Recent Developments on Relaxor-PbTiO3 Ferroelectric Crystals

Abstract

1. Introduction

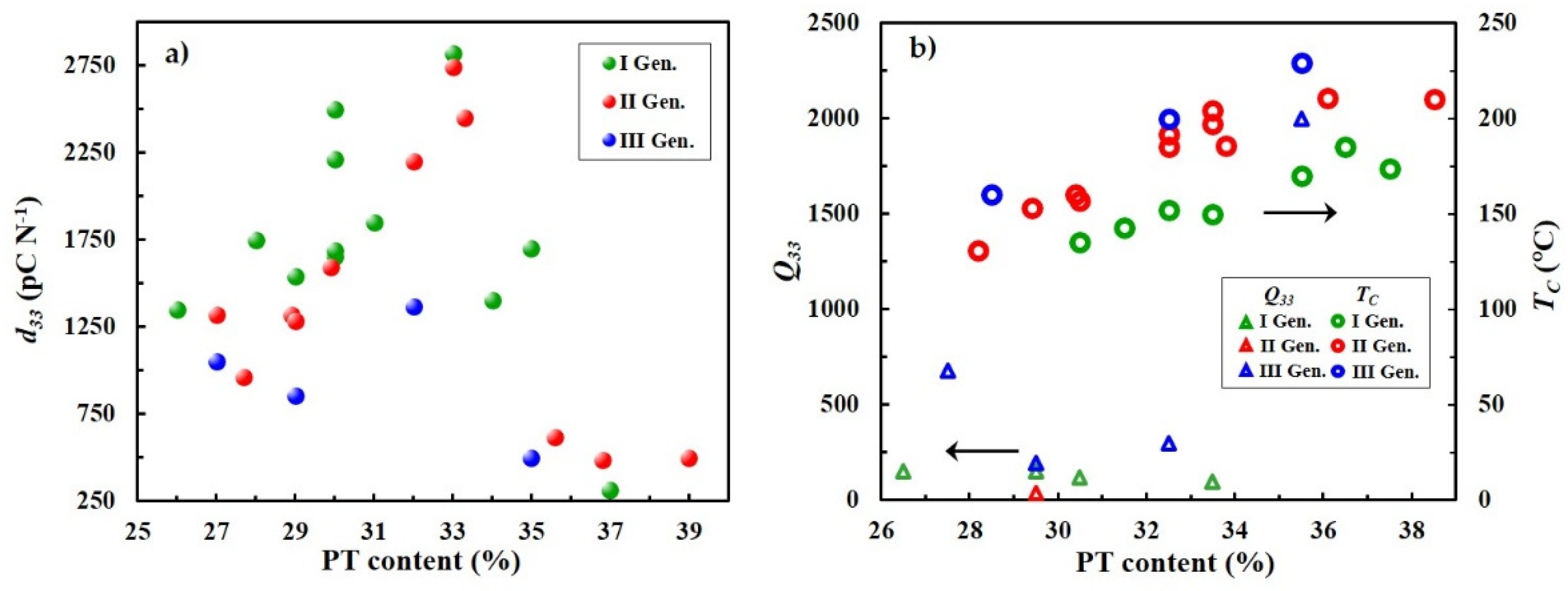

2. Single Crystal Growth

2.1. The Modified Bridgman Method

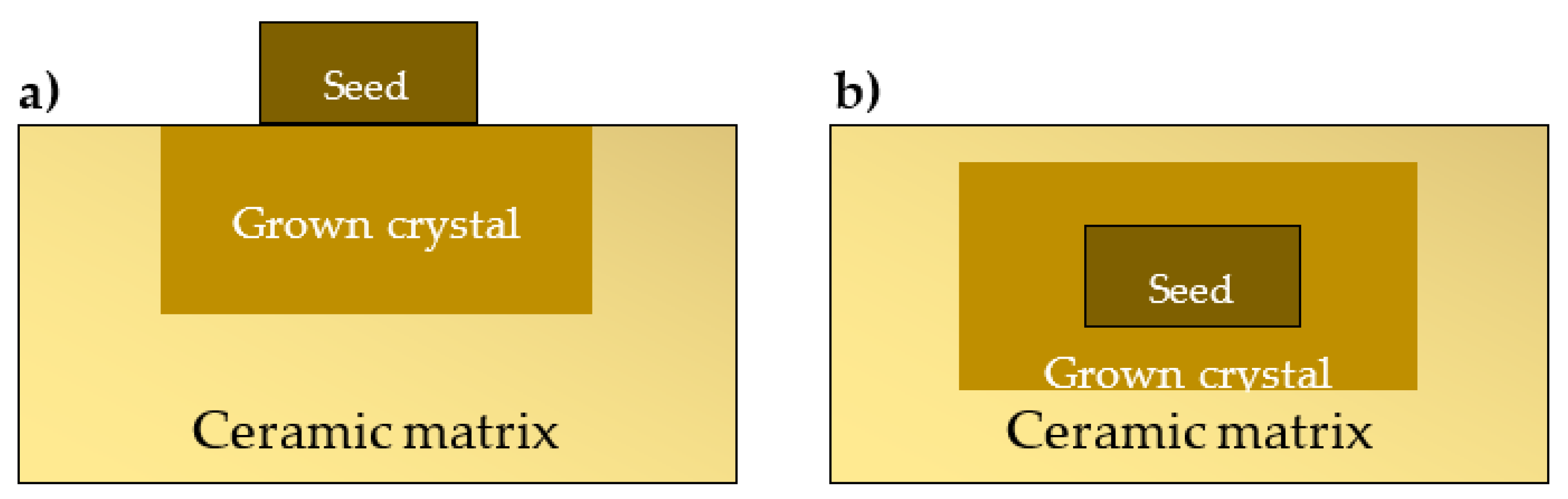

2.2. Solid-State Conversion Growth Method

3. Property Improvements

3.1. Poling Strategy

3.1.1. DCP

Threshold DC Field and Over-Poling Effect

High-Temperature DCP

3.1.2. ACP

3.1.2.1. Increase of Piezoelectricity

3.1.2.2. Improvement of Transparency

3.2. Doping Strategy

3.2.1. Hard Piezoelectric Single Crystals

3.2.2. Soft Piezoelectric Single Crystals

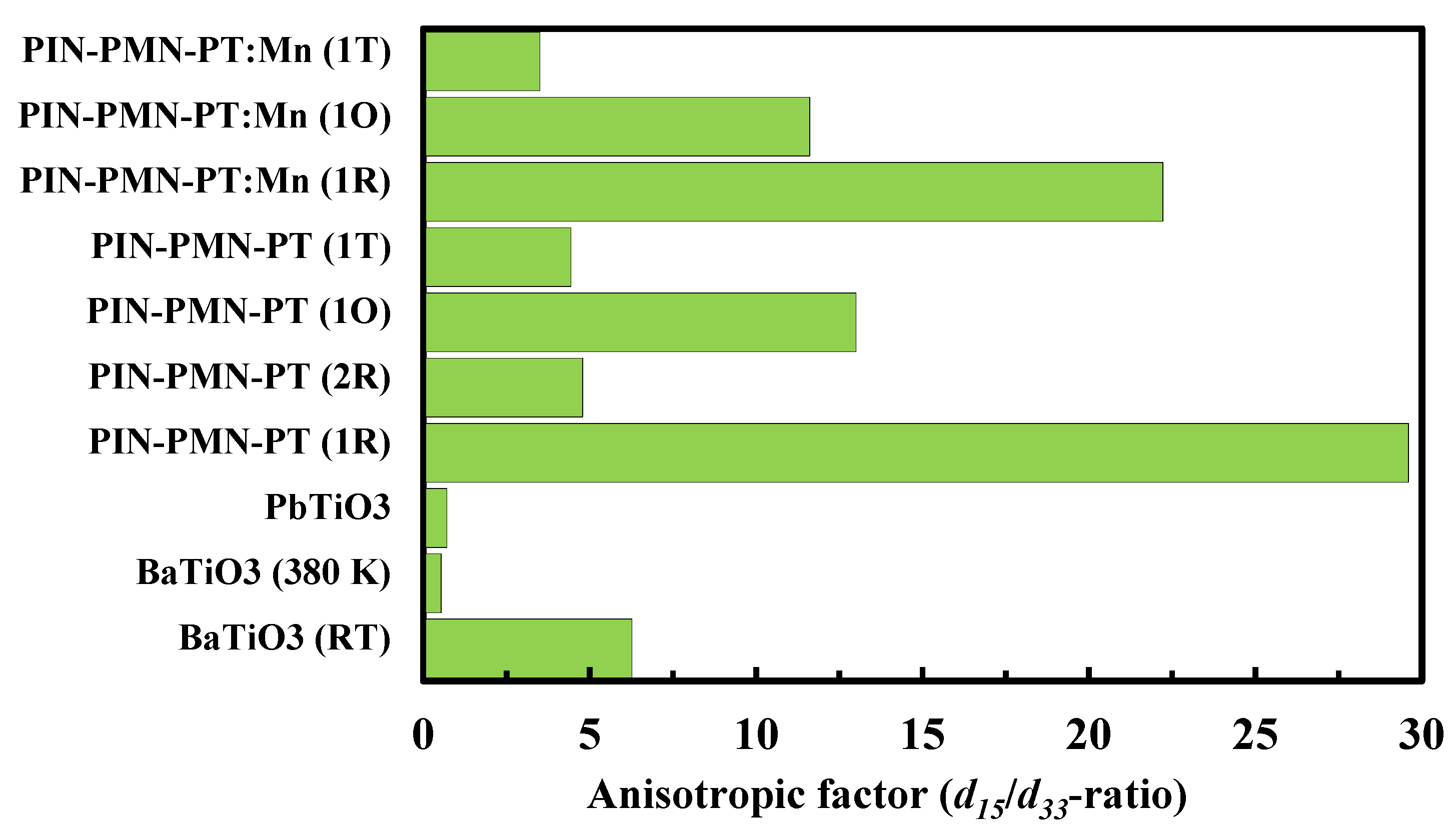

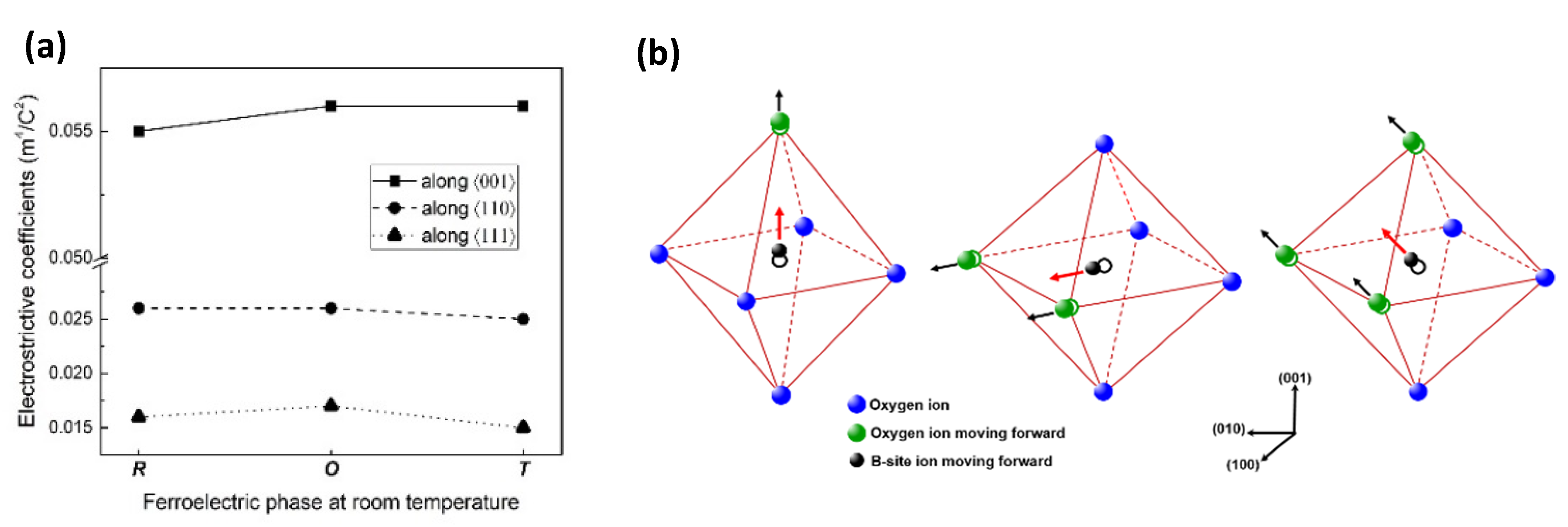

4. Anisotropic Features

5. Application Perspectives

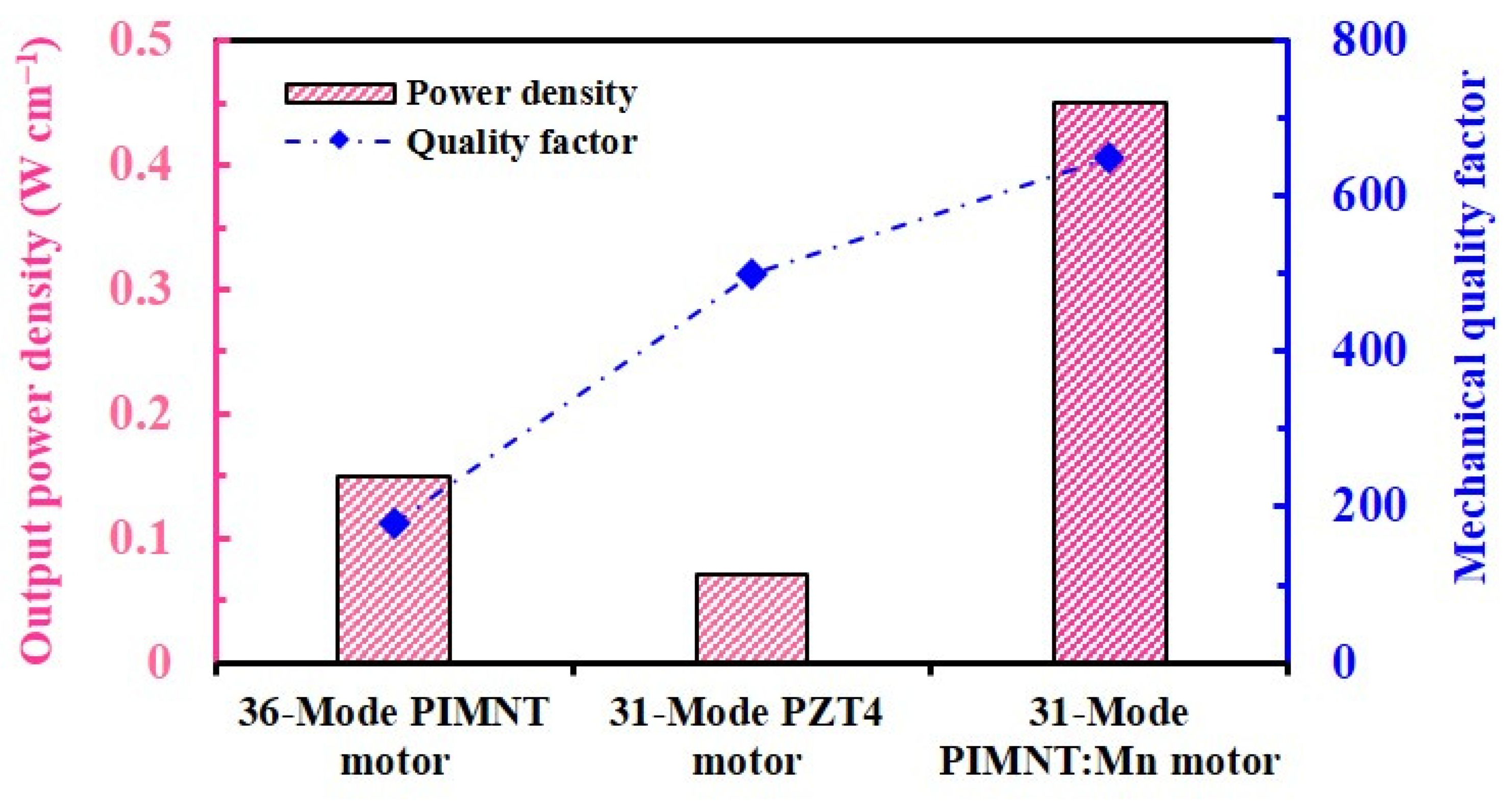

5.1. Doping Advantage

5.2. Poling Advantage

5.3. Anisotropic Advantage

6. Summary

7. Prospectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, S.; Li, F. High performance ferroelectric relaxor-PbTiO3 single crystals: Status and perspective. J. Appl. Phys. 2012, 111, 031301. [Google Scholar] [CrossRef]

- Zhang, S.; Li, F.; Jiang, X.; Kim, J.; Luo, J.; Geng, X. Advantages and challenges of relaxor-PbTiO3 ferroelectric crystals for electroacoustic transducers—A review. Prog. Mater. Sci. 2015, 68, 1–66. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Li, F.; Yu, F.; Jiang, X.; Lee, H.Y.; Luo, J.; Shrout, T.R. Recent developments in piezoelectric crystals. J. Korean Ceram. Soc. 2018, 55, 419–439. [Google Scholar] [CrossRef]

- Trolier-McKinstry, S.; Zhang, S.; Bell, A.J.; Tan, X. High-performance piezoelectric crystals, ceramics, and films. Annu. Rev. Mater. Res. 2018, 48, 191–217. [Google Scholar] [CrossRef]

- Park, S.E.; Shrout, T.R. Relaxor based ferroelectric single crystals for electro-mechanical actuators. Mater. Res. Innov. 1997, 1, 20–25. [Google Scholar] [CrossRef]

- Luo, H.; Xu, G.; Wang, P.; Yin, Z. Growth and characterization of relaxor ferroelectric PMNT single crystals. Ferroelectrics 1999, 231, 97–102. [Google Scholar] [CrossRef]

- Shimanuki, S.; Saito, S.; Yamashita, Y. Single crystal of the Pb(Zn1/3Nb2/3)O3–PbTiO3 system grown by the vertical Bridgeman method and its characterization. Jpn. J. Appl. Phys. 1998, 37, 3382. [Google Scholar] [CrossRef]

- Zhang, S.; Lebrun, L.; Jeong, D.Y.; Randall, C.A.; Zhang, Q.; Shrout, T.R. Growth and characterization of Fe-doped Pb(Zn1/3Nb2/3)O3−PbTiO3 single crystals. J. Appl. Phys. 2003, 93, 9257–9262. [Google Scholar] [CrossRef]

- Zhang, S.; Randall, C.A.; Shrout, T.R. Characterization of perovskite piezoelectric single crystals of 0.43BiScO3–0.57PbTiO3 with high Curie temperature. J. Appl. Phys. 2004, 95, 4291–4295. [Google Scholar] [CrossRef]

- Zhang, S.; Rhee, S.; Randall, C.A.; Shrout, T.R. Dielectric and piezoelectric properties of high Curie temperature single crystals in the Pb(Yb1/2Nb1/2)O3–xPbTiO3 solid solution series. Jpn. J. Appl. Phys. 2002, 41, 722. [Google Scholar] [CrossRef]

- Zhang, S.; Lee, S.M.; Kim, D.H.; Lee, H.; Shrout, T.R. Characterization of high TC Pb(Mg1/3Nb2/3)O3-PbZrO3-PbTiO3 single crystals fabricated by solid state crystal growth. Appl. Phys. Lett. 2007, 90, 232911. [Google Scholar] [CrossRef]

- Tian, J.; Han, P.; Huang, X.; Pan, H.; Carroll, J.F., III; Payne, D.A. Improved stability for piezoelectric crystals grown in the lead indium niobate–lead magnesium niobate–lead titanate system. Appl. Phys. Lett. 2007, 91, 222903. [Google Scholar] [CrossRef]

- Hosono, Y.; Yamashita, Y. Piezoelectric ceramics and single crystals for ultrasonic medical transducers. J. Electroceram. 2006, 17, 577–583. [Google Scholar] [CrossRef]

- Zhang, S.; Luo, J.; Hackenberger, W.; Shrout, T.R. Characterization of Pb(In1/2Nb1/2)O3–Pb(Mg1/3Nb2/3)O3–PbTiO3 ferroelectric crystal with enhanced phase transition temperatures. J. Appl. Phys. 2008, 104, 064106. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, S.; Luo, J.; Shrout, T.R.; Cao, W. Complete set of material constants of Pb(In1/2Nb1/2)O3–Pb(Mg1/3Nb2/3)O3–PbTiO3 single crystal with morphotropic phase boundary composition. J. Appl. Phys. 2009, 106, 074112. [Google Scholar] [CrossRef]

- Zhang, S.; Li, F.; Sherlock, N.P.; Luo, J.; Lee, H.J.; Xia, R.; Meyer, R.J., Jr.; Hackenberger, W.; Shrout, T.R. Recent developments on high Curie temperature PIN–PMN–PT ferroelectric crystals. J. Cryst. Growth 2011, 318, 846–850. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Lee, S.M.; Kim, D.H.; Lee, H.Y.; Shrout, T.R. Characterization of Mn-modified Pb(Mg1/3Nb2/3)O3-PbZrO3-PbTiO3 single crystals for high power broad bandwidth transducers. Appl. Phys. Lett. 2008, 93, 122908. [Google Scholar] [CrossRef] [PubMed]

- Luo, J.; Hackenberger, W.; Zhang, S.; Shrout, T.R. A high Qm relaxor ferroelectric single crystal: Growth and characterization. In Proceedings of the 2010 IEEE International Ultrasonics Symposium, San Diego, CA, USA, 11–14 October 2010; pp. 68–71. [Google Scholar]

- Jaffe, B.; Cook, W.R.; Jaffe, H. Piezoelectric Ceramics; Academic Press: New York, NY, USA, 1971. [Google Scholar]

- Zhao, X.; Fang, B.; Cao, H.; Guo, Y.; Luo, H. Dielectric and piezoelectric performance of PMN–PT single crystals with compositions around the MPB: Influence of composition, poling field and crystal orientation. Mater. Sci. Eng. B 2002, 96, 254–262. [Google Scholar] [CrossRef]

- Colla, E.; Yushin, N.K.; Viehland, D. Dielectric properties of (PMN)(1−x)(PT)x single crystals for various electrical and thermal histories. J. Appl. Phys. 1998, 83, 3298–3304. [Google Scholar] [CrossRef]

- Guo, Y.; Luo, H.; Chen, K.; Xu, H.; Zhang, X.; Yin, Z. Effect of composition and poling field on the properties and ferroelectric phase-stability of Pb(Mg1/3Nb2/3)O3–PbTiO3 crystals. J. Appl. Phys. 2002, 92, 6134–6138. [Google Scholar] [CrossRef]

- Chang, W.Y.; Chung, C.C.; Luo, C.; Kim, T.; Yamashita, Y.; Jones, J.L.; Jiang, X. Dielectric and piezoelectric properties of 0.7Pb(Mg1/3Nb2/3)O3-0.3PbTiO3 single crystal poled using alternating current. Mater. Res. Lett. 2018, 6, 537–544. [Google Scholar] [CrossRef]

- Li, F.; Cabral, M.J.; Xu, B.; Cheng, Z.; Dickey, E.C.; LeBeau, J.M.; Wang, J.; Luo, J.; Taylor, S.; Hackenberger, W.; et al. Giant piezoelectricity of Sm-doped Pb(Mg1/3Nb2/3)O3-PbTiO3 single crystals. Science 2019, 364, 264–268. [Google Scholar] [CrossRef] [PubMed]

- Xu, G.; Chen, K.; Yang, D.; Li, J. Growth and electrical properties of large size Pb(In1/2Nb1/2)O3-Pb(Mg1/3Nb2/3)O3-PbTiO3 crystals prepared by the vertical Bridgman technique. Appl. Phys. Lett. 2007, 90, 032901. [Google Scholar] [CrossRef]

- Swartz, S.L.; Shrout, T.R. Fabrication of perovskite lead magnesium niobate. Mater. Res. Bull. 1982, 17, 1245–1250. [Google Scholar] [CrossRef]

- Cao, W. Full-set material properties and domain engineering principles of ferroelectric single crystals. In Handbook of Advanced Dielectric, Piezoelectric and Ferroelectric Materials; Ye, Z.G., Ed.; Woodhead: Cambridge, UK, 2008; pp. 235–265. [Google Scholar]

- Song, K.; Li, Z.; Guo, H.; Xu, Z.; Fan, S. Compositional segregation and electrical properties characterization of [001]-and [011]-oriented co-growth Pb(In1/2Nb1/2)O3-Pb(Mg1/3Nb2/3)O3-PbTiO3 single crystal. J. Appl. Phys. 2018, 123, 154107. [Google Scholar] [CrossRef]

- Li, F.; Zhang, S.; Xu, Z.; Wei, X.; Luo, J.; Shrout, T.R. Composition and phase dependence of the intrinsic and extrinsic piezoelectric activity of domain engineered Pb(Mg1/3Nb2/3)O3-PbTiO3 crystals. J. Appl. Phys. 2010, 108, 034106. [Google Scholar] [CrossRef] [PubMed]

- Feng, Z.; Zhao, X.; Luo, H. Composition and orientation dependence of dielectric and piezoelectric properties in poled Pb(Mg1/3Nb2/3)O3-PbTiO3 crystals. J. Appl. Phys. 2006, 100, 024104. [Google Scholar] [CrossRef]

- Zhang, S.; Lee, S.M.; Kim, D.H.; Lee, H.Y.; Shrout, T.R. Elastic, piezoelectric, and dielectric properties of 0.71Pb(Mg1/3Nb2/3)O3-0.29PbTiO3 crystals obtained by solid-state crystal growth. J. Am. Ceram. Soc. 2008, 91, 683–686. [Google Scholar] [CrossRef]

- Han, J.; Cao, W. Electric field effects on the phase transitions in [001]-oriented (1 − x)Pb(Mg1/3Nb2/3)O3−xPbTiO3 single crystals with compositions near the morphotropic phase boundary. Phys. Rev. B 2003, 68, 134102. [Google Scholar] [CrossRef]

- Luo, C.; Karaki, T.; Sun, Y.; Yamashita, Y.J.; Xu, J. Effect of field cooling AC poling on electrical and physical properties for Pb(Mg1/3Nb2/3)O3-PbTiO3-based single crystals manufactured by a continuous-feeding Bridgman process. Jpn. J. Appl. Phys. 2020, 59, SPPD07. [Google Scholar] [CrossRef]

- Sun, E.; Zhang, R.; Wu, F.; Yang, B.; Cao, W. Influence of manganese doping to the full tensor properties of 0.24Pb(In1/2Nb1/2)O3-0.47Pb(Mg1/3Nb2/3)O3-0.29PbTiO3 single crystals. J. Appl. Phys. 2013, 113, 074108. [Google Scholar] [CrossRef]

- Huo, X.; Zhang, S.; Liu, G.; Zhang, R.; Luo, J.; Sahul, R.; Cao, W.; Shrout, T.R. Elastic, dielectric and piezoelectric characterization of single domain PIN-PMN-PT:Mn crystals. J. Appl. Phys. 2012, 112, 124113. [Google Scholar] [CrossRef]

- Kong, L.; Liu, G.; Zhang, S.; Liu, H. The role of tetragonal side morphotropic phase boundary in modified relaxor-PbTiO3 crystals for high power transducer applications. J. Appl. Phys. 2013, 114, 144106. [Google Scholar] [CrossRef]

- Li, F.; Zhang, S.; Xu, Z.; Wei, X.; Luo, J.; Shrout, T.R. Electromechanical properties of tetragonal Pb(In1/2Nb1/2)O3−Pb(Mg1/3Nb2/3)O3−PbTiO3 ferroelectric crystals. J. Appl. Phys. 2010, 107, 054107. [Google Scholar] [CrossRef] [PubMed]

- Jing, Y.; Zheng, L.; Lü, W.; Xi, Z.; Zheng, P.; Du, J.; Zhang, R. Full tensor properties of single-domain tetragonal 0.63Pb(Mg1/3Nb2/3)O3-0.37PbTiO3 single crystal and their orientation dependence. Phys. Status Solidi B 2016, 253, 1994–2000. [Google Scholar] [CrossRef]

- Zhang, R.; Jiang, B.; Cao, W. Elastic, piezoelectric, and dielectric properties of multidomain 0.67Pb(Mg1/3Nb2/3)O3–0.33PbTiO3 single crystals. J. Appl. Phys. 2001, 90, 3471–3475. [Google Scholar] [CrossRef]

- Li, F.; Jin, L.; Xu, Z.; Wang, D.; Zhang, S. Electrostrictive effect in Pb(Mg1/3Nb2/3)O3-xPbTiO3 crystals. Appl. Phys. Lett. 2013, 102, 152910. [Google Scholar]

- Zhang, S.; Sherlock, N.P.; Meyer, R.J., Jr.; Shrout, T.R. Crystallographic dependence of loss in domain engineered relaxor-PT single crystals. Appl. Phys. Lett. 2009, 94, 162906. [Google Scholar] [CrossRef]

- Li, F.; Zhang, S.; Xu, Z.; Wei, X.; Luo, J.; Shrout, T.R. Temperature independent shear piezoelectric response in relaxor-PbTiO3 based crystals. Appl. Phys. Lett. 2010, 97, 252903. [Google Scholar] [CrossRef]

- Bridgman, P.W. Certain physical properties of single crystals of tungsten, antimony, bismuth, tellurium, cadmium, zinc, and tin. Proc. Am. Acad. Arts Sci. USA 1925, 60, 305. [Google Scholar] [CrossRef]

- Stockbarger, D.C. The production of large single crystals of lithium fluoride. Rev. Sci. Instrum. 1936, 7, 133–136. [Google Scholar] [CrossRef]

- Han, P.; Tian, J.; Yan, W. Bridgman growth and properties of PMN-PT-based single crystals. In Handbook of Advanced Dielectric, Piezoelectric and Ferroelectric Materials: Synthesis, Properties and Applications; Ye, Z.G., Ed.; Woodhead: Cambridge, UK, 2008; pp. 3–37. [Google Scholar]

- Hackenberger, W.; Luo, J.; Jiang, X.N.; Snook, K.A.; Rehrig, P.W.; Zhang, S.J.; Shrout, T.R. Recent developments and applications of piezoelectric crystals. In Handbook of Advanced Dielectric, Piezoelectric and Ferroelectric Materials–Synthesis, Characterization and Applications; Ye, Z.G., Ed.; Woodhead: Cambridge, UK, 2008; pp. 73–100. [Google Scholar]

- Luo, J.; Zhang, S. Advances in the growth and characterization of relaxor-PT-based ferroelectric single crystals. Crystals 2014, 4, 306–330. [Google Scholar] [CrossRef]

- Luo, H.; Xu, G.; Xu, H.; Wang, P.; Yin, Z. Compositional homogeneity and electrical properties of lead magnesium niobate titanate single crystals grown by a modified Bridgman technique. Jpn. J. Appl. Phys. 2000, 39, 5581. [Google Scholar] [CrossRef]

- Zawilski, K.T.; Custodio, M.C.C.; DeMattei, R.C.; Lee, S.G.; Monteiro, R.G.; Odagawa, H.; Feigelson, R.S. Segregation during the vertical Bridgman growth of lead magnesium niobate–lead titanate single crystals. J. Cryst. Growth 2003, 258, 353–367. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, Z.; Yang, X.; Long, X.; He, C. Composition uniformity of Pb(In1/2Nb1/2)O3-Pb (Mg1/3Nb2/3)O3-PbTiO3 single crystals grown in 〈001〉 direction. J. Cryst. Growth 2021, 560, 126061. [Google Scholar] [CrossRef]

- Zawilski, K.T.; DeMattei, R.C.; Feigelson, R.S. Zone leveling of lead magnesium niobate–lead titanate crystals using RF heating. J. Cryst. Growth 2005, 277, 393–400. [Google Scholar] [CrossRef]

- Echizenya, K.; Matsushita, M. Continuous feed growth and characterization of PMN-PT single crystals. In Proceedings of the 2011 IEEE International Ultrasonics Symposium, Orlando, FL, USA, 18–21 October 2011; pp. 1813–1816. [Google Scholar]

- Matsushitata, M.; Echizenya, K. Continuous feeding growth of ternary PIN-PMN-PT single crystals. In Proceedings of the 2014 Joint IEEE International Symposium on the Applications of Ferroelectric, International Workshop on Acoustic Transduction Materials and Devices & Workshop on Piezoresponse Force Microscopy, University Park, PA, USA, 12–16 May 2014; pp. 1–4. [Google Scholar]

- Echizenya, K.; Nakamura, K.; Mizuno, K. PMN-PT and PIN-PMN-PT single crystals grown by continuous-feeding Bridgman method. J. Cryst. Growth 2020, 531, 125364. [Google Scholar] [CrossRef]

- Li, Z.; Song, K.; Guo, H.; Liu, Y.; Ma, M.; Fan, S.; Xu, Z. High composition uniformity of 4″ of PIN-PMN-PT single crystals grown by the modified Bridgman method. J. Cryst. Growth 2017, 468, 331–334. [Google Scholar] [CrossRef]

- Song, K.; Li, Q.; Guo, H.; Hu, Q.; Li, Z.; Li, F.; Fan, S.; Xu, Z. Composition and electrical properties characterization of a 5″ diameter PIN-PMN-PT single crystal by the modified Bridgman method. J. Alloys Compd. 2021, 851, 156145. [Google Scholar] [CrossRef]

- Lee, H.Y. Development of high-performance piezoelectric single crystals by using solid-state single crystal growth (SSCG) method. In Handbook of Advanced Dielectric, Piezoelectric and Ferroelectric Materials; Ye, Z.G., Ed.; Woodhead: Cambridge, UK, 2008; pp. 158–172. [Google Scholar]

- Kabakov, P.; Dean, C.; Kurusingal, V.; Cheng, Z.; Lee, H.Y.; Zhang, S. Solid-state crystal growth of lead-free ferroelectrics. J. Mater. Chem. C 2020, 8, 7606–7649. [Google Scholar] [CrossRef]

- Zhang, S.; Lee, S.M.; Kim, D.H.; Lee, H.Y.; Shrout, T.R. Electromechanical properties of PMN–PZT piezoelectric single crystals near morphotropic phase boundary compositions. J. Am. Ceram. Soc. 2007, 90, 3859–3862. [Google Scholar] [CrossRef]

- Kang, S.J.L.; Park, J.H.; Ko, S.Y.; Lee, H.Y. Solid-state conversion of single crystals: The principle and the state-of-the-art. J. Am. Ceram. Soc. 2015, 98, 347–360. [Google Scholar] [CrossRef]

- Kang, S.J.L.; Ko, S.Y.; Moon, S.Y. Mixed control of boundary migration and the principle of microstructural evolution. J. Ceram. Soc. Jpn. 2016, 124, 259–267. [Google Scholar] [CrossRef]

- Yamamoto, T.; Sakuma, T. Fabrication of barium titanate single crystals by solid-state grain growth. J. Am. Ceram. Soc. 1994, 77, 1107–1109. [Google Scholar] [CrossRef]

- Yoo, Y.S.; Kang, M.K.; Han, J.H.; Kim, H.; Kim, D.Y. Fabrication of BaTiO3 single crystals by using the exaggerated grain growth method. J. Eur. Ceram. Soc. 1997, 17, 1725–1727. [Google Scholar] [CrossRef]

- Rehrig, P.W.; Messing, G.L.; Trolier-McKinstry, S. Templated grain growth of barium titanate single crystals. J. Am. Ceram. Soc. 2000, 83, 2654–2660. [Google Scholar] [CrossRef]

- Lee, H.Y.; Kim, J.S.; Kim, D.Y. Fabrication of BaTiO3 single crystals using secondary abnormal grain growth. J. Eur. Ceram. Soc. 2000, 20, 1595–1597. [Google Scholar] [CrossRef]

- Li, T.; Scotch, A.M.; Chan, H.M.; Harmer, M.P.; Park, S.E.; Shrout, T.R.; Michael, J.R. Single crystals of Pb(Mg1/3Nb2/3)O3—35mol%PbTiO3 from polycrystalline precursors. J. Am. Ceram. Soc. 1998, 81, 244–248. [Google Scholar] [CrossRef]

- Chen, Z.; Liao, X.; Chen, J.; Zhang, S. The visible hand behind properties. Microstructures 2021, 1, 2021001. [Google Scholar] [CrossRef]

- Kim, M.S.; Fisher, J.G.; Kang, S.J.L.; Lee, H.Y. Grain growth control and solid-state crystal growth by Li2O/PbO addition and dislocation introduction in the PMN-35PT system. J. Am. Ceram. Soc. 2006, 89, 1237–1243. [Google Scholar] [CrossRef]

- Lim, J.B.; Zhang, S.; Lee, H.Y.; Shrout, T.R. Solid state crystal growth of BiScO3-Pb(Mg1/3Nb2/3)O3-PbTiO3. J. Electroceram. 2012, 29, 139–143. [Google Scholar] [CrossRef]

- King, P.T.; Gorzkowski, E.P.; Scotch, A.M.; Rockosi, D.J.; Chan, H.M.; Harmer, M.P. Kinetics of {001} Pb(Mg1/3Nb2/3)O3–35mol%PbTiO3 single crystals grown by seeded polycrystal conversion. J. Am. Ceram. Soc. 2003, 86, 2182–2187. [Google Scholar] [CrossRef]

- Khan, A.; Meschke, F.A.; Li, T.; Scotch, A.M.; Chan, H.M.; Harmer, M.P. Growth of Pb(Mg1/3Nb2/3)O3-35mol% PbTiO3 single crystals from (111) substrates by seeded polycrystal conversion. J. Am. Ceram. Soc. 1999, 82, 2958–2962. [Google Scholar] [CrossRef]

- Khan, A.; Gorzkowski, E.P.; Scotch, A.M.; Leite, E.R.; Li, T.; Chan, H.M.; Harmer, M.P. Influence of excess PbO additions on {111} single-grystal growth of Pb(Mg1/3Nb2/3)O3-35mol%PbTiO3 by seeded polycrystal conversion. J. Am. Ceram. Soc. 2003, 86, 2176–2181. [Google Scholar] [CrossRef]

- Liu, G.; Kong, L.; Hu, Q.; Zhang, S. Diffused morphotropic phase boundary in relaxor-PbTiO3 crystals: High piezoelectricity with improved thermal stability. Appl. Phys. Rev. 2020, 7, 021405. [Google Scholar] [CrossRef]

- Li, F.; Zhang, S.; Yang, T.; Xu, Z.; Zhang, N.; Liu, G.; Wang, J.; Wang, J.; Cheng, Z.; Ye, Z.G.; et al. The origin of ultrahigh piezoelectricity in relaxor-ferroelectric solid solution crystals. Nat. Commun. 2016, 7, 1–9. [Google Scholar] [CrossRef]

- Bell, A.J. Phenomenologically derived electric field-temperature phase diagrams and piezoelectric coefficients for single crystal barium titanate under fields along different axes. J. Appl. Phys. 2001, 89, 3907–3914. [Google Scholar] [CrossRef]

- Feng, Z.; Zhao, X.; Luo, H. Effect of poling field and temperature on dielectric and piezoelectric property of 〈001〉-oriented 0.70Pb(Mg1/3Nb2/3)O3–0.30PbTiO3 crystals. Mater. Res. Bull. 2006, 41, 1133–1137. [Google Scholar] [CrossRef]

- Davis, M. Phase Transitions, Anisotropy and Domain Engineering: The Piezoelectric Properties of Relaxor-Ferroelectric Single Crystals. Doctoral Thesis, EPFL, Lausanne, Switzerland, 2006. [Google Scholar]

- Guo, Y.; Luo, H.; Ling, D.; Xu, H.; He, T.; Yin, Z. The phase transition sequence and the location of the morphotropic phase boundary region in (1 − x)[Pb(Mg1/3Nb2/3)O3]–xPbTiO3 single crystal. J. Condens. Matter Phys. 2003, 15, L77. [Google Scholar] [CrossRef]

- Shanthi, M.; Hoe, K.H.; Lim, C.Y.H.; Lim, L.C. Overpoling-induced property degradation in Pb(Mg1/3Nb2/3)O3-PbTiO3 single crystals of near-morphotropic phase boundary compositions. Appl. Phys. Lett. 2005, 86, 262908. [Google Scholar]

- Bokov, A.A.; Ye, Z.G. Field-induced shift of morphotropic phase boundary and effect of overpoling in (1 − x)Pb(Mg1/3Nb2/ 3)O3–xPbTiO3 piezocrystals. Appl. Phys. Lett. 2008, 92, 082901. [Google Scholar] [CrossRef]

- Tu, C.S.; Chien, R.R.; Lee, S.C.; Schmidt, V.H.; Luo, H. Rapid piezoelectric response and origin in (001)Pb(In1/2Nb1/2)0.70Ti0.30O3 crystal. J. Appl. Phys. 2009, 106, 016102. [Google Scholar] [CrossRef]

- Tu, C.S.; Hsieh, C.M.; Schmidt, V.H.; Chien, R.R.; Luo, H. Piezoelectric response and origin in (001)Pb(Mg1/3Nb2/3)0.70Ti0.30O3 crystal. Appl. Phys. Lett. 2008, 93, 172905. [Google Scholar] [CrossRef]

- Jiang, Z. Over-poling study of PMN-PT and PIN-PMN-PT crystal grown by Vertical Gradient Freeze method. In Proceedings of the 2016 Joint IEEE International Symposium on the Applications of Ferroelectrics, European Conference on Application of Polar Dielectrics, and Piezoelectric Force Microscopy Workshop (ISAF/ECAPD/PFM), Darmstadt, Germany, 21–25 August 2016; pp. 1–4. [Google Scholar]

- Yamamoto, N.; Yamashita, Y.; Itsumi, K.; Hosono, Y. Temperature dependence of dielectric constant with different poling fields in lead magnesium niobate-lead titanate single crystal. Trans. Mater. Res. Soc. Jpn. 2010, 35, 95–98. [Google Scholar] [CrossRef][Green Version]

- Chen, H.Y.; Tu, C.S.; Hung, C.M.; Chien, R.R.; Schmidt, V.H.; Ku, C.S.; Lee, H.Y. Poling effect and piezoelectric response in high-strain ferroelectric 0.70Pb(Mg1/3Nb2/3)O3–0.30 PbTiO3 crystal. J. Appl. Phys. 2010, 108, 044101. [Google Scholar] [CrossRef]

- Lin, D.; Li, Z.; Zhang, S.; Xu, Z.; Yao, X. Electric-field and temperature induced phase transitions in Pb(Mg1/3Nb2/3)O3–0.3PbTiO3 single crystals. J. Appl. Phys. 2010, 108, 034112. [Google Scholar] [CrossRef]

- Chen, Z.; Hong, L.; Wang, F.; Ringer, S.P.; Chen, L.Q.; Luo, H.; Liao, X. Facilitation of ferroelectric switching via mechanical manipulation of hierarchical nanoscale domain structures. Phys. Rev. Lett. 2017, 118, 017601. [Google Scholar] [CrossRef]

- Chen, Z.; Hong, L.; Wang, F.; An, X.; Wang, X.; Ringer, S.; Chen, L.Q.; Luo, H.; Liao, X. Kinetics of domain switching by mechanical and electrical stimulation in relaxor-based ferroelectrics. Phys. Rev. Appl. 2017, 8, 064005. [Google Scholar] [CrossRef]

- Chen, Z.; Li, F.; Huang, Q.; Liu, F.; Wang, F.; Ringer, S.P.; Luo, H.; Zhang, S.; Chen, L.Q.; Liao, X. Giant tuning of ferroelectricity in single crystals by thickness engineering. Sci. Adv. 2020, 6, eabc7156. [Google Scholar] [CrossRef]

- Huang, Q.; Chen, Z.; Cabral, M.J.; Wang, F.; Zhang, S.; Li, F.; Li, Y.; Ringer, S.P.; Luo, H.; Mai, Y.W.; et al. Direct observation of nanoscale dynamics of ferroelectric degradation. Nat. Commun. 2021, 12, 1–7. [Google Scholar] [CrossRef]

- Noheda, B.; Zhong, Z.; Cox, D.E.; Shirane, G.; Park, S.E.; Rehrig, P. Electric-field-induced phase transitions in rhombohedral Pb(Zn1/3Nb2/3)1−xTixO3. Phys. Rev. B 2002, 65, 224101. [Google Scholar] [CrossRef]

- Bai, F.; Wang, N.; Li, J.; Viehland, D.; Gehring, P.M.; Xu, G.; Shirane, G. X-ray and neutron diffraction investigations of the structural phase transformation sequence under electric field in 0.7Pb(Mg1/3Nb2/3)-0.3PbTiO3 crystal. J. Appl. Phys. 2004, 96, 1620–1627. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, D.; Yuan, G.; Ma, H.; Xu, F.; Li, J.; Viehland, D.; Gehring, P.M. Fragile morphotropic phase boundary and phase stability in the near-surface region of the relaxor ferroelectric (1 − x)Pb(Zn1/3Nb2/3)O3−xPbTiO3:[001] field-cooled phase diagrams. Phys. Rev. B 2016, 94, 174103. [Google Scholar] [CrossRef]

- Li, F.; Wang, L.; Jin, L.; Xu, Z.; Zhang, S. Achieving single domain relaxor-PT crystals by high temperature poling. CrystEngComm 2014, 16, 2892–2897. [Google Scholar] [CrossRef]

- Hu, W.; Xi, Z.; Fang, P.; Long, W.; Li, X.; Bu, Q. A novel poling technique to obtain excellent piezoelectric properties of Pb(Mg1/3Nb2/3)O3–0.32PbTiO3 single crystals. J. Mater. Sci. Mater. Electron. 2015, 26, 3282–3286. [Google Scholar] [CrossRef]

- Li, F.; Zhang, S.; Xu, Z.; Li, Z.; Wei, X. DC bias electric field dependent piezoelectricity for [001] poled Pb(In1/2Nb1/2)O3–Pb(Mg1/3Nb2/3) O3–PbTiO3 crystals. J. Adv. Dielectr. 2011, 1, 303–308. [Google Scholar] [CrossRef]

- Lin, D.; Zhang, S.; Li, Z.; Li, F.; Xu, Z.; Wada, S.; Luo, J.; Shrout, T.R. Domain size engineering in tetragonal Pb(In1/2Nb1/2)O3-Pb(Mg1/3Nb2/3)O3-PbTiO3 crystals. J. Appl. Phys. 2011, 110, 084110. [Google Scholar] [CrossRef]

- Shen, Z.Y.; Tang, Y.; Zhang, S.; Luo, J.; Li, Y.; Shrout, T.R. Enhanced piezoelectric activity and temperature stability of [111]-oriented orthorhombic 0.68Pb(Mg1/3Nb2/3)O3–0.32PbTiO3 single crystals by domain size engineering. Scr. Mater. 2014, 72, 17–20. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, S.; Fu, X.; Zhuang, Y.; Yang, R.; Yang, Z.; Li, Z.; Xu, Z.; Wei, X. Thermal annealing and single–domain preparation in tetragonal Pb(In1/2Nb1/2)O3-Pb(Mg1/3Nb2/3)O3–PbTiO3 crystal for electro–optic and non–linear optical applications. J. Appl. Phys. 2018, 123, 084104. [Google Scholar] [CrossRef]

- Xu, J.; Deng, H.; Zeng, Z.; Zhang, Z.; Zhao, K.; Chen, J.; Nakamori, N.; Wang, F.; Ma, J.; Li, X.; et al. Piezoelectric performance enhancement of Pb(Mg1/3Nb2/3)O3-0.25PbTiO3 crystals by alternating current polarization for ultrasonic transducer. Appl. Phys. Lett. 2018, 112, 182901. [Google Scholar] [CrossRef]

- Luo, C.; Karaki, T.; Wang, Z.; Sun, Y.; Yamashita, Y.; Xu, J. High piezoelectricity after field cooling AC poling in ferroelectric crystals manufactured by continuous-feeding Bridgman. J. Adv. Ceram. 2021, 11, 57–65. [Google Scholar] [CrossRef]

- Wan, H.; Luo, C.; Chung, C.C.; Yamashita, Y.; Jiang, X. Enhanced dielectric and piezoelectric properties of manganese-doped Pb(In1/2Nb1/2)O3-Pb (Mg1/3Nb2/3)O3-PbTiO3 single crystals by alternating current poling. Appl. Phys. Lett. 2021, 118, 102904. [Google Scholar] [CrossRef]

- Sun, Y.; Karaki, T.; Fujii, T.; Yamashita, Y. Alternate current poling and direct current poling for Pb(Mg1/3Nb2/3)O3–PbTiO3 single crystals. Jpn. J. Appl. Phys. 2019, 58, SLLC06. [Google Scholar] [CrossRef]

- Ma, M.; Xia, S.; Song, K.; Guo, H.; Fan, S.; Li, Z. Enhanced dielectric and piezoelectric properties in the [001]-poled 0.25Pb(In1/2Nb1/2)O3-0.43Pb(Mg1/3Nb2/3)O3-0.32PbTiO3 single crystal near morphotropic phase boundary by alternating current treatment. J. Appl. Phys. 2020, 127, 064106. [Google Scholar] [CrossRef]

- Guo, L.; Su, B.; Wang, C.; He, X.; Wang, Z.; Yang, X.; Long, X.; He, C. Orientation dependence of dielectric and piezoelectric properties of tetragonal relaxor ferroelectric single crystals by alternate current poling. J. Appl. Phys. 2020, 127, 184104. [Google Scholar] [CrossRef]

- He, C.; Karaki, T.; Yang, X.; Yamashita, Y.J.; Sun, Y.; Long, X. Dielectric and piezoelectric properties of Pb[(Mg1/3Nb2/3)0.52(Yb1/2Nb1/2)0.15Ti0.33]O3 single-crystal rectangular plate and beam mode transducers poled by alternate current poling. Jpn. J. Appl. Phys. 2019, 58, SLLD06. [Google Scholar] [CrossRef]

- Vanderbilt, D.; Cohen, M.H. Monoclinic and triclinic phases in higher-order Devonshire theory. Phys. Rev. B 2001, 63, 094108. [Google Scholar] [CrossRef]

- Noheda, B.; Cox, D.E.; Shirane, G.; Park, S.E.; Cross, L.E.; Zhong, Z. Polarization rotation via a monoclinic phase in the piezoelectric 92%PbZn1/3Nb2/3O3-8%PbTiO3. Phys. Rev. Lett. 2001, 86, 3891. [Google Scholar] [CrossRef]

- Qiu, C.; Wang, B.; Zhang, N.; Zhang, S.; Liu, J.; Walker, D.; Wang, Y.; Tian, H.; Shrout, T.R.; Xu, Z.; et al. Transparent ferroelectric crystals with ultrahigh piezoelectricity. Nature 2020, 577, 350–354. [Google Scholar] [CrossRef] [PubMed]

- Qiu, C.; Xu, Z.; An, Z.; Liu, J.; Zhang, G.; Zhang, S.; Chen, L.Q.; Zhang, N.; Li, F. In-situ domain structure characterization of Pb(Mg1/3Nb2/3)O3-PbTiO3 crystals under alternating current electric field poling. Acta Mater. 2021, 210, 116853. [Google Scholar] [CrossRef]

- Wan, H.; Luo, C.; Liu, C.; Chang, W.Y.; Yamashita, Y.; Jiang, X. Alternating current poling on sliver-mode rhombohedral Pb(Mg1/3Nb2/3)O3-PbTiO3 single crystals. Acta Mater. 2021, 208, 116759. [Google Scholar] [CrossRef]

- Liu, J.; Qiu, C.; Qiao, L.; Song, K.; Guo, H.; Xu, Z.; Li, F. Impact of alternating current electric field poling on piezoelectric and dielectric properties of Pb(In1/2Nb1/2)O3–Pb(Mg1/3Nb2/3)O3–PbTiO3 ferroelectric crystals. J. Appl. Phys. 2020, 128, 094104. [Google Scholar] [CrossRef]

- Wang, B.; Li, F.; Chen, L.Q. Inverse domain-size dependence of piezoelectricity in ferroelectric crystals. Adv. Mater. 2021, 33, 2105071. [Google Scholar] [CrossRef]

- Ma, M.; Xia, S.; Song, K.; Guo, H.; Xu, Z.; Li, Z. Temperature dependence of the transverse piezoelectric properties in the [001]-poled 0.25Pb(In1/2Nb1/2)O3-0.42Pb(Mg1/3Nb2/3)O3-0.33PbTiO3 single crystal with alternating current treatment. J. Appl. Phys. 2021, 129, 114102. [Google Scholar] [CrossRef]

- Deng, T.; Fang, B.; Chen, Z.; Chen, J.; Luo, H. Improving fatigue resistance of PIMNT single crystal via two-step poling process. J. Phys. Chem. Solids 2022, 161, 110378. [Google Scholar] [CrossRef]

- Sun, Y.; Karaki, T.; Fujii, T.; Yamashita, Y.J. Spurious-mode vibrations caused by alternating current poling and their solution process for Pb(Mg1/3Nb2/3)O3-PbTiO3 single crystals. J. Mater. 2021, in press. [Google Scholar] [CrossRef]

- Luo, C.; Karaki, T.; Yamashita, Y.J.; Xu, J. High temperature and low voltage AC poling for 0.24Pb(In1/2Nb1/2)O3-0.46Pb(Mg1/3Nb2/3)O3-0.30PbTiO3 piezoelectric single crystals manufactured by continuous-feeding Bridgman method. J. Mater. 2021, 7, 621–628. [Google Scholar] [CrossRef]

- Wan, H.; Luo, C.; Chang, W.Y.; Yamashita, Y.; Jiang, X. Effect of poling temperature on piezoelectric and dielectric properties of 0.7Pb(Mg1/3Nb2/3)O3-0.3PbTiO3 single crystals under alternating current poling. Appl. Phys. Lett. 2019, 114, 172901. [Google Scholar] [CrossRef]

- Luo, C.; Wan, H.; Chang, W.Y.; Yamashita, Y.; Paterson, A.R.; Jones, J.; Jiang, X. Effect of low-frequency alternating current poling on 5-mm-thick 0.7Pb(Mg1/3Nb2/3)O3-0.3PbTiO3 single crystals. Appl. Phys. Lett. 2019, 115, 192904. [Google Scholar] [CrossRef]

- Sun, Y.; Karaki, T.; Fujii, T.; Yamashita, Y. Enhanced electric property of relaxor ferroelectric crystals with low AC voltage high-temperature poling. Jpn. J. Appl. Phys. 2020, 59, SPPD08. [Google Scholar] [CrossRef]

- Jiang, H.; Zou, Y.K.; Chen, Q.; Li, K.K.; Zhang, R.; Wang, Y.; Ming, H.; Zheng, Z. Transparent electro-optic ceramics and devices. Proc. SPIE 2005, 5644, 380–394. [Google Scholar]

- Fang, Z.; Jiang, X.; Tian, X.; Zheng, F.; Cheng, M.; Zhao, E.; Ye, W.; Qin, Y.; Zhang, Y. Ultratransparent PMN-PT electro-optic ceramics and its application in optical communication. Adv. Opt. Mater. 2021, 9, 2002139. [Google Scholar] [CrossRef]

- Berlincourt, D. Piezoelectric ceramic compositional development. J. Acoust. Soc. Am. 1992, 91, 3034–3040. [Google Scholar] [CrossRef]

- Luo, N.; Zhang, S.; Li, Q.; Yan, Q.; Zhang, Y.; Ansell, T.; Luo, J.; Shrout, T.R. Crystallographic dependence of internal bias in domain engineered Mn-doped relaxor-PbTiO3 single crystals. J. Mater. Chem. C 2016, 4, 4568–4576. [Google Scholar] [CrossRef]

- Sherlock, N.P.; Zhang, S.; Luo, J.; Lee, H.Y.; Shrout, T.R.; Meyer, R.J., Jr. Large signal electromechanical properties of low loss (1 − x)Pb(Mg1/3Nb2/3)O3−xPbTiO3 single crystals. J. Appl. Phys. 2010, 107, 074108. [Google Scholar] [CrossRef]

- Moffett, M.B.; Robinson, H.C.; Powers, J.M.; Baird, P.D. Single-crystal lead magnesium niobate-lead titanate (PMN/PT) as a broadband high power transduction material. J. Acoust. Soc. Am. 2007, 121, 2591–2599. [Google Scholar] [CrossRef]

- Chen, Y.H.; Uchino, K.; Shen, M.; Viehland, D. Substituent effects on the mechanical quality factor of Pb(Mg1/3Nb2/3)O3–PbTiO3 and Pb(Sc1/2Nb1/2)O3–PbTiO3 ceramics. J. Appl. Phys. 2001, 90, 1455–1458. [Google Scholar] [CrossRef]

- Zhang, S.; Lebrun, L.; Randall, C.A.; Shrout, T.R. Orientation dependence properties of modified tetragonal 0.88Pb(Zn1/3Nb2/3)O3–0.12PbTiO3 single crystals. Phys. Status Solidi A 2005, 202, 151–157. [Google Scholar] [CrossRef]

- Qiao, H.; He, C.; Wang, Z.; Pang, D.; Li, X.; Liu, Y.; Long, X. Influence of Mn dopants on the electrical properties of Pb(In0.5Nb0.5)O3–PbTiO3 ferroelectric single crystals. RSC Adv. 2017, 7, 32607–32612. [Google Scholar] [CrossRef]

- Huo, X.; Zhang, S.; Liu, G.; Zhang, R.; Luo, J.; Sahul, R.; Cao, W.; Shrout, T.R. Complete set of elastic, dielectric, and piezoelectric constants of [011]C poled rhombohedral Pb(In0.5Nb0.5)O3-Pb(Mg1/3Nb2/3)O3-PbTiO3:Mn single crystals. J. Appl. Phys. 2013, 113, 074106. [Google Scholar] [CrossRef]

- Zheng, L.; Sahul, R.; Zhang, S.; Jiang, W.; Li, S.; Cao, W. Orientation dependence of piezoelectric properties and mechanical quality factors of 0.27Pb(In1/2Nb1/2)O3-0.46Pb(Mg1/3Nb2/3)O3-0.27PbTiO3:Mn single crystals. J. Appl. Phys. 2013, 114, 104105. [Google Scholar] [CrossRef]

- Zhang, S.; Xia, R.; Lebrun, L.; Anderson, D.; Shrout, T.R. Piezoelectric materials for high power, high temperature applications. Mater. Lett. 2005, 59, 3471–3475. [Google Scholar] [CrossRef]

- Sun, E.; Zhang, S.; Luo, J.; Shrout, T.R.; Cao, W. Elastic, dielectric, and piezoelectric constants of Pb(In1/2Nb1/2)O3–Pb(Mg1/3Nb2/3)O3–PbTiO3 single crystal poled along [011]c. Appl. Phys. Lett. 2010, 97, 032902. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Taylor, S.; Li, F.; Luo, J.; Meyer, R.J., Jr. Piezoelectric property of relaxor-PbTiO3 crystals under uniaxial transverse stress. Appl. Phys. Lett. 2013, 102, 172902. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, S.; Jiang, W.; Cao, W. Losses in ferroelectric materials. Mater. Sci. Eng. R Rep. 2015, 89, 1–48. [Google Scholar] [CrossRef] [PubMed]

- Rhim, S.M.; Shin, M.C.; Lee, S.G. Piezoelectric single crystals for medical ultrasonic transducers. In Handbook of Advanced Dielectric, Piezoelectric and Ferroelectric Materials; Ye, Z.G., Ed.; Woodhead Publishing: Cambridge, UK, 2008; pp. 101–129. [Google Scholar]

- Viehland, D.; Li, J.F.; Jang, S.J.; Cross, L.E.; Wuttig, M. Glassy polarization behavior of relaxor ferroelectrics. Phys. Rev. B 1992, 46, 8013. [Google Scholar] [CrossRef]

- Haertling, G.H. Ferroelectric ceramics: History and technology. J. Am. Ceram. Soc. 1999, 82, 797–818. [Google Scholar] [CrossRef]

- Dai, X.; DiGiovanni, A.; Viehland, D. Dielectric properties of tetragonal lanthanum modified lead zirconate titanate ceramics. J. Appl. Phys. 1993, 74, 3399–3405. [Google Scholar] [CrossRef]

- Samara, G.A. The relaxational properties of compositionally disordered ABO3 perovskites. J. Condens. Matter Phys. 2003, 15, R367. [Google Scholar] [CrossRef]

- Liu, Y.; Ling, Z.; Zhuo, Z. High piezoelectricity of PLZT ceramics with strong frequency-dielectric dispersion below depolarization temperature. J. Alloys Compd. 2017, 727, 925–930. [Google Scholar] [CrossRef]

- Seshadri, S.B.; Nolan, M.M.; Tutuncu, G.; Forrester, J.S.; Sapper, E.; Esteves, G.; Granzow, T.; Thomas, P.A.; Nino, J.C.; Rojac, T.; et al. Unexpectedly high piezoelectricity of Sm-doped lead zirconate titanate in the Curie point region. Sci. Rep. 2018, 8, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Gao, B.; Yao, Z.; Lai, D.; Guo, Q.; Pan, W.; Hao, H.; Cao, M.; Liu, H. Unexpectedly high piezoelectric response in Sm-doped PZT ceramics beyond the morphotropic phase boundary region. J. Alloys Compd. 2020, 836, 155474. [Google Scholar] [CrossRef]

- Kumar, N.; Mishra, A.; De, A.; Shankar, U.; Ranjan, R. Factors contributing to the local polar-structural heterogeneity and ultrahigh piezoelectricity in Sm-modified Pb(Mg1/3Nb2/3)O3–PbTiO3. J. Phys. D Appl. Phys. 2020, 53, 165302. [Google Scholar] [CrossRef]

- Li, Y.; Borbely, M.; Bell, A. The influence of oxygen vacancies on piezoelectricity in samarium-doped Pb(Mg1/3Nb2/3)O3-PbTiO3 ceramics. J. Am. Ceram. Soc. 2021, 104, 2678–2688. [Google Scholar] [CrossRef]

- Li, F.; Lin, D.; Chen, Z.; Cheng, Z.; Wang, J.; Li, C.; Xu, Z.; Huang, Q.; Liao, X.; Chen, L.Q.; et al. Ultrahigh piezoelectricity in ferroelectric ceramics by design. Nat. Mater. 2018, 17, 349–354. [Google Scholar] [CrossRef] [PubMed]

- Guo, Q.; Meng, X.; Li, F.; Xia, F.; Wang, P.; Gao, X.; Wu, J.; Sun, H.; Hao, H.; Liu, H.; et al. Temperature-insensitive PMN-PZ-PT ferroelectric ceramics for actuator applications. Acta Mater. 2021, 211, 116871. [Google Scholar] [CrossRef]

- Wang, P.; Guo, Q.; Li, F.; Xia, F.; Hao, H.; Sun, H.; Liu, H.; Zhang, S. Modified Pb(Mg1/3Nb2/3)O3-PbZrO3–PbTiO3 ceramics with high piezoelectricity and temperature stability. J. Am. Ceram. Soc. 2021, 104, 5127–5137. [Google Scholar] [CrossRef]

- Guo, Q.; Li, F.; Xia, F.; Wang, P.; Gao, X.; Hao, H.; Liu, H.; Sun, H.; Zhang, S. Piezoelectric ceramics with high piezoelectricity and broad temperature usage range. J. Mater. 2021, 7, 683–692. [Google Scholar] [CrossRef]

- Guo, Q.; Li, F.; Xia, F.; Gao, X.; Wang, P.; Hao, H.; Sun, H.; Liu, H.; Zhang, S. High-performance Sm-doped Pb(Mg1/3Nb2/3)O3-PbZrO3–PbTiO3-based piezoceramics. ACS Appl. Mater. Interfaces 2019, 11, 43359–43367. [Google Scholar] [CrossRef]

- Li, F.; Zhang, S.; Damjanovic, D.; Chen, L.Q.; Shrout, T.R. Local structural heterogeneity and electromechanical responses of ferroelectrics: Learning from relaxor ferroelectrics. Adv. Funct. Mater. 2018, 28, 1801504. [Google Scholar] [CrossRef]

- Li, C.; Xu, B.; Lin, D.; Zhang, S.; Bellaiche, L.; Shrout, T.R.; Li, F. Atomic-scale origin of ultrahigh piezoelectricity in samarium-doped PMN-PT ceramics. Phys. Rev. B 2020, 101, 140102. [Google Scholar] [CrossRef]

- Srimathy, B.; Kumar, J. Effect of donor dopants on the properties of flux grown PZN-PT single crystals. Appl. Phys. A 2021, 127, 1–7. [Google Scholar] [CrossRef]

- Davis, M.; Budimir, M.; Damjanovic, D.; Setter, N. Rotator and extender ferroelectrics: Importance of the shear coefficient to the piezoelectric properties of domain-engineered crystals and ceramics. J. Appl. Phys. 2007, 101, 054112. [Google Scholar] [CrossRef]

- Jin, J.; Rajan, K.K.; Lim, L.C. Properties of single domain Pb(Zn1/3Nb2/3)O3–(6–7)%PbTiO3 single crystal. Jpn. J. Appl. Phys. 2006, 45, 8744. [Google Scholar] [CrossRef]

- Zhang, R.; Jiang, B.; Cao, W. Orientation dependence of piezoelectric properties of single domain 0.67Pb(Mn1/3Nb2/3)O3–0.33PbTiO3 crystals. Appl. Phys. Lett. 2003, 82, 3737–3739. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, G.; Jiang, W.; Luo, J.; Cao, W.; Shrout, T.R. Characterization of single domain Pb(In0.5Nb0.5)O3-Pb(Mg1/3Nb2/3)O3-PbTiO3 crystals with monoclinic phase. J. Appl. Phys. 2011, 110, 064108. [Google Scholar] [CrossRef]

- Sun, E.; Qi, X.; Cao, W.; Zhang, R.; Yang, B.; Zhao, L. Electromechanical properties of orthorhombic 0.24Pb(In1/2Nb1/2)O3–0.43Pb(Mg1/3Nb2/3)O3–0.33PbTiO3 single-domain crystal. Mater. Lett. 2015, 157, 163–165. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Liu, X.; Zhang, S.; Luo, J.; Shrout, T.R.; Cao, W. A complete set of material properties of single domain 0.26Pb(In1/2Nb1/2)O3–0.46Pb(Mg1/3Nb2/3)O3–0.28PbTiO3 single crystals. Appl. Phys. Lett. 2010, 96, 012907. [Google Scholar] [CrossRef]

- Damjanovic, D. A morphotropic phase boundary system based on polarization rotation and polarization extension. Appl. Phys. Lett. 2010, 97, 062906. [Google Scholar] [CrossRef]

- Sun, E.; Cao, W.; Jiang, W.; Han, P. Complete set of material properties of single domain 0.24Pb(In1/2Nb1/2)O3-0.49Pb(Mg1/3Nb2/3)O3-0.27PbTiO3 single crystal and the orientation effects. Appl. Phys. Lett. 2011, 99, 032901. [Google Scholar] [CrossRef]

- Han, P.; Yan, W.; Tian, J.; Huang, X.; Pan, H. Cut directions for the optimization of piezoelectric coefficients of lead magnesium niobate–lead titanate ferroelectric crystals. Appl. Phys. Lett. 2005, 86, 052902. [Google Scholar] [CrossRef]

- Kuwata, J.; Uchino, K.; Nomura, S. Dielectric and piezoelectric properties of 0.91Pb(Zn1/3Nb2/3)O3-0.09PbTiO3 single crystals. Jpn. J. Appl. Phys. 1982, 21, 1298. [Google Scholar] [CrossRef]

- Damjanovic, D.; Budimir, M.; Davis, M.; Setter, N. Monodomain versus polydomain piezoelectric response of 0.67P(Mg1/3Nb2/3)O3–0.33PbTiO3 single crystals along nonpolar directions. Appl. Phys. Lett. 2003, 83, 527–529. [Google Scholar] [CrossRef]

- Luan, Z.; Jiang, G.; Wang, J.; Liu, D.; Yang, B.; Wu, F. The intrinsic and extrinsic contributions in [001] oriented (1-x)Pb(Mg1/3Nb2/3)O3-xPbTiO3 crystals. Ferroelectrics 2019, 548, 26–33. [Google Scholar] [CrossRef]

- Haun, M.J.; Furman, E.; Jang, S.J.; McKinstry, H.A.; Cross, L.E. Thermodynamic theory of PbTiO3. J. Appl. Phys. 1987, 62, 3331–3338. [Google Scholar] [CrossRef]

- Zgonik, M.; Bernasconi, P.; Duelli, M.; Schlesser, R.; Günter, P.; Garrett, M.H.; Rytz, D.; Zhu, Y.; Wu, X. Dielectric, elastic, piezoelectric, electro-optic, and elasto-optic tensors of BaTiO3 crystals. Phys. Rev. B 1994, 50, 5941. [Google Scholar] [CrossRef]

- Li, F.; Jin, L.; Xu, Z.; Zhang, S. Electrostrictive effect in ferroelectrics: An alternative approach to improve piezoelectricity. Appl. Phys. Rev. 2014, 1, 011103. [Google Scholar] [CrossRef]

- Zhang, S.; Li, F.; Luo, J.; Xia, R.; Hackenberger, W.; Shrout, T.R. Investigation of single and multidomain Pb(In0.5Nb0.5)O3–Pb(Mg1/3Nb2/3)O3–PbTiO3 crystals with mm 2 symmetry. Appl. Phys. Lett. 2010, 97, 132903. [Google Scholar] [CrossRef]

- Zhang, S.; Laurent, L.; Liu, S.; Rhee, S.; Randall, C.A.; Shrout, T.R. Piezoelectric shear coefficients of Pb(Zn1/3Nb2/3)O3–PbTiO3 single crystals. Jpn. J. Appl. Phys. 2002, 41, L1099. [Google Scholar] [CrossRef]

- Zhang, S.; Jiang, W.; Meyer, R.J., Jr.; Li, F.; Luo, J.; Cao, W. Measurements of face shear properties in relaxor-PbTiO3 single crystals. J. Appl. Phys. 2011, 110, 064106. [Google Scholar] [CrossRef]

- Zhang, S.; Li, F.; Jiang, W.; Luo, J.; Meyer, R.J., Jr.; Cao, W.; Shrout, T.R. Face shear piezoelectric properties of relaxor-PbTiO3 single crystals. Appl. Phys. Lett. 2011, 98, 182903. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, Q.; Xu, C.; Zhuo, F.; Liu, D.; Yan, Q.; Zhang, Y.; Chu, X. Anisotropic temperature–electric field phase diagrams and domain structure evolution in rhombohedral Mn-doped PIN–PMN–PT single crystals. CrystEngComm 2018, 20, 5169–5179. [Google Scholar] [CrossRef]

- Fang, H.; Wang, L.; Kuai, W.; Du, J.; Jiang, G.; Lu, X.; Zhao, M.; Wang, C.; Su, W.; Zheng, L.; et al. Reversible and irreversible domain wall dynamics in [011]C oriented relaxor ferroelectric single crystals. J. Am. Ceram. Soc. 2020, 103, 3257–3264. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, Q.; Zhuo, F.; Xu, C.; Yan, Q.; Zhang, Y.; Chu, X. Domain switching and polarization fatigue in rhombohedral PIN-PMN-PT and Mn-doped PIN-PMN-PT single crystals. J. Am. Ceram. Soc. 2019, 102, 6668–6679. [Google Scholar] [CrossRef]

- Thakre, A.; Kumar, A.; Jeong, D.Y.; Hwang, G.T.; Yoon, W.H.; Lee, H.Y.; Ryu, J. Enhanced mechanical quality factor of 32 mode Mn doped 71Pb(Mg1/3Nb2/3)O3–29PbZrTiO3 piezoelectric single crystals. Electron. Mater. Lett. 2020, 16, 156–163. [Google Scholar] [CrossRef]

- Sherlock, N.P.; Garten, L.M.; Zhang, S.J.; Shrout, T.R.; Meyer, R.J., Jr. Nonlinear dielectric response in piezoelectric materials for underwater transducers. J. Appl. Phys. 2012, 112, 124108. [Google Scholar] [CrossRef]

- Zheng, L.; Yang, L.; Li, Y.; Lu, X.; Huo, D.; Lü, W.; Zhang, R.; Yang, B.; Cao, W. Origin of improvement in mechanical quality factor in acceptor-doped relaxor-based ferroelectric single crystals. Phys. Rev. Appl. 2018, 9, 064028. [Google Scholar] [CrossRef]

- Jing, Y.; Zheng, L.; Liu, F.; Qi, X.; Jiang, G.; Fan, J.; Liu, G.; Lü, W. A large and anisotropic enhancement of the mechanical quality factor in ternary relaxor-PbTiO3 single crystals. Appl. Phys. Lett. 2021, 118, 182902. [Google Scholar] [CrossRef]

- Sherlock, N.P. Relaxor-PT Single Crystals for Broad Bandwidth, High Power Sonar Projectors. Ph.D. Thesis, The Pennsylvania State University, University Park, PA, USA, 2010. [Google Scholar]

- Meyer, R.J.; Montgomery, T.C.; Hughes, W.J. Tonpilz transducers designed using single crystal piezoelectrics. In Proceedings of the 2002 OCEANS’02 MTS/IEEE, Biloxi, MI, USA, 29–31 October 2002; pp. 2328–2333. [Google Scholar]

- Thompson, S.C.; Meyer, R.J.; Markley, D.C. Performance of tonpilz transducers with segmented piezoelectric stacks using materials with high electromechanical coupling coefficient. J. Acoust. Soc. Am. 2014, 135, 155–164. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Huang, D.; Chen, B.R.; Tang, Y.Z. Wideband Single Crystal Longitudinal Transducer for Underwater Sound. In Proceedings of the 2019 14th Symposium on Piezoelectricity, Acoustic Waves and Device Applications (SPAWDA), Shijiazhuang, China, 1–4 November 2019; pp. 1–3. [Google Scholar]

- Sherlock, N.P.; Meyer, R.J. Modified single crystals for high-power underwater projectors. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2012, 59, 1285–1291. [Google Scholar] [CrossRef] [PubMed]

- Guo, R.; Li, S.; An, D.; Han, T.; Chen, J.; Cao, W. Comprehensive analysis of Mn:PIN-PMN-PT single crystals for Class IV flextensional transducer. Ceram. Int. 2018, 44, 2864–2868. [Google Scholar] [CrossRef]

- Zhou, Q.; Lam, K.H.; Zheng, H.; Qiu, W.; Shung, K.K. Piezoelectric single crystal ultrasonic transducers for biomedical applications. Prog. Mater. Sci. 2014, 66, 87–111. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.J.; Zhang, S.; Bar-Cohen, Y.; Sherrit, S. High temperature, high power piezoelectric composite transducers. Sensor 2014, 14, 14526–14552. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Q.; Wu, D.; Jin, J.; Hu, C.H.; Xu, X.; Williams, J.; Cannata, J.M.; Lim, L.; Shung, K.K. Design and fabrication of PZN-7%PT single crystal high frequency angled needle ultrasound transducers. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2008, 55, 1394–1399. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Q.; Xu, X.; Gottlieb, E.J.; Sun, L.; Cannata, J.M.; Ameri, H.; Humayun, M.S.; Han, P.; Shung, K.K. PMN-PT single crystal, high-frequency ultrasonic needle transducers for pulsed-wave Doppler application. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2007, 54, 668–675. [Google Scholar] [CrossRef]

- Shung, K.K.; Cannata, J.M.; Zhou, Q.F. Piezoelectric materials for high frequency medical imaging applications: A review. J. Electroceram. 2007, 19, 141–147. [Google Scholar] [CrossRef]

- Lam, K.H.; Chen, Y.; Cheung, K.F.; Dai, J.Y. PMN–PT single crystal focusing transducer fabricated using a mechanical dimpling technique. Ultrasonics 2012, 52, 20–24. [Google Scholar] [CrossRef]

- Chen, Y.; Lam, K.H.; Zhou, D.; Cheng, W.F.; Dai, J.Y.; Luo, H.S.; Chan, H.L.W. High frequency PMN–PT single crystal focusing transducer fabricated by a mechanical dimpling technique. Ultrasonics 2013, 53, 345–349. [Google Scholar] [CrossRef]

- Chen, Y.; Qiu, W.B.; Lam, K.H.; Liu, B.Q.; Jiang, X.P.; Zheng, H.R.; Luo, H.S.; Chan, H.L.W.; Dai, J.Y. Focused intravascular ultrasonic probe using dimpled transducer elements. Ultrasonics 2015, 56, 227–231. [Google Scholar] [CrossRef]

- Fei, C.; Yang, Y.; Guo, F.; Lin, P.; Chen, Q.; Zhou, Q.; Sun, L. PMN-PT single crystal ultrasonic transducer with half-concave geometric design for IVUS imaging. IEEE Trans. Biomed. Eng. 2017, 65, 2087–2092. [Google Scholar] [CrossRef]

- Jae Lee, H.; Zhang, S.; Meyer, R.J., Jr.; Sherlock, N.P.; Shrout, T.R. Characterization of piezoelectric ceramics and 1–3 composites for high power transducers. Appl. Phys. Lett. 2012, 101, 032902. [Google Scholar] [CrossRef]

- Lee, H.J.; Zhang, S. Design of low-loss 1-3 piezoelectric composites for high-power transducer applications. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2012, 59, 1969–1975. [Google Scholar]

- Wong, C.M.; Chen, Y.; Luo, H.; Dai, J.; Lam, K.H.; Chan, H.L.W. Development of a 20-MHz wide-bandwidth PMN-PT single crystal phased-array ultrasound transducer. Ultrasonics 2017, 73, 181–186. [Google Scholar] [CrossRef] [PubMed]

- Zhou, D.; Chen, J.; Luo, H. Piezoelectric single crystals of Pb(Mg1/3Nb2/3)O3-PbTiO3 and their applications in medical ultrasonic transducers. In Proceedings of the 2008 International Conference on BioMedical Engineering and Informatics, Sanya, China, 27–30 May 2008; pp. 662–666. [Google Scholar]

- Zhou, D.; Cheung, K.F.; Chen, Y.; Lau, S.T.; Zhou, Q.; Shung, K.K.; Luo, H.S.; Dai, J.; Chan, H.L.W. Fabrication and performance of endoscopic ultrasound radial arrays based on PMN-PT single crystal/epoxy 1–3 composite. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2011, 58, 477–484. [Google Scholar] [CrossRef] [PubMed]

- Lau, S.T.; Li, H.; Wong, K.S.; Zhou, Q.F.; Zhou, D.; Li, Y.C.; Luo, H.S.; Shung, K.K.; Dai, J.Y. Multiple matching scheme for broadband 0.72Pb(Mg1/3Nb2/3)O3−0.28PbTiO3 single crystal phased-array transducer. J. Appl. Phys. 2009, 105, 094908. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Chen, M.; Zhao, X.; Wang, F.; Tang, Y.; Lin, D.; Luo, H. Fabrication and high acoustic performance of high frequency needle ultrasound transducer with PMN-PT/Epoxy 1–3 piezoelectric composite prepared by dice and fill method. Sens. Actuator A Phys. 2021, 318, 112528. [Google Scholar] [CrossRef]

- Yang, X.; Li, Z.; Fei, C.; Liu, Y.; Li, D.; Hou, S.; Zhang, L.; Li, F.; Yang, Y.; Zhou, Q.; et al. High frequency needle ultrasonic transducers based on Mn doped piezoelectric single crystal. J. Alloys Compd. 2020, 832, 154951. [Google Scholar] [CrossRef]

- Lee, H.J.; Zhang, S.; Luo, J.; Li, F.; Shrout, T.R. Thickness-dependent properties of relaxor-PbTiO3 ferroelectrics for ultrasonic transducers. Adv. Funct. Mater. 2010, 20, 3154–3162. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.J.; Zhang, S.; Shrout, T.R. Scaling effects of relaxor-PbTiO3 crystals and composites for high frequency ultrasound. J. Appl. Phys. 2010, 107, 124107. [Google Scholar] [CrossRef]

- Wan, H.; Kim, H.; Wu, H.; Luo, C.; Jiang, X. Characterization of high-frequency ultrasound transducers made of alternating current poled Pb(Mg1/3Nb2/3)O3-xPbTiO3 single crystals. In Proceedings of the 2020 IEEE International Ultrasonics Symposium (IUS), Las Vegas, NV, USA, 7–11 September 2020; pp. 1–4. [Google Scholar]

- Xu, J.; Zhang, Z.; Liu, S.; Xiao, J.; Yue, Q.; Deng, H.; Wang, X.; Lin, D.; Wang, F.; Zhang, R.; et al. Optimizing the piezoelectric vibration of Pb(Mg1/3Nb2/3)O3-0.25PbTiO3 single crystal by alternating current polarization for ultrasonic transducer. Appl. Phys. Lett. 2020, 116, 202903. [Google Scholar] [CrossRef]

- Qiu, C.; Liu, J.; Li, F.; Xu, Z. Thickness dependence of dielectric and piezoelectric properties for alternating current electric-field-poled relaxor-PbTiO3 crystals. J. Appl. Phys. 2019, 125, 014102. [Google Scholar] [CrossRef]

- Uchino, K. Electro-optic ceramics and their display applications. Ceram. Int. 1995, 21, 309–315. [Google Scholar] [CrossRef]

- Zheng, L.; Jing, Y.; Lu, X.; Li, S.; Yang, L.; Lü, W.; Cao, W. Temperature dependent piezoelectric anisotropy in tetragonal 0.63Pb(Mg1/3Nb2/3)-0.37PbTiO3 single crystal. Appl. Phys. Lett. 2018, 113, 102903. [Google Scholar] [CrossRef]

- Li, F.; Zhang, S.; Lin, D.; Luo, J.; Xu, Z.; Wei, X.; Shrout, T.R. Electromechanical properties of Pb(In1/2Nb1/2)O3–Pb(Mg1/3Nb2/3)O3–PbTiO3 single crystals. J. Appl. Phys. 2011, 109, 014108. [Google Scholar] [CrossRef]

- Lin, D.; Lee, H.J.; Zhang, S.; Li, F.; Li, Z.; Xu, Z.; Shrout, T.R. Influence of domain size on the scaling effects Pb(Mg1/3Nb2/3)O3-PbTiO3 ferroelectric crystals. Scr. Mater. 2011, 64, 1149–1151. [Google Scholar] [CrossRef]

- Li, F.; Zhang, S.; Luo, J.; Geng, X.; Xu, Z.; Shrout, T.R. [111]-oriented PIN-PMN-PT crystals with ultrahigh dielectric permittivity and high frequency constant for high-frequency transducer applications. J. Appl. Phys. 2016, 120, 074105. [Google Scholar] [CrossRef]

- Lebrun, L.; Sebald, G.; Guiffard, B.; Richard, C.; Guyomar, D.; Pleska, E. Investigations on ferroelectric PMN–PT and PZN–PT single crystals ability for power or resonant actuators. Ultrasonics 2004, 42, 501–505. [Google Scholar] [CrossRef]

- Hou, X.Y.; Lee, H.P.; Lim, S.P.; Ong, C.J. Performance enhancement of ultrasonic motors using single crystalline piezo-materials. In Proceedings of the 2012 Digest APMRC, Singapore, 31 October–2 November 2012; pp. 1–2. [Google Scholar]

- Li, S.; Jiang, W.; Zheng, L.; Cao, W. A face-shear mode single crystal ultrasonic motor. Appl. Phys. Lett. 2013, 102, 183512. [Google Scholar] [CrossRef]

- Ci, P.; Liu, G.; Chen, Z.; Zhang, S.; Dong, S. High-order face-shear modes of relaxor-PbTiO3 crystals for piezoelectric motor applications. Appl. Phys. Lett. 2014, 104, 242911. [Google Scholar] [CrossRef]

- Ou, W.; Li, S.; Cao, W.; Yang, M. A single-mode Mn-doped 0.27PIN-0.46PMN-0.27PT single-crystal ultrasonic motor. J. Electroceram. 2016, 37, 121–126. [Google Scholar] [CrossRef]

| BM | SSCG | |

|---|---|---|

| Cost | High | Medium |

| Complexity of operation | High | Medium |

| Homogeneity of product | Low | High |

| Porosity of product | Low | High |

| Quantity of product | Large | Large |

| Progress in issue | Successful | Successful |

| Single Crystal | Domain Configuration | DC Field (kV cm−1) | Poling Temp. (°C) | Domain Size (μm) | ε33/ε0 | Loss (%) | d33 (pC N−1) |

|---|---|---|---|---|---|---|---|

| PIN–PMN–PT a | 3T | 4.0 | 210 | 0.5 | 13,800 | 0.7 | 1630 |

| PIN–PMN–PT | 3T | 4.0 | 150 | 50.0 | 3000 | 0.4 | 450 |

| 0.68PMN–0.32PT b | 3O | 2.0 | 150 | ~2.0 | 6400 | 0.3 | 900 |

| 0.68PMN–0.32PT | 3O | 4.0 | 25 | ~20.0 | 4400 | 0.4 | 450 |

| Poling Condition | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Single Crystal (Poling) | εT33/ε0 | Differ. from DCP | tanδ (%) | d33 (pC N−1) | Differ. from DCP | Field (kV cm−1) | Freq. (Hz) | Cycle | Temp. (°C) |

| 0.75PMN-0.25PT (DCP) [100] | 5321 | / | / | 1220 | / | 6.0–18.0 | / | / | RT |

| 0.75PMN-0.25PT(ACP) | 6397 | 20% | / | 1730 | 40% | 12.0–18.0 | 20–40 | 20 | RT |

| 0.71PMN-0.29PT (DCP) [103] | 7740 | / | 0.60 | 2030 | / | 5.0 | / | / | 50 |

| 0.71PMN-0.29PT (ACP) | 8840 | 12% | 0.98 | 2850 | 28% | 12.0 (Vp-p) | 20 | 40 | 50 |

| 0.70PMN-0.30PT (DCP) [103] | 8490 | / | 0.41 | 2710 | / | 5.0 | / | / | 50 |

| 0.70PMN-0.30PT (ACP) | 8800 | 4% | 0.45 | 3050 | 12% | 12.0 (Vp-p) | 20 | 40 | 50 |

| 0.70PMN-0.30PT (DCP) [23] | 6160 | / | / | 1650 | / | 10.0 | / | / | RT |

| 0.70PMN-0.30PT (ACP) | 8500 | 38% | / | 2000 | 21% | 10.0 (Vp-p) | 1.0 | 7 | RT |

| 0.70PMN-0.30PT (DCP) [101] | 5110 | / | 0.39 | 1760 | / | 8.0 | / | / | 50 |

| 0.70PMN-0.30PT (ACP) | 8330 | 35% | 0.33 | 2750 | 56% | 4.0 (rms) | 0.1 | 20 | 100 to 70 |

| 0.24PIN-0.46PMN-0.30PT (DCP) [117] | 5440 | / | / | 1810 | / | 4.0 | / | / | 50 |

| 0.24PIN-0.46PMN-0.30PT (ACP) | 7000 | 29% | 0.59 | 2340 | 29% | 4.0 (rms) | 10 | 12 | 90 |

| Mn: PIN-PMN-27PT (DCP) [102] | 3700 | / | 0.30 | 1350 | / | 5.0–15.0 | / | / | RT |

| Mn: PIN-PMN-27PT (ACP) | 5300 | 43% | 0.30 | 1750 | 29% | 20.0 (Vp-p) | 0.1 | 20 | RT |

| Material (Domain State) | Orientation | TC (°C) | EC (kV/cm) | εT33/ε0 | tanδ (%) | Q33 | k33 | d33 (pC/N) | Growth Method | Ref. |

|---|---|---|---|---|---|---|---|---|---|---|

| 0.70PMN–0.33PT | <001> c | 155 | 2.8 | 8200 | / | 100 | 0.94 | 2820 | MB b | [2] |

| PIN–PMN–PT (MPB) a | <001> c | 197 | 5.5 | 7244 | / | 120 | 0.95 | 2742 | MB | [2] |

| PIN-PMN-PT:Mn (2R) a | <011> c | 197 | 5.1 | 3523 | 0.6 | 1000 | 0.90 | 1053 | MB | [130] |

| 0.27PIN-0.46PMN-0.27PT:Mn (1R) | <111> c | 194 | 9.1 | 1299 | / | 1200 | 0.346 | 95 | MB | [131] |

| 0.26PIN-0.42PMN-0.32PT:Mn (1O) | <011> c | 208 | 5.6 | 1240 | 0.1 | 1230 | 0.70 | 267 | MB | [35] |

| 0.26PIN-0.42PMN-0.32PT:Mn (4O) | <001> c | 208 | 4.9 | 4280 | 0.4 | 300 | 0.91 | 1370 | MB | [35] |

| 0.88PZN-0.12PT:Mn | <110> c | 180 | 8.6 | 5300 | 0.4 | 750 | 0.60 | 500–600 | CFG c | [128] |

| 0.88PZN-0.12PT | <110> c | 185 | 12.3 | 5500 | / | 150 | 0.615 | 530 | CFG | [128] |

| 0.4PMN–0.25PZ–0.35PT:Mn | <001> c | 203 | 6.3 | 3410 | 0.2 | 1050 | 0.92 | 1140 | SSCG d | [17] |

| 0.4PMN–0.25PZ–0.35PT | <001> c | 211 | 4.5 | 4850 | 0.5 | 100 | 0.93 | 1530 | SSCG | [17] |

| 0.68PIN-0.32PT:Mn | <001> c | 231 | 9.7 | 1284 | 1.0 | / | 0.80 | 730 | CFG | [129] |

| Composition | Domain Configur. | Ref. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PIN–PMN–28PT | 2R | 2920 | 5000 | 1030 | 2203 | 460 | −1156 | 782 | 0.67 | 0.87 | 0.91 | [133] |

| PIN–PMN–28PT | 1R | 702 | 6286 | / | 2190 | −34 | / | 74 | 0.13 | 0.36 | 0.92 | [159] |

| PIN–PMN–33PT | 4O | 7244 | 10,081 | / | 232 | −1337 | / | 2742 | 0.65 | 0.95 | 0.20 | [15] |

| PIN–PMN–33PT | 1O | 1500 | 8070 | 30,000 | 4550 | 153 | −346 | 350 | 0.44 | 0.74 | 0.96 | [157] |

| PIN–PMN–(39–41)PT | 1T | 1090 | 15,000 | / | 2350 | −200 | / | 530 | 0.50 | 0.84 | 0.85 | [37] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baasandorj, L.; Chen, Z. Recent Developments on Relaxor-PbTiO3 Ferroelectric Crystals. Crystals 2022, 12, 56. https://doi.org/10.3390/cryst12010056

Baasandorj L, Chen Z. Recent Developments on Relaxor-PbTiO3 Ferroelectric Crystals. Crystals. 2022; 12(1):56. https://doi.org/10.3390/cryst12010056

Chicago/Turabian StyleBaasandorj, Lkhagvasuren, and Zibin Chen. 2022. "Recent Developments on Relaxor-PbTiO3 Ferroelectric Crystals" Crystals 12, no. 1: 56. https://doi.org/10.3390/cryst12010056

APA StyleBaasandorj, L., & Chen, Z. (2022). Recent Developments on Relaxor-PbTiO3 Ferroelectric Crystals. Crystals, 12(1), 56. https://doi.org/10.3390/cryst12010056