Abstract

In the present investigation, the physical, mechanical and durability properties of six concrete mixtures were evaluated, one of conventional concrete (CC) with 100% Portland cement (PC) and five mixtures of Ecofriendly Ternary Concrete (ETC) made with partial replacement of Portland Cement by combinations of sugar cane bagasse ash (SCBA) and silica fume (SF) at percentages of 10, 20, 30, 40 and 50%. The physical properties of slump, temperature, and unit weight were determined, as well as compressive strength, rebound number, and electrical resistivity as a durability parameter. All tests were carried out according to the ASTM and ONNCCE standards. The obtained results show that the physical properties of ETC concretes are very similar to those of conventional concrete, complying with the corresponding regulations. Compressive strength results of all ETC mixtures showed favorable performances, increasing with aging, presenting values similar to CC at 90 days and greater values at 180 days in the ETC-20 and ETC-30 mixtures. Electrical resistivity results indicated that the five ETC mixtures performed better than conventional concrete throughout the entire monitoring period, increasing in durability almost proportionally to the percentage of substitution of Portland cement by the SCBA–SF combination; the ETC mixture made with 40% replacement had the highest resistivity value, which represents the longest durability. The present electrical resistivity indicates that the durability of the five ETC concretes was greater than conventional concrete. The results show that it is feasible to use ETC, because it meets the standards of quality, mechanical resistance and durability, and offers a very significant and beneficial contribution to the environment due to the use of agro-industrial and industrial waste as partial substitutes up to 50% of CPC, which contributes to reduction in CO2 emissions due to the production of Portland cement, responsible for 8% of total emissions worldwide.

Keywords:

properties; mechanical; electrical resistivity; durability; ecofriendly ternary concrete; SCBA; SF 1. Introduction

Concrete is the most widely used construction material worldwide, due to its great mechanical and physical properties, with a demand that grows every year due to the need for the development of civil infrastructure across all countries in the world [1,2,3,4,5,6,7,8]. Even though concrete is durable, it is compromised when exposed to aggressive media where chloride and sulfate ions may be present, which are considered to be the main responsible agents for the premature deterioration of reinforced concrete structures, in which the main problem is the corrosion of reinforcing steel [9,10,11,12,13,14]. This compromises sustainable development by not complying with the useful lifetime for which the structures were designed; additionally, it is known that the manufacture of Portland cement, the main component for the development of concrete, is responsible for around 5 to 8% of total CO2 emissions worldwide [15,16,17]. This has led the scientific community to look for options to reduce the environmental impact due to the use of concrete, of which the addition of supplementary materials to Portland cement is a very favorable option. These materials are industrial wastes, of which Fly ash is a waste material in the power generation industry, and reusing this highly active pozzolan in the construction industry may bring about several advantages [18]; silica fume (SF) is a byproduct from the production of silicon alloys such as ferro-chromium, ferro-manganese, calcium silicon, etc., which also creates environmental pollution and health hazards [19]; blast furnace slag is a waste product of the steel manufacturing process [20]; and among agro-industrial wastes, the most used as alternative materials to Portland cement are rice husk ash [21] and sugar cane bagasse ash (SCBA) [22,23,24].

Lua et al. found that fly ash (FA) and blast furnace slag (BFS) with various contents (cement replacement ratio at 0%, 20%, and 40%) significantly affected the autogenous self-healing ability of early age cracks. The self-healing efficiency of early age cracks decreased with increases in FA and BFS content. BFS mortars exhibited greater recovery in relation to water penetration resistance compared to the reference and FA mortars [25]. Likewise, Anandan et al. determined that the mechanical properties of processed fly ash based concrete with 50% OPC replacement had equal or better strength gain at later ages than unprocessed fly ash based concrete with 25% OPC replacement [26], and in another research work it was shown that binary concretes with 20% fly ash reinforced with AISI 304 Steel presented a higher corrosion resistance than AISI 1018 steel when exposed to a simulated marine environment [27].

Atis et al. showed that the compressive strength of silica fume concrete cured at 65% RH was easier to influence than that of Portland cement concrete. It was found that the compressive strength of silica fume concrete cured at 65% RH was, on average, 13% lower than silica fume concrete cured at 100% RH in concretes with three different water/cement ratios and SF percentages of 10, 15 and 20% [28]. Bhanja et al., based on findings of compressive and tensile strength increases with silica fume incorporation, determined that the optimum replacement percentage is not a constant one but depends on the water–cementitious material (w/cm) ratio of the mix [29]. Ozcan et al. concluded that inclusion of silica fume in concrete increased the compressive strength between 20% and 50% compared to control PC concrete and there was an optimum replacement ratio of silica fume, which could be predicted using artificial neural networks (ANN) and fuzzy logic (FL) [30]. Landa et al. determined that sustainable binary concretes made with 10% SF provided high corrosion resistance to AISI 1018 steel when exposed to sulfates for more than 300 days [31].

Fly ash, silica fume and SCBA have been used in various investigations as supplementary materials to cement with excellent results, such as from Srinivasan et al. who in their studies showed that SCBA in blended concrete had significantly higher compressive strength, tensile strength, and flexural strength compared to concrete without SCBA. It was found that the cement could be advantageously replaced with SCBA up to a maximum limit of 10% [32]. Another study showed that green concretes with substitution of 20% of Portland cement for with SCBA presented a great resistance to corrosion when reinforced with stainless steel [33]. Kawade et al. obtained results showing that SCBA concrete had significantly higher compressive strength compared to concrete without SCBA. The optimal level of SCBA content was achieved with 15.0% replacement and the partial replacement of cement by SCBA increased workability of fresh concrete; therefore, use of super plasticizer was not essential [34]. Castaldelli et al. evaluated different BFS/SCBA mixtures, replacing part of the BFS with SCBA from 0 to 40% by weight; the results of the mechanical resistance values were approximately 60 MPa of compressive strength for BFS/SCBA systems after 270 days of curing at 20 °C. This demonstrated that sugar cane bagasse ash is an interesting source for preparing alkali-activated binders [35]. There are several studies of sustainable concretes, including SCBA, that have shown that corrosion resistance increased compared to that of reinforcing steel when exposed to sulfated media or marine media [22,36,37,38,39], and some research has also been reported on the use of SCBA for green road construction [40,41].

Despite the fact that a large number of studies have been carried out worldwide on the benefits of the inclusion of SCBA for the preparation of concretes and mortars, there is still no standardized process for its commercial use as there is for fly ash and silica fume.

When using alternative materials to Portland cement, there are three very important impacts on development in the construction field. The first is the improvement in physical, mechanical and durability properties of the concretes. The second is the reduction in CO2 emissions when making concrete to build civil infrastructure (bridges, houses, dams, hospitals, roads) by reducing the amount of Portland cement per cubic meter of concrete. The decrease is proportional to the amount in which the Pozzolanic material replaces Portland cement, so that the more volume of Portland cement is replaced, the greater the impact on the environment will be, in accordance with the findings of Dong et al.: when 50% of the cement content was replaced by FA, the embodied CO2 emissions for the UHPC mixture were reduced by approximately 50% as compared to the CO2 emissions calculated from conventional normal-strength concrete [42]. The third is the impact on the culture of recycling waste materials. In first-world countries, the use of fly ash and silica fume is already significant compared to emerging countries, such as Mexico, where at the moment there does not exist civil infrastructure where concrete has been used with replacement in large volumes by this type of material.

Therefore, in this research work, physical, mechanical and durability tests were carried out on Ecological Ternary Concretes (ETC), made with substitution of Portland cement in 10, 20, 30, 40 and 50% of combinations of SCBA and SF, in order to determine the most suitable substitution percentage for the fabrication of ETC that provides better performance than a conventional mixture. Six concrete mixes were produced with a water–cement ratio of 0.65. The physical properties of the concrete in the fresh state, such as slump, volumetric weight, and temperature, were determined according to ASTM and ONNCCE standards. For the mechanical properties, compressive strength tests were carried out as well as rebound number tests, and for the durability parameter of all the study mixtures, the electrical resistivity was determined.

2. Materials and Methods

2.1. Materials

For the elaboration of the study specimens, Portland cement type CPC 30R was used according to the NMX-C-414-ONNCCE standard [43], sugar cane bagasse ash (SCBA) was obtained from a sugar mill located in the town of Mahuixtlán, Veracruz, México, and silica fume (SF) was acquired commercially. Six concrete mixtures were made for the present research, the first of conventional concrete, denoted the control mix (MC), and the remaining five of Ecofriendly Ternary Concrete (ETC), made by substituting the CPC 30R for combinations of SCBA and SF at percentages of 10, 20, 30, 40 and 50%. SCBA and SF were used because they are agro-industrial and industrial wastes with pozzolanic properties due to their chemical composition. The results of the chemical characterization of the cementitious materials used, obtained by X-ray fluorescence (XRF) analysis, are presented in Table 1.

Table 1.

Chemical composition of the cementitious materials obtained by XRF.

The coarse and fine aggregates used for the preparation of the study mixtures were from banks of the Xalapa region. Table 2 summarizes the physical characteristics of the materials used; the tests were carried out according to ASTM standards [44,45,46,47].

Table 2.

Physical characteristics of the aggregates.

2.2. Proportioning of the Mixtures MC and ETC

For the design and proportioning of the concrete mixtures, the ACI 211.1 method [48] was used; a water/cement ratio = 0.65 and a slump of 10 cm were measured for all concrete mixes. Table 3 presents the dosing of the six studied mixtures, the control mix (MC) and the five Ecofriendly Ternary Concrete (ETC) mixtures made with substitution of CPC 30 with combinations of SCBA-SF at 10, 20, 30, 40 and 50% (ETC-10, ETC-20, ETC-30, ETC-40, ETC-50).

Table 3.

Dosage of ternary concrete mixtures (Kg/m3).

2.3. Physical Properties of Concrete Mixtures

To determine the physical properties of the six studied mixtures (MC, ETC-10, ETC-20, ETC-30, ETC-40, ETC-50), slump, temperature and unit weight tests were carried out. All tests were carried out in accordance with the ASTM and ONNCCE.

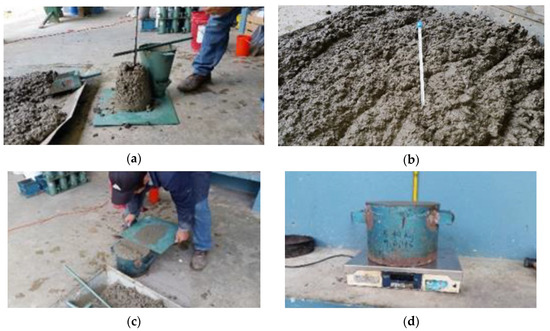

According to the NMX-C-156-ONNCCE-2010 standard [49] for determining slump, a truncated conical mold was used where the fresh concrete was poured and compacted. The mold was placed over a base and raised upwards. The measure of the consistency or workability of the concrete was provided by the amount of concrete slumped and the distance slumped, see Figure 1a.

Figure 1.

Tests of (a) Slump, (b) Temperature, (c,d) Unit weight.

The temperature was determined according to the ASTM C 1064/C1064M-08 standard [50], which indicates that the concrete must be placed in a non-absorbent container with at least 75 mm of concrete in all directions from the temperature sensor, which must have a resolution of ±1.0 °C or smaller with an interval of 0 °C to 50 °C. The thermometer was submerged in fresh concrete to a minimum depth of 75 mm, leaving it for over 2 min until the reading was established (see Figure 1b). The unitary mixture was calculated according to the NMX-C-162-ONNCCE-2014 standard [51]; the equipment used for this test was a balance with a precision of 50 gr., maze of gum, ruler plate, verification plate, measuring container and compaction rod. The concrete was placed in three layers inside the container, and each one was compacted via 25 penetrations with the compaction rod. When compression was complete, the mold was made flush with the ruler plate; finally, the container with the compacted concrete was weighed (see Figure 1c,d).

2.4. Mechanical and Durability Properties of Eco-Friendly Ternary Concrete Mixtures

2.4.1. Compressive Strength

Compressive strength is the parameter or property of the mechanical behavior of hydraulic concrete most necessary for the structural design of civil infrastructure built on the basis of reinforced concrete. Compressive strength testing was carried out according to the NMX-C-083 ONNCCE standard [52], for which specimens were manufactured using cylindrical steel molds of 100 × 200 mm. After 24 h they were removed from the molds and placed in a curing tank according to the NMX-C-ONNCCE standard [53]. The specimens of the six study mixtures were tested at the ages of 7, 14, 28, 90 and 180 days using a loading rate of 0.3 MPa/s (see Figure 2). The compressive strength values analyzed in the results section are the average of the values of three specimens of each mix of concrete.

Figure 2.

Compressive Strength Test.

2.4.2. Rebound Number

To determine the rebound number of specimens of the six concrete mixtures used in this study, tests were carried out according to the NMX-C-192-ONNCCE-2018 standard [54], in which a procedure is established to determine the rebound index for hardened concrete using a device known as a sclerometer or rebound hammer, to evaluate the compressive strength as well as the surface uniformity of the concrete. The results are considered relative rather than absolute values, but the test has the advantages of being non-destructive and widely used worldwide, and is used for evaluating the compressive strength of in-situ concrete [55] and in conjunction with the UPV test to predict the compressive strength of concrete in studies according to the findings of Amine et al. [56]. A rebound hammer, abrasive stone, spatula, flannel and brush were used to carry out the test. The test surface preparation was at least 150 mm in diameter and 100 mm thick. The surface was free of any layer other than concrete (see Figure 3).

Figure 3.

Rebound Number test.

2.4.3. Electrical Resistivity

Electrical resistivity tests were carried out on the six concrete mixtures MC, ETC-10, ETC-20, ETC-30, ETC-40 and ETC-50. Electrical resistivity is considered a very important physical property to determine the quality and durability of concrete [57,58]. Several investigations have shown that the level of corrosion or resistance to corrosion of reinforcing steel in concrete exposed to aggressive media can be determined by electrical resistivity [59,60].

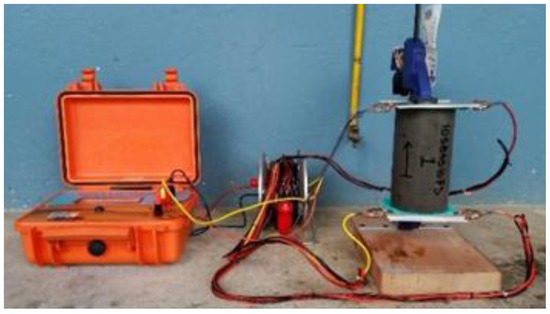

The electrical resistivity test was carried out according to the ASTM G57-07 standard [61], according to the specified equipment requirements and procedures for the measurement of resistivity in the laboratory and on site. The DURAR Network manual [62] indicates the criteria for interpretation of the resistivity results obtained and their relationship with the risk of corrosion of the reinforced concrete, which are presented in Table 4. The tests were carried out at 7, 14, 28, 90 and 180 days. Figure 4 shows the arrangement to carry out the electrical resistivity test.

Table 4.

Electrical resistivity in concrete and risk of corrosion [20].

Figure 4.

Characteristics of the electrical resistivity test.

3. Results and Discussion

3.1. Slump

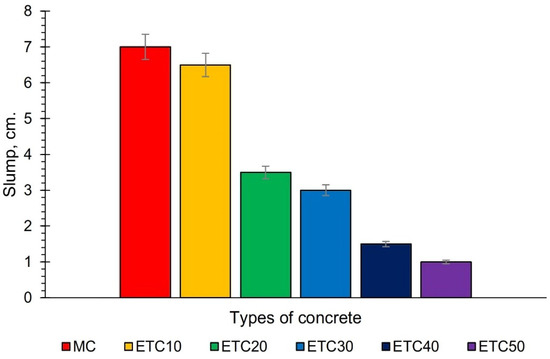

Figure 5 shows the slumps in cm of the six study mixes, the control mix (MC) and the five Eco-friendly Ternary Concrete mixtures (ETC-10, ETC-20, ETC-30, ETC-40, ETC-50ETC).

Figure 5.

Slump of study mixtures (cm).

A decrease in workability or slump was observed in the five ETC mixtures; however, the ETC-10 mixture presented only a 7% decrease (0.5 cm) with respect to the control mixture (MC), with a value of 6.5 cm, which is considered an acceptable workability slump. With an increase to 20% in the percentage of substitution of CPC 30R with the combination of SCBA-SF, the slump showed a decrease of 50% (3.5 cm) with respect to the control mix (MC); this decrease in workability is attributed to the demand or absorption in excess of water due to pozzolanic materials [63,64], as is the case for SCBA and SF. For the ETC-30 mixture the slump was similar to that of the ETC-20 mixture, reaching a slump of 3 cm, which indicates a decrease of about 60% compared with the control mixture. In the case of the ETC-40 and ETC-50 mixtures, the effect of substituting CPC 30R by 40% and 50% respectively had a decisive effect in reducing the workability of these mixtures compared to the control mixture, with a decrease in slump of 80% for the ETC-40 mixture and 85% for the ETC-50. This behavior is due to excess water absorption by the supplementary materials used; therefore, in several investigations where concretes with large volumes of pozzolanic materials such as blast furnace slag or fly ash were used, water-reducing or super fluidizers additives were used to obtain slumps greater than 10 cm, which allowed adequate workability of the concrete mixtures [65,66].

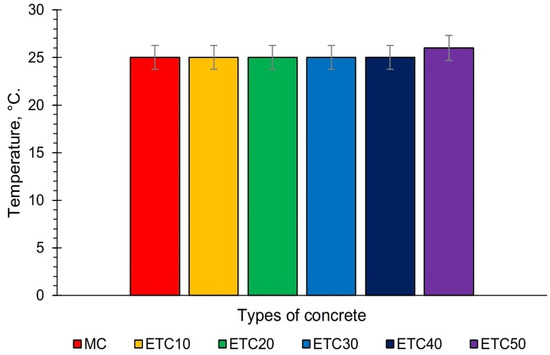

3.2. Temperature

Figure 6 presents the behavior of the temperatures of the six studied concretes. It is observed that five mixtures presented a temperature of 25 °C and the ETC-50 mixture presented a temperature of 26 °C. The reported temperature values are within the specifications of the ASTM C 1064/C1064M-08 standard.

Figure 6.

Temperatures of the studied concretes in fresh states.

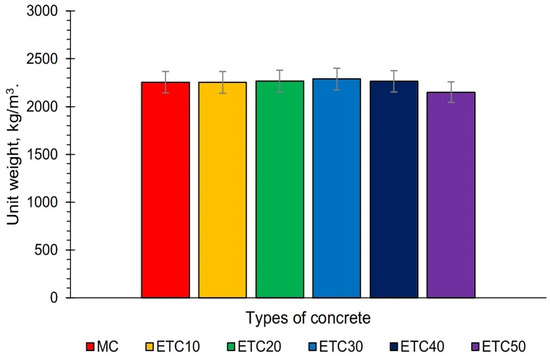

3.3. Unit Weight

Figure 7 presents the unit weight results of the six study mixtures. There was minimal variation between the MC mixture and the ETC mixtures, and all of the unit weight values were within the specifications for the use of concrete in structural elements of civil works according to the NMX-C-155-ONNCCE-2014 standard, which indicates that hydraulic concretes for structural use must have a normal unit weight in fresh condition between 1900 kg/m3 and 2400 kg/m3 [67]. The lowest unit weight obtained was that of the ETC-50 mixture with 2149 kg/m3, with a decrease of 5% compared to the unit mass of the MC mixture; the highest unit weight was presented by the ETC-30 mixture with a value of 2288 kg/m3, 1.5% higher than the control mix. Khawaja et al. who evaluated concrete with Portland cement substitution in 5, 10, 15, 20, and 25% by SCBA, recorded an increase in unit weight of 3.13%, associated with the adhesive property of particles which reduced the concentration of induced air bubbles and consequently generated a stiffer matrix [68].

Figure 7.

Unit weight of the studied concretes.

3.4. Mechanical and Durability Properties

3.4.1. Compressive Strength

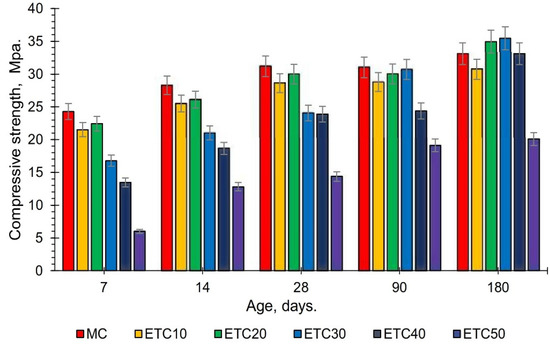

Figure 8 shows the compressive strength results of each of the mixtures, which were tested at the ages of 7, 14, 28, 90 and 180 days. After 7 days, the concrete ETC hadlower compressive strength values than the control mixture, of 11.32, 7.66, 30.92, 44.55 and 75.31% respectively for the ETC-10, ETC-20, ETC-30, ETC-40 and ETC-50 mixtures; this negative effect was due to the presence of alternative pozzolanic materials to cement SCBA and SF, and is in agreement with Wu et al., who showed that FA had a negative effect on strength at early ages, but significantly enhanced the later-age strength [69]. In other studies a similar behavior has been shown even when the specimens of concrete were exposed to an aggressive medium such as sulfates [70]. At 14 days, increases in the resistance of the ETC concretes were observed, and this increase in compressive strength over time continued to 28 days, when the ETC-10 and ETC-20 concretes had 90% of the compressive strength values of the MC, with values of 28 and 29 MPa respectively, while for the ETC-30 and ETC-40 concretes the values were 22 and 23 MPa, and the ETC-50 mixture presenting the lowest compressive strength value with 13 MPa. These compressive strength values in the first 28 days coincide with the findings of various studies, where it has been shown that at 28 days sustainable or ecological concretes that substitute 20% of the CPC with supplementary materials obtain the best performance in compressive strength testing, as demonstrated by Mohamed [71], who found that a ternary concrete mixture made with the substitution of 10% FA + 10% silica fume for Portland Cement presented the highest resistance to compression in a study that covered substitutions from 10% to 50% of fly ash and silica fume for the fabrication of ternary and binary concretes exposed to different types of curing. Arif et al. found that sugar cane bagasse ash used as filler in concretes provided substantial improvements to compressive strength at substitution percentages of up to ≈20% [72]. In other studies, it has been shown that concretes with high FA contents—30%, 40% or higher—presented higher compressive strength values than the control mix, but this was due to the use of superfluidifiers and concretes with a low w/c ratio, equal to or less than 0.40 [73,74].

Figure 8.

Compressive strength of the studied concretes.

At 90 days the differences between the MC and the ETC-10, ETC-20 and ETC-30 concretes were minimal; however, lower values were observed for the specimens of the ETC-40 and ETC-50 mixtures. In percentages, the difference in compressive strength compared to the MC at 90 days was 7.22, 3.24, 1.07, 21.42 and 38.41% for the ETC-10, ETC-20, ETC-30, ETC-40, and ETC-50 mixtures respectively, with the ETC-30 mixture presenting the best performance. This result matches the findings of Le et al. [75], who concluded in their study that the compressive strength of a sample substituting OPC with 30% SCBA and 30% BFS was comparable to that of the control after 91 days [75]. At 180 days, the ETC-30, ETC-20 and ETC-40 specimens had a higher compressive strength than the specimen made with the MC control mixture; these results coincide with the literature, which indicates that at late ages the high amorphous silica content in the SCBA reacts with the calcium hydroxide product of the cement hydration process, giving rise to the formation of additional hydrated calcium hydroxide (C-S-H), which contributes to the increase in compressive strength over time [76]. In another investigation it was found that a concrete mix made with 25% of cement replaced with processed slag, which presented the highest SiO2 content, obtained a superior compressive strength performance, reaching a value greater than 70 MPa at 90 days, which confirms the contribution to the increase in compressive strength due to pozzolanic material. A high content of SiO2 presents a high capacity to yield tobermorite (calcium hydrosilicates (C–S–H)) by reacting with portlandite (a product of concrete mineral hydration) [77]. With the results of compressive strength at 180 days, it can be concluded that the optimal percentage of substitution of CPC with a combination of SCBA-SF is 30%, followed by 20%, with increases in compressive strength of 7.13 and 5.58% respectively compared to the MC, and in third place the ETC-40 mixture, which presented a compressive strength equal to the MC. Only the mixture of Ecofriendly Ternary Concrete with 50% substitution of SCBA-SF (ETC-50) failed to develop a mechanical resistance close to that of the control mix, reaching a resistance of 20.09 MPa at 90 days.

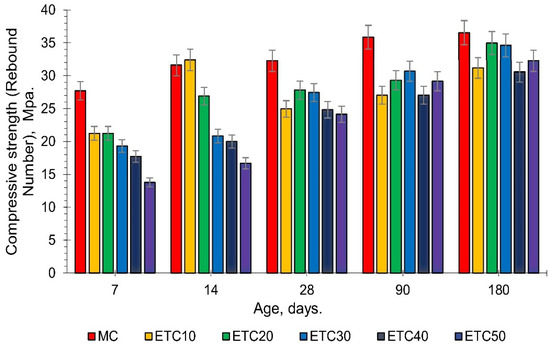

3.4.2. Rebound Number

Figure 9 shows the results obtained from the rebound number tests to determine the compressive strength. It can be seen that the values obtained for the MC are similar to those presented in Figure 8: at the age of 28 days the control had an approximate value of 33 MPa for both simple compressive strength and rebound number tests. In the 7 day test, the ETC concretes reported compressive strength values lower than the MC by higher percentages than those reported in Figure 8, while over time these values increased in the five ETC mixtures, with this behavior likely being due to the effect of using materials with pozzolanic characteristics such as SCBA and SF. Unlike the compressive strength test using the cylinder, the values reported using the sclerometer for the five ETC concrete mixtures at the ages of 28, 90 and 180 days were always lower for the five ETC mixtures than for the MC; however, the mixtures with the best performances were still ETC20 and ETC30, which confirms the behavior in the compression test reported in Figure 8, where it was shown ETC20 and ETC30 were the best ETC mixtures at 90 and 180 days. The results obtained with the non-destructive rebound number test coincide with those reported in the literature on the use of said test to approximate the mechanical resistance of concrete elements in situ or in the laboratory, as reference values of resistance which must be supported by compressive strength tests of the evaluated concretes [78,79].

Figure 9.

Compressive strength according to the rebound number.

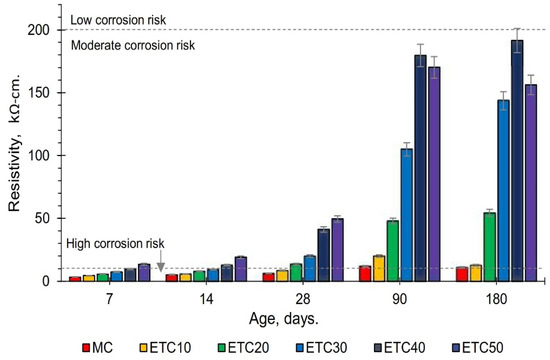

3.4.3. Electrical Resistivity of Concrete Mixtures

Figure 10 shows the results obtained from the Electrical Resistivity test of the six concrete mixtures in this study. The tests were carried out at the ages of 7, 14, 28, 90 and 180 days. In Table 4 it can be seen that at the age of 7 days, almost all mixtures were found to have high corrosion risk, with values less than 10 kΩ-cm for the specimens of the MC, ETC-10, ETC-20, ETC-30 and ETC-40, mixtures. These values coincide with findings from the literature, where at early ages resistivity values are lower [80]. The only specimen that presented a higher value was the ETC50 mixture, reporting a resistivity of 13.45 kΩ-cm after 7 days, which indicates a moderate risk of corrosion. At the age of 14 days, all concretes showed a minimal increase in Electrical Resistivity, but both the ETC-40 and ETC-50 mixtures presented electrical resistivity values greater than 10 kΩ-cm, representing a moderate corrosion risk. At the age of 28 days, the benefit of the combination of the SCBA and the SF as pozzolanic materials was observed, as the durability of the ETC-20, ETC-30, ETC-40 and ETC-50 mixtures increased, with increases in the electrical resistivity values correlating with the percentage of substitution, with values that placed all of them in the moderate corrosion risk zone. ETC-20 and ETC-30 possessed electrical resistivities of 13.43 and 20.03 kΩ-cm while ETC-40 and ETC-50 presented the best performance with values of 47.5 and 51.4 kΩ-cm respectively. This is in agreement with the results of Bagheri et al., who evaluated concretes with different percentages of substitution of Portland cement with FA and SF, and found that the concretes with 20% and 30% FA and SF possessed electrical resistivity values at 28 days two times greater than that of the control mix [81]. At the age of 90 days, all Ecological Ternary Concretes (ETC-10, ETC-20, ETC-30, ETC-40, ETC-50ETC) reached the stage of moderate corrosion risk. The ETC-40 and ETC-50 concretes continued to present the best performances, with electrical resistivity values of 179.56 and 170.24 kΩ-cm respectively.

Figure 10.

Electrical resistivity of the study concretes.

Finally, at the age of 180 days, the concretes that presented low electrical resistivity were the control mixture MC with a value of 10.88 kΩ-cm, followed by the concretes ETC-10 and ETC-20 with values of 12.74 and 54.39 kΩ-cm respectively. The concretes that presented the best performances were the ETC-30, ETC-40 and ETC-50 specimens, with values of 143.53, 191.44 and 156.20 kΩ-cm respectively. As can be seen, the Ecofriendly Ternary Concrete with 40% substitution of the SCBA-SF combination for Portland cement, mixture ETC-40, showed the best performance; this increase in electrical resistivity agrees with the results of Sadrmomtazi et al. [82], showing that including silica fume has positive effects on the fiber–matrix transition zone structure while increasing mechanical strength and specific electrical resistivity by up to 20 times compared to controls, due to the production of pozzolanic reactions and decreased concentration of portlandite, which increases uniformity and density as well as bond quality. It is observed that all ETC mixtures performed better in the electrical resistance test compared to the compression resistance test, and this behavior coincides with a report in the literature and is associated with the fact that the total volume of concrete pores is not reduced by pozzolanic reactions, but the pore structure becomes more discrete [83].

4. Conclusions

In all ETC mixtures there was a decrease in workability, which is attributed to the demand or absorption in excess of water due to pozzolanic materials. However, there were no significant variations in temperature or unit weight in the fresh state compared to the control mixture. The tested slump, temperature and unit weight of the ETC mixtures in their fresh state met requirements for the construction of civil works, such as bridges, pavements, buildings, dams, etc.

The results of compressive strength at 180 days indicated that the optimal percentage of substitution of CPC by combination of SCBA-SF was 30% followed by 20%, due to their increases in compressive strength of 7.13 and 5.58% respectively compared with the MC. The ETC-40 mixture also presented a compression resistance equal to that of the MC.

The rebound number test is a non-destructive test that can be used to evaluate the compressive strength of ETC concretes in the laboratory and on site, with the reservation that they are not considered as definitive values but rather as approximations, and it is always recommended to supplement rebound number tests with simple compression tests on cylinders and cubes.

All ETC mixtures presented better results in the electrical resistance test compared to the compression resistance test, suggesting that the ETC concretes were more durable and had a higher resistance to corrosion compared to the control mixture.

The Eco-friendly Ternary Concrete with 50% substitution of SCBA-SF (ETC-50) displayed a resistance of 20.09 MPa at 180 days, sufficient for the construction of minor works.

The use of ETC concretes has a very significant sustainability impact by contributing to the reduction of CO2 emissions caused by Portland cement, replacing up to 50% of it with SCBA and SF waste and generating a culture of recycling in countries such as Mexico for the use of waste that, like SCBA, has lacked a defined use and previously been discarded as garbage.

Author Contributions

Conceptualization, M.A.B.-Z., R.C., G.S.-H. and V.M.M.-L.; Methodology, L.L.-R., A.L.-G., J.M.M.-R., H.A.-F., A.L.-S., C.T.M.-R., M.A.B.-Z. and R.C.; Data Curation, L.L.-R., J.M.M.-R., M.A.B.-Z., R.C., G.S.-H., and V.M.M.-L.; Writing—Review and Editing, L.L.-R., M.A.B.-Z., R.C., G.S.-H. and V.M.M.-L.; Visualization: M.A.B.-Z., R.C., G.S.-H. and V.M.M.-L.; Supervision: M.A.B.-Z., R.C., G.S.-H. and V.M.M.-L.; Funding acquisition: M.A.B.-Z. and R.C. All authors have read and agreed to the published version of the manuscript.

Funding

M.A. Baltazar-Zamora, et al., thank PRODEP for the support granted by the SEP to the Academic Body UV-CA-458 “Sustainability and Durability of Materials for Civil Infrastructure”, within the framework of the 2018 Call for the Strengthening of Academic Bodies with IDCA 28593.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The results are original of the research work.

Acknowledgments

M.A. Baltazar-Zamora, et al., thank PRODEP for the support granted by the SEP to the Academic Body UV-CA-458 “Sustainability and Durability of Materials for Civil Infrastructure”, within the framework of the 2018 Call for the Strengthening of Academic Bodies with IDCA 28593. The authors thank Brenda Paola Baltazar García for technical support.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Raczkiewicz, W.; Wójcicki, A. Temperature impact on the assessment of reinforcement corrosion risk in concrete by galvanostatic pulse method. Appl. Sci. 2020, 10, 1089. [Google Scholar] [CrossRef]

- Baltazar, M.A.; Márquez, S.; Landa, L.; Croche, R.; López, O. Effect of the type of curing on the corrosion behavior of concrete exposed to urban and marine environment. Eur. J. Eng. Technol. Res. 2020, 5, 91–95. [Google Scholar] [CrossRef]

- Cramer, S.D.; Covino, B.S., Jr.; Bullard, S.J.; Holcomb, G.R.; Russell, J.H.; Nelson, F.J.; Laylor, H.M.; Soltesz, S.M. Corrosion prevention and remediation strategies for reinforced concrete coastal bridge. Cem. Concr. Compos. 2002, 24, 101–117. [Google Scholar] [CrossRef]

- Troconis de Rincón, O.; Montenegro, J.C.; Vera, R.; Carvajal, A.M.; De Gutiérrez, R.M.; Del Vasto, S.; Saborio, E.; Torres-Acosta, A.; Pérez-Quiroz, J.; Martínez-Madrid, M.; et al. Reinforced Concrete Durability in Marine Environments DURACON Project: Long-Term Exposure. Corrosion 2016, 72, 824–833. [Google Scholar] [CrossRef]

- Liang, M.T.; Lan, J.-J. Reliability analysis for the existing reinforced concrete pile corrosion of bridge substructure. Cem. Concr. Res. 2005, 35, 540–550. [Google Scholar] [CrossRef]

- Baltazar, M.A.; Maldonado, M.; Tello, M.; Santiago, G.; Coca, F.; Cedano, A.; Barrios, C.P.; Nuñez, R.; Zambrano, P.; Gaona, C.; et al. Efficiency of galvanized steel embedded in concrete previously contaminated with 2, 3 and 4% of NaCl. Int. J. Electrochem. Sci. 2012, 7, 2997–3007. [Google Scholar]

- Landa, L.; Croche, R.; Santiago, G.; Moreno, V.; Cuevas, J.; Méndez, C.; Jara, M.; Baltazar, M.A. Evaluation of the Influence of the Level of Corrosion of the Reinforcing Steel in the Moment-Curvature Diagrams of Rectangular Concrete Columns. Eur. J. Eng. Technol. Res. 2021, 6, 74–80. [Google Scholar] [CrossRef]

- Santiago, G.; Baltazar, M.A.; Galván, R.; López, L.; Zapata, F.; Zambrano, P.; Gaona, C.; Almeraya, F. Electrochemical evaluation of reinforcement concrete exposed to soil Type SP contaminated with sulphates. Int. J. Electrochem. Sci. 2016, 11, 4850–4864. [Google Scholar] [CrossRef]

- Saricimen, H.; Mohammad, M.; Quddus, A.; Shameem, M.; Barry, M.S. Effectiveness of concrete inhibitors in retarding rebar corrosion. Cem. Concr. Compos. 2002, 24, 89–100. [Google Scholar] [CrossRef]

- Baltazar, M.; Almeraya, F.; Nieves, D.; Borunda, A.; Maldonado, E.; Ortiz, A. Corrosión del acero inoxidable 304 como refuerzo en concreto expuesto a cloruros y sulfatos. Sci. Tech. 2007, 13, 353–357. [Google Scholar]

- Shaheen, F.; Pradhan, B. Influence of sulfate ion and associated cation type on steel reinforcement corrosion in concrete powder aqueous solution in the presence of chloride ions. Cem. Concr. Res. 2017, 91, 73–86. [Google Scholar] [CrossRef]

- Baltazar, M.A.; Santiago, G.; Gaona, C.; Maldonado, M.; Barrios, C.P.; Nunez, R.; Perez, T.; Zambrano, P.; Almeraya, F. Evaluation of the corrosion at early age in reinforced concrete exposed to sulfates. Int. J. Electrochem. Sci. 2012, 7, 588–600. [Google Scholar]

- Roventi, G.; Bellezze, T.; Giuliani, G.; Conti, C. Corrosion resistance of galvanized steel reinforcements in carbonated concrete: Effect of wet–dry cycles in tap water and in chloride solution on the passivating layer. Cem. Concr. Res. 2014, 65, 76–84. [Google Scholar] [CrossRef]

- Baltazar, M.A.; Mendoza, J.M.; Croche, R.; Gaona, C.; Hernández, C.; López, L.; Olguín, F.; Almeraya, F. Corrosion behavior of galvanized steel embedded in concrete exposed to soil type MH contaminated with chlorides. Front. Mater. 2019, 6, 257. [Google Scholar] [CrossRef]

- Mahasenan, N.; Smith, S.; Humphreys, K. The cement industry and global climate change current and potential future cement Industry CO2 emissions. In Greenhouse Gas Control Technologies—6th International Conference, Kyoto, Japan, 1–4 October 2002; Elsevier: Amsterdam, The Netherlands, 2003; pp. 995–1000. [Google Scholar]

- Worrell, E.; Price, L.; Martin, N.; Hendriks, C.; Ozawa, L.M. Carbon dioxide emissions from the global cement industry. Annu. Rev. Energy Environ. 2001, 26, 303–329. [Google Scholar] [CrossRef]

- Monteiro, P.; Miller, S.; Horvath, A. Towards sustainable concrete. Nat. Mater. 2017, 16, 698–699. [Google Scholar] [CrossRef] [PubMed]

- Mehdi, M.; Hamidreza, S.; Farhangi, V.; Karakouzian, M. Predicting the Effect of Fly Ash on Concrete’s Mechanical Properties by ANN. Sustainability 2021, 13, 1469. [Google Scholar]

- Shinga, D.; Sil, A. Effect of Partial Replacement of Cement by Silica Fume on Hardened Concrete. Int. J. Emerg. Technol. Adv. Eng. 2012, 2, 472–475. [Google Scholar]

- Zhang, X.; An Yan, K.W. Carbonation property of hardened binder pastes containing super-pulverized blast-furnace slag. Cem. Concr. Compos. 2004, 26, 371–374. [Google Scholar] [CrossRef]

- Safiuddin, M.; West, J.S.; Soudki, K.A. Hardened properties of self-consolidating high performance concrete including rice husk ash. Cem. Concr. Compos. 2010, 32, 708–717. [Google Scholar] [CrossRef]

- Baltazar, M.A.; Ariza, H.; Landa, L.; Croche, R. Electrochemical evaluation of AISI 304 SS and galvanized steel in ternary ecological concrete based on sugar cane bagasse ash and silica fume (SCBA-SF) exposed to Na2SO4. Eur. J. Eng. Res. Sci. 2020, 5, 353–357. [Google Scholar] [CrossRef]

- Jagadesha, P.; Ramachandramurthy, A.; Murugesan, R. Evaluation of mechanical properties of Sugar Cane Bagasse Ash concrete. Constr. Build. Mater. 2018, 176, 608–617. [Google Scholar] [CrossRef]

- Baltazar, M.A.; Landa, A.; Landa, L.; Ariza, H.; Gallego, P.; Ramírez, A.; Croche, R.; Márquez, S. Corrosion of AISI 316 stainless steel embedded in sustainable concrete made with sugar cane bagasse ash (SCBA) exposed to marine environment. Eur. J. Eng. Res. Sci. 2020, 5, 127–131. [Google Scholar] [CrossRef][Green Version]

- Luo, M.; Jing, K.; Bai, J.; Ding, Z.; Yang, D.; Huang, H.; Go, Y. Effects of Curing Conditions and Supplementary Cementitious Materials on Autogenous Self-Healing of Early Age Cracks in Cement Mortar. Crystals 2021, 11, 752. [Google Scholar] [CrossRef]

- Anandan, S.; Manoharan, S.V. Strength Properties of Processed Fly Ash Concrete. J. Eng. Technol. Sci. 2015, 47, 320–334. [Google Scholar] [CrossRef]

- Baltazar, M.A.; Bastidas, D.M.; Santiago, G.; Mendoza, J.M.; Gaona, C.; Bastidas, J.M.; Almeraya, F. Effect of silica fume and fly ash admixtures on the corrosion behavior of AISI 304 embedded in concrete exposed in 3.5% NaCl solution. Materials 2019, 12, 4007. [Google Scholar] [CrossRef]

- Atis, C.D.; Ozcan, F.; Kılıc, A.; Karahan, O.; Bilim, C.; Severcan, M.H. Influence of dry and wet curing conditions on compressive strength of silica fume concrete. Build. Environ. 2005, 40, 1678–1683. [Google Scholar] [CrossRef]

- Bhanja, S.; Sengupta, B. Influence of silica fume on the tensile strength of concrete. Cem. Concr. Res. 2005, 35, 743–747. [Google Scholar] [CrossRef]

- Ozcan, F.; Atis, C.D.; Karahan, O.; Uncuoglu, E.; Tanyildizi, H. Comparison of artificial neural network and fuzzy logic models for prediction of long-term compressive strength of silica fume concrete. Adv. Eng. Softw. 2009, 40, 856–863. [Google Scholar] [CrossRef]

- Landa-Ruiz, L.; Baltazar-Zamora, M.A.; Bosch, J.; Ress, J.; Santiago-Hurtado, G.; Moreno-Landeros, V.M.; Márquez-Montero, S.; Méndez, C.; Borunda, A.; Juárez-Alvarado, C.A.; et al. Electrochemical Corrosion of Galvanized Steel in Binary Sustainable Concrete Made with Sugar Cane Bagasse Ash (SCBA) and Silica Fume (SF) Exposed to Sulfates. Appl. Sci. 2021, 11, 2133. [Google Scholar] [CrossRef]

- Srinivasan, R. Experimental Study on Bagasse Ash in Concrete. Int. J. Serv. Learn. Eng. 2010, 5, 60–66. [Google Scholar] [CrossRef]

- Landa-Sánchez, A.; Bosch, J.; Baltazar-Zamora, M.A.; Croche, R.; Landa-Ruiz, L.; Santiago-Hurtado, G.; Moreno-Landeros, V.M.; Olguín-Coca, J.; López-Léon, L.; Bastidas, J.M.; et al. Corrosion behavior of steel-reinforced green concrete containing recycled coarse aggregate additions in sulfate media. Materials 2020, 13, 4345. [Google Scholar] [CrossRef] [PubMed]

- Kawade, U.R.; Rathi, V.R.; Girge, V.D. Effect of use of Bagasse Ash on Strength of Concrete. Int. J. Innov. Res. Sci. Eng. Technol. 2013, 2, 2997–3000. [Google Scholar]

- Castaldelli, V.; Akasaki, J.; Melges, J.; Tashima, M.; Soriano, L.; Borrachero, M.; Monzó, J.; Payá, J. Use of Slag/Sugar Cane Bagasse Ash (SCBA) Blends in the Production of Alkali-Activated Materials. Materials 2013, 6, 3108–3127. [Google Scholar] [CrossRef] [PubMed]

- Ariza-Figueroa, H.A.; Bosch, J.; Baltazar-Zamora, M.A.; Croche, R.; Santiago-Hurtado, G.; Landa-Ruiz, L.; Mendoza-Rangel, J.M.; Bastidas, J.M.; Almeraya-Calderón, F.A.; Bastidas, D.M. Corrosion behavior of AISI 304 stainless steel reinforcements in SCBA-SF ternary ecological concrete exposed to MgSO4. Materials 2020, 13, 2412. [Google Scholar] [CrossRef]

- Ganesan, K.; Rajagopal, K.; Thangavel, K. Evaluation of bagasse ash as corrosion resisting admixture for carbon steel in concrete. Anti-Corros. Methods Mater. 2007, 54, 230–236. [Google Scholar] [CrossRef]

- Landa-Gómez, A.E.; Croche, R.; Márquez-Montero, S.; Villegas Apaez, R.; Ariza-Figueroa, H.A.; Estupiñan López, F.; Gaona Tiburcio, G.; Almeraya Calderón, F.; Baltazar-Zamora, M.A. Corrosion behavior 304 and 316 stainless steel as reinforcement in sustainable concrete based on sugar cane bagasse ash exposed to Na2SO4. ECS Trans. 2018, 84, 179–188. [Google Scholar] [CrossRef]

- Ramakrishnan, K.; Ganesh, V.; Vignesh, G.; Vignesh, M.; Shriram, V.; Suryaprakash, R. Mechanical and durability properties of concrete with partial replacement of fine aggregate by sugarcane bagasse ash (SCBA). Mater. Today Proc. 2021, 42, 1070–1076. [Google Scholar] [CrossRef]

- Ojeda, O.; Mendoza, J.M.; Baltazar, M.A. Influence of sugar cane bagasse ash inclusion on compacting, CBR and unconfined compressive strength of a subgrade granular material. Rev. Alconpat 2018, 8, 194–208. [Google Scholar]

- Landa, L.; Márquez, S.; Santiago, G.; Moreno, V.; Mendoza, J.M.; Baltazar, M.A. Effect of the addition of sugar cane bagasse ash on the compaction properties of a granular material type hydraulic base. Eur. J. Eng. Technol. Res. 2021, 6, 76–79. [Google Scholar] [CrossRef]

- Dong, P.; Van Tuan, N.; Thanh, L.; Thang, N.C.; Cu, V.; Mun, J.H. Compressive Strength Development of High-Volume Fly Ash Ultra-High-Performance Concrete under Heat Curing Condition with Time. Appl. Sci. 2020, 10, 7107. [Google Scholar] [CrossRef]

- NMX-C-414-ONNCCE-2014–Industria de la Construcción-Cementantes Hidráulicos-Especificaciones y Métodos de Ensayo; ONNCCE, Cd.: México City, México, 2014.

- ASTM C33/C33m-16e1. Standard Specification for Concrete Aggregates; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ASTM C29/C29M-07. Standard Test Method for Bulk Density (“Unit Weight”) and Voids in Aggregate; ASTM International: West Conshohocken, PA, USA, 2007. [Google Scholar]

- ASTM C127-15. Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM C128-15. Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ACI 211.1-2004 Standard. Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete; American Concrete Institute: Indianapolis, IN, USA, 2004. [Google Scholar]

- NMX-C-156-ONNCCE-2010. Determinación de Revenimiento en Concreto Fresco; ONNCCE S.C.: México City, México, 2010. [Google Scholar]

- ASTM C 1064/C1064M-08. Standard Test Method for Temperature of Freshly Mixed Hydraulic-426 Cement Concrete; ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- NMX-C-162-ONNCCE-2014. Determinación de la Masa Unitaria, Cálculo del Rendimiento y Contenido de Aire del Concreto Fresco por el Método Gravimétrico; ONNCCE S.C.: México City, México, 2014. [Google Scholar]

- NMX-C-083-ONNCCE-2014. Determinación de la Resistencia a la Compresión de Especímenes–Método de Prueba; ONNCCE S.C.: México City, México, 2014. [Google Scholar]

- NMX-C-159-ONNCCE-2004. Industria de la Construcción-Concreto-Elaboración y Curado de Especímenes en el Laboratorio. ONNCCE, Cd.: México City, México, 2004. [Google Scholar]

- NMX-C-192-ONNCCE-2018. Industria de la Construcción-Concreto-Determinación del Número de Rebote Utilizando el Dispositivo Conocido como Esclerómetro-Método de Ensayo; ONNCCE, Cd.: México City, México, 2018. [Google Scholar]

- Deng, P.; Sun, Y.; Liu, Y.; Song, X. Revised Rebound Hammer and Pull-Out Test Strength Curves for Fiber-Reinforced Concrete. Adv. Civ. Eng. 2020, 2020, 8263745. [Google Scholar] [CrossRef]

- Amini, K.; Jalalpour, M.; Delatte, N. Advancing concrete strength prediction using non-destructive testing: Developmentand verification of a generalizable model. Constr. Build. Mater. 2016, 102, 762–768. [Google Scholar] [CrossRef]

- Sengul, O. Use of electrical resistivity as an indicator for durability. Constr. Build. Mater. 2014, 73, 434–441. [Google Scholar] [CrossRef]

- Lubeck, A.; Gastaldini, A.L.G.; Barin, D.S.; Siqueira, H.C. Compressive strength and electrical properties of concrete with white Portland cement and blast-furnace slag. Cem. Concr. Comp. 2012, 34, 392–399. [Google Scholar] [CrossRef]

- Hornbostel, K.; Larsen, C.K.; Geiker, M.R. Relationship between concrete resistivity and corrosion rate—A literature review. Cem. Concr. Comp. 2013, 39, 60–72. [Google Scholar] [CrossRef]

- Morris, W.; Vico, A.; Vazquez, M. Chloride induced corrosion of reinforcing steel evaluated by concrete resistivity measurements. Electrochim. Acta. 2004, 49, 4447–4453. [Google Scholar] [CrossRef]

- ASTM C1760-12. Standard Test Method for Bulk Electrical Conductivity of Hardened Concrete (Withdrawn 2021); ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Troconis De Rincón, O.; Carruyo, A.R.; Andrade, C.; Helene, P.R.L. ; Díaz. I. Manual de Inspección, Evaluación y Diagnóstico de Corrosión en Estructuras de Hormigón Armado. Red DURAR; CYTED: Caracas, Venezuela, 1997. [Google Scholar]

- Vouk, D.; Nakic, D.; Stirmer, N.; Cheeseman, C.R. Use of sewage sludge ash in cementitious materials. Rev. Adv. Mater. Sci. 2017, 49, 158–170. [Google Scholar]

- Minnu, S.N.; Bahurudeen, A.; Athira, G. Comparison of sugarcane bagasse ash with fly ash and slag: An approach towards industrial acceptance of sugar industry waste in cleaner production of cement. J. Clean. Prod. 2021, 285, 124836. [Google Scholar] [CrossRef]

- Patra, R.K.; Mukharjee, B.B. Influence of incorporation of granulated blast furnace slag as replacement of fine aggregate on properties of concrete. J. Clean. Prod. 2017, 165, 468–476. [Google Scholar] [CrossRef]

- Choi, S.; Kim, Y.; Oh, T.; Cho, B. Compressive Strength, Chloride Ion Penetrability, and Carbonation Characteristic of Concrete with Mixed Slag Aggregate. Materials 2020, 13, 940. [Google Scholar] [CrossRef] [PubMed]

- NMX-C-155-ONNCCE-2014. Industria de la Construcción–Concreto Hidráulico–Dosificado en Masa–Especificaciones y Métodos de Ensayo; ONNCCE, Cd.: México City, México, 2014. [Google Scholar]

- Khawaja, S.A.; Javed, U.; Zafar, T.; Riaz, M.; Zafar, M.S.; Khan, M. Eco-friendly incorporation of sugarcane bagasse ash as partial replacement of sand in foam concrete. Clean. Eng. Technol. 2021, 4, 100164. [Google Scholar] [CrossRef]

- Wu, W.; Wang, R.; Zhu, C.; Meng, Q. The effect of fly ash and silica fume on mechanical properties and durability of coral aggregate concrete. Constr. Build. Mater. 2018, 185, 69–78. [Google Scholar] [CrossRef]

- Landa, L.; Ariza, H.; Santiago, G.; Moreno, V.; López, R.; Villegas, R.; Márquez, S.; Croche, R.; Baltazar, M. Evaluation of the behavior of the physical and mechanical properties of green concrete exposed to magnesium sulfate. Eur. J. Eng. Res. Sci. 2020, 5, 1353–1356. [Google Scholar] [CrossRef]

- Mohamed, H.A. Effect of fly ash and silica fume on compressive strength of self-compacting concrete under different curing conditions. Ain Shams Eng. J. 2011, 2, 79–86. [Google Scholar] [CrossRef]

- Arif, E.; Clark, M.W.; Lake, N. Sugar cane bagasse ash from a high-efficiency co-generation boiler as filler in concrete. Constr. Build. Mater. 2017, 151, 692–703. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P. Effect of Fly Ash on the Durability Properties of High Strength Concrete. Procedia Eng. 2011, 14, 1149–1156. [Google Scholar] [CrossRef]

- Yu, J.; Lu, C.; Leung, K.Y.; Li, G. Mechanical properties of green structural concrete with ultrahigh-volume fly ash. Constr. Build. Mater. 2017, 147, 510–518. [Google Scholar] [CrossRef]

- Le, D.; Sheen, Y.; Lam, M. Fresh and hardened properties of self-compacting concrete with sugarcane bagasse ash–slag blended cement. Constr. Build. Mater. 2018, 185, 138–147. [Google Scholar] [CrossRef]

- Xu, Q.; Ji, T.; Gao, S.; Yang, Z.; Wu, N. Characteristics and Applications of Sugar Cane Bagasse Ash Waste in Cementitious Materials. Materials 2018, 12, 39. [Google Scholar] [CrossRef]

- Parron-Rubio, M.E.; Perez-García, F.; Gonzalez-Herrera, A.; Rubio-Cintas, M.D. Concrete Properties Comparison When Substituting a 25% Cement with Slag from Different Provenances. Materials 2018, 11, 1029. [Google Scholar] [CrossRef] [PubMed]

- Poorarbabi, A.; Ghasemi, M.; Azhdary Moghaddam, M.A. Concrete compressive strength prediction using non-destructive tests through response surface methodology. Ain Shams Eng. J. 2020, 11, 939–949. [Google Scholar] [CrossRef]

- Qasrawy, H.Y. Concrete strength by combined nondestructives methods Simply and reliably predicted. Cem. Concr. Res. 2000, 30, 739–746. [Google Scholar] [CrossRef]

- Landa, A.; Croche, R.; Márquez-Montero, S.; Galván-Martínez, R.; Tiburcio, C.G.; Almeraya Calderón, F.; Baltazar, M. Correlation of compression resistance and rupture module of a concrete of ratio w/c = 0.50 with the corrosion potential, electrical resistivity and ultrasonic pulse speed. ECS Trans. 2018, 84, 217–227. [Google Scholar] [CrossRef]

- Bagueri, A.; Zanganeh, H.; Alizadeh, H.; Shakerinia, M.; Marian, M.A. Comparing the performance of fine fly ash and silica fume in enhancing the properties of concretes containing fly ash. Constr. Build. Mater. 2013, 47, 321–333. [Google Scholar]

- Sadrmomtazi, A.; Tahmouresi, B.; Saradar, A. Effects of silica fume on mechanical strength and microstructure of basalt fiber reinforced cementitious composites (BFRCC). Constr. Build. Mater. 2018, 162, 321–333. [Google Scholar] [CrossRef]

- Buenfeld, N.R.; Glass, G.K.; Hassanein, A.M.; Zhang, J.Z. Chloride transport in concrete subjected to electrical field. J. Mater. Civ. Eng. 1998, 10, 220–228. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).