] [CrossRef]

- Szkliniarz, W.; Szkliniarz, A. Fundamentals of manufacturing technologies for aircraft engine parts made of TiAl based alloys. Arch. Metall. Mater. 2016, 61, 1385–1390. [Google Scholar] [CrossRef]

- Szkliniarz, A.; Moskal, G.; Szkliniarz, W.; Swadźba, R. Improvement of oxidation resistance of Ti-47Al-2W-0.5Si alloy modified by aluminizing method. Surf. Coat. Technol. 2015, 277, 270–277. [Google Scholar] [CrossRef]

- Szkliniarz, A. Grain refinement of Ti-48Al-2Cr-2Nb alloy by heat treatment method. Solid State Phenom. 2012, 191, 221–234. [Google Scholar] [CrossRef]

- Szkliniarz, A.; Szkliniarz, W. Microstructure and properties of a new generation of TiAl based alloys. Solid State Phenom. 2015, 229, 125–130. [Google Scholar] [CrossRef]

- Tetsui, T.; Shindo, K.; Satoshi, K.; Kobayashi, S.; Takeyama, M. Fabrication of TiAl components by means of hot forging and machining. Intermetallics 2005, 13, 971–978. [Google Scholar] [CrossRef]

- Imayev, R.M.; Imayev, V.M.; Oehring, M.; Appel, F. Alloy design concepts for refined gamma titanium aluminide based alloys. Intermetallics 2007, 15, 451–460. [Google Scholar] [CrossRef]

- Tetsui, T.; Shindo, K.; Kobayashi, S.; Takeyama, M. A newly developed hot worked TiAl alloy for blades and structural components. Scr. Mater. 2002, 47, 399–403. [Google Scholar] [CrossRef]

- Tetsui, T.; Kobayashi, T.; Harada, H. Achieving high strength and low cost for hot-forged TiAl based alloy containing beta phase. Mater. Sci. Eng. A 2012, 552, 345–352. [Google Scholar] [CrossRef]

- Xu, H.; Li, X.B.; Xing, W.W.; Shu, L.; Ma, Y.C.; Liu, K. Solidification pathway and phase transformation behavior in a beta-solidified gamma-TiAl based alloy. J. Mater. Sci. Technol. 2019, 35, 2652–2657. [Google Scholar] [CrossRef]

- Kastenhuber, M.; Rashkova, B.; Clemens, H.; Mayer, S. Effect of microstructural instability on the creep resistance of an advanced intermetallic γ-TiAl based alloy. Intermetallics 2017, 80, 1–9. [Google Scholar] [CrossRef]

- Huber, D.; Werner, R.; Clemens, H.; Stockinger, M. Influence of process parameter variation during thermo-mechanical processing of an intermetallic β-stabilized γ-TiAl based alloy. Mater. Charact. 2015, 109, 116–121. [Google Scholar] [CrossRef]

- Wang, Y.C.; Xue, X.Y.; Kou, H.C.; Yu, Y.H.; Jia, M.Y.; Li, J.S. The interfacial β0 phase strengthening the creep properties of powder hot isostatic pressing γ-TiAl alloy. Mater. Res. Lett. 2022, 10, 327–333. [Google Scholar] [CrossRef]

- Zhang, S.Z.; Zhao, Y.B.; Zhang, C.J.; Han, J.C.; Sun, M.J.; Xu, M. The microstructure, mechanical properties, and oxidation behavior of beta-gamma TiAl alloy with excellent hot workability. Mater. Sci. Eng. A 2017, 700, 366–373. [Google Scholar] [CrossRef]

- Brotzu, A.; Felli, F.; Marra, F.; Pilone, D.; Pulci, G. Mechanical properties of a TiAl-based alloy at room and high temperatures. Mater. Sci. Technol. 2018, 34, 1847–1853. [Google Scholar] [CrossRef]

- Klein, T.; Usategui, L.; Rashkova, B.; Nó, M.; Juan, J.S.; Clemens, H.; Mayer, S. Mechanical behavior and related microstructural aspects of a nano-lamellar TiAl alloy at elevated temperatures. Acta Mater. 2017, 128, 440–450. [Google Scholar] [CrossRef]

- Nizamoglu, S.; Lang, K.H.; Guth, S.; Heilmaier, M. A new method for determining the brittle-to-ductile transition temperature of a TiAl intermetallic. Metals 2020, 10, 1550. [Google Scholar] [CrossRef]

- Xu, X.; Ding, H.; Huang, H.; Liang, H.; Chen, R.; Guo, J.; Fu, H. Effect of V on the microstructure and brittle-to-ductile transition of directionally solidified high-Nb TiAl alloy. Intermetallics 2022, 142, 107455. [Google Scholar] [CrossRef]

- Guo, Y.; Tian, J.; Xiao, S.; Xu, L.; Chen, Y. Elevated temperature performance and creep behavior of Y2O3 reinforced Ti-48Al-6Nb alloy at the brittle-ductile transition temperature. J. Alloys Compd. 2021, 871, 159497. [Google Scholar] [CrossRef]

- Imayev, V.M.; Ganeev, A.A.; Trofimov, D.M.; Parkhimovich, N.J.; Imayev, R.M. Effect of Nb, Zr and Zr + Hf on the microstructure and mechanical properties of β-solidifying γ-TiAl alloys. Mater. Sci. Eng. A 2021, 817, 141388. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Q.; Ding, H.; Chen, R.; Zeng, L. High-temperature tensile behaviors and microstructural evolutions of a directionally solidified Ti-45Al-5Nb-2Mn alloy. Mater. Sci. Eng. A 2021, 825, 141904. [Google Scholar] [CrossRef]

- Lin, D.; Wang, Y.; Liu, J.; Law, C.C. The effects of temperature, strain rate and minor boron on tensile properties of wrought Ti-47Al-2Mn-2Nb alloy. Intermetallics 2000, 8, 549–558. [Google Scholar] [CrossRef]

- Kim, Y.W.; Kim, S.L. Effects of microstructure and C and Si additions on elevated temperature creep and fatigue of gamma TiAl alloys. Intermetallics 2014, 53, 92–101. [Google Scholar] [CrossRef]

- Tetsui, T.; Harada, H. The influence of oxygen concentration and phase composition on the manufacturability and high-temperature strength of Ti-42Al-5Mn (at%) forged alloy. J. Mater. Process. Technol. 2013, 213, 752–758. [Google Scholar] [CrossRef]

- Schwaighofer, E.; Clemens, H.; Mayer, S.; Lindemann, J.; Klose, J.; Smarsly, W.; Güther, V. Microstructural design and mechanical properties of a cast and heat-treated intermetallic multi-phase TiAl based alloy. Intermetallics 2014, 44, 128–140. [Google Scholar] [CrossRef]

- Burtscher, M.; Klein, T.; Lindemann, J.; Lehmann, O.; Mayer, S. An advanced TiAl alloy for high-performance racing applications. Materials 2020, 13, 4720. [Google Scholar] [CrossRef] [PubMed]

- Wallgram, W.; Schmölzer, T.; Cha, L.; Das, G.; Clemens, H. Technology and mechanical properties of advanced γ-TiAl based alloys. Int. J. Mater. Res. 2009, 100, 1021–1030. [Google Scholar] [CrossRef]

- Ge, G.; Wang, Z.; Liang, S.; Zhang, L. Achievement of forging without canning for β-solidifying γ-TiAl alloy containing high content of niobium. Mater. Manuf. Process. 2021, 36, 1667–1676. [Google Scholar] [CrossRef]

- Appel, F.; Paul, J.D.H.; Oehring, M. Gamma Titanium Aluminide Alloys: Science and Technology, 1st ed.; Wiley-VCH: Weinheim, Germany, 2011; pp. 5–13. [Google Scholar]

- Ye, L.H.; Wang, H.; Zhou, G.; Hu, Q.M.; Yang, R. Phase stability of TiAl-X (X=V, Nb, Ta, Cr, Mo, W, and Mn) alloys. J. Alloys Compd. 2020, 819, 153291. [Google Scholar] [CrossRef]

- Kenel, C.; Leinenbach, C. Influence of Nb and Mo on microstructure formation of rapidly solidified ternary TiAl-(Nb, Mo) alloys. Intermetallics 2016, 69, 82–89. [Google Scholar] [CrossRef]

- Schmoelzer, T.; Liss, K.D.; Zickler, G.A.; Watson, I.J.; Droessler, L.M.; Wallgram, W.; Buslaps, T.; Studer, A.; Clemens, H. Phase fractions, transition and ordering temperatures in TiAl-Nb-Mo alloys: An in- and ex-situ study. Intermetallics 2010, 18, 1544–1552. [Google Scholar] [CrossRef]

- Duan, Z.; Song, X.; Han, Y.; Pei, W.; Chen, H. Enhancing high-temperature strength and ductility of γ-TiAl matrix composites with controllable dual alloy structure. Mater. Sci. Eng. A 2021, 823, 141723. [Google Scholar] [CrossRef]

- Wang, Q.; Zeng, L.; Ding, H.; Chen, R.; Guo, J.; Fu, H. On the high temperature deformation of a directionally solidified γ-TiAl alloy. Mater. Sci. Eng. A 2019, 758, 19–27. [Google Scholar] [CrossRef]

- Ilyas, M.U.; Kabir, M.R. Modelling high temperature deformation of lamellar TiAl crystal using strain-rate enhanced crystal plasticity. Mater. Sci. Eng. A 2020, 788, 139524. [Google Scholar] [CrossRef]

- Wang, L.; Kou, H.; Qiang, F.; Li, J. β0 precipitation in α2 lamellae of the β-solidifying multiple-phase γ-TiAl alloy. Mater. Charact. 2020, 167, 110474. [Google Scholar]

- Klein, T.; Rashkova, B.; Holec, D.; Clemens, H.; Mayer, S. Silicon distribution and silicide precipitation during annealing in an advanced multi-phase γ-TiAl based alloy. Acta Mater. 2016, 110, 236–245. [Google Scholar] [CrossRef]

- Kastenhuber, M.; Rashkova, B.; Clemens, H.; Mayer, S. Enhancement of creep properties and microstructural stability of intermetallic β-solidifying γ-TiAl based alloys. Intermetallics 2015, 63, 19–26. [Google Scholar] [CrossRef]

- Mitao, S.; Bendersky, L.A. Morphology and growth kinetics of discontinuous coarsening in fully lamellar Ti-44 Al (at.%) alloy. Acta Mater. 1997, 45, 4475–4489. [Google Scholar] [CrossRef]

- Guyon, J.; Hazotte, A.; Wagner, F.; Bouzy, E. Recrystallization of coherent nanolamellar structures in Ti48Al2Cr2Nb intermetallic alloy. Acta Mater. 2016, 103, 672–680. [Google Scholar] [CrossRef]

- Xu, H.; Li, X.; Xing, W.; Shu, L.; Ma, Y.; Liu, K. Processing map and hot working mechanism of as-cast Ti-42Al-5Mn alloy. Adv. Eng. Mater. 2018, 20, 1701059. [Google Scholar] [CrossRef]

- Belov, N.A.; Akopyan, T.K.; Belov, V.D.; Gershman, J.S.; Gorshenkov, M.V. The effect of Cr and Zr on the structure and phase composition of TNM gamma titanium aluminide alloy. Intermetallics 2017, 84, 121–129. [Google Scholar] [CrossRef]

- Xu, H.; Li, X.; Xing, W.; Shu, L.; Ma, Y.; Liu, K. Phase transformation behavior of a Mn containing β-solidifying γ-TiAl alloy during continuous cooling. Intermetallics 2018, 99, 51–58. [Google Scholar] [CrossRef]

- Kolb, M.; Wheeler, J.M.; Mathur, H.N.; Neumeier, S.; Korte-Kerzel, S.; Pyczak, F.; Michler, J.; Göken, M. Local mechanical properties of the (β0+ω0) composite in multiphase titanium aluminides studied with nanoindentation at room and high temperatures. Mater. Sci. Eng. A 2016, 665, 135–140. [Google Scholar] [CrossRef]

- Jiao, Z.; Whang, S.H.; Yoo, M.H.; Feng, Q. Stability of ordinary dislocations on cross-slip planes in γ-TiAl. Mater. Sci. Eng. A 2002, 329, 171–176. [Google Scholar] [CrossRef]

- Jiao, Z.; Whang, S.H.; Wang, Z. Stability and cross-slip of [101] superdislocations in γ-TiAl. Intermetallics 2001, 9, 891–898. [Google Scholar] [CrossRef]

- Whang, S.H.; Feng, Q.; Wang, Z.M. Deformation characteristics and dislocation structures in single phase gamma titanium aluminides. Intermetallics 2000, 8, 531–537. [Google Scholar] [CrossRef]

- Zhang, S.; Tian, N.; Li, D.; Li, J.; Jin, F.; Wang, G.; Tian, S. Microstructure evolution and fracture mechanism of a TiAl-Nb alloy during high-temperature tensile testing. Mater. Sci. Eng. A 2022, 831, 142094. [Google Scholar] [CrossRef]

- Wu, D.; Hu, G.; Inui, H.; Yamaguchi, M. Deformation behavior of γ-TiAl single crystals at different temperatures. Acta Metall. Sin. 1998, 34, 39–44. [Google Scholar]

- Jiang, Z.H.; Li, N.; Zhao, C.Z.; Zhang, H.X.; Li, Z.M. Effect of Cr/Mo on microstructure and mechanical properties of Ti-Al-Nb alloy. Mater. Sci. Forum 2018, 936, 178–186. [Google Scholar] [CrossRef]

- Soyama, J.; Limberg, W.; Ebel, T.; Pyczak, F. Sintering and creep resistance of powder metallurgy processed Ti-(43-47)Al-5Nb-0.2B-0.2C. Adv. Eng. Mater. 2020, 22, 2000377. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).