Effects of Scanning Strategy on the Microstructure and Mechanical Properties of Sc-Zr-Modified Al–Mg Alloy Manufactured by Laser Powder Bed Fusion

Abstract

1. Introduction

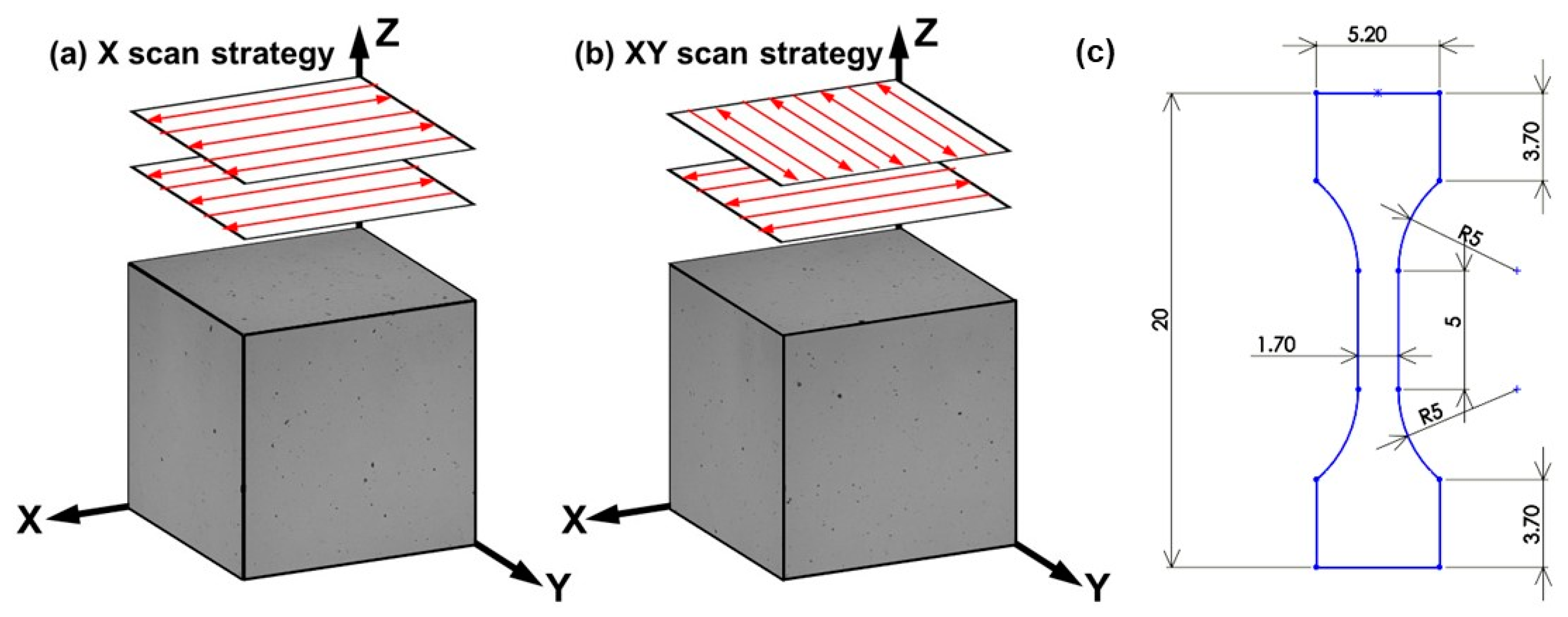

2. Materials and Methods

2.1. Scalmalloy Fabrication via LPBF

2.2. Microstructure Characterization and the Evolution of Mechanical Properties

2.3. Statistical Analysis

3. Results

4. Discussion

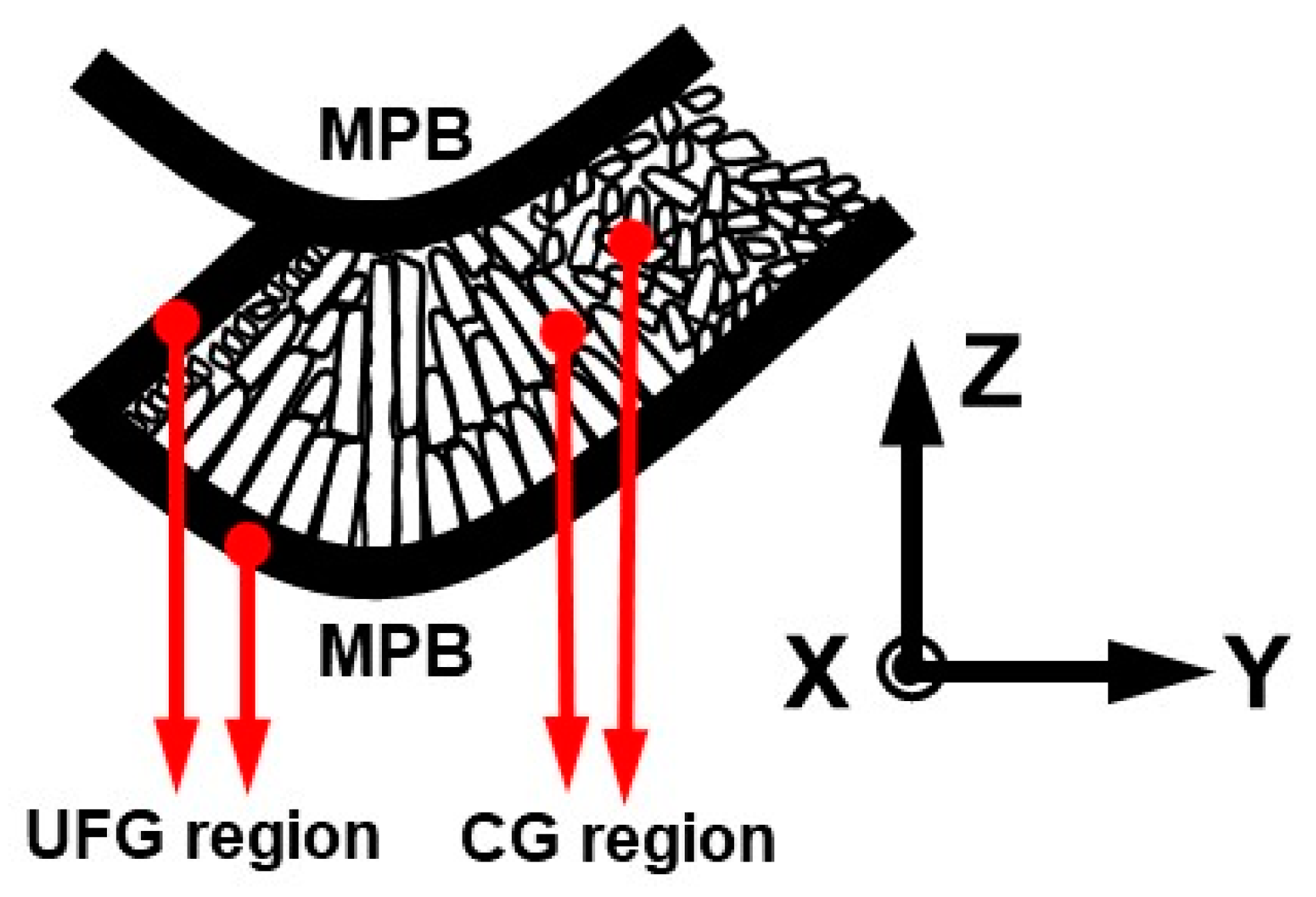

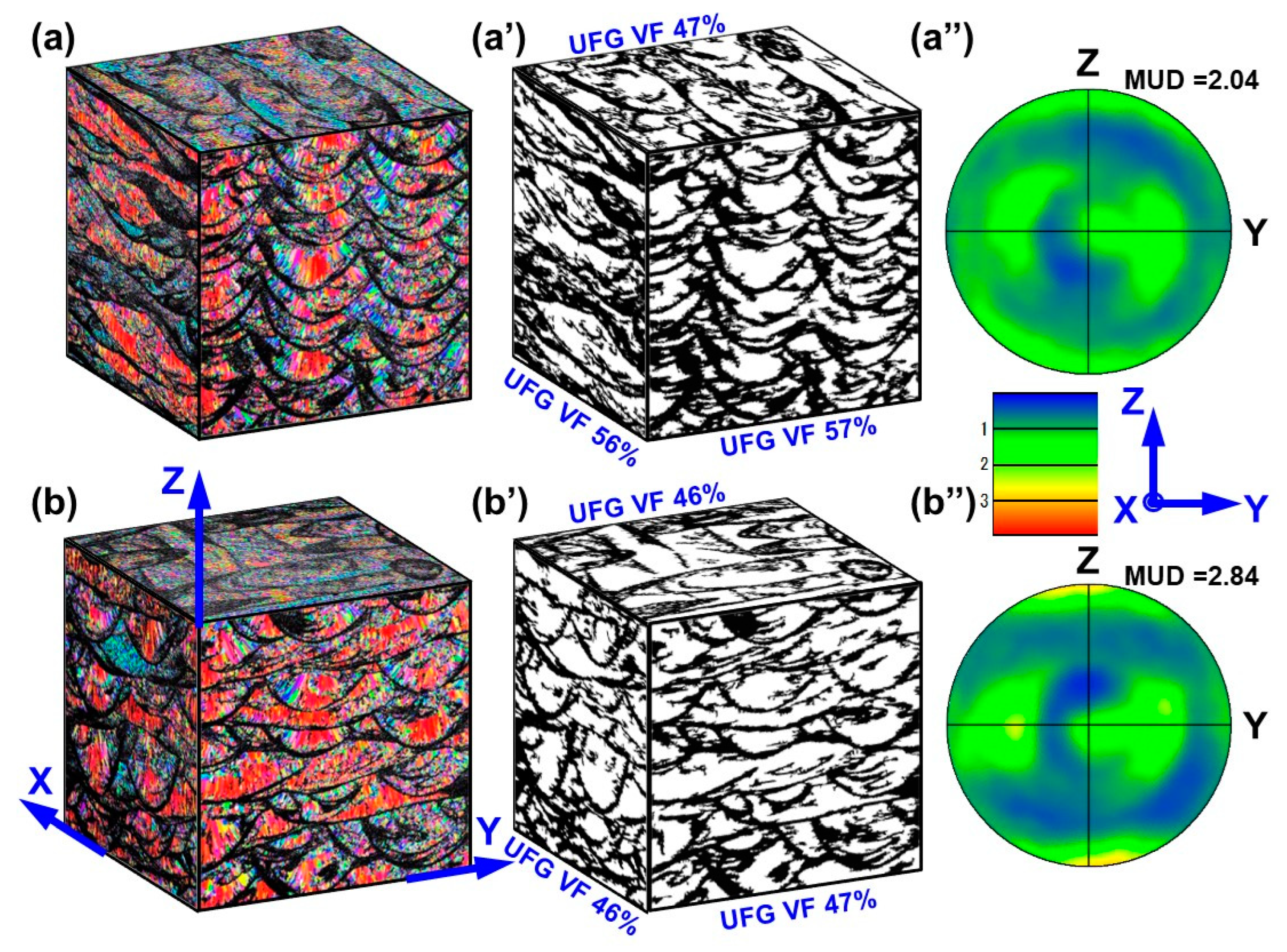

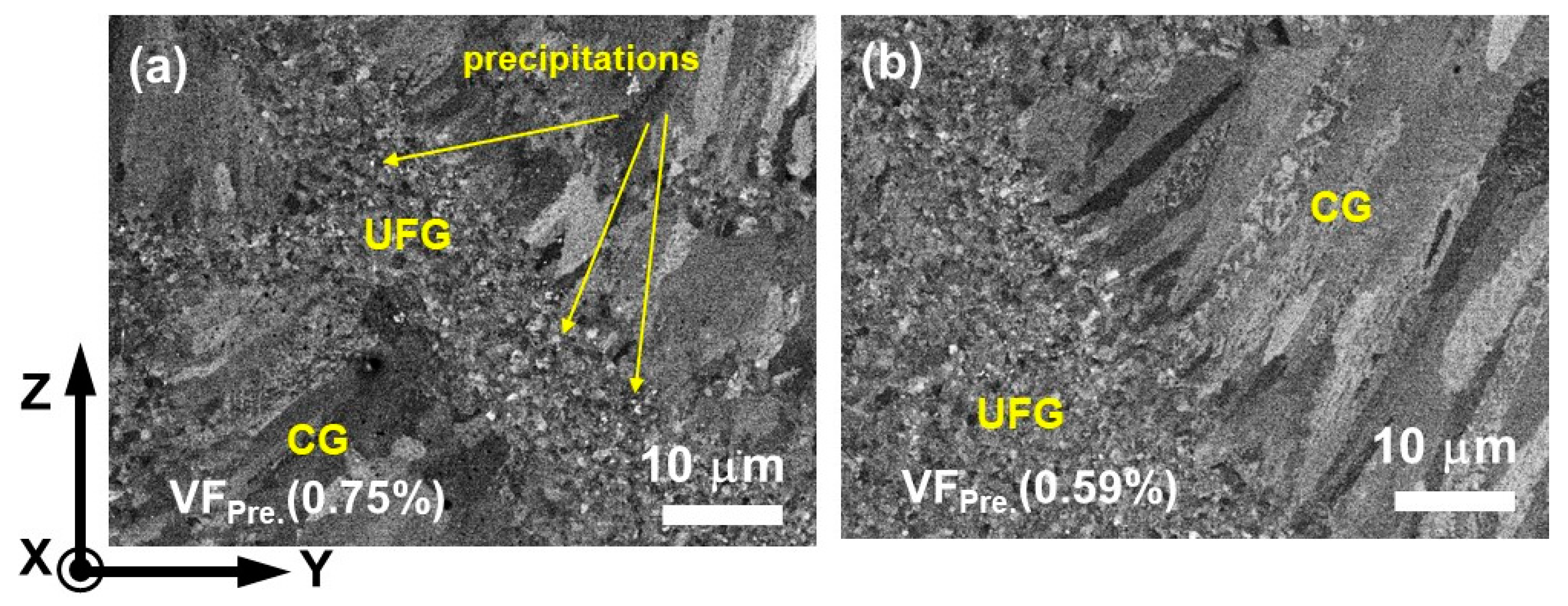

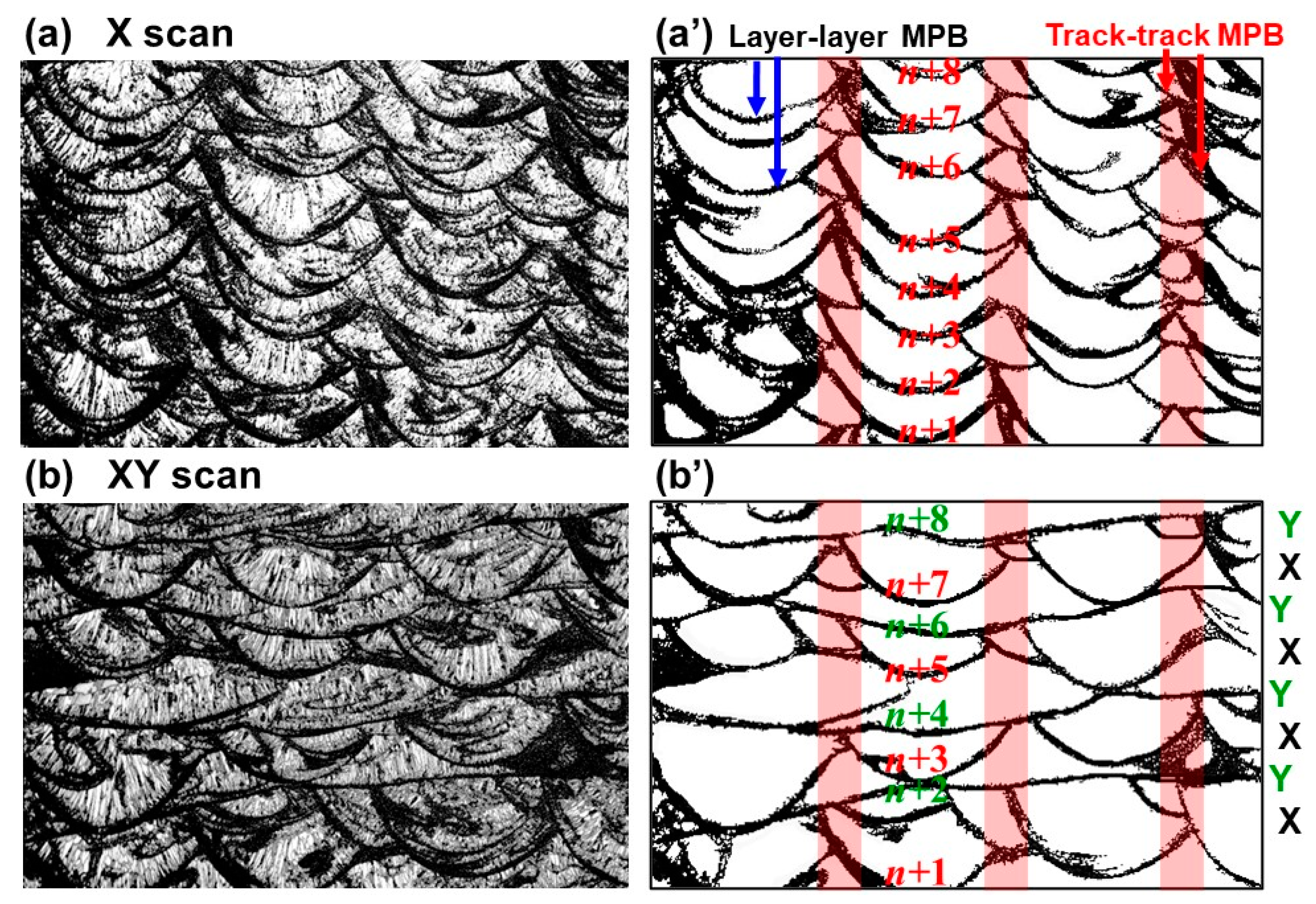

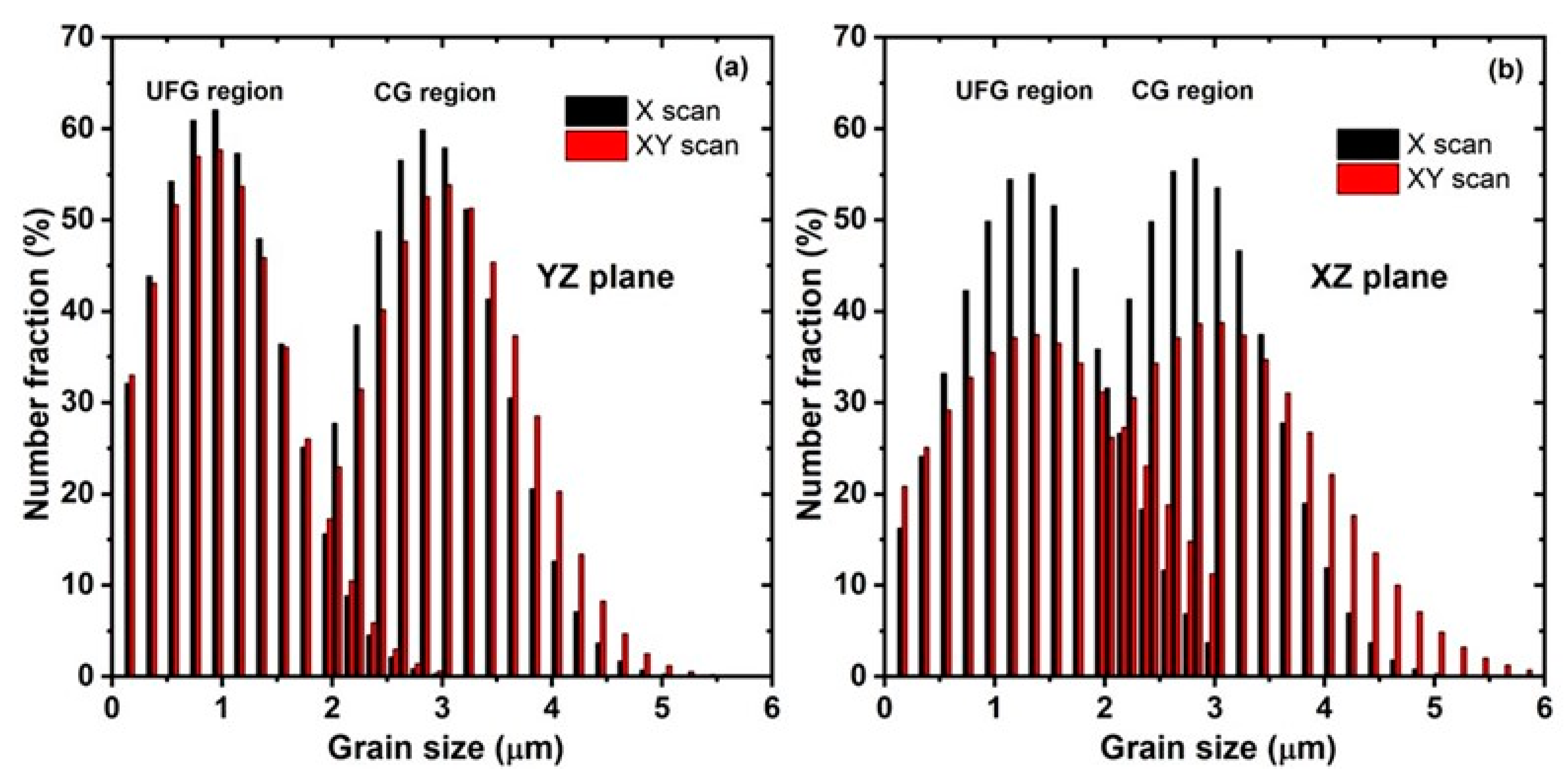

4.1. Effect of Scan Strategy on the Microstructure

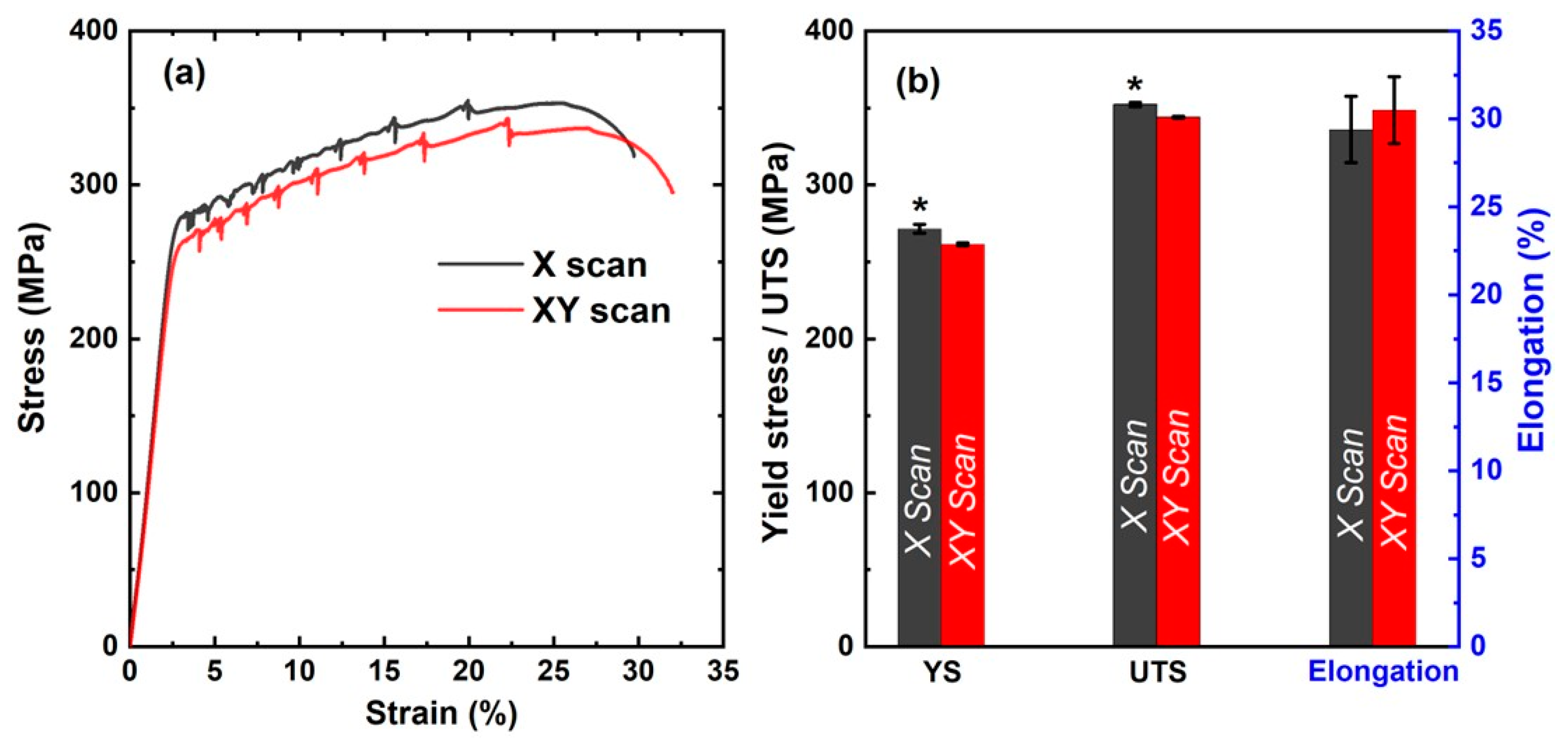

4.2. Effect of Scan Strategy on the Mechanical Properties

5. Conclusions

- (1)

- For the as-built Scalmalloy samples, a relative density of >99.5% was achieved by employing X- and XY-scan strategies and processing with laser parameters of d = 0.1 mm, P = 360 W, v = 1200 mm/s, and h = 0.06 mm.

- (2)

- Detailed microstructural analyses revealed that the scan strategy significantly affected the microstructure and increased the VFs of UFGs and precipitates, which were greater for the X-scan strategy than for the XY-scan strategy owing to a higher amount of MPBs in the case of X-scan.

- (3)

- Consequently, the tensile strength of the X-scan specimen was higher than that of the XY-scan specimen. The maximum YS (271.5 ± 2.7 MPa) was obtained for the X-scan strategy, which was approximately two times higher than that obtained for casting.

- (4)

- Significant grain growth and differences in the precipitation behavior between the X- and XY-scan strategies were not observed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rometsch, P.; Jia, Q.; Yang, K.V.; Wu, X. Aluminum alloys for selective laser melting–towards improved performance. Addit. Manuf. Aerosp. Ind. 2019, 301–325. [Google Scholar] [CrossRef]

- Vora, P.; Mumtaz, K.; Todd, I.; Hopkinson, N. AlSi12 in-situ alloy formation and residual stress reduction using anchorless selective laser melting. Addit. Manuf. 2015, 7, 12–19. [Google Scholar] [CrossRef]

- Li, X.; Wang, X.; Saunders, M.; Suvorova, A.; Zhang, L.; Liu, Y.; Fang, M.; Huang, Z.; Sercombe, T. A selective laser melting and solution heat treatment refined Al–12Si alloy with a controllable ultrafine eutectic microstructure and 25% tensile ductility. Acta Mater. 2015, 95, 74–82. [Google Scholar] [CrossRef]

- Kimura, T.; Nakamoto, T. Microstructures and mechanical properties of A356 (AlSi7Mg0.3) aluminum alloy fabricated by selective laser melting. Mater. Des. 2016, 89, 1294–1301. [Google Scholar] [CrossRef]

- Rao, J.H.; Zhang, Y.; Zhang, K.; Wu, X.; Huang, A. Selective laser melted Al-7Si-0.6Mg alloy with in-situ precipitation via platform heating for residual strain removal. Mater. Des. 2019, 182, 108005. [Google Scholar] [CrossRef]

- Thijs, L.; Kempen, K.; Kruth, J.-P.; Van Humbeeck, J. Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powder. Acta Mater. 2013, 61, 1809–1819. [Google Scholar] [CrossRef]

- Spierings, A.; Dawson, K.; Dumitraschkewitz, P.; Pogatscher, S.; Wegener, K. Microstructure characterization of SLM-processed Al-Mg-Sc-Zr alloy in the heat treated and HIPed condition. Addit. Manuf. 2018, 20, 173–181. [Google Scholar] [CrossRef]

- Spierings, A.B.; Dawson, K.; Heeling, T.; Uggowitzer, P.J.; Schäublin, R.; Palm, F.; Wegener, K. Microstructural features of Sc- and Zr-modified Al-Mg alloys processed by selective laser melting. Mater. Des. 2017, 115, 52–63. [Google Scholar] [CrossRef]

- Spierings, A.; Dawson, K.; Kern, K.; Palm, F.; Wegener, K. SLM-processed Sc- and Zr- modified Al-Mg alloy: Mechanical properties and microstructural effects of heat treatment. Mater. Sci. Eng. A 2017, 701, 264–273. [Google Scholar] [CrossRef]

- Spierings, A.B.; Dawson, K.; Uggowitzer, P.J.; Wegener, K. Influence of SLM scan-speed on microstructure, precipitation of Al3Sc particles and mechanical properties in Sc- and Zr-modified Al-Mg alloys. Mater. Des. 2018, 140, 134–143. [Google Scholar] [CrossRef]

- Schneller, W.; Leitner, M.; Pomberger, S.; Grün, F.; Leuders, S.; Pfeifer, T.; Jantschner, O. Fatigue strength assessment of additively manufactured metallic structures considering bulk and surface layer characteristics. Addit. Manuf. 2021, 40, 101930. [Google Scholar] [CrossRef]

- Schneller, W.; Leitner, M.; Leuders, S.; Sprauel, J.; Grün, F.; Pfeifer, T.; Jantschner, O. Fatigue strength estimation methodology of additively manufactured metallic bulk material. Addit. Manuf. 2020, 39, 101688. [Google Scholar] [CrossRef]

- Ekubaru, Y.; Gokcekaya, O.; Ishimoto, T.; Sato, K.; Manabe, K.; Wang, P.; Nakano, T. Excellent strength–ductility balance of Sc-Zr-modified Al–Mg alloy by tuning bimodal microstructure via hatch spacing in laser powder bed fusion. Mater. Des. 2022, 221. [Google Scholar] [CrossRef]

- Fuller, C.B.; Seidman, D.N.; Dunand, D.C. Mechanical properties of Al(Sc,Zr) alloys at ambient and elevated temperatures. Acta Mater. 2003, 51, 4803–4814. [Google Scholar] [CrossRef]

- Kendig, K.L.; Miracle, D.B. Strengthening mechanisms of an Al-Mg-Sc-Zr alloy. Acta Mater. 2002, 50, 4165–4175. [Google Scholar] [CrossRef]

- Li, R.; Wang, M.; Li, Z.; Cao, P.; Yuan, T.; Zhu, H. Developing a high-strength Al-Mg-Si-Sc-Zr alloy for selective laser melting: Crack-inhibiting and multiple strengthening mechanisms. Acta Mater. 2020, 193, 83–98. [Google Scholar] [CrossRef]

- Zhao, J.; Luo, L.; Xue, X.; Liu, T.; Luo, L.; Wang, B.; Wang, Y.; Wang, L.; Su, Y.; Guo, J.; et al. The evolution and characterizations of Al3(ScxZr1-x) phase in Al–Mg-based alloys proceeded by SLM. Mater. Sci. Eng. A 2021, 824, 141863. [Google Scholar] [CrossRef]

- Wang, Z.; Lin, X.; Kang, N.; Hu, Y.; Chen, J.; Huang, W. Strength-ductility synergy of selective laser melted Al-Mg-Sc-Zr alloy with a heterogeneous grain structure. Addit. Manuf. 2020, 34, 101260. [Google Scholar] [CrossRef]

- Li, R.; Chen, H.; Zhu, H.; Wang, M.; Chen, C.; Yuan, T. Effect of aging treatment on the microstructure and mechanical properties of Al-3.02Mg-0.2Sc-0.1Zr alloy printed by selective laser melting. Mater. Des. 2019, 168, 107668. [Google Scholar] [CrossRef]

- Yang, K.V.; Shi, Y.; Palm, F.; Wu, X.; Rometsch, P. Columnar to equiaxed transition in Al-Mg(-Sc)-Zr alloys produced by selective laser melting. Scr. Mater. 2018, 145, 113–117. [Google Scholar] [CrossRef]

- Gokcekaya, O.; Hayashi, N.; Ishimoto, T.; Ueda, K.; Narushima, T.; Nakano, T. Crystallographic orientation control of pure chromium via laser powder bed fusion and improved high temperature oxidation resistance. Addit. Manuf. 2020, 36, 101624. [Google Scholar] [CrossRef]

- Gokcekaya, O.; Ishimoto, T.; Hibino, S.; Yasutomi, J.; Narushima, T.; Nakano, T. Unique crystallographic texture formation in Inconel 718 by laser powder bed fusion and its effect on mechanical anisotropy. Acta Mater. 2021, 212, 116876. [Google Scholar] [CrossRef]

- Gokcekaya, O.; Ishimoto, T.; Todo, T.; Suganuma, R.; Fukushima, R.; Narushima, T.; Nakano, T. Effect of Scan Length on Densification and Crystallographic Texture Formation of Pure Chromium Fabricated by Laser Powder Bed Fusion. Crystals 2020, 11, 9. [Google Scholar] [CrossRef]

- Ishimoto, T.; Hagihara, K.; Hisamoto, K.; Sun, S.-H.; Nakano, T. Crystallographic texture control of beta-type Ti–15Mo–5Zr–3Al alloy by selective laser melting for the development of novel implants with a biocompatible low Young’s modulus. Scr. Mater. 2017, 132, 34–38. [Google Scholar] [CrossRef]

- Todo, T.; Ishimoto, T.; Gokcekaya, O.; Oh, J.; Nakano, T. Single crystalline-like crystallographic texture formation of pure tungsten through laser powder bed fusion. Scr. Mater. 2022, 206, 114252. [Google Scholar] [CrossRef]

- Hagihara, K.; Nakano, T. Control of Anisotropic Crystallographic Texture in Powder Bed Fusion Additive Manufacturing of Metals and Ceramics—A Review. JOM 2021, 74, 1760–1773. [Google Scholar] [CrossRef]

- Gokcekaya, O.; Ishimoto, T.; Todo, T.; Wang, P.; Nakano, T. Influence of powder characteristics on densification via crystallographic texture formation: Pure tungsten prepared by laser powder bed fusion. Addit. Manuf. Lett. 2021, 1, 100016. [Google Scholar] [CrossRef]

- Wilson-Heid, A.E.; Novak, T.C.; Beese, A.M. Characterization of the Effects of Internal Pores on Tensile Properties of Additively Manufactured Austenitic Stainless Steel 316L. Exp. Mech. 2018, 59, 793–804. [Google Scholar] [CrossRef]

- Moussaoui, K.; Rubio, W.; Mousseigne, M.; Sultan, T.; Rezai, F. Effects of Selective Laser Melting additive manufacturing parameters of Inconel 718 on porosity, microstructure and mechanical properties. Mater. Sci. Eng. A 2018, 735, 182–190. [Google Scholar] [CrossRef]

- Fadida, R.; Shirizly, A.; Rittel, D. Dynamic Tensile Response of Additively Manufactured Ti6Al4V with Embedded Spherical Pores. J. Appl. Mech. 2018, 85. [Google Scholar] [CrossRef]

- Spierings, A.B.; Dawson, K.; Voegtlin, M.; Palm, F.; Uggowitzer, P.J. Microstructure and mechanical properties of as-processed scandium-modified aluminium using selective laser melting. CIRP Ann. 2016, 65, 213–216. [Google Scholar] [CrossRef]

- Shi, Y.; Rometsch, P.; Yang, K.; Palm, F.; Wu, X. Characterisation of a novel Sc and Zr modified Al–Mg alloy fabricated by selective laser melting. Mater. Lett. 2017, 196, 347–350. [Google Scholar] [CrossRef]

- Wang, M.; Li, R.; Yuan, T.; Chen, C.; Zhou, L.; Chen, H.; Zhang, M.; Xie, S. Microstructures and mechanical property of AlMgScZrMn-A comparison between selective laser melting, spark plasma sintering and cast. Mater. Sci. Eng. A 2019, 756, 354–364. [Google Scholar] [CrossRef]

- Zhu, Z.; Ng, F.L.; Seet, H.L.; Lu, W.; Liebscher, C.H.; Rao, Z.; Raabe, D.; Nai, S.M.L. Superior mechanical properties of a selective-laser-melted AlZnMgCuScZr alloy enabled by a tunable hierarchical microstructure and dual-nanoprecipitation. Mater. Today 2021, 52, 90–101. [Google Scholar] [CrossRef]

- Schmidtke, K.; Palm, F.; Hawkins, A.; Emmelmann, C. Process and Mechanical Properties: Applicability of a Scandium modified Al-alloy for Laser Additive Manufacturing. Phys. Procedia 2011, 12, 369–374. [Google Scholar] [CrossRef]

| Powder | Al | Mg | Sc | Zr | Mn | Fe | Si | Ti |

|---|---|---|---|---|---|---|---|---|

| SCALMA40B5 | Bal. | 4.8 | 0.74 | 0.29 | 0.57 | 0.10 | 0.04 | 0.02 |

| Scan Strategy | d | P | v | E | YS | UTS | Elongation |

|---|---|---|---|---|---|---|---|

| (mm) | (W) | (mm/s) | (J/mm3) | (MPa) | (MPa) | (%) | |

| X-scan | 0.1 | 360 | 1200 | 50 | 271.5 ± 2.7 * | 352.2 ± 1.4 * | 29.4 ± 1.9 |

| XY-scan | 0.1 | 360 | 1200 | 50 | 261.3 ± 1.0 | 343.8 ± 0.6 | 30.5 ± 1.9 |

| Casting [33] | 131 ± 2 | 188 ± 2 | 3.7 ± 0.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ekubaru, Y.; Gokcekaya, O.; Nakano, T. Effects of Scanning Strategy on the Microstructure and Mechanical Properties of Sc-Zr-Modified Al–Mg Alloy Manufactured by Laser Powder Bed Fusion. Crystals 2022, 12, 1348. https://doi.org/10.3390/cryst12101348

Ekubaru Y, Gokcekaya O, Nakano T. Effects of Scanning Strategy on the Microstructure and Mechanical Properties of Sc-Zr-Modified Al–Mg Alloy Manufactured by Laser Powder Bed Fusion. Crystals. 2022; 12(10):1348. https://doi.org/10.3390/cryst12101348

Chicago/Turabian StyleEkubaru, Yusufu, Ozkan Gokcekaya, and Takayoshi Nakano. 2022. "Effects of Scanning Strategy on the Microstructure and Mechanical Properties of Sc-Zr-Modified Al–Mg Alloy Manufactured by Laser Powder Bed Fusion" Crystals 12, no. 10: 1348. https://doi.org/10.3390/cryst12101348

APA StyleEkubaru, Y., Gokcekaya, O., & Nakano, T. (2022). Effects of Scanning Strategy on the Microstructure and Mechanical Properties of Sc-Zr-Modified Al–Mg Alloy Manufactured by Laser Powder Bed Fusion. Crystals, 12(10), 1348. https://doi.org/10.3390/cryst12101348