High Hole Mobility Polycrystalline GaSb Thin Films

Abstract

:1. Introduction

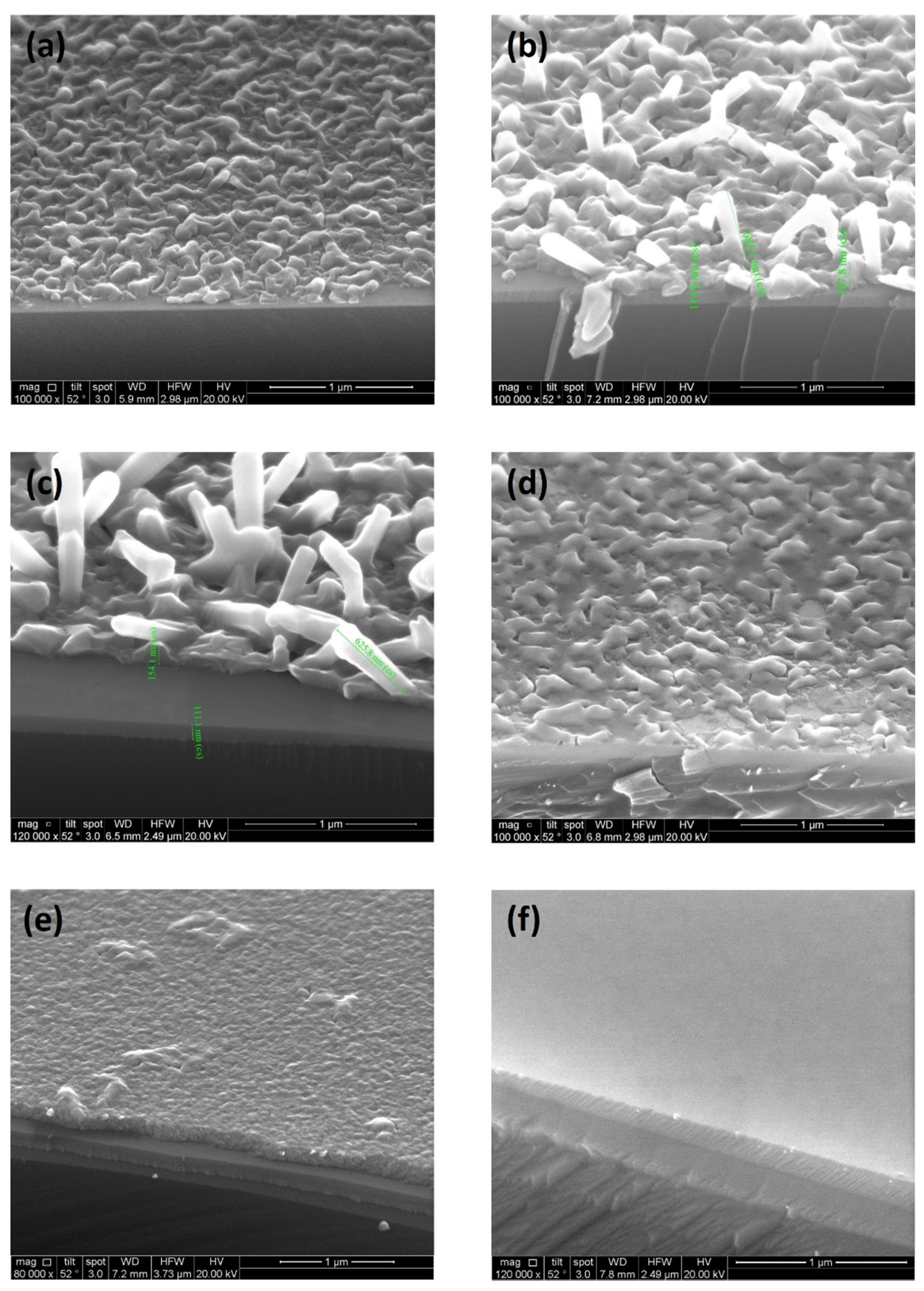

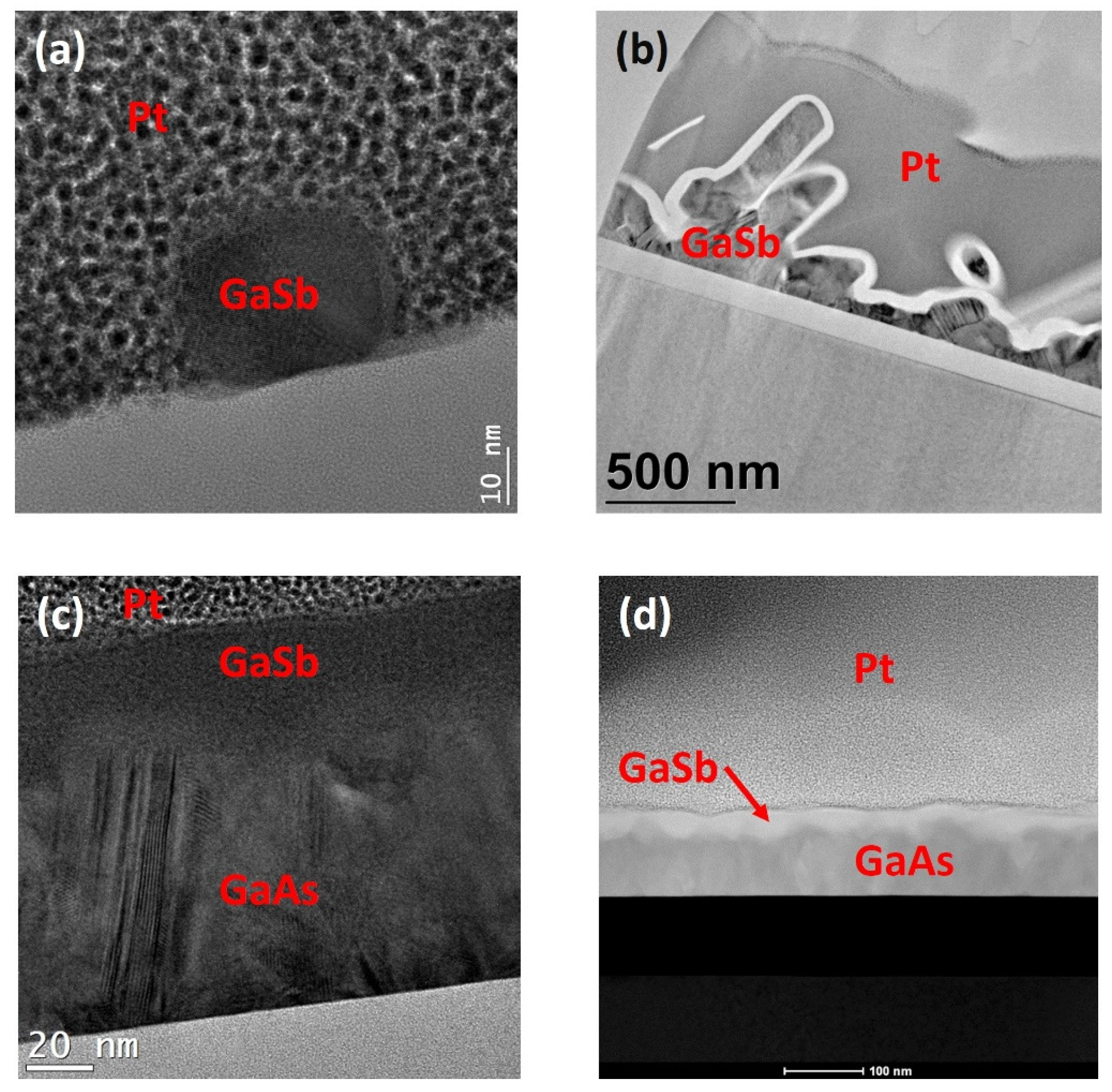

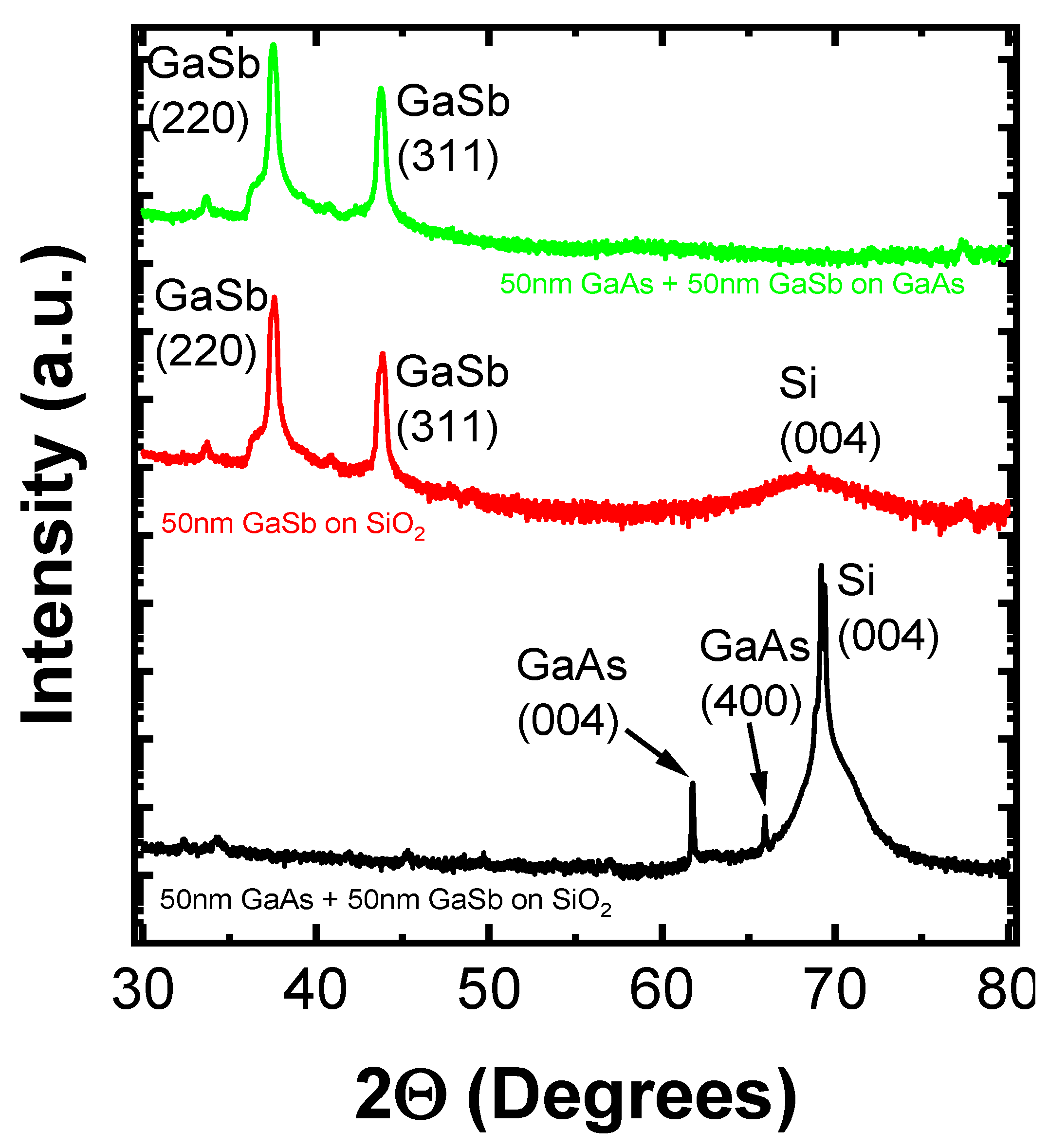

2. Materials and Methods

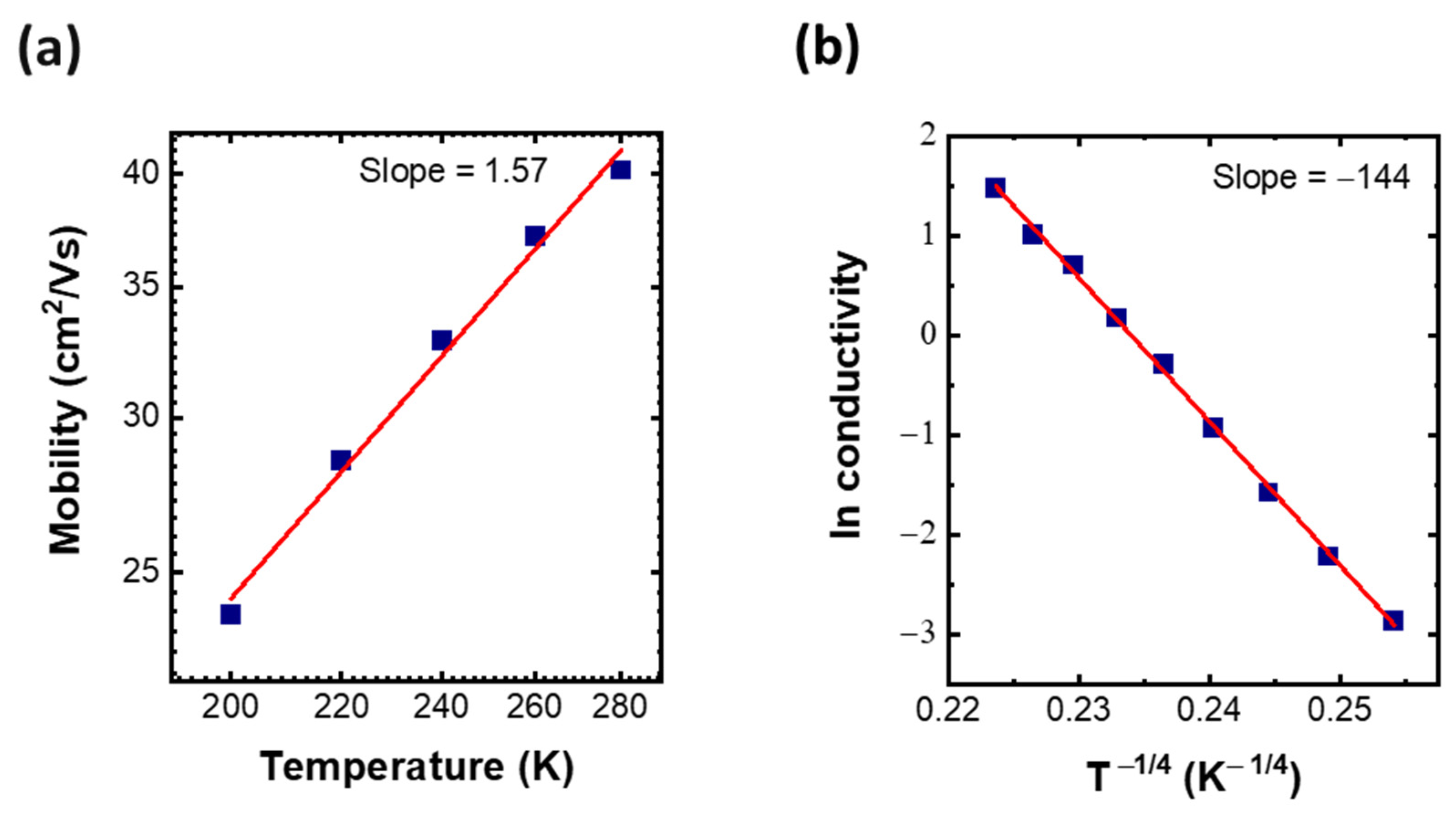

3. Results

4. Discussion

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- von Neumann, J. First draft of a report on the EDVAC. IEEE Ann. Hist. Comput. 1993, 15, 27–75. [Google Scholar] [CrossRef]

- Datta, S.; Dutta, S.; Grisafe, B.; Smith, J.; Srinivasa, S.; Ye, H. Back-End-of-Line Compatible Transistors for Monolithic 3-D Integration. IEEE Micro 2019, 39, 8–15. [Google Scholar] [CrossRef]

- Wong, H.-S.P.; Salahuddin, S. Memory leads the way to better computing. Nat. Nanotechnol. 2015, 10, 191–194. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.-H.S.; Chakrabarty, K. Test Challenges for 3D Integrated Circuits. IEEE Des. Test Comput. 2009, 26, 26–35. [Google Scholar] [CrossRef] [Green Version]

- Shulaker, M.M.; Wu, T.F.; Sabry, M.M.; Wei, H.; Wong, H.-P.; Mitra, S. Monolithic 3D integration: A path from concept to reality. In Proceedings of the 2015 Design, Automation & Test in Europe Conference & Exhibition (DATE), Grenoble, France, 9–13 March 2015; pp. 1197–1202. [Google Scholar]

- Wolf, S.; Tauber, R. Process Technology. In Silicon Processing for the VLSI ERA, 2nd ed.; Lattice Press: Sunset Beach, CA, USA, 2000; Volume 1, pp. 12–13. [Google Scholar]

- Esro, M.; Vourlias, G.; Somerton, C.; Milne, W.I.; Adamopoulos, G. High-Mobility ZnO Thin Film Transistors Based on Solution-processed Hafnium Oxide Gate Dielectrics. Adv. Funct. Mater. 2015, 25, 134–141. [Google Scholar] [CrossRef]

- Shih, C.W.; Chin, A.; Lu, C.-F.; Su, W.-F. Remarkably high mobility ultra-thin-film metal-oxide transistor with strongly overlapped orbitals. Sci. Rep. 2016, 6, srep19023. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gaspar, D.; Pereira, L.; Gehrke, K.; Galler, B.; Fortunato, E.; Martins, R. High mobility hydrogenated zinc oxide thin films. Sol. Energy Mater. Sol. Cells 2017, 163, 255–262. [Google Scholar] [CrossRef]

- Faber, H.; Das, S.; Lin, Y.-H.; Pliatsikas, N.; Zhao, K.; Kehagias, T.; Dimitrakopulos, G.; Amassian, A.; Patsalas, P.A.; Anthopoulos, T.D. Heterojunction oxide thin-film transistors with unprecedented electron mobility grown from solution. Sci. Adv. 2017, 3, e1602640. [Google Scholar] [CrossRef] [Green Version]

- Zheng, J.; Yan, X.; Lu, Z.; Qiu, H.; Xu, G.; Zhou, X.; Wang, P.; Pan, X.; Liu, K.; Jiao, L. High-Mobility Multilayered MoS2 Flakes with Low Contact Resistance Grown by Chemical Vapor Deposition. Adv. Mater. 2017, 29. [Google Scholar] [CrossRef]

- Yang, R.; Li, H.; Smithe, K.K.H.; Kim, T.R.; Okabe, K.; Pop, E.; Fan, J.A.; Wong, H.-S.P. 2D molybdenum disulfide (MoS2) transistors driving RRAMs with 1T1R configuration. In Proceedings of the 2017 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 2–6 December 2017; pp. 19.5.1–19.5.4. [Google Scholar]

- Wu, J.; Tan, C.; Tan, Z.; Liu, Y.; Yin, J.; Dang, W.; Wang, M.; Peng, H. Controlled Synthesis of High-Mobility Atomically Thin Bismuth Oxyselenide Crystals. Nano Lett. 2017, 17, 3021–3026. [Google Scholar] [CrossRef]

- Wang, Z.; Nayak, P.K.; Caraveo-Frescas, J.A.; Alshareef, H.N. Recent Developments in p-Type Oxide Semiconductor Materials and Devices. Adv. Mater. 2016, 28, 3831–3892. [Google Scholar] [CrossRef] [Green Version]

- Atahan-Evrenk, Ş.; Aspuru-Guzik, A. Prediction and Theoretical Characterization of p-Type Organic Semiconductor Crystals for Field-Effect Transistor Applications. In Prediction and Calculation of Crystal Structures: Methods and Applications; Springer International Publishing: Manhattan, NY, USA, 2014; pp. 95–138. [Google Scholar]

- Dutta, P.S.; Bhat, H.L.; Kumar, V. The physics and technology of gallium antimonide: An emerging optoelectronic material. J. Appl. Phys. 1997, 81, 5821–5870. [Google Scholar] [CrossRef]

- Myronov, M. Chapter 3—Molecular Beam Epitaxy of High Mobility Silicon, Silicon Germanium and Germanium Quantum Well Heterostructures. In Molecular Beam Epitaxy, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 37–54. [Google Scholar]

- Alamo, J.A.D. Nanometre-scale electronics with III–V compound semiconductors. Nature 2011, 479, 317–323. [Google Scholar] [CrossRef]

- Nainani, A.; Irisawa, T.; Yuan, Z.; Bennett, B.R.; Boos, J.B.; Nishi, Y.; Saraswat, K.C. Optimization of the Al2O3/GaSb Interface and a High-Mobility GaSb pMOSFET. IEEE Trans. Electron. Devices 2011, 58, 3407–3415. [Google Scholar] [CrossRef]

- Zaixiang, Q.; Yun, S.; Weiyu, H.; Qing, H.; Changjian, L. Polycrystalline GaSb thin films grown by co-evaporation. J. Semicond. 2009, 30. [Google Scholar] [CrossRef]

- Dong, Y.; Scott, D.W.; Wei, Y.; Gossard, A.C.; Rodwell, M.J. Low-resistance p-type polycrystalline GaSb grown by molecular beam epitaxy. J. Cryst. Growth 2003, 256, 223–229. [Google Scholar] [CrossRef]

- Ha, M.T.H.; Huynh, S.H.; Do, H.B.; Nguyen, T.A.; Luc, Q.H.; Lee, C.T.; Chang, E.Y. Entirely relaxed lattice-mismatched GaSb/GaAs/Si(001) heterostructure grown via metalorganic chemical vapor deposition. Appl. Phys. Express 2018, 11, 051202. [Google Scholar] [CrossRef]

- Gocalinska, A.; Pescaglini, A.; Secco, E.; Mura, E.E.; Thomas, K.; Curran, A.; Gity, F.; Nagle, R.; Schmidt, M.; Michałowski, P.P.; et al. Next generation low temperature polycrystalline materials for above IC electronics. High mobility n- and p-type III–V metalorganic vapour phase epitaxy thin films on amorphous substrates. J. Phys. Photonics 2020, 2, 025003. [Google Scholar] [CrossRef]

- Bai, S.; Cao, M.; Jin, Y.; Dai, X.; Liang, X.; Ye, Z.; Li, M.; Cheng, J.; Xiao, X.; Wu, Z.; et al. Low-Temperature Combustion-Synthesized Nickel Oxide Thin Films as Hole-Transport Interlayers for Solution-Processed Optoelectronic Devices. Adv. Energy Mater. 2014, 4, 1301460. [Google Scholar] [CrossRef]

- Shih, C.W.; Chin, A.; Lu, C.-F.; Su, W.-F. Remarkably High Hole Mobility Metal-Oxide Thin-Film Transistors. Sci. Rep. 2018, 8, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Saji, K.J.; Tian, K.; Snure, M.; Tiwari, A. 2D Tin Monoxide—An Unexplored p-Type van der Waals Semiconductor: Material Characteristics and Field Effect Transistors. Adv. Electron. Mater. 2016, 2, 1500453. [Google Scholar] [CrossRef]

- Vandalon, V.; Verheijen, M.A.; Kessels, W.M.M.; Bol, A.A. Atomic Layer Deposition of Al-Doped MoS2: Synthesizing a p-type 2D Semiconductor with Tunable Carrier Density. ACS Appl. Nano Mater. 2020, 3, 10200–10208. [Google Scholar] [CrossRef]

- Minari, F.; Billia, B. Mixed cells in directional solidification of In-doped GaAs; cellular profile and shape-induced stresses. J. Cryst. Growth 1994, 140, 264–276. [Google Scholar] [CrossRef]

- Nakashima, K. Electrical and Optical Studies in Gallium Antimonide. Jpn. J. Appl. Phys. 1981, 20, 1085–1094. [Google Scholar] [CrossRef]

- Seto, J.Y.W. The electrical properties of polycrystalline silicon films. J. Appl. Phys. 1975, 46, 5247–5254. [Google Scholar] [CrossRef]

- Ng, H.M.; Doppalapudi, D.; Moustakas, T.D.; Weimann, N.; Eastman, L.F. The role of dislocation scattering in n-type GaN films. Appl. Phys. Lett. 1998, 73, 821–823. [Google Scholar] [CrossRef]

- Pödör, B. Electron Mobility in Plastically Deformed Germanium. Phys. Status Solidi B 1966, 16, K167–K170. [Google Scholar] [CrossRef]

- Mott, N.F. Conduction in non-crystalline materials. Philos. Mag. A J. Theor. Exp. Appl. Phys. 1969, 19, 835–852. [Google Scholar] [CrossRef]

- Lewis, A.J. Conductivity and thermoelectric power of amorphous germanium and amorphous silicon. Phys. Rev. B 1976, 13, 2565–2575. [Google Scholar] [CrossRef]

- Scheller, L.-P.; Nickel, N.H. Charge transport in polycrystalline silicon thin-films on glass substrates. J. Appl. Phys. 2012, 112, 013713. [Google Scholar] [CrossRef]

- Shklovskii, B.I.; Efros, A.L. Variable-Range Hopping Conduction. In Electronic Properties of Doped Semiconductors; Springer: Berlin/Heidelberg, Germany, 1984; pp. 202–227. [Google Scholar]

- Liu, A.; Zhu, H.; Park, W.-T.; Kang, S.-J.; Xu, Y.; Kim, M.-G.; Noh, Y.-Y. Room-Temperature Solution-Synthesized p-Type Copper(I) Iodide Semiconductors for Transparent Thin-Film Transistors and Complementary Electronics. Adv. Mater. 2018, 30, e1802379. [Google Scholar] [CrossRef]

- Xu, W.; Zhang, J.; Li, Y.; Zhang, L.; Chen, L.; Zhu, D.; Cao, P.; Liu, W.; Han, S.; Liu, X.; et al. p-Type transparent amorphous oxide thin-film transistors using low-temperature solution-processed nickel oxide. J. Alloys Compd. 2019, 806, 40–51. [Google Scholar] [CrossRef]

- Jun, T.; Kim, J.; Sasase, M.; Hosono, H. Material Design of p-Type Transparent Amorphous Semiconductor, Cu–Sn–I. Adv. Mater. 2018, 30, 1706573. [Google Scholar] [CrossRef] [PubMed]

| 250 nm GaSb on SiO2 | 150 nm GaSb on SiO2 | 50 nm GaSb on SiO2 | 50 nm GaAs + 50 nm GaSb on SiO2 | |

|---|---|---|---|---|

| Hall Mobility (cm2/V·s) | 66.5 | 22.9 | 24.2 | 9.1 |

| Carrier Type | p | p | p | p |

| Sheet carrier conc. (cm−2) | 4.6 × 1012 | 3.26 × 1012 | 9.92 × 1010 | 1.65 × 1012 |

| Carrier conc (cm−3) | 1.84 × 1017 | 2.17 × 1017 | 1.98 × 1016 | 1.37 × 1017 |

| 250 nm GaSb on GaAs | 150 nm GaSb on GaAs | 50 nm GaSb on GaAs | 50 nm GaAs + 50 nm GaSb on GaAs | |

|---|---|---|---|---|

| Hall Mobility (cm2/V·s) | 293.2 | 172 | 76.8 | 218.57 |

| Carrier Type | p | p | p | p |

| Sheet carrier conc. (cm−2) | 2.92 × 1012 | 5.92 × 1012 | 4.27 × 1012 | 1.65 × 1012 |

| Carrier conc. (cm−3) | 1.17 × 1017 | 3.9 × 1017 | 8.54 × 1017 | 3.3 × 1017 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Curran, A.; Gity, F.; Gocalinska, A.; Mura, E.; Nagle, R.E.; Schmidt, M.; Sheehan, B.; Pelucchi, E.; O’Dwyer, C.; Hurley, P.K. High Hole Mobility Polycrystalline GaSb Thin Films. Crystals 2021, 11, 1348. https://doi.org/10.3390/cryst11111348

Curran A, Gity F, Gocalinska A, Mura E, Nagle RE, Schmidt M, Sheehan B, Pelucchi E, O’Dwyer C, Hurley PK. High Hole Mobility Polycrystalline GaSb Thin Films. Crystals. 2021; 11(11):1348. https://doi.org/10.3390/cryst11111348

Chicago/Turabian StyleCurran, Anya, Farzan Gity, Agnieszka Gocalinska, Enrica Mura, Roger E. Nagle, Michael Schmidt, Brendan Sheehan, Emanuele Pelucchi, Colm O’Dwyer, and Paul K. Hurley. 2021. "High Hole Mobility Polycrystalline GaSb Thin Films" Crystals 11, no. 11: 1348. https://doi.org/10.3390/cryst11111348

APA StyleCurran, A., Gity, F., Gocalinska, A., Mura, E., Nagle, R. E., Schmidt, M., Sheehan, B., Pelucchi, E., O’Dwyer, C., & Hurley, P. K. (2021). High Hole Mobility Polycrystalline GaSb Thin Films. Crystals, 11(11), 1348. https://doi.org/10.3390/cryst11111348