Structural Optimization of Steel—Epoxy Asphalt Pavement Based on Orthogonal Design and GA—BP Algorithm

Abstract

1. Introduction

2. GA—BP Optimization Method Based on Orthogonal Design

2.1. Orthogonal Experimental Design Method

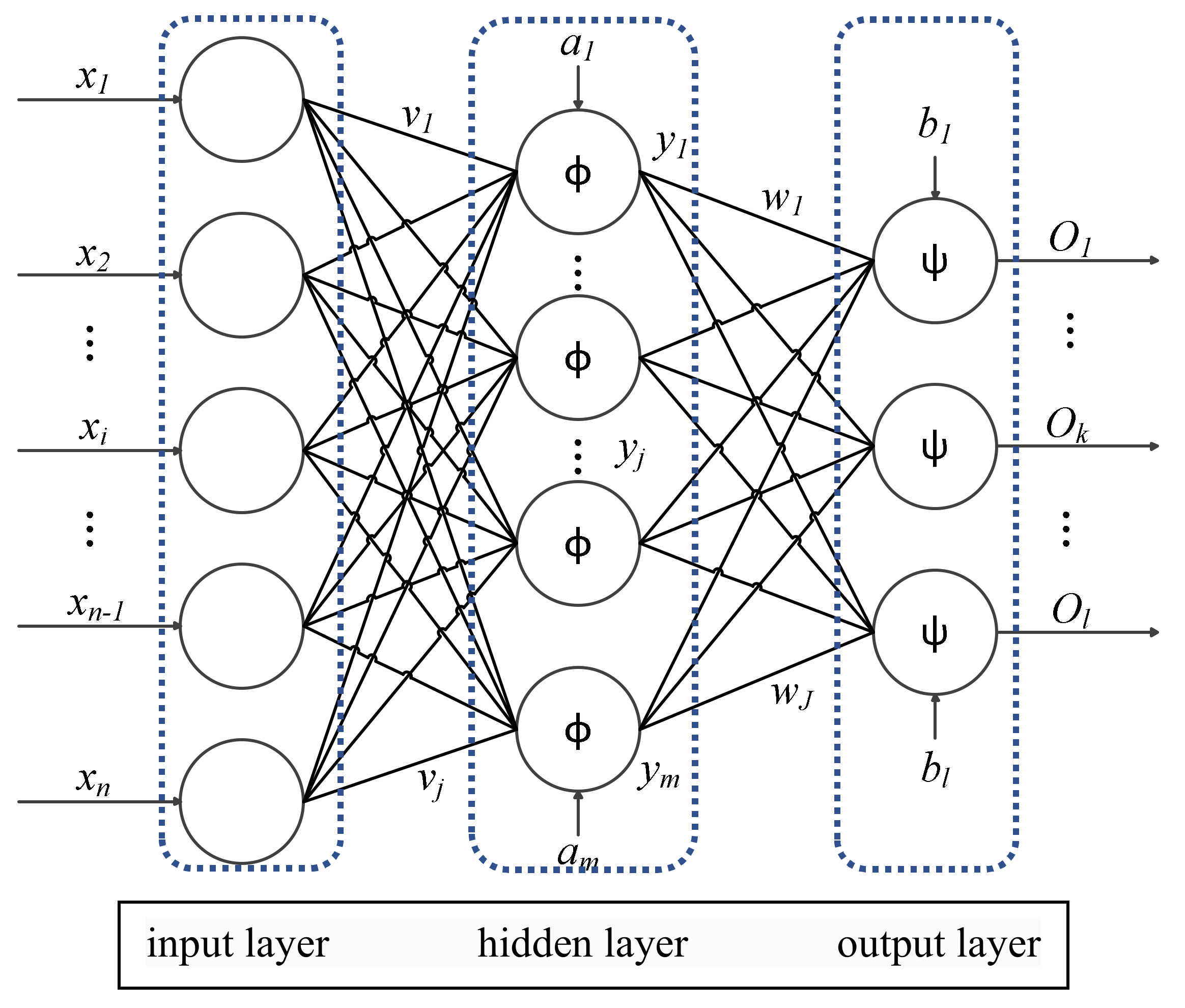

2.2. BP Neural Network

2.3. GA—BP Optimization Method

3. Optimization Design of the Steel Bridge Deck Asphalt Pavement Structure

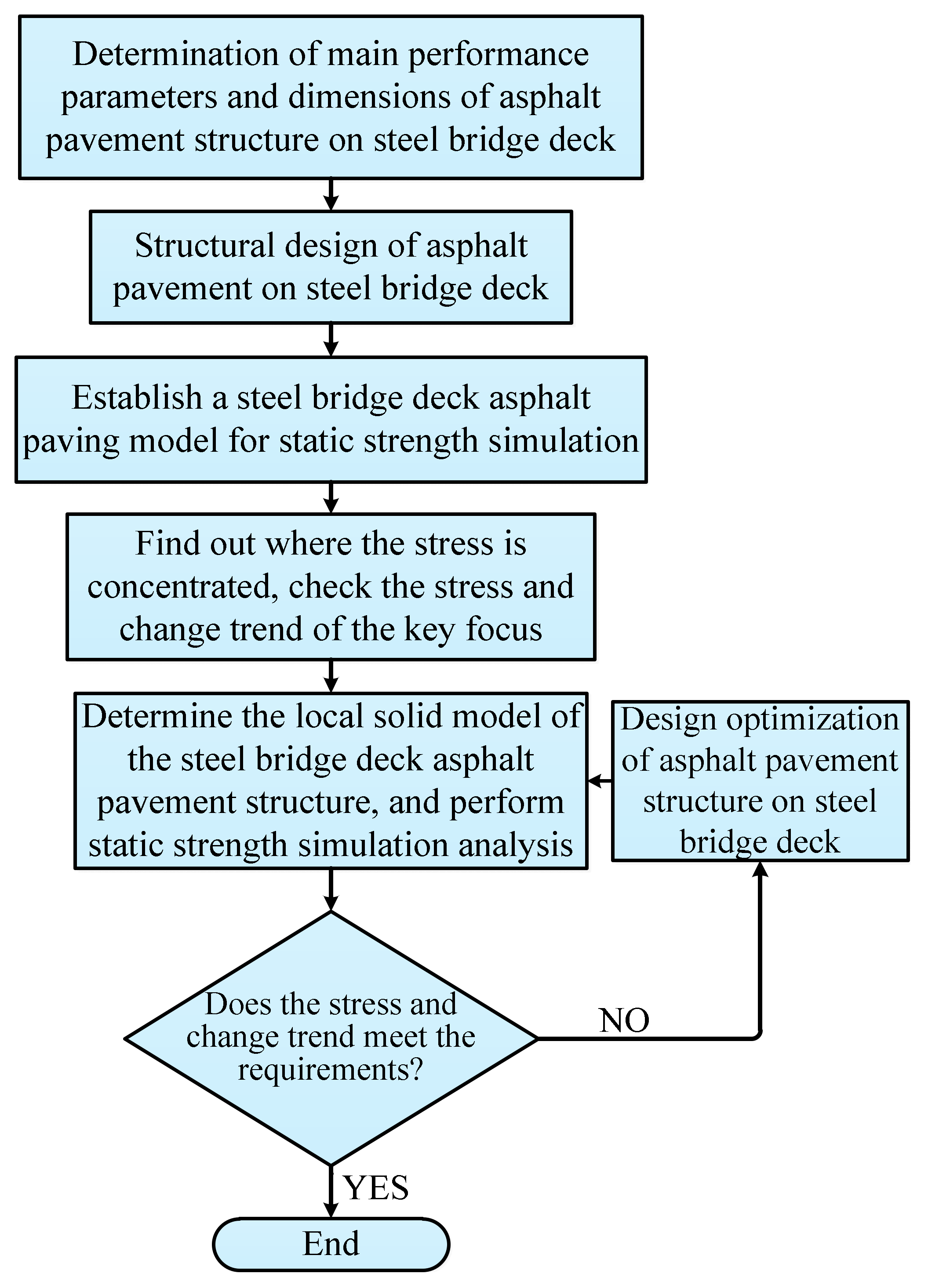

3.1. Optimization of the Design Strategy of the Asphalt Pavement Structure on the Steel Bridge Deck

3.1.1. Traditional Design Strategy of Steel Bridge Deck Asphalt Pavement Structure

3.1.2. Disadvantages of Traditional Design Strategy of Steel Bridge Deck Asphalt Pavement Structure

3.1.3. Design Strategy Optimization

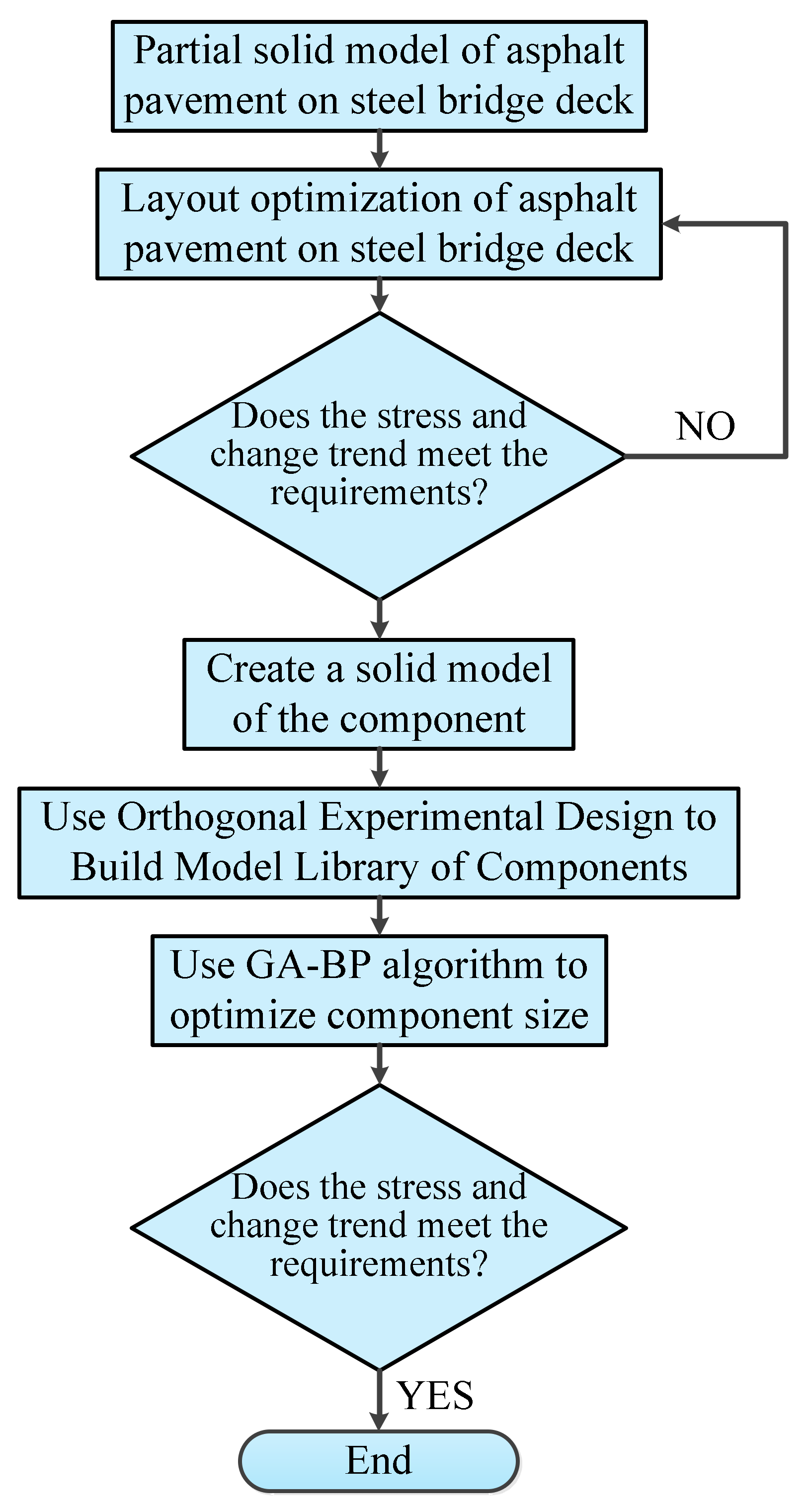

3.2. Mathematical Model for Component Optimization

3.3. Optimization Design of Steel Bridge Deck Asphalt Pavement Structure Based on GA—BP Method

4. Optimization of Epoxy Asphalt Pavement Structure of Steel Bridge Deck

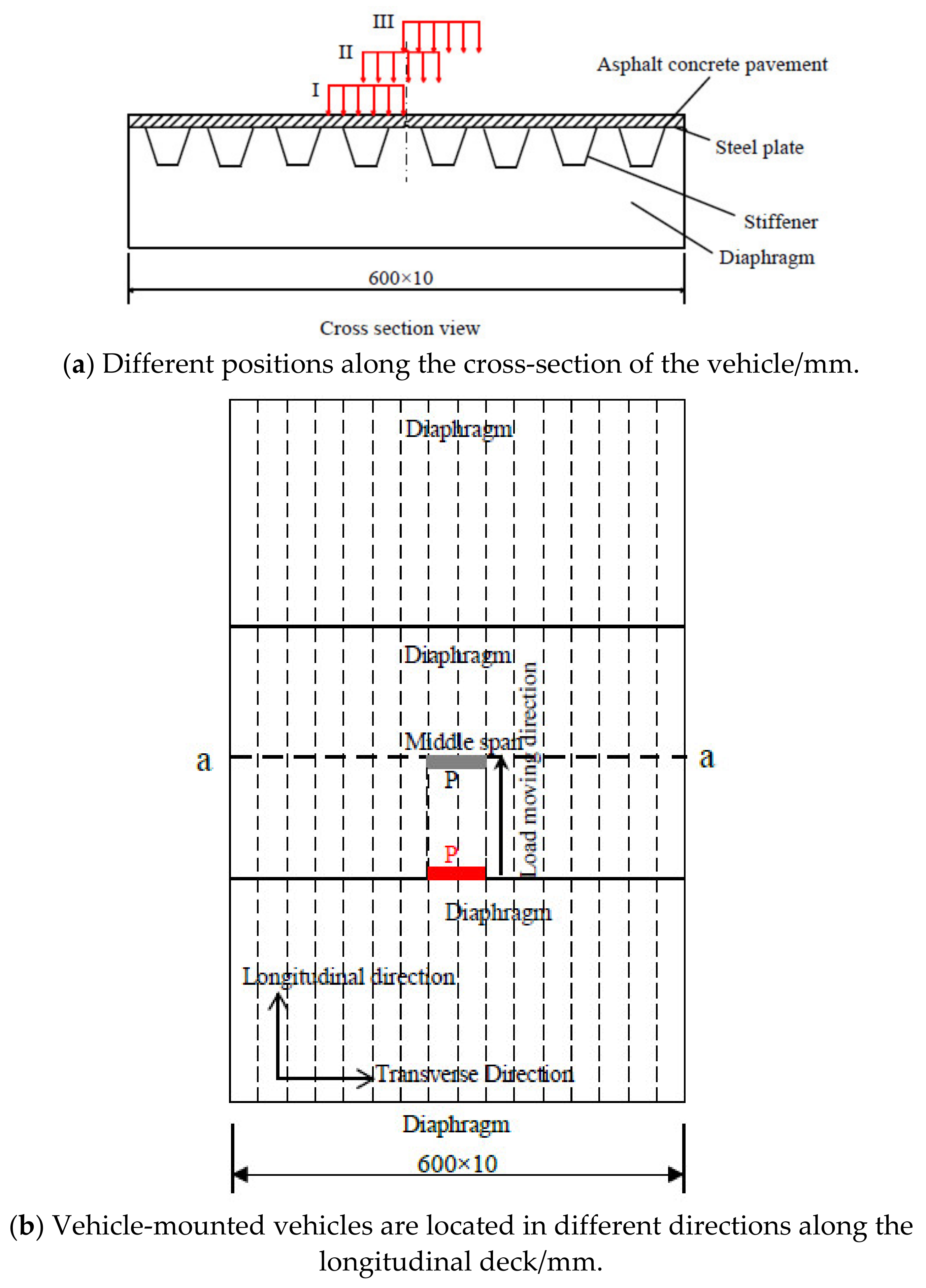

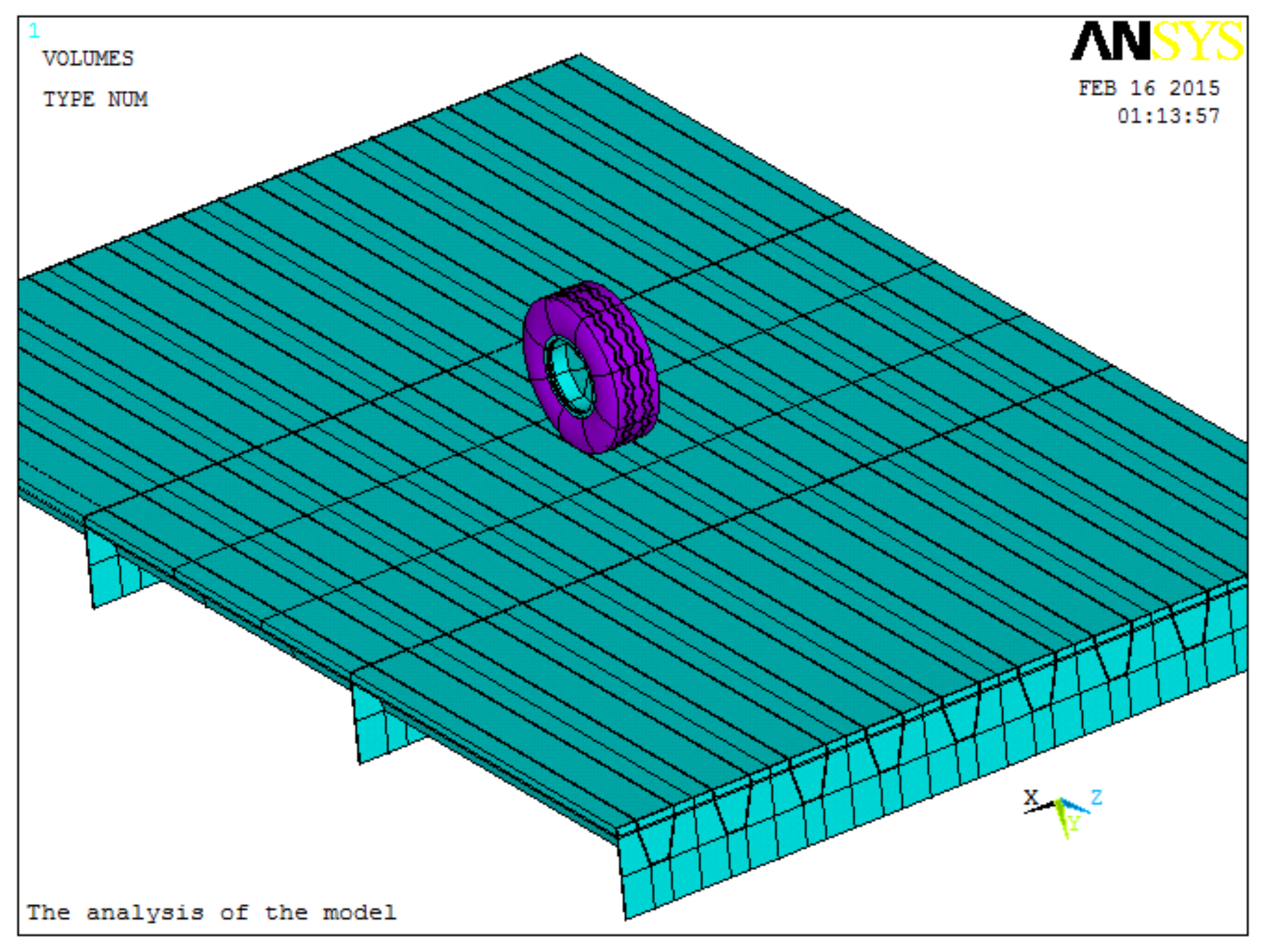

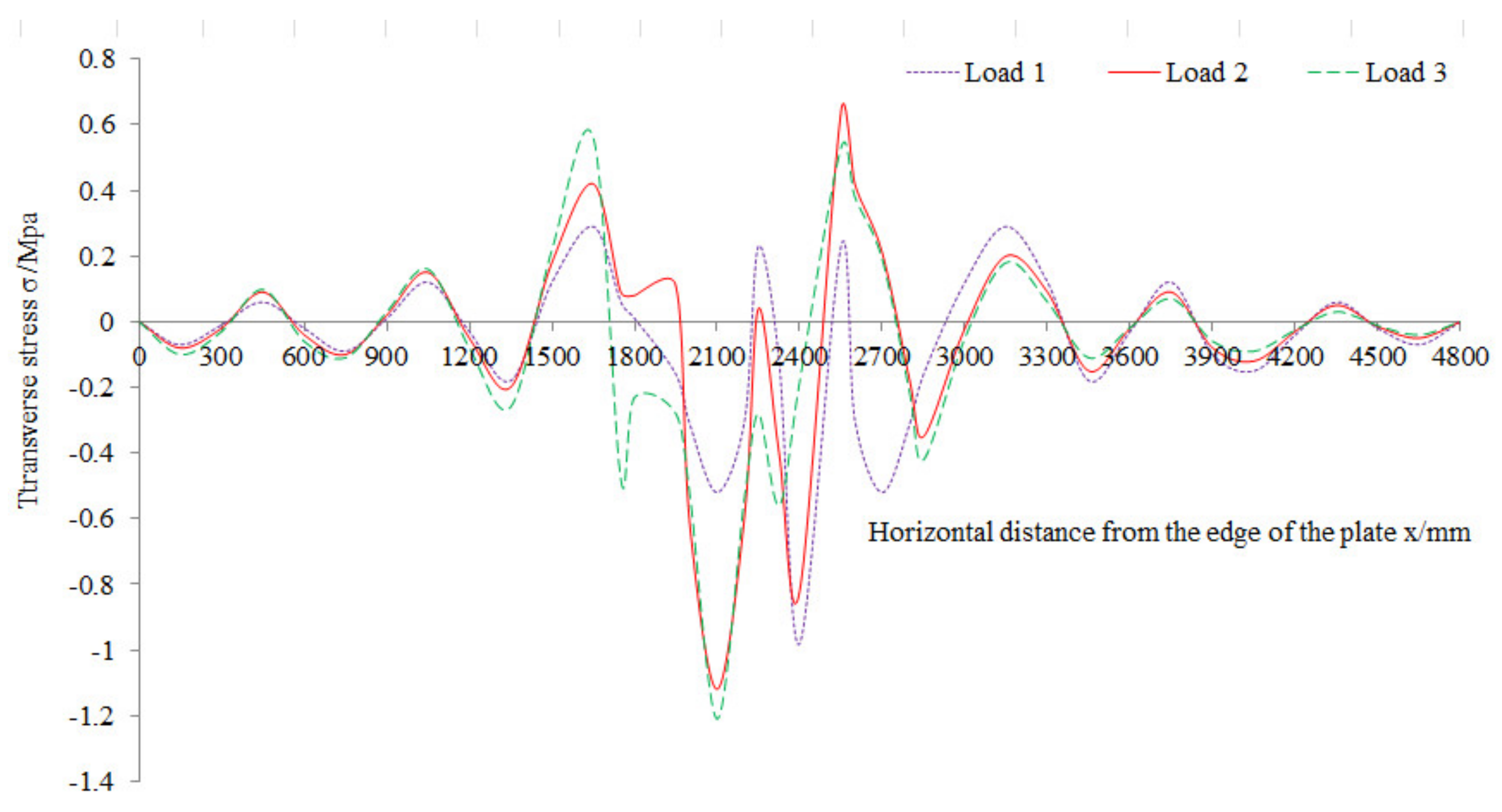

4.1. Finite Element Simulation of Epoxy Asphalt Pavement on the Steel Bridge Deck

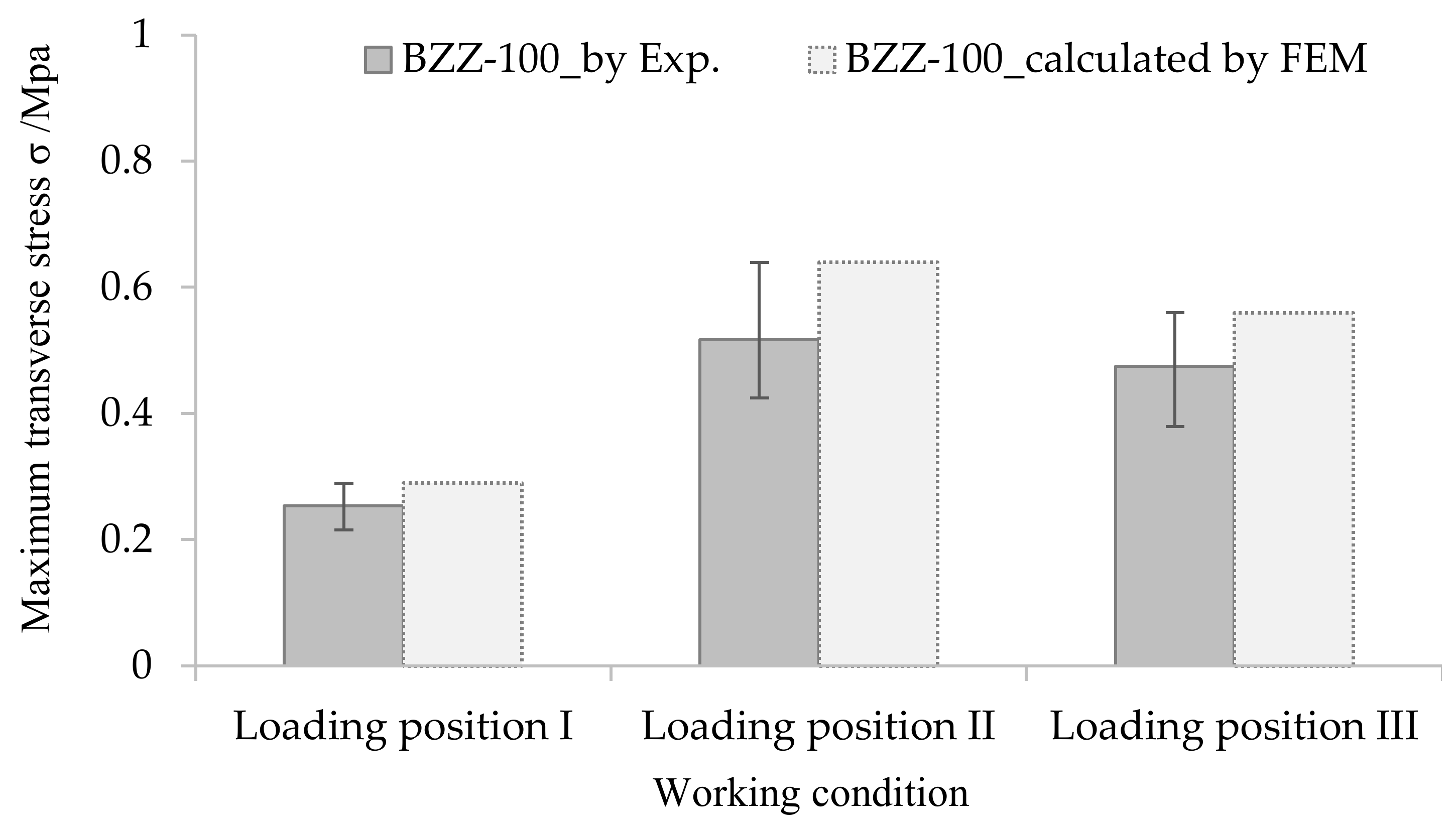

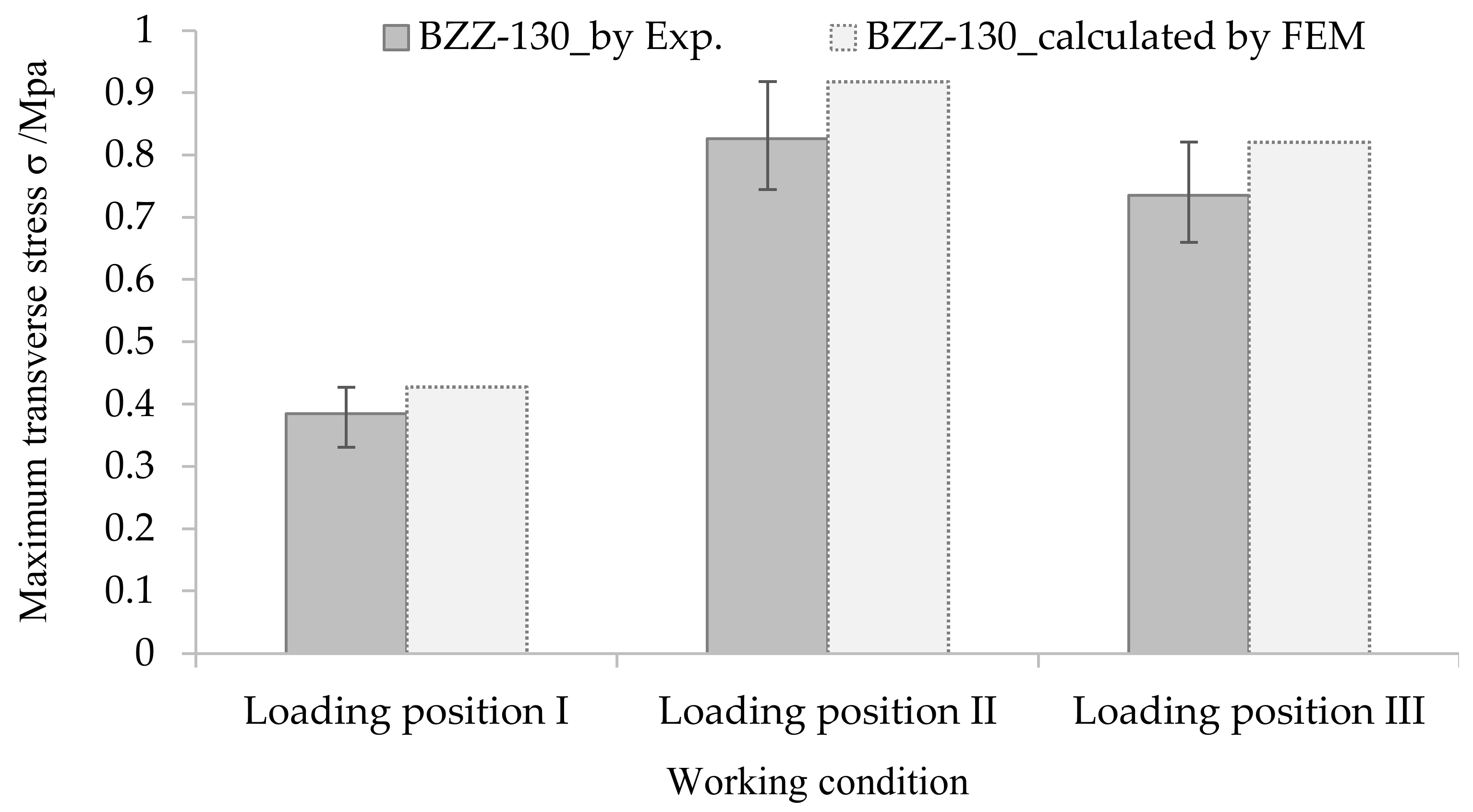

4.2. Verification of Epoxy Asphalt Pavement Testing on the Steel Bridge Deck

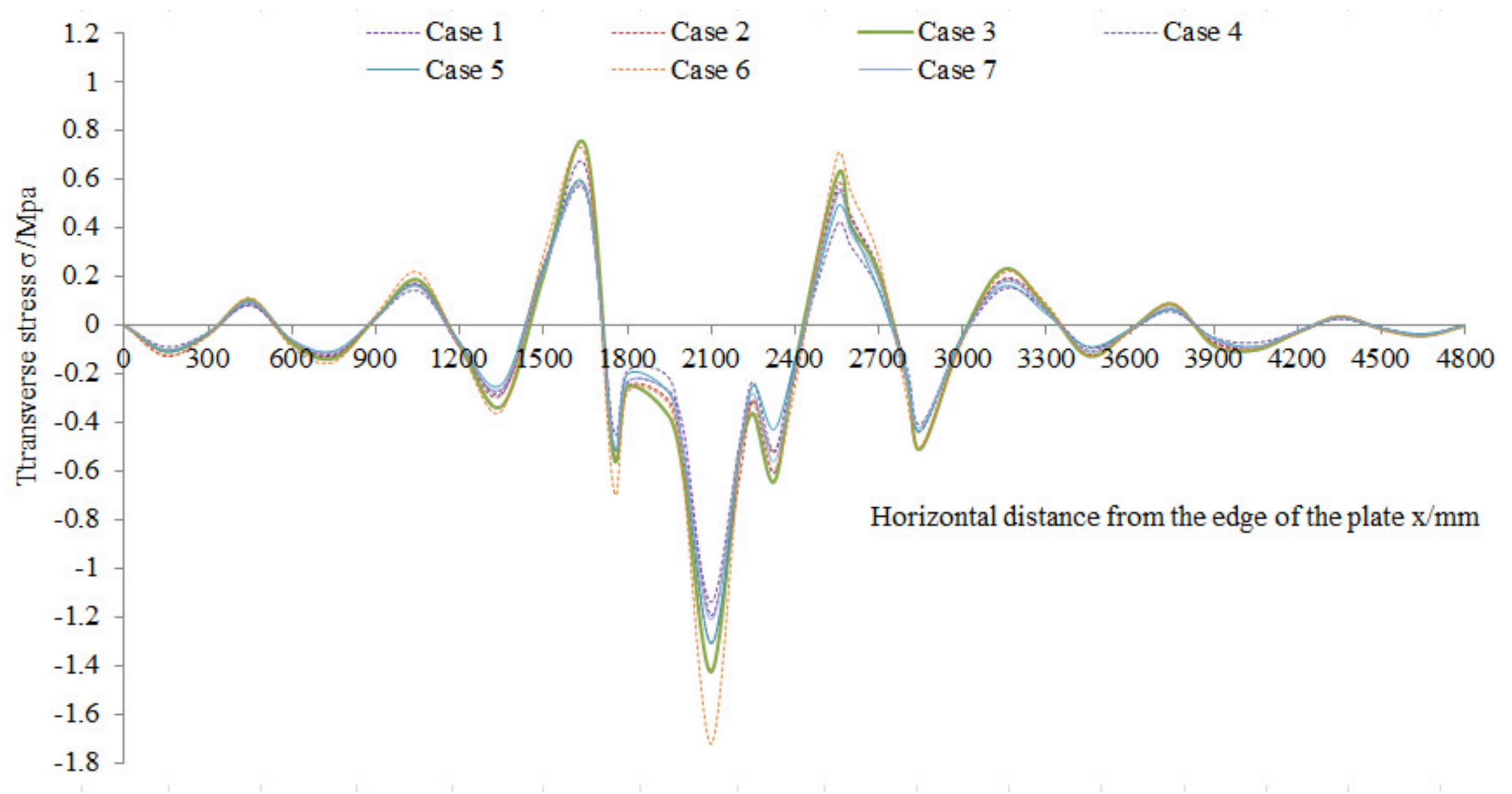

4.3. Epoxy Asphalt Pavement Structure Layout Sensitivity

5. Optimization of the Epoxy Asphalt Pavement Structure of the Steel Bridge Deck

5.1. Optimization Objective and Optimization Parameter Selection

5.2. Orthogonal Experimental Design

5.3. GA—BP Optimized Analysis

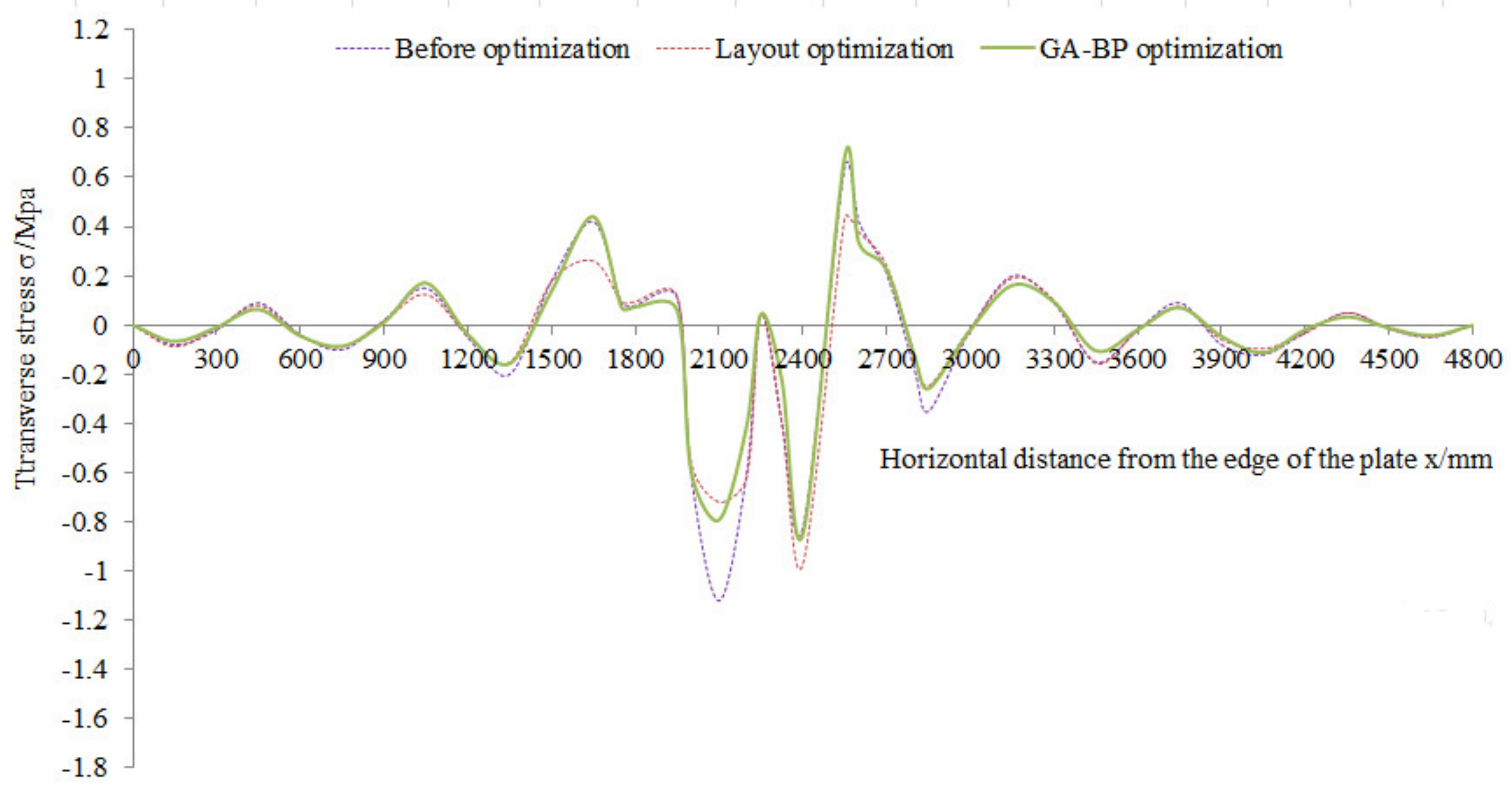

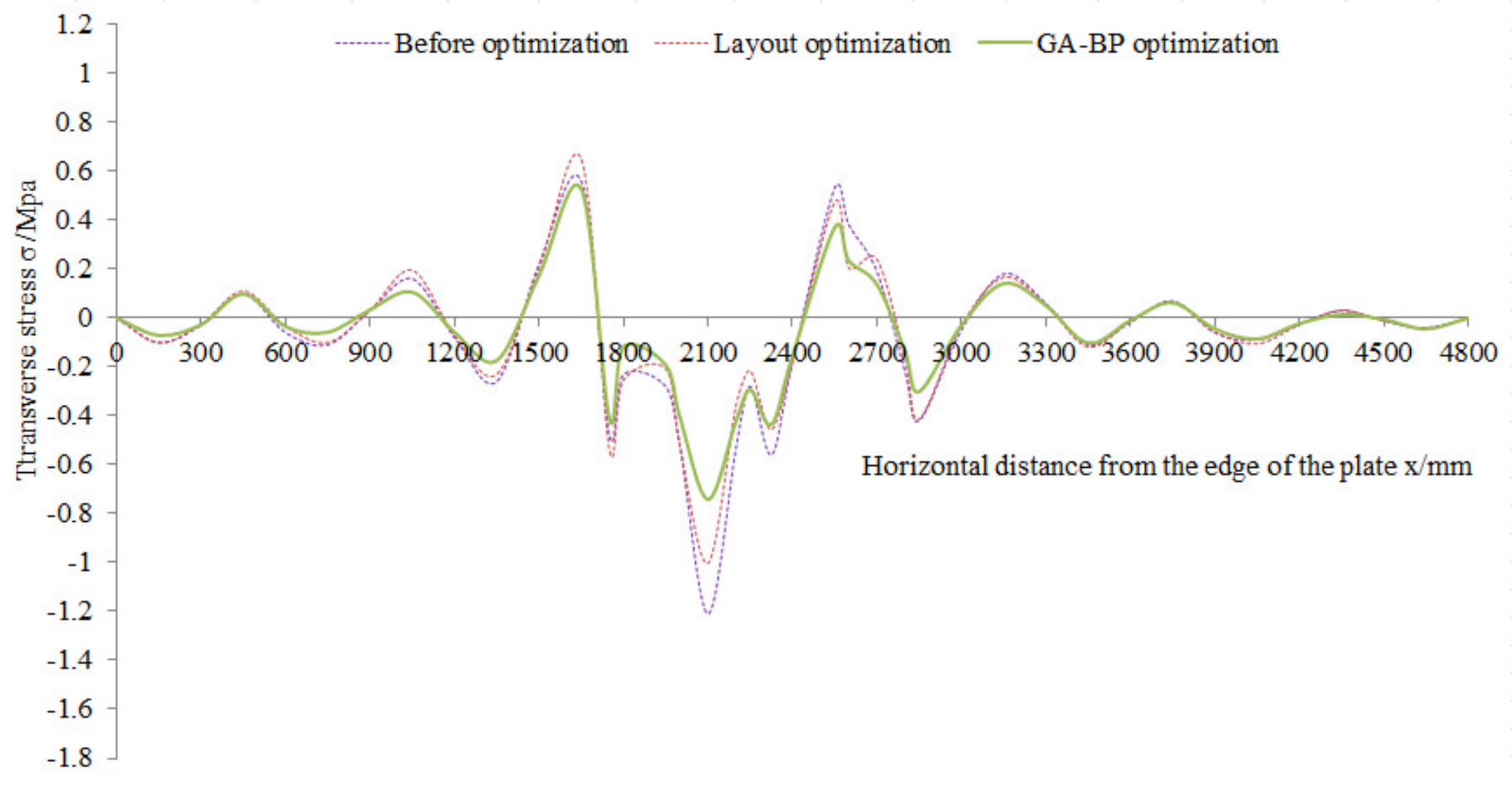

5.4. Verification of GA—BP Optimization Results

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wolchuk, R. Orthotrope Fahrbahnplatte—Entwicklungen und Möglichkeiten für die Zukunft. Stahlbau 2007, 76, 478–494. [Google Scholar] [CrossRef]

- Chavel, B. Steel Bridge Design Handbook: Bridge Deck Design; Rep. No. FHWA-IF-12-052-Vol. 17; Federal Highway Administration: Washington, DC, USA, 2012.

- Huang, W. Integrated design procedure for epoxy asphalt concrete—based wearing surface on long-span orthotropic steel deck bridges. J. Mater. Civ. Eng. 2016, 28, 4015189. [Google Scholar] [CrossRef]

- Xu, X.; Yang, X.; Huang, W.; Xiang, H.; Yang, W. New damage evolution law for steel—asphalt concrete composite pavement considering wheel load and temperature variation. Materials 2019, 12, 3723. [Google Scholar] [CrossRef] [PubMed]

- Hornyak, N.; Crovetti, J.A. Analysis of load pulse durations for marquette interchange instrumentation project. Transp. Res. Rec. 2009, 2094, 53–61. [Google Scholar] [CrossRef]

- Medani, T.; Liu, X.; Huurman, M.; Scarpas, A.; Molenaar, A. Characterisation of surfacing materials for orthotropic steel deck bridges. Part 1: Experimental work. Int. J. Surf. Eng. 2010, 11, 237–253. [Google Scholar] [CrossRef]

- Kozy, B.M.; Connor, R.J.; Paterson, D.; Mertz, D.R. Proposed revisions to AASHTO-LRFD bridge design specifications for orthotropic steel deck bridges. J. Bridge Eng. 2010, 16, 759–767. [Google Scholar] [CrossRef]

- De Freitas, S.T.; Kolstein, H.; Bijlaard, F. Fatigue assessment of full-scale retrofitted orthotropic bridge decks. J. Bridge Eng. 2017, 22, 4017092. [Google Scholar] [CrossRef]

- Liu, W.; Xu, S.; Li, Q. Experimental study on fracture performance of ultra-high toughness cementitious composites with J-integral. Eng. Fract. Mech. 2012, 96, 656–666. [Google Scholar] [CrossRef]

- Campbell, F.C. Fatigue and Fracture: Understanding the Basics; ASM International: Materials Park, OH, USA, 2012. [Google Scholar]

- Saboo, N.; Kumar, P. Optimum blending requirements for EVA modified binder. Int. J. Surf. Res. Technol. 2015, 8, 172–178. [Google Scholar] [CrossRef]

- Delgadillo, R.; Bahia, H.U.; Lakes, R. A nonlinear constitutive relationship for asphalt binders. Mater. Struct. 2012, 45, 457–473. [Google Scholar] [CrossRef]

- Bayat, A.; Knight, M. Field evaluation and analysis of flexible surfacing structural responses under dynamic loads. Road Mater. Surf. Des. 2012, 13, 26–37. [Google Scholar]

- Ameri, M.; Nowbakht, S.; Molayem, M.; Mirabimoghaddam, M.H. A study on fatigue modeling of hot mix asphalt mixtures based on the viscoelastic continuum damage properties of asphalt binder. Constr. Build. Mater. 2016, 106, 243–252. [Google Scholar] [CrossRef]

- Zhou, X.; Zhao, G.; Tighe, S.; Chen, M.; Wu, S.; Adhikari, S.; Gao, Y. Quantitative comparison of surface and interface adhesive properties of fine aggregate asphalt mixtures composed of basalt, steel slag, and andesite. Mater. Struct. 2020, 246, 118507. [Google Scholar] [CrossRef]

- Liu, J.; Yu, B.; Hong, Q. Molecular dynamics simulation of distribution and adhesion of asphalt components on steel slag. Mater. Struct. 2020, 255, 119332. [Google Scholar] [CrossRef]

- Ren, S.; Liu, X.; Zhang, Y.; Chen, X. Multi-scale characterization of lignin modified bitumen using experimental and molecular dynamics simulation methods. Mater. Struct. 2021, 287, 123058. [Google Scholar]

- Talatahari, S. Optimum design of skeletal structures using ant lion optimizer. Int. J. Optim. Civ. Eng. 2016, 6, 13–25. [Google Scholar]

- Cho, J.G.; Koo, J.S.; Jung, H.S. A lightweight design approach for an EMU carbody using a material selection method and size optimization. J. Mech. Sci. Technol. 2016, 30, 673–681. [Google Scholar] [CrossRef]

- Liu, H.; Yang, D. IGS-SIMP method based stress-constrained topology optimization of continuous structures. Chin. J. Comput. Mech. 2018, 35, 144–151. [Google Scholar]

- Su, R.; Wang, X.; Gui, L. Multi-objective topology and sizing optimization of truss structures based on adaptive multi-island search strategy. Struct. Multidiscip. Optim. 2011, 43, 275–286. [Google Scholar] [CrossRef]

- Zhai, Y.F.; Li, H.Y.; Liu, H.B.; Qing, Z.K. Method for optimizing initial weights of ANNs by GAs. J. Jilin Univ. 2003, 33, 45–50. [Google Scholar]

- Yan, C.; Hao, Y.; Liu, K. Fatigue life prediction of materials based on bp neural networks optimized by genetic algorithm. J. Jilin Univ. 2014, 44, 1710–1715. [Google Scholar]

- Cheng, H.; Liu, L.; Sun, L. Field measurements of dynamic strain responses of asphalt surfacing on steel deck bridge. China Civ. Eng. J. 2019, 52, 100–108. [Google Scholar]

- Kainuma, S.; Jeong, Y.-S.; Ahn, J.-H.; Yamagami, T.; Tsukamoto, S. Behavior and stress of orthotropic deck with bulb rib by surface corrosion. J. Constr. Steel Res. 2015, 113, 135–145. [Google Scholar] [CrossRef]

- Chenjs, L.K.Y. Mechanism and behavior of bitumen strength reinforcement using fibers. J. Mater. Sci. 2005, 40, 87–95. [Google Scholar]

- Zhang, X.C.; Huang, W.; Wei, Q.; Zhang, J.; Tong, X.D. A fatigue damage analysis of composite construction composed asphalt concrete surfacing and steel-box beam deck of steel bridge. Key Eng. Trans. Tech. Pub. 2004, 274, 223–228. [Google Scholar]

- Losa, M.; Di Natale, A. Evaluation of representative loading frequency for linear elastic analysis of asphalt surfacing. Transp. Res. Rec. 2012, 2305, 150–161. [Google Scholar] [CrossRef]

- Yin, C.; Zhang, H.; Pan, Y. Cracking mechanism and repair techniques of epoxy asphalt on steel bridge deck surfacing. Transp. Res. Rec. 2016, 2550, 123–130. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, W.; Lu, Q.; Chen, X. An innovative approach to determine deck surfacing modulus and interfacial slip stiffness based on a composite beam model. Constr. Build. Mater. 2013, 40, 411–418. [Google Scholar] [CrossRef]

- Kim, T.W.; Baek, J.; Lee, H.J.; Lee, S.Y. Effect of surfacing design parameters on the behavior of orthotropic steel bridge deck surfacings under traffic loading. Int. J. Surf. Eng. 2014, 15, 471–482. [Google Scholar]

- Barra, B.S.; Momm, L.; Guerrero, Y.; Bernucci, L. Fatigue behavior of dense asphalt mixes in dry and environmental-conditioning states. Constr. Build. Mater. 2012, 29, 128–134. [Google Scholar] [CrossRef]

- Bocci, E.; Graziani, A.; Canestrari, F. Mechanical 3D characterization of epoxy asphalt concrete for surfacing layers of orthotropic steel decks. Constr. Build. Mater. 2015, 79, 145–152. [Google Scholar] [CrossRef]

- Yoo, P.J.; Al-Qadi, I.L. A strain-controlled hot-mix asphalt fatigue model considering low and high cycles. Int. J. Surf. Eng. 2010, 11, 565–574. [Google Scholar] [CrossRef]

- Pokorski, P.; Radziszewski, P.; Sarnowski, M. Fatigue life of asphalt surfacings on bridge decks. Procedia Eng. 2016, 153, 556–562. [Google Scholar] [CrossRef][Green Version]

- Alencar, G.; de Jesus, A.M.P.; Alencar, G.; de Jesus, A.M.P.; Calçada, R.A.B.; da Silva, J.G.S. Fatigue life evaluation of a composite steel-concrete roadway bridge through the hot-spot stress method considering progressive surfacing deterioration. Eng. Struct. 2018, 166, 46–61. [Google Scholar] [CrossRef]

- Qian, Z.; Wang, J.-Y.; Chen, L.-L.; Wang, L.-B. Three-dimensional discrete element modeling of crack development in epoxy asphalt concrete. J. Test. Eval. 2014, 43, 20140086. [Google Scholar] [CrossRef]

- China Communications Press. Standard Test Material of Bitumen and Bituminous Mixtures for Highway Engineering, CN-JT; JTG E20-2011; China Communications Press: Beijing, China, 2011. [Google Scholar]

- China Communications Press. Specifications for Design of Highway Asphalt Surfacing, CN-JT; JTG D50-2017; China Communications Press: Beijing, China, 2017. [Google Scholar]

| Scheme | Height h/mm | Upper Width u/mm | |

|---|---|---|---|

| 1 | 250 | 10 | 300 |

| 2 | 350 | 10 | 280 |

| 3 | 250 | 8 | 280 |

| 4 | 280 | 8 | 300 |

| 5 | 300 | 6 | 320 |

| 6 | 320 | 6 | 320 |

| 7 | 300 | 8 | 300 |

| Level | d/mm | ||

|---|---|---|---|

| 1 | 12 | 30 | 320 |

| 2 | 14 | 50 | 280 |

| 3 | 16 | 70 | 240 |

| Number | d/mm | σ/Mpa | |||

|---|---|---|---|---|---|

| II | III | ||||

| 1 | 12 | 30 | 320 | 2.4135 | 2.3108 |

| 2 | 12 | 50 | 280 | 2.0493 | 2.1237 |

| 3 | 12 | 70 | 240 | 1.4006 | 1.5631 |

| 4 | 14 | 30 | 280 | 1.7905 | 1.6981 |

| 5 | 14 | 50 | 240 | 1.2615 | 1.3542 |

| 6 | 14 | 70 | 320 | 0.7106 | 0.7914 |

| 7 | 16 | 30 | 240 | 1.3430 | 1.4256 |

| 8 | 16 | 50 | 320 | 0.5786 | 0.6245 |

| 9 | 16 | 70 | 280 | 0.3939 | 0.3786 |

| Method | d/mm | σ/Mpa | |||

|---|---|---|---|---|---|

| II | III | ||||

| Initial design | 14 | 60 | 300 | 0.78139 | 0.7639 |

| - | - | - | - | - | - |

| GA—BP optimized | 16 | 55 | 280 | 0.6201 | 0.5724 |

| Simulation | 16 | 50 | 280 | 0.5986 | 0.5602 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, X.; Gu, Y.; Huang, W.; Chen, D.; Zhang, C.; Yang, X. Structural Optimization of Steel—Epoxy Asphalt Pavement Based on Orthogonal Design and GA—BP Algorithm. Crystals 2021, 11, 417. https://doi.org/10.3390/cryst11040417

Xu X, Gu Y, Huang W, Chen D, Zhang C, Yang X. Structural Optimization of Steel—Epoxy Asphalt Pavement Based on Orthogonal Design and GA—BP Algorithm. Crystals. 2021; 11(4):417. https://doi.org/10.3390/cryst11040417

Chicago/Turabian StyleXu, Xunqian, Yuwen Gu, Wei Huang, Dakai Chen, Chen Zhang, and Xiao Yang. 2021. "Structural Optimization of Steel—Epoxy Asphalt Pavement Based on Orthogonal Design and GA—BP Algorithm" Crystals 11, no. 4: 417. https://doi.org/10.3390/cryst11040417

APA StyleXu, X., Gu, Y., Huang, W., Chen, D., Zhang, C., & Yang, X. (2021). Structural Optimization of Steel—Epoxy Asphalt Pavement Based on Orthogonal Design and GA—BP Algorithm. Crystals, 11(4), 417. https://doi.org/10.3390/cryst11040417