Nanoindentation-Based Micro-Mechanical and Electrochemical Properties of Quench-Hardened, Tempered Low-Carbon Steel

Abstract

1. Introduction

2. Materials and Methods

2.1. Production of Low-Carbon Steel

2.2. Quench Hardening and Tempering Process

2.3. Microstructure Analysis

2.4. Micro Vickers Hardness Testing

2.5. Nanoindentation Analysis

2.6. Electrochemical Analysis

3. Results and Discussion

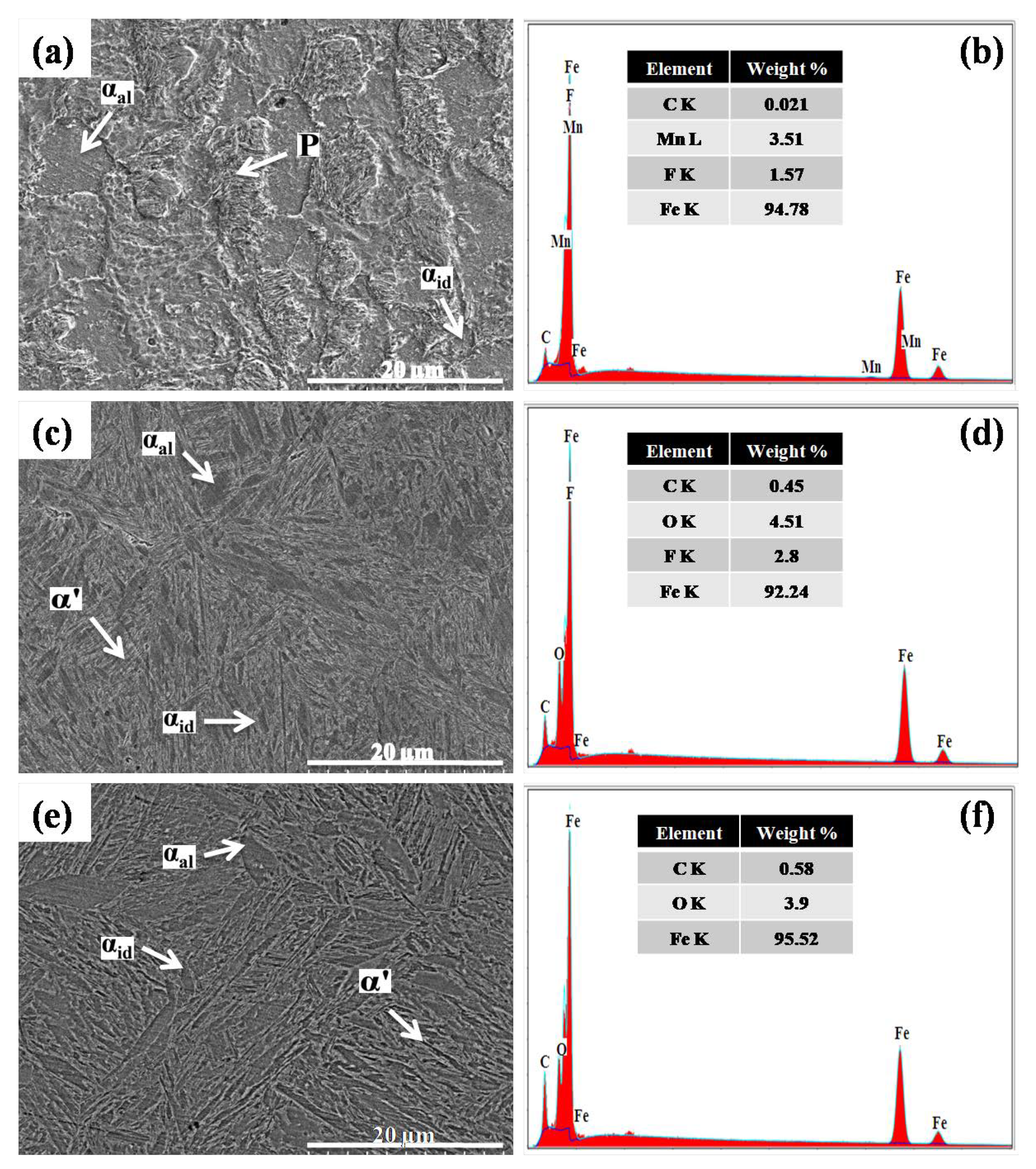

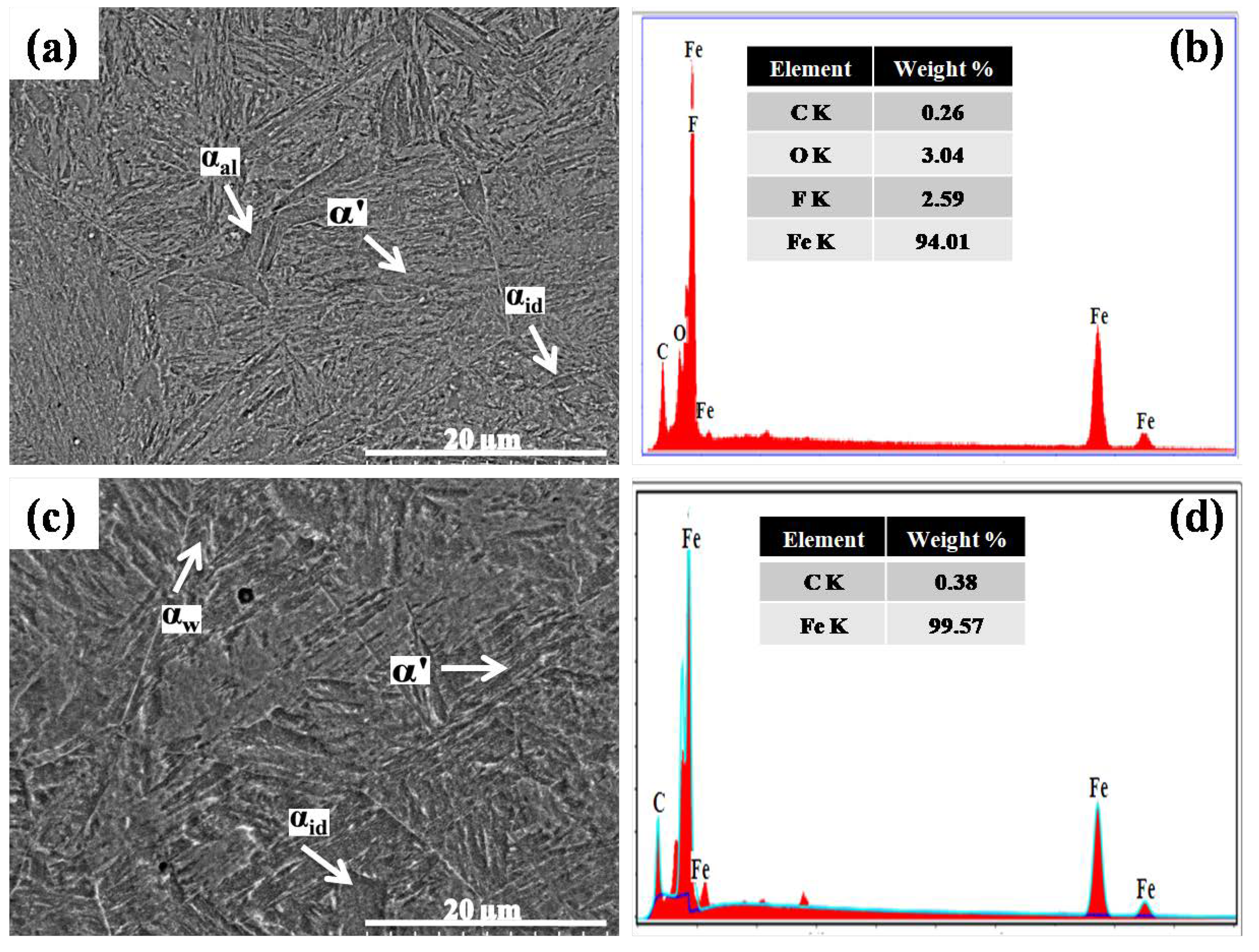

3.1. Microstructure

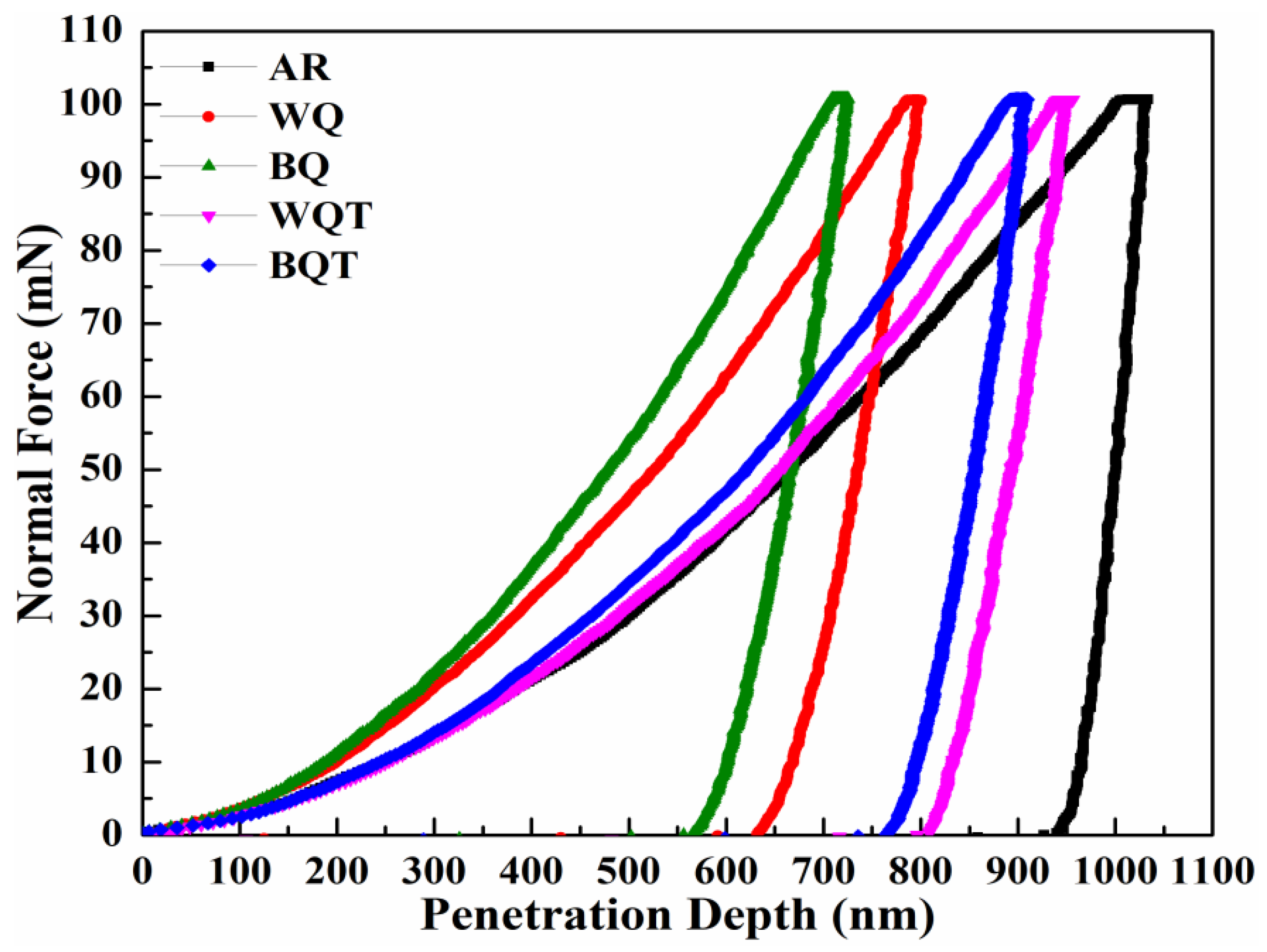

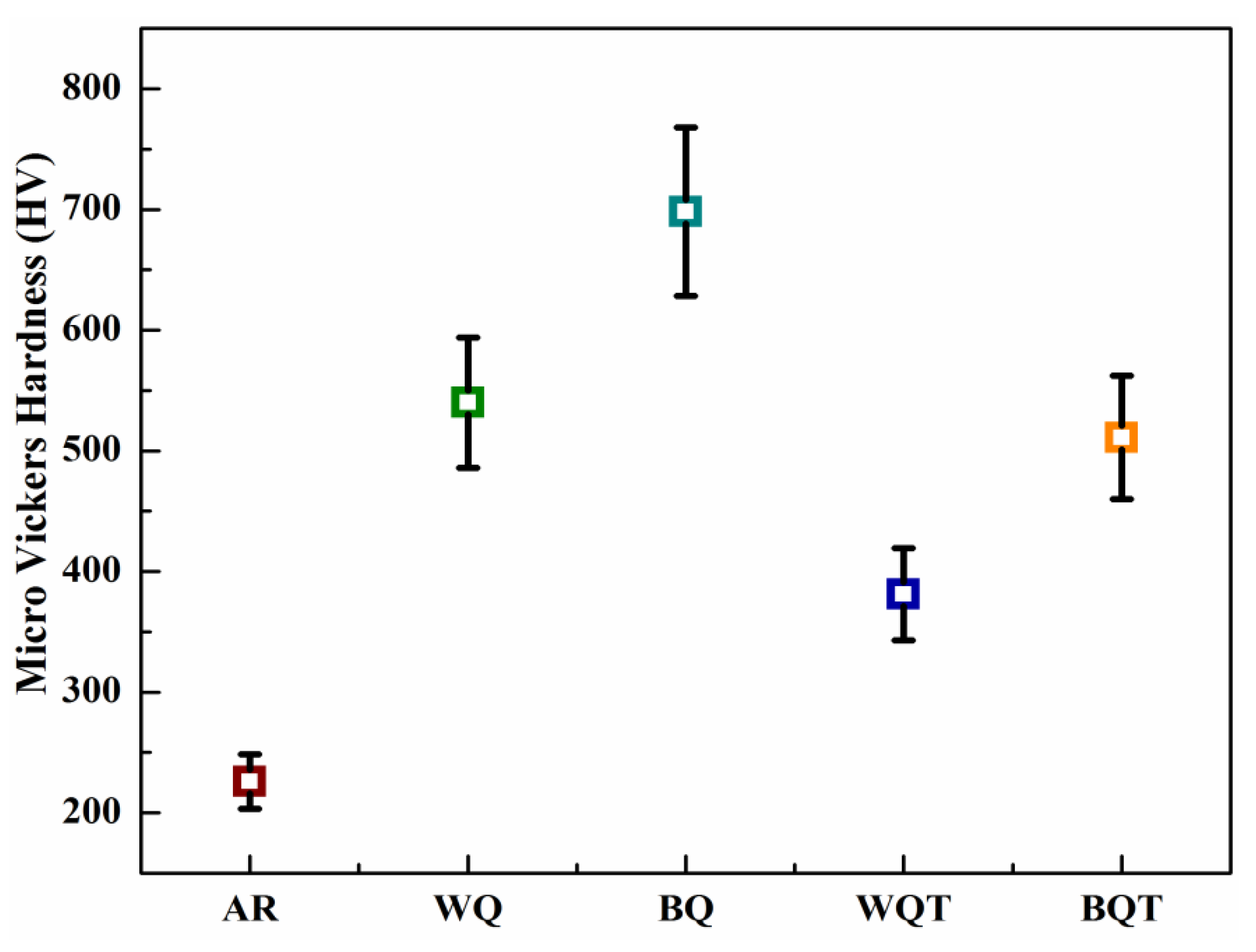

3.2. Micro-Mechanical Properties

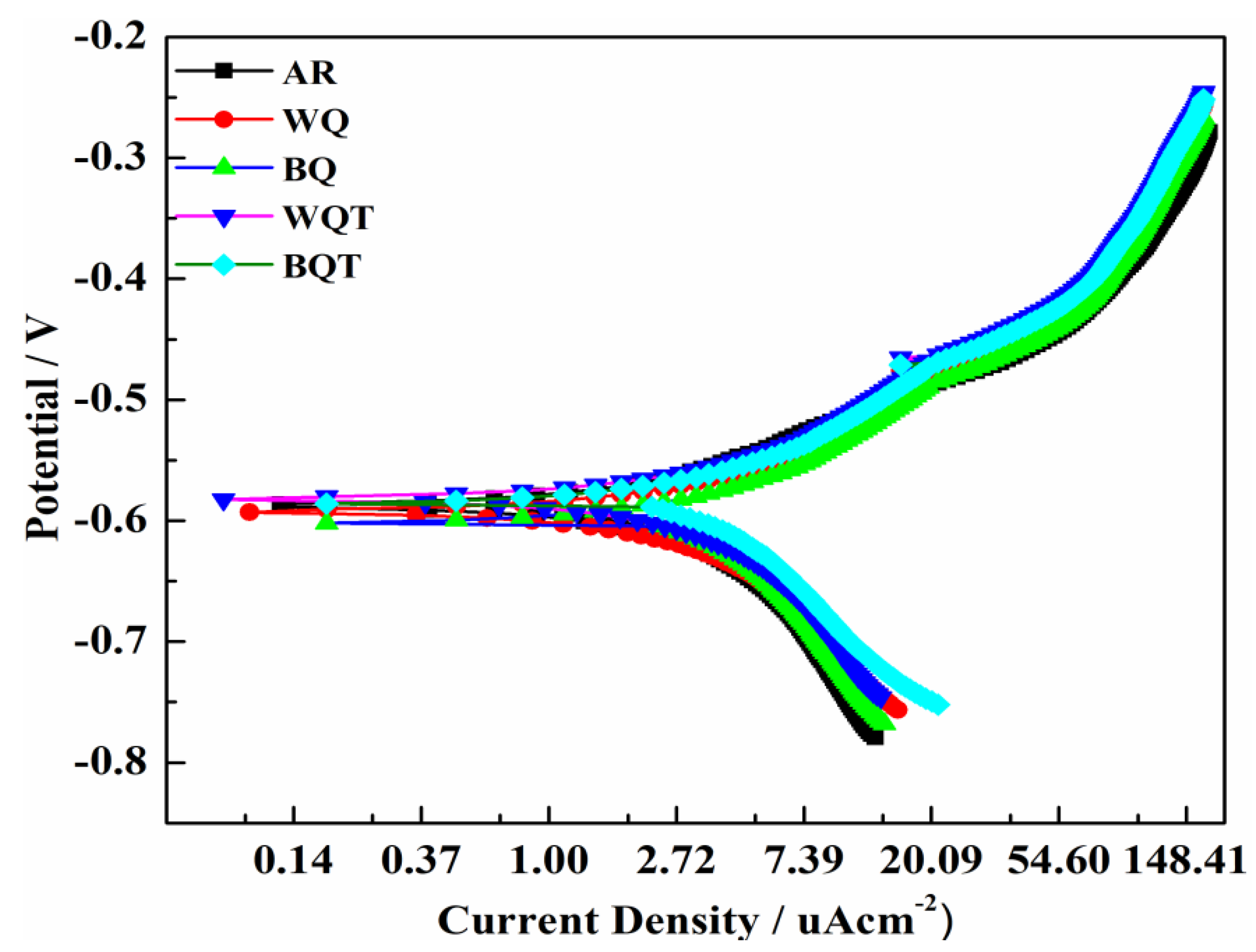

3.3. Electrochemical Properties

4. Conclusions

- ▪

- Microstructures comprising a lath α’ phase with different carbon percentages ranging from 0.26% to 0.58% and an α phase of different morphologies were achieved after all quench hardening and tempering processes. αal and αid phases were observed in both water and brine quench-hardened samples, and αw and αid phases in brine quench-hardened and tempered samples. The lath α’ phase was formed due to the high cooling rates provided by water and brine quench hardening processes, whereas the α phase was formed due to the presence of a low carbon percentage in the steel composition. The subsequent tempering process caused lattice relaxation in the lath α’ phase due to carbon diffusion from the α’ phase to the α phase.

- ▪

- A maximum twofold improvement in H, threefold in HV, and 51% in S, and a 29% reduction in Er were achieved after the brine quench hardening process compared with the as-received steel. This is attributed to the formation of the lath α’ phase in the microstructure due to the higher cooling rate of the brine solution. On the other hand, an 80% improvement in H, twofold improvement in HV, 43% improvement in S, and 38% reduction in Er were achieved after the water quench hardening process compared with the as-received steel, attributed to the formation of the lath α’ phase. However, this α’ phase has a lower carbon percentage than in the brine quench-hardened sample due to the relatively lower cooling rate than in brine solution. An optimum amalgamation of micro-mechanical properties was obtained after the water and brine quench hardening processes, beyond that of all other heat treatments.

- ▪

- The excellent corrosion resistance of low-carbon steel against the HNO3 electrolyte was observed after all quench hardening and tempering processes, as evidenced by a very low corrosion rate. The water quench-hardened and tempered sample exhibited the highest corrosion resistance, whereas the brine quench-hardened sample displayed the lowest corrosion resistance among all the heat-treated samples. The high corrosion resistance of the water quench-hardened and tempered sample and the low corrosion resistance of the brine quench-hardened sample are attributed to the formation of a lath α’ phase with different carbon percentages. The lath α’ phase formed after the brine quench hardening process possessed a higher carbon percentage, whereas that formed after the water quench hardening process possessed a relatively lower carbon percentage.

- ▪

- Nanoindentation was proved to be an accurate technique for measuring the indentation hardness, reduced elastic modulus, and stiffness of low-carbon steel at the micro-level. The nanoindentation technique cannot only measure the micro-mechanical properties but can also be implemented to determine the fracture toughness, creep, and yield stress of steels in the future. The nanoindentation technique also has some limitations. The most major limitation is associated with “pile-up” or “sink-in” of the material across the edges of the indent during indentation. Conventional calculation methods for the modulus of elasticity are useful only for linear and isotropic materials like metal and glass, which is another limitation of the nanoindentation technique. All these properties can also be explored using this technique in other steels after other novel heat treatment processes including austenite reverted transformation annealing, quenching-partitioning, and quenching-partitioning-tempering. The micro-level properties of inverse bainite and graphite phases can also be evaluated through this technique, allowing for engineering applications [47,48].

Author Contributions

Funding

Conflicts of Interest

References

- Cho, K.; Rao, V.S.; Sang, K.H. Microstructure and electrochemical characterization of trivalent chromium based conversion coating on zinc. Electrochem. Acta 2007, 52, 4449–4456. [Google Scholar] [CrossRef]

- Costa, M.; Klein, C.B. Toxicity and carcinogenicity of chromium compounds in humans. Crit. Rev. Toxicol. 2006, 36, 155–163. [Google Scholar] [CrossRef]

- Majd, M.T.; Shahrabi, T.; Ramezanzadeh, B. Low carbon steel surface modification by an effective corrosion protective nano composite film based on neodymium-polyacrylic acid benzimidazole. J. Alloys Compd. 2019, 783, 952–968. [Google Scholar] [CrossRef]

- Khanna, A.S. High Temperature Oxidation, Handbook of Environmental Degradation of Materials, 2nd ed.; Elsevier publishers: Amsterdam, The Netherlands, 2012; pp. 127–194. [Google Scholar]

- Loto, R.T.; Loto, C.A. Data on the corrosion inhibition properties of centrimonium bromide with thiocarbanilide and with vanillin on low carbon steel in dilute acid media. Chem. Data Collect. 2019, 22, 100250. [Google Scholar] [CrossRef]

- Aminah, Z.S.; Kanchana, M.; Anasyida, A.S.; Zuhailawati, H.; Hiromi, M. Effect of Pre-heat treatment on microstructure and mechanical properties of cryorolled low carbon steel. Mater. Today Proc. 2019, 17, 1176–1182. [Google Scholar] [CrossRef]

- Kanwal, T.; Nazir, R.; Zulqernain, S.; Salam, A.; Ahmad, J. Quench hardening and tempering behaviour of a low carbon steel. JPIChE 2009, 37, 51–53. [Google Scholar]

- Xu, W.; Han, E.H.; Wang, Z. Effect of tannic acid on corrosion behavior of carbon steel in NaCl solution. J. Mater. Sci. Technol. 2019, 35, 64–75. [Google Scholar] [CrossRef]

- Cen, H.; Chen, Z.; Guo, X. N, S co-doped carbon dots as effective corrosion inhibitor for carbon steel in CO2-saturated 3.5% NaCl solution. J. Taiwan Inst. Chem. E 2019, 99, 224–238. [Google Scholar] [CrossRef]

- Yu, J.; Zhang, Y.; Jin, X.; Chen, L.; Du, J.; Xue, W. Fabrication and optical emission spectroscopy of enhanced corrosion-resistant CPEO films on Q235 low carbon steel. Surf. Coat. Technol. 2019, 363, 411–418. [Google Scholar] [CrossRef]

- Miernik, K.; Bogucki, R.; Pytel, S. Effect of quenching techniques on the mechanical properties of low carbon structural steel. Arch. Foundry Eng. 2010, 10, 91–96. [Google Scholar]

- Hafeez, M.A.; Farooq, A. Effect of heat treatments on the mechanical and electrochemical behavior of 38CrSi and AISI 4140 steels. Metallogr. Microstruct. Anal. 2019, 8, 479–487. [Google Scholar] [CrossRef]

- Zhang, P.; Chen, Y.; Xiao, W.; Ping, D.; Zhao, X. Twin structure of the lath martensite in low carbon steel. Prog. Nat. Sci.-Mater. 2016, 26, 169–172. [Google Scholar] [CrossRef]

- Saastamoinen, A.; Kaijalainen, A.; Porter, D.; Suikkanen, P. The effect of thermo-mechanical treatment and tempering on the subsurface microstructure and bendability of direct-quenched low-carbon strip steel. Mater. Charact. 2017, 134, 172–181. [Google Scholar] [CrossRef]

- Pereloma, E.; Edmonds, D.V. Phase Transformation in Steels; Wood Head: Cambridge, UK, 2012; Volume 2. [Google Scholar]

- Hafeez, M.A.; Inam, A.; Arshad, M.A. Investigation on microstructural, mechanical, and electrochemical properties of water, brine quenched and tempered low carbon steel. Mater. Res. Express 2019, 6, 096524. [Google Scholar] [CrossRef]

- Xiao, X.; Yu, L. Nano-indentation of ion-irradiated nuclear structural materials: A review. Nucl. Mater. Energy 2020, 22, 100721. [Google Scholar] [CrossRef]

- Lin, P.; Nie, J.; Liu, M. Study on irradiation effect in stress-strain response with CPFEM during nano-indentation. Nucl. Mater. Energy 2020, 22, 100737. [Google Scholar] [CrossRef]

- Jiang, Y.; Wu, Q.; Li, Y.; Peng, Y.; Gong, J. Mechanical properties of low-temperature gaseous carburizated layer in 316L stainless steel based on nano-indentation and four-point bending tests. Surf. Coat. Technol. 2020, 387, 125501. [Google Scholar] [CrossRef]

- Elghazal, H.; Lormand, G.; Hamel, A.; Girodin, D.; Vincent, A. Microplasticity characteristics obtained through nano-indentation measurements: Application to surface hardened steels. Mater. Sci. Eng. A 2001, 303, 110–119. [Google Scholar] [CrossRef]

- Jacq, C.; Lormand, G.; Nelias, D.; Girodin, D.; Vincent, A. On the influence of residual stresses in determining the micro-yield stress profile in a nitrided steel by nano-indentation. Mater. Sci. Eng. A 2003, 342, 311–319. [Google Scholar] [CrossRef]

- Oka, H.; Sato, Y.; Hashimoto, N.; Ohnuki, S. Evaluation of multi-layered hardness in ion-irradiated stainless steel by nano-indentation technique. J. Nucl. Mater. 2015, 462, 470–474. [Google Scholar] [CrossRef]

- Xiao, X.; Yu, L. Cross-sectional nano-indentation of ion-irradiated steels: Finite element simulations based on the strain-gradient crystal plasticity theory. Int. J. Eng. Sci. 2019, 143, 56–72. [Google Scholar] [CrossRef]

- Qiao, X.; Han, L.; Zhang, W.; Gu, J. Nano-indentation investigation on the mechanical stability of individual austenite in high-carbon steel. Mater. Charact. 2015, 110, 86–93. [Google Scholar] [CrossRef]

- Jiang, B.; Doi, K.; Tsuchiya, K.; Kawano, Y.; Kori, A.; Ikushima, K. Micromechanical properties of steel corrosion products in concrete studied by nano-indentation technique. Corros. Sci. 2019, 163, 108304. [Google Scholar] [CrossRef]

- Kim, Y.S.; Kim, J.G. Improvement of corrosion resistance for low carbon steel pipeline in district heating environment using transient oxygen injection method. J. Ind. Eng. Chem. 2019, 70, 169–177. [Google Scholar] [CrossRef]

- Kim, G.W.; Kim, Y.S.; Yang, H.W.; Ko, Y.G.; Shin, D.H. Influence of ZrO2 incorporation into coating layer on electrochemical response of low-carbon steel processed by electrochemical plasma coating. Surf. Coat. Technol. 2015, 269, 314–318. [Google Scholar] [CrossRef]

- Ren, R.K.; Zhang, S.; Pang, X.L.; Gao, K.W. A novel observation of the interaction between the macroelastic stress and electrochemical corrosion of low carbon steel in 3.5 wt% NaCl solution. Electrochem. Acta 2012, 85, 283–294. [Google Scholar] [CrossRef]

- Othman, N.K.; Yahya, S.; Ismail, M.C. Corrosion inhibition of steel in 3.5% NaCl by rice straw extract. J. Ind. Eng. Chem. 2019, 70, 299–310. [Google Scholar] [CrossRef]

- Hafeez, M.A.; Farooq, A. Effect of quenching baths on microstructure and hardness of AISI 1035 steel. Nigerian J. Technol. Sci. 2018, 13, 82–88. [Google Scholar]

- Dhua, S.K.; Mukerjee, D.; Sarma, D.S. Effect of cooling rate on the as-quenched microstructure and mechanical properties of HSLA-100 steel plates. Metall. Mater. Trans. A 2003, 34, 2494–2504. [Google Scholar] [CrossRef]

- Altaweel, A.R.; Rad, M.T. Effect of quenching media, specimen size and shape on the hardenability of AISI-4140 steel. EJER 2014, 19, 33–39. [Google Scholar]

- Nakagawa, Y.; Mori, K.; Suzuki, Y.; Shimizu, Y. Tailored tempering without die heating in hot stamping of ultra-high strength steel parts. Mater. Des. 2020, 192, 108704. [Google Scholar] [CrossRef]

- Soleimani, M.; Mirzadeh, H.; Dehghanian, C. Effects of tempering on the mechanical and corrosion properties of dual phase steel. Mater. Today Commun. 2020, 22, 100745. [Google Scholar] [CrossRef]

- Xie, C.; Liu, Z.; Wang, X.; He, X.; Qiao, S. Effect of two-step tempering treatment on microstructure and impact toughness of bainitic steel for heavy wall thickness reactor pressure vessels. Mater. Charact. 2019, 160, 110070. [Google Scholar] [CrossRef]

- Babatunde, Y.S.; Felix, A.; Esor, E.E.; Dennis, A.O. Heat treatment of a low carbon steel (A case study of the mechanical properties). J. Sci. Eng. 2015, 2, 35–39. [Google Scholar]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Guillonneau, G.; Kermouche, G.; Bec, S.; Loubet, J.L. Determinationof mechanical properties by nanoindentation independently of indentation depth measurement. J. Mater. Res. 2012, 27, 2551–2560. [Google Scholar] [CrossRef]

- Pierre, R. Roberge, Handbook of Corrosion Engineering; McGraw-Hill: New York, NY, USA, 2000. [Google Scholar]

- Winston Revie, R.; Herbert, H. Corrosion and Corrosion Control, 4th ed.; John Wiley and Sons Inc.: New York, NY, USA, 2008. [Google Scholar]

- Hafeez, M.A.; Inam, A.; Hassan, M.U.; Umer, M.A.; Usman, M.; Hanif, A. Optimized corrosion performance of AISI 1345 steel in hydrochloric acid through thermo–mechanical cyclic annealing processes. Crystals 2020, 10, 265. [Google Scholar] [CrossRef]

- Hafeez, M.A. Investigation on mechanical properties and immersion corrosion performance of 0.35%C–10.5%Mn steel processed by austenite reverted transformation (ART) annealing process. Metallogr. Microstruct. Anal. 2020, 9, 159–168. [Google Scholar] [CrossRef]

- Hafeez, M.A.; Inam, A.; Farooq, A. Mechanical and corrosion properties of medium carbon low alloy steel after cyclic quenching and tempering heat-treatments. Mater. Res. Express 2020, 7, 016553. [Google Scholar] [CrossRef]

- Inam, A.; Imtiaz, Y.; Hafeez, M.A.; Munir, S.; Ali, Z.; Ishtiaq, M.; Hassan, M.H.; Maqbool, A.; Haider, W. Effect of tempering time on microstructure, mechanical, and electrochemical properties of quenched-partitioned-tempered Advanced High Strength Steel (AHSS). Mater. Res. Express 2019, 6, 126509. [Google Scholar] [CrossRef]

- Hafeez, M.A.; Farooq, A. Microstructural, mechanical and tribological investigation of 30CrMnSiNi2A ultra-high strength steel under various tempering temperatures. Mater. Res. Express 2018, 5, 016505. [Google Scholar] [CrossRef]

- Hafeez, M.A. Effect of microstructural transformation during tempering on mechanical properties of quenched and tempered 38CrSi steel. Mater. Res. Express 2019, 6, 086552. [Google Scholar] [CrossRef]

- Farooq, H.; Usman, M.; Mehmood, K.; Malik, M.S.; Hanif, A. Effect of steel confinement on axially loaded short concrete columns. IOP Conf. Ser. 2018, 414, 012026. [Google Scholar] [CrossRef]

- Usman, M.; Farooq, S.H.; Umair, M.; Hanif, A. Axial compressive behavior of confined steel fiber reinforced high strength concrete. Constr. Build. Mater. 2020, 230, 117043. [Google Scholar] [CrossRef]

| Raw Materials | Wt. (kg) | C | Si | Mn | Cr | Cu | S | P | Fe |

|---|---|---|---|---|---|---|---|---|---|

| Mild Steel Scrap | 50.0 | 0.11 | 0.24 | 0.26 | 0.07 | 0.05 | 0.03 | 0.02 | Balance |

| Ferro-Silicon | 0.05 | – | 70.0 | – | – | – | – | – | Balance |

| Ferro-Manganese | 0.38 | 6.00 | 0.97 | 60.0 | – | – | 0.02 | 0.25 | Balance |

| Ferro-Chrome | 0.09 | – | – | – | 65.0 | – | – | – | Balance |

| Low-Carbon Steel | 50.5 | 0.14 | 0.26 | 0.52 | 0.16 | 0.04 | 0.02 | 0.03 | Balance |

| Sample ID | Austenitizing Temperature (°C) | Soaking Time (min) | Cooling Media | Tempering Temperature (°C) | Tempering Time (min) | Cooling Media |

|---|---|---|---|---|---|---|

| WQ | 950 | 30 | Water | – | – | – |

| BQ | 950 | 30 | Brine | – | – | – |

| WQT | 950 | 30 | Water | 400 | 120 | Air |

| BQT | 950 | 30 | Brine | 400 | 120 | Air |

| Sample ID | H (GPa) | Er (GPa) | S (mN/nm) |

|---|---|---|---|

| AR | 3.83 | 367.57 | 0.636 |

| WQ | 6.89 | 226.29 | 0.912 |

| BQ | 7.76 | 259.89 | 0.961 |

| WQT | 5.01 | 208.79 | 0.998 |

| BQT | 5.24 | 231.66 | 1.066 |

| Sample | βa mv/Dec | βc mV/Dec | Icorr µA.cm−2 | Ecorr mV | Corrosion Rate mpy |

|---|---|---|---|---|---|

| AR | 58 | 54 | 1.53 | −0.588 | 0.394 |

| WQ | 85 | 63 | 1.65 | −0.582 | 0.630 |

| BQ | 93 | 71 | 1.79 | −0.592 | 0.669 |

| WQT | 105 | 82 | 1.63 | −0.566 | 0.610 |

| BQT | 72 | 58 | 1.04 | −0.578 | 0.620 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

ArslanHafeez, M.; Usman, M.; Arshad, M.A.; AdeelUmer, M. Nanoindentation-Based Micro-Mechanical and Electrochemical Properties of Quench-Hardened, Tempered Low-Carbon Steel. Crystals 2020, 10, 508. https://doi.org/10.3390/cryst10060508

ArslanHafeez M, Usman M, Arshad MA, AdeelUmer M. Nanoindentation-Based Micro-Mechanical and Electrochemical Properties of Quench-Hardened, Tempered Low-Carbon Steel. Crystals. 2020; 10(6):508. https://doi.org/10.3390/cryst10060508

Chicago/Turabian StyleArslanHafeez, Muhammad, Muhammad Usman, Muhammad Adnan Arshad, and Malik AdeelUmer. 2020. "Nanoindentation-Based Micro-Mechanical and Electrochemical Properties of Quench-Hardened, Tempered Low-Carbon Steel" Crystals 10, no. 6: 508. https://doi.org/10.3390/cryst10060508

APA StyleArslanHafeez, M., Usman, M., Arshad, M. A., & AdeelUmer, M. (2020). Nanoindentation-Based Micro-Mechanical and Electrochemical Properties of Quench-Hardened, Tempered Low-Carbon Steel. Crystals, 10(6), 508. https://doi.org/10.3390/cryst10060508