Optimization of the Physical and Mechanical Properties of Grouting Material for Non-Soil-Squeezing PHC Pipe Pile

Abstract

:1. Introduction

2. Experimental Program and Test Method

2.1. Grouting Material and Experimental Program

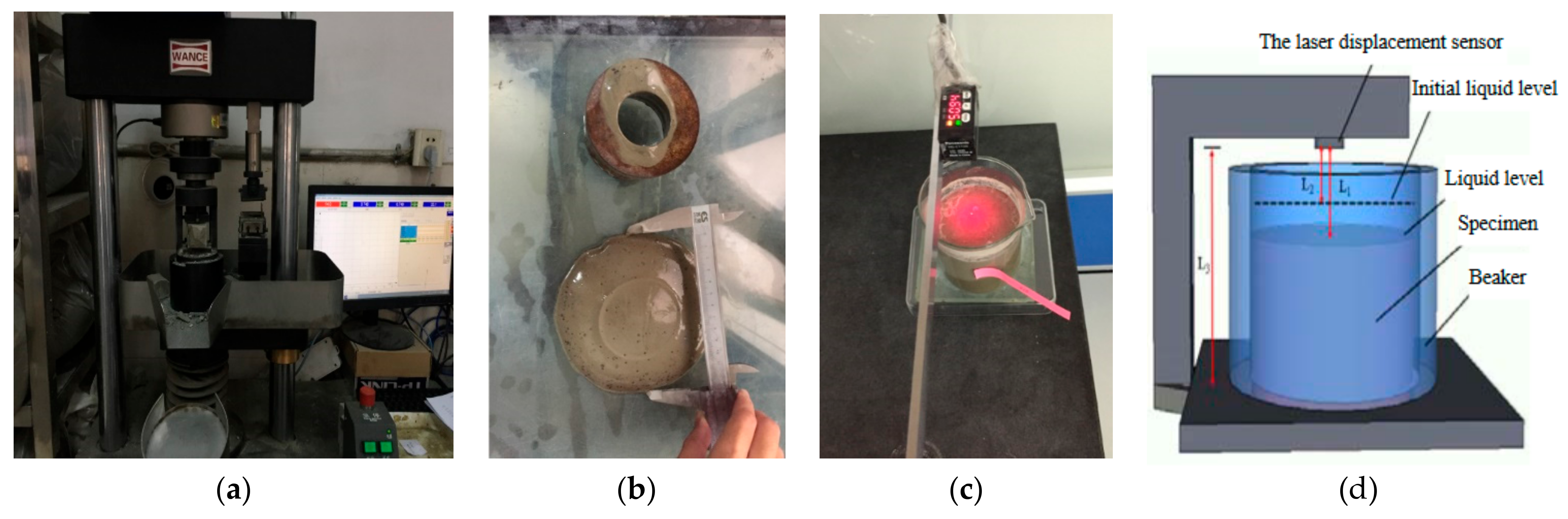

2.2. Test Method

- (1)

- Testing method for compressive strength

- (2)

- Testing method for fluidity

- (3)

- Testing method for the volume growth rate of the grouting body

3. Experimental Results and Analysis

3.1. Experimental Results for Compressive Strength

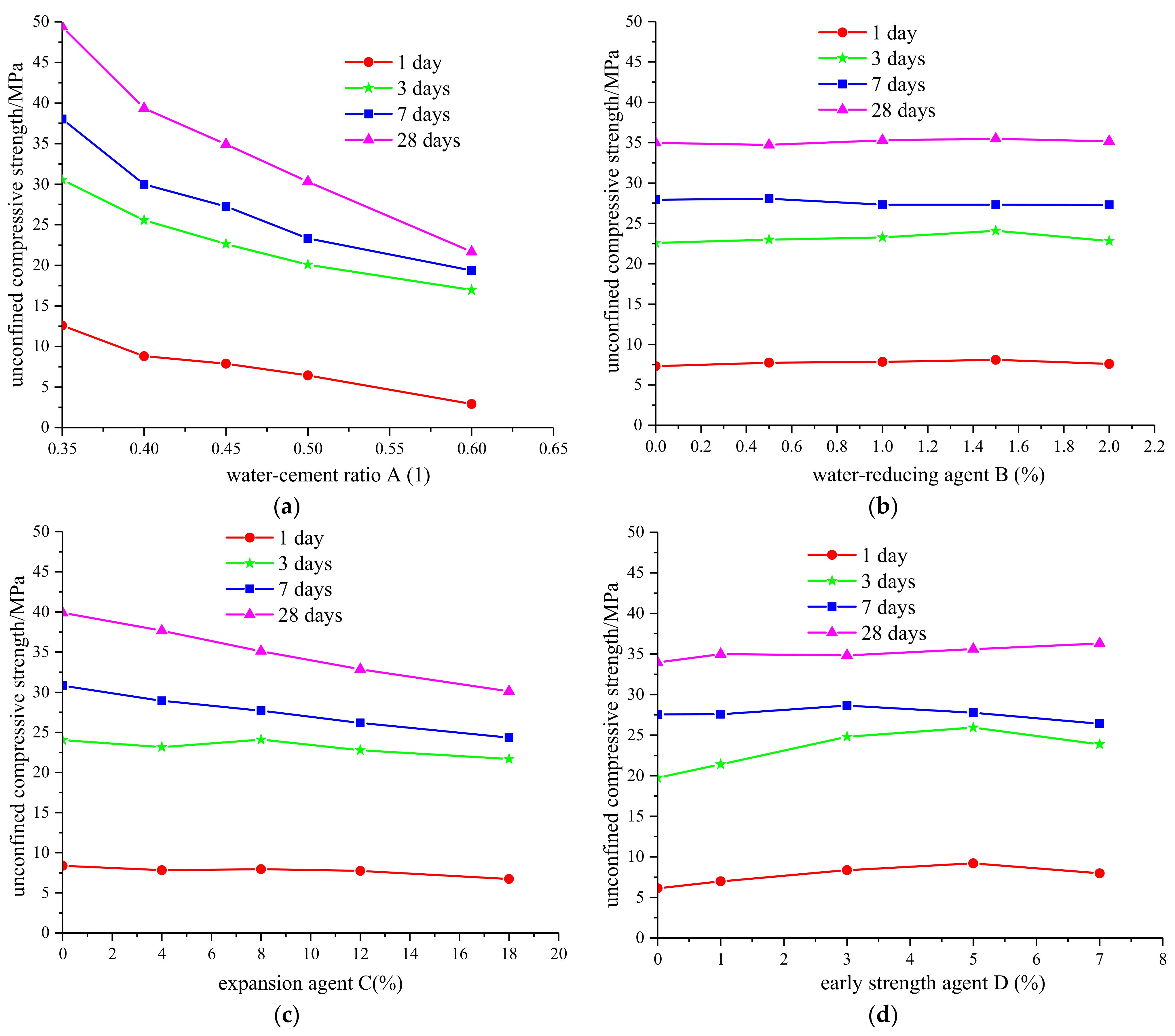

3.1.1. The Influence of Various Factors on the Development Trend of Compressive Strength

- (1)

- Figure 3a reflects the change law of the compressive strength of the grouting body with the water–cement ratio ranging from 0.35 to 0.6. As the water–cement ratio increased, the strength of the grouting body decreased almost linearly. When the solidification time was less than 1 day, its strength was not high for the insufficient initial setting time. After the solidification time reached 3 days, the compressive strength increased rapidly and was further improved when the solidification time reached 7 days. Compared with the setting time of 3 days, the compressive strength increase rate with a setting time of 7 days or 28 days became slower.

- (2)

- It can be seen from Figure 3b that the dosage of water-reducing agent had no obvious effect on the strength change of the grouting body.

- (3)

- Figure 3c reflects the change law of the compressive strength of the grouting body with the percentages of expansion agent content in cement mass ranging from 0% to 18%. The strength of the grouting body dropped rapidly with the increase of the expansion agent content, whose descent rate gradually decreased and was not as large as the corresponding descent rate of the water–cement ratio. The amount of expansion agent was negatively related to the compressive strength and mainly acted in the middle and late stages of the hardening process of the grouting body. The hydration reaction of the expansion agent removed part of the water needed for the cement hydration reaction, disrupting the normal hydration process of cement, which made the water supply for the hydration reaction of the grouting body insufficient, resulting in the strength of the grouting body decreasing, especially in the middle and late stages [29,30,31].

- (4)

- Figure 3d reflects the change law of the compressive strength of the grouting body with the percentages of early-strength agent content in the cement mass ranging from 0% to 7%. The early-strength agent had the greatest impact on the compressive strength with a setting time of 3 days, followed by 1 day and again after 7 days and had almost no effect on the compressive strength with a setting time of 28 days. When the slurry solidification time was no more than 3 days, the compressive strength gradually increased with the increase of the early-strength agent content and the situation was opposite when the slurry solidification time was over 3 days. When the percentages of early-strength agent content in the cement mass reached 5%, the magnitude of compressive strength reached its peak value. When the percentages of early-strength agent were more than 5%, the improvement of the early strength of the grouting body by increasing the early-strength agent content was poor and even had a negative effect; that is to say, the best percentages of early-strength agent content in cement mass were 5%.

3.1.2. Range Analysis and Variance Calculation of Uniaxial Compressive Strength

3.1.3. Synthetic Analysis on Uniaxial Compressive Strength

- (1)

- Range and variance analysis for compressive strength under a solidification time of 1 day

- (2)

- Range and variance analysis for compressive strength under a solidification time of 3 days

- (3)

- Range and variance analysis for compressive strength under a solidification time of 7 days and 28 days

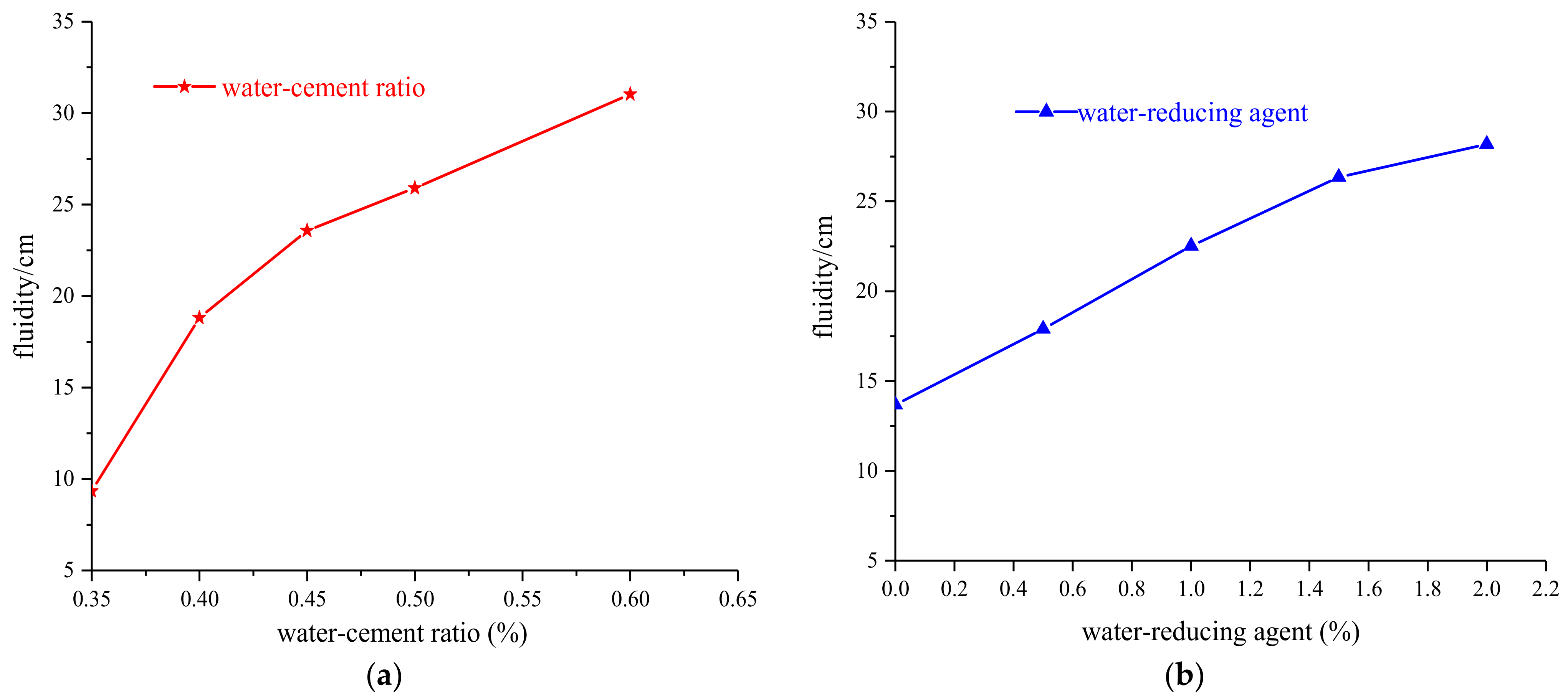

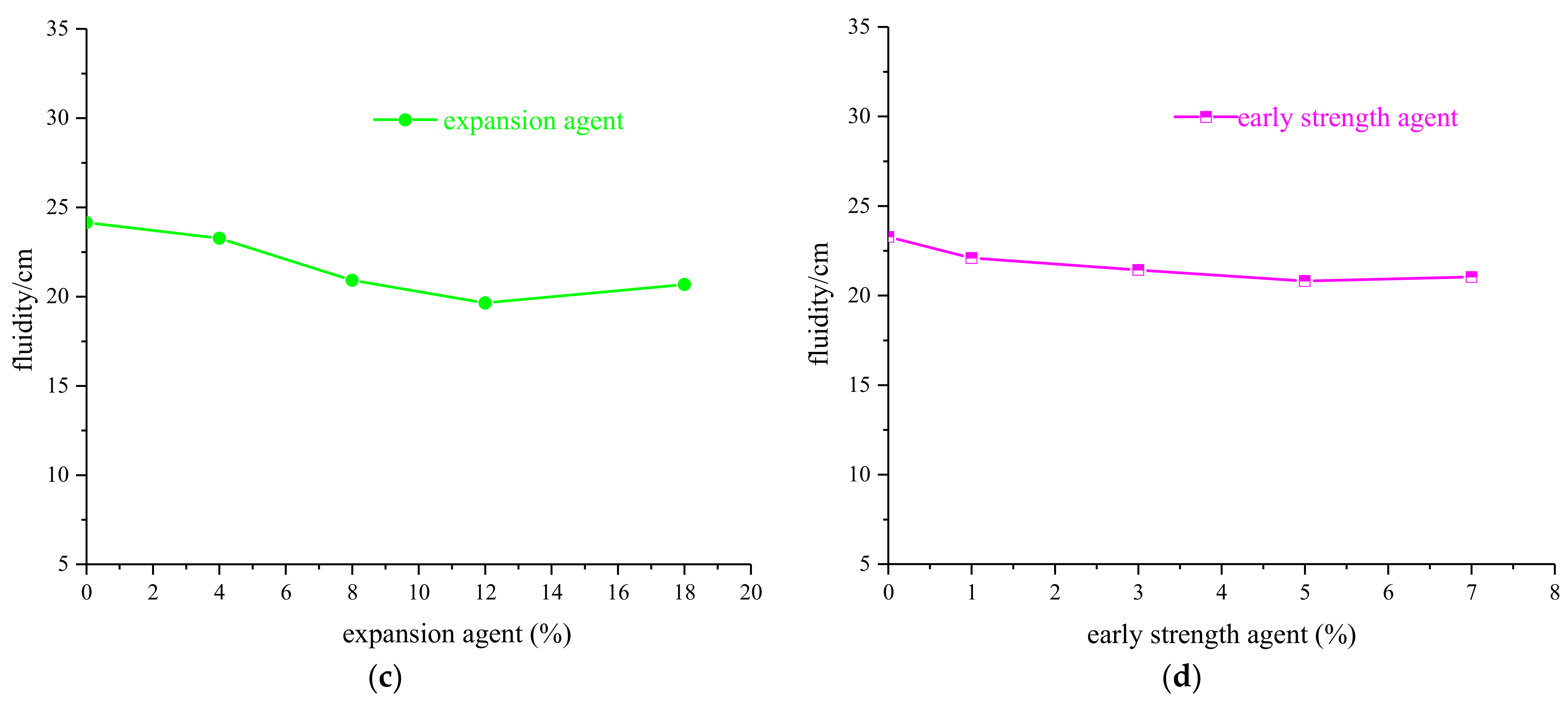

3.2. Experimental Results for Fluidity

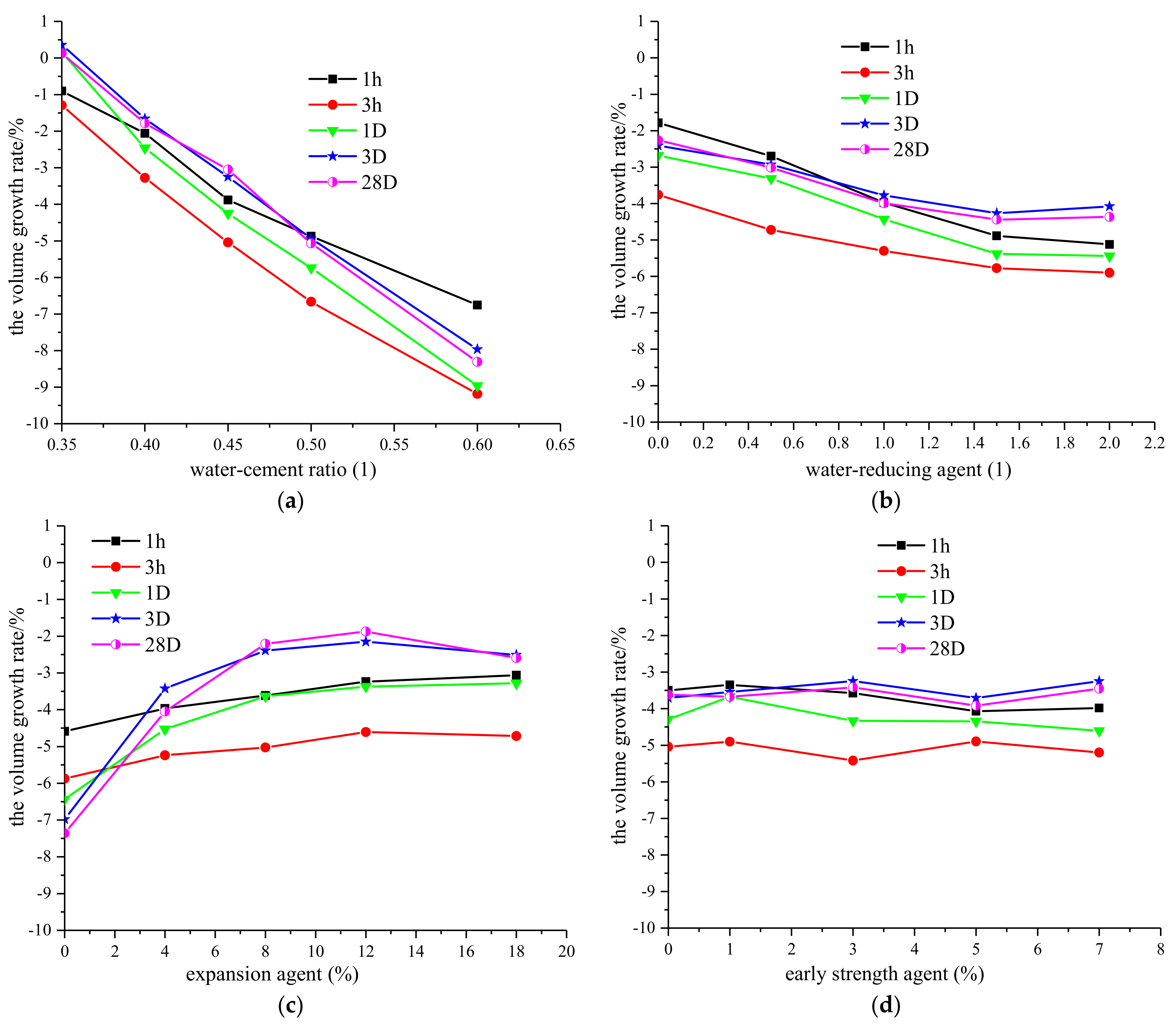

3.3. Experimental Results for the Volume of Grouting Body

4. The Proportional Optimization Design of Water–Cement Mixture

5. Conclusions

- (1)

- The strength of the grouting body decreases linearly with the increase of the water–cement ratio, and the dosage of water-reducing agent has no obvious effect on the strength. As the dosage of the expansion agent increases, the strength of the grouting body decreases rapidly. The expansion agent mainly acts in the middle and late stages of the hardening process of the grouting material.

- (2)

- The early-strength agent has the greatest influence on the strength of the grouting body when it has been solidified for 3 h, followed by 1 day and again after 7 days and has almost no effect on the compressive strength when the grout curing time is 28 days.

- (3)

- When the grout curing time is 3 h, the optimal dosage of the early-strength agent is 5%. Excessive mixing of the early-strength agent is easy to chemically react with cement molecules to generate ettringite crystals, thereby destroying the structure of the grouting body and causing the strength of the grouting body to decrease.

- (4)

- Expansion agents have little effect on the compressive strength in the early stage but have a greater effect on the strength in the later stage. The compressive strength in the later stage is inversely proportional to the amount of expansion agent. Early-strength agents have a greater impact on the early strength but less on the later strength. The compressive strength on the first day and the third day after adding the early-strength agent was increased by 50.18% and 31.32%, respectively, which can significantly shorten the construction period.

- (5)

- The fluidity of the water–cement mixture can be improved significantly by increasing the water–cement ratio. The water-reducing agent dosage has a saturation point (about 1.5%), exceeding which, the effect of increasing the amount of water-reducing agent to enhance the fluidity of the slurry will be very limited. The fluidity of water–cement mixture shows a decreasing trend with the increase of the expansion agent dosage or the early-strength agent dosage.

- (6)

- The grouting body volume decreases linearly with the increase of the water–cement ratio and decreases rapidly with the increase of the dosage of the water-reducing agent. The volume of the grouting body cannot be increased by steadily adding the water-reducing agent after the water-reducing agent has been already added to a certain level.

- (7)

- When the solidification time is more than 3 days, the expansion agent plays an increasing role, which can guarantee that the volume increment of the grouting body caused by the presence of the expansion agent exceeds or at least equals the volume shrinkage caused by the hardening of the grouting body.

- (8)

- The water–cement ratio is always the greatest influencing factor on the volume growth rate of the grouting body, followed by the water-reducing agent and the expansion agent; the dosage of the early-strength agent has almost no obvious effect. The water-reducing agent and the expansion agent mainly play a key role in the bleeding stage and in the solidification stage of the slurry, respectively.

- (9)

- The optimal combination of grouting material for drilling with PHC pipe cased pile is A3B4C4D4. That is to say that the water–cement ratio is 0.45, the dosage of the 4% water-reducing agent mother liquor accounts for 1.5% of the cement mass, the dosage of expansion agent accounts for 12% of the cement mass and the dosage of early-strength agent accounts for 5% of cement mass, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tang, M.; Hu, H.; Cui, J.; Yang, X.; Hu, H.; Chen, H. The Vertical Bearing Mechanism of Hybrid Bored Pre-stressed Concrete Cased Piles. Int. J. Civ. Eng. 2020, 18, 293–302. [Google Scholar] [CrossRef]

- Hou, Z.; Tang, M.; Hu, H.; Lin, Z.; Chen, Y.; Zhao, S.; Zhang, S. A new type of PHC pile-sinking technology: Drilling with PHC Pipe Cased Pile and its development directions. IOP Conf. Ser. Earth Environ. Sci. 2020, 580, 012013. [Google Scholar] [CrossRef]

- Yang, X. Experimental Study on Vertical Compressive Bearing Capacity and Seismic Performance of Drilling with Large Diameter PHC Pipe Cased Pile. Master’s thesis, Guangzhou University, Guangzhou, China, 2018. [Google Scholar]

- Hou, Z.; Tang, M.; Hu, H.; Li, J.; Zhang, S.; Xu, X.; Liu, C. Comparative study on the vertical load-bearing capacity of the drilling with pre-stressed concrete pipe cased pile based on in-situ and physical simulation tests. Rock Soil Mech. 2021, 42, 419–429. [Google Scholar]

- Zhang, C.; Yang, J.S.; Xie, Y.P.; Gong, F.H.; Liang, X.; Lei, J.S.; Su, B.Z. Experiment and application for grouting materials for karst under conditions of underground water flow before shield tunneling. Chin. J. Rock Mech. Eng. 2018, 37, 133–143. [Google Scholar]

- Rickstal, F.V. Grout Injection of Masonry, Scientific Approach and Modeling. Ph.D. Thesis, Katholieke Universiteit, Leuven, Belgium, 2000. [Google Scholar]

- Yuan, B.; Li, Z.; Zhao, Z.; Ni, H.; Su, Z.; Li, Z. Experimental study of displacement field of layered soils surrounding laterally loaded pile based on Transparent Soil. J. Soils Sediments 2021, 21, 3072–3083. [Google Scholar] [CrossRef]

- Du, Y.; Pei, X.; Huang, R.; He, Z.; Zhang, J. Study on flow characteristics and application of viscosity time-varying grouting material. Rock Soil Mech. 2017, 38, 3498–3504. [Google Scholar]

- Guo, Y. Study of Mechanical Model of Reinforced Soil by Pregrouting and Its Application in Tunnel Practices. Doctoral Thesis, Beijing Jiaotong University, Beijing, China, 2016. [Google Scholar]

- Baltazar, L.G.; Henriques, F.M.A.; Jorne, F. Optimisation of flow behaviour and stability of superplasticized fresh hydraulic lime grouts through design of experiments. Constr. Build. Mater. 2012, 35, 838–845. [Google Scholar] [CrossRef]

- Pei, X.; Huang, R.; Li, Z.; Luo, J. Research on grouting reinforcement of unloading fractured loose rock mass in left bank of jinping I hydropower station. Chin. J. Rock Mech. Eng. 2011, 30, 284–288. [Google Scholar]

- He, Z. Study on Test and Operation Mechanism of the Watertight and Water Shut-Off Grout in Fractured Rock Mass. Doctoral Thesis, Central South University, Changsha, China, 2007. [Google Scholar]

- Yun, J.W.; Park, J.J.; Kwon, Y.S.; Kim, B.K.; Lee, I.M. Cement-based fracture grouting phenomenon of weathered granite soil. KSCE J. Civ. Eng. 2016, 21, 232–242. [Google Scholar] [CrossRef]

- Zhang, C.; Yang, J.S.; Ye, X.T.; Zhang, Y.; Zhang, Z.B.; Su, B.Z. Experiment and application research on stability performance of filling grouting slurry. Chin. J. Rock Mech. Eng. 2018, 37, 3604–3612. [Google Scholar]

- Dreese, T.L.; Wilson, D.B.; Heenan, D.M.; Cockburn, J. State of the Art in Computer Monitoring and Analysis of Grouting. In Proceedings of the Third International Conference on Grouting and Ground Treatment, New Orleans, LA, USA, 10–12 February 2003. [Google Scholar]

- Karol, R.H. Chemical Grouting and Soil Stabilization, 3rd ed.; Marcel Dekker, Inc.: New York, NY, USA, 2003. [Google Scholar]

- Wang, Q.; Qu, L.; Guo, H.; Wang, Q. Grouting reinforcement technique of qingdao jiaozhou bay subsea tunnel. Chin. J. Rock Mech. Eng. 2011, 30, 790–802. [Google Scholar]

- Sui, W.; Liu, J.; Hu, W.; Qi, J.; Zhan, K. Experimental investigation on sealing efficiency of chemical grouting in rock fracture with flowing water. Tunn. Undergr. Space Technol. 2015, 50, 239–249. [Google Scholar] [CrossRef]

- Hou, Z.; Tang, M.; Hu, H.; Lin, Z.; Chen, H.; Liu, C. Quantitative Characterization of Grouting Stones for Drilling with Pre-stressed Concrete Pile Cased Pile. IOP Conf. Ser. Earth Environ. Sci. 2021, 632, 022008. [Google Scholar] [CrossRef]

- Hou, Z.; Tang, M.; Hu, H.; Liu, C.; Su, D. Physical model tests on bearing performance of drilling pre-stressed concrete pile cased pipe-cased pile considering hole collapse. Chin. J. Rock Mech. Eng. 2022, 44, 1–10. [Google Scholar]

- Jiang, L.; Yan, B.; Xiao, Z.; Wang, W.; Zhang, D. GB175—2007, General Portland Cement, Interpretation of standard provisions. Cement 2008, 4, 2. [Google Scholar]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. JGJ/T344-2014 Technical Specification for Pile While Drilling; China Construction Industry Press: Beijing, China, 2014. [Google Scholar]

- Wu, S. Test and Numerical Analysis of the Vertical Compressive Bearing Performance of Large Diameter Core-filled Pipe Piles While Drilling. Master’s thesis, Guangzhou University, Guangzhou, Chin, 2019. [Google Scholar]

- Li, Z.; Du, S. Experimental Optimization Design and Statistical Analysis; Science Press: Beijing, China, 2010. [Google Scholar]

- Zhang, C.; Liang, J.-W.; Yang, J.-S.; Zhang, G.-J.; Xie, Y.-P.; Ye, X.-T. Sealing mechanism of slurry materials considering temporal and spatial variation of viscosity. Chin. J. Geotechnol. Eng. 2019, 5, 2130–2139. [Google Scholar]

- National Bureau of Quality and Technical Supervision of the People’s Republic of China. GB/T 17671-1999 Cement Mortar Strength Inspection Method (ISO Law); China Construction Industry Press: Beijing, China, 1999. [Google Scholar]

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. GBT-2419-2005 Cement Mortar Fluidity Determination Method Specification; China Construction Industry Press: Beijing, China, 2005. [Google Scholar]

- Yang, X.; Peng, C.; Jiang, Y. Guidelines for Testing Granular Grouting Materials; New Century Press: Beijing, China, 2010. [Google Scholar]

- Peng, C.; Geng, C.; Liu, Y.; Shi, H.; Yu, S.; Ding, Q. Effect of expansion agent and pottery sand on UHPC anti-wear performance and volume stability. Bull. Chin. Ceram. Soc. 2020, 39, 1132–1139. [Google Scholar]

- Hu, S.; Lu, L.; He, Y.; Li, Y.; Ding, Q. The hydration of blended cement at low W/B ratio. J. Wuhan Univ. Technol. Mater 2003, 18, 72–75. [Google Scholar]

- Wang, H. Research on application of anti-scouring admixture in hydraulic concrete. China Concr. Cem. Prod. 2008, 4, 20–22. [Google Scholar]

- Shi, H.; Sun, Z.; Deng, K. Encyclopedia of Concrete Admixture Technology; Chemical Industry Press: Beijing, China, 2013. [Google Scholar]

- Wu, Y.; Liu, D. Effect of early strength agents on early performance of composite foamed lightweight concrete. China Concr. Cem. Prod. 2016, 35, 3351–3356. [Google Scholar]

- Sheng, Y.; Li, G.; Jiang, H. Effects of superplasticizers and fly ash on rheological properties of cemented tailings backfill. J. Chongqing Univ. 2020, 43, 55–64. [Google Scholar]

| Level | Influencing Factor | |||

|---|---|---|---|---|

| Water–Cement Ratio A | Water-Reducing Agent B | Expansion Agent C | Early-Strength Agent D | |

| 1 | 0.35 | 0.00% | 0% | 0% |

| 2 | 0.40 | 0.50% | 4% | 1% |

| 3 | 0.45 | 1.00% | 8% | 3% |

| 4 | 0.50 | 1.50% | 12% | 5% |

| 5 | 0.60 | 2.00% | 18% | 7% |

| Number | Water–Cement Ratio | Water-Reducing Agent | Expansion Agent | Early-Strength Agent | Blank Column | Blank Column | Unconfined Compressive Strength /MPa | |||

|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | 1 Day | 3 Days | 7 Days | 28 Days | |

| S1 | 0.35 | 0.0% | 0% | 0% | 1 | 1 | 10.63 | 27.21 | 41.69 | 53.04 |

| S2 | 0.35 | 0.5% | 4% | 1% | 2 | 2 | 11.42 | 28.10 | 40.12 | 51.70 |

| S3 | 0.35 | 1.0% | 8% | 3% | 3 | 3 | 13.51 | 32.98 | 38.75 | 49.29 |

| S4 | 0.35 | 1.5% | 12% | 5% | 4 | 4 | 15.01 | 35.10 | 36.32 | 47.46 |

| S5 | 0.35 | 2.0% | 18% | 7% | 5 | 5 | 12.35 | 29.24 | 33.24 | 45.56 |

| S6 | 0.4 | 0.0% | 4% | 3% | 4 | 5 | 9.45 | 27.01 | 32.18 | 41.61 |

| S7 | 0.4 | 0.5% | 8% | 5% | 5 | 1 | 10.63 | 28.99 | 30.92 | 39.47 |

| S8 | 0.4 | 1.0% | 12% | 7% | 1 | 2 | 8.41 | 25.57 | 27.45 | 37.91 |

| S9 | 0.4 | 1.5% | 18% | 0% | 2 | 3 | 6.15 | 21.70 | 26.24 | 33.62 |

| S10 | 0.4 | 2.0% | 0% | 1% | 3 | 4 | 9.39 | 24.53 | 33.06 | 44.13 |

| S11 | 0.45 | 0.0% | 8% | 7% | 2 | 4 | 8.34 | 24.23 | 26.72 | 36.12 |

| S12 | 0.45 | 0.5% | 12% | 0% | 3 | 5 | 6.89 | 18.02 | 26.13 | 31.86 |

| S13 | 0.45 | 1.0% | 18% | 1% | 4 | 1 | 6.06 | 19.96 | 23.44 | 30.24 |

| S14 | 0.45 | 1.5% | 0% | 3% | 5 | 2 | 9.47 | 25.73 | 31.68 | 39.15 |

| S15 | 0.45 | 2.0% | 4% | 5% | 1 | 3 | 8.66 | 25.25 | 28.38 | 37.25 |

| S16 | 0.5 | 0.0% | 12% | 1% | 5 | 3 | 5.34 | 17.61 | 22.18 | 26.98 |

| S17 | 0.5 | 0.5% | 18% | 3% | 1 | 4 | 6.31 | 20.64 | 21.78 | 23.93 |

| S18 | 0.5 | 1.0% | 0% | 5% | 2 | 5 | 8.86 | 23.50 | 26.27 | 36.59 |

| S19 | 0.5 | 1.5% | 4% | 7% | 3 | 1 | 7.18 | 21.12 | 23.33 | 35.28 |

| S20 | 0.5 | 2.0% | 8% | 0% | 4 | 2 | 4.53 | 17.48 | 23.05 | 28.82 |

| S21 | 0.6 | 0.0% | 18% | 5% | 3 | 2 | 2.82 | 16.83 | 16.94 | 17.19 |

| S22 | 0.6 | 0.5% | 0% | 7% | 4 | 3 | 3.55 | 19.21 | 21.36 | 26.61 |

| S23 | 0.6 | 1.0% | 4% | 0% | 5 | 4 | 2.42 | 14.33 | 20.68 | 22.48 |

| S24 | 0.6 | 1.5% | 8% | 1% | 1 | 5 | 2.74 | 16.80 | 19.06 | 21.88 |

| S25 | 0.6 | 2.0% | 12% | 3% | 2 | 1 | 3.05 | 17.61 | 18.83 | 20.14 |

| Days | Number | Water–Cement Ratio A | Water-Reducing Agent B | Expansion Agent C | Early-Strength Agent D | Blank Column E | Blank Column F | Primary and Secondary Factors |

|---|---|---|---|---|---|---|---|---|

| 1 day | K1 | 12.58 | 7.31 | 8.38 | 6.12 | 7.35 | 7.51 | Water–cement ratio > early-strength agent > expansion agent > water-reducing agent |

| K2 | 8.8 | 7.76 | 7.83 | 6.99 | 7.56 | 7.33 | ||

| K3 | 7.88 | 7.85 | 7.95 | 8.36 | 7.96 | 7.44 | ||

| K4 | 6.44 | 8.11 | 7.74 | 9.19 | 7.72 | 8.29 | ||

| K5 | 2.92 | 7.59 | 6.74 | 7.97 | 8.04 | 8.06 | ||

| Range R | 9.67 | 0.79 | 1.64 | 3.07 | 0.69 | 0.96 | ||

| 3 days | K1 | 30.53 | 22.58 | 24.04 | 19.75 | 23.09 | 22.98 | Water–cement ratio > early-strength agent > expansion agent > water-reducing agent |

| K2 | 25.56 | 22.99 | 23.16 | 21.4 | 23.03 | 22.74 | ||

| K3 | 22.64 | 23.27 | 24.1 | 24.8 | 22.7 | 23.35 | ||

| K4 | 20.07 | 24.09 | 22.78 | 25.93 | 23.75 | 23.77 | ||

| K5 | 16.96 | 22.82 | 21.68 | 23.87 | 23.18 | 22.91 | ||

| Range R | 13.57 | 1.51 | 2.42 | 6.18 | 1.06 | 1.02 | ||

| 7 days | K1 | 38.02 | 27.94 | 30.81 | 27.56 | 27.67 | 27.64 | Water–cement ratio > Expansive agent > Early-strength agent > Water-reducing agent |

| K2 | 29.97 | 28.06 | 28.94 | 27.57 | 27.63 | 27.85 | ||

| K3 | 27.27 | 27.32 | 27.7 | 28.64 | 27.64 | 27.38 | ||

| K4 | 23.32 | 27.33 | 26.18 | 27.77 | 27.27 | 27.71 | ||

| K5 | 19.37 | 27.31 | 24.33 | 26.42 | 27.74 | 27.38 | ||

| Range R | 18.65 | 0.75 | 6.48 | 2.22 | 0.47 | 0.47 | ||

| 28 days | K1 | 49.41 | 34.99 | 39.9 | 33.96 | 34.8 | 35.64 | Water–cement ratio > Expansive agent > Early-strength agent > Water-reducing agent |

| K2 | 39.35 | 34.71 | 37.66 | 34.98 | 35.63 | 34.95 | ||

| K3 | 34.92 | 35.3 | 35.11 | 34.83 | 35.55 | 34.75 | ||

| K4 | 30.32 | 35.48 | 32.87 | 35.59 | 34.95 | 34.82 | ||

| K5 | 21.66 | 35.18 | 30.11 | 36.3 | 34.73 | 35.5 | ||

| Range R | 27.75 | 0.76 | 9.8 | 2.33 | 0.9 | 0.89 |

| Sources of Variation | Compressive Strength for 1 Day | Compressive Strength for 3 Days | Compressive Strength for 7 Days | Compressive Strength for 28 Days | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Square Deviation | F- Value | Significance | Square Deviation | F- Value | Significance | Square Deviation | F- Value | Significance | Square Deviation | F-Value | Significance | |

| water–cement ratio A | 61.97 | 95.59 | ** | 135.38 | 171.99 | ** | 250.45 | 1288.98 | ** | 532.96 | 612.88 | ** |

| water-reducing agent B | 0.44 | 0.68 | 1.69 | 2.15 | 0.71 | 3.63 | 0.43 | 0.50 | ||||

| expansion agent C | 1.84 | 2.83 | 4.99 | 6.34 | * | 31.04 | 159.74 | ** | 74.43 | 85.59 | ** | |

| early-strength agent D | 7.16 | 11.04 | ** | 32.01 | 40.67 | ** | 3.14 | 16.14 | ** | 3.81 | 4.38 | * |

| Fα | F0.05(4,8) = 3.84; F0.01(4,8) = 7.01 | |||||||||||

| annotation | *: significant; **: highly significant. | |||||||||||

| Number | Water–Cement Ratio | Water-Reducing Agent | Expansion Agent | Early-Strength Agent | Blank Column | Blank Column |

|---|---|---|---|---|---|---|

| A | B | C | D | E | F | |

| K1(K1j) | 46.69 | 68.43 | 120.72 | 116.40 | 111.48 | 111.06 |

| K2(K2j) | 94.07 | 89.52 | 116.36 | 110.49 | 108.81 | 110.10 |

| K3(K3j) | 117.86 | 112.63 | 104.58 | 107.13 | 107.21 | 109.61 |

| K4(K4j) | 129.50 | 131.77 | 98.24 | 104.07 | 107.37 | 106.15 |

| K5(K5j) | 155.16 | 140.94 | 103.38 | 105.19 | 108.41 | 106.38 |

| K1 | 9.34 | 13.69 | 24.14 | 23.28 | 22.30 | 22.21 |

| K2 | 18.81 | 17.90 | 23.27 | 22.10 | 21.76 | 22.02 |

| K3 | 23.57 | 22.53 | 20.92 | 21.43 | 21.44 | 21.92 |

| K4 | 25.90 | 26.35 | 19.65 | 20.81 | 21.47 | 21.23 |

| K5 | 31.03 | 28.19 | 20.68 | 21.04 | 21.68 | 21.28 |

| Range R | 21.69 | 14.50 | 4.50 | 2.47 | 0.85 | 0.98 |

| Primary and secondary factors (fluidity): Water–cement ratio > water-reducing agent > expansion agent > early-strength agent | ||||||

| Curing Time | Number | Water–Cement Ratio | Water-Reducing Agent | Expansion Agent | Early-Strength Agent | Blank Column | Blank Column | Test Results |

|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | |||

| 1 h | 001 | −0.90 | −1.79 | −4.59 | −3.50 | −3.60 | −3.41 | Primary and secondary factors: Water–cement ratio > water-reducing agent > expansion agent > early-strength agent |

| K2 | −2.06 | −2.70 | −3.97 | −3.35 | −3.46 | −3.95 | ||

| K3 | −3.88 | −3.97 | −3.61 | −3.57 | −3.93 | −3.40 | ||

| K4 | −4.87 | −4.89 | −3.24 | −4.07 | −3.63 | −3.65 | ||

| K5 | −6.75 | −5.12 | −3.06 | −3.98 | −3.85 | −4.06 | ||

| Range R | 5.85 | 3.34 | 1.53 | 0.72 | 0.47 | 0.67 | ||

| 3 h | K1 | −1.29 | −3.76 | −5.87 | −5.04 | −5.12 | −5.17 | Primary and secondary factors: Water–cement ratio > water-reducing agent > expansion agent > early-strength agent |

| K2 | −3.28 | −4.72 | −5.24 | −4.90 | −4.83 | −5.38 | ||

| K3 | −5.04 | −5.30 | −5.03 | −5.42 | −5.26 | −4.84 | ||

| K4 | −6.66 | −5.77 | −4.61 | −4.89 | −5.12 | −4.70 | ||

| K5 | −9.19 | −5.90 | −4.71 | −5.20 | −5.12 | −5.37 | ||

| Range R | 7.90 | 2.14 | 1.27 | 0.52 | 0.44 | 0.68 | ||

| 1 day | K1 | 0.16 | −2.68 | −6.43 | −4.29 | −4.17 | −3.96 | Primary and secondary factors: Water–cement ratio > expansion agent >water-reducingagent > early-strength agent |

| K2 | −2.46 | −3.31 | −4.53 | −3.67 | −4.19 | −4.08 | ||

| K3 | −4.25 | −4.43 | −3.63 | −4.33 | −4.31 | −4.45 | ||

| K4 | −5.74 | −5.38 | −3.37 | −4.34 | −4.20 | −4.08 | ||

| K5 | −8.96 | −5.44 | −3.28 | −4.61 | −4.38 | −4.67 | ||

| Range R | 9.12 | 2.76 | 3.15 | 0.93 | 0.21 | 0.71 | ||

| 3 days | K1 | 0.36 | −2.41 | −6.98 | −3.71 | −3.55 | −3.28 | Primary and secondary factors: Water–cement ratio > expansion agent > water-reducing agent > early-strength agent |

| K2 | −1.66 | −2.93 | −3.42 | −3.54 | −3.17 | −3.11 | ||

| K3 | −3.25 | −3.77 | −2.39 | −3.25 | −3.39 | −3.61 | ||

| K4 | −4.94 | −4.27 | −2.15 | −3.71 | −3.45 | −3.61 | ||

| K5 | −7.97 | −4.08 | −2.51 | −3.25 | −3.88 | −3.85 | ||

| Range R | 8.32 | 1.86 | 4.83 | 0.46 | 0.71 | 0.73 | ||

| 28 day | K1 | 0.13 | −2.26 | -7.36 | −3.62 | −3.85 | −3.82 | Primary and secondary factors: Water–cement ratio > expansion agent > water-reducing agent > early-strength agent |

| K2 | −1.78 | −3.02 | −4.05 | −3.68 | −3.85 | −3.44 | ||

| K3 | −3.05 | −3.99 | −2.21 | −3.42 | −3.57 | −3.98 | ||

| K4 | −5.07 | −4.44 | −1.87 | −3.92 | −3.45 | −3.73 | ||

| K5 | −8.31 | −4.37 | −2.59 | −3.45 | −3.36 | −3.11 | ||

| Range R | 8.44 | 2.18 | 5.49 | 0.50 | 0.49 | 0.87 |

| Experimental Index | Primary and Secondary Factors | Optimal Combination |

|---|---|---|

| ① the fluidity | A > B > C > D | A5B4C1D1 |

| ② the volume growth rate of the grouting body corresponding to the curing time of 3 h | A > B > C > D | A1B1C1D1 |

| ③ the compressive strength with a setting time of 3 days | A > D > C > B | A1B1C1D4 |

| ④ the compressive strength with a setting time of 28 days | A > C > D > B | A1B1C1D1 |

| ⑤ the volume growth rate of the grouting body corresponding to the curing time of 1 day | A > C > B > D | A1B1C4D1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, Z.; Tang, M.; Liang, S.; Zhu, Y. Optimization of the Physical and Mechanical Properties of Grouting Material for Non-Soil-Squeezing PHC Pipe Pile. Crystals 2022, 12, 10. https://doi.org/10.3390/cryst12010010

Hou Z, Tang M, Liang S, Zhu Y. Optimization of the Physical and Mechanical Properties of Grouting Material for Non-Soil-Squeezing PHC Pipe Pile. Crystals. 2022; 12(1):10. https://doi.org/10.3390/cryst12010010

Chicago/Turabian StyleHou, Zhenkun, Mengxiong Tang, Shihua Liang, and Yi Zhu. 2022. "Optimization of the Physical and Mechanical Properties of Grouting Material for Non-Soil-Squeezing PHC Pipe Pile" Crystals 12, no. 1: 10. https://doi.org/10.3390/cryst12010010

APA StyleHou, Z., Tang, M., Liang, S., & Zhu, Y. (2022). Optimization of the Physical and Mechanical Properties of Grouting Material for Non-Soil-Squeezing PHC Pipe Pile. Crystals, 12(1), 10. https://doi.org/10.3390/cryst12010010