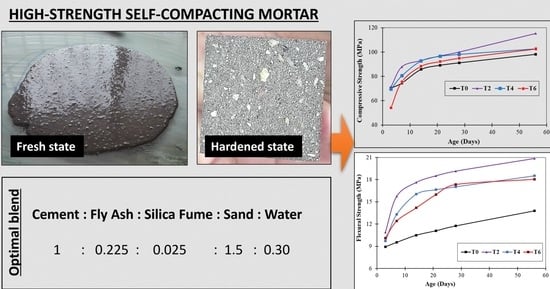

Synergistic Use of Fly Ash and Silica Fume to Produce High-Strength Self-Compacting Cementitious Composites

Abstract

:1. Introduction

2. Materials and Methods

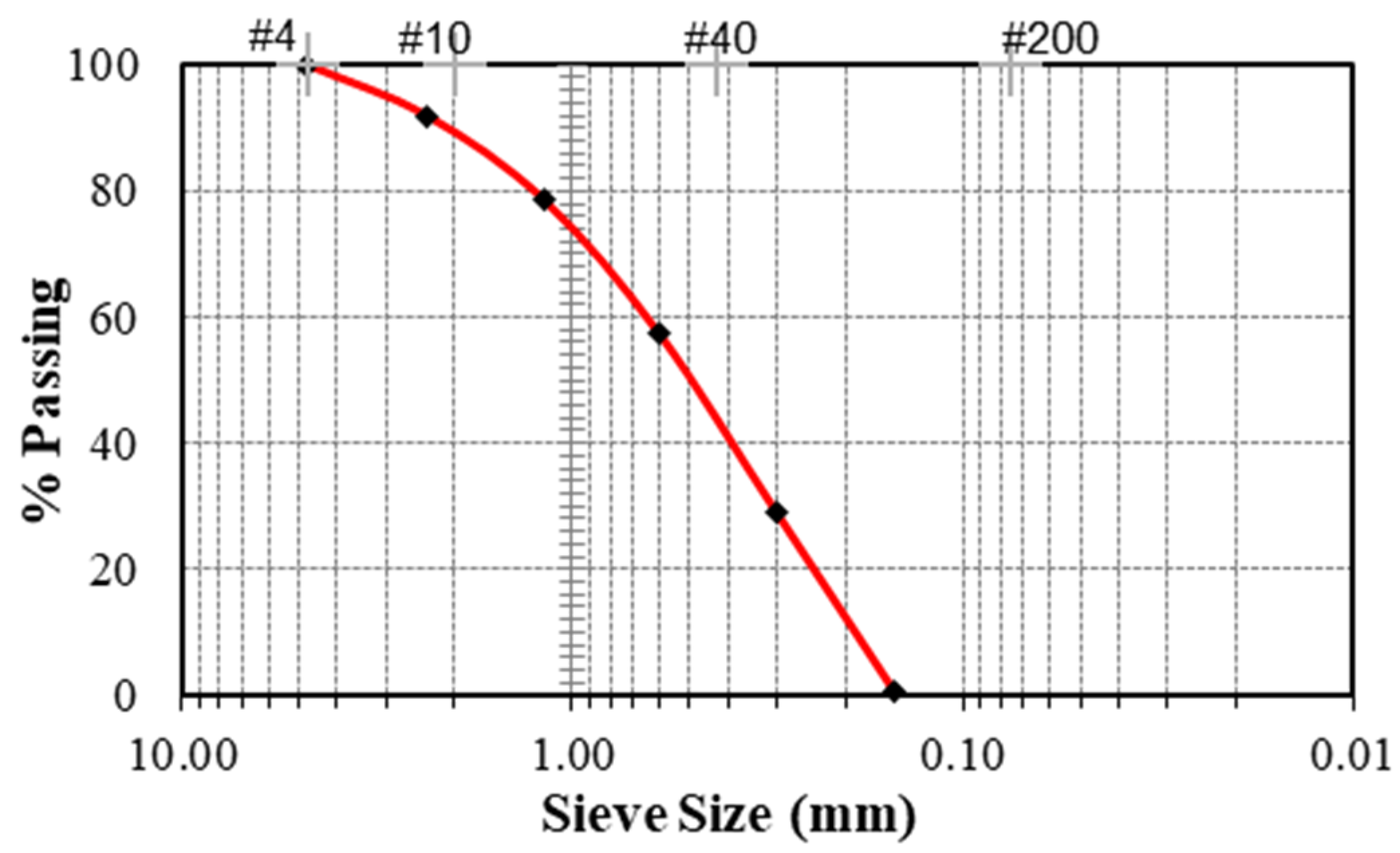

2.1. Materials Characterization and Mix Proportions

| Description | Fly Ash | Silica Fume | OPC * |

|---|---|---|---|

| silicon dioxide | 39.45 | 92.31 | 18.92 |

| aluminum oxide | 24.81 | 2.29 | 5.09 |

| iron oxide | 24.09 | 1.97 | 2.27 |

| calcium oxide | 4.03 | 1.14 | 63.18 |

| sulfur oxide | 5.08 | 0.25 | 3.48 |

| minor constituents | 2.54 | 2.04 | 3.84 |

| loi | 6.71 | 1.6 | 1.35 |

| moisture | 1.71 | - | - |

| % passing #325 sieve | 96.5 | 100 | >95 |

| specific gravity | 2.36 | 2.20 | 3.17 |

2.2. Sample Preparation

2.3. Methodology

2.3.1. Rheological Characterization

2.3.2. Mechanical Strength

2.3.3. Ultrasonic Pulse Velocity

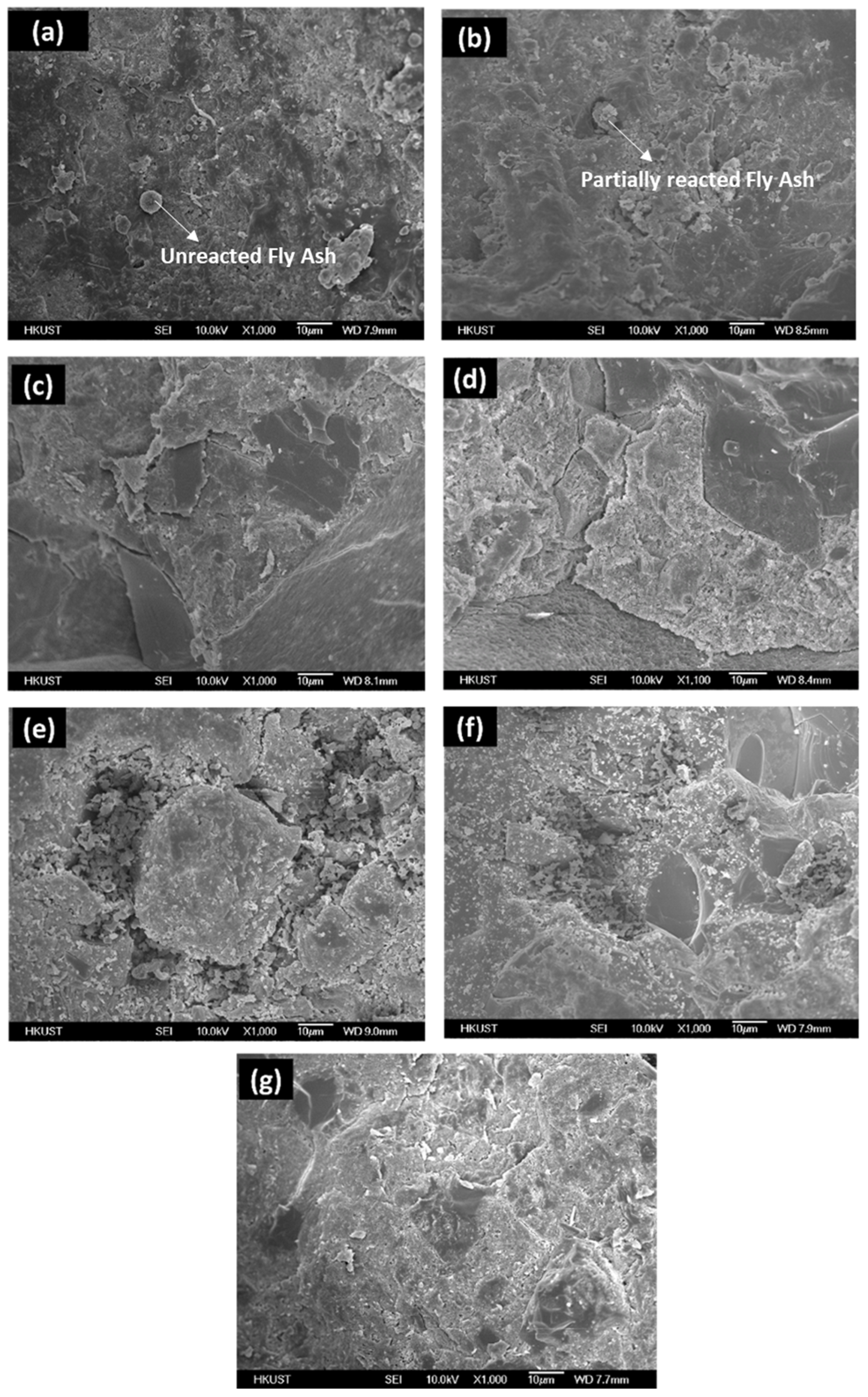

2.3.4. Microstructural Characterization

3. Results and Discussions

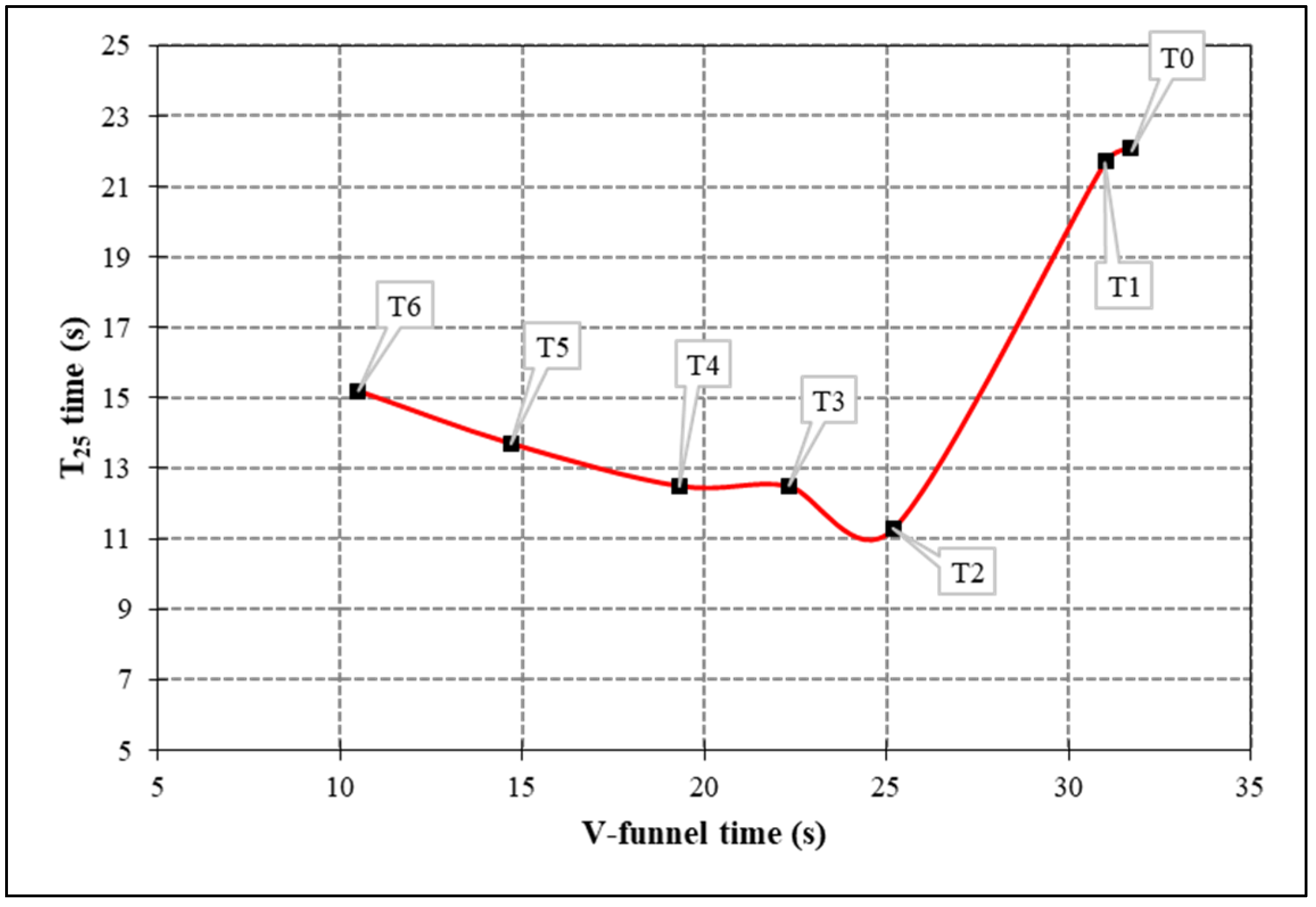

3.1. Rheological Properties

3.2. Mechanical Properties

3.3. Ultrasonic Pulse Velocity (UPV)

3.3.1. Mathematical Model for Estimation of Compressive Strength

3.3.2. Mathematical Model for Estimation of Flexural Strength

3.4. Microstructural Characterization

4. Conclusions

- Replacing fly ash with silica fume gradually increases the flow spread up to 20% replacement level. After that, a decline is observed. Therefore, the optimum blend for maximum spread is 20% silica fume with 80% fly ash content.

- Superplasticizer used in this study was polycarboxylate-based and suitable for increasing the workability of SCMs.

- It is concluded that with the high dosage of silica fume, cement content and superplasticizer may be increased to achieve the target flow.

- T250 time gradually decreases up to 20% replacement level and then starts increasing. This result is in line with the results of flow spread and indicates that the flow spread and the rate of flow decrease after 20% replacement level.

- V- funnel’s time gradually decreases with the increase of silica fume content, indicating that increase of silica fume content enhances the vertical movement of particles by reducing air bubbles, which interfere with the vertical movement of paste. This result complements the results of flow spread and T25 time.

- Proposed models for estimation of compressive and flexure strength from UPV are valid for all mix proportions containing silica fume at the age of 28 and 56 days. For mix proportion containing only fly ash, these are valid for 56 days only. These models can be used to predict the strength of high-strength self-compacting mortar containing fly ash and silica fume.

- The optimum powder content to obtain maximum compressive and flexural strength is 80% of OPC, 18% fly ash, and 2% silica fume.

- Flexural strength follows the compressive strength trend, i.e., the optimum replacement level of fly ash is 10%. Highest achieved flexural strength was 20.86 ± 0.5MPa for mix proportion T2, i.e., 90% FA and 10% SF. Same as compressive strength results gain in flexural strength can be correlated by a power law.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Usman, M.; Khan, A.Y.; Farooq, S.H.; Hanif, A.; Tang, S.; Khushnood, R.A.; Rizwan, S.A. Eco-friendly self-compacting cement pastes incorporating wood waste as cement replacement: A feasibility study. J. Clean. Prod. 2018, 190, 679–688. [Google Scholar] [CrossRef]

- Hanif, A.; Cheng, Y.; Lu, Z.; Li, Z. Mechanical Behavior of Thin-Laminated Cementitious Composites Incorporating Cenosphere Fillers. ACI Mater. J. 2018, 115, 117–127. [Google Scholar] [CrossRef]

- Hanif, A.; Lu, Z.; Sun, M.; Parthasarathy, P.; Li, Z. Green lightweight ferrocement incorporating fly ash cenosphere based fibrous mortar matrix. J. Clean. Prod. 2017, 159, 326–335. [Google Scholar] [CrossRef]

- Bhikshma, V.; Ravandekishore; Srinivas, R. Durability of polymer and fly ash modified ferro cement elements. Procedia Eng. 2011, 14, 2642–2649. [Google Scholar] [CrossRef] [Green Version]

- Mohamed, H.A. Effect of fly ash and silica fume on compressive strength of self-compacting concrete under different curing conditions. Ain. Shams Eng. J. 2011, 2, 79–86. [Google Scholar] [CrossRef] [Green Version]

- Elemam, W.E.; Abdelraheem, A.H.; Mahdy, M.G.; Tahwia, A.M. Optimizing fresh properties and compressive strength of self-consolidating concrete. Constr. Build. Mater. 2020, 249, 118781. [Google Scholar] [CrossRef]

- Felekoǧlu, B.; Tosun, K.; Baradan, B.; Altun, A.; Uyulgan, B. The effect of fly ash and limestone fillers on the viscosity and compressive strength of self-compacting repair mortars. Cem. Concr. Res. 2006, 36, 1719–1726. [Google Scholar] [CrossRef]

- ACI Committee 237. American Concrete Institute. In Self-Consolidating Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2007; ISBN 9780870312441. [Google Scholar]

- Nepomuceno, M.; Oliveira, L.; Lopes, S.M.R. Methodology for mix design of the mortar phase of self-compacting concrete using different mineral additions in binary blends of powders. Constr. Build. Mater. 2012, 26, 317–326. [Google Scholar] [CrossRef]

- Bingöl, A.F.; Tohumcu, I. Effects of different curing regimes on the compressive strength properties of self compacting concrete incorporating fly ash and silica fume. Mater. Des. 2013, 51, 12–18. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; Khayat, K.H. Influence of silica fume content on microstructure development and bond to steel fiber in ultra-high strength cement-based materials (UHSC). Cem. Concr. Compos. 2016, 71, 97–109. [Google Scholar] [CrossRef] [Green Version]

- Rizwan, S.A.; Bier, T.A. Self-consolidating mortars using various secondary raw materials. ACI Mater. J. 2009, 106, 25–32. [Google Scholar] [CrossRef]

- Rasheed, A.; Usman, M.; Farooq, H.; Hanif, A. Effect of Super-plasticizer Dosages on Fresh State Properties and Early-Age Strength of Concrete. IOP Conf. Ser. Mater. Sci. Eng. 2018, 431, 062010. [Google Scholar] [CrossRef] [Green Version]

- Malhotra, V. Fly ash, slag, silicafume, and rice husk ashin concrete:A review. Concr. Int. 1993, 15, 23–28. [Google Scholar]

- Benabed, B.; Kadri, E.-H.; Azzouz, L.; Kenai, S. Properties of self-compacting mortar made with various types of sand. Cem. Concr. Compos. 2012, 34, 1167–1173. [Google Scholar] [CrossRef]

- Faheem, A.; Rizwan, S.A.; Bier, T.A. Properties of self-compacting mortars using blends of limestone powder, fly ash, and zeolite powder. Constr. Build. Mater. 2021, 286, 122788. [Google Scholar] [CrossRef]

- Sua-Iam, G.; Makul, N. Utilization of coal- and biomass-fired ash in the production of self-consolidating concrete: A literature review. J. Clean. Prod. 2015, 100, 59–76. [Google Scholar] [CrossRef]

- Gil, A.M.; Khayat, K.H.; Tutikian, B.F. An experimental approach to design self-consolidating concrete. Constr. Build. Mater. 2019, 229, 116939. [Google Scholar] [CrossRef]

- ACI 234R Guide for the use of silica fume in concrete. In ACI Committee 234 Report; American Concrete Institute: Farmington Hills, MI, USA, 2006; Volume 96, pp. 1–15.

- Singh, N.; Singh, S.P. Carbonation resistance and microstructural analysis of Low and High Volume Fly Ash Self Compacting Concrete containing Recycled Concrete Aggregates. Constr. Build. Mater. 2016, 127, 828–842. [Google Scholar] [CrossRef]

- Li, Z. Advanced Concrete Technology; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2011. [Google Scholar]

- Khan, M.I.; Usman, M.; Rizwan, S.A.; Hanif, A. Self-Consolidating Lightweight Concrete Incorporating Limestone Powder and Fly Ash as Supplementary Cementing Material. Materials 2019, 12, 3050. [Google Scholar] [CrossRef] [Green Version]

- Satish, K.; Kumar, S.; Rai, B. Self Compacting Concrete Using Fly Ash and Silica Fumes as Pozzolanic Material. J. Eng. Technol. 2017, 6, 394–407. Available online: https://www.researchgate.net/publication/318875965. (accessed on 8 July 2021).

- Thomas, M. Optimizing the Use of Fly Ash in Concrete. Available online: www.cement.org. (accessed on 8 July 2021).

- Kwan, A.K.H.; Li, Y. Effects of fly ash microsphere on rheology, adhesiveness and strength of mortar. Constr. Build. Mater. 2013, 42, 137–145. [Google Scholar] [CrossRef]

- Qadir, W.; Ghafor, K.; Mohammed, A. Characterizing and modeling the mechanical properties of the cement mortar modified with fly ash for various water-to-cement ratios and curing times. Adv. Civ. Eng. 2019, 2019. [Google Scholar] [CrossRef] [Green Version]

- ACI Committee 232. Use of fly ash in concrete Reported by ACI Comittee 232. NCHRP Synth. Highw. Pract. 1986, 96, 1–34. [Google Scholar]

- Dinakar, P.; Babu, K.G.; Santhanam, M. Durability properties of high volume fly ash self compacting concretes. Cem. Concr. Compos. 2008, 30, 880–886. [Google Scholar] [CrossRef]

- Xie, Y.; Liu, B.; Yin, J.; Zhou, S. Optimum mix parameters of high-strength self-compacting concrete with ultrapulverized fly ash. Cem. Concr. Res. 2002, 32, 477–480. [Google Scholar] [CrossRef]

- Idorn, G.M. Technica. U. of D.C. Idorn, 30 Years with Alkalis in Concrete. In Proceedings of the ALKALIS in Concrete Research and Practice, Copenhagen, Denmark, 22 June 1983; pp. 19–38. [Google Scholar]

- Bilir, T.; Gencel, O.; Topcu, I.B. Properties of mortars with fly ash as fine aggregate. Constr. Build. Mater. 2015, 93, 782–789. [Google Scholar] [CrossRef]

- Benli, A.; Karatas, M.; Bakir, Y.; Karata, M.; Bakir, Y. An experimental study of different curing regimes on the mechanical properties and sorptivity of self-compacting mortars with fly ash and silica fume. Constr. Build. Mater. 2017, 144, 552–562. [Google Scholar] [CrossRef]

- Seluck Turkel, Y.A. The effect of limestone powder, fly ash and silica fume on the properties of self-compacting repair mortars, Sadhana-Acad. Proc. Eng. Sci. 2009, 2, 331–343. [Google Scholar]

- Sonebi, M. Medium strength self-compacting concrete containing fly ash: Modelling using factorial experimental plans. Cem. Concr. Res. 2004, 34, 1199–1208. [Google Scholar] [CrossRef]

- Bradbury, H.W. The use and potential for fly ash in grouting. In Proceedings of the 5th International Ash Utilization Symposium; DOE/METC/SP-79; U.S Department of Energy, Morgsntown Energy Technology Center: Morgsntown, VA, USA, 1979. [Google Scholar]

- Wu, W.; Wang, R.; Zhu, C.; Meng, Q. The effect of fly ash and silica fume on mechanical properties and durability of coral aggregate concrete. Constr. Build. Mater. 2018, 185, 69–78. [Google Scholar] [CrossRef]

- Steven, D.; Hempling, J.R.P. compressive strength of flyash cement grouting mix. In Proceedings of the 4th International Ash Utilization Symposium (St.Louis, Mar.); ERDA MERC/SP-76; U.S Bureau of Mines: Washington, DC, USA, 1976; pp. 589–598. [Google Scholar]

- Bagheri, A.; Zanganeh, H.; Alizadeh, H.; Shakerinia, M.; Marian, M.A.S. Comparing the performance of fine fly ash and silica fume in enhancing the properties of concretes containing fly ash. Constr. Build. Mater. 2013, 47, 1402–1408. [Google Scholar] [CrossRef]

- Şahmaran, M.; Christianto, H.A.; Yaman, I.Ö. The effect of chemical admixtures and mineral additives on the properties of self-compacting mortars. Cem. Concr. Compos. 2006, 28, 432–440. [Google Scholar] [CrossRef]

- Li, J.; Tan, D.; Zhang, X.; Wan, C.; Xue, G. Mixture design method of self-compacting lightweight aggregate concrete based on rheological property and strength of mortar. J. Build. Eng. 2021, 43, 102660. [Google Scholar] [CrossRef]

- Claisse, P.A.; Lorimer, P.; Al Omari, M. Workability of Cement Pastes. ACI Mater. J. 2001, 98. [Google Scholar] [CrossRef]

- Lei, D.Y.; Guo, L.P.; Sun, W.; Liu, J.; Shu, X.; Guo, X.L. A new dispersing method on silica fume and its influence on the performance of cement-based materials. Constr. Build. Mater. 2016, 115, 716–726. [Google Scholar] [CrossRef]

- Shannag, M.J.; Mourad, S.M. Flowable high strength cementitious matrices for ferrocement applications. Constr. Build. Mater. 2012, 36, 933–939. [Google Scholar] [CrossRef]

- Feldman, R.F. Non destructive testing of concrete. Natl. Res. Counc. Can. Ott. Ont. 1977, 187, 6. [Google Scholar]

- Leslie, J.R.; Cheesman, W.J. An ultrasonic method for studying deterioration and cracking in concrete structures. ACI Mater. J. 1949, 46, 17–36. [Google Scholar]

- Saint-Pierre, F.; Philibert, A.; Giroux, B.; Rivard, P. Concrete Quality Designation based on Ultrasonic Pulse Velocity. Constr. Build. Mater. 2016, 125, 1022–1027. [Google Scholar] [CrossRef]

- ASTM Standard C191-04. Time of Setting of Hydraulic Cement by Vicat Needle; ASTM International: West Conshohocken, PA, USA, 2004. [Google Scholar]

- ASTM Standard C150-04. Standard Specification for Portland Cement; ASTM International: West Conshohocken, PA, USA, 2004. [Google Scholar]

- ASTM Standard C33-02. Standard Specification for Concrete Aggregates; ASTM International: West Conshohocken, PA, USA, 2002. [Google Scholar]

- ASTM Standard C 618-99 Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use as Mineral Admixture in Concrete. Annu. B. ASTM Stand. 1999, 3–6. [CrossRef]

- Zahedi, M. Evaluating the Use of Fluidized Bed Combustion Fly Ash as Concrete Pozzolan. Ph.D. Thesis, Department of Civil Engineering, The Pennsylvania State University, State College, PA, USA, 2019. [Google Scholar]

- Zahedi, M. Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2019; Available online: www.astm.org (accessed on 8 July 2021). [CrossRef]

- Lu, Z.; Hou, D.; Hanif, A.; Hao, W.; Li, Z.; Sun, G. Comparative evaluation on the dispersion and stability of graphene oxide in water and cement pore solution by incorporating silica fume. Cem. Concr. Compos. 2018, 94, 33–42. [Google Scholar] [CrossRef]

- ASTM C 494/C 494M—05 Standard Specification for Chemical Admixtures for Concrete. ASTM Int. 2005, 1–9. [CrossRef]

- British Standards, BS EN 934-2:2001. Admixtures for Concrete, Mortar and, Grout; The British Standards Institution: London, UK, 2001. [Google Scholar]

- Rizwan, S.A.; Bier, T.A. Blends of limestone powder and fly-ash enhance the response of self-compacting mortars. Constr. Build. Mater. 2012, 27, 398–403. [Google Scholar] [CrossRef]

- European Standard Institution [NF EN196-1]. Methods of Testing Cement–Part 1: Determination of Strength; European Committee for Standardization: Brussels, Belgium, 2006. [Google Scholar]

- Maeyama, A.; Mruyama, K.; Midorikowa, T. characterization of powder for self compacting concrete. In Proceedings of the the international Workshop on SCC, Auckland, New Zealand, 8 July 2019; pp. 191–200. [Google Scholar]

- Okamur, H.; Ouchi, M. Self Compacting Concrete. J. Adv. Concr. Technol. 2000, 1, 5–15. [Google Scholar] [CrossRef]

- The European Project Group SCC 028. The European Guidelines for Self-Compacting Concrete. Eur. Guidel. Self Compact. Concr. 2005, 63. Available online: https://www.theconcreteinitiative.eu/images/ECP_Documents/EuropeanGuidelinesSelfCompactingConcrete.pdf (accessed on 8 July 2021).

- EFNARC Specification and Guidelines for Self-Compacting Concrete. Rep. EFNARC 2002, 44, 32.

- Rizwan, S.A.; Ahmad, S.; Bier, T.A. Application of packing concepts to high performance self-consolidating mortar (SCM) systems. Spec. Publ. 2012, 289, 299–315. [Google Scholar] [CrossRef]

- Li, L.G.; Huang, Z.H.; Zhu, J.; Kwan, A.K.H.; Chen, H.Y. Synergistic effects of micro-silica and nano-silica on strength and microstructure of mortar. Constr. Build. Mater. 2017, 140, 229–238. [Google Scholar] [CrossRef]

- Heikal, M.; Zohdy, K.M.; Abdelkreem, M. Mechanical, microstructure and rheological characteristics of high performance self-compacting cement pastes and concrete containing ground clay bricks. Constr. Build. Mater. 2013, 38, 101–109. [Google Scholar] [CrossRef]

- Liu, J.; Li, Q.; Xu, S. Influence of nanoparticles on fluidity and mechanical properties of cement mortar. Constr. Build. Mater. 2015, 101, 892–901. [Google Scholar] [CrossRef]

- Arshad, M.T.; Hanif, A.; Khitab, A.; Iftikhar, A.; Raza, A.; Liaqat, J. Cementitious Composites Reinforced with Multi Walled Carbon Nano Tubes Dispersed in Gum Arabic. In Proceedings of the International Conference on Information Technology, Civil Engineering and Applied Sciences; ITCEA-2018, Bangkok, Thail; Academy of Engineering Technology Leadership: Bangkok, Thailand, 2018; ISBN 978-969-228-897-2. [Google Scholar]

- Hanif, A.; Lu, Z.; Diao, S.; Zeng, X.; Li, Z. Properties investigation of fiber reinforced cement-based composites incorporating cenosphere fillers. Constr. Build. Mater. 2017, 140, 139–149. [Google Scholar] [CrossRef]

- Hanif, A.; Parthasarathy, P.; Ma, H.; Fan, T.; Li, Z. Properties improvement of fly ash cenosphere modified cement pastes using nano silica. Cem. Concr. Compos. 2017, 81, 35–48. [Google Scholar] [CrossRef]

- Bui, D.D.; Hu, J.; Stroeven, P. Particle size effect on the strength of rice husk ash blended gap-graded Portland cement concrete. Cem. Concr. Compos. 2005, 27, 357–366. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete; Pearson Education: London, UK, 2011. [Google Scholar]

- Brink, R.H.; Halstead, W.J. Studies Relating to the Testing of Fly Ash for Use in Concrete. Am. Soc. Testing and Proc. 1956, 56, 1161–1214. [Google Scholar]

- Babu, K.G.; Rao, G.S.N. Efficiency of fly ash in concrete. Cem. Concr. Compos. 1993, 15, 223–229. [Google Scholar] [CrossRef]

- Wang, L.; Guo, F.; Lin, Y.; Yang, H.; Tang, S.W.W. Comparison between the effects of phosphorous slag and fly ash on the C-S-H structure, long-term hydration heat and volume deformation of cement-based materials. Constr. Build. Mater. 2020, 250, 118807. [Google Scholar] [CrossRef]

- Yang, H.J.; Usman, M.; Hanif, A. Suitability of Liquid Crystal Display (LCD) Glass Waste as Supplementary Cementing Material (SCM): Assessment based on strength, porosity, and durability. J. Build. Eng. 2021, 102793. [Google Scholar] [CrossRef]

- Kim, S.; Kim, Y.; Usman, M.; Park, C.; Hanif, A. Durability of slag waste incorporated steel fiber-reinforced concrete in marine environment. J. Build. Eng. 2021, 33, 101641. [Google Scholar] [CrossRef]

| Mix Designation | Fly Ash Content g, (% by Weight of Cement) | Silica Fume Content, g (% by Weight of Cement) |

|---|---|---|

| T0 | 225.00 (25.00) | 00.00 (0.00) |

| T1 | 213.75 (23.75) | 11.25 (1.25) |

| T2 | 202.50 (22.50) | 22.50 (2.50) |

| T3 | 191.25 (21.25) | 33.75 (3.75) |

| T4 | 180.00 (20.00) | 45.00 (5.00) |

| T5 | 168.75 (18.75) | 56.25 (6.25) |

| T6 | 157.50 (17.5) | 67.50 (7.50) |

| Mix Designation | Flow Spread | T250 Time | V-Funnel Time | |||

|---|---|---|---|---|---|---|

| mm | SD | s | SD | s | SD | |

| T0 | 285 | 3.61 | 22.1 | 1.56 | 31.7 | 2.14 |

| T1 | 290 | 4.36 | 21.7 | 1.59 | 31.0 | 1.22 |

| T2 | 330 | 5.29 | 11.3 | 1.33 | 25.2 | 1.91 |

| T3 | 335 | 4.36 | 12.5 | 2.07 | 22.3 | 1.83 |

| T4 | 345 | 3.61 | 12.5 | 0.64 | 19.3 | 1.52 |

| T5 | 330 | 4.36 | 13.7 | 1.68 | 14.7 | 2.04 |

| T6 | 290 | 7.21 | 15.2 | 1.88 | 10.5 | 1.41 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arshad, M.T.; Ahmad, S.; Khitab, A.; Hanif, A. Synergistic Use of Fly Ash and Silica Fume to Produce High-Strength Self-Compacting Cementitious Composites. Crystals 2021, 11, 915. https://doi.org/10.3390/cryst11080915

Arshad MT, Ahmad S, Khitab A, Hanif A. Synergistic Use of Fly Ash and Silica Fume to Produce High-Strength Self-Compacting Cementitious Composites. Crystals. 2021; 11(8):915. https://doi.org/10.3390/cryst11080915

Chicago/Turabian StyleArshad, Muhammad Tausif, Saeed Ahmad, Anwar Khitab, and Asad Hanif. 2021. "Synergistic Use of Fly Ash and Silica Fume to Produce High-Strength Self-Compacting Cementitious Composites" Crystals 11, no. 8: 915. https://doi.org/10.3390/cryst11080915

APA StyleArshad, M. T., Ahmad, S., Khitab, A., & Hanif, A. (2021). Synergistic Use of Fly Ash and Silica Fume to Produce High-Strength Self-Compacting Cementitious Composites. Crystals, 11(8), 915. https://doi.org/10.3390/cryst11080915