Abstract

High-performance cementitious composites with self-compacting characteristics are gaining due importance in meeting the challenges of the modern world. This experimental study deals with developing high-strength self-compacting cement mortar composites containing a binary blend of silica fume and fly ash. Seven specimens series were prepared with fly ash (FA), ranging from 17.5% to 25%, and silica fume (SF), from 1.25% to 7.5% of the cement mass. The control specimen powder content consists of 80% ordinary portland cement (OPC), 20% FA, and 0% SF; in the remaining six series of specimens, OPC is kept constant, whereas FA is reduced by 1% and SF is increased by 1% subsequently. Rheological behavior, mechanical properties, and microstructural characteristics of the developed high-performance composites were evaluated. The optimum binary blend for achieving the maximum flow spread and flow rate of the cement mortar is reported as 80% FA and 20% SF. For superior mechanical characteristics, optimum powder content was found as 80% OPC, 17.5% FA, and 2.5% SF. Using the proposed binary blend for construction applications will produce high-strength composites and promote sustainable development due to the use of industrial wastes as OPC replacement.

1. Introduction

High-performance cementitious composites with self-compacting characteristics are gaining due importance in meeting the challenges of the modern world [1]. Repair, retrofit, and maintenance operations often require the casting of thin laminates or patches of the material in narrow and inaccessible places, necessitating the utilization of highly flowable cementitious composites [2,3,4]. Construction time can be reduced by using self-compacting concrete (SCC) [5,6]. However, these flowable cementitious composites must qualify some specific requirements in the fresh state [7]. The composites need to satisfy the dynamic and static stability requirements for their efficient utilization; the dynamic stability corresponds to the resistance against the separation of blended materials during transportation and placement operations. In contrast, the static stability is related to the resistance of the cementitious composites against bleeding, segregation, and surface settlement during their plastic phase [8]. The stability characteristics and the mechanical properties of the cementitious composites strictly depend on the composition of the mix [9,10]. Therefore, it is imperative to proportion the ingredients for achieving high performance in the fresh and hardened states.

Different flow properties of self-compacting mortars may be achieved by using different chemical and mineral admixtures [11]. These admixtures reduce the water demand while improving flow, strength, and durability [12,13]. The selection of suitable mineral admixtures/secondary raw materials (SRMs) is an essential component of SCC mix design, as already emphasized in the literature [14,15,16]. Different industrial by-products and ashes from coal and agricultural wastes burning can be utilized in SCC because it requires more powder material and superplasticizer to improve its properties [17,18]. Self-compacting mortars (SCMs) incorporating limestone powder, fly ash, rice husk ash, and blends of fly ash with silica fume and rice husk ash have already been studied [12,19,20]. Broadly speaking, there is no widely accepted effect of SRMs, due to interlinked actions. Thus it is not easy to generalize their behavior [7].

Fly ash is a residue of coal burning. It is pozzolanic, and as such, can be added to SCMs for improving their properties. Class F fly ash is a combustion residue of bituminous coal and has pozzolanic properties [17,21,22]. SCC systems in which ordinary Portland cement (OPC) is replaced by fly ash reduce the high-range water-reducing admixture (HRWRA) quantity by lowering the water demand [12,17,23]. Usually, fly ash ranging from 15% to 25% by mass of binder is used in concrete [24]. Certain SCC parameters, like viscosity, yield stress, flow rate, and spread, can be enhanced by adding high fly ash content [25]. Water requirement for concrete can be reduced by using ultra-fine fly ash; each 10% addition of fly ash lowers the water demand by 3% [24,26]. If concrete is continuously cured for a prolonged period, there will be a continuous increase in strength due to the pozzolanic activity of fly ash [27]. Fly ash is a substitute viscosity-modifying agent in SCCs [28]. Ultra-fine particles of fly ash can enhance the viscosity and compressive strength of the SCC systems without affecting the rheological properties [29]. The principal reaction of fly ash with portlandite and alkali is analogous to OPC hydration, i.e., secondary C-S-H gel formation. The microstructure of the fly ash reaction product is more gel-like and compacted as compared with that of OPC [30]. The use of fly ash as fine aggregates in the SCC system reduces workability, unit weight, and compressive strength drastically [31].

Silica fume is an excellent amorphous powder obtained as a by-product in electric arc furnaces. It has a particle size ranging from 0.1 to 0.2 µm. It is reported that, annually, approximately 900,000 metric tons of silica fume are produced [19]. Silica fume enhances the hydration reaction rate by releasing OH- ions and alkalis [32]. Silica fume improves the rheological, mechanical, and chemical properties by mitigating corrosion in reinforcing steel. It is beneficial for the durability of the concrete. Using varying amounts of different mineral additives, the durability of the cementitious composite can be improved [33,34].

It has been well-established that fly ash results used in grouts and mortar are analogous when used in concrete [35,36]. Due to specific particle morphology and less specific gravity, the use of fly ash mitigates bleeding, enhances flowability, and limits segregation in SCC [37,38]. Workability properties of SCC are assessed by evaluating self-compacting mortars and are an essential part of SCC design [39,40]. Different researchers have used SRMs to enhance the fresh and hardened properties of the SCC system [4]. Fly ash and silica fume blend was recommended to produce composites with ultra-high-strength and good rheological properties [12]. However, silica fume increases the HRWRA demand to achieve the target flow. The use of silica fume hinders the flowability of the SCC system due to its large surface area, which requires more water for lubrication [41]. It is reported that fly ash, when used alone in large quantities, retards the strength gain of SCC systems considerably.

In contrast, the blend of fly ash and silica fume enhances the overall response [12]. The fresh properties of the SCC system are affected by the water-to-binder ratio and quantity of different admixtures in many ways. Accurate proportioning of these parameters is essential for the achievement of self-compacting properties. Zeta potential is the potential difference between dispersed particles and the layer of liquid attached to them. Fly ash has zeta potential −38.7 mv, while that of silica fume and OPC is −21 mv and +5.5 mv, respectively. This difference in zeta potential is beneficial for enhancing the rheological characteristics of SCMs [7,42].

Based on the past research, it is revealed that instead of using fly ash alone, an SRM combination of fly ash with silica fume is beneficial to enhance the overall response of the SCM system [12]. High-strength mortar composites containing various proportions of silica fume and fly ash can provide a fair balance between flowability and strength [43]. In the current study, the effect of fly ash replacement with silica fume at different levels is carried out. Seven mix proportions were used, replacing fly ash with silica fume in the range of 0 to 30%, at increments of 5%. In this study, the only variable was the replacement level of fly ash with silica fume, while all the other ingredients were kept constant. Rheological properties like flow spread, flow time, and v-funnel time were measured, while the hardened properties, including compressive strength and flexural strength at 3, 7, 14, 21, 28, and 56 days were also determined. Mechanical properties are confirmed by ultrasonic pulse velocity test. This test method is used to investigate the quality, homogeneity, presence of voids and cracks. This technique is an assessment of the effectiveness of the crack repairing technique. Many researchers suggested different criteria to evaluate concrete quality [44,45,46]. According to a study [46], a cementitious composite with UPV > 4.5 km/s is considered excellent quality. Most of the results meet this distinction. The microstructure was also studied by high-resolution SEM images that validate the mechanical properties and ultrasonic pulse velocity results.

2. Materials and Methods

2.1. Materials Characterization and Mix Proportions

Seven mix proportions were prepared by using ordinary Portland cement (grade 52.5N) as binder. The initial and final setting time for cement was determined as per ASTM C191 [47], and it conforms to ASTM C150 [48] specifications. Locally available natural sand (Lawrancepur sand), conforming to ASTM C33 [49] with fineness modulus (FM) of 2.44 and specific gravity of 2.53, was used as fine aggregate to prepare the mortar mixes.

The grain size distribution (GSD) of the fine aggregate is presented in Figure 1. The GSD curve shows that the sand is well-graded and possesses particles of different sizes. Class F fly ash, conforming to ASTM C618 [50], was used. The salient characteristics and oxide composition of fly ash and silica fume are presented in Table 1. The oxide composition of fly ash reveals that the total composition of SiO2, Al2O3, and Fe2O3 is 88.35%, which is far more than that required for a pozzolanic material [51]. Slightly high SO3 content was observed, which indicates that bituminous coal with high sulfur content was burnt, which resulted in such fly ash. The high SO3 content might lead to efflorescence in hardened mortars and concrete. It is also observed that fly ash has a high LOI. Even though the LOI of fly ash is slightly high, it is considered usable in this study. This allowance is provided by ASTM C 618 [52], where it is mentioned that “use of Class F pozzolan containing up to 12.0% loss on ignition may be approved by the user if either acceptable performance records or laboratory test results are made available”. The high value of LOI reduces air entrainment [51]. Air entrainment is beneficial for the flowability of self-compacting mortar/concrete; due to high LOI, a greater superplasticizer dosage will be required to surpass target flow spread [51].

Figure 1.

Grain size distribution curve for fine aggregate.

The presence of amorphous silica in silica fume is primarily responsible for its reactivity in alkaline cementitious systems, which leads to secondary hydrates formation and subsequent higher matrix strength due to greater gel-space ratio [53]. The amounts of CaO, SiO2, and Al2O3 are the most important in determining the reactivity and behavior of the mineral admixtures in the cementitious matrix. Both early-age and long-term properties are, thus, affected.

In the mix proportions, the cement content and total powder content were fixed to 750 kg/m3 and 940 kg/m3, respectively. A w/c of 0.3 was used for all the mixes. Lower w/p was used to ensure resistance against segregation. Superplasticizer (BASF Master glenium ACE 30), which is a polycarboxylate ether with a specific gravity of 1.06g/cc, pH of 6, and total solid content of 30% by weight), was used for attaining suitable flowability. The admixture was selected following ASTM C494 Type F [54] and EN 934-2 T3.1/3 [55].

Table 1.

XRF of fly ash and silica fume (oxide composition expressed in %age).

Table 1.

XRF of fly ash and silica fume (oxide composition expressed in %age).

| Description | Fly Ash | Silica Fume | OPC * |

|---|---|---|---|

| silicon dioxide | 39.45 | 92.31 | 18.92 |

| aluminum oxide | 24.81 | 2.29 | 5.09 |

| iron oxide | 24.09 | 1.97 | 2.27 |

| calcium oxide | 4.03 | 1.14 | 63.18 |

| sulfur oxide | 5.08 | 0.25 | 3.48 |

| minor constituents | 2.54 | 2.04 | 3.84 |

| loi | 6.71 | 1.6 | 1.35 |

| moisture | 1.71 | - | - |

| % passing #325 sieve | 96.5 | 100 | >95 |

| specific gravity | 2.36 | 2.20 | 3.17 |

* Typical values [56].

2.2. Sample Preparation

A self-compacting mortar system with a combination of 1:1.5:0.25 (cement sand Fly ash + silica fume) by weight was prepared using a mixer of capacity 5.0 L (M/S Controls Italy Model 65-L005) conforming to EN 196-1 standard [57]. The mixer moves in two ways; one about its axis and the other in an oscillatory way. The mixing sequence adopted in this study comprises the initial mixing of all the dry materials at a slow speed for 60 s. Then 70% of used water was added and further mixed for 90 s at a slow speed. The mixing was paused for 30 s, and the mixer walls were scraped with a hard rubber scraper. Then, the remaining 30% of used water, along with a superplasticizer, was added and mixed for 150 s at high speed. The total mixing time was 300 s.

The detailed composition of the mortar samples is given in Table 2.

Table 2.

Proportion of fly ash and silica fume *.

2.3. Methodology

The testing was carried out in three phases. Initially, the fresh mortar composites were evaluated for their rheological characteristics. The hardened mortar composites were tested for their mechanical properties, and in the third phase of the investigation, the microstructural characteristics of hardened material were studied in detail.

2.3.1. Rheological Characterization

The deformability and segregation resistance of self-compacting cementitious systems are assessed by slump cone spread and V-funnel time [58,59]. The superplasticizer content was adjusted in the mortar mixes to achieve a target flow of 260 mm by Hagerman’s mini-slump cone. The superplasticizer content was fixed as 2.50% by the weight of cement for all mix proportions after several trials to surpass the minimum flow spread as required by EFNARC 2002 [60].

The flow spread and V-funnel time were determined using the standard method described in EFNARC 2002 [61]. Similar to T500, which is the time of SCC to achieve a spread of 500 mm, some researchers [12] reported measuring the time corresponding to flow diameter of 250mm in case of using a mini-slump cone [62]. Each test is repeated at least three times, and an average of the observation is reported.

2.3.2. Mechanical Strength

Mortar Specimens of 40 mm × 40 mm × 160 mm were cast, cured, and tested per EN196-1 standard [57]. The samples were placed in the moist cabinet (CURACEM M/S Controls Italy Model 65-L0013/D), capable of maintaining the temperature at 20 °C and 95% humidity immediately after casting. After 24 hours, the samples were demolded and placed in CURACEM for curing at 20 °C till the day of testing. The samples tested for compression and flexure, in saturated surface dry condition, in a compression testing machine (Flexure frame model M/S Controls Italy 50-C1601/B attached with MCC8 Console) capable of controlling load rate up to 1 N/s at the age of 3, 7, 14, 21, 28 and 56 days. Three specimens were tested for flexure at each testing age and four specimens in compression for each mix proportion.

2.3.3. Ultrasonic Pulse Velocity

Ultrasonic pulse velocities of the mortar specimens were recorded at the age of 3, 7, 14, 21, 28, and 56 days using an ultrasonic pulse velocity tester (M/S Controls Italy Model 58-E4800). During measurement of ultrasonic pulse velocity, compressive strength, and flexural strength tests, working conditions (temperature, humidity, mix regime, filling) were kept the same.

2.3.4. Microstructural Characterization

Scanning electron microscopy (SEM) is an advanced technique to elaborate the microstructure and phase composition of the cementitious hydration products [63,64,65,66]. In this study, SEM was done by JSM-6390 and JSM-6700F (ultra-high resolution SEM; 1 nm at 15 kV and 2.2 nm at 1 kV) (Jeol USA Inc., Peabody, MA, USA) [67,68]. For scanning electron microscopy, small chips of mortar composite samples were obtained from the broken pieces of the prism samples after their compression tests. The small chips were coated with a layer of gold particles before the SEM observations. Several images for each sample are taken to elaborate on different phases such as fully or partially hydrated or residue raw materials, porosity interface between different hydration products, etc.

3. Results and Discussions

3.1. Rheological Properties

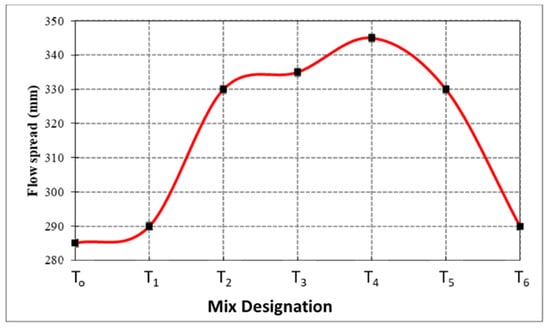

The results obtained from the experiments with their respective standard deviations (SD) are reported in Table 3. The flow results indicate that all the formulations have surpassed the targeted flow of 260 mm and exhibited maximum spread for the mortar formulation containing 80% fly ash and 20% silica fume. All the mixed proportions with silica fume exhibit no segregation and lixiviation. While T0 was well cohesive, but a little bit of lixiviation was observed. As W/C and superplasticizer, the content was kept constant for all mix proportions. Mix proportions with silica fume engaged water more efficiently. The total spread of the mortar formulations represents the strong influence of relative quantities of included SRMs in the mix (referred to Figure 2).

Table 3.

Total flow spread, T250 time, and V-funnel times.

Figure 2.

Variation of flow spread with SF content.

The mini-slump flow, which is a direct function of the yield stress of the formulation, exhibited an increasing trend in the total flow with a small quantity of silica fume inclusion. After 20% content, the total spread indicated a sharp reduction in the total flow. The enhanced flow obtained from 20% inclusion of silica fume is attributed to the packing effect achieved from the inclusion of ultra-fine particles of silica fume in the matrix of fly ash particles and similarly filling effect of fly ash particles in the matrix of fine aggregates [69].

Further, the packing effect was more pronounced due to the spherical shape of silica fume and fly ash particles producing a ball-bearing effect. The lubricated spherical particles produced efficient rolling with reduced intra-particle friction. The water and superplasticizer contents were kept constant throughout the formulations; therefore, up to 20% replacement level lubrication was enough to achieve the rolling effect. After that, the overall surface area of the powder content increased, requiring a higher amount of water and superplasticizer for achieving the same workability level. Due to this effect, the total spread gradually decreases after the replacement level of 20%. This phenomenon is also evident from the T250 time.

The results of T250 indicate a sharp decrease in the flow time between 5% and 10% silica fume replacement levels. Afterward, there is a slight increase in flow time. As silica fume content increases from 5% to 10%, it increases the ball bearing effect; thus, the time required to touch 250 mm circles reduces. Afterward, this effect is reduced due to the increased viscosity of the mortar.

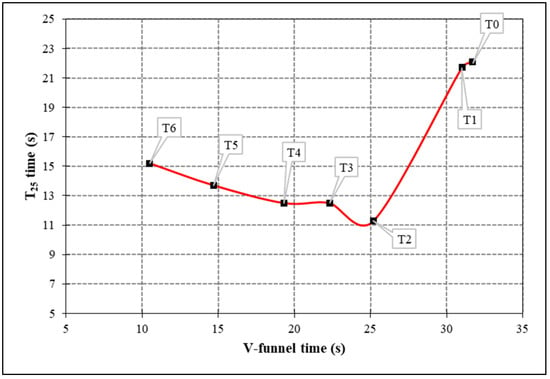

The relationship between T250 and V-funnel time for all the mortar formulations with varying replacement levels of silica fume is presented in Figure 3. V-funnel time decreases with an increase in silica fume content. This may be attributed to the reduction in internal friction and shear stress with the inclusion of silica fume.

Figure 3.

Relationship of V-funnel time with T25 with varying silica fume content.

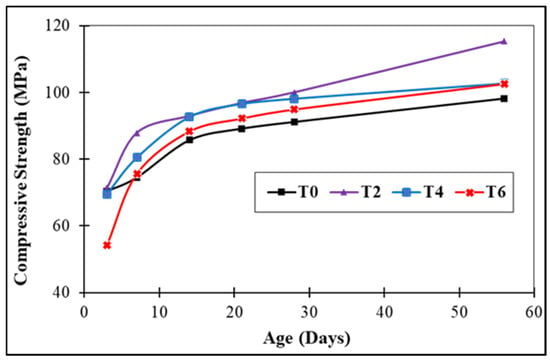

3.2. Mechanical Properties

The compressive strength results of the mortar formulations are presented in Figure 4. The total strength gain of mortar composites containing silica fume and fly ash is higher than the control mix. This may be due to the pozzolanic activity of silica fume at the early stage. However, the contribution of fly ash is less, and it only acts as a pore sealer. At a later stage, the fly ash significantly contributes to the strength by reacting with free Ca (OH)2 and converting it into calcium silicate hydrate. Strength for mix proportion T2 is the highest for all ages, and it corresponds to 10% replacement of fly ash with silica fume. This is the optimum value for the replacement of fly ash with silica fume. There is significant increase in strength from 28 to 56 days i.e., 15.9, 19.6%, 15.2%, 5.7%, 4.6%, 5.4%, and 10.16% from T0 to T6, respectively. A gain in delayed strength reduces with increasing the level of fly ash replacement. The possible reason is that the subsequent decrease in fly ash contents limits the pozzolanic activity (known as the delayed effect of fly ash). The continuous pozzolanic activity strengthens the interfacial transition zone by reducing pore sizes and the packing effect phenomena by the excess unreacted fly ash particles and silica fume [3].

Figure 4.

Compressive strength of mortar composites with varying fly ash and silica fume content.

The flexural strength test results of the mortar formulations are reported in Figure 5 below. Usually, cementitious composites are extraordinarily strong in compression and weak in flexure, i.e., ten times weaker than compressive strength. In the present investigation, the flexural strength patterns are much like results of compressive strength.

Figure 5.

Flexural strength of mortar composites with varying fly ash and silica fume content.

Maximum flexural strength was obtained with the mix proportion T2. Maximum flexural strengths were achieved at 28 and 56 days, at 19.15+ and 20.86 + 0.5 MPa, respectively, which is about 19% and 18% of their corresponding compressive strengths. The relationship between compressive strength and flexural strength of cementitious composites is a matter of interest for researchers and structural designers. Different relationships for various cementitious composites are proposed by many researchers and adopted by the code forming committees. A famous relationship as adopted by ACI is given as follows [70].

The linear regression analysis of the mortar composites samples indicates that the ACI relationship for predicting the flexural strength holds good for the present research (refer to the supplementary data for linear regression analysis).

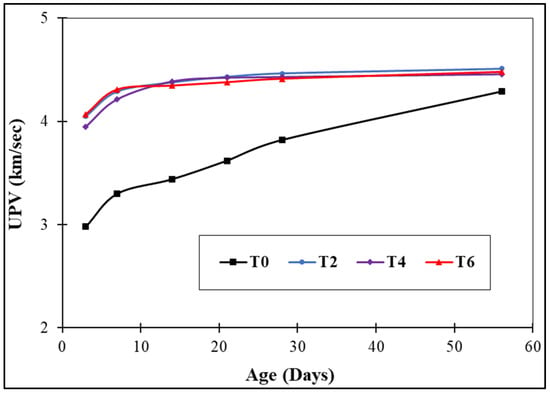

3.3. Ultrasonic Pulse Velocity (UPV)

UPV is an innovative non-destructive technique to measure the mechanical properties of cementitious composites. The results of ultrasonic pulse velocity for a few mix proportions are shown in Figure 6. It was observed that the specimens with only fly ash have the lowest UPV, and samples with a 10% replacement level have a maximum. These results are in close agreement with the mechanical properties. The difference between samples with and without silica fume narrows down at the age of 56 days because hydration products fill voids due to the delayed pozzolanic activity of fly ash [71,72]. The compressive and flexural strength of the SCM composite can be correlated with UPV by an exponential function. Two different models were proposed after analysis of data, one for estimation of compressive strength and the other for flexural strength.

Figure 6.

UPV for various mix proportions.

3.3.1. Mathematical Model for Estimation of Compressive Strength

The proposed model for the estimation of compressive strength from UPV is shown in Equation (2). This model is valid for all mix proportions with silica fume at 28 and 56 days. The maximum error is 4.93 + 0.65% and 8.94+0.30% at 28 and 56 days, respectively.

fc = 1.68 e0.92(UPV)

For mix proportion without silica fume up to an age of 28 days, the error is relatively high, more than 50%, but at the age of 56 days, this error reduces to 14.7 + 4.4%. It is due to the delayed pozzolanic activity of fly ash. These hydration products have filled up the micro and nanosized pores, and UPV is comparable with mix proportions containing silica fume.

3.3.2. Mathematical Model for Estimation of Flexural Strength

The proposed model for the estimation of flexural strength from UPV is shown in Equation (3). This model is valid for all mix proportions with silica fume at 28 and 56 days. The maximum error is 5.5 ± 0.76% and 9.1 ± 0.87% at 28 and 56 days, respectively.

fr = 0.042 e1.37(UPV)

For mix proportion without silica fume up to 28 days, the error is relatively high— more than 35%—but at the age of 56 days, this error reduces to 1.2 ± 0.3%. The reason has already been explained in the case of compressive strength.

3.4. Microstructural Characterization

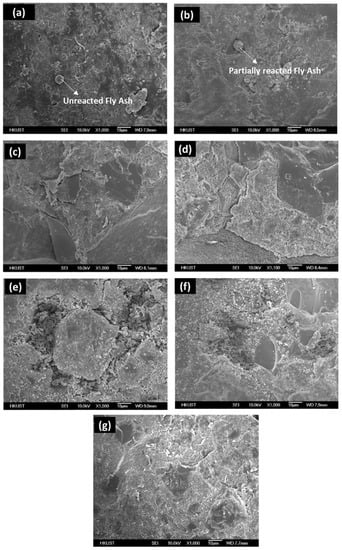

The micrographs for the mix proportions T0 to T6 are presented in Figure 7a–g, respectively. The SEM micrographs show various hydration products as well as partially reacted and unreacted fly ash particles. Typical hydration products, including calcium-silicate-hydrate (CSH) gel and calcium hydroxide (CH), have been identified in the SEM images. Figure 7a is a micrograph for mix proportion T0, which contains only fly ash as SRM. The micrograph shows a flocculent and porous structure with unreacted fly ash particles as well. CSH gel and CH are present as hydration products. Many pores are present within the cementitious matrix.

Figure 7.

Scanning electron micrographs of mortar composites (a) T0, (b) T1, (c) T2, (d) T3, (e) T4, (f) T5 and (g) T6.

Figure 7b is the micrograph of mix proportion T1, which corresponds to 95% of fly ash and 5% of silica fume as SRM. The micrograph shows a denser microstructure as compared to T0. The dense microstructure of the composites with silica fume incorporation is attributed to the pore filling effect (due to the smaller particle size of silica fume than OPC) and secondary hydrates formation [21]. The presence of high amounts of amorphous silica (as shown in Table 1 in the XRF results) is responsible for reaction with calcium hydroxide crystals at a later age. Reduced portlandite amount and increased gel formation are, thus, expected, which leads to lower total porosity and higher compressive strength. Figure 7c is the micrograph for mix proportion T2, which corresponds to 90% FA and 10% SF as SRMs. The microstructure is dense and well compacted, with a few minor cracks indicating strong interface contact between the hydration products. This indicates the pozzolanic reaction; secondary hydration products have filled the pores and improved the interfacial properties. It is also evident from compressive and flexural strength results. The highest strength results are related to this mix proportion. Figure 7d corresponds to the mix proportion T3, which contained 85% of fly ash and 15% of silica fume. Even denser microstructure in T2 is seen. Interfacial separation is also observed. Figure 7e–g correspond to the mix proportion T4 (which contains 80% FA and 20% SF), T5 (which contains 75% FA and 25% of SF), and T6 (which has 70% FA and 30% SF. At some points, large voids with a weak interface between hydration products have been observed.

4. Conclusions

In this study, the role of fly ash replacement with silica fume on fresh and hardened properties of SCM with a moderate volume of fly ash is presented. From the results of this study, the following conclusions may be drawn.

- Replacing fly ash with silica fume gradually increases the flow spread up to 20% replacement level. After that, a decline is observed. Therefore, the optimum blend for maximum spread is 20% silica fume with 80% fly ash content.

- Superplasticizer used in this study was polycarboxylate-based and suitable for increasing the workability of SCMs.

- It is concluded that with the high dosage of silica fume, cement content and superplasticizer may be increased to achieve the target flow.

- T250 time gradually decreases up to 20% replacement level and then starts increasing. This result is in line with the results of flow spread and indicates that the flow spread and the rate of flow decrease after 20% replacement level.

- V- funnel’s time gradually decreases with the increase of silica fume content, indicating that increase of silica fume content enhances the vertical movement of particles by reducing air bubbles, which interfere with the vertical movement of paste. This result complements the results of flow spread and T25 time.

- Proposed models for estimation of compressive and flexure strength from UPV are valid for all mix proportions containing silica fume at the age of 28 and 56 days. For mix proportion containing only fly ash, these are valid for 56 days only. These models can be used to predict the strength of high-strength self-compacting mortar containing fly ash and silica fume.

- The optimum powder content to obtain maximum compressive and flexural strength is 80% of OPC, 18% fly ash, and 2% silica fume.

- Flexural strength follows the compressive strength trend, i.e., the optimum replacement level of fly ash is 10%. Highest achieved flexural strength was 20.86 ± 0.5MPa for mix proportion T2, i.e., 90% FA and 10% SF. Same as compressive strength results gain in flexural strength can be correlated by a power law.

High-strength mortar developed in this study can be used for repair, maintenance, retrofitting, and strengthening of existing reinforced concrete and structures. It can also be used as the matrix for ferrocement and laminated cementitious composites. Studies on optimal amounts of ternary and quaternary blends containing new SRMs [73,74,75] should be further investigated.

Author Contributions

Conceptualization, M.T.A.; Methodology, M.T.A.; Format analysis, M.T.A. and A.K.; Investigation, M.T.A.; Writing-Original draft preparation, M.T.A.; Partial resources, M.T.A. and S.A.; Validation of Results, S.A.; Supervision, S.A.; Writing-Review and editing, A.K. and A.H.; Data curation, A.K. and A.H.; Project administration, A.H.; Funding acquisition, A.H. All authors have read and agreed to the published version of the manuscript.

Funding

Funding support from China National Key R&D Program—Intergovernmental International Scientific and Technological Innovation Cooperation Key Project, “Research on the application and demonstration of the green construction materials for the post-disaster reconstruction in Pakistan and Nepal”, Grant No. 2018YFE0106300, 2019.07-2022.06, is gratefully acknowledged.

Acknowledgments

The authors acknowledge the support of laboratory staff of Department of Civil Engineering at Mirpur university of Science and Technology (MUST), Mirpur, AJK, and University of Engineering and Technology (UET), Taxila during experimentations. In addition, technical help in doing the SEM imaging from HKUST, Hong Kong by Pavithra Parthasarathy is gratefully acknowledged.

Conflicts of Interest

The authors declare no conflict of interest of any kind.

References

- Usman, M.; Khan, A.Y.; Farooq, S.H.; Hanif, A.; Tang, S.; Khushnood, R.A.; Rizwan, S.A. Eco-friendly self-compacting cement pastes incorporating wood waste as cement replacement: A feasibility study. J. Clean. Prod. 2018, 190, 679–688. [Google Scholar] [CrossRef]

- Hanif, A.; Cheng, Y.; Lu, Z.; Li, Z. Mechanical Behavior of Thin-Laminated Cementitious Composites Incorporating Cenosphere Fillers. ACI Mater. J. 2018, 115, 117–127. [Google Scholar] [CrossRef]

- Hanif, A.; Lu, Z.; Sun, M.; Parthasarathy, P.; Li, Z. Green lightweight ferrocement incorporating fly ash cenosphere based fibrous mortar matrix. J. Clean. Prod. 2017, 159, 326–335. [Google Scholar] [CrossRef]

- Bhikshma, V.; Ravandekishore; Srinivas, R. Durability of polymer and fly ash modified ferro cement elements. Procedia Eng. 2011, 14, 2642–2649. [Google Scholar] [CrossRef] [Green Version]

- Mohamed, H.A. Effect of fly ash and silica fume on compressive strength of self-compacting concrete under different curing conditions. Ain. Shams Eng. J. 2011, 2, 79–86. [Google Scholar] [CrossRef] [Green Version]

- Elemam, W.E.; Abdelraheem, A.H.; Mahdy, M.G.; Tahwia, A.M. Optimizing fresh properties and compressive strength of self-consolidating concrete. Constr. Build. Mater. 2020, 249, 118781. [Google Scholar] [CrossRef]

- Felekoǧlu, B.; Tosun, K.; Baradan, B.; Altun, A.; Uyulgan, B. The effect of fly ash and limestone fillers on the viscosity and compressive strength of self-compacting repair mortars. Cem. Concr. Res. 2006, 36, 1719–1726. [Google Scholar] [CrossRef]

- ACI Committee 237. American Concrete Institute. In Self-Consolidating Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2007; ISBN 9780870312441. [Google Scholar]

- Nepomuceno, M.; Oliveira, L.; Lopes, S.M.R. Methodology for mix design of the mortar phase of self-compacting concrete using different mineral additions in binary blends of powders. Constr. Build. Mater. 2012, 26, 317–326. [Google Scholar] [CrossRef]

- Bingöl, A.F.; Tohumcu, I. Effects of different curing regimes on the compressive strength properties of self compacting concrete incorporating fly ash and silica fume. Mater. Des. 2013, 51, 12–18. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; Khayat, K.H. Influence of silica fume content on microstructure development and bond to steel fiber in ultra-high strength cement-based materials (UHSC). Cem. Concr. Compos. 2016, 71, 97–109. [Google Scholar] [CrossRef] [Green Version]

- Rizwan, S.A.; Bier, T.A. Self-consolidating mortars using various secondary raw materials. ACI Mater. J. 2009, 106, 25–32. [Google Scholar] [CrossRef]

- Rasheed, A.; Usman, M.; Farooq, H.; Hanif, A. Effect of Super-plasticizer Dosages on Fresh State Properties and Early-Age Strength of Concrete. IOP Conf. Ser. Mater. Sci. Eng. 2018, 431, 062010. [Google Scholar] [CrossRef] [Green Version]

- Malhotra, V. Fly ash, slag, silicafume, and rice husk ashin concrete:A review. Concr. Int. 1993, 15, 23–28. [Google Scholar]

- Benabed, B.; Kadri, E.-H.; Azzouz, L.; Kenai, S. Properties of self-compacting mortar made with various types of sand. Cem. Concr. Compos. 2012, 34, 1167–1173. [Google Scholar] [CrossRef]

- Faheem, A.; Rizwan, S.A.; Bier, T.A. Properties of self-compacting mortars using blends of limestone powder, fly ash, and zeolite powder. Constr. Build. Mater. 2021, 286, 122788. [Google Scholar] [CrossRef]

- Sua-Iam, G.; Makul, N. Utilization of coal- and biomass-fired ash in the production of self-consolidating concrete: A literature review. J. Clean. Prod. 2015, 100, 59–76. [Google Scholar] [CrossRef]

- Gil, A.M.; Khayat, K.H.; Tutikian, B.F. An experimental approach to design self-consolidating concrete. Constr. Build. Mater. 2019, 229, 116939. [Google Scholar] [CrossRef]

- ACI 234R Guide for the use of silica fume in concrete. In ACI Committee 234 Report; American Concrete Institute: Farmington Hills, MI, USA, 2006; Volume 96, pp. 1–15.

- Singh, N.; Singh, S.P. Carbonation resistance and microstructural analysis of Low and High Volume Fly Ash Self Compacting Concrete containing Recycled Concrete Aggregates. Constr. Build. Mater. 2016, 127, 828–842. [Google Scholar] [CrossRef]

- Li, Z. Advanced Concrete Technology; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2011. [Google Scholar]

- Khan, M.I.; Usman, M.; Rizwan, S.A.; Hanif, A. Self-Consolidating Lightweight Concrete Incorporating Limestone Powder and Fly Ash as Supplementary Cementing Material. Materials 2019, 12, 3050. [Google Scholar] [CrossRef] [Green Version]

- Satish, K.; Kumar, S.; Rai, B. Self Compacting Concrete Using Fly Ash and Silica Fumes as Pozzolanic Material. J. Eng. Technol. 2017, 6, 394–407. Available online: https://www.researchgate.net/publication/318875965. (accessed on 8 July 2021).

- Thomas, M. Optimizing the Use of Fly Ash in Concrete. Available online: www.cement.org. (accessed on 8 July 2021).

- Kwan, A.K.H.; Li, Y. Effects of fly ash microsphere on rheology, adhesiveness and strength of mortar. Constr. Build. Mater. 2013, 42, 137–145. [Google Scholar] [CrossRef]

- Qadir, W.; Ghafor, K.; Mohammed, A. Characterizing and modeling the mechanical properties of the cement mortar modified with fly ash for various water-to-cement ratios and curing times. Adv. Civ. Eng. 2019, 2019. [Google Scholar] [CrossRef] [Green Version]

- ACI Committee 232. Use of fly ash in concrete Reported by ACI Comittee 232. NCHRP Synth. Highw. Pract. 1986, 96, 1–34. [Google Scholar]

- Dinakar, P.; Babu, K.G.; Santhanam, M. Durability properties of high volume fly ash self compacting concretes. Cem. Concr. Compos. 2008, 30, 880–886. [Google Scholar] [CrossRef]

- Xie, Y.; Liu, B.; Yin, J.; Zhou, S. Optimum mix parameters of high-strength self-compacting concrete with ultrapulverized fly ash. Cem. Concr. Res. 2002, 32, 477–480. [Google Scholar] [CrossRef]

- Idorn, G.M. Technica. U. of D.C. Idorn, 30 Years with Alkalis in Concrete. In Proceedings of the ALKALIS in Concrete Research and Practice, Copenhagen, Denmark, 22 June 1983; pp. 19–38. [Google Scholar]

- Bilir, T.; Gencel, O.; Topcu, I.B. Properties of mortars with fly ash as fine aggregate. Constr. Build. Mater. 2015, 93, 782–789. [Google Scholar] [CrossRef]

- Benli, A.; Karatas, M.; Bakir, Y.; Karata, M.; Bakir, Y. An experimental study of different curing regimes on the mechanical properties and sorptivity of self-compacting mortars with fly ash and silica fume. Constr. Build. Mater. 2017, 144, 552–562. [Google Scholar] [CrossRef]

- Seluck Turkel, Y.A. The effect of limestone powder, fly ash and silica fume on the properties of self-compacting repair mortars, Sadhana-Acad. Proc. Eng. Sci. 2009, 2, 331–343. [Google Scholar]

- Sonebi, M. Medium strength self-compacting concrete containing fly ash: Modelling using factorial experimental plans. Cem. Concr. Res. 2004, 34, 1199–1208. [Google Scholar] [CrossRef]

- Bradbury, H.W. The use and potential for fly ash in grouting. In Proceedings of the 5th International Ash Utilization Symposium; DOE/METC/SP-79; U.S Department of Energy, Morgsntown Energy Technology Center: Morgsntown, VA, USA, 1979. [Google Scholar]

- Wu, W.; Wang, R.; Zhu, C.; Meng, Q. The effect of fly ash and silica fume on mechanical properties and durability of coral aggregate concrete. Constr. Build. Mater. 2018, 185, 69–78. [Google Scholar] [CrossRef]

- Steven, D.; Hempling, J.R.P. compressive strength of flyash cement grouting mix. In Proceedings of the 4th International Ash Utilization Symposium (St.Louis, Mar.); ERDA MERC/SP-76; U.S Bureau of Mines: Washington, DC, USA, 1976; pp. 589–598. [Google Scholar]

- Bagheri, A.; Zanganeh, H.; Alizadeh, H.; Shakerinia, M.; Marian, M.A.S. Comparing the performance of fine fly ash and silica fume in enhancing the properties of concretes containing fly ash. Constr. Build. Mater. 2013, 47, 1402–1408. [Google Scholar] [CrossRef]

- Şahmaran, M.; Christianto, H.A.; Yaman, I.Ö. The effect of chemical admixtures and mineral additives on the properties of self-compacting mortars. Cem. Concr. Compos. 2006, 28, 432–440. [Google Scholar] [CrossRef]

- Li, J.; Tan, D.; Zhang, X.; Wan, C.; Xue, G. Mixture design method of self-compacting lightweight aggregate concrete based on rheological property and strength of mortar. J. Build. Eng. 2021, 43, 102660. [Google Scholar] [CrossRef]

- Claisse, P.A.; Lorimer, P.; Al Omari, M. Workability of Cement Pastes. ACI Mater. J. 2001, 98. [Google Scholar] [CrossRef]

- Lei, D.Y.; Guo, L.P.; Sun, W.; Liu, J.; Shu, X.; Guo, X.L. A new dispersing method on silica fume and its influence on the performance of cement-based materials. Constr. Build. Mater. 2016, 115, 716–726. [Google Scholar] [CrossRef]

- Shannag, M.J.; Mourad, S.M. Flowable high strength cementitious matrices for ferrocement applications. Constr. Build. Mater. 2012, 36, 933–939. [Google Scholar] [CrossRef]

- Feldman, R.F. Non destructive testing of concrete. Natl. Res. Counc. Can. Ott. Ont. 1977, 187, 6. [Google Scholar]

- Leslie, J.R.; Cheesman, W.J. An ultrasonic method for studying deterioration and cracking in concrete structures. ACI Mater. J. 1949, 46, 17–36. [Google Scholar]

- Saint-Pierre, F.; Philibert, A.; Giroux, B.; Rivard, P. Concrete Quality Designation based on Ultrasonic Pulse Velocity. Constr. Build. Mater. 2016, 125, 1022–1027. [Google Scholar] [CrossRef]

- ASTM Standard C191-04. Time of Setting of Hydraulic Cement by Vicat Needle; ASTM International: West Conshohocken, PA, USA, 2004. [Google Scholar]

- ASTM Standard C150-04. Standard Specification for Portland Cement; ASTM International: West Conshohocken, PA, USA, 2004. [Google Scholar]

- ASTM Standard C33-02. Standard Specification for Concrete Aggregates; ASTM International: West Conshohocken, PA, USA, 2002. [Google Scholar]

- ASTM Standard C 618-99 Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use as Mineral Admixture in Concrete. Annu. B. ASTM Stand. 1999, 3–6. [CrossRef]

- Zahedi, M. Evaluating the Use of Fluidized Bed Combustion Fly Ash as Concrete Pozzolan. Ph.D. Thesis, Department of Civil Engineering, The Pennsylvania State University, State College, PA, USA, 2019. [Google Scholar]

- Zahedi, M. Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2019; Available online: www.astm.org (accessed on 8 July 2021). [CrossRef]

- Lu, Z.; Hou, D.; Hanif, A.; Hao, W.; Li, Z.; Sun, G. Comparative evaluation on the dispersion and stability of graphene oxide in water and cement pore solution by incorporating silica fume. Cem. Concr. Compos. 2018, 94, 33–42. [Google Scholar] [CrossRef]

- ASTM C 494/C 494M—05 Standard Specification for Chemical Admixtures for Concrete. ASTM Int. 2005, 1–9. [CrossRef]

- British Standards, BS EN 934-2:2001. Admixtures for Concrete, Mortar and, Grout; The British Standards Institution: London, UK, 2001. [Google Scholar]

- Rizwan, S.A.; Bier, T.A. Blends of limestone powder and fly-ash enhance the response of self-compacting mortars. Constr. Build. Mater. 2012, 27, 398–403. [Google Scholar] [CrossRef]

- European Standard Institution [NF EN196-1]. Methods of Testing Cement–Part 1: Determination of Strength; European Committee for Standardization: Brussels, Belgium, 2006. [Google Scholar]

- Maeyama, A.; Mruyama, K.; Midorikowa, T. characterization of powder for self compacting concrete. In Proceedings of the the international Workshop on SCC, Auckland, New Zealand, 8 July 2019; pp. 191–200. [Google Scholar]

- Okamur, H.; Ouchi, M. Self Compacting Concrete. J. Adv. Concr. Technol. 2000, 1, 5–15. [Google Scholar] [CrossRef]

- The European Project Group SCC 028. The European Guidelines for Self-Compacting Concrete. Eur. Guidel. Self Compact. Concr. 2005, 63. Available online: https://www.theconcreteinitiative.eu/images/ECP_Documents/EuropeanGuidelinesSelfCompactingConcrete.pdf (accessed on 8 July 2021).

- EFNARC Specification and Guidelines for Self-Compacting Concrete. Rep. EFNARC 2002, 44, 32.

- Rizwan, S.A.; Ahmad, S.; Bier, T.A. Application of packing concepts to high performance self-consolidating mortar (SCM) systems. Spec. Publ. 2012, 289, 299–315. [Google Scholar] [CrossRef]

- Li, L.G.; Huang, Z.H.; Zhu, J.; Kwan, A.K.H.; Chen, H.Y. Synergistic effects of micro-silica and nano-silica on strength and microstructure of mortar. Constr. Build. Mater. 2017, 140, 229–238. [Google Scholar] [CrossRef]

- Heikal, M.; Zohdy, K.M.; Abdelkreem, M. Mechanical, microstructure and rheological characteristics of high performance self-compacting cement pastes and concrete containing ground clay bricks. Constr. Build. Mater. 2013, 38, 101–109. [Google Scholar] [CrossRef]

- Liu, J.; Li, Q.; Xu, S. Influence of nanoparticles on fluidity and mechanical properties of cement mortar. Constr. Build. Mater. 2015, 101, 892–901. [Google Scholar] [CrossRef]

- Arshad, M.T.; Hanif, A.; Khitab, A.; Iftikhar, A.; Raza, A.; Liaqat, J. Cementitious Composites Reinforced with Multi Walled Carbon Nano Tubes Dispersed in Gum Arabic. In Proceedings of the International Conference on Information Technology, Civil Engineering and Applied Sciences; ITCEA-2018, Bangkok, Thail; Academy of Engineering Technology Leadership: Bangkok, Thailand, 2018; ISBN 978-969-228-897-2. [Google Scholar]

- Hanif, A.; Lu, Z.; Diao, S.; Zeng, X.; Li, Z. Properties investigation of fiber reinforced cement-based composites incorporating cenosphere fillers. Constr. Build. Mater. 2017, 140, 139–149. [Google Scholar] [CrossRef]

- Hanif, A.; Parthasarathy, P.; Ma, H.; Fan, T.; Li, Z. Properties improvement of fly ash cenosphere modified cement pastes using nano silica. Cem. Concr. Compos. 2017, 81, 35–48. [Google Scholar] [CrossRef]

- Bui, D.D.; Hu, J.; Stroeven, P. Particle size effect on the strength of rice husk ash blended gap-graded Portland cement concrete. Cem. Concr. Compos. 2005, 27, 357–366. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete; Pearson Education: London, UK, 2011. [Google Scholar]

- Brink, R.H.; Halstead, W.J. Studies Relating to the Testing of Fly Ash for Use in Concrete. Am. Soc. Testing and Proc. 1956, 56, 1161–1214. [Google Scholar]

- Babu, K.G.; Rao, G.S.N. Efficiency of fly ash in concrete. Cem. Concr. Compos. 1993, 15, 223–229. [Google Scholar] [CrossRef]

- Wang, L.; Guo, F.; Lin, Y.; Yang, H.; Tang, S.W.W. Comparison between the effects of phosphorous slag and fly ash on the C-S-H structure, long-term hydration heat and volume deformation of cement-based materials. Constr. Build. Mater. 2020, 250, 118807. [Google Scholar] [CrossRef]

- Yang, H.J.; Usman, M.; Hanif, A. Suitability of Liquid Crystal Display (LCD) Glass Waste as Supplementary Cementing Material (SCM): Assessment based on strength, porosity, and durability. J. Build. Eng. 2021, 102793. [Google Scholar] [CrossRef]

- Kim, S.; Kim, Y.; Usman, M.; Park, C.; Hanif, A. Durability of slag waste incorporated steel fiber-reinforced concrete in marine environment. J. Build. Eng. 2021, 33, 101641. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).