Correlation between Solution Treatment Temperature, MicroStructure, and Yield Strength of Forged Ti-17 Alloys

Abstract

1. Introduction

2. Materials and Methods

3. Results

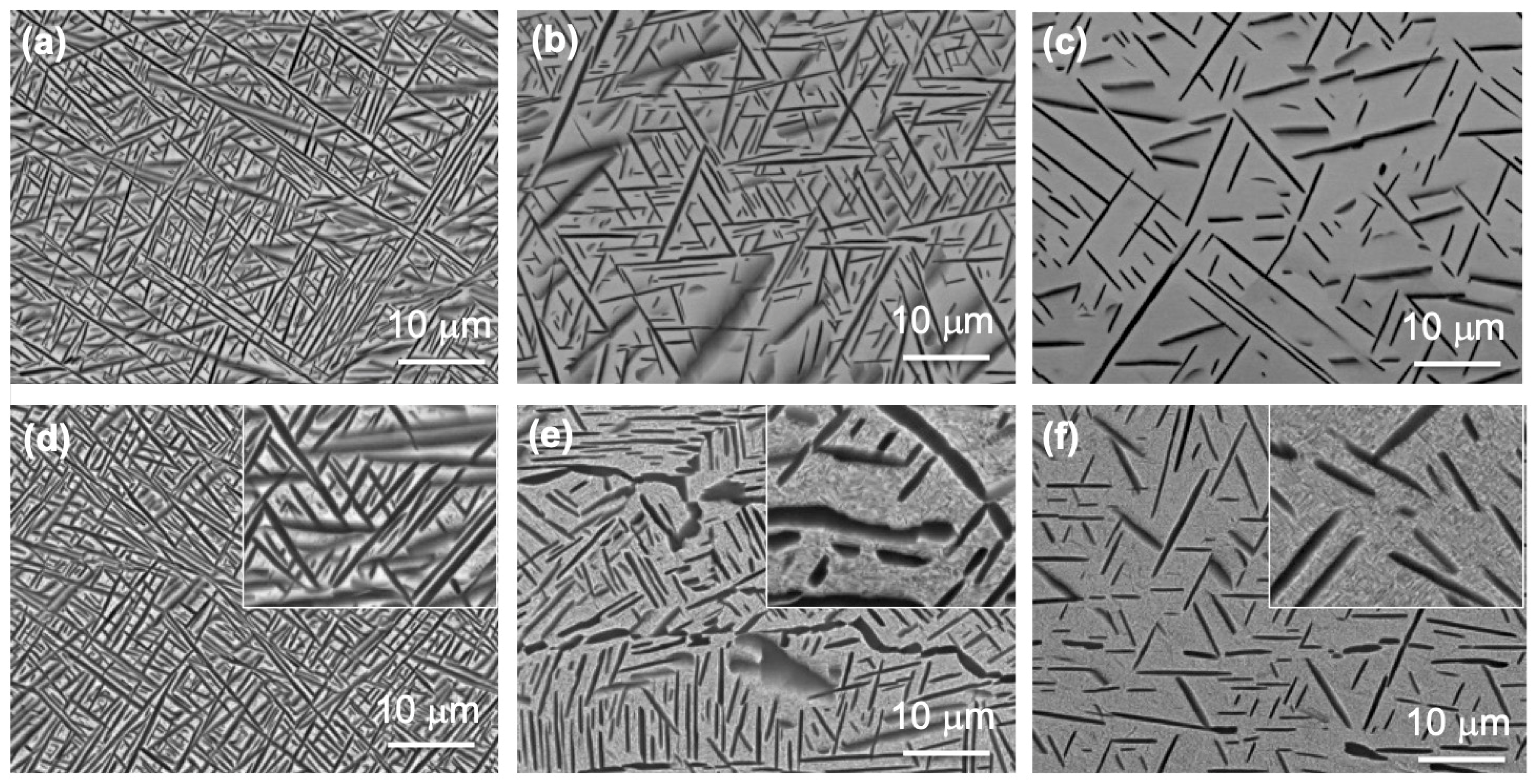

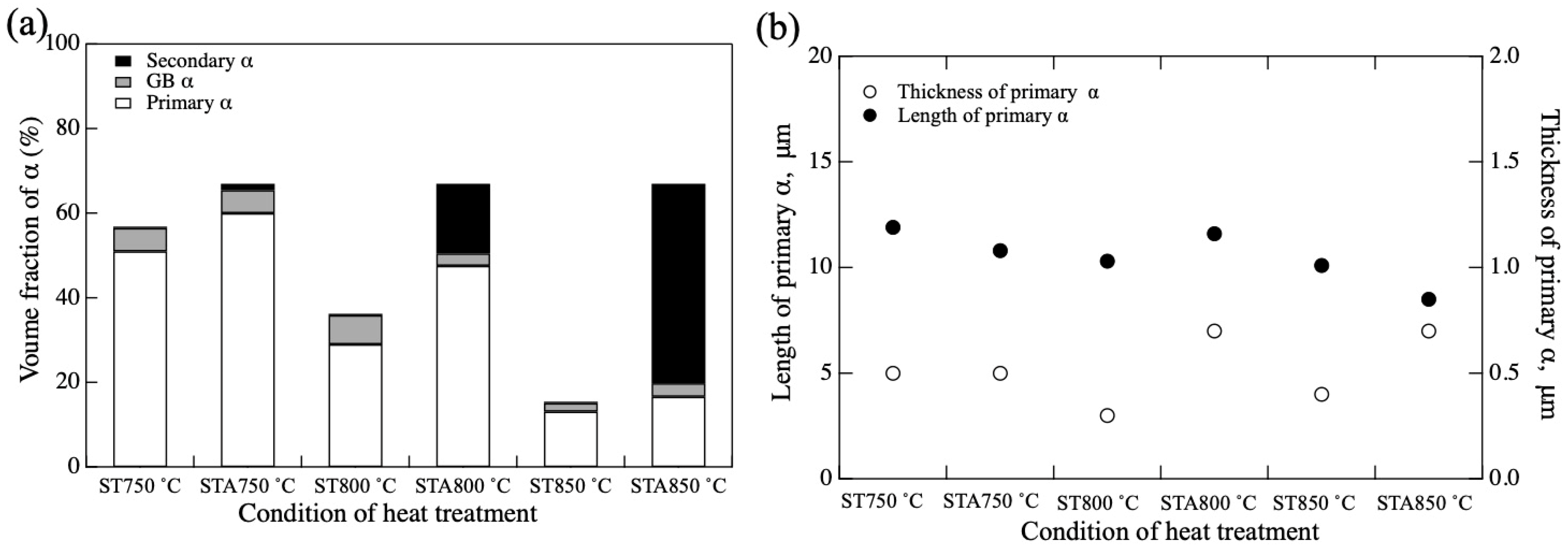

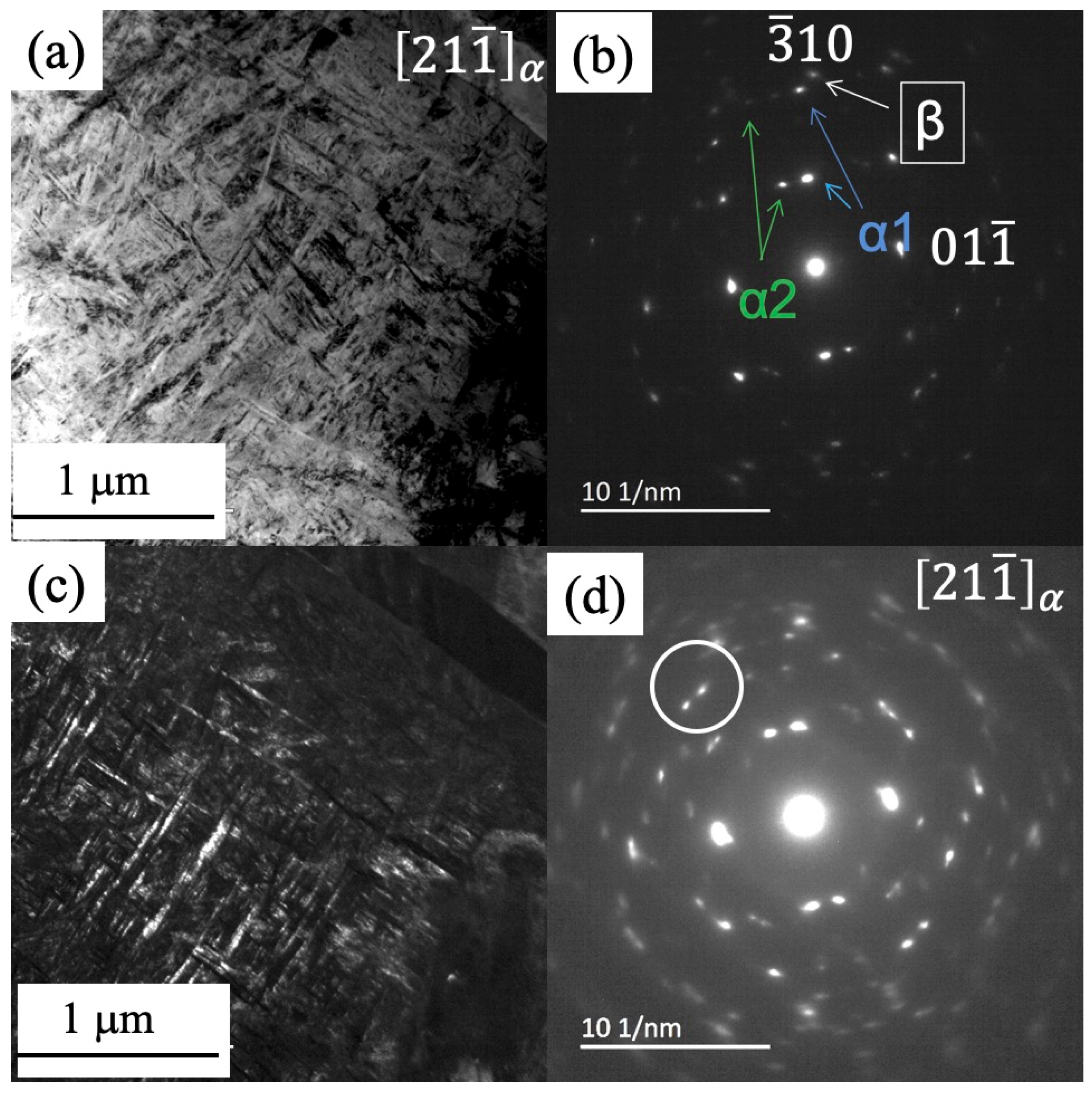

3.1. Microstructure

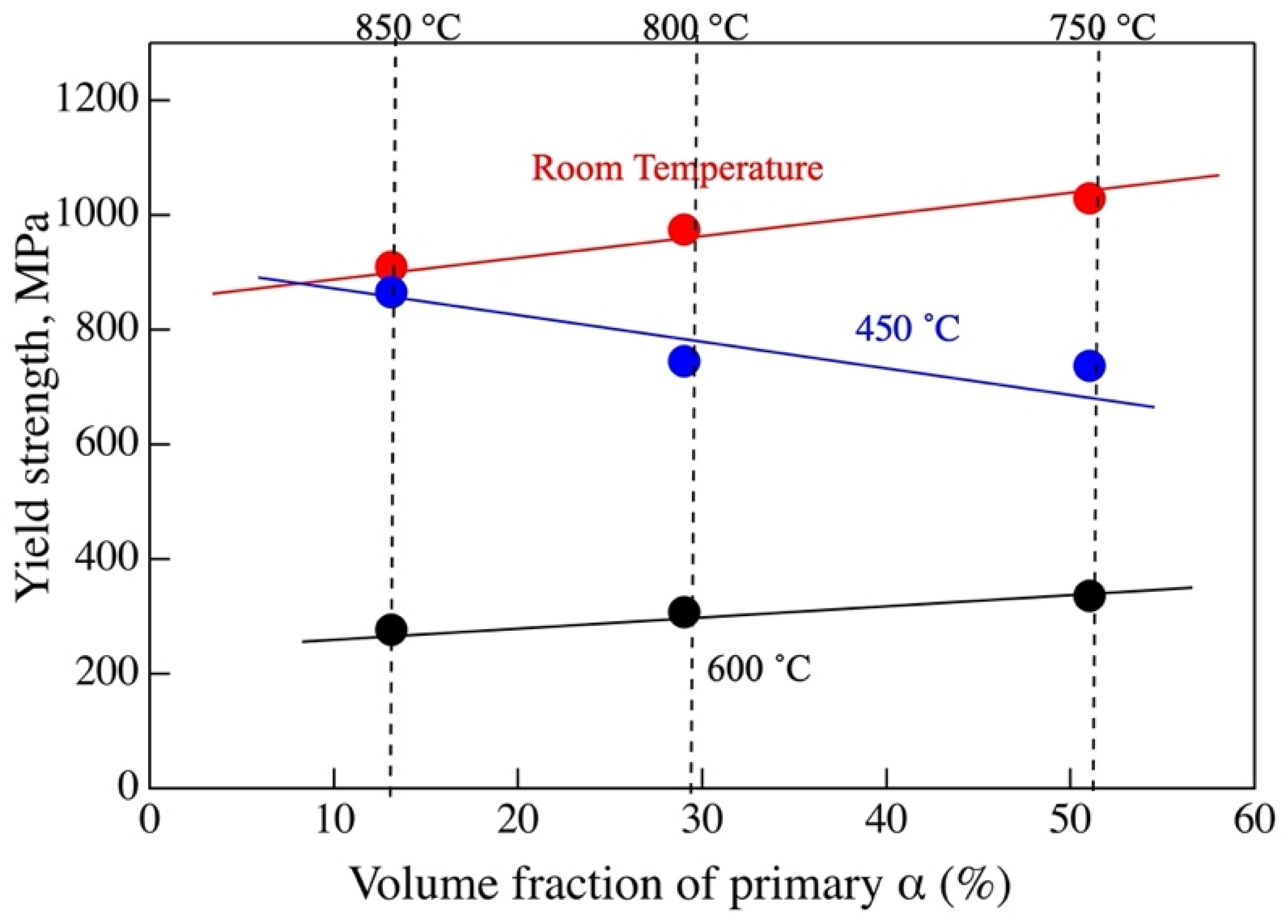

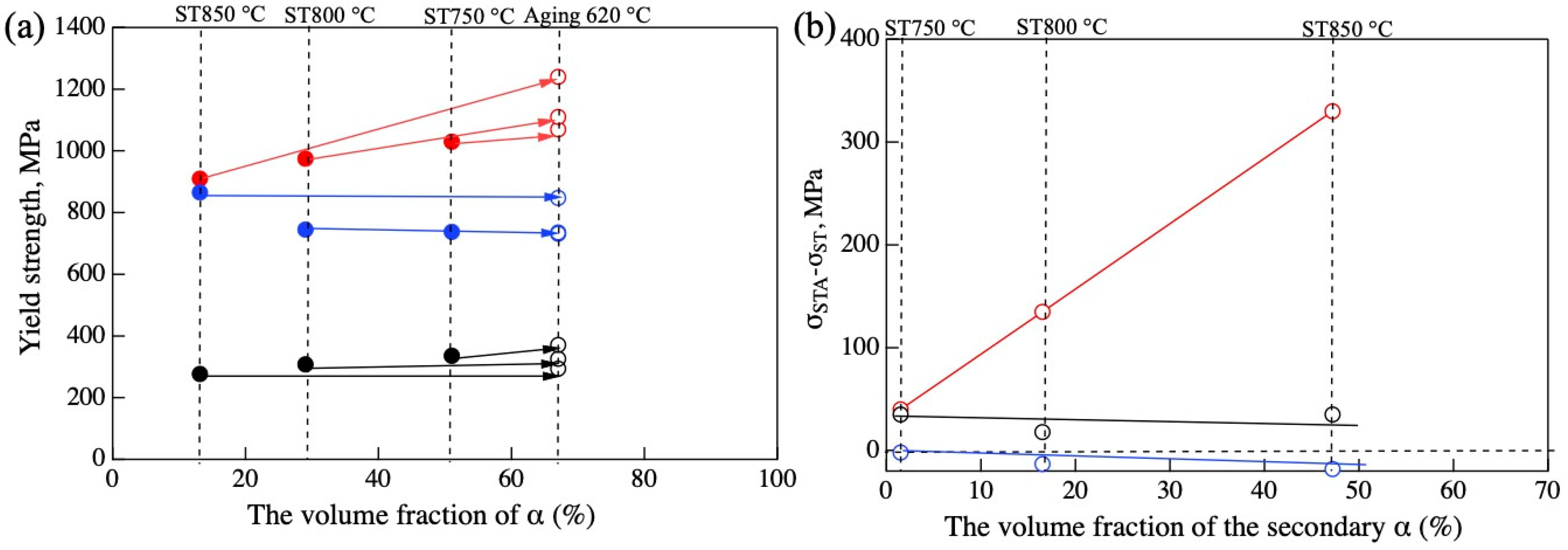

3.2. Mechanical Properties

4. Discussion

4.1. Mechanical Properties at Different Testing Temperatures

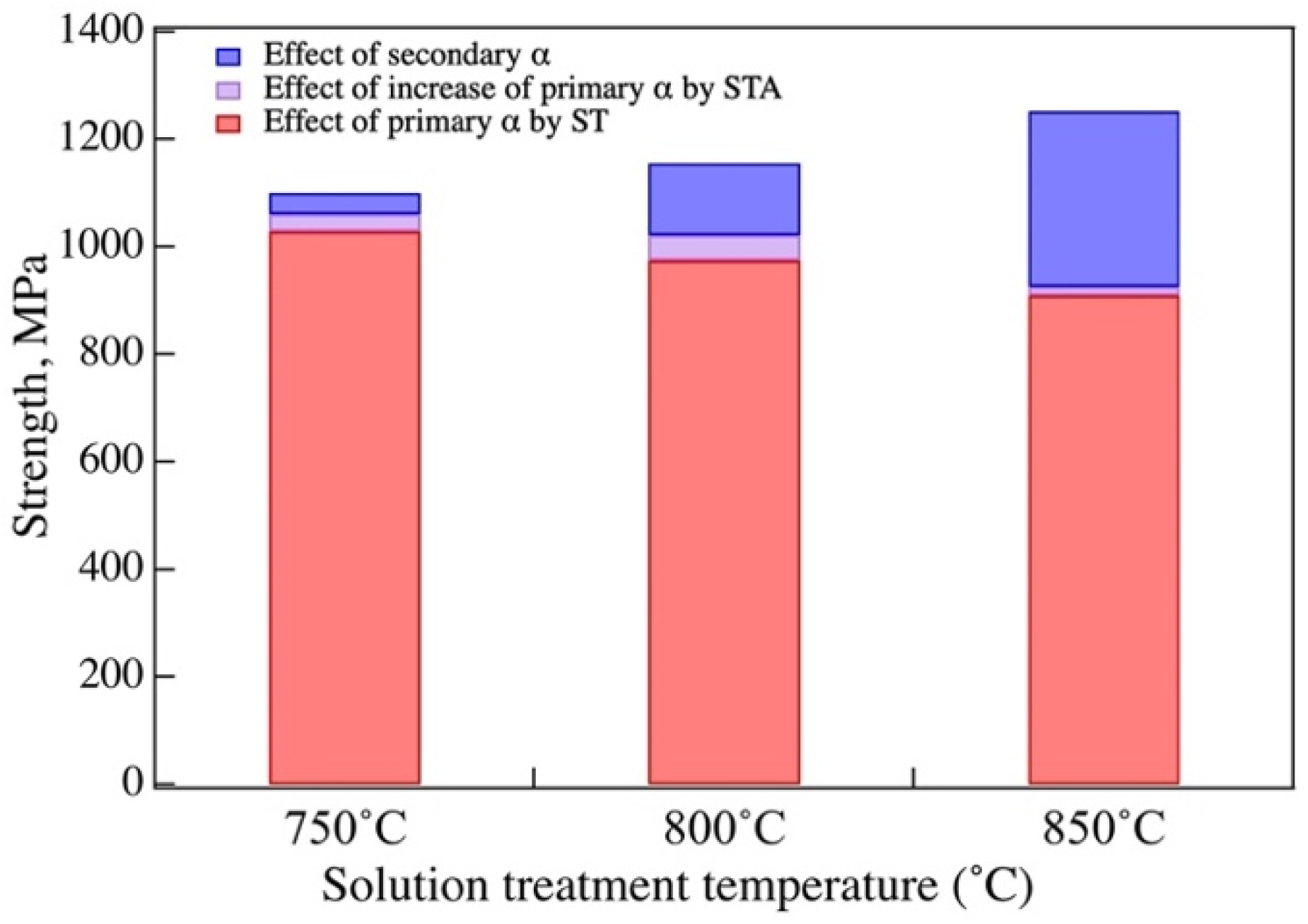

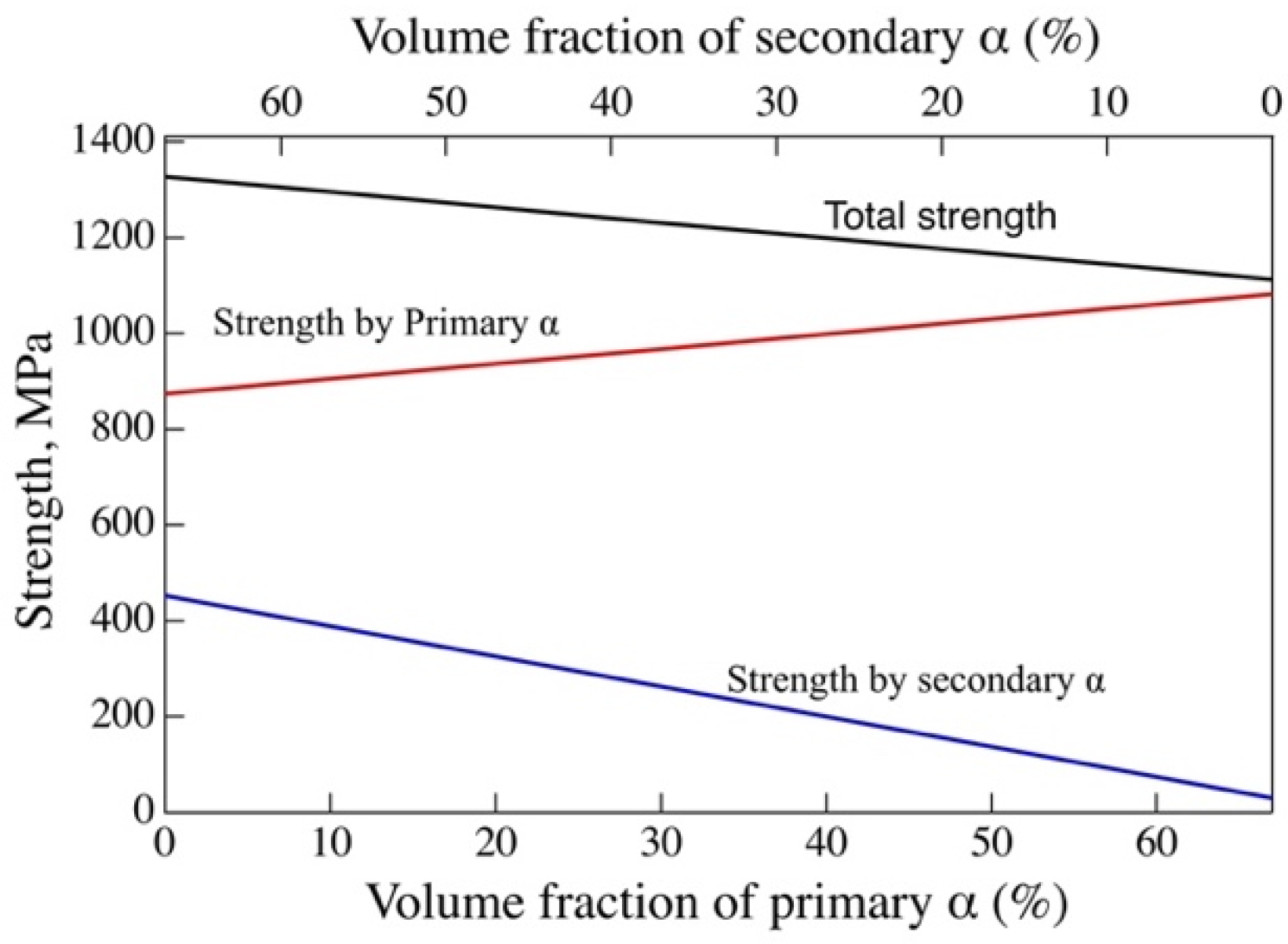

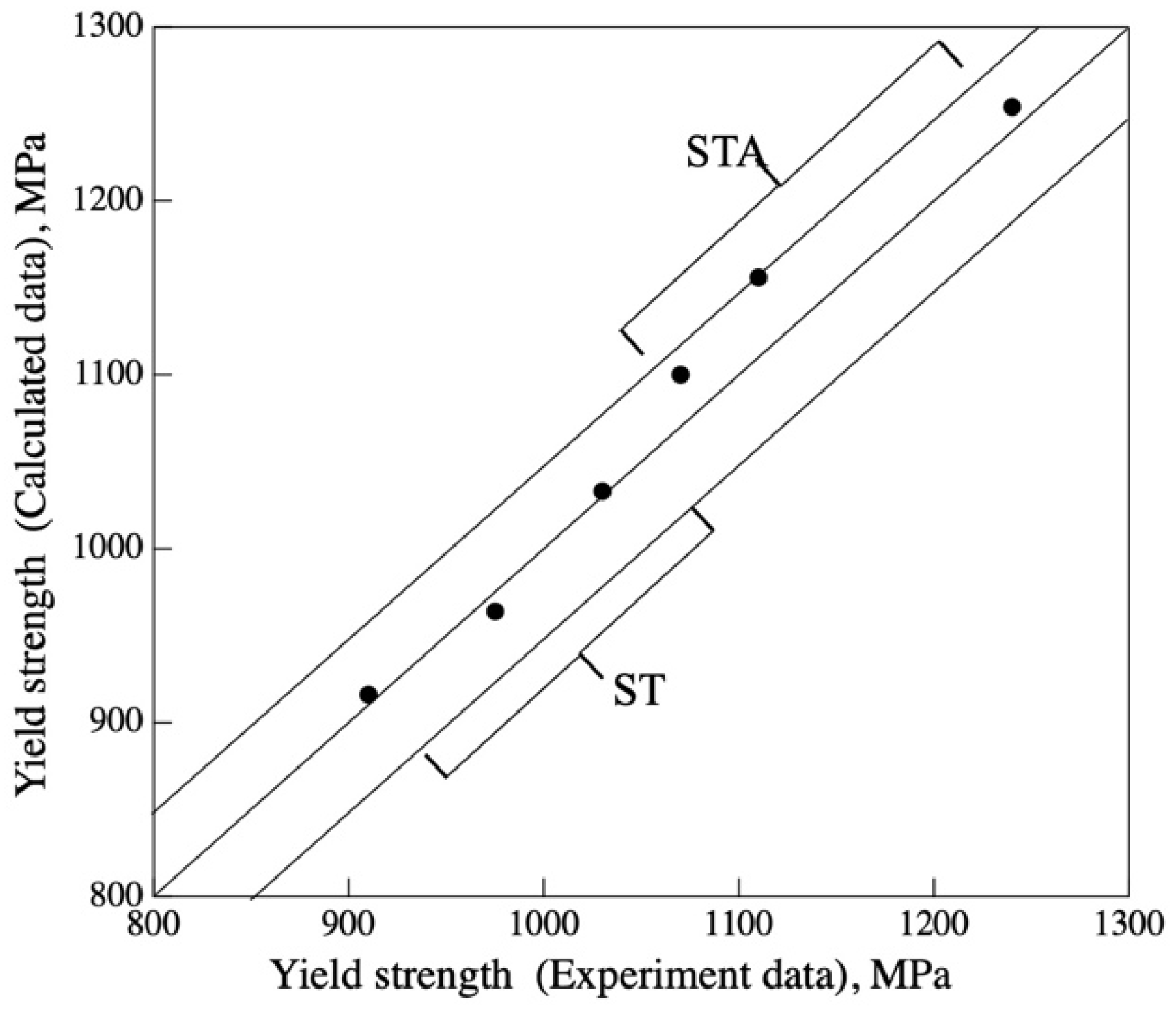

4.2. Effect of the Primary and Secondary α Phase on the Yield Strength

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Farrahi, G.H.; Tirehdast, M.; Masoumi Khalil Abad, E.; Parsa, S.; Motakefpoor, M. Failure analysis of a gas turbine compressor. Eng. Fail. Anal. 2011, 18, 474–484. [Google Scholar] [CrossRef]

- Shlyannikov, V.N.; Ishtyryakov, I.S. Crack growth rate and lifetime prediction for aviation gas turbine engine compressor disk based on nonlinear fracture mechanics parameters. Theor. Appl. Fract. Mech. 2019, 103, 102313. [Google Scholar] [CrossRef]

- Lypchanskyi, O.; Sleboda, T.; Wojtaszek, M.; Muszka, K.; Lukaszek-Solek, A.; Stanik, R.; Gude, M. The analysis of flow behavior of Ti-6Al-2Sn-4Zr-6Mo alloy based on the processing maps. Int. J. Mater. Form. 2020. [Google Scholar] [CrossRef]

- Choda, T.; Oyama, H.; Murakami, S. Technologies for process design of titanium alloy forging for aircraft parts. KOBELCO Technol. Rev. 2015, 33, 44–49. [Google Scholar]

- Alluaibi, M.H.I.; Cojocaru, E.M.; Rusea, A.; Serban, N.; Coman, G.; Cojocaru, V.D. Microstructure and mechanical properties evolution during solution and ageing treatment for a hot deformed, above, β-transus, Ti-6246 alloy. Metals 2020, 10, 1114. [Google Scholar] [CrossRef]

- Matsumoto, H. Globularization and recrystallization of a Ti-6Al-2Sn-4Zr-6Mo alloy under forging in the (α+β) region: Experiment, phenomenological modeling and machine learning. ISIJ Inter. 2021, 61, 1011–1021. [Google Scholar] [CrossRef]

- Xu, J.; Zeng, W.; Jia, Z.; Sun, X.; Zhou, J. Microstructure coarsening behavior of Ti-17 alloy with equiaxed alpha during heat treatment. J. Alloys Compd. 2015, 618, 343–348. [Google Scholar] [CrossRef]

- Xu, J.; Zeng, W.; Jia, Z.; Sun, X.; Zhou, J. Static globularization kinetics for Ti-17 alloy with initial lamellar microstructure. J. Alloys Compd. 2014, 603, 239–247. [Google Scholar] [CrossRef]

- Xu, J.; Zeng, W.; Sun, X.; Jia, Z.; Zhou, J. Static coarsening behavior of the lamellar alpha in Ti-17 alloy. J. Alloys Compd. 2015, 631, 248–254. [Google Scholar] [CrossRef]

- Jia, Z.; Zeng, W.; Xu, J.; Zhou, J.; Wang, Z. Development of the dynamic globularization prediction model for Ti-17 titanium alloy using finite element method. J. Mater. Eng. Perform. 2015, 24, 1771–1780. [Google Scholar] [CrossRef]

- Xu, J.; Zeng, W.; Sun, X.; Jia, Z. Microstructure evolution during isothermal forging and subsequent heat treatment of Ti-17 alloy with a lamellar colony structure. J. Alloys Compd. 2015, 637, 449–455. [Google Scholar] [CrossRef]

- Zhang, J.; Li, H.; Zhan, M. Review on globularization of titanium alloy with lamellar colony. Manuf. Rev. 2020, 7, 18. [Google Scholar] [CrossRef]

- Ning, Y.; Fu, M.W.; Hou, H.; Yao, Z.; Guo, H. Hot deformation behavior of Ti-5.0Al-2.40Sn-2.02Zr-3.86Mo-3.91Cr alloy with an initial lamellar microstructure in the α + β phase field. Mater. Sci. Eng. A 2011, 528, 1812–1818. [Google Scholar] [CrossRef]

- Ma, X.; Zeng, W.; Wang, K.; Lai, Y.; Zhou, Y. The investigation on the unstable flow behavior of Ti17 alloy in α + β phase field using processing map. Mater. Sci. Eng. A 2012, 550, 131–137. [Google Scholar] [CrossRef]

- Li, H.; Li, M.Q.; Han, T.; Liu, H.B. The deformation behavior of isothermally compressed Ti-17 titanium alloy in α + β field. Mater. Sci. Eng. A 2012, 546, 40–45. [Google Scholar] [CrossRef]

- Ma, X.; Zeng, W.; Sun, Y.; Wang, K.; Lai, Y.; Zhou, Y. Modeling constitutive relationship of Ti17 titanium alloy with lamellar starting microstructure. Mater. Sci. Eng. A 2012, 538, 182–189. [Google Scholar] [CrossRef]

- Matsumoto, H.; Naito, D.; Miyoshi, K.; Yamanaka, K.; Chiba, A.; Yamabe-Mitarai, Y. Forging property, processing map, and mesoscale microstructural evolution modeling of a Ti-17 alloy with a lamellar (α+β) starting microstructure. STAM 2017, 18, 893–904. [Google Scholar] [CrossRef] [PubMed]

- Matsumoto, H.; Yamanaka, K.; Chiba, A.; Yamabe-Mitarai, Y.; Itsumi, Y. Macro-mesoscale microstructural evolution modeling under hot forging of a Ti-17 alloy with a lamellar (α+β) starting microstructure. MATEC Web Conf. 2020, 13005. [Google Scholar] [CrossRef]

- Yamanaka, K.; Matsumoto, H.; Chiba, A. A Constitutive model and processing maps describing the high-temperature deformation behavior of Ti-17 alloy in the β -phase field. Adv. Eng. Mater. 2019, 21, 1800775. [Google Scholar] [CrossRef]

- Shi, X.; Zeng, W.; Zhao, Q. The effects of lamellar features on the fracture toughness of Ti-17 titanium alloy. Mater. Sci. Eng. A 2015, 636, 543–550. [Google Scholar] [CrossRef]

- Liang, R.; Ji, Y.; Wang, S.; Liu, S. Effect of microstructure on fracture toughness and fatigue crack growth behavior of Ti17 alloy. Metals 2016, 6, 186. [Google Scholar] [CrossRef]

- Xu, J.; Zeng, W.; Zhao, Y.; Jia, Z.; Sun, X. Effect of globularization behavior of the lamellar alpha on tensile properties of Ti-17 alloy. J. Alloys Compd. 2016, 673, 86–92. [Google Scholar] [CrossRef]

- Niinomi, M.; Akahori, T.; Nakai, M.; Koizumi, Y.; Chiba, A.; Nakano, T.; Kakeshita, T.; Yamabe-Mitarai, Y.; Kuroda, S.; Motohashi, N.; et al. Quantitative and qualitative relationship between microstructural factors and fatigue lives under load- and strain-controlled conditions of Ti-5Al-2Sn-2Zr-4Cr-4Mo (Ti-17) fabricated using a 1500-ton forging simulator. Mater. Trans. 2019, 60, 1740–1748. [Google Scholar] [CrossRef]

- Niinomi, M.; Akahori, T.; Nakai, M.; Koizumi, Y.; Chiba, A.; Nakano, T.; Kakeshita, T.; Yamabe-Mitarai, Y.; Kuroda, S.; Motohashi, N.; et al. Quantitative relationship between microstructural factors and fatigue life of Ti-5Al-2Sn-2Zr-4Cr-4Mo (Ti-17) fabricated using a 1500-ton forging simulator. MATEC Web Conf. 2020, 321, 11015. [Google Scholar] [CrossRef]

- Yamabe-Mitarai, Y.; Kuroda, S.; Motohashi, N.; Matsumoto, H.; Miyamoto, G.; Chandiran, E.; Yoshida, Y.; Itsumi, Y. Effect of forging temperature on microstructure evolution and tensile properties of Ti-17 alloys. Mater. Trans. 2019, 60, 1733–1739. [Google Scholar] [CrossRef]

- Yamabe-Mitarai, Y.; Kuroda, S.; Motohashi, N.; Matsumoto, H.; Miyamoto, G.; Yoshida, Y.; Yamanaka, K.; Niinomi, M.; Itsumi, Y. Effect of microstructure on tensile properties of Ti-17 alloys forged using a 1500-ton forging simulator. MATEC Web Conf. 2020, 321, 04014. [Google Scholar] [CrossRef]

- Chundiran, E.; Miyamoto, G.; Furuhara, T. Microstructure formation during thermomechanical processing in Ti-17 alloy. MATEC Web Conf. 2020, 321, 12006. [Google Scholar] [CrossRef]

- Shimagami, K.; Matsunaga, S.; Yumoto, A.; Ito, T.; Yamabe-Mitarai, Y. Solid solution hardening and precipitation hardening of α2-Ti3Al in Ti–Al–Nb alloys. Mater. Trans. 2017, 58, 1404–1410. [Google Scholar] [CrossRef]

| Sample | Volume Fraction of Primary α (%) | Volume Fraction of Secondary α (%) | Volume Fraction of GB α (%) | Length of Primary α (μm) | Thickness of Primary α (μm) |

|---|---|---|---|---|---|

| ST at 750 °C | 51 | 0 | 5.5 | 11.9 | 0.5 |

| Aged after 750 °C ST | 60 | 1.5 | 5.5 | 10.8 | 0.5 |

| ST at 800 °C | 29 | 0 | 6.9 | 10.3 | 0.3 |

| Aged after 800 °C ST | 47.6 | 16.5 | 2.9 | 11.6 | 0.7 |

| ST at 850 °C | 13.1 | 0 | 2 | 10.1 | 0.4 |

| Aged after 850 °C ST | 16.6 | 47.2 | 3.2 | 8.5 | 0.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yamabe-Mitarai, Y.; Kuroda, S.; Motohashi, N.; Hiroto, T.; Ishida, A.; Murakami, H.; Itsumi, Y. Correlation between Solution Treatment Temperature, MicroStructure, and Yield Strength of Forged Ti-17 Alloys. Crystals 2021, 11, 625. https://doi.org/10.3390/cryst11060625

Yamabe-Mitarai Y, Kuroda S, Motohashi N, Hiroto T, Ishida A, Murakami H, Itsumi Y. Correlation between Solution Treatment Temperature, MicroStructure, and Yield Strength of Forged Ti-17 Alloys. Crystals. 2021; 11(6):625. https://doi.org/10.3390/cryst11060625

Chicago/Turabian StyleYamabe-Mitarai, Yoko, Syuji Kuroda, Norie Motohashi, Takanobu Hiroto, Akira Ishida, Hideyuki Murakami, and Yoshio Itsumi. 2021. "Correlation between Solution Treatment Temperature, MicroStructure, and Yield Strength of Forged Ti-17 Alloys" Crystals 11, no. 6: 625. https://doi.org/10.3390/cryst11060625

APA StyleYamabe-Mitarai, Y., Kuroda, S., Motohashi, N., Hiroto, T., Ishida, A., Murakami, H., & Itsumi, Y. (2021). Correlation between Solution Treatment Temperature, MicroStructure, and Yield Strength of Forged Ti-17 Alloys. Crystals, 11(6), 625. https://doi.org/10.3390/cryst11060625