A Taguchi Approach for Optimizing Design Mixture of Geopolymer Concrete Incorporating Fly Ash, Ground Granulated Blast Furnace Slag and Silica Fume

Abstract

:1. Introduction

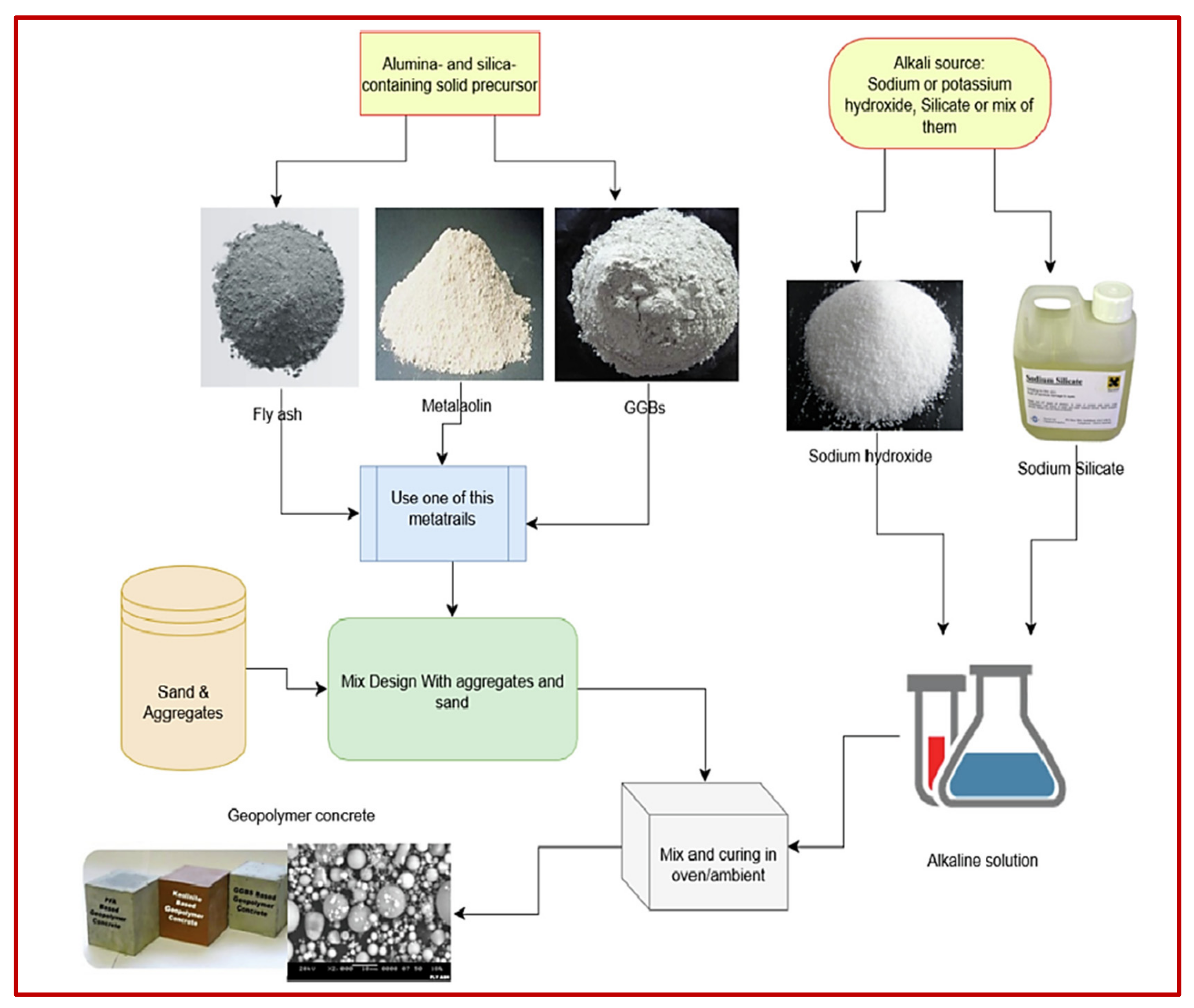

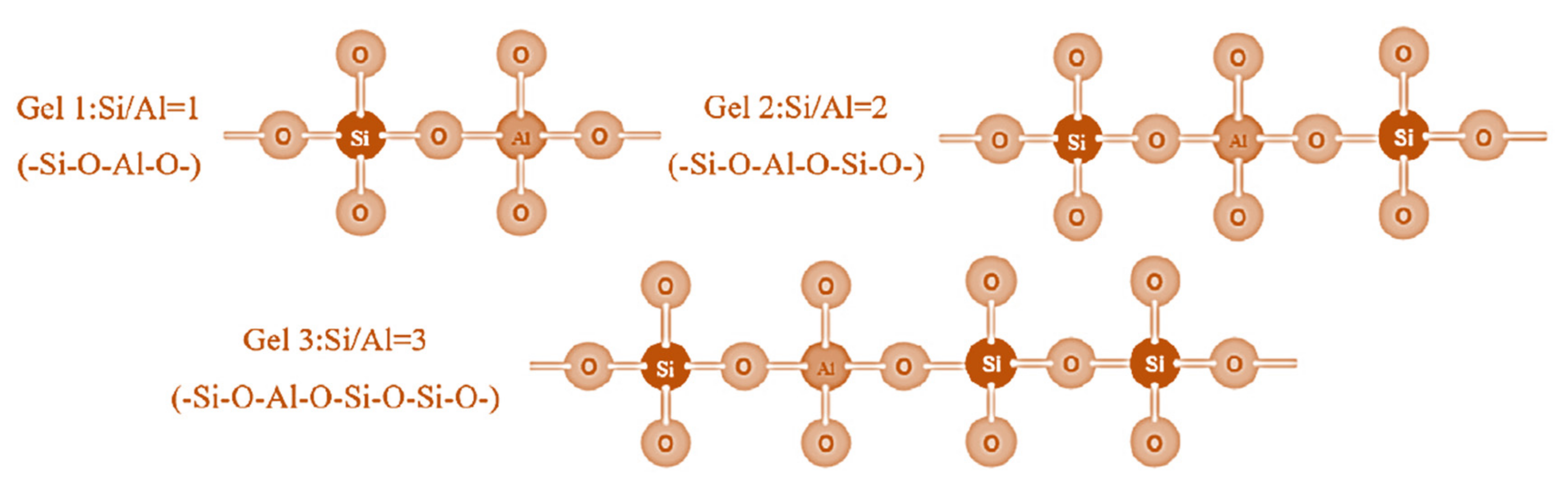

1.1. Geopolymer Reaction Mechanism

1.2. Probable Source Materials

| Type | Item | Acronym | Reference | Constituents |

|---|---|---|---|---|

| Source material | Pozzolana blast furnace slag | BFS | [37,38,39,40,41] | SiO2 Al2O3 Fe2O3 CaO P2O5 Na2O K2O MnO MgO SO3 TiO2 |

| Metakaolin | MK | [42,43,44,45] | ||

| Bottom ash | BA | [46,47,48] | ||

| Fly ash | FA | [13,49,50,51,52,53,54] | ||

| Silico-manganese fume | SMF | [55] | ||

| Biomass fly ash | BFA | [56,57] | ||

| Ultra fine kaolite high performance ash | HFA | [58,59] | ||

| Ferrochrome slag | FS | [60] | ||

| Rice husk ash | RHA | [43,61,62] | ||

| Granulated lead smelter slag | GLSS | [63,64] | ||

| Palm oil fuel ash | POFA | [19,65,66,67] | ||

| Natural zeolites kaolin | KL | [68,69] | ||

| Additives | Silica fume | SF | [50,70] | |

| Ordinary Portland cement | OPC | [71,72,73] | ||

| Calcium hydroxide | Ca(OH)2 | [46] | ||

| Nano-silica | [74] | |||

| Calcium aluminate cement | CAC | [75] |

2. Research Significance

3. Experimental Methods

3.1. Raw Materials

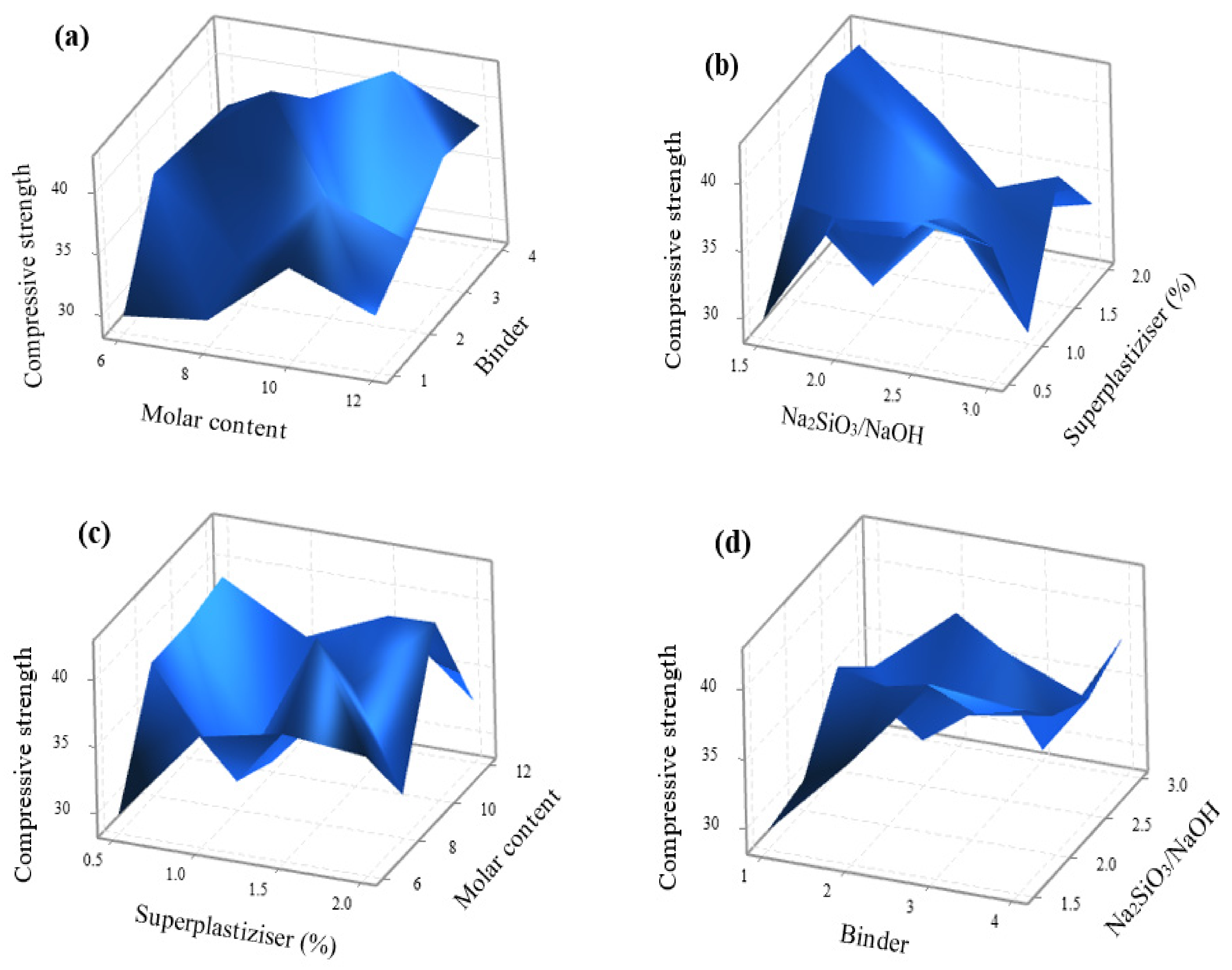

3.2. Mix Design Preparation Using the Taguchi Method Orthogonal Array

3.3. Mixing Combination, Mixing Procedure

3.4. Testing Methodology

4. Discussion of Results

- SS: compressive strength is calculated using the sum of squares.

- N: every test requires a different sample number. (N = 3)

- L: every factor has a set of level numbers (L = 4)

- : level i mean strength (mean of 4 × 4 = 16 values)

- = the average strength of the experiments (average of 16 × 3 = 48 values)

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Esen, Y.; Yilmazer, B. Investigation of some physical and mechanical properties of concrete produced with barite aggregate. Sci. Res. Essays 2010, 5, 3826–3833. [Google Scholar]

- Murali, G.; Gayathri, R.; Ramkumar, V.R.; Karthikeyan, K. Two statistical scrutinize of impact strength and strength reliability of steel Fibre-Reinforced Concrete. KSCE J. Civ. Eng. 2018, 22, 257–269. [Google Scholar] [CrossRef]

- Strieder, E.; Hilber, R.; Stierschneider, E.; Bergmeister, K. FE-study on the effect of gradient concrete on early constraint and crack risk. Appl. Sci. 2018, 8, 246. [Google Scholar] [CrossRef] [Green Version]

- Hu, H.T.; Lin, F.M.; Liu, H.T.; Huang, Y.F.; Pan, T.C. Constitutive modeling of reinforced concrete and prestressed concrete structures strengthened by fiber-reinforced plastics. Compos. Struct. 2010, 92, 1640–1650. [Google Scholar] [CrossRef]

- Esen, Y.; Orhan, E. Investigation of the effect on the physical and mechanical properties of the dosage of additive in self-consolidating concrete. KSCE J. Civ. Eng. 2016, 20, 2849–2858. [Google Scholar] [CrossRef]

- Zhang, P.; Zheng, Y.; Wang, K.; Zhang, J. A review on properties of fresh and hardened geopolymer mortar. Compos. Part B Eng. 2018, 152, 79–95. [Google Scholar] [CrossRef]

- Davidovits, P.J. 30 Years of Successes and Failures in Geopolymer Applications. Market Trends and Potential Breakthroughs. In Proceedings of the Geopolymer 2002 Conference, Melbourne, VIC, Australia, 28–29 October 2002; pp. 1–16. [Google Scholar]

- Habert, G.; D’Espinose De Lacaillerie, J.B.; Roussel, N. An environmental evaluation of geopolymer based concrete production: Reviewing current research trends. J. Clean. Prod. 2011, 19, 1229–1238. [Google Scholar] [CrossRef]

- Sandanayake, M.; Gunasekara, C.; Law, D.; Zhang, G.; Setunge, S. Greenhouse gas emissions of different fly ash based geopolymer concretes in building construction. J. Clean. Prod. 2018, 204, 399–408. [Google Scholar] [CrossRef]

- Bajpai, R.; Choudhary, K.; Srivastava, A.; Sangwan, K.S.; Singh, M. Environmental impact assessment of fly ash and silica fume based geopolymer concrete. J. Clean. Prod. 2020, 254, 120147. [Google Scholar] [CrossRef]

- Puertas, F.; Palacios, M.; Manzano, H.; Dolado, J.S.; Rico, A.; Rodríguez, J. A model for the C–A–S–H gel formed in alkali-activated slag cements. J. Eur. Ceram. Soc. 2011, 31, 2043–2056. [Google Scholar] [CrossRef]

- Yang, K.; Yang, C.; Magee, B.; Nanukuttan, S.; Ye, J. Establishment of a preconditioning regime for air permeability and sorptivity of alkali-activated slag concrete. Cem. Concr. Compos. 2016, 73, 19–28. [Google Scholar] [CrossRef] [Green Version]

- Zhuang, X.Y.; Chen, L.; Komarneni, S.; Zhou, C.H.; Tong, D.S.; Yang, H.M.; Yu, W.H.; Wang, H. Fly ash-based geopolymer: Clean production, properties and applications. J. Clean. Prod. 2016, 125, 253–267. [Google Scholar] [CrossRef]

- Hassan, A.; Arif, M.; Shariq, M. Use of geopolymer concrete for a cleaner and sustainable environment—A review of mechanical properties and microstructure. J. Clean. Prod. 2019, 223, 704–728. [Google Scholar] [CrossRef]

- Zhang, P.; Gao, Z.; Wang, J.; Guo, J.; Hu, S.; Ling, Y. Properties of fresh and hardened fly ash/slag based geopolymer concrete: A review. J. Clean. Prod. 2020, 270, 122389. [Google Scholar] [CrossRef]

- Junaid, M.T.; Khennane, A.; Kayali, O.; Sadaoui, A.; Picard, D.; Fafard, M. Aspects of the deformational behaviour of alkali activated fly ash concrete at elevated temperatures. Cem. Concr. Res. 2014, 60, 24–29. [Google Scholar] [CrossRef]

- Somna, K.; Jaturapitakkul, C.; Kajitvichyanukul, P.; Chindaprasirt, P. NaOH-activated ground fly ash geopolymer cured at ambient temperature. Fuel 2011, 90, 2118–2124. [Google Scholar] [CrossRef]

- Puligilla, S.; Mondal, P. Role of slag in microstructural development and hardening of fly ash-slag geopolymer. Cem. Concr. Res. 2013, 43, 70–80. [Google Scholar] [CrossRef]

- Ariffin, M.A.M.; Bhutta, M.A.R.; Hussin, M.W.; Mohd Tahir, M.; Aziah, N. Sulfuric acid resistance of blended ash geopolymer concrete. Constr. Build. Mater. 2013, 43, 80–86. [Google Scholar] [CrossRef]

- Khater, H.M. Studying the effect of thermal and acid exposure on alkali activated slag Geopolymer. MATEC Web Conf. 2014, 11, 01032. [Google Scholar] [CrossRef] [Green Version]

- Ferdous, W.; Manalo, A.; Khennane, A.; Kayali, O. Geopolymer concrete-filled pultruded composite beams—Concrete mix design and application. Cem. Concr. Compos. 2015, 58, 1–13. [Google Scholar] [CrossRef]

- Ding, Y.; Dai, J.G.; Shi, C.J. Mechanical properties of alkali-activated concrete: A state-of-the-art review. Constr. Build. Mater. 2016, 127, 68–79. [Google Scholar] [CrossRef] [Green Version]

- Moon, J.; Bae, S.; Celik, K.; Yoon, S.; Kim, K.H.; Kim, K.S.; Monteiro, P.J.M. Characterization of natural pozzolan-based geopolymeric binders. Cem. Concr. Compos. 2014, 53, 97–104. [Google Scholar] [CrossRef] [Green Version]

- Davidovits, J. Geopolymers and geopolymeric materials. J. Therm. Anal. 1989, 35, 429–441. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, S.; Zuo, Y.; Chen, W.; Ye, G. Chemical deformation of metakaolin based geopolymer. Cem. Concr. Res. 2019, 120, 108–118. [Google Scholar] [CrossRef]

- Rees, C.A.; Provis, J.L.; Lukey, G.C.; van Deventer, J.S.J. The mechanism of geopolymer gel formation investigated through seeded nucleation. Colloids Surf. A Physicochem. Eng. Asp. 2008, 318, 97–105. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Li, H.H.; Wang, Y.C.; Xu, D.L. Geopolymer microstructure and hydration mechanism of alkali-activated fly ash-based geopolymer. Adv. Mater. Res. 2012, 374–377, 1481–1484. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers—Inorganic polymeric new materials. J. Therm. Anal. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Palomo, A.; Shi, C.; Jiménez, A.F. New cements for the 21st century: The pursuit of an alternative to Portland cement. Cem. Concr. Res. 2011, 41, 750–763. [Google Scholar]

- Hardjito, D.; Wallah, S.E.; Sumajouw, D.M.J.; Rangan, B.V. On the Development of Fly Ash-Based Geopolymer Concrete. ACI Mater. 2004, 101, 467–472. [Google Scholar]

- Fernández-Jiménez, A.; Palomo, Á.; Vazquez, T.; Vallepu, R.; Terai, T.; Ikeda, K. Alkaline activation of blends of metakaolin and calcium aluminate. J. Am. Ceram. Soc. 2008, 91, 1231–1236. [Google Scholar] [CrossRef]

- Duxson, P.; Lukey, G.C.; Separovic, F.; Van Deventer, J.S.J. Effect of alkali cations on aluminum incorporation in geopolymeric gels. Ind. Eng. Chem. Res. 2005, 44, 832–839. [Google Scholar] [CrossRef]

- Ranjbar, N.; Talebian, S.; Mehrali, M.; Kuenzel, C.; Cornelis Metselaar, H.S.; Jumaat, M.Z. Mechanisms of interfacial bond in steel and polypropylene fiber reinforced geopolymer composites. Compos. Sci. Technol. 2016, 122, 73–81. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Chareerat, T.; Sirivivatnanon, V. Workability and strength of coarse high calcium fly ash geopolymer. Cem. Concr. Compos. 2007, 29, 224–229. [Google Scholar] [CrossRef]

- Kupaei, R.H.; Alengaram, U.J.; Jumaat, M.Z.B.; Nikraz, H. Mix design for fly ash based oil palm shell geopolymer lightweight concrete. Constr. Build. Mater. 2013, 43, 490–496. [Google Scholar] [CrossRef]

- Diaz-Loya, E.I.; Allouche, E.N.; Vaidya, S. Mechanical properties of fly-ash-based geopolymer concrete. ACI Mater. J. 2011, 108, 300–306. [Google Scholar] [CrossRef]

- Akbarnezhad, A.; Huan, M.; Mesgari, S.; Castel, A. Recycling of geopolymer concrete. Constr. Build. Mater. 2015, 101, 152–158. [Google Scholar] [CrossRef]

- Deb, P.S.; Nath, P.; Sarker, P.K. The effects of ground granulated blast-furnace slag blending with fly ash and activator content on the workability and strength properties of geopolymer concrete cured at ambient temperature. Mater. Des. 2014, 62, 32–39. [Google Scholar] [CrossRef] [Green Version]

- Karthik, A.; Sudalaimani, K.; Vijayakumar, C.T. Durability study on coal fly ash-blast furnace slag geopolymer concretes with bio-additives. Ceram. Int. 2017, 43, 11935–11943. [Google Scholar] [CrossRef]

- Patel, Y.J.; Shah, N. Enhancement of the properties of Ground Granulated Blast Furnace Slag based Self Compacting Geopolymer Concrete by incorporating Rice Husk Ash. Constr. Build. Mater. 2018, 171, 654–662. [Google Scholar] [CrossRef]

- Sun, Z.; Lin, X.; Vollpracht, A. Pervious concrete made of alkali activated slag and geopolymers. Constr. Build. Mater. 2018, 189, 797–803. [Google Scholar] [CrossRef]

- Li, X.; Rao, F.; Song, S.; Corona-Arroyo, M.A.; Ortiz-Lara, N.; Aguilar-Reyes, E.A. Effects of aggregates on the mechanical properties and microstructure of geothermal metakaolin-based geopolymers. Results Phys. 2018, 11, 267–273. [Google Scholar] [CrossRef]

- Billong, N.; Kinuthia, J.; Oti, J.; Melo, U.C. Performance of sodium silicate free geopolymers from metakaolin (MK) and Rice Husk Ash (RHA): Effect on tensile strength and microstructure. Constr. Build. Mater. 2018, 189, 307–313. [Google Scholar] [CrossRef]

- Nuaklong, P.; Sata, V.; Chindaprasirt, P. Influence of recycled aggregate on fly ash geopolymer concrete properties. J. Clean. Prod. 2016, 112, 2300–2307. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, W.; Lin, W.; Zheng, K.; Sha, J.; Liu, S. Quantitative in situ study on the hydration process of K-PS geopolymer with ESEM. J. Southeast Univ. Nat. Sci. Ed. 2003, 33, 351–354. [Google Scholar]

- Huang, G.; Ji, Y.; Li, J.; Hou, Z.; Jin, C. Use of slaked lime and Portland cement to improve the resistance of MSWI bottom ash-GBFS geopolymer concrete against carbonation. Constr. Build. Mater. 2018, 166, 290–300. [Google Scholar] [CrossRef]

- Xie, T.; Ozbakkaloglu, T. Behavior of low-calcium fly and bottom ash-based geopolymer concrete cured at ambient temperature. Ceram. Int. 2015, 41, 5945–5958. [Google Scholar] [CrossRef]

- Haddad, R.H.; Alshbuol, O. Production of geopolymer concrete using natural pozzolan: A parametric study. Constr. Build. Mater. 2016, 114, 699–707. [Google Scholar] [CrossRef]

- Kupwade-Patil, K.; Allouche, E.N. Impact of Alkali Silica Reaction on Fly Ash-Based Geopolymer Concrete. J. Mater. Civ. Eng. 2013, 25, 131–139. [Google Scholar] [CrossRef]

- Okoye, F.N.; Prakash, S.; Singh, N.B. Durability of fly ash based geopolymer concrete in the presence of silica fume. J. Clean. Prod. 2017, 149, 1062–1067. [Google Scholar] [CrossRef]

- Rattanasak, U.; Chindaprasirt, P. Influence of NaOH solution on the synthesis of fly ash geopolymer. Miner. Eng. 2009, 22, 1073–1078. [Google Scholar] [CrossRef]

- Stenie, W.; Dwantoro, H.; Sumajouw, D.J.M.; Vijaya, R.B. Performance of Fly Ash-Based Geopolymer Concrete Under Sulfate and Acid Exposure; Ed Nawy Symposium, American Concrete Institute: Indianapolis, IN, USA, 2005; pp. 153–156. [Google Scholar]

- Al-Azzawi, M.; Yu, T.; Hadi, M.N.S. Factors Affecting the Bond Strength Between the Fly Ash-based Geopolymer Concrete and Steel Reinforcement. Structures 2018, 14, 262–272. [Google Scholar] [CrossRef] [Green Version]

- Gunneswara Rao, T.D.; Alfrite, P.; Mallikarjuna Rao, G.; Andal, M. Fracture Parameters of Fly Ash and GGBS Based Geopolymer Concrete. Appl. Mech. Mater. 2015, 764–765, 1090–1094. [Google Scholar] [CrossRef]

- Nasir, M.; Johari, M.A.M.; Yusuf, M.O.; Maslehuddin, M.; Al-Harthi, M.A. Synthesis of alkali-activated binary blended silico-manganese fume and ground blast furnace slag mortar. J. Adv. Concr. Technol. 2019, 17, 728–735. [Google Scholar] [CrossRef] [Green Version]

- Saeli, M.; Novais, R.M.; Seabra, M.P.; Labrincha, J.A. Green geopolymeric concrete using grits for applications in construction. Mater. Lett. 2018, 233, 94–97. [Google Scholar] [CrossRef]

- Saeli, M.; Tobaldi, D.M.; Seabra, M.P.; Labrincha, J.A. Mix design and mechanical performance of geopolymeric binders and mortars using biomass fly ash and alkaline effluent from paper-pulp industry. J. Clean. Prod. 2019, 208, 1188–1197. [Google Scholar] [CrossRef]

- Dahou, Z.; Castel, A.; Noushini, A. Prediction of the steel-concrete bond strength from the compressive strength of Portland cement and geopolymer concretes. Constr. Build. Mater. 2016, 119, 329–342. [Google Scholar] [CrossRef]

- Khan, M.S.H.; Castel, A.; Akbarnezhad, A.; Foster, S.J.; Smith, M. Utilisation of steel furnace slag coarse aggregate in a low calcium fly ash geopolymer concrete. Cem. Concr. Res. 2016, 89, 220–229. [Google Scholar] [CrossRef]

- Karakoç, M.B.; Türkmen, I.; Maraş, M.M.; Kantarci, F.; Demirboğa, R. Sulfate resistance of ferrochrome slag based geopolymer concrete. Ceram. Int. 2016, 42, 1254–1260. [Google Scholar] [CrossRef]

- Nuaklong, P.; Jongvivatsakul, P.; Pothisiri, T.; Sata, V.; Chindaprasirt, P. Influence of rice husk ash on mechanical properties and fire resistance of recycled aggregate high-calcium fly ash geopolymer concrete. J. Clean. Prod. 2020, 252, 119797. [Google Scholar] [CrossRef]

- Kusbiantoro, A.; Nuruddin, M.F.; Shafiq, N.; Qazi, S.A. The effect of microwave incinerated rice husk ash on the compressive and bond strength of fly ash based geopolymer concrete. Constr. Build. Mater. 2012, 36, 695–703. [Google Scholar] [CrossRef]

- Albitar, M.; Mohamed Ali, M.S.; Visintin, P. Experimental study on fly ash and lead smelter slag-based geopolymer concrete columns. Constr. Build. Mater. 2017, 141, 104–112. [Google Scholar] [CrossRef]

- Albitar, M.; Mohamed Ali, M.S.; Visintin, P.; Drechsler, M. Effect of granulated lead smelter slag on strength of fly ash-based geopolymer concrete. Constr. Build. Mater. 2015, 83, 128–135. [Google Scholar] [CrossRef]

- Mo, K.H.; Yeoh, K.H.; Bashar, I.I.; Alengaram, U.J.; Jumaat, M.Z. Shear behaviour and mechanical properties of steel fibre-reinforced cement-based and geopolymer oil palm shell lightweight aggregate concrete. Constr. Build. Mater. 2017, 148, 369–375. [Google Scholar] [CrossRef]

- Islam, A.; Alengaram, U.J.; Jumaat, M.Z.; Bashar, I.I.; Kabir, S.M.A. Engineering properties and carbon footprint of ground granulated blast-furnace slag-palm oil fuel ash-based structural geopolymer concrete. Constr. Build. Mater. 2015, 101, 503–521. [Google Scholar] [CrossRef]

- Kabir, S.M.A.; Alengaram, U.J.; Jumaat, M.Z.; Yusoff, S.; Sharmin, A.; Bashar, I.I. Performance evaluation and some durability characteristics of environmental friendly palm oil clinker based geopolymer concrete. J. Clean. Prod. 2017, 161, 477–492. [Google Scholar] [CrossRef]

- Okoye, F.N.; Durgaprasad, J.; Singh, N.B. Fly ash/Kaolin based geopolymer green concretes and their mechanical properties. Data Brief 2015, 5, 739–744. [Google Scholar] [CrossRef] [Green Version]

- Okoye, F.N.; Durgaprasad, J.; Singh, N.B. Mechanical properties of alkali activated flyash/Kaolin based geopolymer concrete. Constr. Build. Mater. 2015, 98, 685–691. [Google Scholar] [CrossRef]

- Assi, L.N.; Deaver, E.; Elbatanouny, M.K.; Ziehl, P. Investigation of early compressive strength of fly ash-based geopolymer concrete. Constr. Build. Mater. 2016, 112, 807–815. [Google Scholar] [CrossRef] [Green Version]

- Aliabdo, A.A.; Abd Elmoaty, A.E.M.; Salem, H.A. Effect of cement addition, solution resting time and curing characteristics on fly ash based geopolymer concrete performance. Constr. Build. Mater. 2016, 123, 581–593. [Google Scholar] [CrossRef]

- Altwair, N.M.; Megat Johari, M.A.; Saiyid Hashim, S.F. Flexural performance of green engineered cementitious composites containing high volume of palm oil fuel ash. Constr. Build. Mater. 2012, 37, 518–525. [Google Scholar] [CrossRef]

- Nuaklong, P.; Sata, V.; Chindaprasirt, P. Properties of metakaolin-high calcium fly ash geopolymer concrete containing recycled aggregate from crushed concrete specimens. Constr. Build. Mater. 2018, 161, 365–373. [Google Scholar] [CrossRef]

- Çevik, A.; Alzeebaree, R.; Humur, G.; Niş, A.; Gülşan, M.E. Effect of nano-silica on the chemical durability and mechanical performance of fly ash based geopolymer concrete. Ceram. Int. 2018, 44, 12253–12264. [Google Scholar] [CrossRef]

- Cao, Y.F.; Tao, Z.; Pan, Z.; Wuhrer, R. Effect of calcium aluminate cement on geopolymer concrete cured at ambient temperature. Constr. Build. Mater. 2018, 191, 242–252. [Google Scholar] [CrossRef]

- Hadi, M.N.S.S.; Farhan, N.A.; Sheikh, M.N. Design of geopolymer concrete with GGBFS at ambient curing condition using Taguchi method. Constr. Build. Mater. 2017, 140, 424–431. [Google Scholar] [CrossRef] [Green Version]

- Özen, S.; Alam, B. Compressive strength and microstructural characteristics of natural zeolite-based geopolymer. Period. Polytech. Civ. Eng. 2018, 62, 64–71. [Google Scholar] [CrossRef] [Green Version]

- Xu, Z.; Wu, D.; Zheng, L.; Li, D.; Peng, X. Experimental study on geopolymer synthesis from activated zeolite. Disaster Adv. 2013, 6, 159–163. [Google Scholar]

- Assi, L.N.; Eddie Deaver, E.; Ziehl, P. Effect of source and particle size distribution on the mechanical and microstructural properties of fly Ash-Based geopolymer concrete. Constr. Build. Mater. 2018, 167, 372–380. [Google Scholar] [CrossRef]

- Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; ASTM C618-17a; ASTM International: West Conshohocken, PA, USA, 2017.

- Coarse and Fine Aggregate for Concrete—Specification (Third Revision); IS 383: 2016; Bureau of Indian Standards: New Delhi, India, 2016; Volume 19.

- Method of Tests for Strength of Concrete (Eighteenth Reprint 2006); IS 516; 1959; Bureau of Indian Standards: New Delhi, India, 2006.

- Jithendra, C.; Elavenil, S. Role of superplasticizer on GGBS based Geopolymer concrete under ambient curing. Mater. Today Proc. 2019, 18, 148–154. [Google Scholar] [CrossRef]

- Morsy, M.S.; Alsayed, S.H.; Al-Salloum, Y.; Almusallam, T. Effect of Sodium Silicate to Sodium Hydroxide Ratios on Strength and Microstructure of Fly Ash Geopolymer Binder. Arab. J. Sci. Eng. 2014, 39, 4333–4339. [Google Scholar] [CrossRef]

- Škvára, F.; Kopecký, L.; Němeček, J.; Bittnar, Z. Microstructure of geopolymer materials based on fly ash. Ceram. Silik. 2006, 50, 208–215. [Google Scholar]

| Oxide | Class F FA | GGBFS | SF |

|---|---|---|---|

| Titanium Dioxide (TiO2) | 0.1 | - | - |

| Sodium Oxide (Na2O) | 0.2 | - | - |

| Potassium Oxide(K2O) | 1.6 | - | - |

| Magnesium Oxide (MgO) | 5.9 | 8.9 | 0.6 |

| Calcium Oxide (CaO) | 6.4 | 34.62 | - |

| Ferric Oxide (Fe2O3) | 12 | 1 | 0.3 |

| Alumina (Al2O3) | 27 | 17.2 | 0.6 |

| Silica (SiO2) | 51 | 36.7 | 92.8 |

| Factor | Level 1 | Level 2 | Level 3 | Level 4 |

|---|---|---|---|---|

| A. Binder content | B1 | B2 | B3 | B4 |

| B. Dosage of superplasticizer (%) | 0.5 | 1.0 | 1.5 | 2.0 |

| C. Na2SiO3/NaOH ratio | 1.5 | 2 | 2.5 | 3 |

| D. Molar content | 6 | 8 | 10 | 12 |

| Experiment No. | A | B | C | D |

|---|---|---|---|---|

| 1 | 1 | 1 | 1 | 1 |

| 2 | 1 | 2 | 2 | 2 |

| 3 | 1 | 3 | 3 | 3 |

| 4 | 1 | 4 | 4 | 4 |

| 5 | 2 | 1 | 2 | 3 |

| 6 | 2 | 2 | 1 | 4 |

| 7 | 2 | 3 | 4 | 1 |

| 8 | 2 | 4 | 3 | 2 |

| 9 | 3 | 1 | 3 | 4 |

| 10 | 3 | 2 | 4 | 3 |

| 11 | 3 | 3 | 1 | 2 |

| 12 | 3 | 4 | 2 | 1 |

| 13 | 4 | 1 | 4 | 2 |

| 14 | 4 | 2 | 3 | 1 |

| 15 | 4 | 3 | 2 | 4 |

| 16 | 4 | 4 | 1 | 3 |

| Exp No. | A | B | C | D | Fly Ash (kg/m3) | GGBFS (kg/m3) | SF (kg/m3) | Fine Aggregate (kg/m3) | Coarse Aggregate (kg/m3) | Na2SiO3 (kg/m3) | NaOH (kg/m3) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | B1 | 0.5 | 1.5 | 6 | 244.80 | 122.40 | 40.8 | 554.4 | 1293.6 | 101.39 | 69.93 |

| 2 | B2 | 1 | 2 | 8 | 224.40 | 142.80 | 40.8 | 113.25 | 58.07 | ||

| 3 | B3 | 1.5 | 2.5 | 10 | 204.00 | 163.20 | 40.8 | 121.66 | 49.66 | ||

| 4 | B4 | 2 | 3 | 12 | 183.60 | 183.60 | 40.8 | 127.95 | 43.37 | ||

| 5 | B2 | 0.5 | 2 | 10 | 224.40 | 142.80 | 40.8 | 113.25 | 58.07 | ||

| 6 | B2 | 1 | 1.5 | 12 | 224.40 | 142.80 | 40.8 | 101.39 | 69.93 | ||

| 7 | B2 | 1.5 | 3 | 6 | 224.40 | 142.80 | 40.8 | 127.95 | 43.37 | ||

| 8 | B2 | 2 | 2.5 | 8 | 224.40 | 142.80 | 40.8 | 121.66 | 49.66 | ||

| 9 | B3 | 0.5 | 2.5 | 12 | 204.00 | 163.20 | 40.8 | 121.66 | 49.66 | ||

| 10 | B3 | 1 | 3 | 10 | 204.00 | 163.20 | 40.8 | 127.95 | 43.37 | ||

| 11 | B3 | 1.5 | 1.5 | 8 | 204.00 | 163.20 | 40.8 | 101.39 | 69.93 | ||

| 12 | B3 | 2 | 2 | 6 | 204.00 | 163.20 | 40.8 | 113.25 | 58.07 | ||

| 13 | B4 | 0.5 | 3 | 8 | 183.60 | 183.60 | 40.8 | 127.95 | 43.37 | ||

| 14 | B4 | 1 | 2.5 | 6 | 183.60 | 183.60 | 40.8 | 121.66 | 49.66 | ||

| 15 | B4 | 1.5 | 2 | 12 | 183.60 | 183.60 | 40.8 | 113.25 | 58.07 | ||

| 16 | B4 | 2 | 1.5 | 10 | 183.60 | 183.60 | 40.8 | 101.39 | 69.93 |

| Trials | Compressive Strength (MPa) | Standard Deviation | |||

|---|---|---|---|---|---|

| 1 | 2 | 3 | Average | ||

| TR1 | 27.3 | 30.3 | 31.1 | 29.6 | 1.99 |

| TR2 | 32.8 | 30.8 | 27.4 | 30.3 | 2.73 |

| TR3 | 37.5 | 34.4 | 35.2 | 35.7 | 1.59 |

| TR4 | 30.9 | 34.9 | 32.8 | 32.9 | 2.00 |

| TR5 | 35.2 | 38.1 | 41.3 | 38.2 | 3.05 |

| TR6 | 37.4 | 35.6 | 33.6 | 35.5 | 1.88 |

| TR7 | 35.1 | 37.9 | 40.4 | 37.8 | 2.65 |

| TR8 | 33.6 | 29.6 | 31.1 | 31.4 | 2.02 |

| TR9 | 36.1 | 42.3 | 38.5 | 39.0 | 3.11 |

| TR10 | 29.1 | 29.7 | 28.2 | 29.0 | 0.76 |

| TR11 | 41.8 | 44.6 | 40.3 | 42.2 | 2.19 |

| TR12 | 31.8 | 39.1 | 40.5 | 37.2 | 4.68 |

| TR13 | 38.2 | 35.7 | 40.8 | 38.2 | 2.57 |

| TR14 | 36.9 | 38.2 | 34.5 | 36.5 | 1.88 |

| TR15 | 38.2 | 37.1 | 39.2 | 38.2 | 1.05 |

| TR16 | 41.3 | 43.8 | 39.6 | 41.6 | 2.11 |

| Parameter | A | B | C | D |

|---|---|---|---|---|

| SS | 271 | 193 | 46 | 9.29 |

| Sum | 520 | |||

| Contribution | 52.16 | 37.17 | 8.89 | 1.79 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karthik, S.; Mohan, K.S.R. A Taguchi Approach for Optimizing Design Mixture of Geopolymer Concrete Incorporating Fly Ash, Ground Granulated Blast Furnace Slag and Silica Fume. Crystals 2021, 11, 1279. https://doi.org/10.3390/cryst11111279

Karthik S, Mohan KSR. A Taguchi Approach for Optimizing Design Mixture of Geopolymer Concrete Incorporating Fly Ash, Ground Granulated Blast Furnace Slag and Silica Fume. Crystals. 2021; 11(11):1279. https://doi.org/10.3390/cryst11111279

Chicago/Turabian StyleKarthik, Sundaravadivelu, and Kaliyaperumal Saravana Raja Mohan. 2021. "A Taguchi Approach for Optimizing Design Mixture of Geopolymer Concrete Incorporating Fly Ash, Ground Granulated Blast Furnace Slag and Silica Fume" Crystals 11, no. 11: 1279. https://doi.org/10.3390/cryst11111279

APA StyleKarthik, S., & Mohan, K. S. R. (2021). A Taguchi Approach for Optimizing Design Mixture of Geopolymer Concrete Incorporating Fly Ash, Ground Granulated Blast Furnace Slag and Silica Fume. Crystals, 11(11), 1279. https://doi.org/10.3390/cryst11111279