Effects of Depth of Cutting on Damage Interferences during Double Scratching on Single Crystal SiC

Abstract

1. Introduction

2. Experimentation

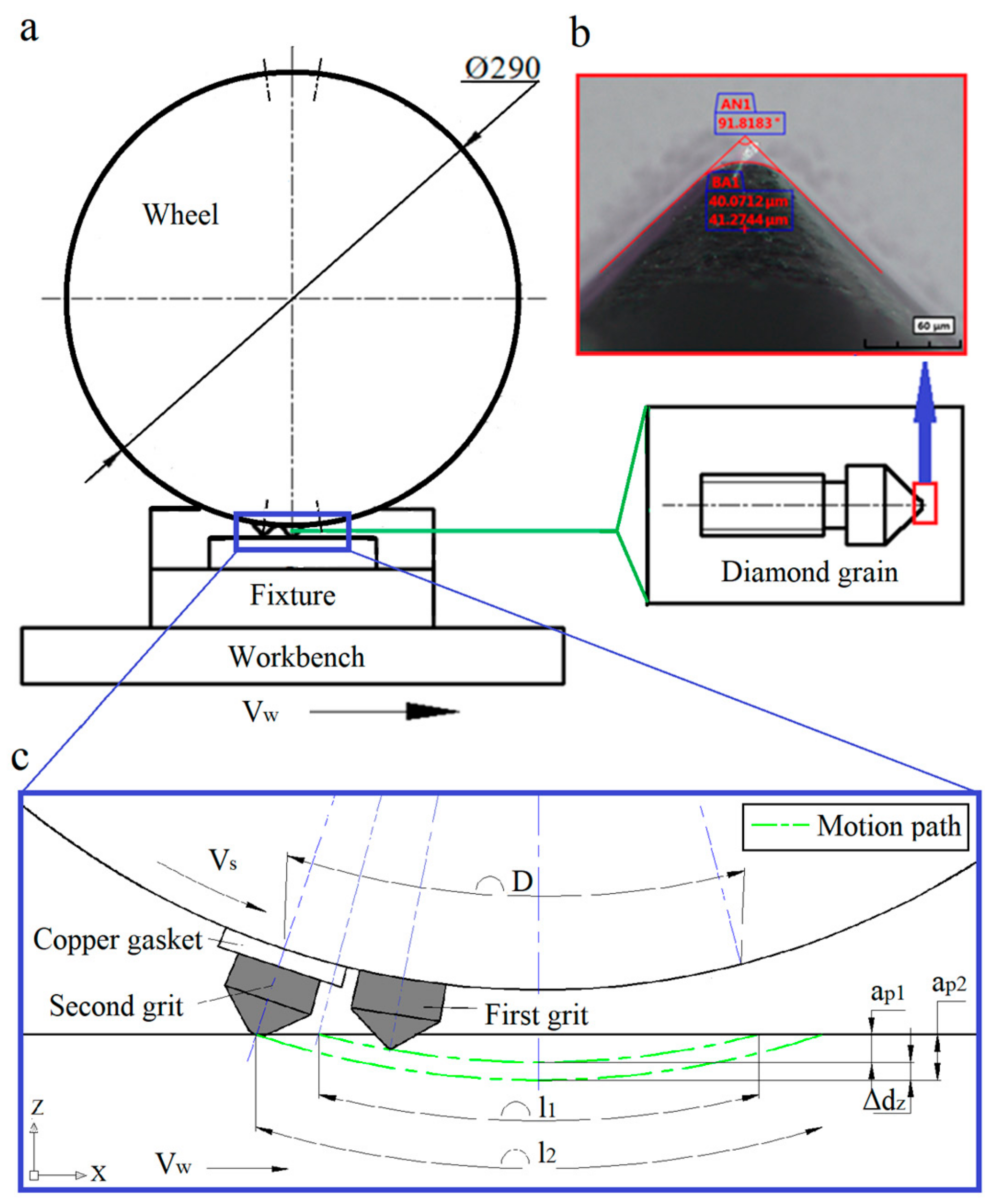

2.1. Scratching

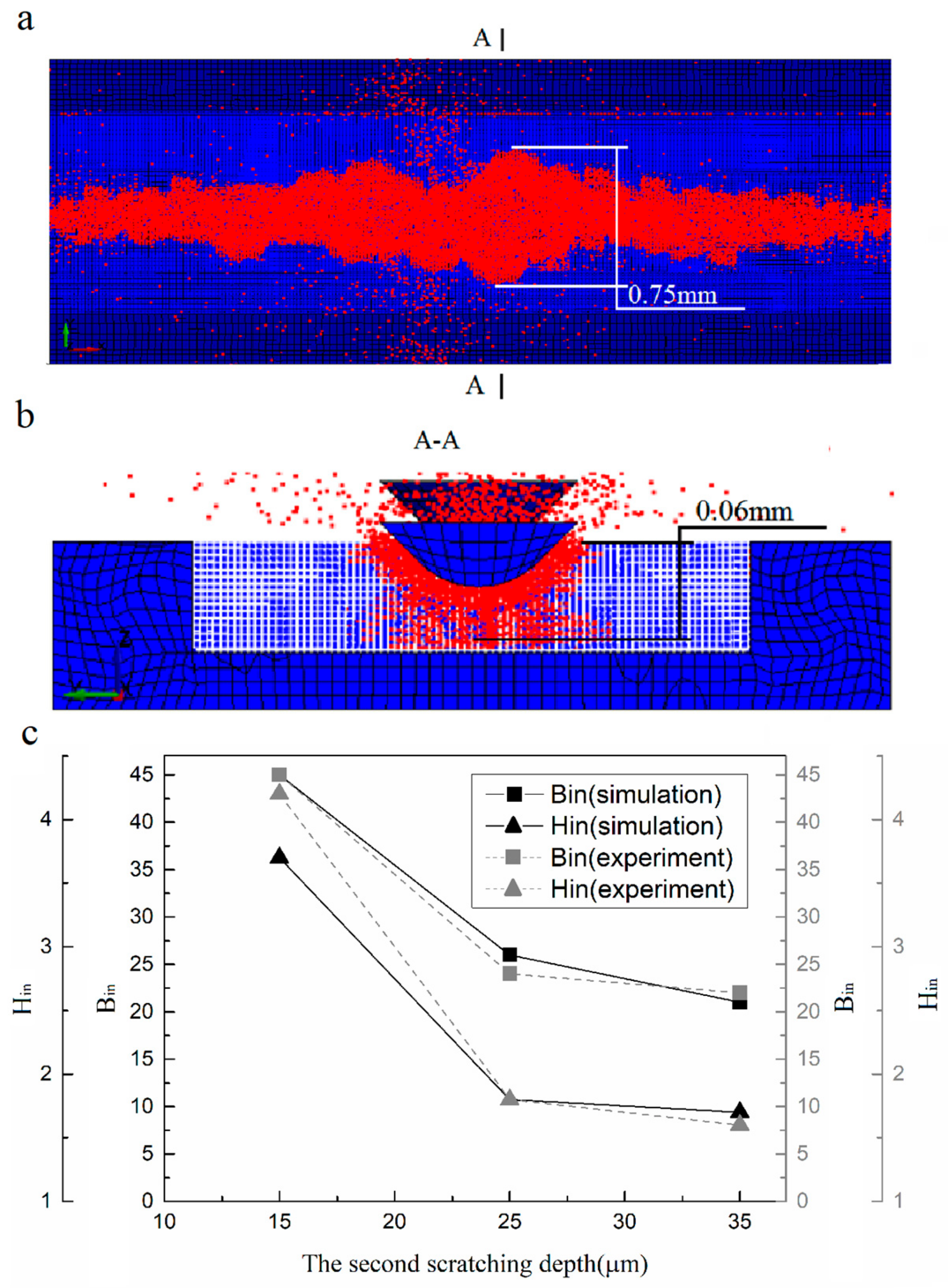

2.2. Results

3. Numerical Analysis

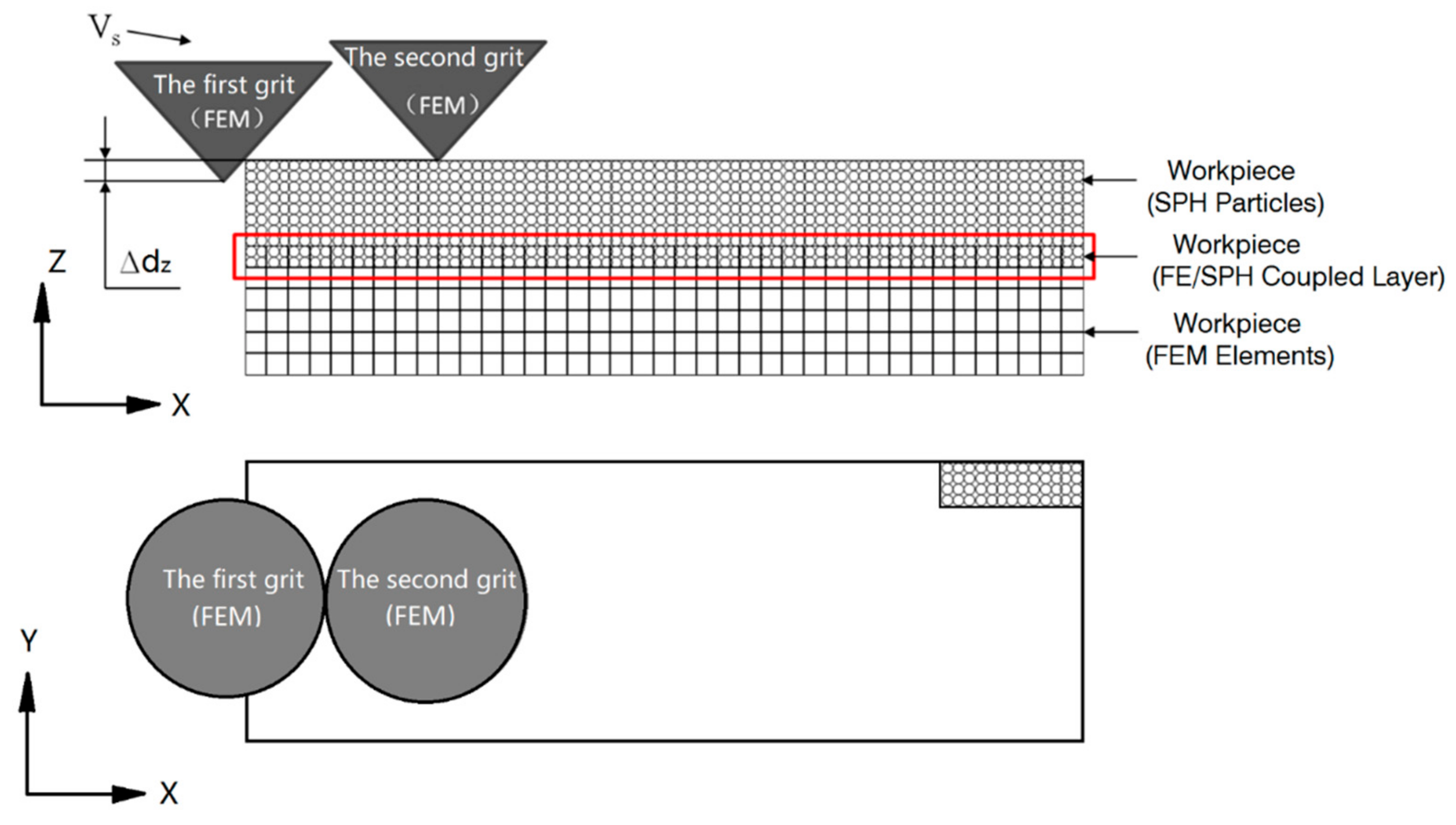

3.1. Model Development

3.2. Validation

4. Discussion

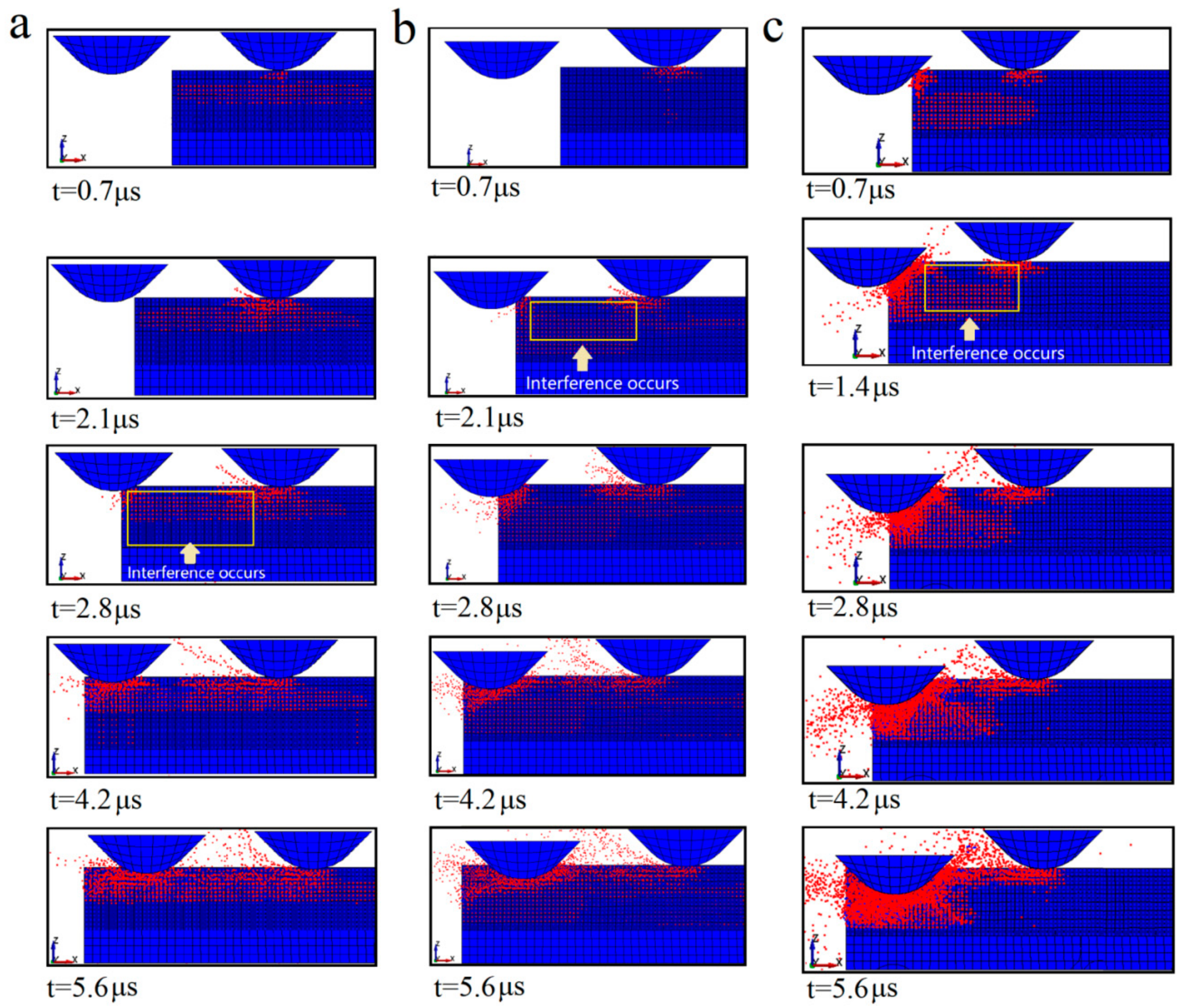

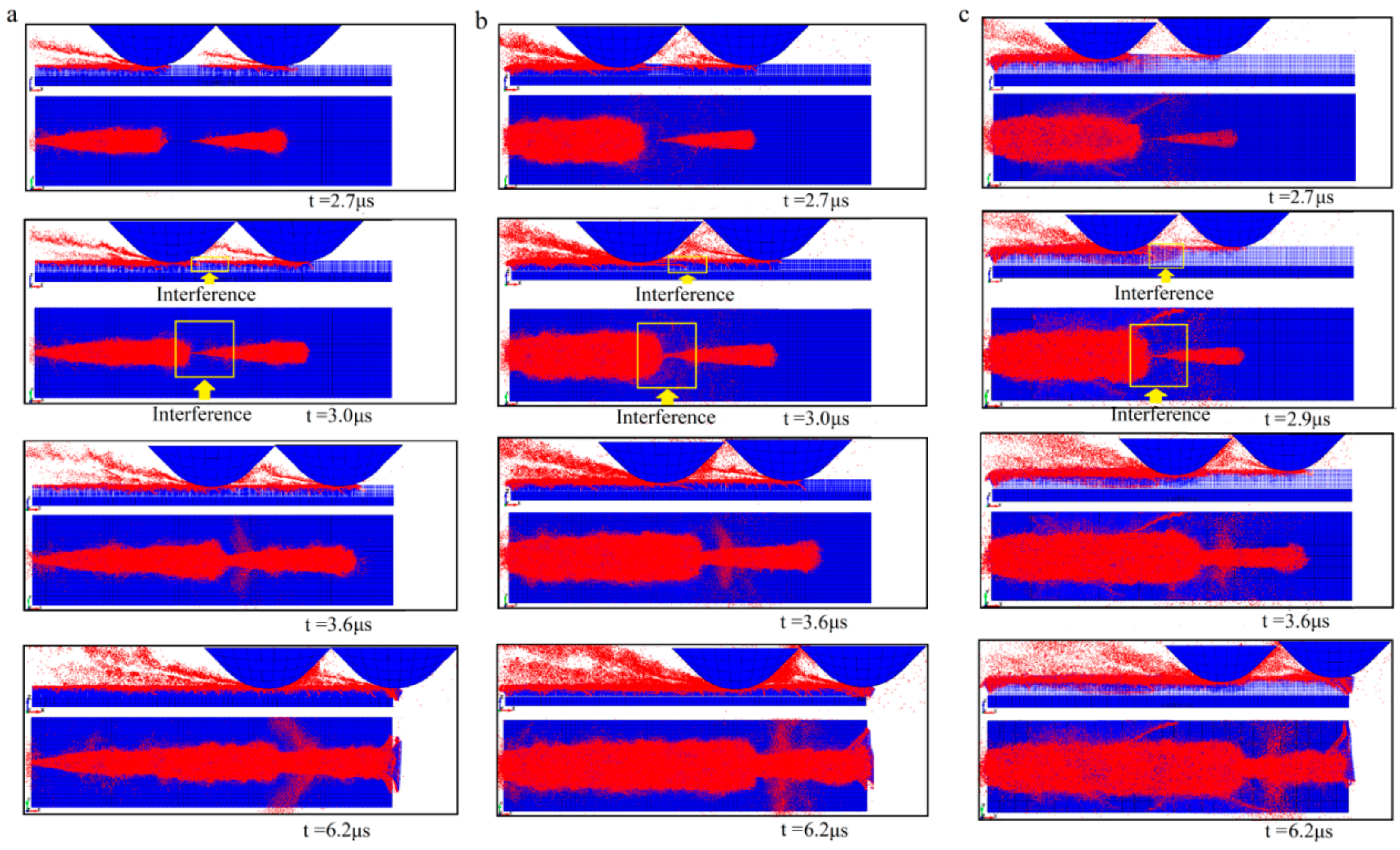

4.1. Damage Interference

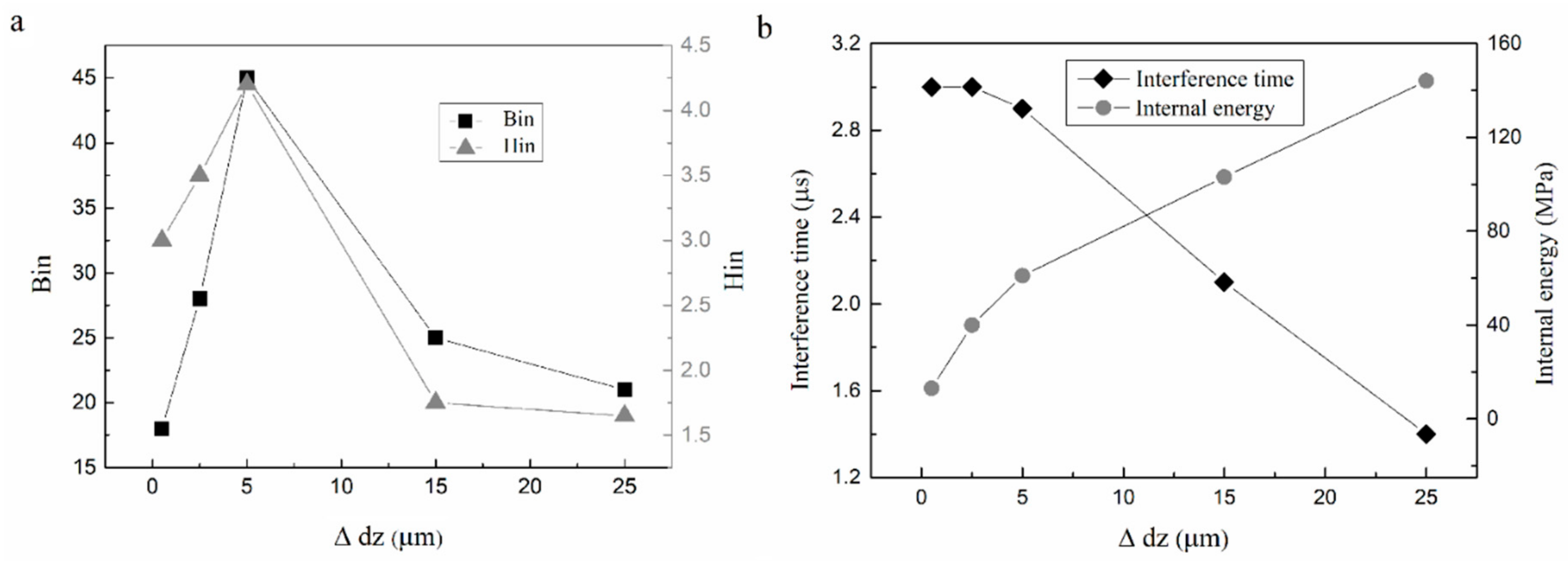

4.2. Role of DOC

4.3. Interference Mechanisms

5. Conclusions

- At micron scales, damage interference can be divided into three stages according to the DOCs: a combined plastic-brittle interference enhancement stage when DOC was less than 5 μm, a crack interference stage as DOC was increased to 5 μm, and a weakened interference stage when fragmentation occurred.

- When the Z-axis spacing along the DOC direction was small and material removal mode was in combined brittle-plastic mode, the interference was mainly in the depth direction. As the Z-axis spacing increased to initiate the brittleness removal of SiC, the scratching damage was mostly interfered in the width direction.

- Initiation time of damage interference was also related to the materials removal modes at variable DOCs, and when SiC was removal completely in the brittle mode, the damage interference was triggered earlier than that in a combined brittle-plastic removal mode.

Funding

Conflicts of Interest

References

- Casady, J.B.; Johnson, R.W. Status of silicon carbide (SiC) as a wide-band gap semiconductor for high-temperature applications. Solid State Electron. 1996, 39, 1409–1422. [Google Scholar] [CrossRef]

- Hobgooda, H.M.; Bradya, M.; Brixius, W. Growth and Characterization of Semiconductor Silicon Carbide for Electronic and Optoelectronic Applications: An Industrial PersPeetive. Ph.D. Thesis, Hiroshima University, Higashihiroshima, Japan, 2001. [Google Scholar]

- Maksakova, O.V.; Simoẽs, S.; Pogrebnjak, A.D.; Bondar, O.V.; Kravchenko, Y.O.; Koltunowicz, T.N.; Shaimardanov, Z.K. Experimental and theoretical studies of the physicochemical and mechanical properties of multi-layered TiN/SiC films: Temperature effects on the nanocomposite structure. Compos. Part B-Eng. 2018, 142B, 85–94. [Google Scholar]

- Liu, B.; Yu, Y.; Tang, X.; Gao, B. Improvement of Growth Interface Stability for 4-Inch Silicon Carbide Crystal Growth in TSSG. Crystals 2019, 9, 653. [Google Scholar] [CrossRef]

- Levinshtein, M.E.; Rumyantsev, S.L.; Shur, M.S. Properties of Advanced Semiconductor Materials: GaN, AlN, InN, BN, SiC, SiGe; Wiley& Sons, Inc.: New York, NY, USA, 2001. [Google Scholar]

- Liao, X.J.; Mu, D.K.; Fu, W.; Huang, H.; Huang, H. Low-temperature wetting mechanisms of polycrystalline chemical vapour deposition (CVD) diamond by Sn-Ti solder alloys. Mater. Design. 2019, 182, 108039. [Google Scholar] [CrossRef]

- Maksakova, O.V.; Webster, R.F.; Tilley, R.D.; Ivashchenko, V.I.; Postolnyi, B.O.; Bondar, O.V.; Takeda, Y.; Rogoz, V.M.; Sakenova, R.E.; Zukowski, P.V.; et al. Nanoscale architecture of (CrN/ZrN)/(Cr/Zr) nanocomposite coatings: Microstructure, composition, mechanical properties and first-principles calculations. J. Alloy. Compd. 2020, 831, 154808. [Google Scholar] [CrossRef]

- Murahara, M.M. Excimer-laser-induced photochemical polishing of SiC mirror. Proc. SPIE. 2002, 4679, 69–74. [Google Scholar]

- Chen, X.F.; Xu, X.G.; Hu, X.B. Anisotropy of Chemical Mechanical Polishing in Silicon Carbide Substrates. Mat. Sci. Eng. B-Solid. 2007, 142, 28–30. [Google Scholar] [CrossRef]

- Zhu, D.H.; Yan, S.J.; Li, B.Z. Single-grit modeling and simulation of crack initiation and propagation in SiC grinding using maximum undeformed chip thickness. Comp. Mater. Sci. 2014, 92, 13–21. [Google Scholar] [CrossRef]

- Petit, F.; Ott, C.; Cambier, F. Multiple scratch tests and surface-related fatigue properties of monolithic ceramics and soda lime glass. J. Eur. Ceram. Soc. 2009, 29, 1299–1307. [Google Scholar] [CrossRef]

- Gu, W.B.; Yao, Z.Q.; Liang, X.G. Material removal of optical glass BK7 during single and double scratch tests. Wear 2011, 270, 241–246. [Google Scholar] [CrossRef]

- Klecka, M.; Subhash, G. Grain size dependence of scratch-induced damage in alumina ceramics. Wear 2008, 265, 612–619. [Google Scholar] [CrossRef]

- Li, C.; Zhang, F.H.; Wang, X.; Rao, X.S. Repeated nano scratch and double nano scratch tests of Lu2O3 transparent ceramics: Material removal and deformation mechanism, and theoretical model of penetration depth. J. Eur. Ceram. Soc. 2018, 38, 705–718. [Google Scholar] [CrossRef]

- Zhang, P.; Zhao, H.W.; Shi, C.L.; Zhang, L.; Huang, H.; Ren, L.Q. Influence of double-tip scratch and single-tip scratch on nano-scratching process via molecular dynamics simulation. Appl. Surf. Sci. 2013, 280, 751–756. [Google Scholar] [CrossRef]

- Benz, W.; Asphaug, E. Simulations of brittle solids using Smoothed Particle Hydrodynamics. Comput. Phys. Commun. 1995, 87, 253–265. [Google Scholar] [CrossRef]

- Sauer, M. Adaptive, Kopplung des Netzfreien SPH-Verfahrens mit Finiten Elementen zur Berechnung von Impaktvorgangen. Ph.D. Thesis, Universitat der Bundeswehr Miinchen, Neubiberg, Germany, 2000. [Google Scholar]

- Limido, J.; Espinosa, C.; Salaun, M.; Lacome, J.L. SPH method applied to high speed cutting modeling. Int. J. Mech. Sci. 2007, 49, 898–908. [Google Scholar] [CrossRef]

- Grimaldi, A.; Sollo, A.; Guida, M.; Marulo, F. Parametric study of a SPH high velocity impact analysis-A birdstrike windshield application. Compos. Struct. 2013, 96, 616–630. [Google Scholar] [CrossRef]

- Lin, J.; Naceur, H.; Coutellier, D.; Laksimi, A. Efficient meshless SPH method for the numerical modeling of thick shell structures undergoing large deformations. Int. J. Nonlin. Mech. 2014, 65, 1–13. [Google Scholar] [CrossRef]

- Mahnama, M.; Movahhedy, M.R. Application of FEM simulation of chip formation to stability analysis in orthogonal cutting process. J. Manuf. Process. 2012, 14, 188–194. [Google Scholar] [CrossRef]

- Han, L.; Zhang, Y.; Li, X.-M.; Jiang, L.-H.; Chen, D. Accelerated Approach for the Band Structures Calculation of Phononic Crystals by Finite Element Method. Crystals 2016, 6, 11. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, M.; Zhao, X.R.; Zhu, G.; McClean, C.; Zhao, Y.Y.; Fan, Y.B. Experimental investigations and finite element simulation of cutting heat in vibrational and conventional drilling of cortical bone. Med. Eng. Phys. 2014, 36, 1408–1415. [Google Scholar] [CrossRef]

- Wang, H.; Lu, C.; Tieu, K. A Combined Experiment and Crystal Plasticity FEM Study of Microstructure and Texture in Aluminium Processed by Reverse and Unidirectional Accumulative Roll-Bonding. Crystals 2019, 9, 119. [Google Scholar] [CrossRef]

- Wu, H.B.; To, S. Serrated chip formation and their adiabatic analysis by using the constitutive model of titanium alloy in high speed cutting. J. Alloy. Compd. 2015, 629, 368–373. [Google Scholar] [CrossRef]

- Cao, J.; Wu, Y.; Li, J.; Zhang, Q. Study on the material removal process in ultrasonic-assisted grinding of SiC ceramics using smooth particle hydrodynamic (SPH) method. Int. J. Adv. Manuf. Tech. 2016, 83, 985–994. [Google Scholar] [CrossRef]

- Duan, N.; Yu, Y.Q.; Wang, W.S.; Xu, X.P. SPH and FE Coupled 3D Simulation of Monocrystal SiC Scratching by Single Diamond Grit. Int. J. Refract. Met. Hard Mater. 2017, 64, 279–293. [Google Scholar] [CrossRef]

- Duan, N.; Yu, Y.Q.; Wang, W.S.; Xu, X.P. Analysis of Grit Interference Mechanisms for the Double Scratching of Monocrystalline Silicon Carbide by Coupling the FEM and SPH. Int. J. Mach. Tool. Manu. 2017, 120, 49–60. [Google Scholar] [CrossRef]

- Duan, N.; Huang, S.G.; Yu, Y.Q.; Huang, H.; Xu, X.P. The Influence of Brittle-Ductile Transition of Monocrystal SiC Scratching by Single Diamond Grit with Different Tip Radius. Chin. J. Mech. Eng-en. 2017, 15, 185–194. [Google Scholar]

- Malkin, S.; Guo, C. Grinding technology: Theory and applications of machining with abrasives. Int. J. Mach. Tool. Manu. 1991, 31, 435–436. [Google Scholar]

- Holmquist, T.J.; Templeto, D.W.; Bishnoi, K.D. Constitutive Modeling of Aluminum Nitride for Large Strain, High-strain Rate, and High-pressure Aplications. Int. J. Impact. Eng. 2001, 25, 211–231. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Velocity of the wheel(vs)(m/s) | 30 |

| Z-axis spacing along the DOC direction (∆dz) (μm) | 5, 15, 25 |

| Velocity of the workbench (vw) (mm/min) | 20000 |

| Material | Density (g/mm3) | Elastic Modulus (MPa) | Poisson’s Ratio |

|---|---|---|---|

| Diamond | 3.5e−3 | 9.64e+5 | 0.07 |

| Single crystal SiC | 3.163e−3 | 1.83e+5 |

| JHC Parameters | A | B | N | C |

|---|---|---|---|---|

| Value | 0.91 | 0.085 | 0.78 | 0.003 |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nian, D. Effects of Depth of Cutting on Damage Interferences during Double Scratching on Single Crystal SiC. Crystals 2020, 10, 519. https://doi.org/10.3390/cryst10060519

Nian D. Effects of Depth of Cutting on Damage Interferences during Double Scratching on Single Crystal SiC. Crystals. 2020; 10(6):519. https://doi.org/10.3390/cryst10060519

Chicago/Turabian StyleNian, Duan. 2020. "Effects of Depth of Cutting on Damage Interferences during Double Scratching on Single Crystal SiC" Crystals 10, no. 6: 519. https://doi.org/10.3390/cryst10060519

APA StyleNian, D. (2020). Effects of Depth of Cutting on Damage Interferences during Double Scratching on Single Crystal SiC. Crystals, 10(6), 519. https://doi.org/10.3390/cryst10060519