Ga-Doped ZnO Coating—A Suitable Tool for Tuning the Electrode Properties in the Solar Cells with CdS/ZnS Core-Shell Quantum Dots

Abstract

1. Introduction

2. Materials and Methods

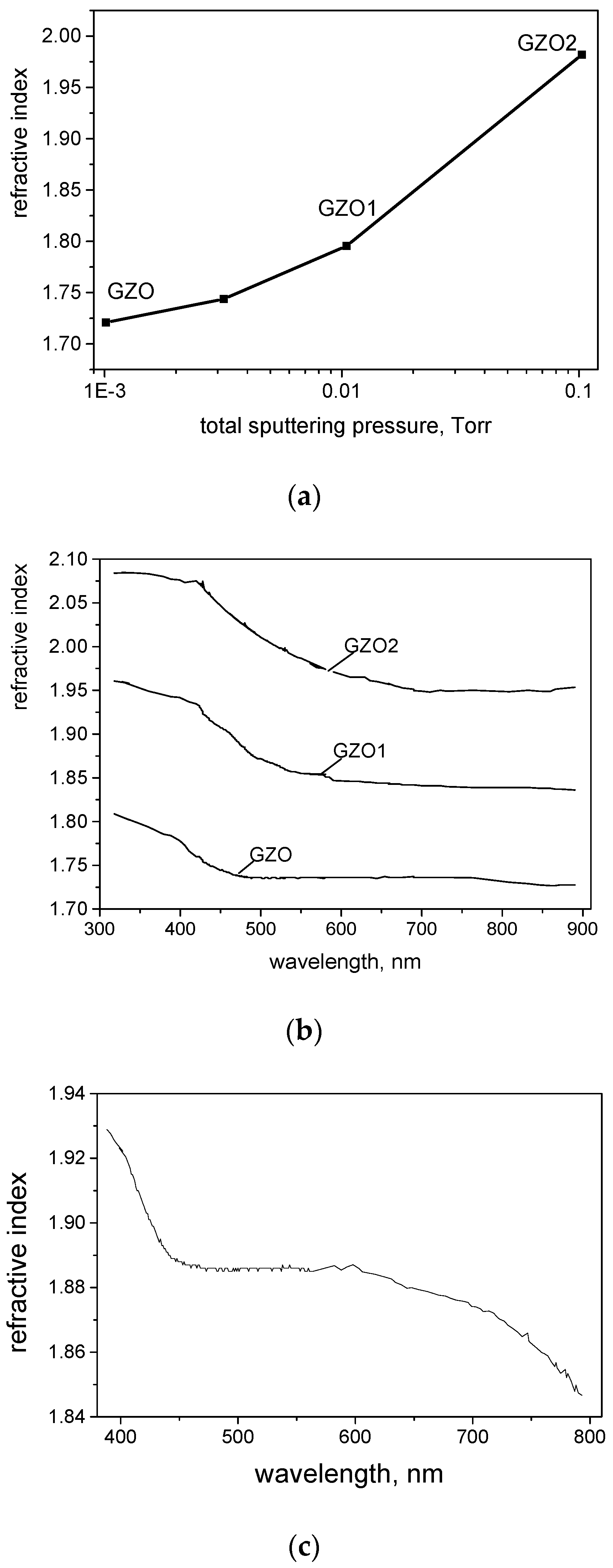

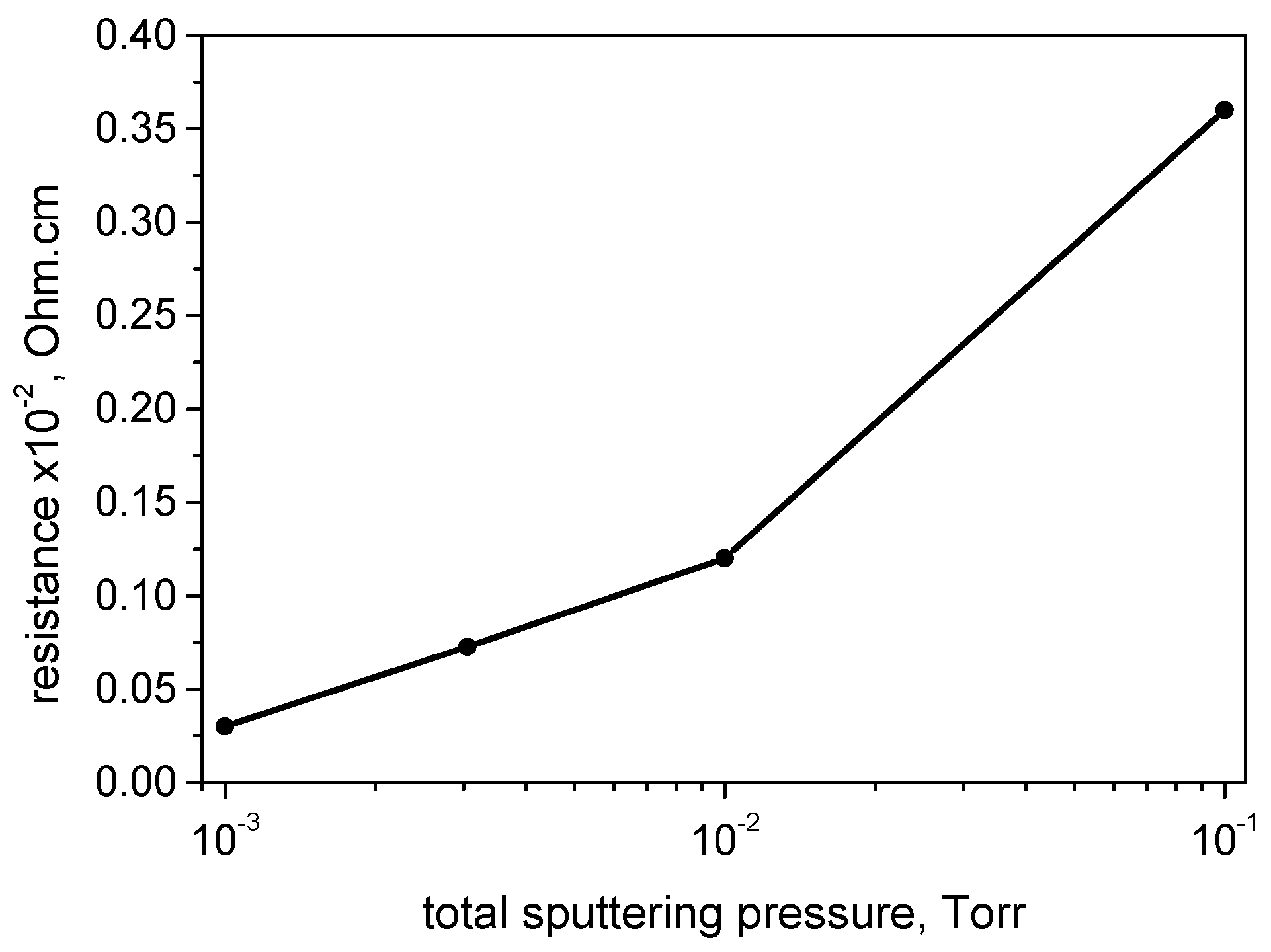

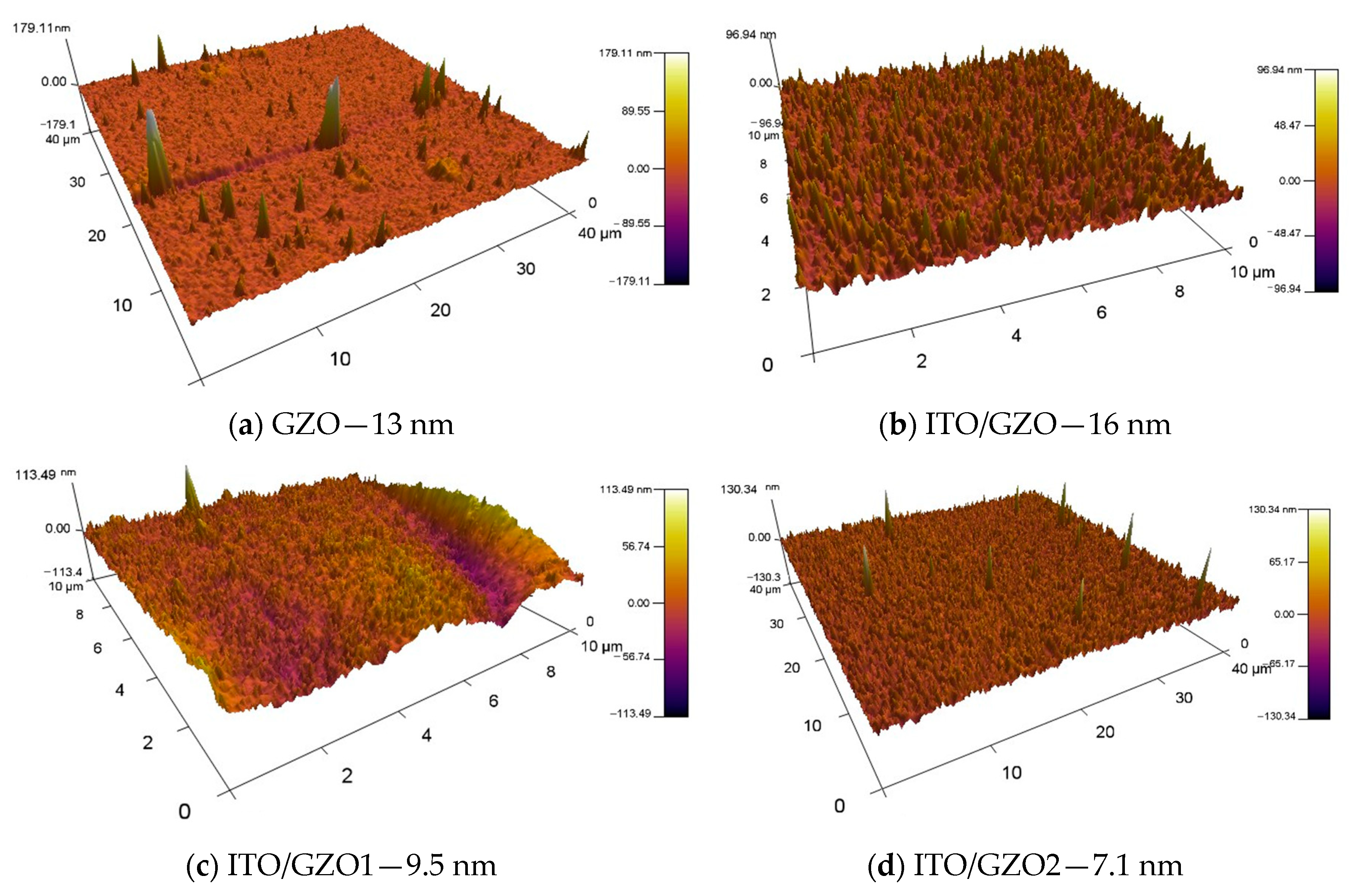

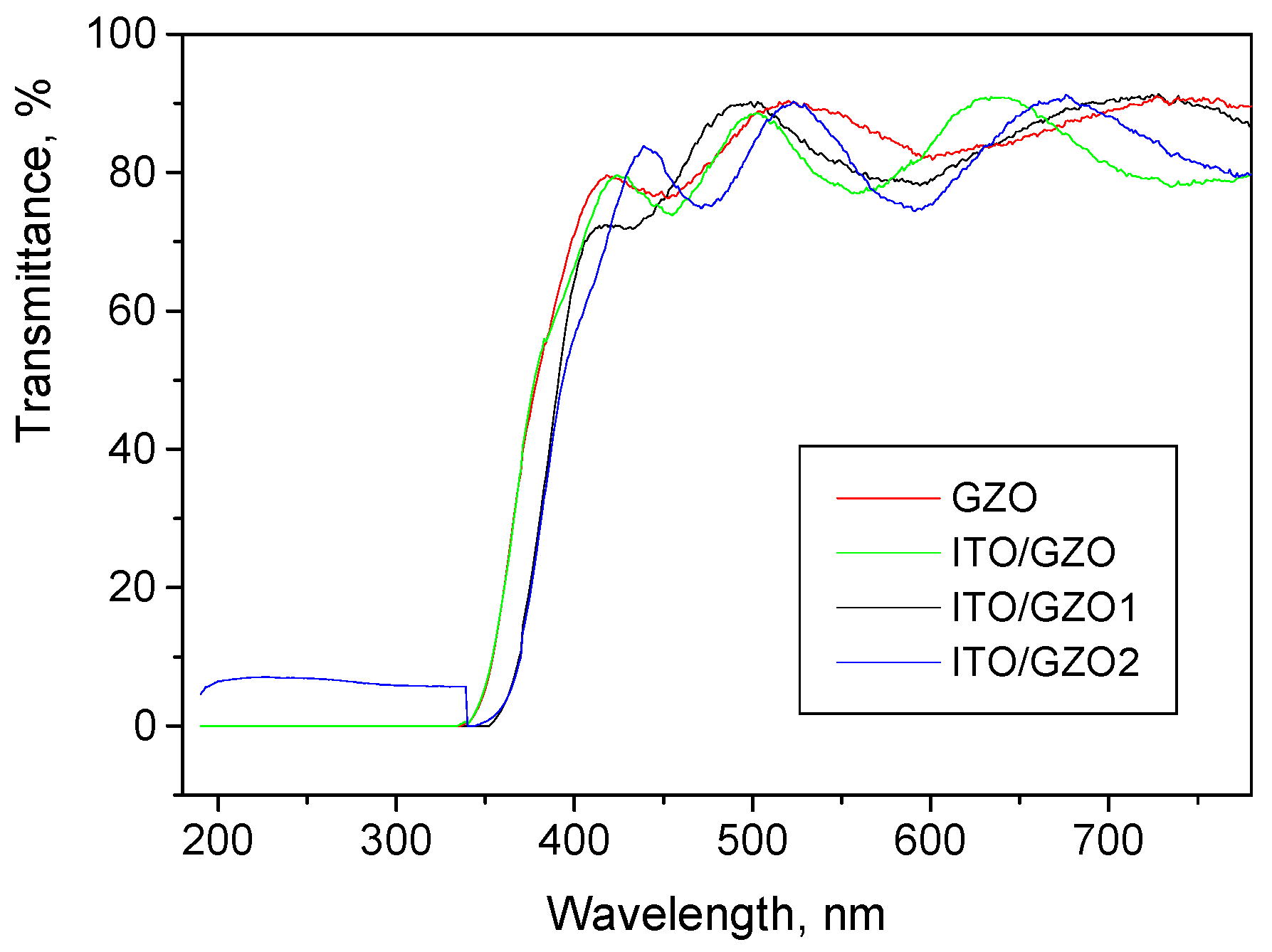

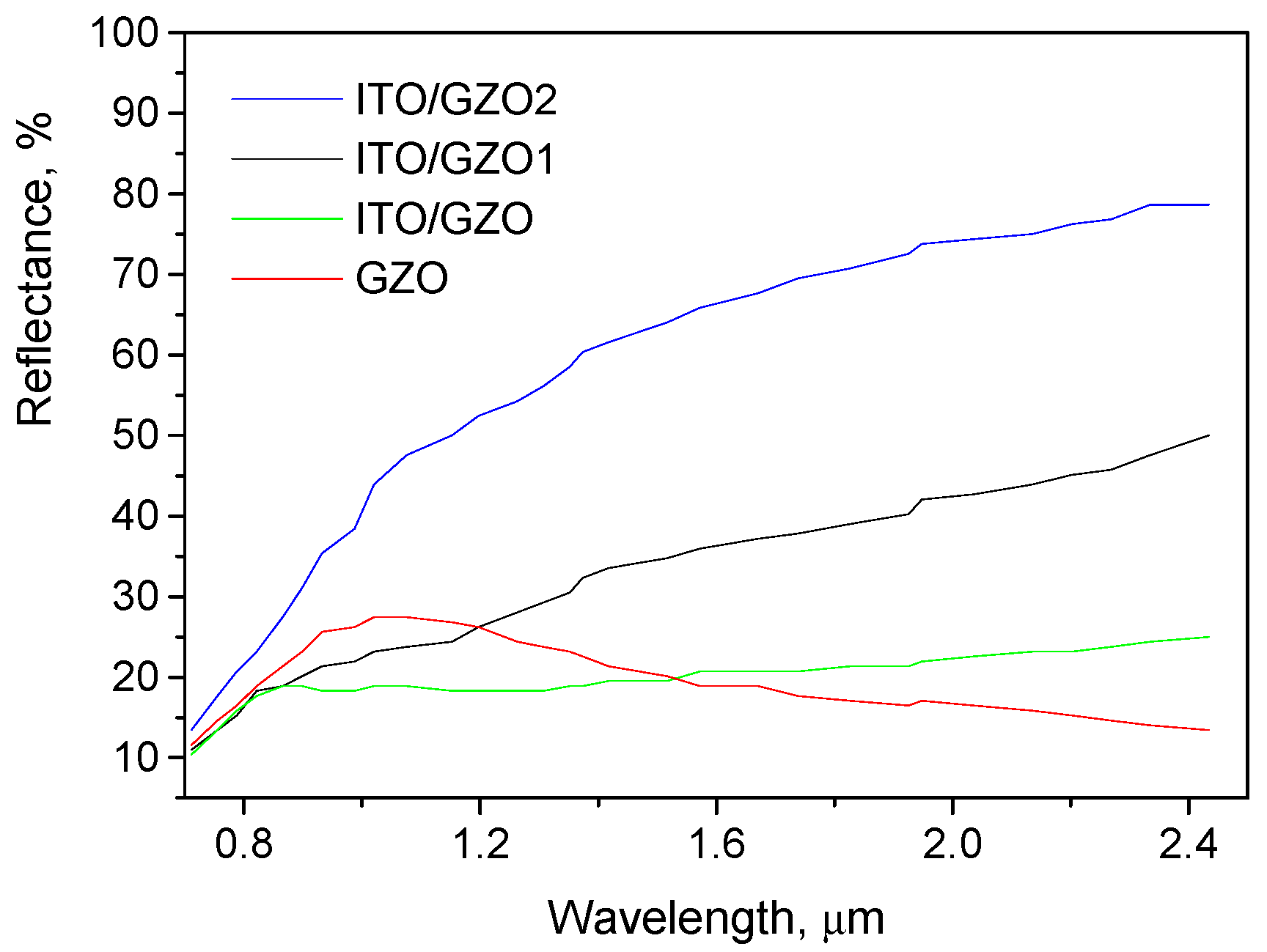

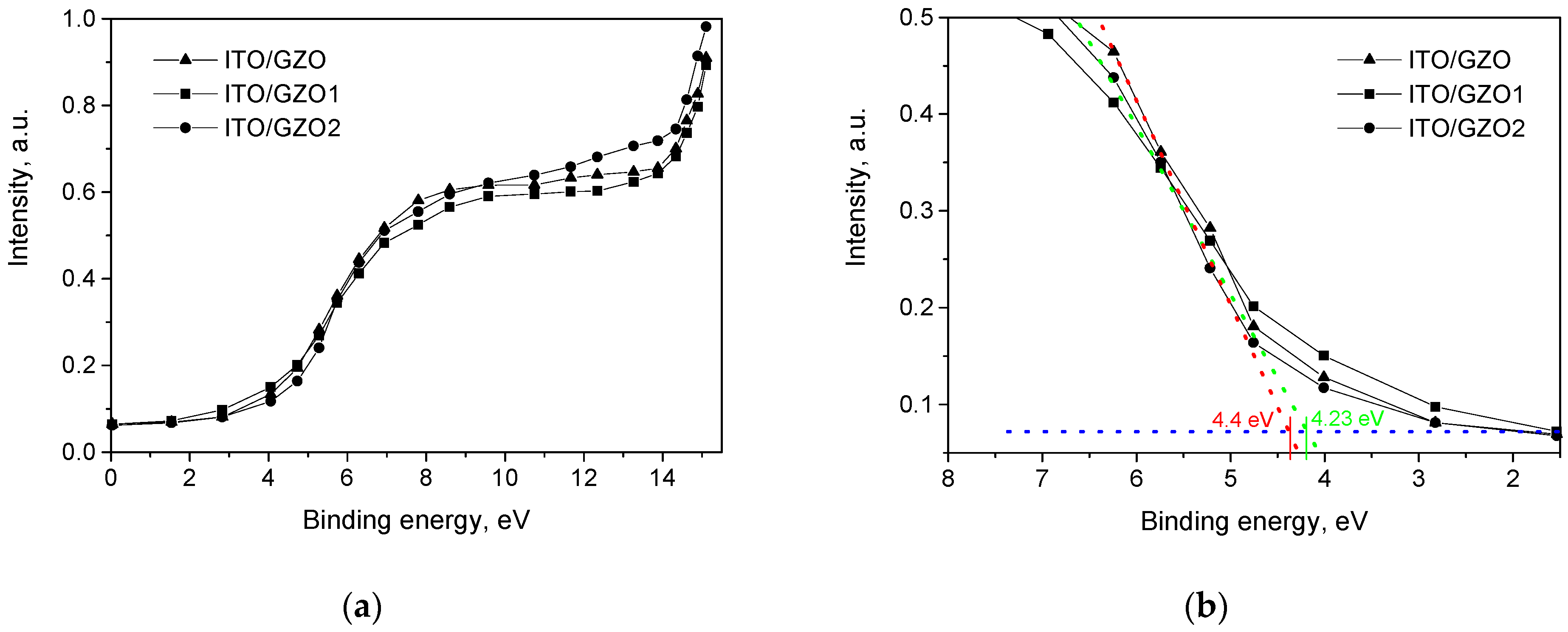

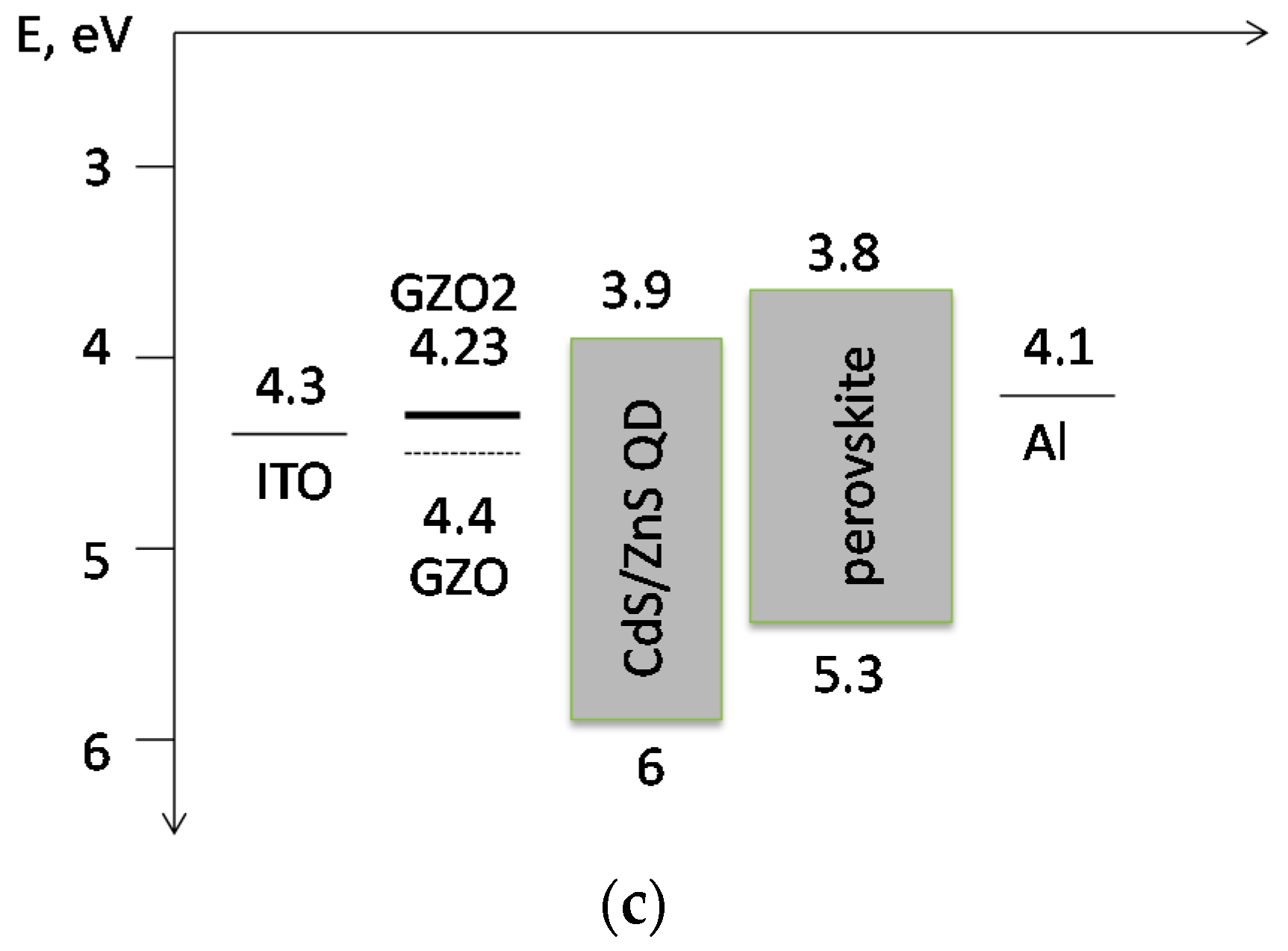

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kumar, A. Predicting efficiency of solar cells based on transparent conducting electrodes. J. Appl. Phys. 2017, 121, 014502. [Google Scholar] [CrossRef]

- Lee, H.B.; Jin, W.-Y.; Ovhal, M.M.; Kumar, N.; Kang, J.-W. Flexible transparent conducting electrodes based on metal meshes for organic optoelectronic device applications: A review. J. Mater. Chem. C 2019, 7, 1087–1110. [Google Scholar] [CrossRef]

- Holman, Z.C.; Filipic, M.; Descoeudres, A.; Wolf, S.D.; Smole, F.; Topic, M.; Ballif, C. Infrared light management in high-efficiency silicon heterojunction and rear-passivated solar cells. J. Appl. Phys. 2013, 113, 013107. [Google Scholar] [CrossRef]

- Abdullah, M.F.; Alghoul, M.A.; Naser, H.; Asim, N.; Ahmadi, S.; Yatim, B.; Sopian, K. Research and development efforts on texturization to reduce the optical losses at front surface of silicon solar cell. Renew. Sustain. Energy Rev. 2016, 66, 380–398. [Google Scholar] [CrossRef]

- Fazal, E.; Khan, S.A.D.; Khan, A.D.; Ullah, N.; Imran, M.; Noman, M. Optical optimization of double-side-textured monolithic perovskite–silicon tandem solar cells for improved light management. RSC Adv. 2020, 10, 26631–26638. [Google Scholar]

- Navid, M.S.J.; Mahmoudysepehr, M.; Sivoththaman, S. Highly conductive TCO by RF sputtering of Al:ZnO for thin film photovoltaics. In Proceedings of the 42nd Photovoltaic Specialist Conference (PVSC), New Orleans, LA, USA, 14–19 June 2015. NSPEC Accession Number: 15664590. [Google Scholar]

- Misra, P.; Ganeshan, V.; Agrawal, N. Low temperature deposition of highly transparent and conducting Al-doped ZnO films by RF magnetron sputtering. J. Alloys Compd. 2017, 725, 60–68. [Google Scholar] [CrossRef]

- Das, R.; Das, H.S.; Nandi, P.K.; Biring, S. Comparative studies on the properties of magnetron sputtered transparent conductive oxide thin films for the application in solar cell. Appl. Phys. A 2018, 124, 631. [Google Scholar] [CrossRef]

- Ali, K.; Khan, S.A.; Jafri, M.Z.M. Structural and optical properties of ITO/TiO2 anti-reflective films for solar cell applications. Nanoscale Res. Lett. 2014, 9, 175. [Google Scholar] [CrossRef]

- Isiyaku, A.K.; Ali, A.H.; Nayan, N. Structural optical and electrical properties of a transparent conductive ITO/Al–Ag/ITO multilayer contact. Beilstein J. Nanotechnol. 2020, 11, 695–702. [Google Scholar] [CrossRef]

- Raoufi, D.; Hosseinpanahi, F. The effect of film thickness on surface morphology of ITO thin films. J. Theor. Appl. Phys. 2013, 7, 21. [Google Scholar]

- Ziemińska-Stolarska, A.; BareckaIreneusz, M.; Zbicinski, Z. Effect of replacement of tin doped indium oxide (ITO) by ZnO: Analysis of environmental impact categories. In Proceedings of the International Conference Energy, Environment and Material Systems (EEMS 2017), Polanica-Zdroj, Poland, 13–15 September 2017; Volume 19, p. 02026. [Google Scholar]

- Ponja, S.D.; Sathasivam, S.; Parkin, I.P.; Carmalt, C.J. Highly conductive and transparent gallium doped zinc oxide thin films via chemical vapor deposition. Sci. Rep. 2020, 10, 638. [Google Scholar] [CrossRef] [PubMed]

- Belkhaoui, C.; Mzabi, N.; Smaoui, H.; Daniel, P. Enhancing the structural, optical and electrical properties of ZnO nanopowders through (Al + Mn) doping. Res. Phys. 2019, 12, 1686–1696. [Google Scholar] [CrossRef]

- Ivanova, T.; Harizanova, A.; Koutzarova, T.; Vertruyen, B.; Closset, R. Structural and optical characterization of nitrogen and gallium co-doped ZnO thin films, deposited by sol-gel method. J. Mol. Struct. 2020, 1206, 127773. [Google Scholar] [CrossRef]

- Chung, A.; Cho, S.; Cheong, W.; Lee, G.H.; Kang, B.S.; Song, P. Investigation on the interface of GZO/ITO double-layered transparent conducting oxide films for solar cells. J. Ceram. Proc. Res. 2012, 13, s10–s15. [Google Scholar]

- Sasabayashi, T.; Song, P.K.; Shigesato, Y.; Utsumi, K.; Kaijo, A.; Mitsui, A. Internal Stress of ITO, IZO and GZO Films Deposited by RF and DC Magnetron Sputtering. MRS Online Proc. Libr. 2000, 666, 241–246. [Google Scholar] [CrossRef]

- Seok, H.-J.; Ali, A.; Seo, J.H.; Lee, H.H.; Jung, N.-E.; Yi, Y.; Kim, H.-K. ZnO: Ga-graded ITO electrodes to control interface between PCBM and ITO in planar perovskite solar cells. Sci. Technol. Adv. Mater. 2019, 20, 389–400. [Google Scholar] [CrossRef]

- Zavaraki, A.J.; Liu, Q.; Ågren, H. Solar cell sensitized with “green” InP-ZnS quantum dots: Effect of ZnS shell deposition. Nano-Struct. Nano-Objects 2020, 22, 100461. [Google Scholar] [CrossRef]

- Liu, L.; Li, H.; Liu, Z.; Xie, Y.-H. The conversion of CuInS2/ZnS core/shell structure from type I to quasi-type II and the shell thickness-dependent solar cell performance. J. Colloid Interface Sci. 2019, 54615, 276–284. [Google Scholar]

- Park, Y.J.; Lee, K.S.; Lim, G.H.; Seo, H.W.; Kim, S.W.; Kim, M.; Yi, Y.; Lee, H.S.; Son, D.I. Role of CdSe and CdSe@ZnS quantum dots interlayers conjugated in inverted polymer solar cells. Org. Electron. 2020, 82, 105707. [Google Scholar] [CrossRef]

- Dobrikov, G.; Rassovska, M.; Andreev, N.; Boyadzhiev, S.; Gesheva, K.; Ivanova, T.; Sharlandjiev, P.; Nazarova, D. Development of transparent heat mirrors based on metal oxide thin film structures. Thin Solid Films 2009, 518, 1091–1094. [Google Scholar] [CrossRef]

- Xu, Z.; Rosso, K.M.; Bruemmer, S. Metal Oxidation Kinetics and the Transition from Thin to Thick Films. Phys. Chem. Chem. Phys. 2012, 14, 14534–14539. [Google Scholar] [CrossRef] [PubMed]

- Konstantinov, I.; Babeva, T.; Kitova, S. Analysis of errors in thin-film optical parameters derived from spectrophotometric measurements at normal light incidence. Appl. Opt. 1998, 37, 4260–4267. [Google Scholar] [CrossRef] [PubMed]

- Babeva, T.; Kitova, S.; Konstantinov, I. Photometric methods for determining the optical constants and the thicknesses of thin absorbing films: Criteria for precise and unambiguous determination of n, k, and d in a wide spectral range. Appl. Opt. 2001, 40, 2682–2686. [Google Scholar] [CrossRef] [PubMed]

- Aleksandrova, M.; Dobrikov, G.; Gesheva, K.; Bodurov, G.; Cholakova, I.; Kolev, G. Deposition of Transparent Electrodes for the Future Generation of Flexible Displays. In Proceedings of the International Scientific Conference on Information, Communication and Energy Systems and Technologies ICEST, Veliko Tarnovo, Bulgaria, 28–30 June 2012. [Google Scholar]

- Li, P.; McDonald, J.F.; Lu, T.M. Densification induced dielectric properties change in amorphous BaTiO3 thin films. J. Appl. Phys. 1992, 71, 5596–5600. [Google Scholar] [CrossRef]

- Hu, H.; Zhu, C.X.; Lu, Y.F.; Liew, Y.; Li, M.F.; Cho, B.J.; Chio, W.K.; Yakovlev, N. Physical and electrical characterization of HfO2 metal-insulator-metal capacitors for Si analog circuit application. J. Appl. Phys. 2003, 94, 551–557. [Google Scholar] [CrossRef]

- Kumar, S.; Bhuyan, R.; Pamu, D. Effect of post annealing on structural, optical and dielectric properties of MgTiO3 thin films deposited by RF magnetron sputtering. Appl. Surf. Sci. 2013, 264, 184–190. [Google Scholar] [CrossRef]

- Zhao, J.L.; Sun, X.W.; Ryu, H.; Moon, Y.B. Thermally stable transparent conducting and highly infrared reflective Ga-doped ZnO thin films by metal organic chemical vapor deposition. Opt. Mat. 2011, 33, 768–772. [Google Scholar] [CrossRef]

- Aleksandrova, M.; Ivanova, T.; Gesheva, K.; Strijkova, V.; Tsanev, T.; Singh, J.; Singh, A.K. Fabrication of transparent ITO/Ga-doped ZnO coating as a front panel electrode toward efficient thin film solar cells. Mater. Proc. 2020, 2, 1. [Google Scholar] [CrossRef]

- Mo, G.; Liu, J.; Lin, G.; Zou, Z.; Wei, Z.; Liu, Y.; He, H.; Fu, Y.; Shen, X. Characterization of low resistivity Ga-doped ZnO thin films on Si substrates prepared by pulsed laser deposition. Mater. Res. Express 2019, 6, 106421. [Google Scholar] [CrossRef]

- Lansåker, P.C.; Petersson, P.; Niklasson, G.A.; Granqvist, C.G. Thin sputter deposited gold films on In2O3:Sn, SnO2:In, TiO2 and glass: Optical, electrical and structural effects. Sol. Energy Mater. Sol. Cells 2013, 117, 462–470. [Google Scholar] [CrossRef]

- Valluzzi, M.G.; Valluzzi, L.G.; Meyer, M.; Hernández-Fenollosa, M.A.; Damonte, L.C. Optical and Electrical Properties of TiO2/Co/TiO2 Multilayer Films Grown by DC Magnetron Sputtering. Adv. Cond. Matt. Phys. 2018, 2018, 1257543. [Google Scholar] [CrossRef]

- Subacius, A.; Baloukas, B.; Bousser, E.; Hinder, S.J.; Baker, M.A.; Rebholz, C.; Matthews, A. Nanostructural Characterisation and OpticalProperties of Sputter-Deposited Thick Indium TinOxide (ITO) Coatings. Coatings 2020, 10, 1127. [Google Scholar] [CrossRef]

- Kim, J.-H.; Fujita, S.; Shiratori, S. Design of a thin film for optical applications, consisting of high and low refractive index multilayers, fabricated by a layer-by-layer self-assembly method. Colloids Surf. A Physicochem. Eng. Asp. 2006, 284–285, 290–294. [Google Scholar] [CrossRef]

- Mada, Y.; Sugitani, S.; Arai, K.; Yamasaki, K. Optical properties of oxygen-ion-implanted benzocyclobutene films. J. Vac. Sci. Technol. A 2001, 19, 883–886. [Google Scholar] [CrossRef]

- Hinczewski, D.S.; Hinczewski, M.; Tepehan, F.Z.; Tepehan, G.G. Optical filters from SiO2 and TiO2 multi-layers using sol–gel spin coating method. Sol. Energy Mater. Sol. Cells 2005, 87, 181–196. [Google Scholar] [CrossRef]

- Pedrotti, F.L.; Pedrotti, L.S. Introduction to Optics; Prentice-Hall: London, UK, 1993; p. 392. [Google Scholar]

- Park, Y.; Choong, V.; Gao, Y. Work function of indium tin oxide transparent conductor measured by photoelectron spectroscopy. Appl. Phys. Lett. 1996, 68, 2699. [Google Scholar] [CrossRef]

- Macleod, H.A. Thin Film Optical Filters, 3rd ed.; The Institute of Physics: London, UK, 2001. [Google Scholar]

- Abdullah, G.H.; Mohammad, E.; Hadeeabud, A.M. Design and analysis narrowband filters, International. J. Photon. 2013, 5, 13–19. [Google Scholar]

- Dhankhar, M.; Singh, O.P.; Singh, V.N. Physical principles of losses in thin film solar cells and efficiency enhancement methods. Renew. Sustain. Energy Rev. 2014, 40, 214–223. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aleksandrova, M.; Ivanova, T.; Strijkova, V.; Tsanev, T.; Singh, A.K.; Singh, J.; Gesheva, K. Ga-Doped ZnO Coating—A Suitable Tool for Tuning the Electrode Properties in the Solar Cells with CdS/ZnS Core-Shell Quantum Dots. Crystals 2021, 11, 137. https://doi.org/10.3390/cryst11020137

Aleksandrova M, Ivanova T, Strijkova V, Tsanev T, Singh AK, Singh J, Gesheva K. Ga-Doped ZnO Coating—A Suitable Tool for Tuning the Electrode Properties in the Solar Cells with CdS/ZnS Core-Shell Quantum Dots. Crystals. 2021; 11(2):137. https://doi.org/10.3390/cryst11020137

Chicago/Turabian StyleAleksandrova, Mariya, Tatyana Ivanova, Velichka Strijkova, Tsvetozar Tsanev, Ajaya Kumar Singh, Jai Singh, and Kostadinka Gesheva. 2021. "Ga-Doped ZnO Coating—A Suitable Tool for Tuning the Electrode Properties in the Solar Cells with CdS/ZnS Core-Shell Quantum Dots" Crystals 11, no. 2: 137. https://doi.org/10.3390/cryst11020137

APA StyleAleksandrova, M., Ivanova, T., Strijkova, V., Tsanev, T., Singh, A. K., Singh, J., & Gesheva, K. (2021). Ga-Doped ZnO Coating—A Suitable Tool for Tuning the Electrode Properties in the Solar Cells with CdS/ZnS Core-Shell Quantum Dots. Crystals, 11(2), 137. https://doi.org/10.3390/cryst11020137