Development of a Sulfate Resistance Performance Test for Concrete by Tensile Strength Measurements: Determination of Test Conditions

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Concrete Composition

2.3. Design of Experiments

2.4. Data Analysis

- T is the temperature in °C,

- b is the binder content in kg/m3,

- c is the sulfate concentration in mg SO42−/L,

- ρ is the fresh concrete density in g/cm3, and

- ai are the coefficients.

2.5. Methods

2.5.1. Strength Testing

2.5.2. Microstructural Analysis

3. Results

3.1. Determination of a Suitable Reference to Evaluate Strength Data

- ftm(t) is the mean tensile strength in MPa at an age t in days,

- ftm,28d is the average tensile strength in MPa at an age of 28 days,

- βtc(t) is a function to describe the strength development with time,

- t is the concrete age in days,

- s is a coefficient, which depends on the strength class of the cement, the water/binder ratio and the SCM content.

- w/b is the free water to binder ratio,

- scm/b is the mass proportion of SCM (fly ash and/or GGBS) in the binder,

- c1, c2 are coefficients depending on the strength class of the cement.

- tT is the temperature-adjusted concrete age in days,

- Δti is the number of days where a temperature Tα prevails in days,

- Tα(Δti) is the temperature of concrete during time interval Δti in °C.

3.2. Strength Development

3.2.1. Flexural Strength

3.2.2. Tensile Strength

3.3. Microstructural Analysis

4. Conclusions and Implications for a Future Testing Procedure

- An adapted concrete mix design based on the planned concrete mixture should be used, while a maximum grain size of 8 mm must be adhered to.

- The authors recommend raising the water to binder ratio by 10% to slightly reduce the density of the concrete, thus accelerating the performance test.

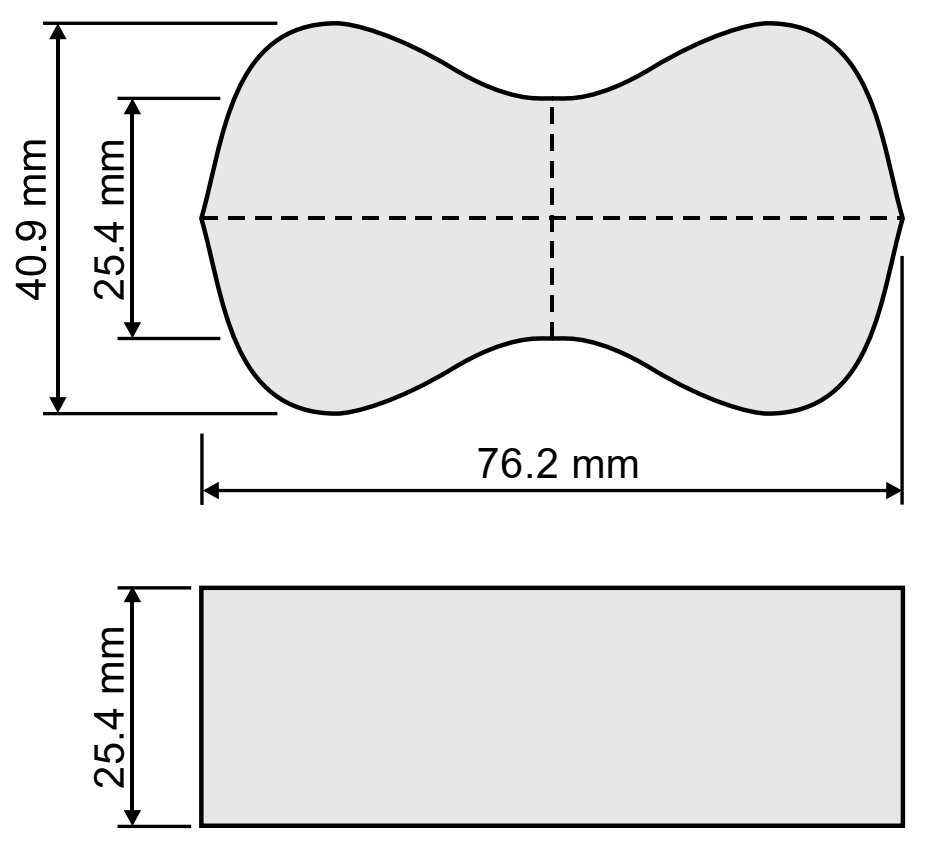

- Briquette molds according to ASTM C307-03 should be used to produce the specimens for testing the tensile strength in one single batch, while after demolding, the samples must be stored in saturated Ca(OH)2 solution at 20 °C until an age of 28 days.

- The tensile strength of the concrete at an age of 28 days is determined and serves as the reference strength.

- The specimens dedicated for sulfate storage are stored in sodium sulfate solution with 6000 mg SO42−/L at 5 °C until testing. The storage solution is renewed every seven days until 28 days of storage and every 14 days afterwards to compensate the consumption of sulfates.

- The tensile strength of the concrete is tested after 119 days (four months), 182 days (six months) and 273 days (nine months) of storage in the solution.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Skalny, J.; Marchand, J.; Odler, I. Sulfate Attack on Concrete; Spon Press: London, UK, 2002. [Google Scholar]

- Santhanam, M. Effect of solution concentration on the attack of concrete by combined sulphate and chloride solutions. Eur. J. Environ. Civ. Eng. 2011, 15, 1003–1015. [Google Scholar] [CrossRef]

- Yu, X.; Zhu, Y.; Liao, Y.; Chen, D. Study of the evolution of properties of mortar under sulfate attack at different concentrations. Adv. Cem. Res. 2016, 28, 617–629. [Google Scholar] [CrossRef]

- DIN Deutsches Institut für Normung e.V. Zement-Prüfung der Leistungsfähigkeit hinsichtlich des Sulfatwiderstands-Bericht zum Stand der Technik. In DIN-Fachbericht CEN/TR 15697; Beuth Verlag GmbH: Berlin, Germany, 2008. [Google Scholar]

- Müllauer, W. Mechanismen des Sulfatangriffs auf Beton-Phasenneubildungen und Expansionsdrücke in Mörteln unter Na2SO4 Belastung. Ph.D. Thesis, Technische Universität München, München, Germany, 2013. [Google Scholar]

- Glasser, F.P.; Marchand, J.; Samson, E. Durability of concrete—Degradation phenomena involving detrimental chemical reactions. Cem. Concr. Res. 2008, 38, 226–246. [Google Scholar] [CrossRef]

- Kunther, W.; Lothenbach, B.; Scrivener, K.L. On the relevance of volume increase for the length changes of mortar bars in sulfate solutions. Cem. Concr. Res. 2013, 46, 23–29. [Google Scholar] [CrossRef]

- Lee, S.T.; Moon, H.Y.; Hooton, R.D.; Kim, J.P. Effect of solution concentrations and replacement levels of metakaolin on the resistance of mortars exposed to magnesium sulfate solutions. Cem. Concr. Res. 2005, 35, 1314–1323. [Google Scholar] [CrossRef]

- Loser, R.; Leemann, A. An accelerated sulfate resistance test for concrete. Mater. Struct. 2016, 49, 3445–3457. [Google Scholar] [CrossRef]

- Müllauer, W.; Beddoe, R.E.; Heinz, D. Sulfate attack expansion mechanisms. Cem. Concr. Res. 2013, 52, 208–215. [Google Scholar] [CrossRef]

- Ogawa, S.; Nozaki, T.; Yamada, K.; Hirao, H.; Hooton, R.D. Improvement on sulfate resistance of blended cement with high alumina slag. Cem. Concr. Res. 2012, 42, 244–251. [Google Scholar] [CrossRef]

- Rozière, E.; Loukili, A.; El Hachem, R.; Grondin, F. Durability of concrete exposed to leaching and external sulphate attacks. Cem. Concr. Res. 2009, 39, 1188–1198. [Google Scholar] [CrossRef] [Green Version]

- Shi, Z.; Ferreiro, S.; Lothenbach, B.; Geiker, M.R.; Kunther, W.; Kaufmann, J.; Herfort, D.; Skibsted, J. Sulfate resistance of calcined clay—Limestone—Portland cements. Cem. Concr. Res. 2019, 116, 238–251. [Google Scholar] [CrossRef]

- Suma, F.M.; Santhanam, M. Influence of Specimen Size on the Expansion of Portland Cement Mortars Immersed in Sodium Sulphate Solution. In External Sulphate Attack–Field Aspects and Lab Tests: RILEM Final Workshop of TC 251-SRT (Madrid-SPAIN, 2018); Menéndez, E., Baroghel-Bouny, V., Eds.; Springer: Cham, Switzerland, 2020; pp. 81–91. ISBN 978-3-030-20331-3. [Google Scholar]

- Wu, K.; Kang, W.; Xu, L.; Sun, D.; Wang, F.; de Schutter, G. Damage evolution of blended cement concrete under sodium sulfate attack in relation to ITZ volume content. Constr. Build. Mater. 2018, 190, 452–465. [Google Scholar] [CrossRef]

- Zhongya, Z.; Xiaoguang, J.; Wei, L. Long-term behaviors of concrete under low-concentration sulfate attack subjected to natural variation of environmental climate conditions. Cem. Concr. Res. 2019, 116, 217–230. [Google Scholar] [CrossRef]

- Bassuoni, M.T.; Nehdi, M.L. Durability of self-consolidating concrete to sulfate attack under combined cyclic environments and flexural loading. Cem. Concr. Res. 2009, 39, 206–226. [Google Scholar] [CrossRef]

- Khayat, K.H.; Tagnit-Hamou, A.; Petrov, N. Performance of concrete wharves constructed between 1901 and 1928 at the Port of Montréal. Cem. Concr. Res. 2005, 35, 226–232. [Google Scholar] [CrossRef]

- Yang, D.; Luo, J. The damage of concrete under flexural loading and salt solution. Constr. Build. Mater. 2012, 36, 129–134. [Google Scholar] [CrossRef]

- Zhu, J.; Cao, Y.; Chen, J. Study on the evolution of dynamic mechanics properties of cement mortar under sulfate attack. Constr. Build. Mater. 2013, 43, 286–292. [Google Scholar] [CrossRef]

- Biricik, H.; Aköz, F.; Türker, F.; Berktay, I. Resistance to magnesium sulfate and sodium sulfate attack of mortars containing wheat straw ash. Cem. Concr. Res. 2000, 30, 1189–1197. [Google Scholar] [CrossRef]

- Guerrero, A.; Goñi, S.; Macías, A. Durability of new fly ash–belite cement mortars in sulfated and chloride medium. Cem. Concr. Res. 2000, 30. [Google Scholar] [CrossRef]

- Guo, Z.; Wang, Y.; Hou, P.; Shao, Y.; Zuo, X.; Li, Q.; Xie, N.; Cheng, X. Comparison study on the sulfate attack resistivity of cement-based materials modified with nanoSiO2 and conventional SCMs: Mechanical strength and volume stability. Constr. Build. Mater. 2019, 211, 556–570. [Google Scholar] [CrossRef]

- Irassar, E.F.; Gonzalez, M.; Rahhal, V. Sulphate resistance of type V cements with limestone filler and natural pozzolana. Cem. Concr. Comp. 2000, 22, 361–368. [Google Scholar] [CrossRef]

- Zhang, M.; Jiang, M.; Chen, J. Variation of flexural strength of cement mortar attacked by sulfate ions. Eng. Fract. Mech. 2008, 75, 4948–4957. [Google Scholar] [CrossRef] [Green Version]

- Boyd, A.J.; Mindess, S. The use of tension testing to investigate the effect of W/C ratio and cement type on the resistance of concrete to sulfate attack. Cem. Concr. Res. 2004, 34, 373–377. [Google Scholar] [CrossRef]

- Mulenga, D.M.; Stark, J.; Nobst, P. Thaumasite formation in concrete and mortars containing fly ash. Cem. Concr. Comp. 2003, 25, 907–912. [Google Scholar] [CrossRef]

- Yan, C.; Yang, D.; Liu, S.; Zhang, J.; Hu, Z. Splitting Tensile Strength of Concrete Corroded by Saline Soil. ACI Mater. J. 2020, 117, 15–23. [Google Scholar] [CrossRef]

- Matschei, T.; Glasser, F.P. Thermal stability of thaumasite. Mater. Struct. 2015, 48, 2277–2289. [Google Scholar] [CrossRef]

- Haufe, J.; Vollpracht, A. Tensile strength of concrete exposed to sulfate attack. Cem. Concr. Res. 2019, 116, 81–88. [Google Scholar] [CrossRef]

- Funk, J.E.; Dinger, D.R. Predictive Process Control of Crowded Particulate Suspensions; Springer: Boston, MA, USA, 1994; ISBN 978-0-7923-9409-9. [Google Scholar]

- Westphal, T. Quantitative Rietveld-Analyse von amorphen Materialien. Ph.D. Thesis, Martin-Luther-Universität Halle-Wittenberg, Halle, Germany, 2007. [Google Scholar]

- FIB. Fib Model Code for Concrete Structures 2010; Ernst & Sohn: Berlin, Germany, 2013; ISBN 9783433604083. [Google Scholar]

- Vollpracht, A.; Soutsos, M.; Kanavaris, F. Strength development of GGBS and fly ash concretes and applicability of fib model code’s maturity function—A critical review. Constr. Build. Mater. 2018, 162, 830–846. [Google Scholar] [CrossRef] [Green Version]

- Matschei, T.; Glasser, F.P. Temperature dependence, 0 to 40 °C, of the mineralogy of Portland cement paste in the presence of calcium carbonate. Cem. Concr. Res. 2010, 40, 763–777. [Google Scholar] [CrossRef]

- Bellmann, F.; Möser, B.; Stark, J. Influence of sulfate solution concentration on the formation of gypsum in sulfate resistance test specimen. Cem. Concr. Res. 2006, 36, 358–363. [Google Scholar] [CrossRef]

- Gollop, R.S.; Taylor, H.F.W. Microstructural and microanalytical studies of sulfate attack. V. Comparison of different slag blends. Cem. Concr. Res. 1996, 26, 1029–1044. [Google Scholar] [CrossRef]

| Component | CEM I 42.5 N | CEM I 42.5 N-SR3 | CEM II/B-S 42.5 N | CEM III/A 42.5 N | Fly Ash |

|---|---|---|---|---|---|

| CaO | 64.7 | 62.8 | 55.5 | 49.8 | 3.2 |

| SiO2 | 21.5 | 19.8 | 25.6 | 30.1 | 50.1 |

| Al2O3 | 4.10 | 4.00 | 5.59 | 7.40 | 25.80 |

| Fe2O3 | 2.71 | 6.55 | 1.83 | 1.17 | 7.29 |

| MgO | 0.87 | 1.38 | 2.58 | 4.36 | 1.64 |

| K2O | 0.62 | 1.01 | 0.63 | 0.58 | 2.03 |

| Na2O | 0.34 | 0.14 | 0.39 | 0.37 | 0.91 |

| TiO2 | 0.18 | 0.14 | 0.33 | 0.49 | 0.93 |

| Cl− | 0.056 | 0.054 | 0.028 | 0.061 | <0.001 |

| SO3 | 2.76 | 2.56 | 2.81 | 3.13 | 0.65 |

| LOI | 2.39 | 1.82 | 0.41 | −0.96 | 4.72 |

| Component | CEM I 42.5 N | CEM I 42.5 N-SR3 | CEM II/B-S 42.5 N | CEM III/A 42.5 N | Fly Ash |

|---|---|---|---|---|---|

| Alite | 57.6 | 53.8 | 33.5 | 18.6 | - |

| Belite | 13.0 | 9.6 | 6.1 | 4.1 | - |

| C3A | 7.4 | 3.0 | 5.0 | 2.7 | - |

| Ferrite | 6.3 | 19.9 | 2.9 | 2.1 | - |

| Gypsum | 0.9 | - | - | - | 0.1 |

| Hemihydrate | 2.0 | 0.7 | 1.1 | 0.4 | 0.3 |

| Anhydrite | 2.0 | 5.4 | 3.8 | 4.5 | - |

| Calcite | 5.7 * | 5.1 | 0.1 | 0.2 | 0.8 |

| Periclase | - | 0.5 | 0.2 | - | 0.2 |

| Quartz | 1.1 | 0.6 | 0.2 | 0.1 | 4.8 |

| Arcanite | 1.7 | 0.7 | 0.1 | - | - |

| Ca-Langbeinite | 0.9 | 0.6 | 0.8 | 0.5 | - |

| Lime | - | - | - | - | 0.1 |

| Portlandite | 1.4 | - | 0.4 | 0.2 | - |

| Mullite | - | - | - | - | 13.2 |

| Hematite | - | - | - | - | 0.6 |

| Magnetite | - | - | - | - | 0.9 |

| Amorphous | - | - | 45.6 | 66.7 | 78.8 |

| Component | M1 (2) | M2 (2) | M3 (2) | M4 (3) | M5 (3) | M6 (3) | M7 (2) | M8 (3) |

|---|---|---|---|---|---|---|---|---|

| Cement in kg/m3 | 320 | 360 | 400 | 270 | 285 | 300 | 360 | 285 |

| Fly ash in kg/m3 | - | - | - | 90 | 94 | 100 | - | 94 |

| Water in kg/m3 | 144 | 162 | 180 | 138 | 145 | 153 | 180 | 162 |

| w/ceq (1) | 0.45 | 0.50 | ||||||

| Quartz filler in kg/m3 | 458 | 408 | 360 | 354 | 323 | 292 | 253 | 249 |

| Aggregate in kg/m3 | 1473 | 1441 | 1767 | 1527 | 1519 | 1511 | 1548 | 1550 |

| Grading curve | mod. Andreasen, n = 0.25 D = 8 mm, d = 1 µm | C8 (DIN 1045-2) | ||||||

| Independent Variable | Variation |

|---|---|

| Temperature | 5 °C, 12 °C, 20 °C |

| Concentration of the sulfate solution | 3000 mg SO42−/L, 6000 mg SO42−/L |

| cement content | 320 kg/m3, 360 kg/m3, 400 kg/m3 |

| cement + fly ash content | (270 + 90) kg/m3, (285 + 94) kg/m3, (300 + 100) kg/m3 |

| Solution | Temperature in °C | Concentration in mg SO42−/L | Concrete Mixture |

|---|---|---|---|

| Na2SO4 | 5 | 3000 | M1/M4 |

| M2/M5 | |||

| 6000 | M1/M4 | ||

| M3/M6 | |||

| 12 | 3000 | M3/M6 | |

| 6000 | M1/M4 | ||

| M2/M5 | |||

| 20 | 3000 | M1/M4 | |

| M3/M6 | |||

| 6000 | M2/M5 | ||

| Ca(OH)2 (1) | 5 | saturated | M1/M4 |

| M2/M5 | |||

| M3/M6 | |||

| 12 | M1/M4 | ||

| M2/M5 | |||

| M3/M6 | |||

| 20 | M1/M4 | ||

| M2/M5 | |||

| M3/M6 |

| Cement | CEM I | CEM I-SR3 | CEM I + FA | CEM II/B-S (1) | CEM III/A (1) | |

|---|---|---|---|---|---|---|

| R2 | 17% | 34% | 68% | 45% | 31% | |

| contribution | T | n. d. | n. d. | 33% | n. d. | n. d. |

| c | 1% | |||||

| T2 | 5% | |||||

| b·c | 34% | |||||

| Cement | CEM I | CEM I-SR3 | CEM I + FA | CEM II/B-S (1) | CEM III/A (1) | |

|---|---|---|---|---|---|---|

| R2 | 54% | 16% | 61% | 12% | 54% | |

| contribution | T | 6 | n. d. | 49 | n. d. | n. i. |

| c | 10 | n. i. | 26 | |||

| ρ | n. i. | n. i. | 18 | |||

| T2 | 36 | 6 | n. i. | |||

| T·ρ | 4 | 8 | n. i. | |||

| c·ρ | n. i. | n. i. | 14 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haufe, J.; Vollpracht, A.; Matschei, T. Development of a Sulfate Resistance Performance Test for Concrete by Tensile Strength Measurements: Determination of Test Conditions. Crystals 2021, 11, 1001. https://doi.org/10.3390/cryst11081001

Haufe J, Vollpracht A, Matschei T. Development of a Sulfate Resistance Performance Test for Concrete by Tensile Strength Measurements: Determination of Test Conditions. Crystals. 2021; 11(8):1001. https://doi.org/10.3390/cryst11081001

Chicago/Turabian StyleHaufe, Johannes, Anya Vollpracht, and Thomas Matschei. 2021. "Development of a Sulfate Resistance Performance Test for Concrete by Tensile Strength Measurements: Determination of Test Conditions" Crystals 11, no. 8: 1001. https://doi.org/10.3390/cryst11081001

APA StyleHaufe, J., Vollpracht, A., & Matschei, T. (2021). Development of a Sulfate Resistance Performance Test for Concrete by Tensile Strength Measurements: Determination of Test Conditions. Crystals, 11(8), 1001. https://doi.org/10.3390/cryst11081001